Oriel Instruments MS257-M-MC-A, MS257-M-FH-D, MS257-M-FH-A, MS257-M-FH-L, MS257-M-MC-D User Manual

...Page 1

MS257 USB/RS232

MONOCHROMATOR

AND

SPECTROGRAPH

User's

MODELS:

MS257-M-MC-L, MS257-M-MC-D, MS257-M-MT-A, MS257-M-MT-L, MS257-MMT-D, MS257-S-FH-A, MS257-S-FH-L, MS257-S-FH-D, MS257-S-MC-A, MS257S-MC-L, MS257-S-MC-D, MS257-S-MT-A, MS257-S-MT-L, MS257-S-MT-D

MS257-M-FH-A, MS257-M-FH-L, MS257-M-FH-D, MS257-M-MC-A,

Family of Brands – Corion

M77781A, Rev B

Manual

®

• New Focus™ • Oriel® Instruments • Richardson Gratings™ • Spectra-Physics

®

Page 2

- 2 -

TABLE OF

CONTENTS

1 SAFETY OPERATING

2

INTRODUCTION .................................................................................................................................... 5

3 SETUP AND MOUNTING

3.1 MOUNTING MS257 TO A FLAT

3.2 MOUNTING OTHER INSTRUMENTS TO THE

3.3 TURRET

4 QUICK

5 INSTRUMENT DESCRIPTION

6 CONFIGURATION

7 INSTRUMENT

8 PROGRAMMING MS257

9

ACCESSORIES .................................................................................................................................... 44

10

SPECIFICATIONS................................................................................................................................ 57

11 APPENDIX A - BASIC GRATING

12 DECLARATION OF

13 WARRANTY AND

START........................................................................................................................................ 9

4.1 WORKING WITH THE HAND

4.2 WORKING WITH A COMPUTER

5.1 LAYOUT AND MAJOR FEATURES

6.1 USE AS A

6.2 USE AS A SPECTROGRAPH

6.3 USE AS AN IMAGING

6.4 INSTRUMENT FEATURES

OPERATION ................................................................................................................ 14

7.1 INSTRUMENT

7.2 UTILITY AND CONFIGURATION SOFTWARE

7.2.1 MS257 UTILITY

7.2.2 UTILITY SOFTWARE

7.2.3 MS257 CONFIGURATION

7.3 77709 HAND CONTROLLER

7.4

COMMUNICATIONS.............................................................................................................

9.1 GRATING

9.2 CONFIGURING THE MS257 FOR TURRET

9.3

GRATINGS............................................................................................................................

9.4 SLITS

9.5 FILTER

9.6 INPUT AND OUTPUT

13.1 CONTACTING ORIEL

13.2 REQUEST FOR ASSISTANCE / SERVICE

13.3 REPAIR

13.4 NON-WARRANTY

13.5 WARRANTY REPAIR

13.6 LOANER / DEMO

....................................................................................................................................

PRECAUTIONS ................................................................................................ 4

...................................................................................................................... 6

SURFACE...........................................................................

MS257 .........................................................

INSTALLATION .......................................................................................................

CONTROLLER .......................................................................

...........................................................................................

............................................................................................................ 10

.....................................................................................

VERSATILITY ....................................................................................................... 11

MONOCHROMATOR..........................................................................................

..............................................................................................

SPECTROGRAPH ...........................................................................

..................................................................................................

CONFIGURATION .......................................................................................

...................................................................

SOFTWARE ...............................................................................

INSTALLATION .................................................................

SOFTWARE ............................................................

...............................................................................................

..................................................................................................................... 43

TURRETS ............................................................................................................

INSTALLATION .............................................

WHEELS ..................................................................................................................

PORTS..............................................................................................

INFORMATION .............................................................................. 60

CONFORMITY..................................................................................................... 67

RETURNS .............................................................................................................. 68

INSTRUMENTS................................................................................

.........................................................................

SERVICE ................................................................................................................

REPAIR ..................................................................................................

...........................................................................................................

MATERIAL...............................................................................................

6

7

8

9

9

10

11

12

12

13

14

16

16

17

25

33

42

44

44

45

46

53

54

68

69

69

70

70

71

Page 3

- 3 -

LIST OF FIGURES

Figure 1: Grating Care and

Figure 2: MS257

Dimensions......................................................................................................................6

Figure 3: Input and Output

Figure 4: Mounting Hole Pattern for Ports

Figure 5: Monochromator Interior

Figure 6: Light Path of a Monochromator

Figure 7: Light Path of a

Figure 8: Light Path of Imaging

Figure 9: Utility Program Main

Figure 10: Configuration Program main

Figure 11: Hand Controller Keypad

Figure 12: Rear Panel

Figure 13: Quadruple Grating

Figure 14: Using Fixed Slits with MS257

Figure 15: Micrometer Driven Slit

Figure 16: Micrometer Driven Slit

Handling ..........................................................................................................4

Ports .................................................................................................................7

..................................................................................................7

Layout..................................................................................................10

.................................................................................................11

Spectrograph .....................................................................................................12

Spectrograph ..........................................................................................12

Window.....................................................................................................24

window ........................................................................................32

..........................................................................................................36

Connections ..........................................................................................................42

Turret.........................................................................................................44

..................................................................................................47

Dimensions...........................................................................................49

Adjustments.........................................................................................50

Figure 17: Micrometer Driven Slit Closed Position

Figure 18: Motorized Slit

Figure 19: Filter

Installation ........................................................................................................................53

Figure 20: Motorized Flip

Figure 21: Dual Source

............................................................................................................................51

Mirror .................................................................................................................55

Configuration........................................................................................................56

Figure 22: Diffraction Geometry of a Plane Reflection

Figure 23: The "Grating

Figure 24: Grating

Figure 25: Diffraction

Figure 26: Polarization and

Equation" .............................................................................................................61

Resolution ....................................................................................................................63

Orders ......................................................................................................................64

Efficiency........................................................................................................66

...................................................................................50

Grating..................................................................60

Page 4

- 4 -

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

1 SAFETY OPERATING PRECAUTIONS

Electrical

The MS257 operates from nominal ac mains of 115/230 Vac. Do not attempt to work in the electrical

compartment without first disconnecting the power cord, since you may contact high voltage areas inside

the compartment.

The MS257 has an internal microprocessor and should be installed with appropriate surge/EMI/RFI

protection on all power lines. Dedicated power lines or line isolation may be required for some extremely

noisy sites.

The circuits used in MS257 are extremely sensitive to static electricity and radiated electromagnetic fields

and therefore MS257 should not be used nor stored in close proximity to EMI/RFI generators,

electromagnetic/electrostatic field generators, radioactive devices, or other similar sources of high energy

fields. Some examples of equipment, which can cause problems, are plasma sources, arc welders, radio

frequency generators, x-ray instruments, and pulsed/ triggered gas discharge optical sources. Operation

of the MS257 close to intense pulsed sources (lasers, xenon strobes or arc lamps, and the like) may

compromise performance if shielding is inadequate, and may cause permanent damage to the

microprocessor. Do not place any containers containing liquids on top of the instrument. There is a

danger that liquid may enter the ventilation holes in the electronics compartment and cause a short

circuit. This may cause the instrument to fail.

Mechanical

Avoid dropping, sudden shocks, or rough handling of the monochromator since this may cause the

system to lose its calibration and may destroy the high precision drive components or optics.

Do not use more than finger force in tightening down the grating mounts, since this may cause damage to

the drive assembly

Optical

Wear powder-free gloves. Do not wear finger cots – hands should be completely covered. Do not touch

any optical surfaces - even if wearing gloves - since this is likely to cause irreparable damage. Do not

attempt to clean an y optical surface except by blowing off dust or lint particles with a stream of dry clean

air or nitrogen. Do not allow condensation from talking or breathing to form on the grating. Gratings can

be scratched easily! Be very careful when removing the plastic grating covers. A cover for a grating must

never touch the grating’s front surface. The cover should only touch the edges of the grating. Customers

should keep the covers on hand to protect gratings during storage or transportation.

Figure 1: Grating Care and Handling

Page 5

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

5

2 INTRODUCTION

The MS257 isn't just another monochromator. It is the heart of a completely automated spectral data

acquisition system. All you need is a PC and a detector system.

The MS257 is an F/3.9 instrument with a focal length of 257 mm for use as a monochromator, true flat

field spectrograph or imaging spectrograph. It incorporates the latest advances in optical design, high

speed wavelength drives, and total system automation.

The MS257 has been designed with a flat exit image plane and an oversized focusing mirror to serve as a

true flat field spectrograph. Adapter flanges are available for lnstaSpec™ diode arrays and CCD

detectors, as well as detectors made by other manufacturers.

The imaging version of MS257 has special corrected optics (toroidal mirrors) which correct the final image

for astigmatism and enable point to point spectral imaging of the input source or sources. The optics have

been designed to work with CCD detectors which are used to record simultaneous spectra from multiple

sources.

Key Features:

1, 2, 3, or 4 grating turret with automatic grating switching

Rapid high torque motor drive

Rigid housing for optical stability with sealed seams for light tightness

2 detector ports with automatic detector switching

Motorized slits for automatic bandpass selection

Advanced optical design results in negligible stray light

Tilted focal plane for eliminating re-entrant spectra from detectors

Corrected optics for spectral imaging (version 77782)

Fine focus adjustment for diode arrays and CCDs

Internal shutter for dark scans

Automated auxiliary input port option

Separate electronics compartment for exceptional temperature stability

On board microprocessor for automated control

Complete computer control via USB or RS232

Page 6

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

6

3 SETUP AND MOUNTING

After unpacking, mount the MS257 in a convenient location, install the grating turret with gratings and

remove the covers from optics. After these steps have been completed, plug in the power cord.

*** WARNING

DO NOT PLUG IN THE POWER

UNTIL ALL THE SAFETY PRECAUTIONS HAVE BEEN

***

CORD

READ.

