Page 1

Stepping Motor and Driver Package

HM-60262-6

Before starting operation

Operation

AZ

Series/

Motorized actuator

equipped the

AZ

Series

Function Edition

I/O signals

Parameter

Method of control via

Modbus RTU

(RS-485 communication)

Method of control via

industrial network

Address list

Measures for various

cases

Alarm and information

Thank you for purchasing an Oriental Motor product.

This Manual describes product handling procedures and safety precautions.

•Please read it thoroughly to ensure safe operation.

•Always keep the manual where it is readily available.

Extended setting for

pulse-input operation

Appendix

Page 2

1 Characteristics of the AZ Series ..........................................................................................................................10

2 Operations possible with the AZ Series ............................................................................................................12

3 Types and overview of driver .............................................................................................................................. 14

4 How to use OPERATING MANUALS for product ...............................................................................................16

5 Expansion of supported contents ......................................................................................................................18

1 Before starting operation

1 Steps of preparation for operation ....................................................................................................................20

2 Starting the

MEXE02

...........................................................................................................................................21

3 Copying the xed value (parameter) of the ABZO sensor to driver .............................................................22

4 Creation of recovery data le and method of recovery ................................................................................. 24

4-1 Creating the recovery data le ....................................................................................................................................................... 24

4-2 Method of recovery ............................................................................................................................................................................ 26

5 Setting of display unit and resolution ...............................................................................................................29

5-1 Setting example for when an index table is used ................................................................................................................... 29

5-2 Setting example for when a linear mechanism is assembled ............................................................................................. 32

6 Home position setting ..........................................................................................................................................36

7 Wrap setting ...........................................................................................................................................................39

8 Setting of software limit ......................................................................................................................................44

9 Operation check ....................................................................................................................................................47

10 Backup of data .......................................................................................................................................................50

2 Operation

1 Flow of setting required for positioning operation ........................................................................................ 52

2 Setting of resolution .............................................................................................................................................53

3 Stored data (SD) operation ..................................................................................................................................55

3-1 Types of stored data (SD) operation ............................................................................................................................................. 55

3-2 Setting of data ...................................................................................................................................................................................... 59

3-3 Positioning SD operation ................................................................................................................................................................. 66

3-4 Positioning push-motion SD operation ...................................................................................................................................... 75

3-5 Continuous SD operation ................................................................................................................................................................. 78

3-6 Mode for link operation of operation data ................................................................................................................................ 83

3-7 Sequence function .............................................................................................................................................................................. 93

3-8 Extended operation data setting .................................................................................................................................................. 99

3-9 Stop operation ...................................................................................................................................................................................101

3-10 Base current and stop current ......................................................................................................................................................103

3-11 Acceleration/deceleration unit ....................................................................................................................................................104

3-12 Starting speed ....................................................................................................................................................................................104

2

Page 3

4 Return-to-home operation ................................................................................................................................105

4-1 High-speed return-to-home operation .....................................................................................................................................105

4-2 Return-to-home operation ............................................................................................................................................................107

5 Macro operation ..................................................................................................................................................121

5-1 Types of macro operation ..............................................................................................................................................................121

5-2 JOG operation.....................................................................................................................................................................................122

5-3 High-speed JOG operation ............................................................................................................................................................124

5-4 Inching operation .............................................................................................................................................................................126

5-5 Combined JOG operation ..............................................................................................................................................................128

5-6 Continuous operation .....................................................................................................................................................................130

5-7 Speed control operation .................................................................................................................................................................132

5-8 Speed control push-motion operation .....................................................................................................................................134

6 Relationship between operation type and operation data and parameter .............................................136

7 Position coordinate management ...................................................................................................................140

7-1 Overview of position coordinate management .....................................................................................................................140

7-2 Position coordinate origin ..............................................................................................................................................................144

7-3 Parameters related to ABZO sensor ............................................................................................................................................145

7-4 Mechanism settings parameter ...................................................................................................................................................146

7-5 Initial coordinate generation & wrap coordinate parameter ............................................................................................147

7-6 Mechanism limit ...............................................................................................................................................................................152

7-7 Mechanism protection ....................................................................................................................................................................152

7-8 Position coordinate information monitor function ..............................................................................................................153

3 I/O signals

1 Overview of I/O signals ......................................................................................................................................158

1-1 Overview of input signals...............................................................................................................................................................158

1-2 Overview of output signals ...........................................................................................................................................................159

1-3 Setting contents of input signals and output signals ..........................................................................................................160

2 Signal list ...............................................................................................................................................................165

2-1 Input signal list ...................................................................................................................................................................................165

2-2 Output signal list ...............................................................................................................................................................................167

3 Signal types ..........................................................................................................................................................172

3-1 Direct I/O ..............................................................................................................................................................................................172

3-2 Remote I/O ...........................................................................................................................................................................................181

4 Input signals .........................................................................................................................................................183

4-1 Operation control ..............................................................................................................................................................................183

4-2 Position coordinate management ..............................................................................................................................................202

4-3 Management of driver .....................................................................................................................................................................204

5 Output signals ......................................................................................................................................................207

5-1 Management of driver .....................................................................................................................................................................207

5-2 Management of operation .............................................................................................................................................................208

5-3 Latch information indication ........................................................................................................................................................217

5-4 Response output ...............................................................................................................................................................................218

3

Page 4

6 Timing chart .........................................................................................................................................................219

7 Power removal function (ETO function: External Torque O function) ....................................................222

7-1 Block diagram .....................................................................................................................................................................................222

7-2 Wiring example ..................................................................................................................................................................................223

7-3 Detection for error of the ETO function ....................................................................................................................................223

7-4 Reset of ETO-mode ...........................................................................................................................................................................224

7-5 Related parameters ..........................................................................................................................................................................224

7-6 Timing chart ........................................................................................................................................................................................225

7-7 For safe use ..........................................................................................................................................................................................227

4 Parameters

1 Parameter: Base setting .....................................................................................................................................230

2 Parameter: Motor and Mechanism (Coordinates/JOG/Home Operation) ................................................233

3 Parameter: ETO and Alarm and Info ................................................................................................................236

4 Parameter: I/O action and function .................................................................................................................239

5 Parameter: Direct-IN function ...........................................................................................................................244

6 Parameter: Direct-OUT function .......................................................................................................................245

7 Parameter: Remote-I/O function (R-I/O) .........................................................................................................246

8 Parameter: EXT-IN and VIR-IN and USR-OUT function (Extend) .................................................................248

9 Parameter: Communication & I/F .....................................................................................................................250

10 I/O signal assignment list ...................................................................................................................................256

10-1 Input signals ........................................................................................................................................................................................256

10-2 Output signals ....................................................................................................................................................................................257

5 Method of control via Modbus RTU (RS-485 communication)

1 Specication of Modbus RTU ............................................................................................................................260

1-1 Communication specications .....................................................................................................................................................260

1-2 Communication timing ...................................................................................................................................................................263

2 Message structure ...............................................................................................................................................264

2-1 Query .....................................................................................................................................................................................................264

2-2 Response ..............................................................................................................................................................................................266

3 Function codes .....................................................................................................................................................268

3-1 Reading from a holding register(s) (03h) ..................................................................................................................................268

3-2 Writing to a holding register (06h) ..............................................................................................................................................269

3-3 Diagnosis (08h) ..................................................................................................................................................................................270

3-4 Writing to multiple holding registers (10h) .............................................................................................................................271

3-5 Read/write of multiple holding registers (17h) ......................................................................................................................272

4 Flow of setting required for Modbus communication .................................................................................274

5 Guidance ...............................................................................................................................................................275

4

Page 5

6 Setting of switches ..............................................................................................................................................279

6-1 Protocol .................................................................................................................................................................................................279

6-2 Address number (slave address) ..................................................................................................................................................280

6-3 Transmission rate...............................................................................................................................................................................280

6-4 Termination resistor .........................................................................................................................................................................281

7 Setting of RS-485 communication ...................................................................................................................282

7-1 Parameters reected when turning on the power ................................................................................................................282

7-2 Parameters reected immediately after rewriting ................................................................................................................283

7-3 Forcible return of parameters to initial values (default function) ....................................................................................283

8 Example of data setting in Modbus RTU mode .............................................................................................284

8-1 Remote I/O command .....................................................................................................................................................................284

8-2 Positioning operation ......................................................................................................................................................................286

8-3 Continuous operation .....................................................................................................................................................................288

8-4 High-speed return-to-home operation .....................................................................................................................................292

9 Data setting method ...........................................................................................................................................294

9-1 Overview of setting method .........................................................................................................................................................294

9-2 Direct reference .................................................................................................................................................................................294

9-3 Indirect reference ..............................................................................................................................................................................295

10 Direct data operation .........................................................................................................................................302

10-1 Overview of direct data operation ..............................................................................................................................................302

10-2 Guidance ..............................................................................................................................................................................................303

10-3 Commands required for direct data operation ......................................................................................................................307

11 Group send ...........................................................................................................................................................312

12 Timing chart .........................................................................................................................................................314

12-1 Communication start .......................................................................................................................................................................314

12-2 Start of operation ..............................................................................................................................................................................314

12-3 Operation stop, speed change .....................................................................................................................................................314

12-4 General signals ...................................................................................................................................................................................315

12-5 Conguration ......................................................................................................................................................................................315

13 Detection of communication errors ................................................................................................................316

13-1 Communication errors ....................................................................................................................................................................316

13-2 Alarms related to RS-485 communication ...............................................................................................................................316

6 Method of control via industrial network

1 Flow of setting required for control via

industrial network ...............................................................................................................................................318

2 Setting of switches ..............................................................................................................................................319

2-1 Protocol .................................................................................................................................................................................................319

2-2 Address number (slave address) ..................................................................................................................................................320

2-3 Transmission rate...............................................................................................................................................................................320

2-4 Termination resistor .........................................................................................................................................................................320

5

Page 6

3 Method of control via CC-Link communication .............................................................................................322

3-1 Guidance ..............................................................................................................................................................................................322

3-2 Operation example of command selection method ............................................................................................................327

3-3 Operation example of command xation method ...............................................................................................................334

4 Method of control via EtherCAT communication ..........................................................................................340

4-1 Guidance ..............................................................................................................................................................................................340

4-2 Basic operating procedures ...........................................................................................................................................................345

5 Group function.....................................................................................................................................................348

5-1 Group address ....................................................................................................................................................................................349

5-2 Group action modes ........................................................................................................................................................................349

6 Simple direct data operation ............................................................................................................................352

6-1 Types of simple direct data operation .......................................................................................................................................352

6-2 How to use simple direct data operation monitor 0 ............................................................................................................353

6-3 How to use simple direct data operation monitor 1 ............................................................................................................355

7 Detection of communication errors ................................................................................................................357

7-1 Communication errors ....................................................................................................................................................................357

7-2 Alarms ....................................................................................................................................................................................................358

7 Address/code lists

1 Update timing of parameters ............................................................................................................................360

2 I/O commands ......................................................................................................................................................361

3 Group commands ................................................................................................................................................363

4 Protect release commands ................................................................................................................................364

5 Direct data operation commands ....................................................................................................................365

6 Simple direct data operation commands .......................................................................................................367

7 Maintenance commands....................................................................................................................................368

7-1 How to execute maintenance commands ...............................................................................................................................369

8 Monitor commands .............................................................................................................................................370

9 Overview of operation data R/W command address arrangement ...........................................................381

9-1 Overview of direct reference .........................................................................................................................................................382

9-2 Overview of oset reference .........................................................................................................................................................382

9-3 Overview of direct reference (compatible) ..............................................................................................................................382

10 Operation data R/W commands .......................................................................................................................383

10-1 Direct reference (Modbus communication) ............................................................................................................................383

10-2 Oset reference (Modbus communication) ............................................................................................................................388

10-3 Oset reference (industrial network) .........................................................................................................................................388

11 Operation data R/W commands (compatible) ...............................................................................................395

11-1 Direct reference (Modbus communication) ............................................................................................................................395

11-2 Direct reference (industrial network) .........................................................................................................................................396

6

Page 7

12 Operation I/O event R/W commands ...............................................................................................................398

12-1 Setting method ..................................................................................................................................................................................398

12-2 Direct reference .................................................................................................................................................................................398

12-3 Oset reference .................................................................................................................................................................................400

13 Extended operation data setting R/W commands ........................................................................................402

14 Parameter R/W commands ................................................................................................................................403

14-1 Driver action simulation setting parameter ............................................................................................................................403

14-2 Base setting parameters .................................................................................................................................................................403

14-3 Position coordinate parameters...................................................................................................................................................404

14-4 Operation parameters .....................................................................................................................................................................405

14-5 Direct data operation parameters ...............................................................................................................................................405

14-6 ABZO sensor setting parameters .................................................................................................................................................406

