Oriental motor 4RK25GN-AM-115, 5RK40GN-AM-115, 4RK25GN-CME, 5RK40GN-CME Instructions Manual

Page 1

HM-9030-2

Thank you for selecting ORIENTAL MOTOR products.

To ensure correct operations, please read these instructions

carefully before using this motor.

INSTRUCTIONS

Electromagnetic Brake Motors

Single Phase 115V, 60Hz 4RK25GN-AM-115, 5RK40GN-AM-115

Single Phase 220/240V, 50Hz 4RK25GN-CME, 5RK40GN-CME

These Electromagnetic Brake Motors are reversible motors with a built-in de-energized electromagnetic brake [Fail-Safe Brake].

These motors are designed for 115V, 60Hz or 220/240V, 50Hz power sources.

■Features

1. Employing a de-energized, electromagnetic brake, the brake is

activated upon power shut off. The motor stops immediately and

holds the load firmly.

2. Sufficient holding torque is obtained regardless to the motor speed or

the power source frequency.

[Holding brake torque: 4RK25 Type 13 oz-in(9.8N-cm), 5RK40

Type 20 oz-in(14.7N-cm)]

3. The overrun at motor shaft is approximately 2〜3 rotations.

(With no-load and motor power shut off simultaneously.)

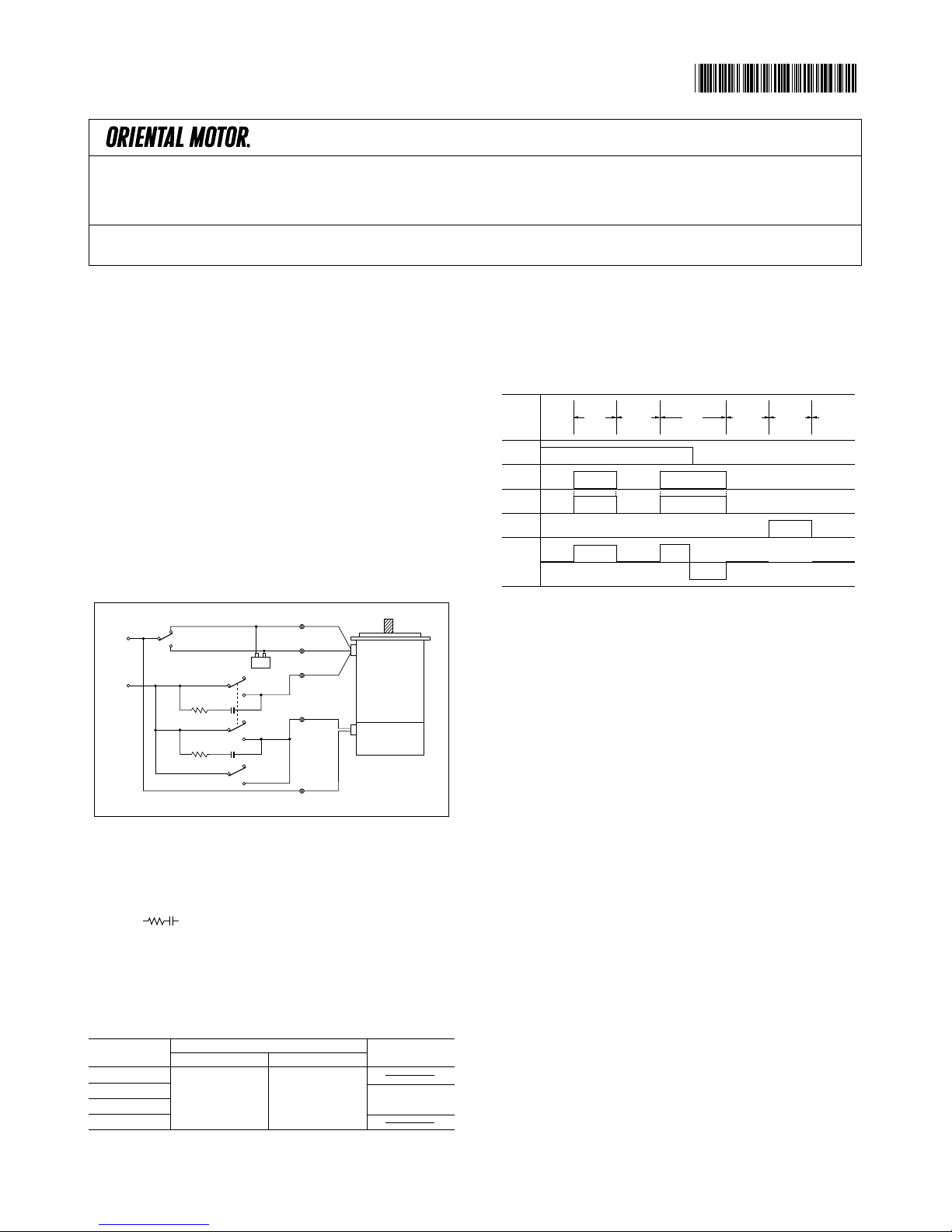

■Connecting Diagrams

●Protection of the relay contacts

The motor switch (SW2) and the electromagnetic brake switch (SW3) emit sparks

when turned on and off. In order to protect the relay contacts.

CR circuit ( ) must be connected.

Co=0.1〜0.2μF 250WV:4RK25GN-AM-115,

5RK40GN-AM-115

500WV:4RK25GN-CME,

5RK40GN-CME

Ro=5〜200Ω, 1/4W minimum

●Switch Specifications

No. of switches

SW1

SW2

SW3

SW4

Switch specifications

Single Phase 115V

AC125V 3A

Minimum

Single Phase 220/240V

AC250V 1.5A

Minimum

Note

Move together

WHITE

Capacitor

STOP

RUN

CCW