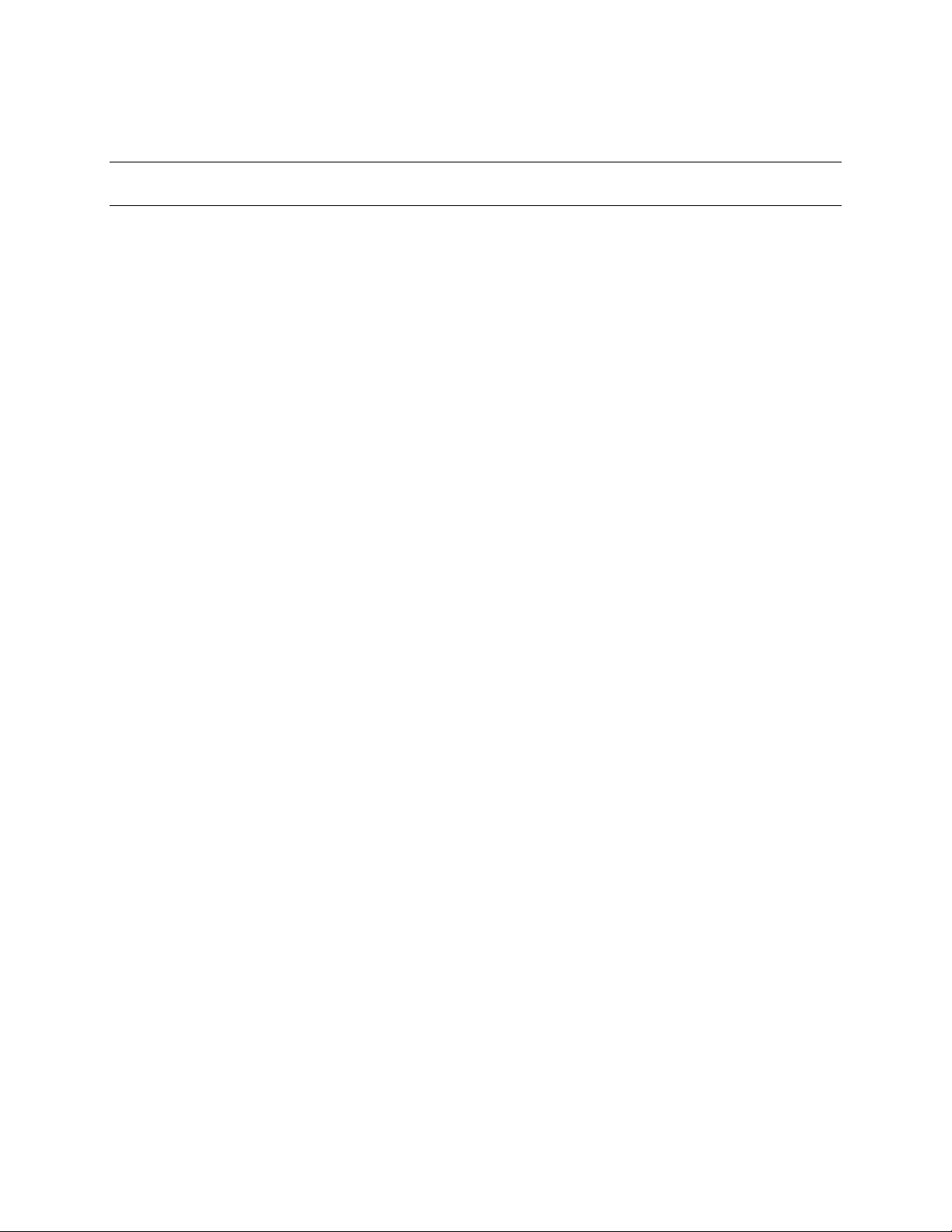

3.1 MOUNTING MS257 TO A FLAT SURFACE

There are three 1/4-20 tapped holes under the housing, these can be used to screw in the

supplied adjustable feet or to mount to other objects. Please refer to Figure 2.

Figure 2: MS257

Dimensi ons

Page 7

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

7

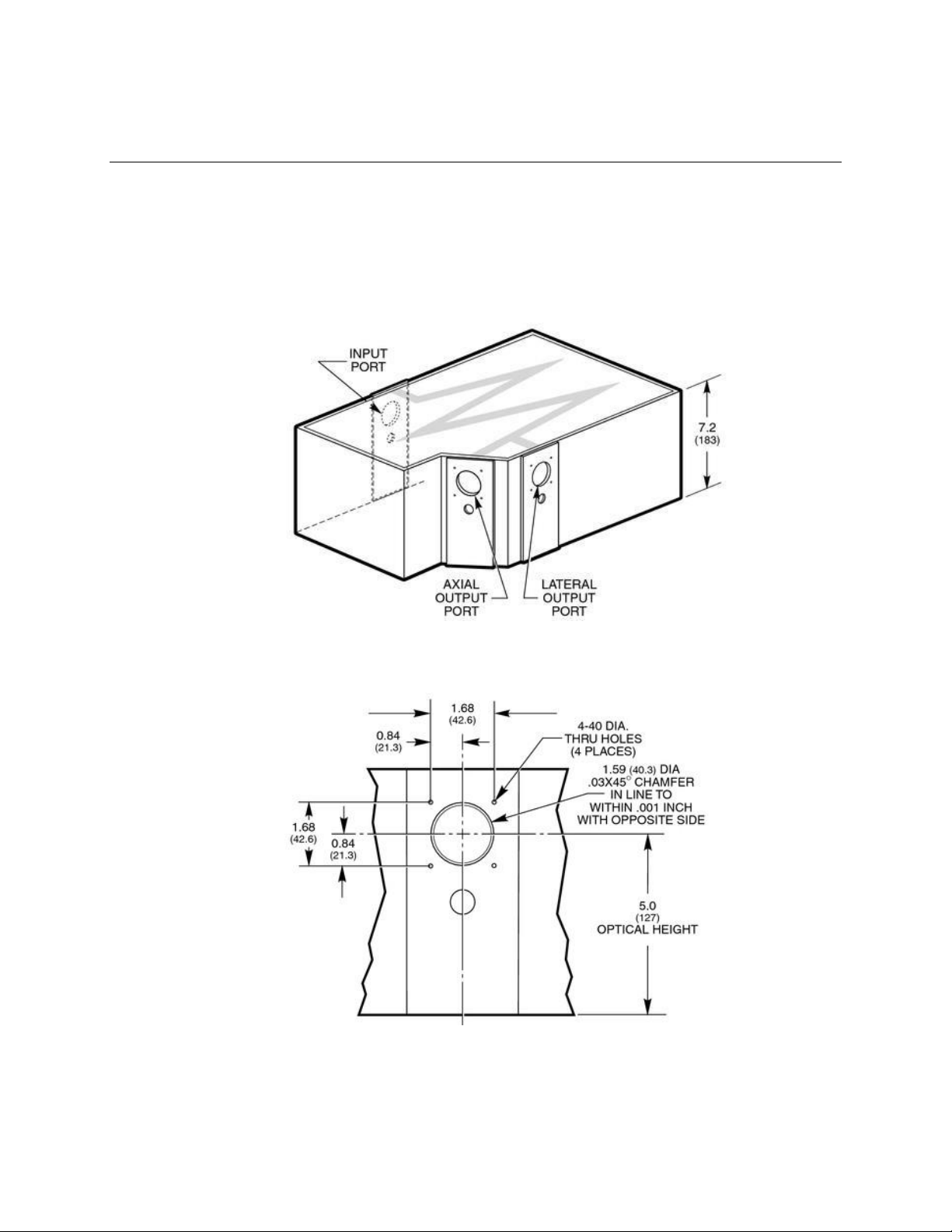

3.2 MOUNTING OTHER INSTRUMENTS TO THE MS257

Sources, detectors and other instruments that have an Oriel 1.5 inch (47 mm) female flange can

be easily attached to any of the MS257 slit ass emblies at the ports. Other accessories can also

be mounted directly to MS257 at any of the input or output ports (Figure 4).

Figure 3: Input and Output

Ports

Figure 4: Mounting Hole Pattern for

Ports

Page 8

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

8

3.3 TURRET INSTALLATION

In order to protect the most sensitive part of the instrument during transportation, the grating

turret is packaged separately from the housing.

Install the turret into the instrument using the following procedure:

Quadruple Grating Turret (may have 2, 3 or 4 gratings installed)

Put gloves on to avoid fingerprinting the gratings.

Remove the MS257 cover.

Leave the protective cover on the gratings.

Make sure the grating turret cable is hanging freely at the side of the turret.

Locate the grating turret on the drive platform by aligning the two captive bolts with their

holes, and the center with the platform boss.

Adjust the position of the turret until it locates on the alignment pin and sits flush with the

platform.

Connect the turret cable.

Tighten the two mounting bolts by hand. Do not over tighten!

Remove the bottom and side protective grating covers, and lastly the upper grating cover.

For the bottom grating, let the plastic cover drop straight down and remove it horizontally

without touching or scraping the bottom grating surface.

Be very careful not to touch the gratings.

Replace the MS257 cover, using all cover screws.

Single Grating Turret

Remove the MS257 cover.

Leave the protective cover on the grating until the mount is screwed down.

Locate the grating mount and twist clockwise to correctly align it.

Tighten the mounting bolt by hand. Do not over tighten!

Remove the protective grating cover.

Be very careful not to touch the grating.

Replace the MS257 cover, using all cover screws.

Page 9

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

9

4 QUICK START

4.1 WORKING WITH THE HAND CONTROLLER

The Hand Controller (Model 77709) controls the MS257 via an RJ11 jack located on the back

panel. Below the LCD screen are five LEDs that indicate the status of various functions. To

operate the MS257 with the hand controller, ensure that the following two LEDs are ON.

Power LED: The MS257 is powered up and the Hand Controller is connected and working

properly.

Local LED: When the Hand Controller has control of the MS257. To activate the LED, press

the "Local" button. The LCD screen will turn on and indicate the current status of the

instrument.

For further instructions on how to operate the instrument using the Hand Controller, please refer

to Section 7.3 of this manual.

4.2 WORKING WITH A COMPUTER

Connect the MS257 to the computer via the provided USB or RS232 cable, or an IEEE to

RS232 adapter (Model 77793).

Use the utility software (details are provided in Section 7.2) to control the instrument.

Page 10

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

10

5 INSTRUMENT DESCRIPTION

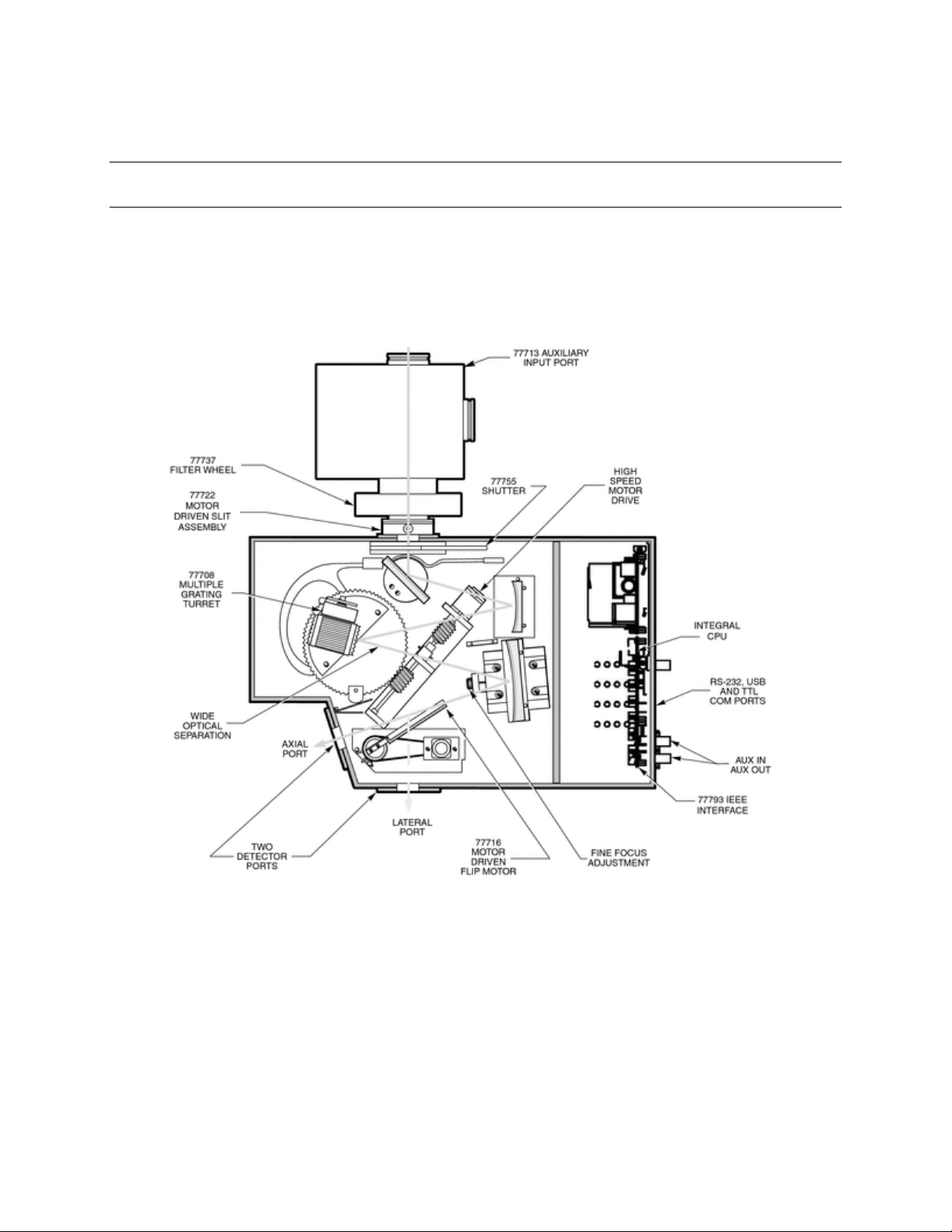

5.1 LAYOUT AND MAJOR FEATURES

Refer to the descriptions of the MS257 accessories throughout this manual for more information

on the items shown in Figure 5.