14-7 Mechanism settings parameters .................................................................................................................................................406

14-8 Initial coordinate generation & wrap coordinate parameters ..........................................................................................407

14-9 JOG/HOME/ZHOME operation information setting parameters .....................................................................................407

14-10 Power removal function setting parameters ..........................................................................................................................409

14-11 Alarm setting parameters ..............................................................................................................................................................409

14-12 Information setting parameters ...................................................................................................................................................409

14-13 I/O parameter .....................................................................................................................................................................................412

14-14 Direct I/O setting parameters .......................................................................................................................................................416

14-15 Remote I/O setting parameters ....................................................................................................................................................419

14-16 Extended input setting parameters ...........................................................................................................................................422

14-17 Dierential output setting parameters .....................................................................................................................................422

14-18 Virtual input parameters .................................................................................................................................................................423

14-19 User output setting parameters ...................................................................................................................................................424

14-20 Driver mode setting parameters .................................................................................................................................................424

14-21 LED status indication setting parameters ................................................................................................................................425

14-22 RS-485 communication setting parameters ............................................................................................................................425

14-23 Indirect reference setting parameters .......................................................................................................................................427

14-24 Our exclusive parameters for maintenance. ............................................................................................................................428

15 I/O signal assignment list ...................................................................................................................................429

15-1 Input signals ........................................................................................................................................................................................429

15-2 Output signals ....................................................................................................................................................................................430

8 Measures for various cases

1 Vibration suppression ........................................................................................................................................434

1-1 LPF (speed lter) and moving average lter............................................................................................................................434

1-2 Smooth drive function ....................................................................................................................................................................435

1-3 Resonance suppression ..................................................................................................................................................................436

2 Suppression of heat generation and noise ....................................................................................................437

2-1 Automatic current cutback function ..........................................................................................................................................437

2-2 Current control mode ......................................................................................................................................................................437

2-3 Ramp up/ramp down rate of operating current ....................................................................................................................440

2-4 Deviation acceleration suppression ...........................................................................................................................................440

7

Page 8

3 Backup of data of

MEXE02

in driver ...............................................................................................................441

4 Check of product information...........................................................................................................................442

5 Copying the setting value of the ABZO sensor to a driver ..........................................................................444

6 Indicating the warning before writing data ...................................................................................................445

7 Monitoring of load factor...................................................................................................................................447

8 Utilizing the waveform monitor .......................................................................................................................448

9 Alarm and information

1 Alarms ....................................................................................................................................................................452

1-1 Alarm reset ...........................................................................................................................................................................................452

1-2 Alarm records......................................................................................................................................................................................452

1-3 Alarm generation conditions ........................................................................................................................................................452

1-4 Alarm list ...............................................................................................................................................................................................453

1-5 Monitor of alarm records ................................................................................................................................................................460

1-6 Timing charts ......................................................................................................................................................................................464

2 Information ...........................................................................................................................................................466

2-1 Information records ..........................................................................................................................................................................469

2-2 Information list ...................................................................................................................................................................................469

2-3 Monitor of information function .................................................................................................................................................472

3 Utilization for maintenance of equipment .....................................................................................................473

3-1 Cumulative load .................................................................................................................................................................................473

3-2 Tripmeter (travel distance) and odometer (cumulative travel distance) .......................................................................475

3-3 Latch function ....................................................................................................................................................................................476

10 Extended setting for pulse-input operation

1 Flow of operation and extended setting ........................................................................................................482

2 Setting with switches (only for pulse-input type) .........................................................................................483

2-1 Resolution ............................................................................................................................................................................................483

2-2 Pulse input mode ..............................................................................................................................................................................484

2-3 Operating current .............................................................................................................................................................................484

2-4 Command lter ..................................................................................................................................................................................485

3 Extending settings by parameters ...................................................................................................................487

3-1 Resolution ............................................................................................................................................................................................487

3-2 Pulse input mode ..............................................................................................................................................................................487

3-3 Operating current .............................................................................................................................................................................489

3-4 Command lter ..................................................................................................................................................................................489

4 I/O signals related to pulse-input operation ..................................................................................................491

4-1 LED (only for the pulse-input type) ............................................................................................................................................491

4-2 Input signals ........................................................................................................................................................................................491

4-3 Output signal ......................................................................................................................................................................................492

4-4 Timing chart ........................................................................................................................................................................................494

8

Page 9

5 Monitor function .................................................................................................................................................495

5-1 I/O position output function .........................................................................................................................................................495

5-2 Pulse request function.....................................................................................................................................................................497

6 Push-motion operation ......................................................................................................................................499

6-1 Preparation for operation ...............................................................................................................................................................499

6-2 Performing the push-motion operation ...................................................................................................................................502

6-3 Timing chart ........................................................................................................................................................................................503

11 Appendix

1 Change of function of HOME PRESET switch .................................................................................................506

2 Change of assignments of A-phase/B-phase outputs ..................................................................................507

3 LEDs on the driver ...............................................................................................................................................509

3-1 Lighting state of LEDs ......................................................................................................................................................................509

3-2 Change of lighting condition of LED ..........................................................................................................................................510

4 Simulating the driver operation .......................................................................................................................511

4-1 Preparation and operating procedure of the driver simulation mode ..........................................................................512

4-2 Coordinate ...........................................................................................................................................................................................516

4-3 Monitor .................................................................................................................................................................................................517

4-4 Operation .............................................................................................................................................................................................518

4-5 I/O signals .............................................................................................................................................................................................519

4-6 Alarm .....................................................................................................................................................................................................520

5 Use of general signals .........................................................................................................................................521

9

Page 10

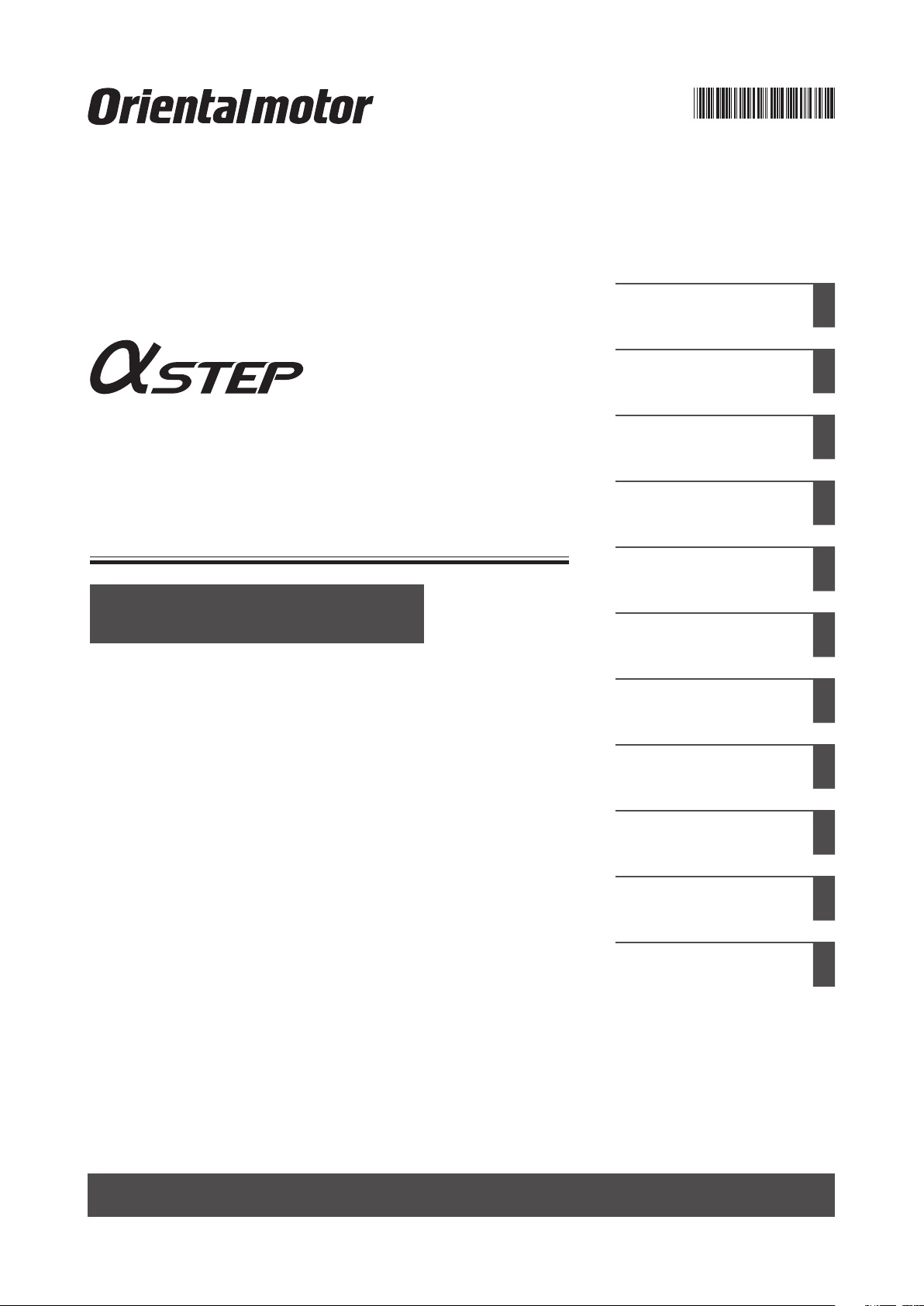

1 Characteristics of the

HOME

(3)

-

LS +LS

ABZO sensor

stored in the AZ Series

Built-in ABZO sensor

The ABZO sensor is a small-sized low-cost mechanical multirotation absolute sensor that does not require a battery.

It can detect the absolute positions for 1800 revolutions of the

motor shaft from the reference home position, so the position is

never missed.

* The motors of frame size 20 mm (0.79 in.) or 28 mm (1.10 in.) are for 900

revolutions.

No external sensor is required

Return-to-home operation can be executed without using external sensors such as the home position sensor and

limit sensors.

zSaving of wiring

AZ

Series

zCost-cutting for the system

zNot inuenced by malfunction of the sensor

No external sensor is required

Return-to-home time has been shortened

zNo return-to-home operation is required

Since the position information is maintained even if the power is interrupted, positioning operation can be continued

without return-to-home operation after emergency stop or power failure.

zHigh-speed return-to-home

Since the ABZO sensor stores the home position, the motor can return to the home position at a high speed.

Home position detection of traditional position-

control motors

The home position is detected at a low speed by sensing

the limit sensor and the home position sensor.

(2)

(1)

Home position detection of the AZ

Series

The motor directly returns to the home position

stored in the ABZO sensor at a high speed.

(1)

Home position

10

Page 11

No battery is required

No battery is required because the position information is maintained by the ABZO sensor.

zReduction of maintenance frequency

zReplacing a battery is not required

zThe position information is maintained for a long transportation period of equipment

