Before using the tool,

read the operating

instructions carefully

.

H-1067

OR-H 47

Hand tool for steel strapping

09/07

ORGA

PACK OR-H 47

Table of contents

1 Technical data 3

2 General information

3 Safety instructions

4 Construction

5 Operating

6 Maintenance

6.1 Cleaning of the tool

6.2 Setting the cutting depth

6.3 Replacing wearing parts 10

7

Recommended spare parts

7.1

Parts list

Exploded drawing 15

1

Technical data

Weight

Dimensions

Tension force Up to approx. 6500 N

Sealing Sealless notched

joint

Steel strap

Strap width 13, 16, 19 mm

Strap thickness

T

ensile strength

3.5 kg ( 7.7 lbs)

L = 370 mm (14.5")

W

= 185 mm (7.27")

H = 122 mm (4.79")

1

5

(

",

",

/

/

2

8

0,38–0,63 mm

(.014"–.025")

650– 1

100 N/mm

5

12

12

3

")

/

4

2

General information

These operating instructions contain

important information concerning the

4

6

7

9

9

9

2

safe, proper and efficient use of the

strapping tool. Compliance with the

instructions will help to avoid danger,

reduce repairs and stoppages and

increase the reliability and service life

of the strapping tool.

In addition to the operating instructions

and the regulations for accident prevention effective in the country of use

and place of application, the recognized technical regulations for safety

and proper working must also be observed.

Use for the intended purpose

a)

This tool is designed for strapping

packages, pallet loads etc.

This tool was designed and manufactured for safe handling during the strapping operation.

The tool processes steel straps only.

b) Possible misuse

Plastic straps cannot be used.

c) Information on environmental

protection

This tool is manufactured with no physical or chemical substances that could

be dangerous to health.

For disposal of all the parts, the

governmental instructions must be

observed.

3

Safety instructions

Inform yourself!

1.

Before using the tool read the operating instructions carefully.

Protect yourself!

2.

When operating the tool, wear eye-,

face- and hand protection (cutting

protected gloves).

Only strap packed goods!

3.

Do not put hands or other parts of

the body between the strap and the

package.

Strap will snap forward when

4.

cutting!

When cutting the strap, hold the

upper portion and stand a safe

distance away from the strap.

Caution:

forward.

5. Strap could break during

tensioning!

Do not stand in line with the strap

while it is tensioned. The strap could

break!

Danger of squeezing!

6.

Do not put your fingers into the

tension wheel area.

7. Original ORGAPACK spare parts!

Only original ORGAPACK spare

parts may be used.

the lower strap will snap

jklsfjklsdjš

lksdfjkl

jkljsdllkjjkljsd

fkljjklkjkljsdafj

asdfjklkjjkljklj

ksldafkjkljklš

jkljklkljsdafjlkj

jkljjkljklkljljlk

1.

.

3

.5 6.

Original

ORGAPACK

.7

2.

.