Figure 5: Monochromator Interior Layout

Page 11

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

11

6 CONFIGURATION VERSATILITY

6.1 USE AS A MONOCHROMATOR

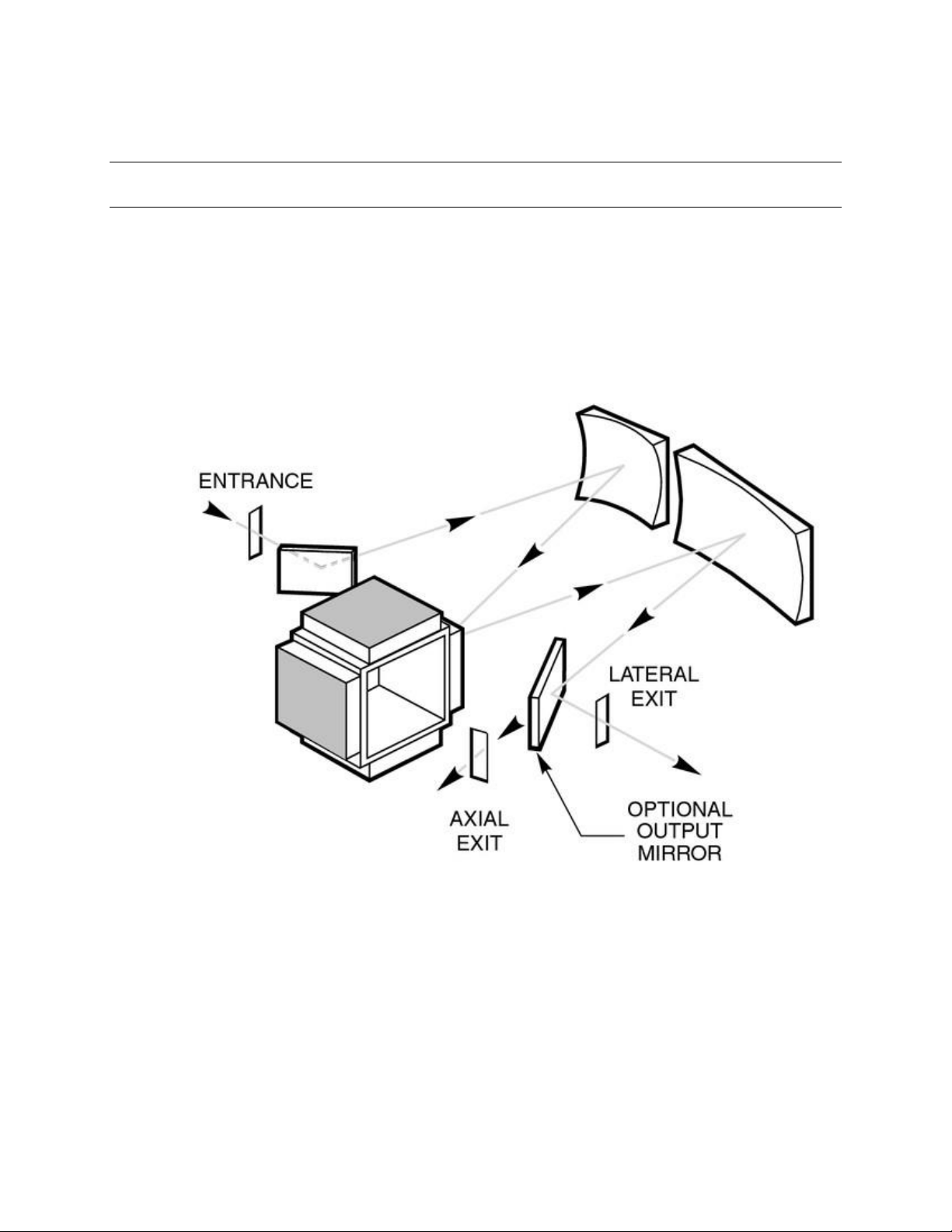

Figure 6 depicts the MS257 in use as a monochromator. The "in-line" configuration uses a turning

mirror at the exit port. This can be either the 77718 Replaceable Turning Mirror on the 77716

Motorized Output Flip Mirr or. When the mirror is not in position, the axial port is selected as the

exit port.

Figure 6: Light Path of a Monochromator

Page 12

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

12

6.2 USE AS A SPECTROGRAPH

Figure 7 depicts the MS257 in use as a spectrograp h. The axial port accommodates detectors

over 4” (100 mm) diameter depending on the distance they need to be mounted from the port

face. This port can readil y accommodate lnstaSpec™ detectors as well as several other

manufacturers. Note that the spectrum at the lateral output port is reversed from that of the axial

output port.

Figure 7: Light Path of a

6.3 USE AS AN IMAGING SPECTROGRAPH

Figure 8 depicts the MS257 in use as an imaging spectrograph. This is similar to the conventional

spectrograph except that the sources are spatially imaged at the exit plane so that there is a

separate spectrum for each input source.

Spectrograph

Figure 8: Light Path of Imaging

Spectrograph

Page 13

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

13

6.4 INSTRUMENT FEATURES

Flexible Instrument Control

The MS257 can be is controlled by using the Hand Controller, a terminal program to send MS257

BASIC language commands or a stand alone computer program. See the relevant sections for

details of these methods of operation.

Negligible Stray Light

Great attention has been paid to eliminating stray light. The wide open optical layout and

exaggerated tilt of the exit focal plane ensure this. While other designs may be more compact it is

inevitable that they'll suffer from’re-entrant' spectra at certain grating angles. It is important that

diffracted light not be allowed to reflect from the mirrors, or from the face of a focal plane detector

such as a diode array or CCD, back onto the grating. This light can then be re-diffracted and

cause ghost images or stray light at the detector. The MS257 was designed to remove this

possibility for CCD detectors - even as large as 28 mm x 28 mm.

Calibrated Motor Drive

The MS257 uses an ultra-rapid stepper motor drive, with an oversize worm gear to ensure high

precision and stability. This computer controlled worm drive is superior to most sine drive

mechanisms. It allows separate calibration factors to acc ommodate for differences between

gratings with nominally the same lines per millimeters (for example, 1200 I/mm blazed ruled

grating and a holographic grating). Scans are automatically linearized so that the wavelength

intervals are equal, no matter which units are chosen: nanometers, microns or wavenumber.

In an ideal world the wavelength should be able to be calculated directly from the step position

(grating angle). However, gears are not perfect. They are slightly non-concentric and have

surface finish flaws, which result in a significant deviation in real position angle (and therefore

wavelength) from theoretical. This is corrected by mapping the entire drive, and charting the

divergence of real from theoretical drive angle. Mathematical curve fitting is then used to correct

the step position and provide real wavelength. The MS257 is spectrally mapped at the factory

with a system default calibration for the grating drive. Remapping of the drive should never be

attempted by unauthorized personnel. If remapping is necessary, the entire MS257 must be

returned to the factory.

lntegrated Shutter

There are two internal shutters available for the MS257. Both shutters are normally closed. They

can be controlled through the MS257 command language or via an externally applied TTL signal.

The 77755 shutter has stray light rejection better than 0.001% for dark scans and dark current

measurements. The shutter may be changed in the field so that it is normally open. Contact the

Oriel Instruments service department for details. The 77755 shutter automatically closes when

changing gratings and filters in order to protect the detector from possible high light intensities at

various grating angles - particularly the zero order white light. This safety feature may be turned

off by setting the shutter to the manual mode. The 77717 fast shutter is available for pulsed work.

Exposure times can be as short a 5 ms, with repetition rates as fast as 40 Hz. A synchronizing

output signal is available from the fast shutter for very precise timing of external events. The

77717 fast shutter does not automatically react to grating changes.

Page 14

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

14

7 INSTRUMENT OPERATION

7.1 INSTRUMENT CONFIGURATION

The instrument configuration is maintained as a collection of parameters and values. Suitable

factory defaults are provided. The Active Configuration is the current setup. This is always

saved and restored when powering up the instrument.

Configurations can be saved and loaded in several ways:

To save the active user configuration and to reload the user configuration, one may use

Hand Controller, the configuration software or a computer terminal program.

The instrument can be configured by Oriel Instruments to have calibrations saved on CD for more

than one grating turret, allowing the user to change the turret and load the appropriate

configuration information as needed.

Individual Grating Calibration

Each grating is precisely aligned on its mount or grating turret. However, small offsets or

calibration adjustments may be required for each grating. This calibration should be performed for

each port in use. The procedure is as follows:

1. Select a grating.

2. Select a source with prominent spectral lines for calibration purposes.

3. Use very small slit sizes. I using a diode array or CCD, use a small entrance slit.

4. Drive the grating to a spectral line such as a HeNe line at 632.8 nm or an Hg line at 546 nm.

5. Step the motor drive using the Hand Controller or MS257 programming language until the line

is centered at the output slit, or in the case of a diode array or CCD at the center pixel.

6. Use the Calib command on the Hand Controller or CALWAV command if using the terminal

program, and enter the correct wavelength for the spectral line.

7. The recalibration of the grating for that port is now complete.

8. Change the detector port using the Hand Controller or MS257 programming language if the

MS257 is equipped with an Output Flip Mirror. Never move the flip mirror manually.

9. Repeat the procedure for the other detector port if it is being used.

10. Repeat Step 1 through 9 for each grating on the turret.

Fine Focus Adjustment

In order to obtain the best optical performance, a fine focus adjustment feature is included. This

enables precise translation of the exit mirror to optimize the image onto focal plane detectors

such as diode arrays and CCDs. These accessories do not have a precisely known detector

positions, which is why the light may have to be focused to achieve best resolution. Note that

after refocusing, one may require a new spectral calibration.

the

Page 15

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

15

Minimizing Stray Light

Stray light is unwanted light which interferes with the light being measured or transmitted. This

results in additional noise to light measurements. At best, this results in incorrect measurements.

At worst, the signal cannot be measured. Stray light can occur for a number of reasons:

Incorrect setup

The most significant sources of stray light are light leakage. Light could enter the MS257 through

misplaced covers, as well as slit holders and detectors without adequate sealing. Make sure that

all covers, detectors and flanges are well seated and screwed down.

Overfilling

lf the F number of the source is lower than the F number of the monochromator this produces

what is referred to as overfilling. The light will spill over the sides of the entrance mirror and will

reflect around the housing resulting in stray light. The MS257 is designed to prevent overfilling.

But even so, the light has already entered the housing and must be absorbed by the baffles. It is

better to match the source F number to the monochromator's F number and prevent overfilling.

Reflections from walls

Light is dispersed by the grating; the selected wavelengths strike the exit mirror and are imaged

at the exit focal plane. Other wavelengths, zero order 'white' light, and other orders of the

diffracted light strike interior walls and must be absorbed before they bounce around and emerge

at the exit as stray light at the detector. The MS257 makes use of light traps and baffles as well

as black paint in order to minimize the amount of light which can eventually find its way to the

detector.

Gratings

Gratings are not perfect reflectors, so a certain amount of incident light is scattered and

contributes to stray light. In fact, gratings are a major source of stray light since they are within

the optical path. Imperfect rulings or ion etched blazed lines contribute to stray light. Often the

major source of stray light is dust - and sometimes even fingerprints. Keep the gratings clean by

minimizing dust and occasionally blowing them clean with dry clean air or nitrogen.