11

Page 12

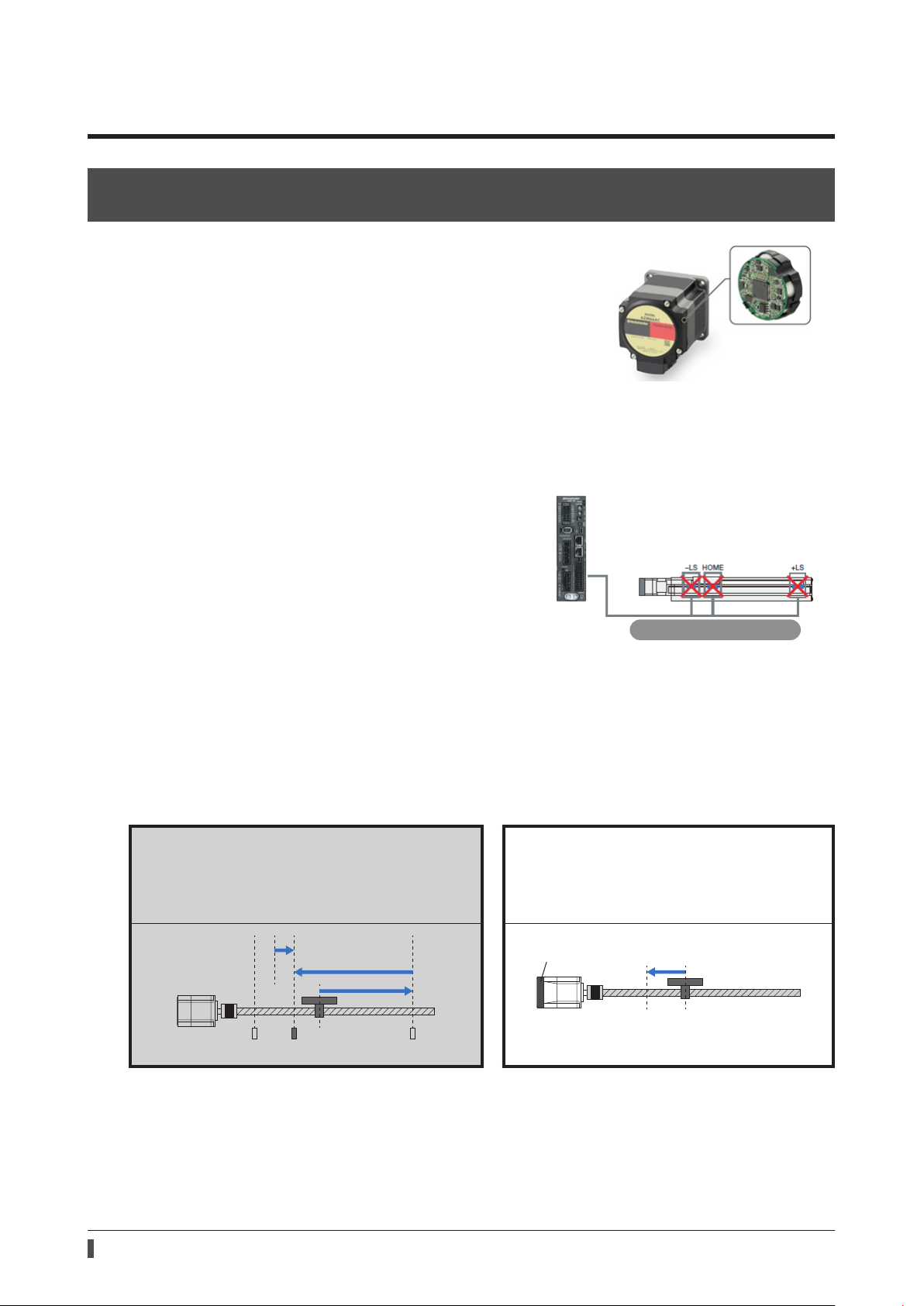

2 Operations possible with the

Speed

Time

START input

Speed

Time

START input

Push-motion

Speed

Time

START input

Speed

Coordinate

Loop oset

push-motion

Sensor

Speed

AZ

Series

Execute operation by setting the motor operating speed, position (travel amount)

and other items as operation data

Stored data (SD) operation p.55

Positioning operation is performed. Push-motion operation is performed. Continuous operation is performed.

0

Positioning SD

operation

The command position of the rotating mechanism is returned to "0" for

every rotation.

p.66

Positioning push-motion

0

SD operation

p.75

0

Continuous SD

operation

p.78

The position and the speed can be set easily

with the

MEXE02.

Wrap function p.142

Use of sequence function

Linked operations are repeated for the number of times specied.

When you use the loop oset function, you can increase or decrease the travel amount every time the operation is repeated.

Absolute positioning

operation

X-axis

Absolute positioning

operation

Loop function p.93 Loop oset function

Operation is transited by setting an arbitrary I/O signal as a trigger.

The motor can transit to a dierent operation depending on whether or not the trigger signal has been detected.

Torque control

Push-motion

operation

Coordinate

With push-motion

Continuous

operation

Z-axis

Absolute positioning

operation

Event jump function p.95

12

Without

Page 13

Return to the home position

ABZO sensor

HOME

(3)

-

LS +LS

The motor returns to the home position at the speed same

as normal positioning operation without using an external

sensor.

(1)

Home position

stored in the AZ Series

High-speed return-to-home

operation

p.105 Return-to-home operation p.107

The motor returns to the home position by using external

sensors or the stopper on the machine.

(2)

(1)

Perform test operation and operation check

zMacro operation (_p.121)

A specic input signal is turned ON to execute the operation corresponding to the signal.

The operating speed, travel amount, acceleration/deceleration rate are set with parameters.

Start operation at the same time as writing of operation data

(Modbus RTU)

zDirect data operation (_p.302)

You can use this operation to change the setting of operation data frequently, to change the speed and travel amount

according to the load, for example.

When the data of the trigger set to be reected is input by using the touch panel, etc., it is reected to the operation

at the same time as input.

Perform operation by inputting pulses

zPulse-input operation (_p.481)

Operation data are set to the master controller to execute operation. The operation data to be executed are selected

in the master controller.

Pulse input operation cannot be executed with the built-in controller type driver.

13

Page 14

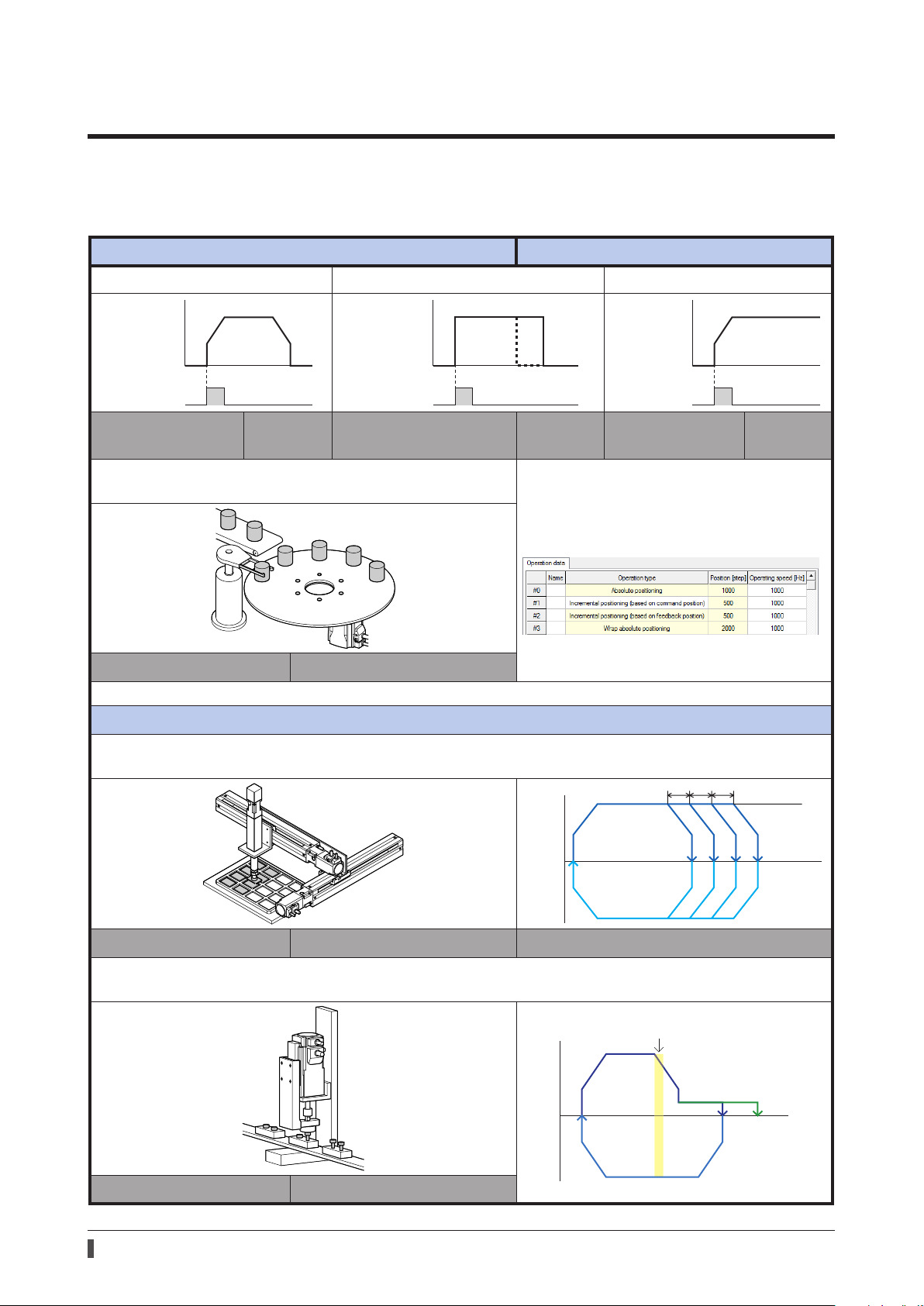

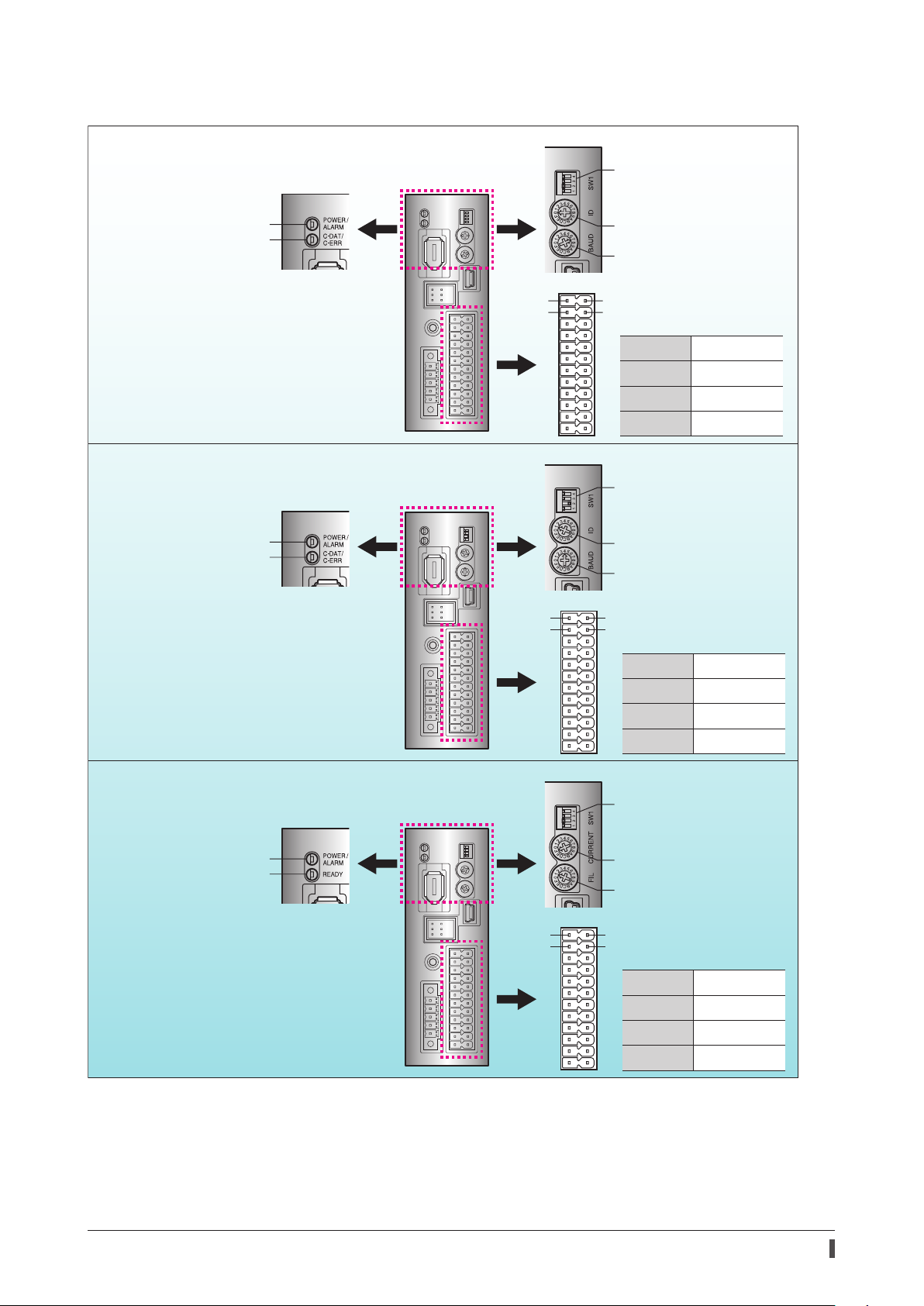

3 Types and overview of driver

There are 3 types of drivers in the AZ Series as shown below. I/O signals, setting items, and LEDs vary depending on

the driver type.