CW

SW2*

Ro Co

SW1

GRAY

LINE

BLACK

Motor

Electromagnetic

Brake

STOP

RUN

OFF

ON

SW3*

Ro Co

YELLOW

YELLOW

SW4

※SW2 and SW3 move together.

■Timing Chart

■Operations

●Run/Stop

1. Motor will rotate when SW2 and SW3 are switched simultaneously to

RUN (short circuit) switching SW4 to OFF (open).

2. When SW2 and SW3 are switched simultaneously to STOP (open),

the motor stops immediately by electromagnetic brake and holds the

load.

3. To rotate the motor shaft by hand during the motor stops, switch

SW4 to ON (short circuit). The electromagnetic brake is released

and the motor shaft can be rotate easily by hand.

(Always switch SW4 to OFF (open) when running and stopping the

motor. SW4 is not necessary when such a operation is not needed.)

●Direction of Rotation

To rotate the motor in a clockwise (CW) direction, switch SW1 to CW.

To rotate it in a counter-clockwise (CCW) direction, switch SW1 to

CCW.

The diagram shows the direction of rotation of the motor shaft as

viewed from the motor shaft end.

SW1

SW2

SW3

SW4

Motor

CW

ONOFF

CCW

RunStop Stop Stop

Brake Release

Run

Run

CW

CCW

CW

Stop Stop Stop

Run

Run

Stop

LoadHolding

Run

Brake

Release

Stop

LoadHolding

Stop

LoadHolding

Page 2

■Gearhead Connection

Specially designed gearheads are available that can be easily coupled

directly to these motors.

Sufficient torque can be obtained while reducing the motor speed to the

required speed on the gearhead output shaft.

●Types of Gearhead

●The box(□) represents the desired gear ratio, which thereby becomes part of

the code for the gearhead.

●Gear Ratio:3, 3.6, 5, 6, 7.5, 9, 12.5, 15, 18, 25, 30, 36, 50, 60, 75, 90, 100,120,