Mirrors

Mirrors gradually accumulate dust, and can have imperfections. These surfaces scale light and

add to stray light. If the bevels of the mirrors are not adequately masked, these also add to the

scatter. Often, the major source of stray light is dust - and sometimes even fingerprints. Keep the

mirrors clean by minimizing dust and occasionally blowing them clean with dry clean air or

nitrogen.

Detectors

The detector has never been considered a source of stray light, since with monochromators there

is a very small exit slit through which light would have to reenter once it has reflected off the

detector surface. Spectrographs however have wide flat focal plane detectors which readily

reflect light. The shiny surface of a silicon diode array can reflect as much as 20% of the light back

into the spectrograph. The stray light can be extremely significant in certain areas of the spectrum,

particularly if light from relatively high intensity wavelengths are finally reimaged onto areas of the

detector which are recording low intensity wavelengths. The MS257 has the focal plane angled in

such a way as to direct light reflected from the detector away from the mirrors and grating and into

'safe' baffles.

Page 16

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

16

7.2 UTILITY AND CONFIGURATION SOFTWARE

The Monochromator Utility Software CD contains:

Installation setup for Mono Utility software.

The utility application provides easy access to almost all MS257 functions.

A folder with the MS257 configuration application installation setup.

The Factory.cfg file, which is a unique file for each instrument with configuration parameters

recorded. If multiple grating turrets have been calibrated, there will be a file for each one.

7.2.1 MS257 UTILITY SOFTWARE

Program Description

This program is written in National Instrument's LabView and is based on a collection of MS257

VIs. The Utility Program diagram may serve as an example or starting point for further

development in LabView. If someone is a LabView programmer and owns a full LabView

development suite, that person can load the Utility Program source code along with MS257 VIs

from the CD. One can also use the dll file included with the Utility Software to create a unique

application in any number of programming languages.

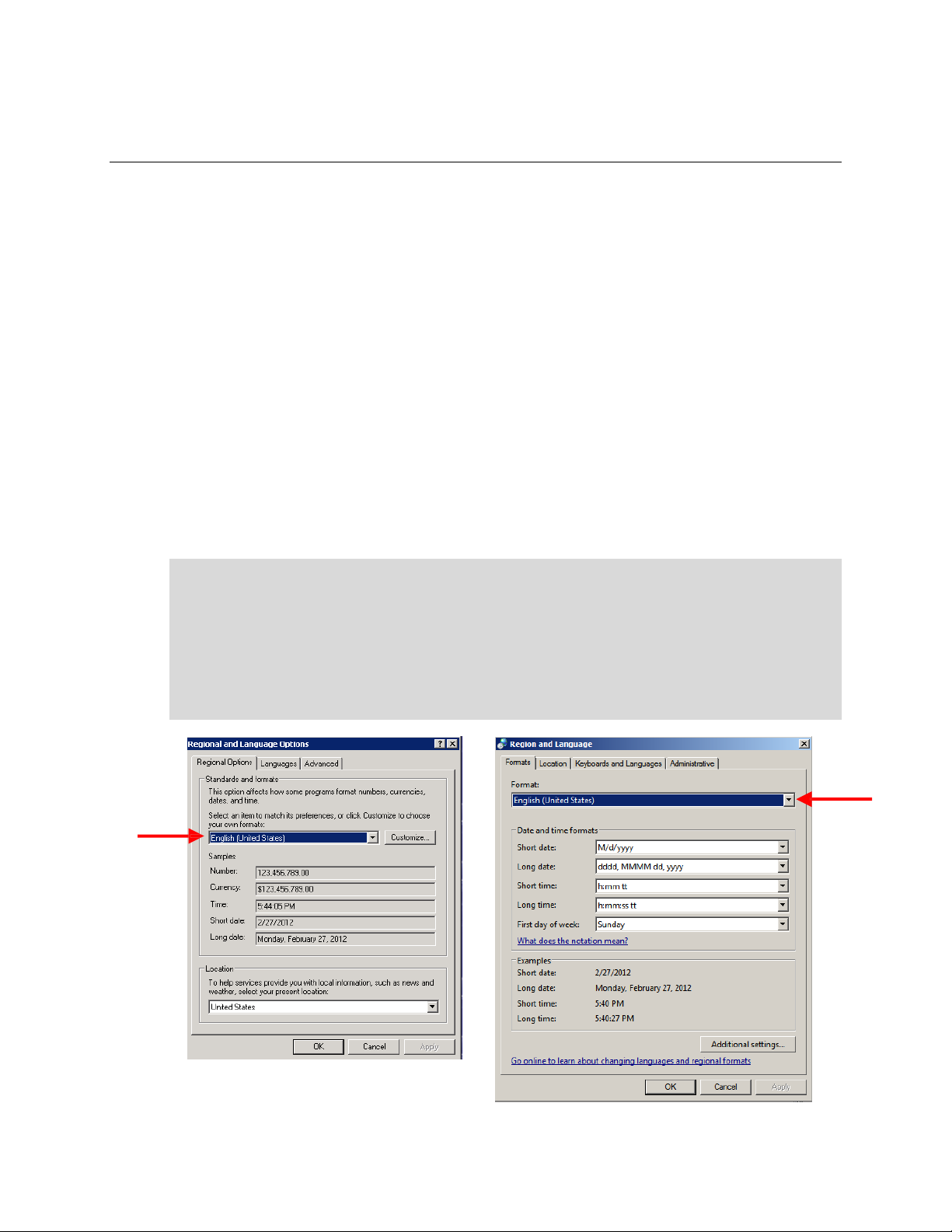

<< IMPORTANT NOTE >>

For the software to send the proper numeric format to the instrument, the Windows must be set

to English (United States). This setting is changed through the Windows Control Panel.

In Windows XP, use the Regional and Language Options setting. The format can be changed

under the Regional Options tab.

In Windows 7, use the Region and Language setting. The format can be changed under the

Formats tab.

Page 17

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

17

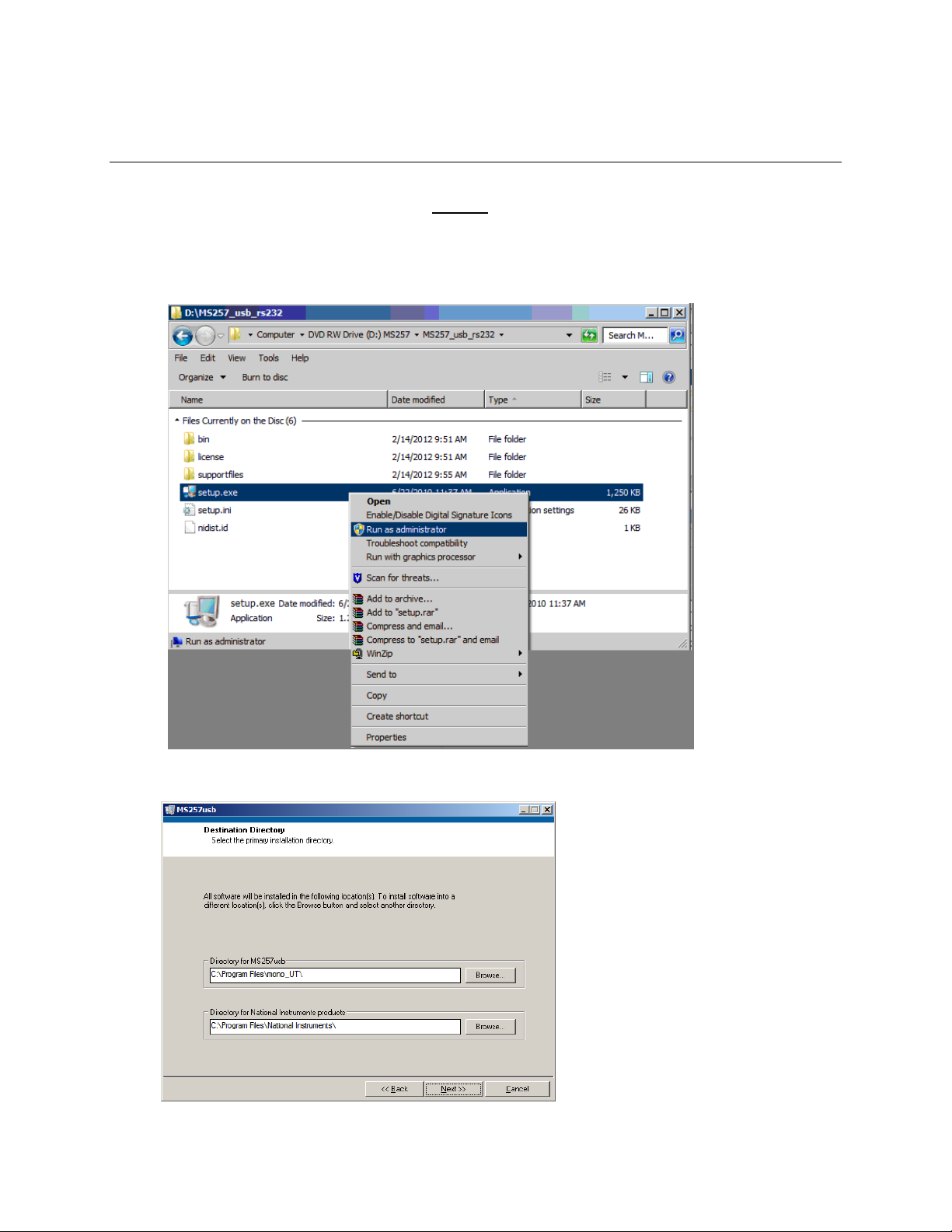

7.2.2 UTILITY SOFTWARE INSTALLATION

The MS257 utility program may be installed on computers with Windows XP or Windows 7 32-bit

operating systems. It is suggested to exit all programs before running the installer.

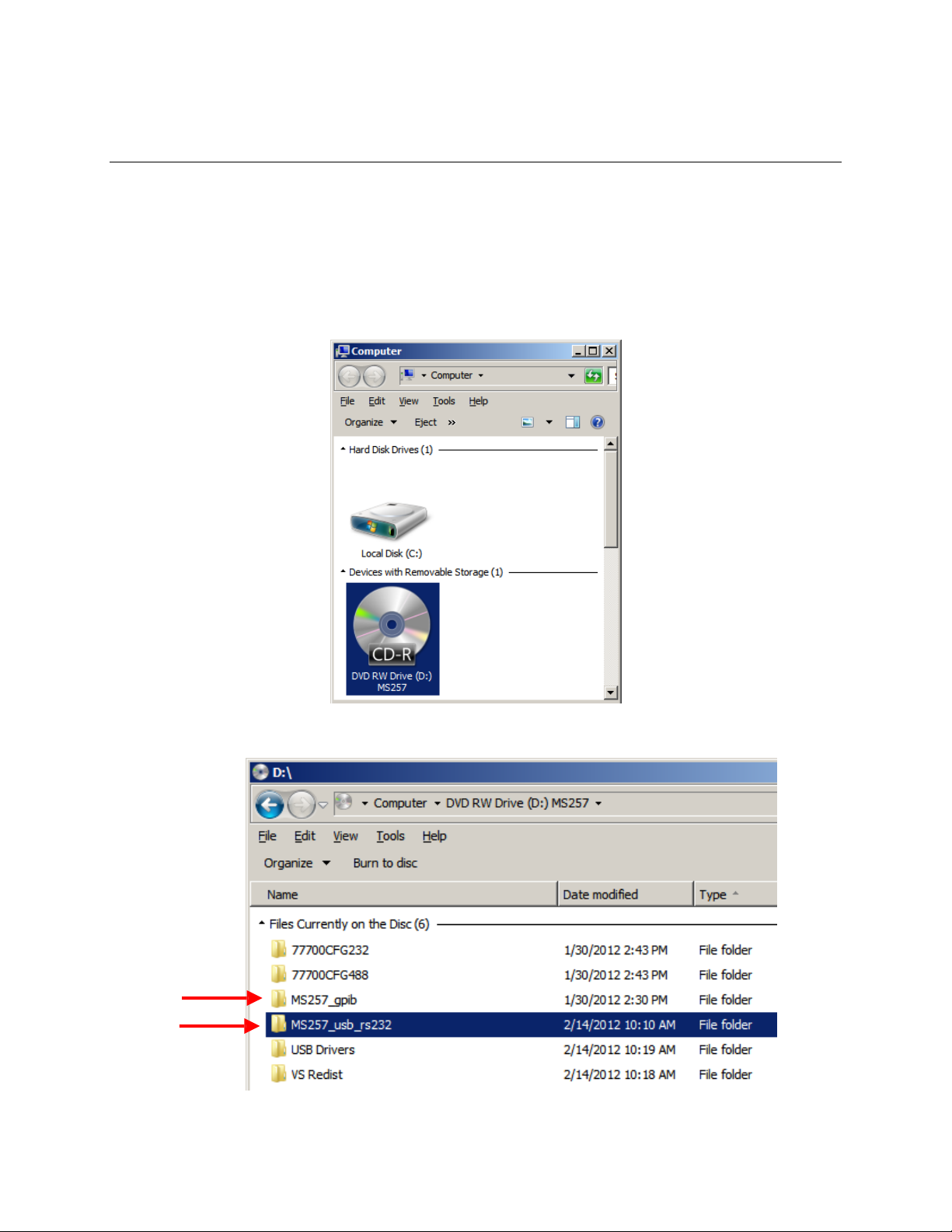

Place the installation CD into the computer which will be used to control the MS257. Open the

CD to view the contents in Computer (or My Computer if using Windows XP).