AC power input type

Built-in controller type

Operates via industrial network

Monitors the motor information via a

programmable controller or touchscreen

Operates via RS-485 communication

Operates via I/O control

Pulse input type with RS-485

communication interface

Operates via industrial network

Monitors the motor information via a

programmable controller or touchscreen

Operates via RS-485 communication

Operates via I/O control

Operates by pulse input

PWR/ALM LED

C-DAT/C-ERR LED

Address number

Transmission rate

Function setting switch

Protocol

Address number (extended)

1

2

1

2

13

Pin Nos.1, 2, 13, and 14

14

are for control input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

PWR/ALM LED

C-DAT/C-ERR LED

Address number

Transmission rate

Function setting switch

Protocol

Address number (extended)

13

Pin Nos.1, 2, 13, and 14

14

are for pulse input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

DIN0 [START]

DIN2 [M1]

DIN1 [M0]

DIN3 [M2]

CW+ [PLS+]

CCW+ [DIR+]

CW- [PLS-]

CCW- [DIR-]

Pulse input type

Operates by pulse input

14

PWR/ALM LED

READY LED

Base current rate

Command lter

Function setting switch

Pulse input mode

Resolution

1

2

13

Pin Nos.1, 2, 13, and 14

14

are for pulse input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

CW+ [PLS+]

CCW+ [DIR+]

CW- [PLS-]

CCW- [DIR-]

Page 15

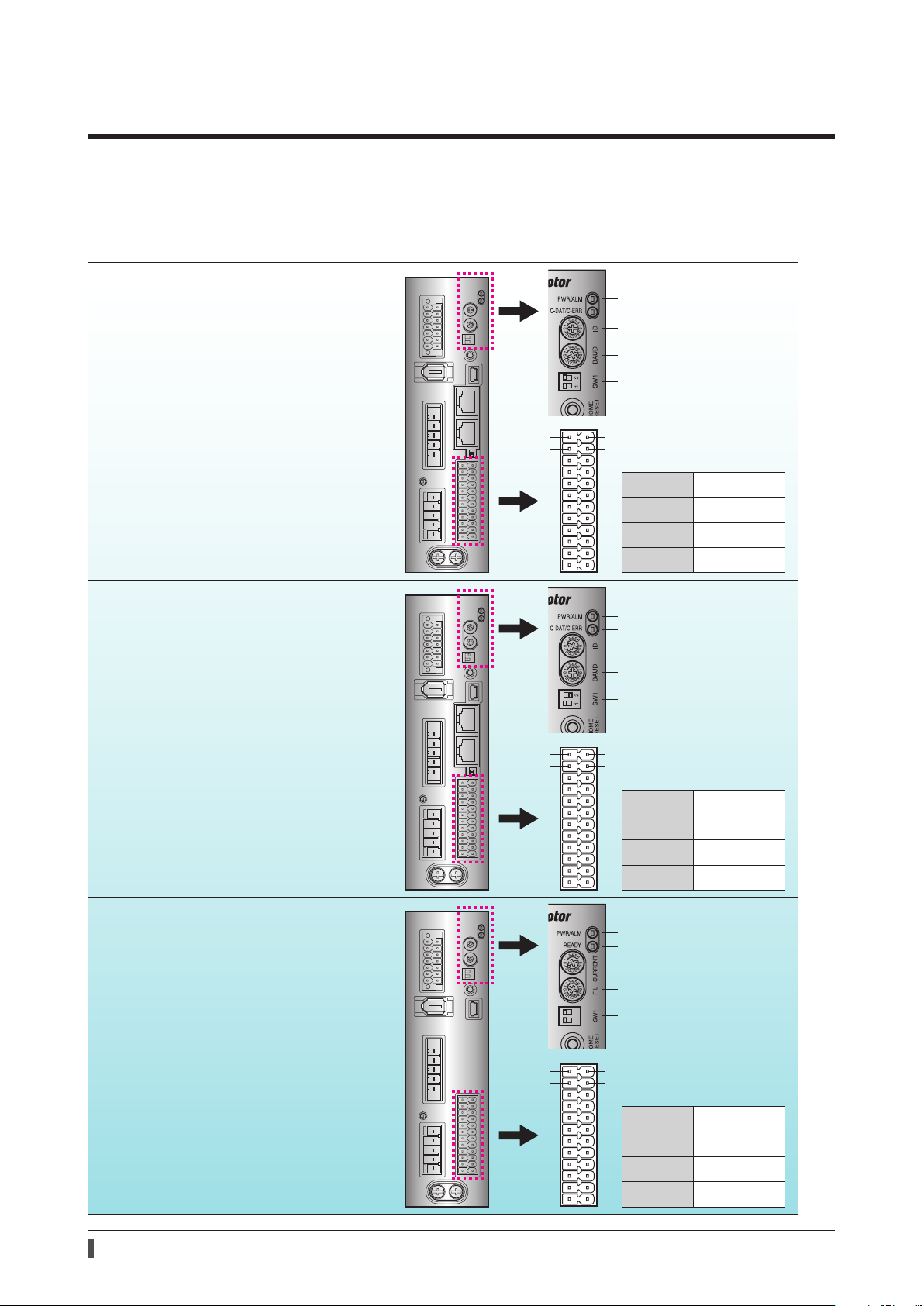

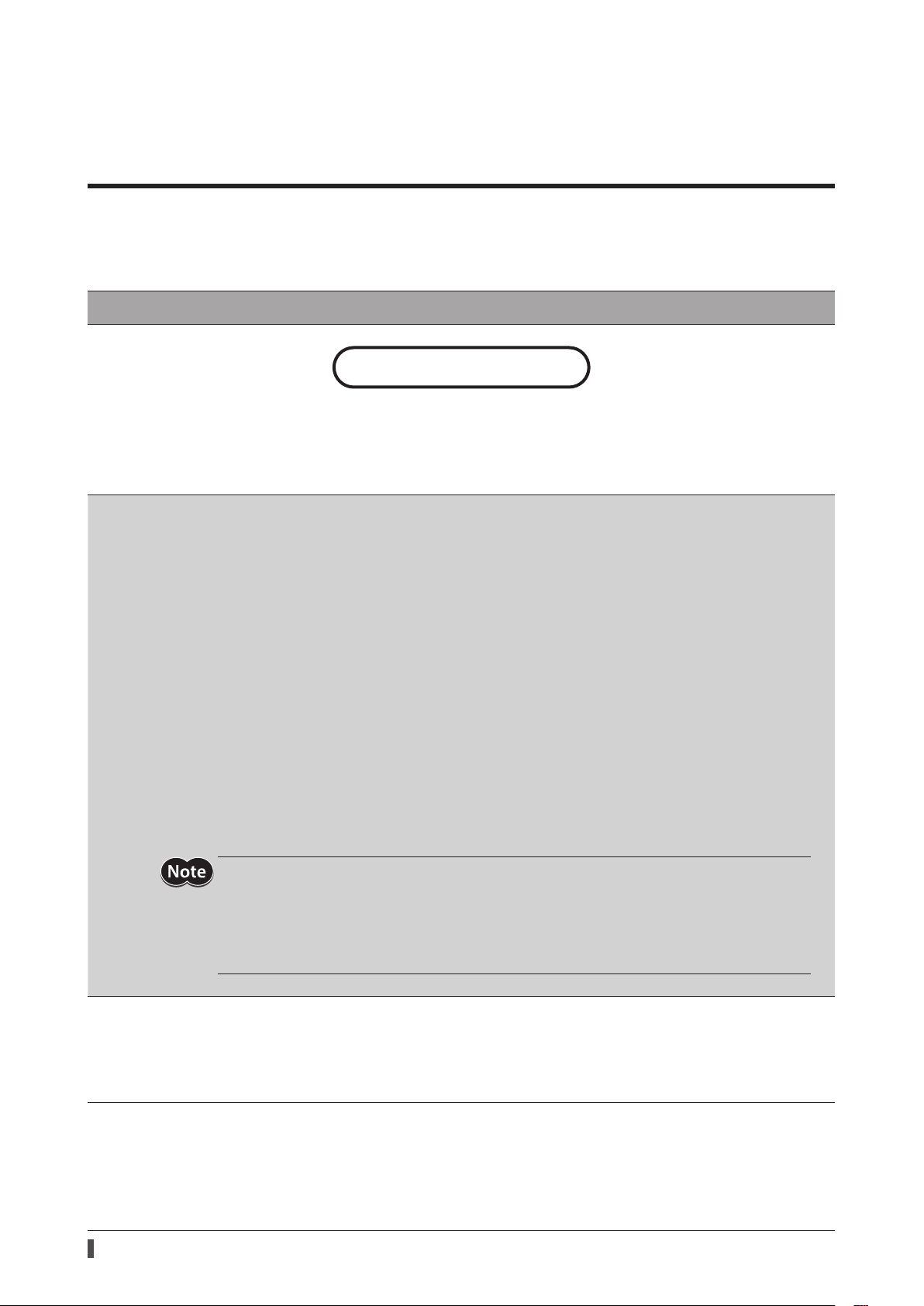

DC power input type

Built-in controller type

POWER/ALARM LED

C-DAT/C-ERR LED

Function setting switch

Protocol

Address number (extended)

Address number

Transmission rate

Operates via industrial network

Monitors the motor information via a

programmable controller or touchscreen

Operates via RS-485 communication

Operates via I/O control

Pulse input type with RS-485

communication interface

POWER/ALARM LED

C-DAT/C-ERR LED

Operates via industrial network

Monitors the motor information via a

programmable controller or touchscreen

Operates via RS-485 communication

Operates via I/O control

Operates by pulse input

1

2

13

Pin Nos.1, 2, 13, and 14

14

are for control input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

DIN0 [START]

DIN2 [M1]

DIN1 [M0]

DIN3 [M2]

Function setting switch

Protocol

Address number (extended)

Address number

Transmission rate

1

2

13

Pin Nos.1, 2, 13, and 14

14

are for pulse input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

CW+ [PLS+]

CCW+ [DIR+]

CW- [PLS-]

CCW- [DIR-]

Pulse input type

POWER/ALARM LED

READY LED

Operates by pulse input

When "PULSE-I/F" is described in this manual or the

When "PULSE-I/F" is described in this manual or the

•Pulse input type with RS-485 communication interface.

•Pulse input type

MEXE02

Function setting switch

Pulse input mode

Resolution

Base current rate

Command lter

1

2

13

Pin Nos.1, 2, 13, and 14

14

are for pulse input

Pin No.1

Pin No.2

Pin No.13

Pin No.14

CW+ [PLS+]

CCW+ [DIR+]

CW- [PLS-]

CCW- [DIR-]

MEXE02

, the contents are applied to the following drivers.

15

Page 16

4 How to use OPERATING MANUALS for

product

OPERATING MANUALS for the AZ Series are listed below.

The OPERATING MANUAL Function Edition (this manual) does not come with the product.

Always keep the manual where it is readily available.

Type and description of OPERATING MANUAL

Read these manuals rst

Series AC Power Input/DC Power Input

AZ

•Motor Edition (supplied with the motor)

•Driver Edition (supplied with the driver)

These manuals explain items from preparation to basic

operations, etc.

This manual explains more detailed operations, functions,

etc. that are not described in OPERATING MANUAL

supplied with the product.

Series AC Power Input/DC Power Input

AZ

•Function Edition (this manual)

•The setting unit may vary depending on the application such as the

Note that when you set the operation data and parameters.

This manual use a setting unit "step" for explanation.

•This manual describes the contents of the driver Ver.4.00 and later.

Note that some functions can not be used in a driver older than Ver.4.00.

You can check the driver version on the unit information monitor of the

Series UL APPENDIX

AZ

•APPENDIX UL Standards for the AZ Series

* Attached to the UL Standard qualied product.

•Before starting operation

•Operation

•I/O signals

•Parameter

•Method of control via Modbus RTU (RS-485

communication)

•Method of control via industrial network

•Address list

•Measures for various cases

•Alarm and information

•Extended setting for pulse input operation

MEXE02.

This appendix includes information required for

certication of the UL Standards.

MEXE02.

(

_

p.442)

16

Page 17

Type and description of OPERATING MANUAL

Motorized actuator

•Actuator Edition (supplied with the actuator)

•Function Setting Edition

The Actuator Edition explains setting methods and

maintenance for actuators.

The Function Setting Edition explains settings of

parameters required for when an actuator is combined

with a driver.

Network Converter

•USER MANUAL

About terms and units

Terms and units to be used vary depending on a motor or motorized actuator. This manual explains by using the

terms of the motor.

When the motorized actuator is used, read this manual by replacing the terms.

Ter m

Unit

Motor Motorized actuator

Torque Thrust force

Moment of inertia Mass

Rotation Movement

CW direction Forward direction

CCW direction Reverse direction

Rotation speed Speed

Resolution Minimum travel amount

N·m N

kHz/s m/s

2

This manual explains functions, installation/connection

methods, operating methods and others about the

network converter.

