Page 1

Many other useful features are also available

HM-5190

For example.....

The motor can be operated by external signals

Motor

To power supply

Driver

Operating using

external signals

OPERATING MANUAL

Operating in two or

more speeds

OPERATING MANUAL

Programmable controller,

etc.

p. 33

p. 40

Be sure to ground the Protective Earth Terminal

(ground terminal) to ensure the safe use of the product.

Brushless Motors

BLE2

Series

Refer to "1 Connecting" for details, and ground securely.

QUICK START GUIDE

Thank you for purchasing an Oriental Motor product.

Use the product correctly after thoroughly reading the section "Safety precautions" of the operating

manual.

This document describes methods till rotating the motor after connecting it to the driver.

For details about how to use the product, refer to the supplied with the driver.

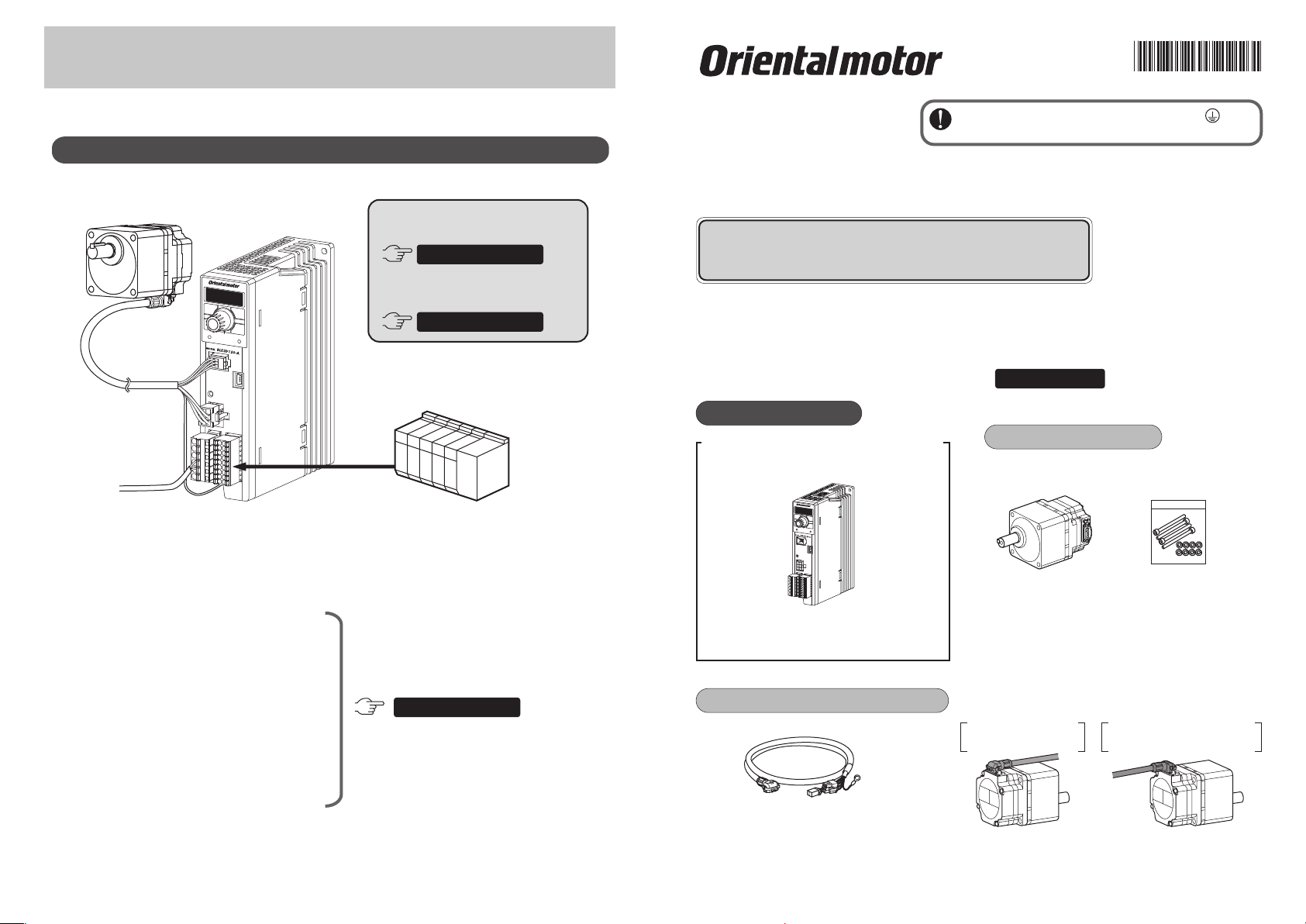

Package contents

The package includes the items shown below.