Open the MS257 folder, based upon the communication method being used.

Page 18

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

18

NOTE: If one is planning to use GPIB, the 77793 converter will be required to operate the

instrument. The 77793 must be set to G Mode.

In the MS257 folder, run the setup.exe application.

If using Windows 7, right click on the application and choose “Run as administrator.

In Windows XP, double click to run the application.

Click Next.

Page 19

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

19

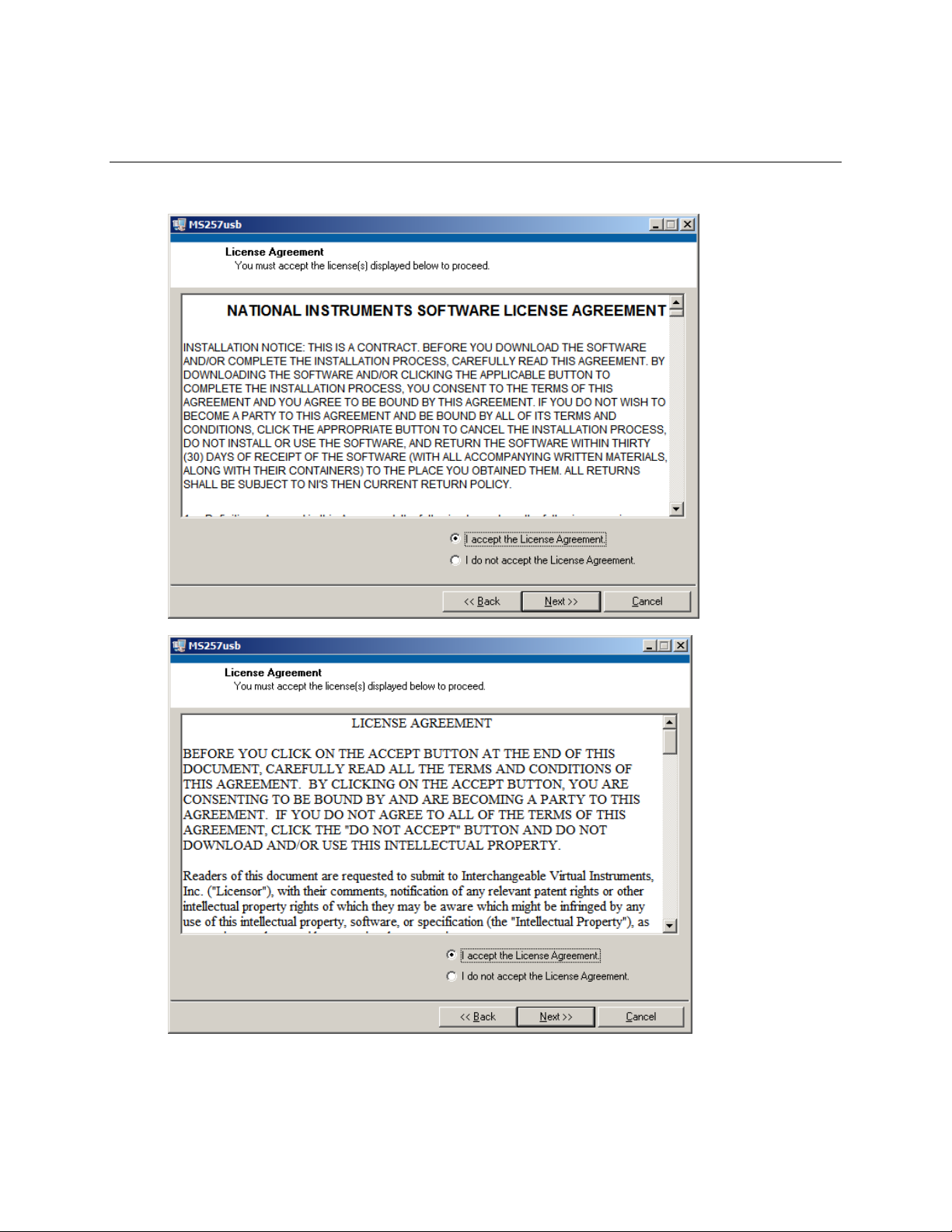

Choose to accept the two License Agreements and click Next to proceed.

Page 20

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

20

Click the Next button to begin the installation.

When complete, click Next for USB and RS232 installation.

For the GPIB installation, click Finish.

Page 21

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

21

The following window will appear briefly only if installing the USB/RS232 utility program.

If installing onto a Windows XP computer, the following message may appear. Click Continue

Anyway.

Restart the computer.

If using Windows XP, the utility program installation is now complete.

If using Windows 7, additional steps are required. Details are provided on the following pages.

Page 22

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

22

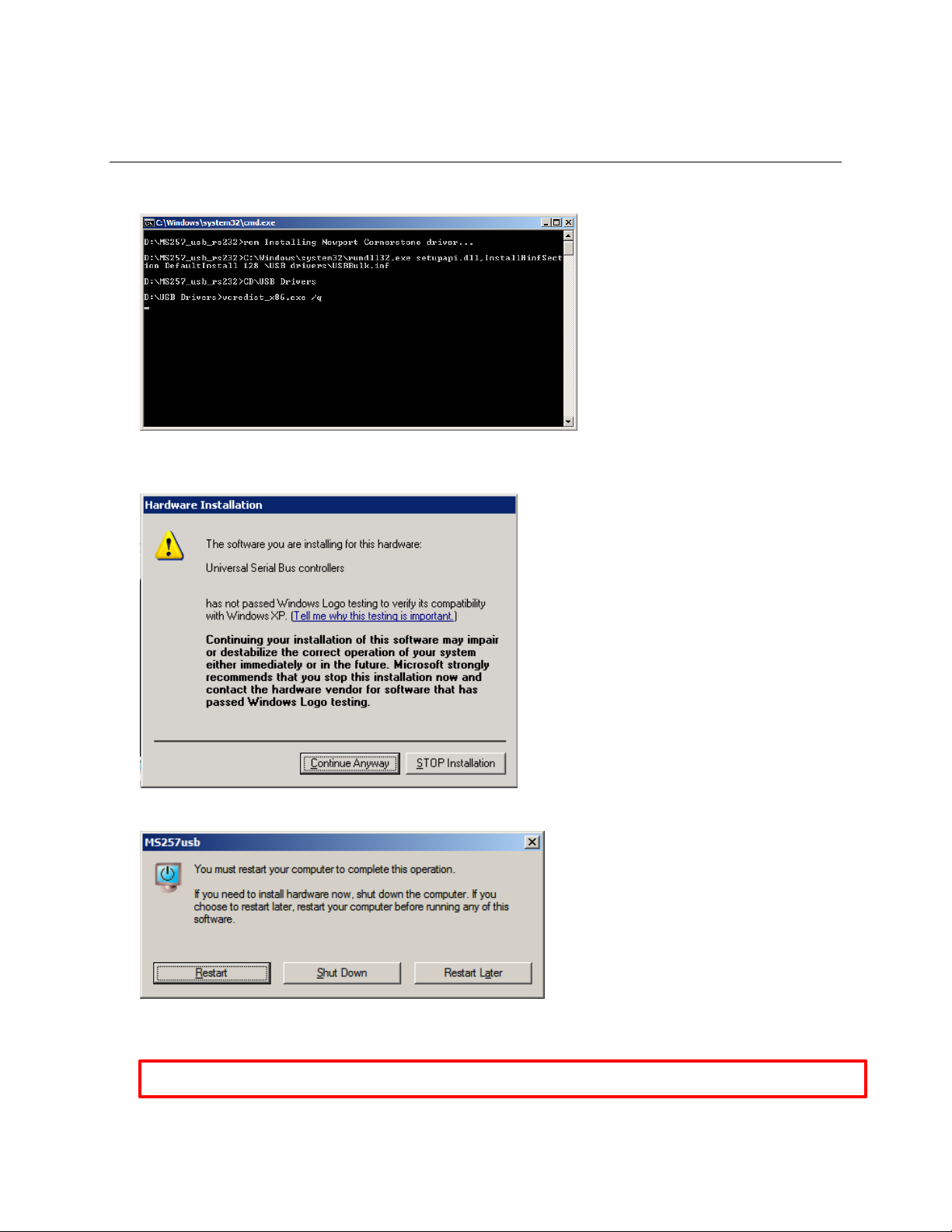

ADDITIONAL INSTRUCTIONS FOR WINDOWS 7, 32-BIT USERS

On the CD, open the USB Drivers folder.

Copy the file USBBulk.sys to the computer’s

Copy the USBBulk.info file to the computer’s Windows\Inf folder

Windows\system32\drivers

folder.

Page 23

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

23

Open the Program Files\Mono_UT folder on the computer. Then open the folder which contains

the utility program, based upon the communications method being used.

Right click on the .exe application and select “Properties”.

Click on the “Compatibility” tab Check the box “Run this program as an administrator” and click

OK.

Page 24

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

24

Using the Utility Software

Launch the application from Start/Programs/MonosUtility.

Enter the SERIAL port number if you are trying to communicate to MS257 from the RS232

host. The default port number is set to 1. If unsure of the port, check the Device Manager.

Control or view the instrument settings by invoking specific (Grating, Filter, Port, Shutter,

Units) dialog windows using push buttons on main window.

To move the instrument to a prescribed wavelength, simply enter a value in the 'Wavelength'

edit box, then click on 'GoTo'.

Fine motion control is achieved by clicking either the '>>' button to move forward or the '<<'

button to move backward.

'Calibrate' menu item can be used to induce wavelength offset in the MS257 memory.

'Setup' dialog displays gratings parameters and filters labels. To edit filter labels, select

number (1,..5). Please do not change the gratings parameters unless the intent is to override

factory configuration parameters of the instrument.

The Scan Parameters area in the main window can be used to set up a scan, which would

then be activated by 'Go Scan' button.

Figure 9: Utility Program Main

Window

Page 25

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

25

7.2.3 MS257 CONFIGURATION SOFTWARE

Program Description

The stand-alone Configuration program is included for setup and configuration of MS257 and its

accessories. The software was developed using National Instruments Labview. The Labview

Runtime Engine is included on the installation CD to enable use of this program without requiring

the full development version of Labview.