17

Page 18

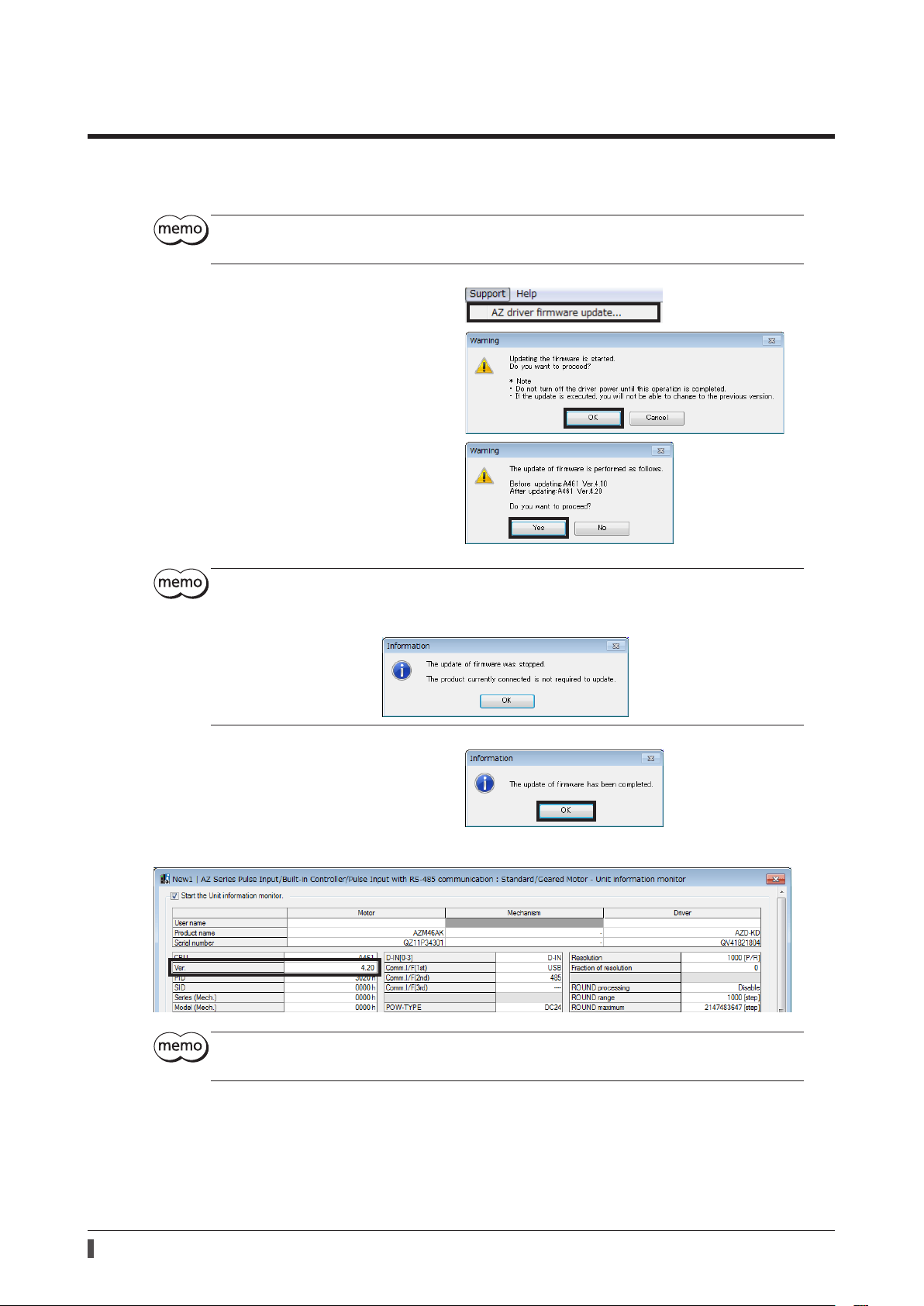

5 Expansion of supported contents

For drivers of the AZ Series, the rmware can be updated using the support software

Download the latest

•Stop the motor before starting the update of rmware.

•Check on the Oriental Motor Website for the latest rmware version.

1. Click on [AZ driver rmware update] from the

[Support] menu.

2. Click [OK].

3. Click [Yes].

Updating the rmware starts.

•Do not turn o the driver power until the update of rmware is completed.

•Once the update of rmware is executed, the version cannot be returned to the previous one.

•If the rmware has already been updated, the following dialog box is shown.

MEXE02

from Oriental Motor Website Download Page.

MEXE02

(ver.3.51 or later).

4. After it is completed, click [OK].

The rmware version can be checked with the unit information monitor.

Even if the rmware is updated, the settings for the operation data and parameters before updating

have been retained.

18

Page 19

1

Before starting operation

This chapter explains contents to be performed before starting

operation.

1 Steps of preparation for operation .........................................................................20

2 Starting the

3 Copying the xed value (parameter) of the ABZO sensor to driver ........... 22

4 Creation of recovery data le and method of recovery .................................. 24

5 Setting of display unit and resolution ................................................................... 29

6 Home position setting ................................................................................................ 36

7 Wrap setting ................................................................................................................... 39

8 Setting of software limit ............................................................................................. 44

9 Operation check ............................................................................................................ 47

10 Backup of data ............................................................................................................... 50

MEXE02

................................................................................................. 21

Page 20

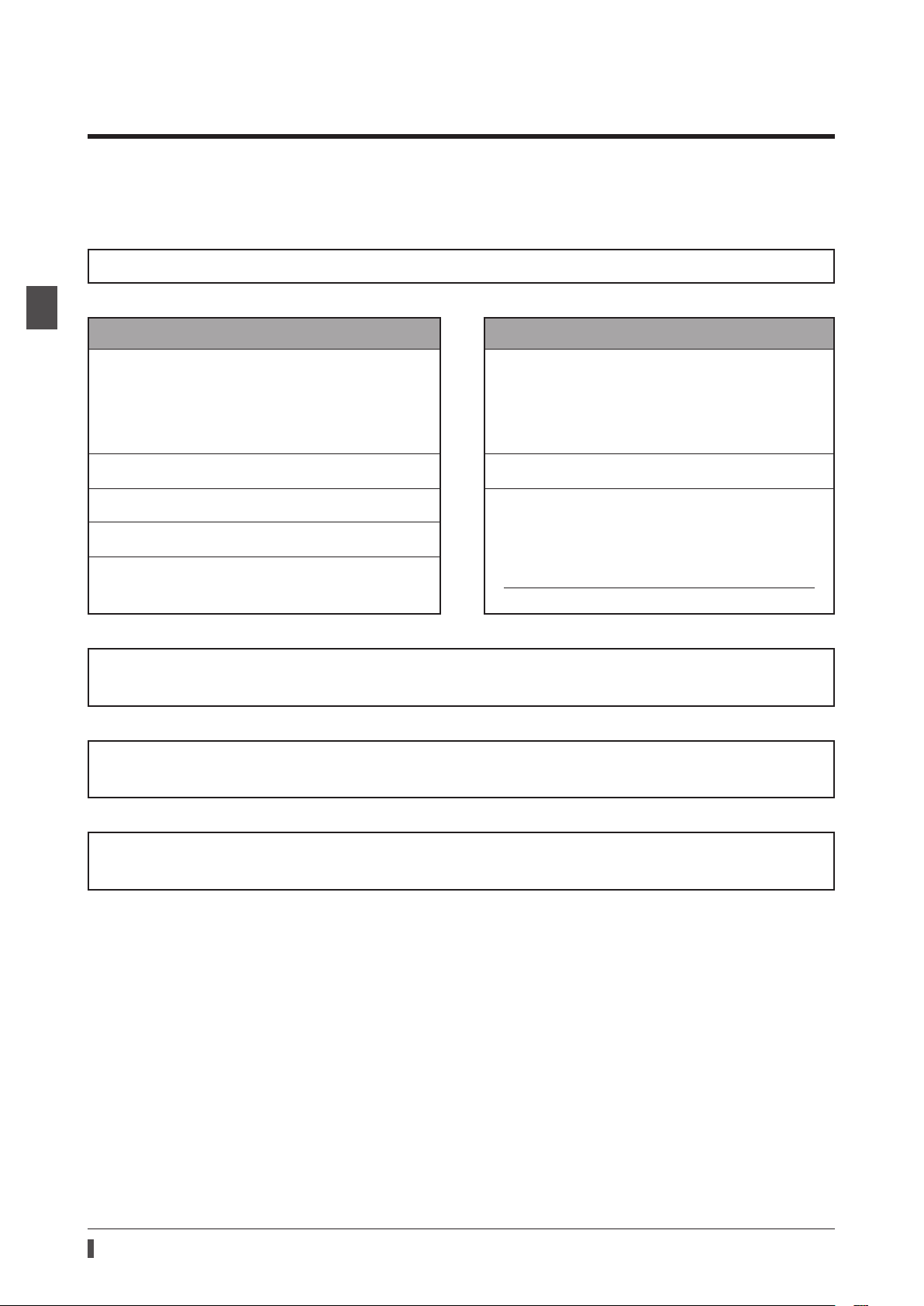

Steps of preparation for operation

1 Steps of preparation for operation

1 Before starting operation

To prepare for operation, use the

Since the procedure is dierent in motors and motorized actuators, perform the preparation for operation according

to the product used.

Motor (standard type/geared type) Motorized actuator

Setting of display unit and resolution

p.29

_

Set the display unit and resolution with the "User unit

setting support wizard" of the

Home position setting

Wrap setting

Set the wrap function as necessary.

_

MEXE02

_

p.39

MEXE02

p.36

.

Starting the

.

MEXE02

Match the xed value of the ABZO sensor with the setting

p.21

_

Copying the xed value (parameter)

of the ABZO sensor to driver _p.22

value of the driver parameter in the

Creation of recovery data le and method of

recovery _p.24

Save the information of the factory setting.

Perform before installing to equipment without fail.

MEXE02

.

Setting of software limit

If a sensor is not used, the setting of the software limit is recommended.

Operation check

Check the set operation with "Teaching, remote operation" of the

Backup of data

Back up the set data.

_

_

_

p.47

p.50

p.44

MEXE02

.

20

Page 21

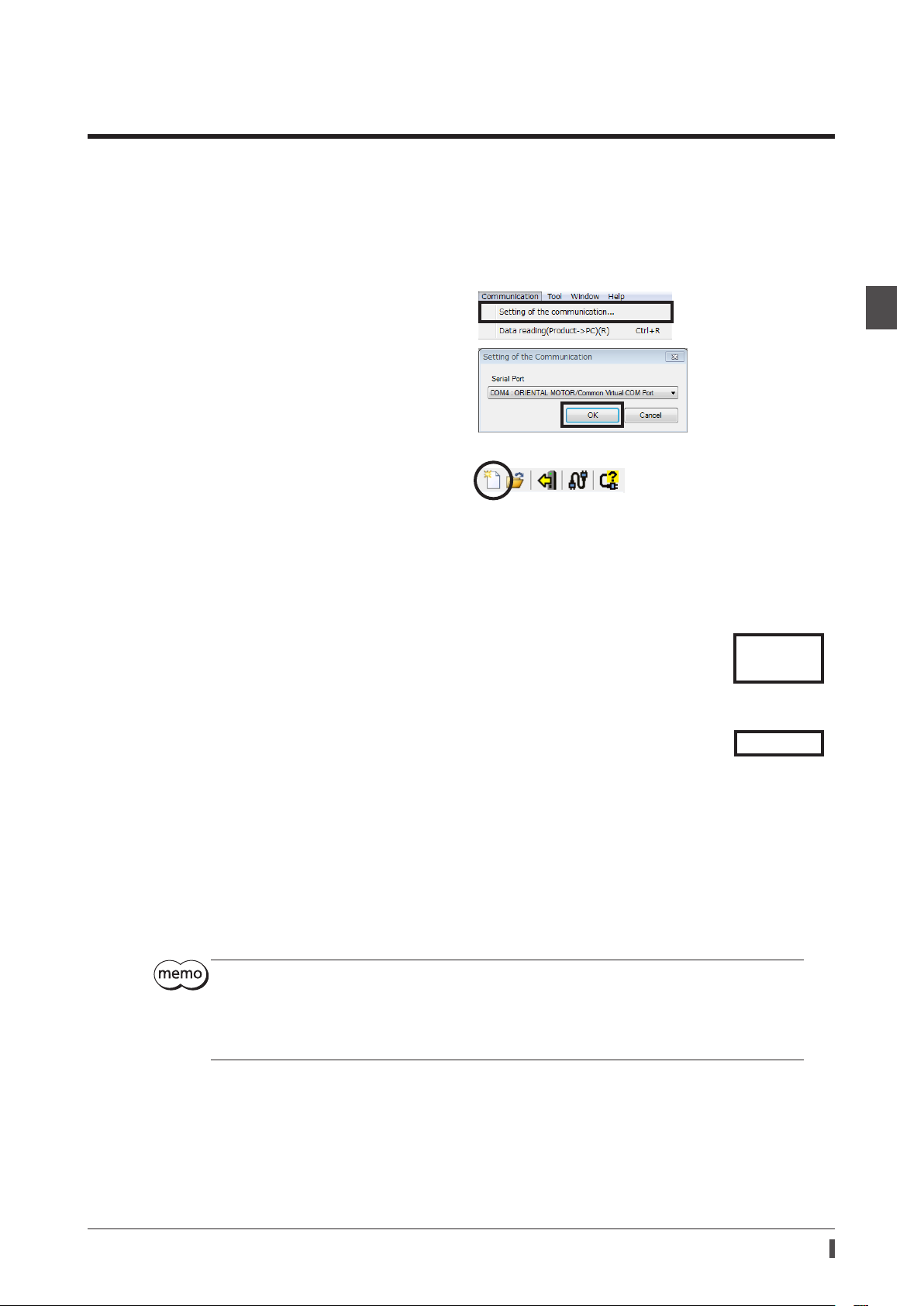

Starting the MEXE02

2 Starting the

1. Connect the PC on which the

1) Start the

2) Connect the driver and PC with a USB cable.