150, 180

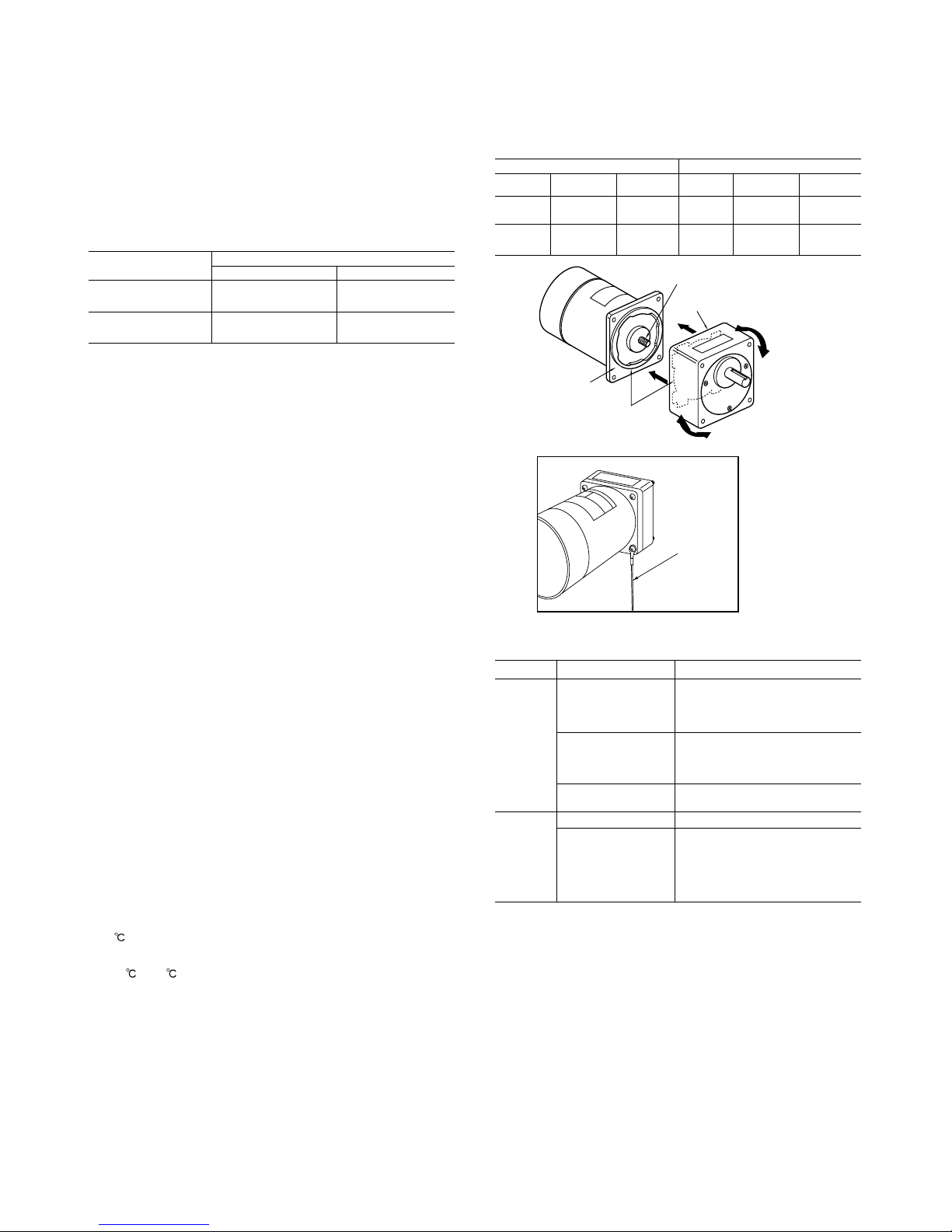

■Precautions for Connecting Gearhead to the Motor

1. Connecting Gearhead

As the figure to the right shows, motor and gearhead are put together

using the recessed areas on each unit as guides while gently turning

the gearhead back and forth for smooth engagement of gearing and

cog. Care should be taken not to damage the shaft by applying

excessively large force during attachment. Then use the mounting

screws that come with the gearhead to screw the gearhead onto the

motor until if fits snugly.

Note:Note that attempt to put motor and gearhead together by force or

entrapping of material like metal chips can result in damage to the geared

section of the shaft or the cog leading to abnormal noise and shortened

operating life. Assembly should be carried out with the necessary care.

2. Installation

Install the motor firmly to your equipment. The heat-sink effectiveness

and protection of vibration are required as much as possible. Useful

motor mountings are available separately.

3. Grounding

Any one of the mounting bolts may serve to fix the grounding wire to

the motor casing at the time of installation of the unit. If necessary,

remove all the bolt hamptom that may impede conductivity around the

bolt mounting hole.

