Page 1

Original Instruction Manual

Chainsaw Model CS1500-093

Page 2

Page 3

WARNING: Read and understand all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

Page 4

4

Chainsaw Model CS1500

Table of Contents

Table of Contents

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Signal Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

General Power Tool Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Work Area Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Power Tool Use and Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chainsaw Safety Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Causes and Operator Prevention of Kickback . . . . . . . . . . . . . . . . . . . . . . .8

Kickback Safety Devices on this Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Storage, Transporting, and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Symbols and Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chainsaw Names and Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preparing for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the Front Hand Guard Position . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filling the Bar and Chain Oil Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Tensioning the Saw Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating the Chainsaw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Meter Power Cord Use and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Sharpening with PowerSharp® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Maintaining the Guide Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Replacing a Worn Saw Chain and Sharpening Stone . . . . . . . . . . . . . . . . . . 26

Replacing a Worn Guide Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing a Worn Chain Tensioning Gear . . . . . . . . . . . . . . . . . . . . . . . . . 27

Replacing the Drive Sprocket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Tensioning the Saw Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Additional Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Specifications and Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Warranty and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

EC – Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

© Blount, Inc. Pricing and specifications subject to change without notice. All rights reserved. Oregon® is a registered trademark of

Blount, Inc. in the United States and/or in other countries.

Page 5

5

Chainsaw Model CS1500

Important Safety Instructions

Important Safety Instructions

Introduction

This chainsaw is designed for occasional light-duty use. It is not designed to fell large trees or cut

large diameter logs. This chainsaw is not designed for tree service. Do not cut trees or wooden

timbers that have a diameter greater than the effective cutting length of the chain saw, inches

( cm).

Safety Signal Definitions

SYMBOL SIGNAL MEANING

WARNING

Indicates a potential hazard which could result in serious injury.

CAUTION

Indicates a potential hazard which could seriously damage the tool or

cause minor to moderate injury.

IMPORTANT

Following this instruction will increase satisfaction with the tool.

General Power Tool Safety Warnings

WARNING: Read and understand all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock,

fire and / or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the

warnings refers to your mains-operated (corded) power tool or battery operated (cordless)

power tool.

Work Area Safety

• Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

• Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

• Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. There is an

increased risk of electric shock if your body is

earthed or grounded.

• Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators. Water

entering the charger will increase the risk of

electric shock.

• Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the meter cord. Never use

the meter cord for carrying, pulling or

unplugging the power tool. Keep meter

cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

• When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

• If operating a power tool in a damp

location is unavoidable, use a ground

fault circuit interrupter (GFCI) protected

supply. Use of a GFCI reduces the risk of

electric shock.

Page 6

6

Chainsaw Model CS1500

Important Safety Instructions

Personal Safety

• Stay alert, watch what you are doing

and use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid safety

shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal

injuries.

• Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger on

the switch or energising power tools that have

the switch on invites accidents.

• Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

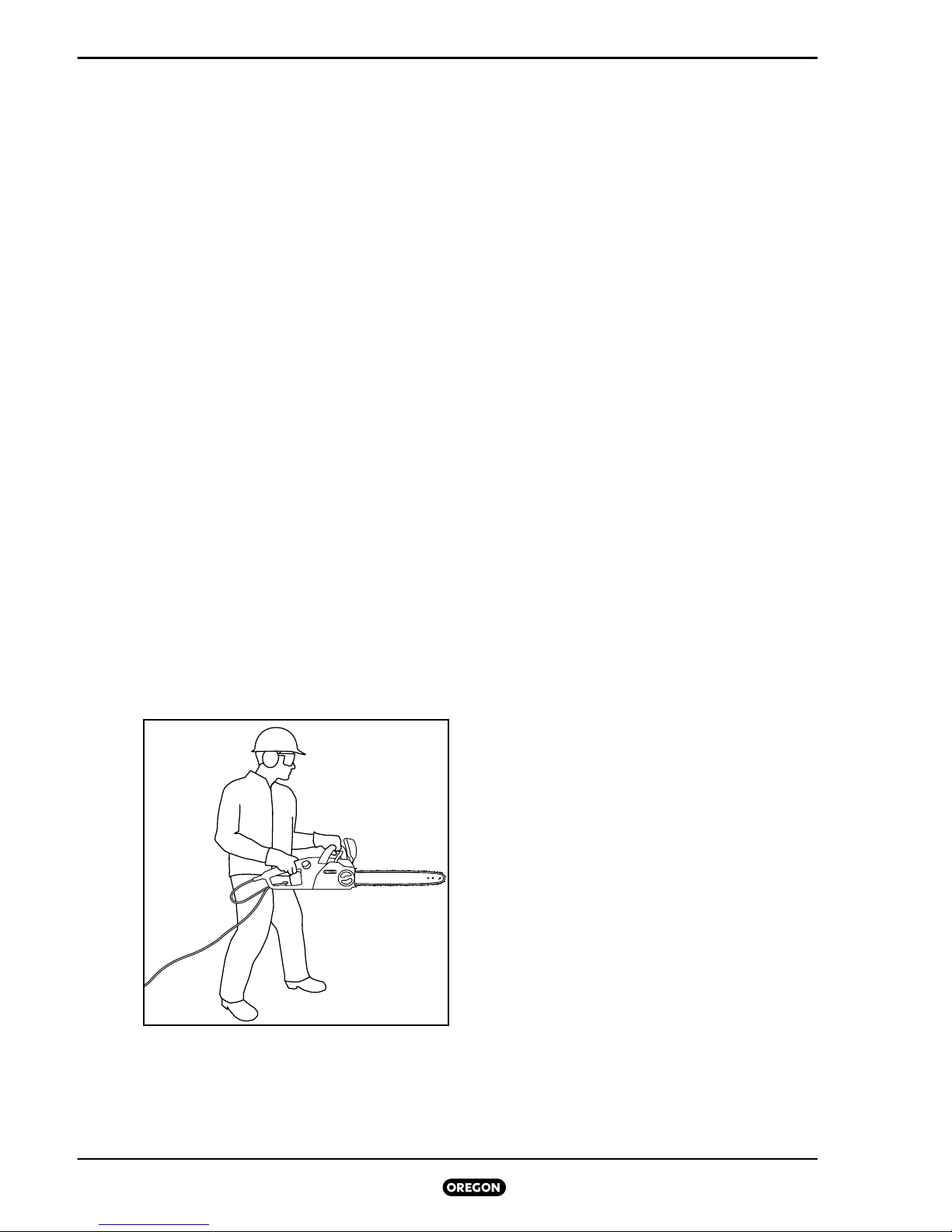

• Do not overreach. Keep proper footing and

balance at all times (Fig. ). This enables

better control of the power tool in unexpected

situations.

• Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

• If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce

dust-related hazards.

Power Tool Use and Care

• Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it was

designed.

• Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

• Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories or

storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

• Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many accidents

are caused by poorly maintained power tools.

• Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

• Use the power tool, accessories and

tool bits, etc. in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended could

result in a hazardous situation.

FIG. 1

Page 7

7

Chainsaw Model CS1500

Important Safety Instructions

Service

Have your power tool serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Chainsaw Safety Warnings

• Keep all parts of the body away from

the saw chain when the chainsaw is

operating. Before you start the chainsaw,

make sure the saw chain is not contacting

anything. A moment of inattention while

operating chainsaws may cause entanglement

of your clothing or body with the saw chain.