3) Turn on the power to the driver.

2. Set the communication port.

1) Click [Setting of the communication] from the

[Communication] menu.

2) Select the "ORIENTAL MOTOR/Common virtual

COM port", and click [OK].

3. Select the product.

1) Click the [New] icon in the toolbar.

2) Click [Search model] on the Select product

window.

MEXE02

.

MEXE02

MEXE02

has been installed and a driver.

1 Before starting operation

3) Check the connected product is selected and

click [OK].

For the pulse input type driver, if No.1 of the function setting switch (SW1) is set to ON (10,000 P/R),

"Resolution 10,000 P/R" is selected in the "Motor/actuator" eld on the "Select product" window. If

"Resolution 10,000 P/R" is selected, the setting by the user unit setting support wizard cannot be

performed. When the resolution is set with the parameter, set the No.1 of the SW1 to OFF. The new

settings of SW1 will become eective after the power is cycled.

After this, the procedure varies based on the product used. Refer to the corresponding page.

Customers who use the standard type and geared type motors _p.29

Customers who use motorized actuators _p.22

21

Page 22

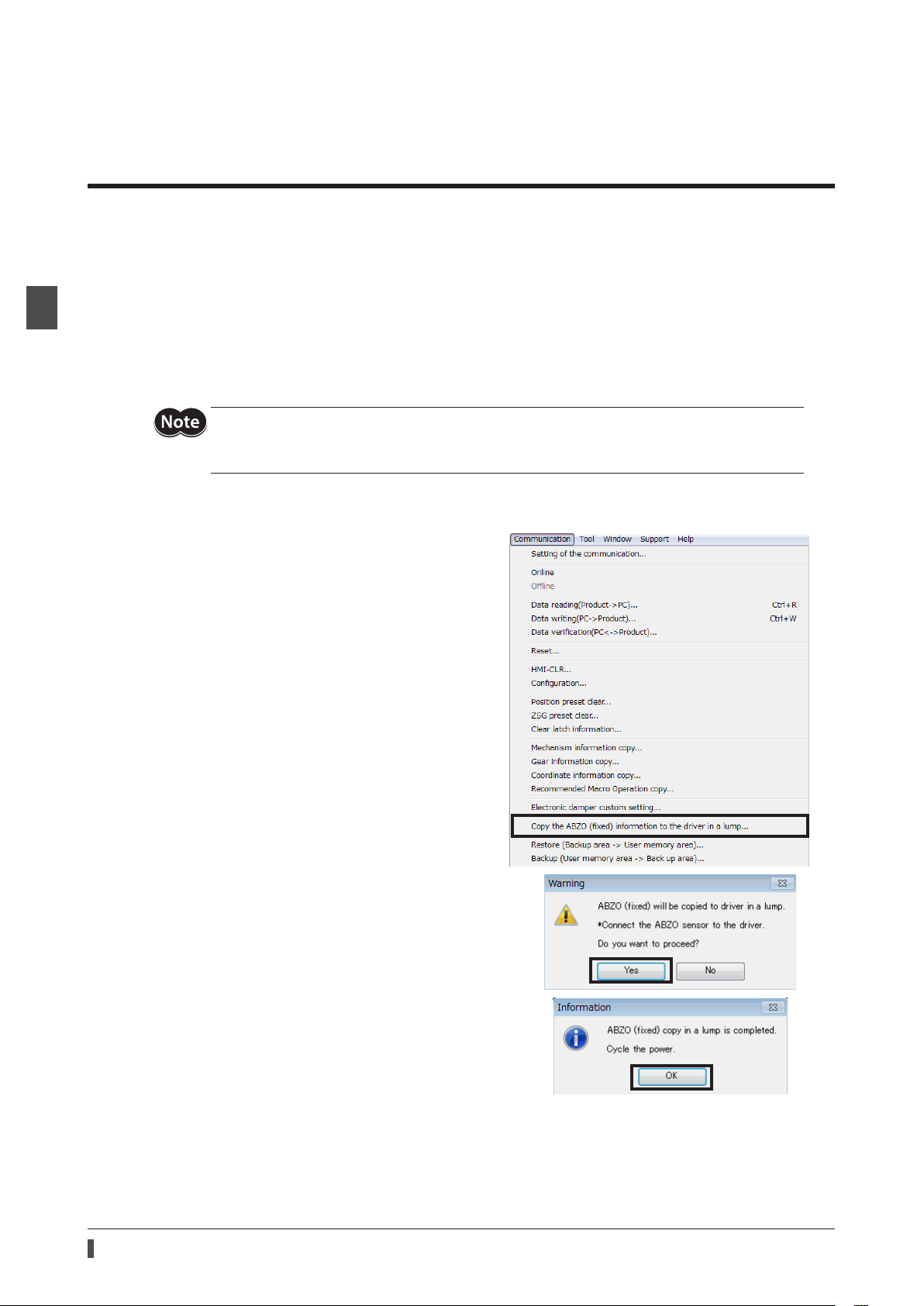

1 Before starting operation

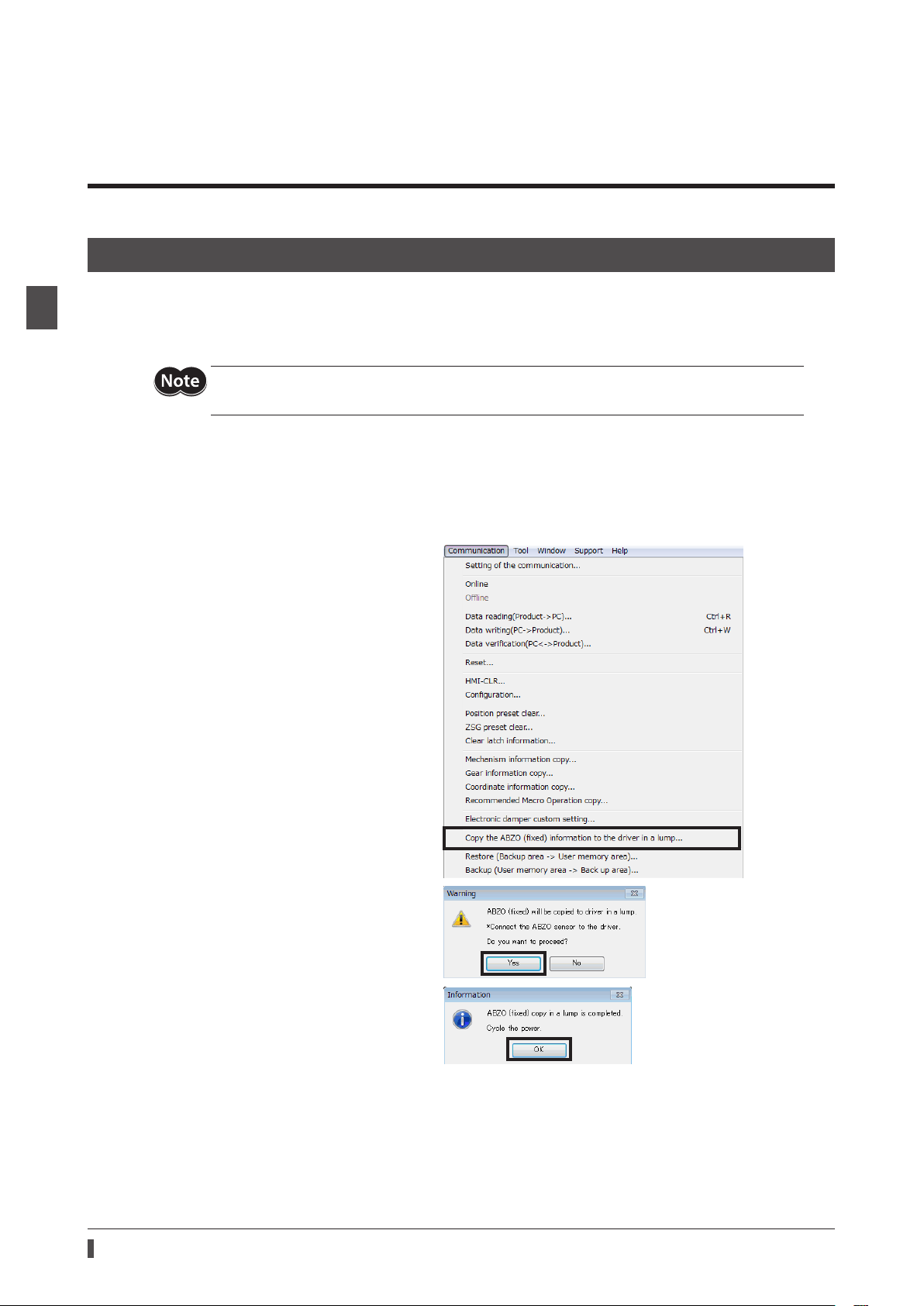

Copying the xed value (parameter) of the ABZO sensor to driver

3 Copying the xed value (parameter) of

the ABZO sensor to driver

For parameters of the AZ Series, the dierent values are stored in the ABZO sensor and driver.

The values based on the product specications such as recommended macro operation and position coordinate

information are stored in the ABZO sensor. The values stored in the ABZO sensor cannot be changed because of the

xed value.

Meantime, the values for the standard type (motor only) are stored in the driver parameters.

In a state of the factory shipment, parameters stored in the ABZO sensor are used preferentially. However, if

parameters are changed with the

be changed to the values set in the driver parameters. Therefore, an unexpected movement may cause when an

operation is executed. In order to prevent such troubles, copy the xed value in the ABZO sensor to the driver

parameter, and match the setting value of the driver parameter and the xed value of the ABZO sensor.

After writing the parameter (example: electronic gear, etc.), which was changed to [Manual setting]

and set, from the

parameter that was changed with the manual setting does not return to the xed value.

MEXE02

MEXE02

or other methods, all parameters including the changed parameters will

to the driver, even if the xed value of the ABZO sensor is copied, the

Procedure

1. Click the [Communication] menu of the

select the [Copy the ABZO (xed) information to the

driver in a lump].

2. Click [Yes].

The ABZO information (xed value) is copied in the

driver.

MEXE02

, and

22

3. After it is completed, click [OK].

4. Cycle the driver power.

5. Check whether the copied value is applied on the unit

information monitor window.