■Precaution on Operation

●If the motor is ON continuously for a period of 30 minutes or more,

the rated temperature may be exceeded. Under no circumstances

should the temperature of the motor case be allowed to rise above

90

(194ºF).

●Use the motor in a place where the working ambient temperature is

−10

to 50 (14ºF to 122ºF) and humidity is 85% less.

●Do not use the components in a place where a corrosive gas, water,

oil, dust and/or direct sunlight may contact the components.

●Avoid places where vibration/shocks are heavy and/or constant.

The geared section of the shaft

Edge of recessed area

Recessed area

Flange surface

Ground Wire

Motor Models

4RK25GN-AM-115

4RK25GN-CME

5RK40GN-AM-115

5RK40GN-CME

Gearhead Models

Inch size output shaft

4GN□KA

(Ball bearing type)

5GN□KA

(Ball bearing type)

Metric size output shaft

4GN□K

(Ball bearing type)

5GN□K

(Ball bearing type)

Inch size shaft gearhead Metric size shaft gearhead

Models

4GN□KA

5GN□KA

Shaft Diameter

0.375" dia.

(9.525mm dia.)

0.5" dia.

(12.7mm dia.)

Shape of

Shaft

Flat cutted

Flat cutted

Models

4GN□K

5GN□K

Shaft Diameter

10mm dia.

12mm dia.

Shape of

Shaft

Key slot

(Key provided)

Key slot

(Key provided)

●Size of Gearhead output shaft

■Trouble Shooting

Symptoms

Motor does

not turn

Motor turns

wrong

direction

Causes

No voltage coming to

motor

Electromagnetic brake is

ON

Load is too large

Motor is mis-wired

Gearhead is attached

Check Point

Check that motor has no looseconnection

Check that lead wires have no

interruption

Check that the electromagnetic brake is

released

Check that the electromagnetic brake

has been energized

Remove the load and check operation of

motor alone

Check the motor connection

Check the gear ratio

When connecting gearhead to reduce

the speed, the gearhead output shaft

can be made to rotate in an opposite

direction as the motor depending on

which speed reduction ratio is chosen.

Page 3

Printed on Recycled Paper

・Characteristics, specifications and dimensions are subject to change without notice.

・Please contact your nearest ORIENTAL MOTOR office for further information.

ORIENTAL MOTOR U.S.A CORP.

Los Angeles Office Tel:(310)784-8200 Fax:(310)325-1076

San Jose Office Tel:(408)358-6900 Fax:(408)358-8200

Chicago Office Tel:(847)240-2649 Fax:(847)240-2753

Cincinnati Office Tel:(513)563-2722 Fax:(513)956-3183

Austin Office Tel:(512)918-9438 Fax:(512)335-5983

New York Office Tel:(973)359-1100 Fax:(973)359-1090

Boston Office Tel:(781)848-2426 Fax:(781)848-2617

Atlanta Office Tel:(770)716-2800 Fax:(770)719-8515

Canada Office Tel:(905)502-5333 Fax:(905)502-5444

Technical Support Line Tel:(800)468-3982

Available from 8:30 AM to 8:00 PM , Eastern Time

ORIENTAL MOTOR (EUROPA) GmbH

Headquarters and Düsseldorf Office

Tel:02131-95280Fax:02131-952899

Munich Office Tel:08131-59880 Fax:08131-598888

Hamburg Office Tel:04076-910443 Fax:04076-910445

ORIENTAL MOTOR (UK) LTD.

Tel:01252-519809 Fax:01252-547086

ORIENTAL MOTOR (FRANCE) SARL

Tel:01 47 86 97 50 Fax:01 47 82 45 16

ORIENTAL MOTOR ITALIA s. r. l

Tel:02-3390541 Fax:02-33910033

TAIWAN ORIENTAL MOTOR CO.,LTD.

Tel:(02)2299-9360 Fax:(02)2299-4173

SINGAPORE ORIENTAL MOTOR PTE LTD.

Tel:(745)7344 Fax:(745)9405

ORIENTAL MOTOR .KOREA CO.,LTD.

Tel:(02)632-9122 Fax:(02)679-4588

ORIENTAL MOTOR CO.,LTD.

Headquarters

Tel:(03)3835-0684 Fax:(03)3835-1890

Loading...

Loading...