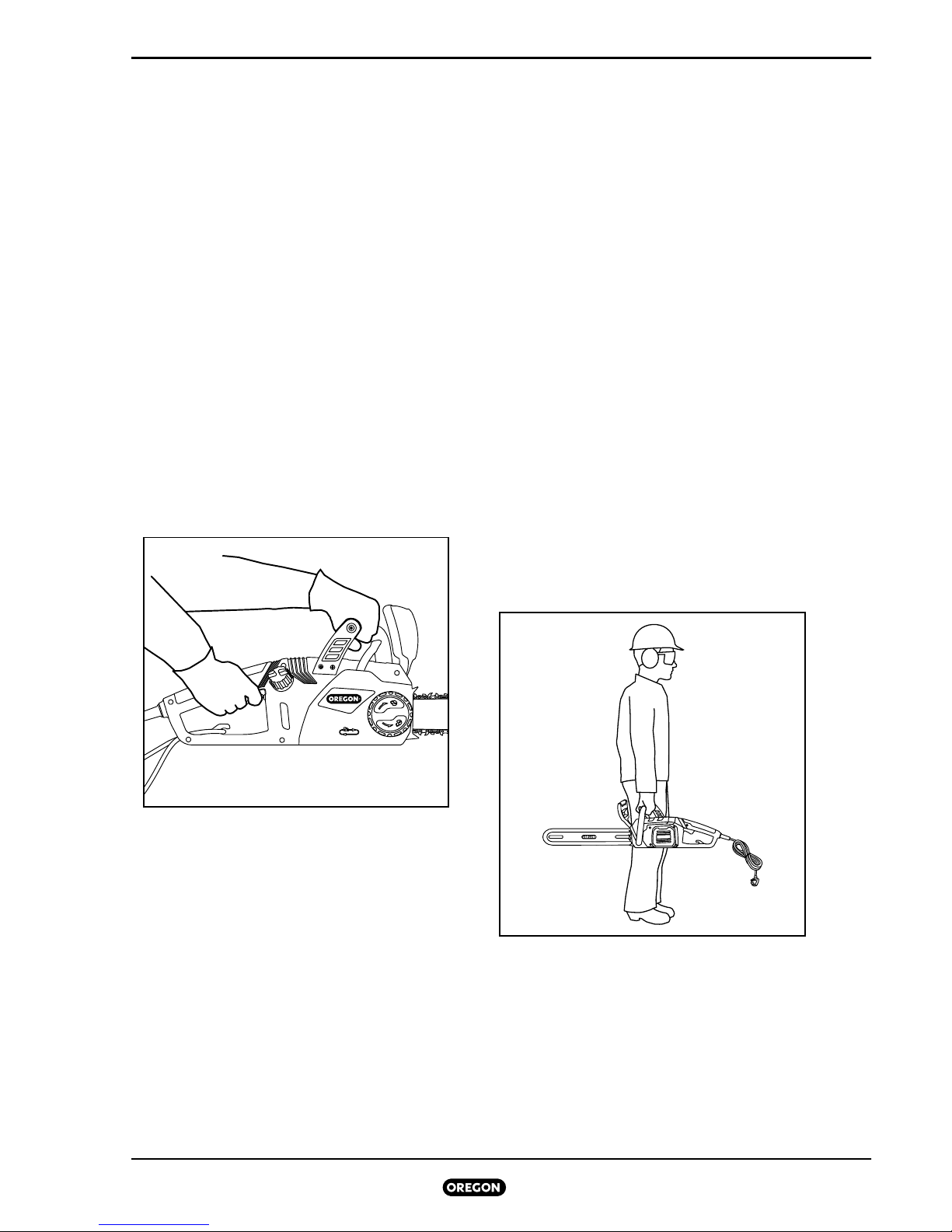

• Always hold the chainsaw with your right

hand on the rear handle and your left

hand on the front handle (Fig. ). Holding

the chainsaw with a reversed hand

configuration increases the risk of personal

injury and should never be done.

• Hold the power tool by insulated gripping

surfaces only, because saw chain may

contact hidden wiring or its own meter

cord. Saw chains contacting a “live” wire may

make exposed metal parts of the power tool

“live” and could give the operator an electric

shock.

• Wear safety glasses and hearing

protection. Further protective equipment

for head, hands, legs and feet is

recommended. Adequate protective clothing

will reduce personal injury by flying debris or

accidental contact with the saw chain.

• Do not operate a chainsaw in a tree.

Operation of a chainsaw while up in a tree may

result in personal injury.