Driver

□

Operating manual

Motor (sold separately)

Motor

□

□

Mounting screw set

And others.....

To display the rotation speed of the

gearhead output shaft.

To display the conveyor transfer speed.

To set the rotation speed externally.

To suppress the motor torque.

To hold a load by the slight

position-keeping function.

To lock the data setting.

© Copyright

ORIENTAL MOTOR CO., LTD. 2016

As mentioned in the right, various

functions are available.

OPERATING MANUAL

Refer to "Convenient functions."

ORIENTALMOTOR CO.,LTD.

QUICK START GUIDE (this document)

□

OPERATING MANUAL

□

Connection cable (sold separately)

There are two types of connection cables

which cable leading directions are dierent.

(→ Refer to the right gure)

The gure shows an

example of the

combination type.

OPERATING MANUAL

□

Be sure to match the motor output power with the

∗

driver output power.

To connect the motor and driver, the dedicated

connection cable is always needed.

Leading in direction of

output shaft

Model:

CC__HBLF

For the round shaft type, only the cable for leading in

opposite direction of output shaft can be used.

Supplied with the

combination type.

Leading in opposite direction

of output shaft

Model:

CC__HBLB

Page 2

OPERATING MANUAL OPERATING MANUAL

1 Connecting 2 Operating a motor

Refer to "Connecting" Refer to "Operating"

Motor

Driver

CN4

Connection cable

To power supply

Ground terminal

CN2

Insert into CN1

Connect a power supply cable according to the power-supply

voltage specications of the driver. Prepare the power supply

cable since it is not supplied with the product.

Single-phase

100-120 VAC

L

N

Single-phase

200-240 VAC

L 1

L 2

Three-phase

200-240 VAC

Lead wire

Note

Screwdriver

Be sure to ground the product. Failure to do so may result in electric shock or damage to the product.

Static electricity may cause damage to the product if the Protective Earth Terminals are not grounded.

AWG18 to 14

(0.75 to 2.0 mm )

10 mm

(0.39 in.)

2

Connection for motor and cable

This is an example for when the cable is "leading

in direction of output shaft." In the case of the

cable of "leading in opposite direction of output

shaft," the cable leading direction is opposite in

3

2

and .

Remove

1

Attach

2

Locking

lever

Position of lever

Keep the locking

lever in the position

shown in the gure, and insert.

Secure

3

Be sure to turn down the locking lever

till the position shown in the gure.

Connector

cap

Ground

Be sure to ground using the

Protective Earth Terminal .

L 1

L 2

L 3

Prepare a grounding wire since

it is not supplied with the product.

AWG18 to 14 (0.75 to 2.0 mm )

Protective Earth

Terminal

M4

Grounding

Operation panel

AC power ON

1

When the power supply is turned on, the

display shows as follows.

Display: Rotation speed

0 r/min (standstill)

Operation selection

2

Press the LOCAL key.

LOCAL

3

Press

The LOCAL LED

is lit in green.

The operation using the operation

panel was set, and the rotation speed

and rotation direction are alternately

continued to show on the display.

Interval of approximately 1 second

Start of motor

4

Press

Change of motor speed

5

The motor rotates.

50 r/min (factory setting)

[ Example: 50 → 1000 r/min ]

Adjustment

Press

2

The display blinks.

You can adjust the speed while blinking.

Decelerate

MODE key

LOCAL key

LOCAL LED

Rotation direction selection

Press

The gures show the round shaft type.

∗

With the combination type, the gearhead output

shaft rotates in the opposite direction to the above

gure when the gear ratio is 30, 50, and 100.

(When the gear ratio is 30 and 50 for the 200 W type)

To stop the motor

Accelerate

Turn

The motor rotation

direction changes whenever

the MODE key is pressed.

Press

The motor stops.

Set

The display changes to lighting

from blinking, and the speed will

be set.

When you start the motor next

time, it will rotate at the set speed.

RUN key

STOP key

Setting dial

Press

Loading...

Loading...