4

Page 2 of 7

09/07

ORGA

PACK OR-H 47

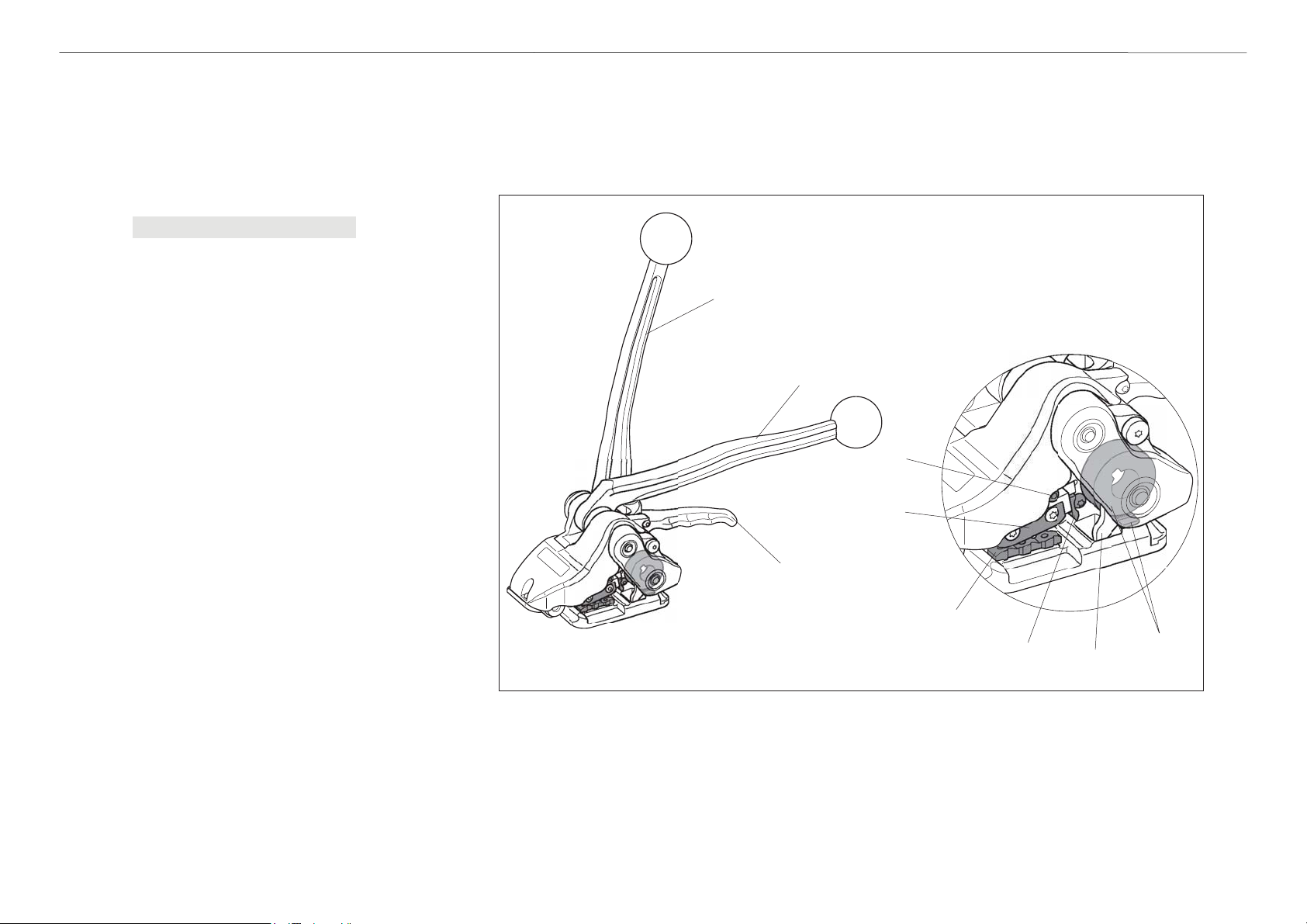

4

Construction

1. Tensioning lever

2. Sealing lever

3. Rocker lever

4. Tension wheel and tension plug

5. Strap guide pawl

6. Cutter knife

7. Die

8. Punch

Adjusting screw (cutting depth)

9.

Fig. a

1

2

9

8

3

7

6

5

4

Page 3 of 7

09/07

ORGA

PACK OR-H 47

5

Operating

Fig. 1

– Place strap round packed goods

(Fig. 1/1), so that the straps lie

above each other on top of the

package.

Fig. 2

– Hold tool in right hand and raise

rocker lever (Fig. 2/1) against

sealing lever (2/2).

– Place tool against the strap until it

contacts the stop.

– Release rocker lever.

–

Strap can now be manually preten-

sioned.

Fig. 3

–

Hold sealing lever (Fig. 3/1) in left

hand and with the right hand move

the tensioning lever (3/2) backwards

and forwards until the required strap

tension is obtained.

Fig. 1

Page 4 of 7

Fig. 2

2

1

1

F

ig. 3

2

1

09/07

ORGA

Fig 4.

1

PACK OR-H 47

Fig. 4

– When the strap tension is reached,

move sealing lever (Fig. 4/1) to the

stop.The right hand remains on the

tensioning lever to resist the opposing force. The strap is sealed and

cut.

If the strap cut is incorrect (see

chapter 6.2).

Fig. 5

– Return sealing lever to initial position.

– Raise the rocker lever against the

sealing lever.

– Swivel the tool away from the

strapping backwards and to the

right.

Seal check

Fig. 6

T

o obtain the maximum seal efficiency,

the notches must be cut and interlocked properly into the straps: Check

this regularly. If these notches are not

correctly cut, replace die and tension

plug (see chapter 6.3).

Page 5 of 7

F

ig. 5

. 6

Fig

ca. 1 mm (.039")

.

09/07

ORGAPACK OR-H 47

6

Maintenance

6.1 Cleaning the tool

The tool should be regulary cleaned.

The tension wheel and the tension

plug, in

The easiest way to do this, is to use

compressed air to blow out the dust.

Wear eye protection.

Periodically lubricate all moving parts

with one or two drops of light machine

oil.

particular,should

be kept clean.

6.2 Setting the cutting depth

The setting of the cutting depth must

correspond to the thickness of the relevant strap. If set incorrectly, the sealing

strength may be reduced.

– Set adjusting screw marked in red

(Fig. 7/1) with screwdriver (Torx).

– Turning adjusting screw clockwise:

increases cutting depth.

– Turning adjusting screw

counterclockwise:

decreases cutting depth.

Set cutting depth so that the lower

strap is not touched during cutting.

.

6.3

Replacing wearing parts

a)

Replacing die

–

Release tallow-drop screw (8/16).

–

Raise die (8/93) with screwdriver,

remove and replace it .

b)

Replacing punch complete

–

Release screws (8/21), remove and

replace punch complete (8/93).

Fig. 7

c)

Replacing cutter knife

–

Release tallow-drop screw (8/8) and

remove and replace cutter knife

(8/20).Adjust the setting depth after

replacement ( refer to chapter 6.2).

d)Replacing tension plug

– Release two counter sunk screws

(8/35).

–

Remove tension plug support (8/30).

–

Remove and replace tension plug

(8/34).

+

1

Fig. 8

Page 6 of 7

93

(Loctite 222)

16

93

21

20

8

(Loctite 222)

34

(Loctite 222)

35

30

09/07

ORGA

PACK OR-H 47

e) Replacing tension wheel

– Release shoulder screw (9/64).

– Lift rocker lever and remove bearing

– Remove distance washer (9/58),

– Remove and replace tension wheel

– During installation, observe strap

Fig. 9

cover (9/61).

strap guide pawl (9/59) and dis

tance washer (9/58).

(9/57).

width adjustment (see Fig. 9).

Page 7 of 7

e)

57

58

59

58

16 mm (

61

5

")

/

8

19 mm (

3

)

"

/

4

1

")

(

mm31

/

2

80

64

09/07

Loading...

Loading...