• Always keep proper footing and operate

the chainsaw only when standing on a

fixed, secure and level surface. Slippery

or unstable surfaces may cause a loss of

balance or control of the chainsaw.

• When cutting a limb that is under tension,

be alert for spring back. When the tension

in the wood fibres is released, the spring

loaded limb may strike the operator and/or

throw the chainsaw out of control.

• Use extreme caution when cutting brush

and saplings. The slender material may catch

the saw chain and be whipped toward you or

pull you off balance.

• Carry the chainsaw by the front handle

with the chainsaw switched off and away

from your body. When transporting or

storing the chainsaw, always fit the guide

bar cover (Fig. ). Proper handling of the

chainsaw will reduce the likelihood of

accidental contact with the moving saw chain.

• Follow instructions for lubricating, chain

tensioning and changing accessories.

Improperly tensioned or lubricated chain

may either break or increase the chance of

kickback.

• Keep handles dry, clean and free of oil

and grease. Greasy, oily handles are slippery

causing loss of control.

FIG. 2

FIG. 3

Page 8

8

Chainsaw Model CS1500

Important Safety Instructions

• Cut wood only. Do not use the chainsaw

for purposes not intended. For example:

do not use chainsaw for cutting plastic,

masonry or non-wood building materials. Use

of the chainsaw for operations different than

intended could result in a hazardous situation.

• It is recommended that the first time user

should have practical instruction in the

use of the chainsaw and the recommended

protective equipment from an experienced

operator. The initial practice should be

cutting logs on a saw-horse or cradle.

• Other than the wear parts identified in

this manual, the chainsaw has no user

serviceable parts.

• The work piece, bar and chain can be hot

after cutting. Wear gloves to avoid burns.

• Prolonged use of power tools has been

reported to cause vascular, muscular

and/or neurological disorders (such

as vibration white finger or Raynaud’s

syndrome), particularly when operating

the tool in cold weather. If you experience

numbness or loss of feeling in your

extremities, stop using the tool until

symptoms fade. To reduce the incidence

of vibration induced trauma, follow these

instructions:

– Wear gloves and keep hands and body

warm.

– Maintain a firm grip on the chainsaw,

but do not use prolonged, excessive

pressure. Let the chainsaw do the work.

– Assure that the cutting system is

maintained properly.

– Take frequent breaks.

The vibration in normal use can differ from

the stated values in this manual, depending

on the material being cut, maintenance of the

cutting system and other factors.

• Keep the meter cord behind you, and

know the position of the meter cord at

all times. Keeping the meter cord behind

you and knowing the position of the meter

cord will help minimize tripping hazards and

prevent severing of the meter cord with the

chainsaw.

• If the meter cord is cut or damaged,

immediately stop using the chainsaw

and disconnect the meter cord from

the mains. A damaged or cut meter cord

increases the risk of electrical shock.

• When used in a wet environment, use a

GFCI with a tripping current of less than

mA. Use of a GFCI reduces the risk of

electric shock.