The software enables the user to upload a variety of configuration files to the MS257 for different

setups through the RS232 port. For example, if one has two different grating turrets, each turret

would have its own configuration parameters located in a .cfg file. The .cfg files are created

during calibration at the factory and are located on the CD that came with the instrument.

In most cases, only one .cfg file is provided with the instrument. In this situation, the

Configuration Software should only be used if the MS257's memory is corrupted or erased. If the

instrument is not working properly, review the information found in the instruction manuals. It is

suggested to contact the Oriel Instruments service department before .

NOTE: This program does not allow making changes to the parameters. Changes must be

made to the configuration file (.cfg) by using a text editor or word processor software.

The computer must communicate with the instrument through the RS232 connector, not the USB

interface. One must use the RS232 port connected directly to a computer, or connected through

the 77793 GPIB adapter. USB/RS232 adapters are commercially available if the computer being

used does not have a serial port.

Installation

The MS257 configuration program may be installed on computers with Windows XP or Windows

7 32-bit operating systems. It is suggested to exit all programs before running the installer.

Place the installation CD into the computer which will be used to control the MS257. Open the

CD to view the contents in Computer (or My Computer if using Windows XP).

Page 26

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

26

Open the 77700CFG folder, based upon the communication method being used.

NOTE: If one is planning to use GPIB, the 77793 converter will be required to operate the

instrument. The 77793 must be set to G Mode.

In the MS257 folder, run the setup.exe application.

If using Windows 7, right click on the application and choose “Run as administrator.

In Windows XP, double click to run the application.

Page 27

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

27

Click Next to continue.

If the GPIB software is being installed, fill in the Name and Company fields and click Next to

continue. Both fields must be filled in before proceeding.

Page 28

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

28

Browse to choose an installation location on the computer, if desired. The default location of the

Configuration program will be Program Files\OrielInstruments\77700cfg…

Click Next to proceed.

Rename the program folder, if desired, and click Next.

Page 29

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

29

Click Next to proceed.

When the setup has been completed, check the box to launch the program file. Then click Finish.

Page 30

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

30

The following window will appear briefly.

Click Next to proceed with installing the Labview Runtime Engine. Do not cancel this setup, even

if a different version had already been installed onto this computer in the past.

If the GPIB version of the software is being installed, fill in the Name and Company fields before

clicking Next. These fields are required to continue with the installation.

Page 31

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

31

Select Yes to accept the license agreement.

Click Next to install the Labview Runtime Engine into the default directory.

Page 32

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

32

Using the Configuration Software

Launch the configuration program from Start/Programs/77700cfg ...

Use the 'Retrieve Current Memory' menu to read MS257 memory and save to a file.

To view the retrieved memory selectively, click any one of the four buttons at the bottom of

the screen.

Compare MS257 configuration parameters with factory configuration parameters (Factory.cfg

on Newpo

Parameters'.

rt’s Monochromator

Utility

Software CD-ROM) by selecting ''Verify Config

If necessary to restore MS257 memory click the 'Restore From File' and when asked for file

name browse to Factory.cfg on Newport's Monochromator Utility Software CD-ROM.

Figure 10: Configuration Program main window

Page 33

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

33

7.3 77709 HAND CONTROLLER

The Hand Controller is a very compact hand held device with backlit LCD, and 40-key keypad.

Virtually every function of the MS257 can be controlled from the keypad, from simply moving to a

particular wavelength, to changing the grating and filter selections. It comes with a 14 ft (4.5 m)

cable.

MS257 Hand Controller Operation

The Hand Controller controls MS257 via an RJ11 jack on the back panel. System parameters

may be edited from the controller's front panel. The grating's position can be changed from the

hand controller and devices can be selected (filters, slits, slow shutter, output flip mirror and

grating changer).

The Hand Controller has three functional areas:

5 System Status LEDs

4 x 20 LCD screen for system information and parameter editing

5 x 8 Keypad (10 numeric, 5 editing keys, 24 command keys, 1 shift key)

The MS257 starts up in the Remote mode of operation (controlled via the USB or RS232 port). To

initiate control by the hand controller, the Local command key must be pressed. The shifted

command, Rem, returns control of MS257 to the computer.

Transferring of control of the MS257 between the Hand Controller and the computer can only be

initiated with the Hand Controller.

Configuring the MS257 Hand Controller

The Hand Controller comes preconfigured and ready for use. You may alter the configuration

using this procedure:

Apply power to the Hand Controller while holding down any of its keys.

Release the key when a version number appears in the upper left hand corner of the

LCD. The word 'CONTRAST' should then appear in this same area. The contrast can

then be adjusted using the Step> and Step< keys. Press Go Wav when the contrast is

set as desired.

The next number in the corner should be '9600' baud rate. If it is not use the Step> and

Step< to find '9600' and press Go Wav.

The next number in the corner should be '8n11. If it is not use the Step> and Step< to

find '8n11 and press Go Wav.

Now press Local and the Hand Controller status should show on the LCD.

Page 34

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

34

Line

1:

Wave:

Gr:

Line

2:

Lines:

Blz:

Line

3:

F1: F2:

Line

4

>

The LCD Screen Layout

The backlit liquid crystal display has four 20 character lines. The backlight can be turned

on and off by pressing the Local key.

System information is displayed as shown below:

Line 1 indicates the wavelength position in the currently specified units (see Units key),

and the Grating number in use.

Line 2 indicates the number of lines per mm for the selected grating, and the blaze

wavelength label assigned to this grating.

Line 3 indicates filter wheel information, first for Filter Wheel 1 and then for Filter Wheel

2, the selected filter position and filter label assigned to that filter.

Line 4 is the command prompt line where all parameters are edited and the command

status is reported after a key has been pressed. A > sign is displayed if the command has

been accepted, or an error code is displayed if there is a problem.

The System LEDs

Below the LCD screen are five LEDs that indicate the status of various functions:

Power - The MS257 is powered up and the Hand Controller is properly connected

Wait - The wavelength drive is stationary at a data point when the LED is on.

When the LED is blinking, a scan is in progress.

Shutr - The shutter is activated (open).

PortB - Output port B is in use.

Page 35

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

35

Sending Commands using the Hand Controller

System parameters can be queried or changed using the Hand Controller's keys:

Action Keys (Lt. Blue) - These keys cause an immediate action to take place and have no

parameters. After the key is pressed the prompt line indicates the action taken or an error code if

there is a problem.

(Command Keys (Red, Orange, Green, Lt. Blue, and Dark Blue Borders) - The majority of

keys; are termed command keys. Command keys are all the keys which control MS257

parameters. The command keys are grouped by related function. When a command key is

pressed, the command with its current parameter value is displayed on the prompt line. The

cursor is positioned at the start of the field to be edited. The parameter can be edited by using the

DEL key and entering a new parameter. Various parameters can be reviewed by simply pressing

the respective command keys in sequence.

Numeric Keys (Black) - These are used for entering parameter values.

Shift Key (Yellow) - Some command keys have the upper division colored yellow. These

indicate the keys' Shift command. Shift functions do not need two fingers (or hands) to operate

since the Shift key can be pressed with one finger and locks for the next key press, then it

returns to normal.

Clear Key (CLR) - This clears the value field in the prompt line of the current value.

Delete Key (DEL) - This deletes the character at the previous position.

Enter Key (ENT) - If ENT is pressed immediately after a command key, the current parameter

associated with that command is preserved. If ENT is pressed after a new parameter has been

typed, this accepts the displayed parameter for the associated command. It executes a RETURN

and the LCD and LEDs are updated. If the parameter is illegal, an error code is reported on the

prompt line (see the MS257 Programming Manual for the error codes).

Escape Key (ESC) - This aborts any command and parameter entry and returns the > prompt. If

ESC is pressed when a table of parameters is being entered, all parameters are discarded.

Pressing another command key will have the same effect as would normally occur, and will

initiate a new command.

Page 36

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

36

Figure 11: Hand Controller Keypad

Page 37

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

37

Parameter Tables

Changeover tables for grating turrets, filter wheels and detector port need to have their

parameters entered as tables. A table consists of a list of records, each having a wavelength and

the corresponding selected device number. The prompt indicates the record number with

wavelength and device. The cursor is positioned at the start of the parameter to be edited, first

the wavelength is edited and then the selected device number. Each parameter is viewed or

entered in turn with the ENT key. The ENT key moves through the fields. After the position field it

goes to the next record's wavelength field. The first record's wavelength is always zero and

cannot be edited. At the last record the "ENT" saves the table. For creation of tables smaller than

an existing table's size, enter 0 wavelength and 0 position in unused records. All records must

be entered to accept any portion of the table.

Example: >[Shift] [Grat]

Wav:Gr>O:1 [ENT]

Wav:Gr>200:2 [ENT]

Wav:Gr>200:2 [ENT]

Wav:Gr>300:3 [ENT]

Wav:Gr>300:3 [ENT]

Wav:Gr>500:4 [ENT]

Wav:Gr>500:4 [ENT]

In the above example, the keys Shift and Grat were pressed to display the Grating Table. The

response displayed the parameters for the first record. In this case, the first grating was already in

the active position. When ENT was pressed the second record is displayed and the cursor is at

the start of the changeover wavelength. The wavelength was changed to 250. When ENT was

pressed, the wavelength was accepted and the cursor is on the grating position. This process

was repeated until all the records were accepted.

Page 38

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

38

LCD Display

Action and Explanation

>[F1]

F1 Pos>3:Auto

F1 Pos>4:Auto [ENT]

>

>[F1]

Pos>4:Manual

Press the [F1] key

Response shows filter 3 and Auto

Press number 4 and [ENT]

Response is >

Press the [F1] key

Response shows filter 4 and Manual

>[Grat]

Grat Pos>2:Manual

Grat Pos>0:Manual [ENT]

≥

>[Grat]

Grat Pos>2:Auto

Press the [Grat] key

Response shows grating 2 and Manual

Press number 0 and [ENT]

Response is >

Press the [Grat] key

Response shows grating 2 and Auto

>[Port]

Out Port>C:Manual

Out Port>0:Manual [ENT]

>

>[Port]

Out Port>B:Auto

Press the [Port] key

Response shows Port C and Manual

Press number 0 and

[ENT]

Response

is >

Press the [Port] key

Port B is selected in Auto mode

Selecting Auto Mode

The wavelength changeover table is not used by the MS257 unless the device is placed into

automatic operation mode. This is done by selecting '0' for the device position. The prompt line

indicates the device's current position and whether or not the device's automatic changeover

mode is enabled. Selecting '0' for a device's position enables the automatic mode. Selecting any

other valid position disables automatic mode.

Example:

Page 39

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

39

Key

Shifted Key

Command

Type

Description

Abort

Action

Aborts a scan in progress. The Prompt Line is ‘Aborted>’ or an

error code.

Go Action

Initiates a scan. If system information is enabled (Inf) the

Prompt Line is ‘Scanning>’. The LCD general information and

LEDs are updated during the scan. If system information is

disabled for faster scans (No Inf) the Prompt Line is only the

wavelength position. The WAIT LED signals at each scan data

point.

Go Hme

Action

Drives the grating to its home position. The Prompt Line is

‘Homed.’

Go Wav

Read/Write

The Prompt Line is ‘Wav>’. Enter the desired wavelength

position.

Step>

Action

Moves the grating up by one motor step position. The Prompt

Line is ‘Stepup>’.

Step<

Action

Moves the grating down by one motor step position. The Prompt

Line is ‘Stepdown>’.

Step>

Read/Write

Moves the grating up by the step position value entered. Prompt

Line = ‘Stepup>’. Enter the number of steps to move.

Step<

Read/Write

Moves the grating down by the step position value entered.

Prompt Line = ‘Stepdown>’ Enter the number of steps to move.