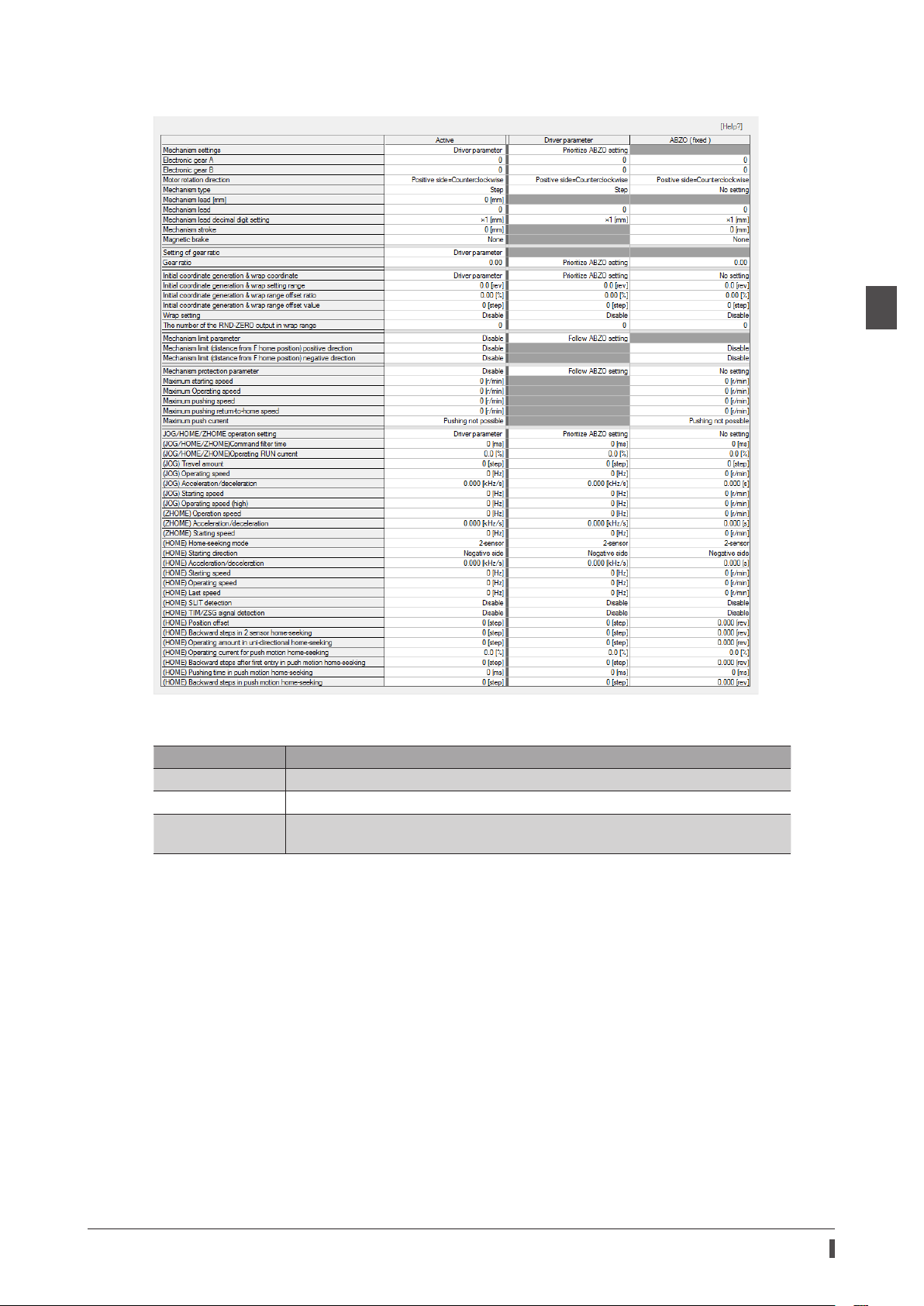

Page 23

Copying the xed value (parameter) of the ABZO sensor to driver

zUnit information monitor window

1 Before starting operation

zDescription of each item

Item Description

Active Parameter value presently used is shown.

Driver parameter Parameter value set in the driver using the

ABZO (xed)

The values of parameters stored in the ABZO sensor are shown.

They cannot be changed because of the xed value.

MEXE02

or communication is shown.

23

Page 24

1 Before starting operation

Creation of recovery data le and method of recovery

4 Creation of recovery data le and

method of recovery

4-1 Creating the recovery data le

The recovery data le is a le that information of the factory setting is stored.

At the beginning, create the recovery data le for when the product is replaced with maintenance or the product is

malfunctioned.

Save the recovery data le in a PC as a data le.

•If you are the customer to use a motorized actuator, create the recovery data le without fail.

•Be sure to create the recovery data le before installing the motorized actuator to equipment.

Creating procedure for recovery data le

1. Start the

Check the connected product is selected.

2. Copy the ABZO information (xed value).

1) Click [Copy the ABZO (xed) information

2) Click [Yes].

MEXE02

to the driver in a lump] from the

[Communication] menu.

The ABZO information (xed value) is

copied in the driver.

in the steps of "2 Starting the

MEXE02

" on p.21.

24

3) After it is completed, click [OK].

4) Cycle the driver power.

Page 25

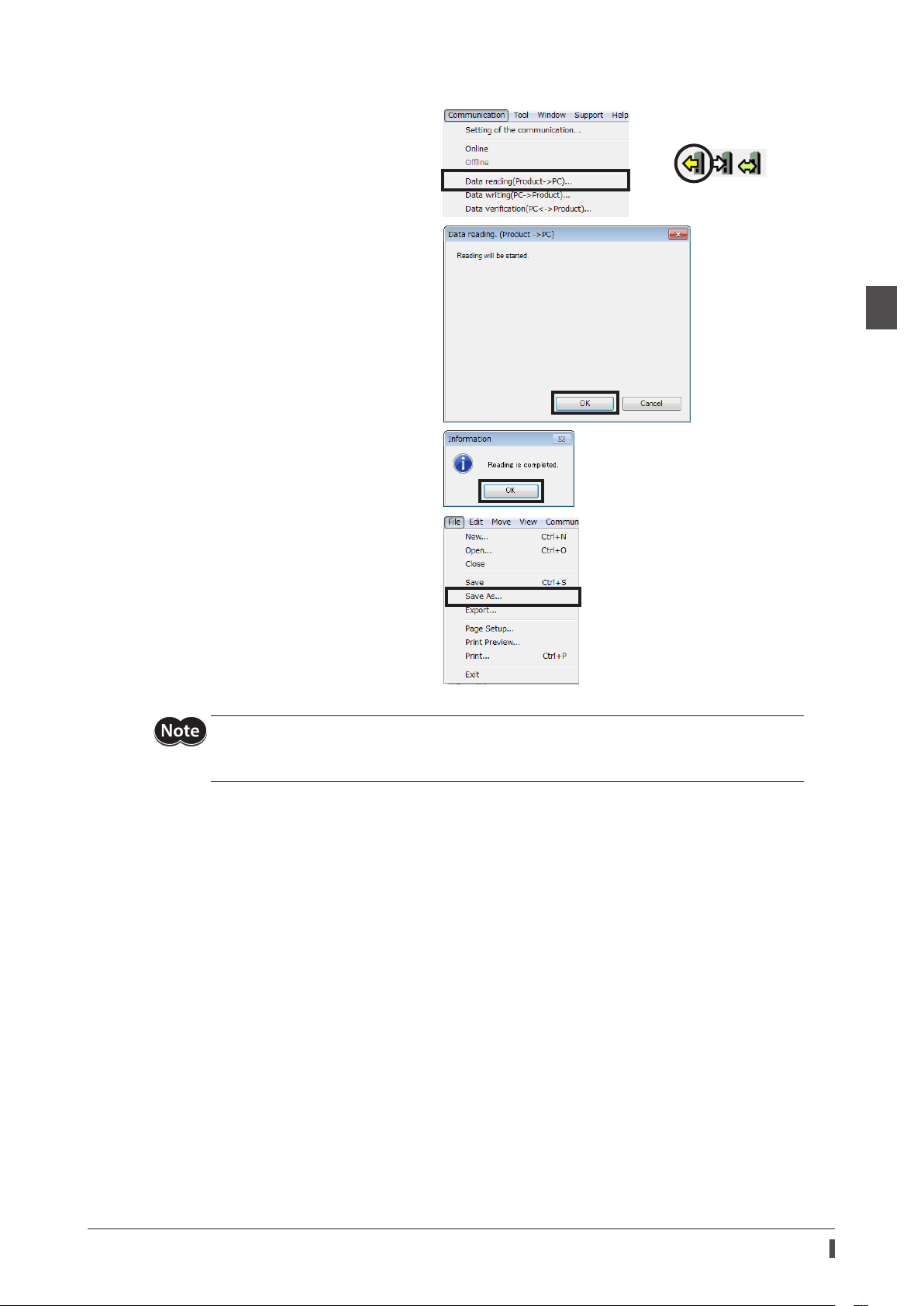

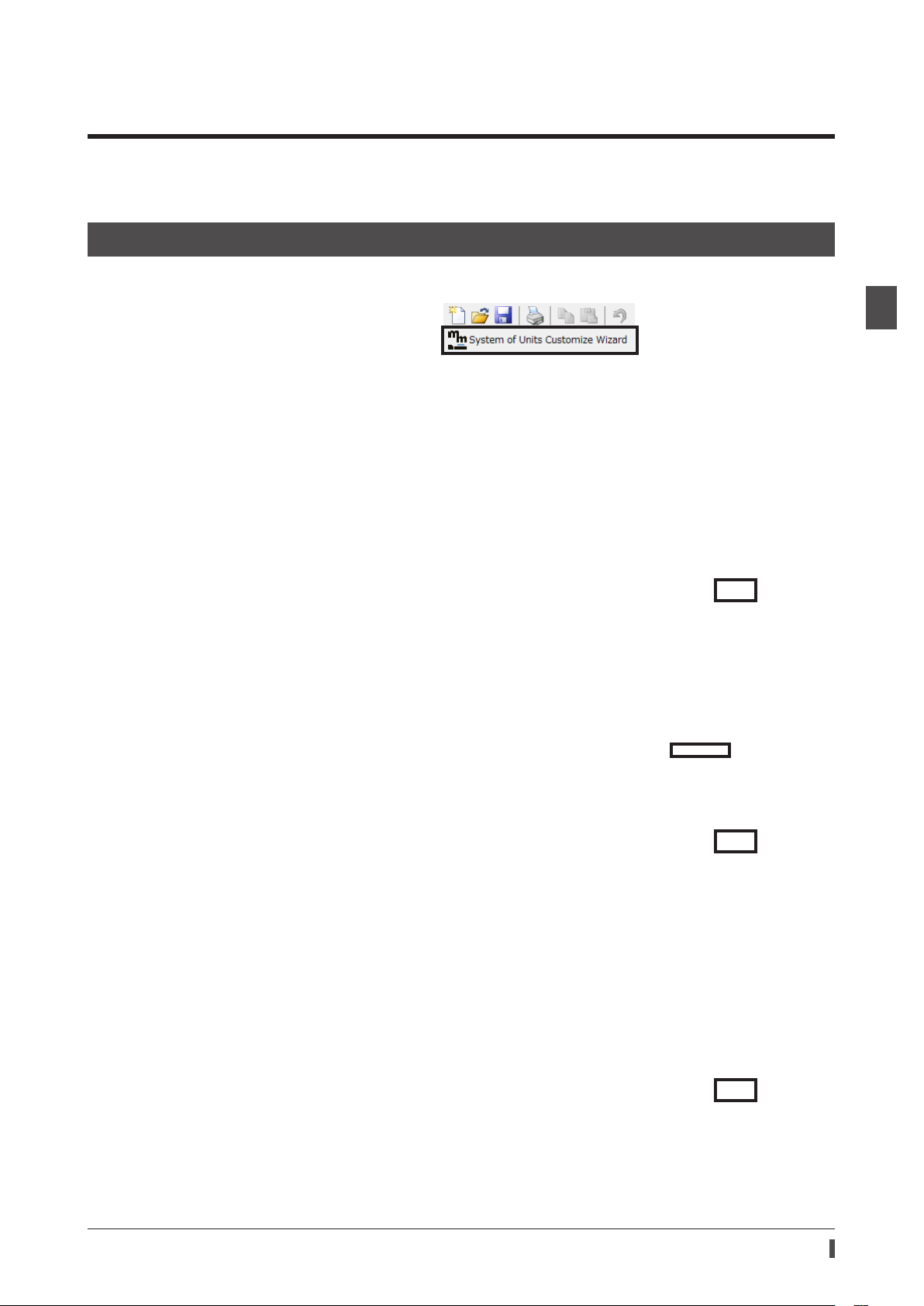

3. Read the ABZO information stored in the driver.

1) Click the [Data reading (Product → PC)]

from the [Communication] menu or click

the [Data reading (Product → PC)] icon in

the toolbar.

2) Click [OK].

Data reading is started.

3) After it is completed, click [OK].

The read data is shown on the screen.

Creation of recovery data le and method of recovery

or

1 Before starting operation

4. Create the recovery data le.

Click [Save as] from the [File] menu.

A desired le name and storage destination

can be used.

The factory setting of the motorized actuator is saved as the recovery data le.