Start

Read/Write

Sets the start wavelength for a scan. The Prompt Line is ‘Start

Wv>’. Enter the starting wavelength of a scan.

End Read/Write

Sets the end wavelength for a scan. The Prompt Line is ‘End

Wav>’ enters the end wavelength of a scan.

Grat

Read/Write

Selects the grating. The Prompt Line is ‘Gr Pos>’ grating

position’:Manual’ or grating position’:Auto’. Enter the desired

position, 0 for Auto.

Grat

Table

Read/Write

Wavelength Changeover Table key. The Prompt Line is e.g.

‘1)Wav:Gr>0:’ there is one record for each grating position.

Enter wavelength and device position number.

Lines

Read/Write

Sets the current grating’s lines/mm. The Prompt Line is ‘Lines>’.

Enter the number of lines/mm.

Blaze

Read/Write

Sets the current grating’s 4 character blaze label. The Prompt

Line is ‘Blaze>’.

Home

Read/Write

Sets the current grating’s Home wavelength position. The

Prompt Line is ‘Home>’. Enter the home wavelength.

Calib

Read/Write

Sets the current step position for the current grating to be the

calibrated wavelength. The Prompt Line is ‘Cal Wav>’. Enter

the calibration wavelength.

Points

Read/Write

Sets the number of data points in a scan. The Prompt Line is

Points>’. Enter the number of points.

Intvl

Read/Write

Sets the wavelength interval between scan da ta points. The

Prompt Line is ‘Interval>’. Enter the interval between data

points.

Wait

Read/Write

Sets the wait time at each data point for a scan. The Prompt

Line is ‘Wait>’. Enter the wait time at each data point.

Page 40

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

40

Key

Shifted Key

Command Type

Description

F1

Read/Write

Filter wheel 1 position ‘:Manual’ or ‘:Automatic’. The

Prompt Line is ‘F1 Pos>’. Enter the filter number.

Table (F1)

Read/Write

Wavelength Changeover Table Key for Filter wheel 1. The

Prompt Line is e.g. ’1)Wav:F1>0:’. There are 9 records in

the table. Enter the wavelength and device position

number.

F2

Read/Write

Filter wheel 2 position ‘:Manual’ or :’Automatic’. The

Prompt Line is ‘F2 Pos>’. Enter the filter number.

Table (F2)

Read/Write

Wavelength Changeover Table key for Filter wheel 2. The

Prompt Line is e.g. ‘1)Wav:F2>0:’. There are 9 records in

the table. Enter the wavelength and device position

number.

F1 Lbl

Read/Write

Sets the 4 character label for the current filter wheel 1

position. The Prompt Line is ‘F1 Label>’. Enter the label.

F2 Lbl

Read/Write

Sets the 4 character label for the current filter wheel 2

position. The Prompt Line is ‘F2 Label>’. Enter the label.

Inf

Action

Enable reporting of system information during a scan. The

Prompt Line is ‘Info On>’.

No Inf Action

Disable reporting of system information during a scan.

The Prompt Line is ‘Info Off>’.

Int St

Action

Disable external BNC/GO signal from controlling scans.

The Prompt Line is ‘Int Strt>’. Used on legacy models

77700 & 77702.

Ext St

Action

Enable external BNC/GO signal from controlling scans.

The Prompt Line is ‘Ext Strt>’. Used on legacy models

77700 & 77702.

Slit A

Read/Write

Set the width of Slit A. The Prompt Line is ‘Slit A>’. Enter

the slit size in micrometers.

Slit B

Read/Write

Set the width of Slit B. The Prompt Line is ‘Slit B>’. Enter

the slit size in micrometers.

Slit C

Read/Write

Set the width of Slit C. The Prompt Line is ‘Slit C>’. Enter

the slit size in micrometers.

Band

Read/Write

Set the bandpass used for automatically adjusting the slits.

Prompt Line=”Bandpass>”. Enter the bandpass in

wavelength units. () indicates slit adjustment is set

manually using the Slit commands.

Port

Read/Write

Select detector port. The Prompt Line is e.g.

“OutPort>C:Manual”. Enter the output port B or C, 0 is for

automatic selection.

Table (Port)

Read/Write

Wavelength Changeover Table for the detector port. The

Prompt Line is e.g.’1)Wav:OP>0:C’. Enter the wavelength

and output port.

Op Sh Action

Opens the shutter. The Prompt Line is ‘Op Shtr>’.

Cl Sh

Action

Closes the shutter. The Prompt Line is ‘Cl Shtr>’.

Load Action

Recalls the saved system parameters. The Prompt Line is

‘Loaded>’.

Page 41

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

41

Key

Shifted Key

Command

Type

Description

Save

Action

Saves the current system parameters. The Prompt Line is

‘Saved>’.

Ver

Action

MS257 firmware version number. The Prompt Line is e.g.

‘1.00>’.

Units

Read/Write

Set the wavelength units. The Prompt Line is ‘Units>’. Enter the

wavelength units as nanometers (NM), microns (UM), or wave

number (WN).

Rem

Action

Change control of MS257 to the computer. The LCD goes blank,

control of MS257 is released to the RS232 or USB port. The

Prompt Line is ‘>’.

Local

Action

Change control of MS257 to the Hand Controller. The Prompt

Line is ‘>’. The ‘Power’ LED indicates if the hand controller is

plugged into MS257. Each time the key is pressed the LCD

backlight is toggled.

Page 42

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

42

7.4 COMMUNICATIONS

Communicating with MS257

There are three ways of sending commands to MS257:

Using the Hand Controller. The MS257 is already configured for operation with a Hand

Controller

Using the USB or RS232 interface and protocols. The MS257 is already configured for

operation via USB or RS232 communications.

Direct digital (TTL) I/O provided for specific functions.

Direct control of MS257

The MS257 is the first commercial monochromator/spectrograph to have digital input/output

communication facilities built into the unit. Figure 12 shows the connectors at the back of

MS257. The BNC connectors enable the shutter to be closely integrated with data acquisition by

providing the following TTL synchronizing signals:

AUX OUT - A TTL signal (high) is output from the this BNC connector when the Input Port is

set to Port A (axial). A TTL signal (low) is output from the BNC connector when the external

input port is set to Port D (lateral).

AUX IN - The normally closed integrated shutter can be opened by an external TTL signal

(high) applied to this BNC connector. The shutter remains activated as long as the signal

remains high. Note that if the shutter was opened using the utility software, handcontroller or

terminal program command, the shutter must be closed prior to applying an external control

signal .

Figure 12: Rear Panel

Connections

Page 43

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

43

8 PROGRAMMING MS257

The MS257 can be controlled using the Hand Controller or by direct communication with the internal

microprocessor. We have provided three levels of program control:

Direct communication via USB 2.0 using the MS257 command language through a dll.

Direct communication via RS232 using the MS257 command language.

Direct communication using National Instruments LabView Vls for inclusion in custom

programs.

TRACQ Data Acquisition Software.

MS257 command language

The MS257 has been designed as that it can easily be programmed and controlled using

software. Control is easy because many functions can be relegated the internal microprocessor, although

of course every function can be directly programmed if need be. Programming through the dll allows any

language to control the MS257 using USB communication. The user can also control the MS257 through

an RS232 cable. For GPIB communication, an adapter cable that works through the RS232 port is

available.

custom

-written

Page 44

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

44

9 ACCESSORIES

9.1 GRATING TURRETS

The drive can control kinematically interchangeable grating turrets. The Oriel Instruments

patented Quadruple grating turret offers an unequaled degree of automation with no compromise

in optical performance. This high precision turret scans about the face of the selected grating, as

do traditional monochromators, thus offering the best resolution and light throughput over the

grating scan range. The grating selection mechanism uses a second motor perpendicular to the

scan axis, so it does not interfere with the accurate wavelength positioning of the grating. All

turrets require that the gratings be mounted, aligned and calibrated at the factory.

9.2 CONFIGURING THE MS257 FOR TURRET INSTALLATION

With an MS257, there is no need to configure the system for the turret type in use. MS257 will

recognize whether it has a Single or Quadruple grating turret.

The Single Grating Mount

The Single Grating Mount is a kinematic mount. It can be removed and re-installed without losing

the calibration. Each grating comes pre-aligned in a sturdy mount. The mount simply screws

down onto the drive. For detailed information about the Grating Turret installation see Section 3.3.

The Quadruple Grating Turret

The Quadruple Grating Turret is a kinematic mount, it can be removed and replaced without

losing the calibration. Up to four gratings come pre-aligned in a sturdy mount. The turret simply

screws down onto the drive. For detailed information regarding the Grating Turret installation,

refer to Section 3.3.

Figure 13: Quadruple Grating Turret

Page 45

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

45

Groove

Spacing

Lines/mm

Blaze

Wavelength

(nm)

Type

Peak %

Efficiency

Primary

Wavelength

Region

(nm)*

Reciprocal

Dispersion

(nm/mm)***

Array

Bandpass

(nm)****

Model

Number

2400

250

Holo 65

200 - 700

1.6 41

77740

1800

500

Holo 65

300 - 925**

2.1 53

77753

1200

250

Holo 80

180 - 650

3.2 81

77741

1200

350

Ruled 80

200 - 1400

3.2 81

77742

1200

750

Ruled 80

450 - 1400

3.1 79

77752

600 200

Ruled 70

180 - 500

6.4 163

77743

600 400

Ruled 85

250 - 1300

6.5 165

77744

600 1000

Ruled 80

600 - 2500

6.4 163

77745

600 1250

Ruled 85

750 - 2800**

6.4 163

77767

600 1600

Ruled 90

900- 2800**

6.2 155

77768

400 1200

Ruled 90

700 - 2500

9.7 246

77746

400 1600

Ruled 85

900 - 2900

9.6 244

77769

300 500

Ruled 80

250 - 1150

12.8

325

77747

300 1000

Ruled 85

575 - 2500

12.9

328

77770

300 2000

Ruled 90

1100 - 3400

12.9

328

77748

246.16

226

Ruled 60

190 - 450

15.5

396

77771

200 1000

Ruled 85

600 - 2200

19.3

490

77749

150 300

Ruled 70

190 - 800

25.5

648

77772

150 800

Ruled 85

425 - 1600

25.6

650

77773

150 1250

Ruled 85

725 - 2800

25.7

655

77774

150 4000

Ruled 95

2500 - 9000

25.8

655

77750

121.6

413

Ruled 60

250 - 1000

31.3

798

77754

75 7000

Ruled 80

4500 – 20000

51.7

1313

77751

9.3 GRATINGS

The standard gratings available for the MS257 are listed below. Other gratings can be specially

ordered from Oriel Instruments.

* The primary wavelength region is defined by grating efficiency ≥ 20%

** The primary wavelength region for gratings 77753, 77767, 77768 is restricted by the

instrument’s mechanical design.

*** The reciprocal dispersion is given at the blaze wavelength.

**** The array band pass assumes a 25 nm wide spectrographic field.

Page 46

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

46

Configuring MS257 for the New Gratings

Gratings should be installed only by users who are extremely experienced with optical

calibrations. It is strongly recomm ended that any grating replacements and recalibrations be

performed by trained personnel from Oriel Instruments or Newport Corporation.

The MS257 must be configured for the newly installed grating. This can be done using the

following methods:

Use the hand controller to select a grating (GRAT). Change the number of lines/mm (LINES),

blaze (BLAZE), and changeover points (CHNGR). Save the new parameters (SAVE).

Use a text editor or word processor software to edit the Configuration file. Change the grating

lines/mm, blaze and changeover points. Save the file and use the Configuration program open

the file and download it to MS257.

A new grating also requires updating the calibration of the instrument. As mentioned above,

performing this process is not recommended. Instead, contact Oriel Instruments or the regional

sales representative. They will issue an RMA (Return Material Authorization) number, so that the

instrument can be sent to an authorized repair facility for refitting.

9.4 SLITS

The MS257 must have slits installed in order to function properly. Removing and re-installing or

replacing the slits will result in the need to modify the calibration parameters. Three types of slits

may be used with MS257:

Fixed slits of varying widths

Micrometer driven slit assemblies

Motorized slit assemblies

Interchangeable Fixed Slits

lnterchangeable fixed slits are available for applications where precisely repeatable slit widths are

important or where the expense of continuously variable slits is not warranted. Each of the slits

listed in the table below is available separately mounted in machined slides for quick and

repeatable interchange into the fixed slit housings. The model 77721 fixed slit holder has a flange

which enables it to be mounted of all Oriel 1.5 inch (47 mm) series accessories.

The fixed slit is inserted into a slit holder, which is mounted to the instrument’s port. When

inserting a fixed slit, ensure that the slit plate is correctly oriented. There is a notch on one corner

of the slit plate which must match up with a pin inside the fixed slit housing. If the plate is correctly

inserted the Oriel logo should face the exterior and the slit should lie n the center of the aperture.

Make sure that the slit plate is fully inserted for best reproducibility (see Figure 14).

Page 47

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

47

Important tips for fixed slit installation:

The slit should always be inserted with its reflective side facing out (for example, towards the

light source or the detector.)

If the slit entrance is located on the right side of the slit holder, then the slit should be inserted

with the notch located in the upper left corner.

If the slit entrance is located on the left side of the slit holder, then the slit should be inserted

with the notch located in the lower right corner (this will keep the reflective side facing out).

The top portion of the figure above illustrates the correct slit insertion from the left side of the

slit holder.

Figure 14: Using Fixed Slits with MS257

Page 48

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

48

Fixed Slit Model

Slit Width (µm)

Slit Height (mm)

Resolution (nm)

77222

10 2

0.10

77220

25 3

0.15

77725

25 6

0.15

77221

50 3

0.25

77219

50 6

0.25

77728

100 3 0.45

77729

100 10 0.45

77730

200 3 0.8

77731

200 10 0.8

77732

500 15 2 77733

1000 15 4 77734

2000 20 6 77736

1500 15 8 77735

5000 20 20

The standard fixed slits available for the MS257 are listed below.

The typical resolutions listed in the above table apply to use with a 1200 line per mm grating. For

other gratings, multiply the resolution listed by 1200 and then divide by the other grating’s groove

density.

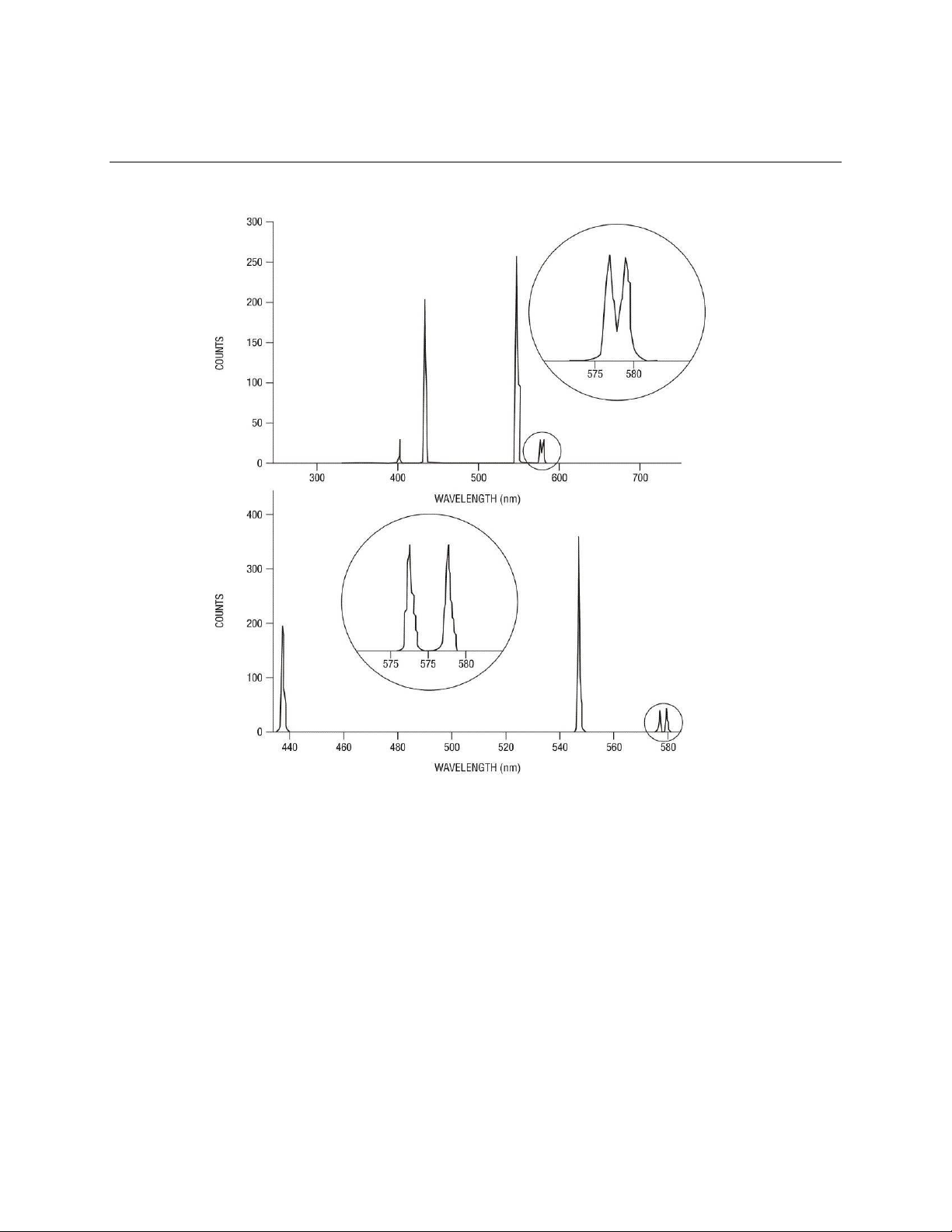

Resolution is defined here as the width of a single wavelength line at the point of half maximum

intensity - also known as FWHM, full width at half maximum. Refer to Appendix A for more

information on bandpass and resolution.

Page 49

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

49

Micrometer Driven Slit Assembly

The 74002 Micrometer Driven Slit Assembly uses a precision micrometer drive to adjust the slit

width from closed to 3 mm. Apply a 10x multiplier to the micrometer markings to readout the slit

opening; thus, each mark on the micrometer barrel corresponds to 10 µm of slit width. The “0”

position on the micrometer is the closed position. The height is also continuously adjustable from

3 mm to 12 mm tall, using the manual slide. As a precaution against damaging the slit blades, do

not adjust beyond its normal operating range.

Please note that optimum spectral resolution for any monochromator is obtained with short,

narrow slits. The 74002 is designed primarily for versatility and convenience in changing

resolution and throughput. Fixed slits should be used for the greatest degree of accuracy and

repeatability, especially at high resolution.

Specifications

Slit Width: Closed to 3 mm

Slit Height: 3 mm to 12 mm

Precision, Width: ±10 µm

Accuracy, Width: ± 10 µm to 250 µm

± 5% from 250 µm to 3 mm

Figure 15: Micrometer Driven Slit Dimensions

Page 50

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

50

The micrometer is used to

adjust the slit width

The slide is used to adjust the

slit height

Figure 16: Micrometer Driven Slit

Micrometer setting for a closed slit

Figure 17: Micrometer Driven Slit Closed

Adjustments

Position

Page 51

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

51

Motor Driven Slit Assembly

The 77722 Motor Driven Slit Assembly has continuously adjustable width from 4 µm to 2000 µm.

The slit height is 15 mm. The motor drive uses a micro-stepping motor and each step

corresponds to a 2 μm change in slit width. The slits are controlled directly by MS257. Each slit’s

width can be individually set or they can all be placed under the automatic control of MS257 in

order to maintain a constant bandpass at all wavelengths. The required bandpass can be

specified using the utility program, hand controller or terminal program.

Note that it is normal for some noise to come from the solenoid, even when the slit width is not

changing. The noise level will vary from between motorized slits. The solenoid will get slightly

warm when powered on.

When using the hand controller, the following needs to be kept in mind. Commanding the slit to

be a width which is an odd number will result in the width being adjusted to the next lower even

width. For example, a slit width entered as 7 um will result in the slit to be set to 6 um wide.

Commanding the slit to be 2 um wide (which is too narrow) will result in the slit width being set to

4 um. Commanding the slit to be 3000 um (which is too wide) will cause error message E0002 to

appear on the hand controller display.

Automatic control works well for a bandpass significantly larger than resolution. If accurate

bandpass value is of critical importance, one may want to experimentally determine proper slit

settings when working at bandpass values close to the instrument resolution.

Figure 18: Motorized

Slit

Page 52

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

52

Slits and the Instrument's Bandpass

This is the band of wavelengths passed by the monochromator at any one wavelength setting. It

may be obtained by multiplying the slit width by the reciprocal linear dispersion, and is usually

specified in nanometers. At large slit widths the bandpass is synonymous with resolution. But at

small slit widths the affect of aberrations tend to limit the resolution even though the bandpass

may be very small. Refer to Appendix A, Bandpass and Resolution for more information.

Using the term “resolution” instead of” bandpass” is more meaningful. However, the concept of

bandpass is particularly well suited to spectrographs. In this case, a wide wavelength range is

spread over an array or CCD. The reciprocal linear dispersion is meaningless in this scenario

because it can vary significantly over the focal plane. The bandpass does still vary with grating

angle but other than at extreme angles it is a good representation of the wavelength range lover

the focal plane.

The bandpass of the MS257 can be calculated using the data from Section 9.3. Assuming that

instrument has the same width input and output slits, multiply the reciprocal dispersion by the slit

width. The number obtained has to be greater than the resolution. If it is not, it means that the

instrument will operate below the resolution limit and its bandpass will be determined by the

resolution, rather than spectral bandpass of the slit.

Mounting Slit Assemblies

All slit assemblies are mounted using four 4-40 screws. The input slit assembly is oriented by an

alignment pin in the MS257 housing that fits into a precision hole in the slit assembly. The exit slit

assemblies do not have alignment pins. This allows one to slightly rotate the exit slits in order to

obtain the best throughput and resolution.

The MS257 comes with all slit assemblies installed and the instrument calibrated. Removing and

replacing or re-installing the exit slits should only be attempted by personnel who are experienced

in optical calibrations. It is strongly suggested to have slits replaced by an authorized service

person. Removal of the input slit is never recommended. Recalibration is required whenever a

slit is installed – even if it is the same slit being re-attached. Never remove slit assemblies or slit

holders for storage or transportation.

When mounting an exit slit assembly, use the following process:

Use a light source to illuminate the input slit.

Set the wavelength to zero, or to a prominent spectral line if using a calibration lamp.

Adjust or change the input slit to a small slit width, or insert a narrow width fixed slit into the

slit holder.

Adjust or change the exit slit to be the same slit width as the input slit.

Adjust the rotation of the exit assembly until it appears to be parallel to the image. The

image height should be at a maximum.

Tighten the mounting screws.

Page 53

M77781A

MS257™ USB/RS232

MONOCHROMATOR AND SPECTROGRAPH

53

9.5 FILTER WHEELS

Up to two optional filter wheels (Model 77737) can be mounted at the input port(s) of the MS257.

Each filter wheel holds up to five filters – neutral density, bandpass, interference, etc. The filter

wheels are mounted externally to prevent the refractive index and thickness of the filters from

affecting the focal distance to the collimating mirror. Altering the focal distance could significantly

affect the resolution. A ribbon cable connects each filter wheel to the back panel of the MS257,

which can be configured to automatically control filter selection.