For the recovery, create two les that are the recovery data le stored the factory setting and the nal

backup le (

have been created in advance, the equipment can be restored smoothly.

p.50) applied the operation data and others. If the recovery data le and backup le

_

25

Page 26

1 Before starting operation

Creation of recovery data le and method of recovery

4-2 Method of recovery

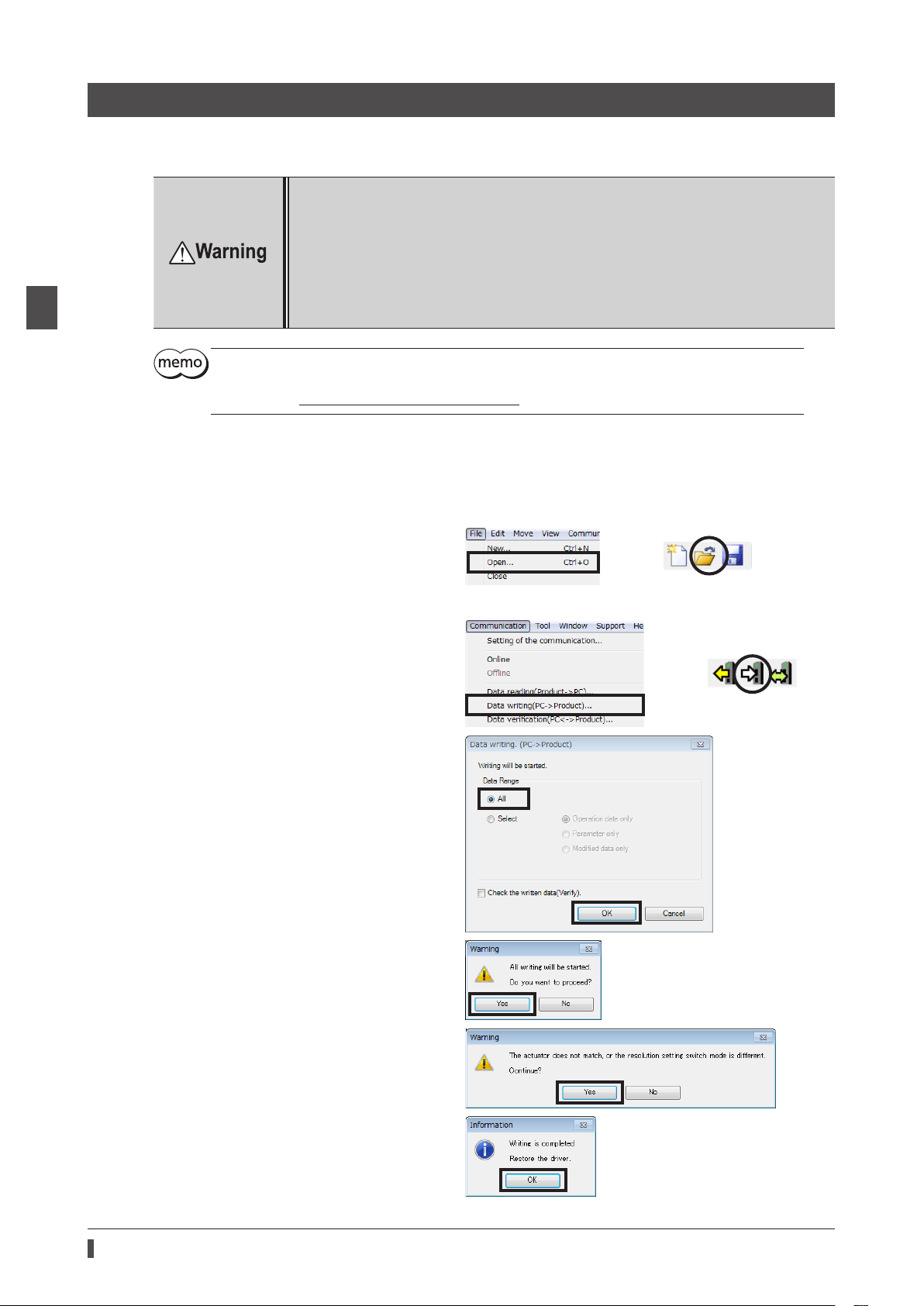

The recovery can be performed under the precondition of having created the recovery data le according to the "4-1

Creating the recovery data le" on p.24.

When the motor or driver was replaced, be sure to perform the recovery and the home

position resetting. Unless the recovery and the home position resetting are performed, the

followings may happen.

•The moving part may cause unexpected operations, resulting in injury or damage to

equipment.

•The moving part of the motorized linear slide or motorized cylinder may collide with the

mechanical stopper.

•A load may collide with other equipment.

•If "Search model" is performed with the

identied as the AZ Series "Standard/geared motor."

•Refer to the OPERATING MANUAL Actuator Edition for how to replace the motor.

MEXE02

after the motor is replaced, the product is

When the motor and driver were malfunctioned

1. Replace the motor and driver, and turn on the power.

2. Open the recovery data le in the

1) Click the [Open] from the [File] menu or click

the [Open] icon in the toolbar.

Select the recovery data le, and click [Open].

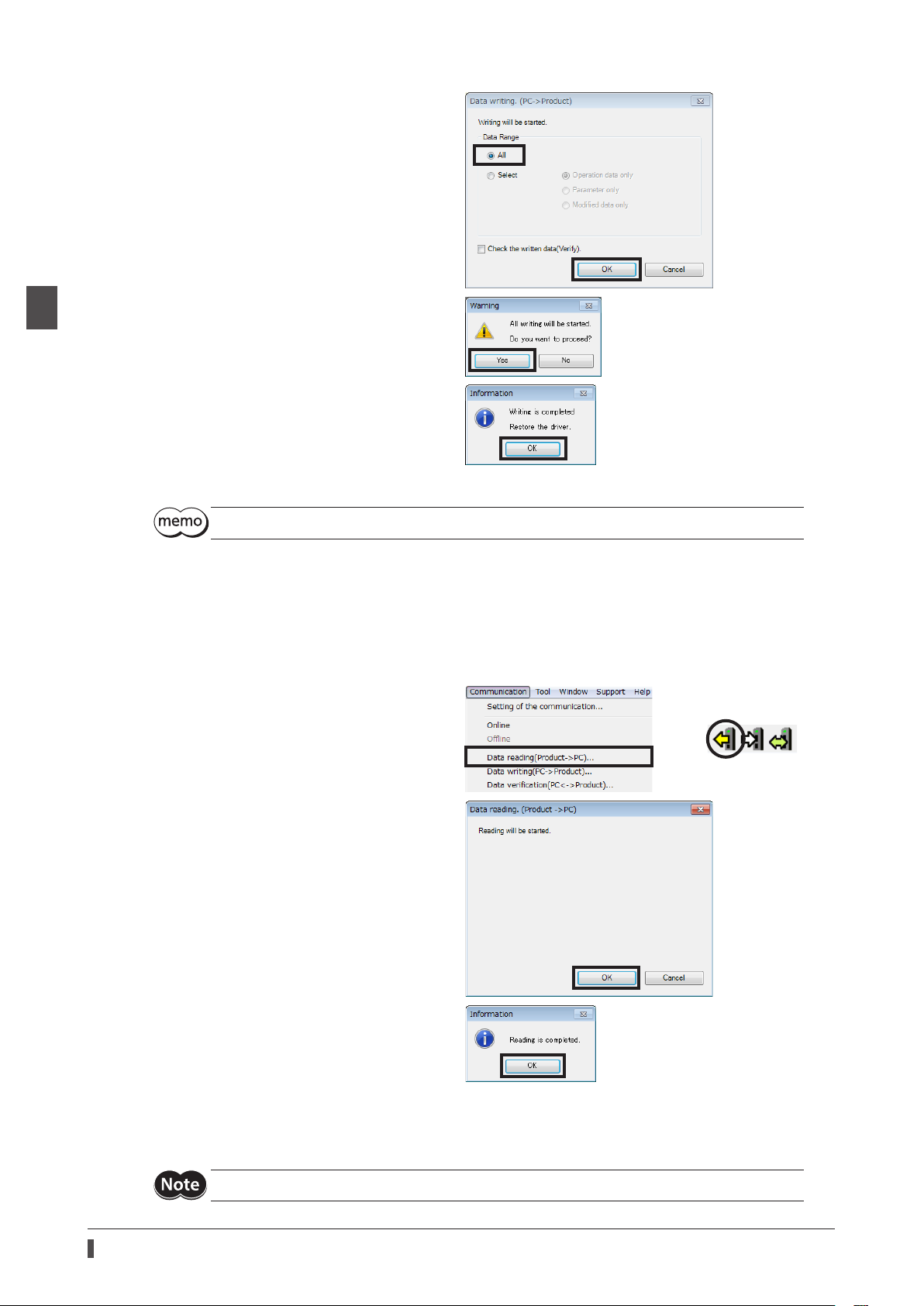

3. Check the data is correct, and write to the driver in the following steps.

1) Click the [Data writing (PC → product)] from

the [Communication] menu or click the [Data

writing (PC → product)] icon in the toolbar.

2) Select the [All], and click [OK].

MEXE02

.

or

or

26

3) Click [Yes].

Writing data is started.

If the following message appears, click [Yes].

4) After it is completed, click [OK].

5) Cycle the driver power.

Page 27

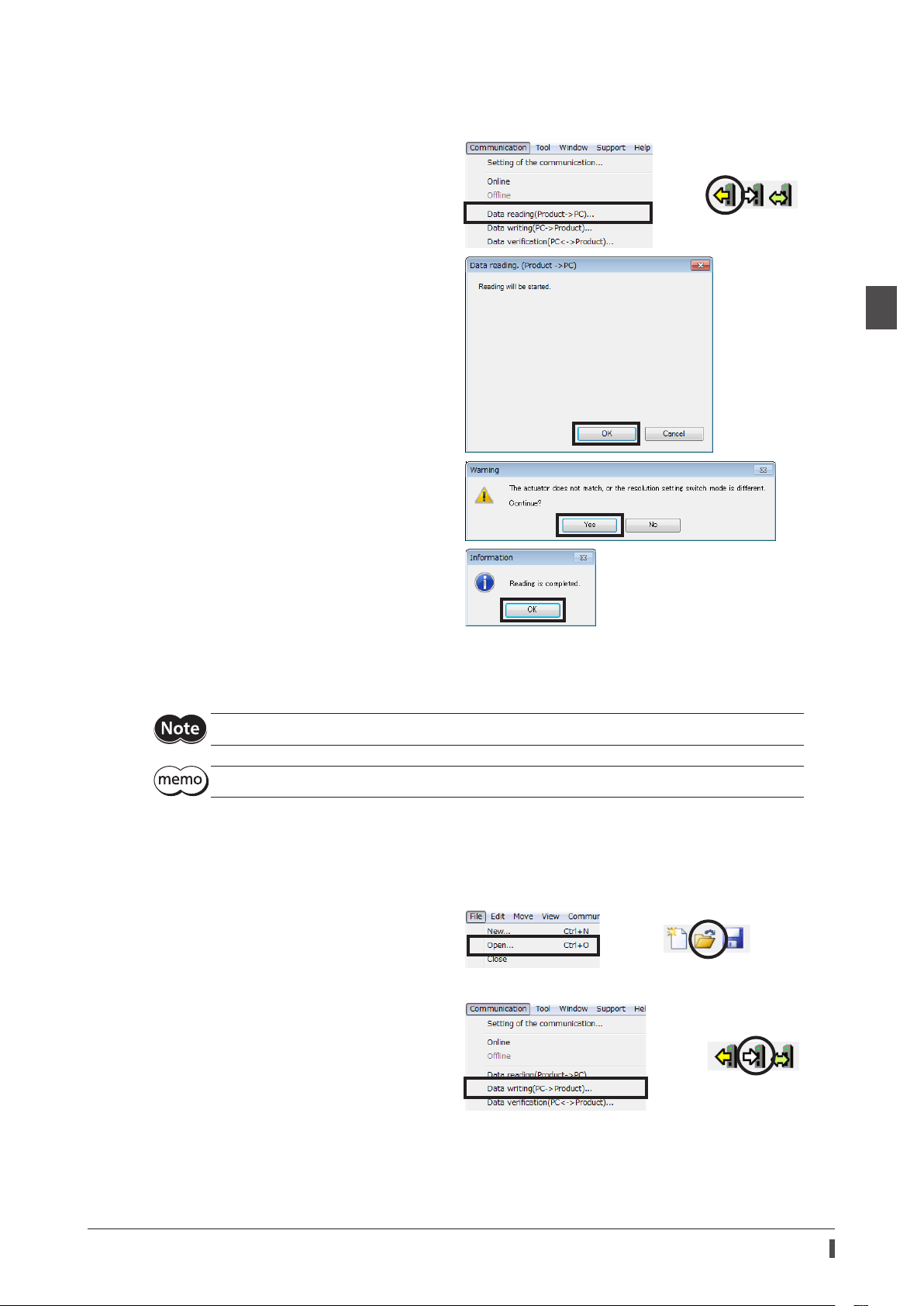

Creation of recovery data le and method of recovery

4. Read the information of the factory setting written to the driver.

When the motor is replaced, set the home position again after reading the driver information.

The communication function of the

1) Click the [Data reading (product → PC)] from

the [Communication] menu or click the [Data

reading (product → PC)] icon in the toolbar.

2) Click [OK].

Data reading is started.

If the following message appears, click [Yes].

MEXE02

cannot be used without reading the driver information.

or

1 Before starting operation

3) After it is completed, click [OK].

The read data is shown on the screen.

All data and parameters in the driver including the ABZO information were read in the

5. Refer to p.36 and set the home position again.

6. Refer to p.24 and create the recovery data le for the product after replacement.

Save the read driver information as the new recovery data le.

The details of the written parameters can be checked with the "unit information monitor."

When the driver was malfunctioned

1. Replace the driver, and turn on the power.

2. Open the recovery data le in the

1) Click the [Open] from the [File] menu or click

the [Open] icon in the toolbar.

Select the recovery data le, and click [Open].

3. Check the data is correct, and write to the driver in the following steps.

1) Click the [Data writing (PC → product)] from

the [Communication] menu or click the [Data

writing (PC → product)] icon in the toolbar.