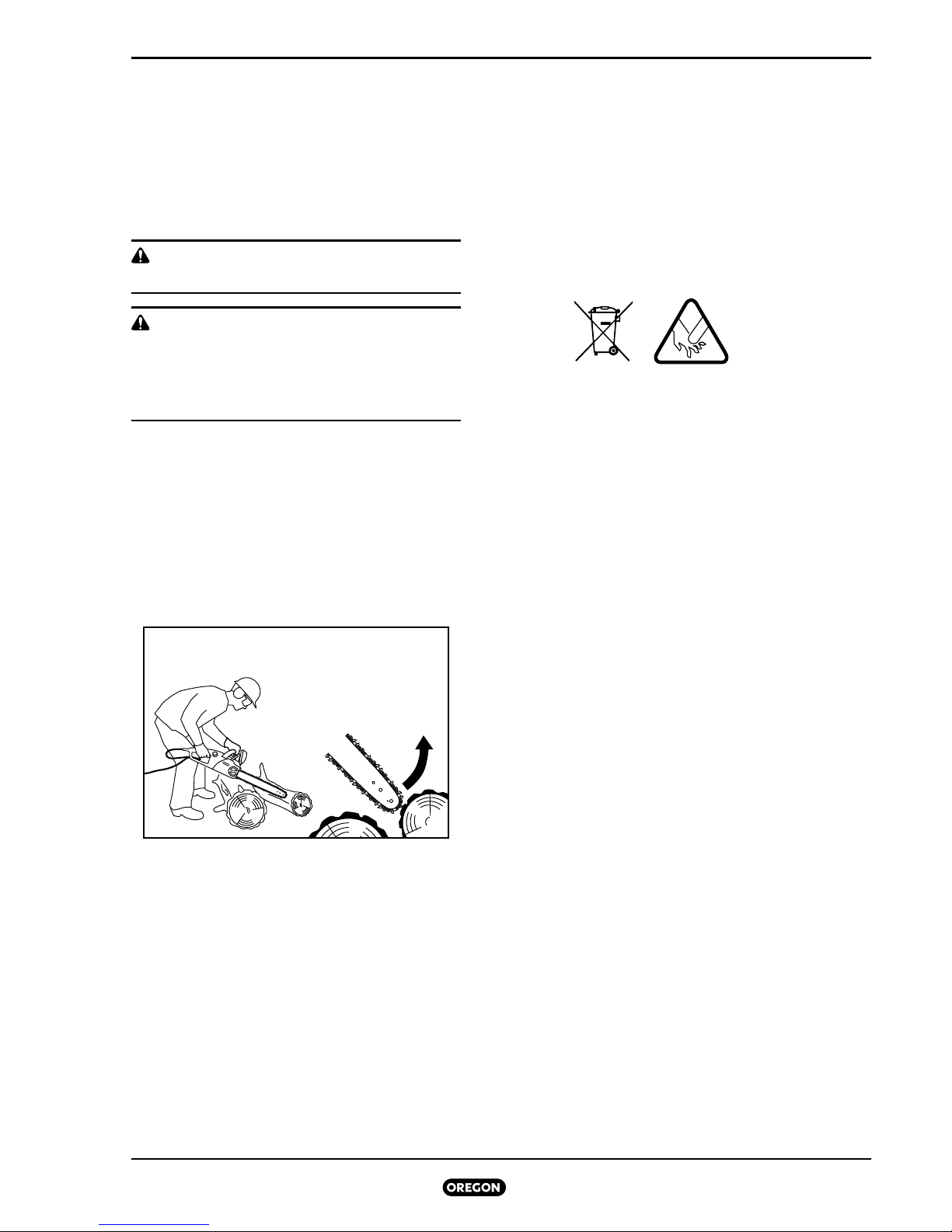

Causes and Operator Prevention

of Kickback

Kickback may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact, in some cases, may cause a sudden

reverse reaction, kicking the guide bar up and

back towards the operator.

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly back

towards the operator.

Either of these reactions may cause you to

lose control of the saw which could result in

serious personal injury. Do not rely exclusively

on the safety devices built into your saw. As a

chainsaw user, you should take several steps

to keep your cutting jobs free from accident and

injury.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions

and can be avoided by taking proper

precautions as given below:

• Maintain a firm grip with thumbs and fingers

encircling the chainsaw handles, with both

hands on the saw and position your body and

arm to allow you to resist kickback forces.

Kickback forces can be controlled by the

operator , if proper precautions are taken. Do

not let go of the chainsaw.

• Do not overreach and do not cut above

shoulder height. This helps prevent

unintended tip contact and enables better

control of the chainsaw in unexpected

situations.

Page 9

9

Chainsaw Model CS1500

Important Safety Instructions

• Follow the Oregon sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to

increased kickback.

Kickback Safety Devices

on this Saw

DANGER: Never modify or attempt to

disable the chain brake.

DANGER: Only use replacement bars

and chains specified by Oregon. Incorrect

replacement bars and chains may cause

chain breakage and increased risk of

kickback injury.

CHAIN BRAKE

This chainsaw comes equipped with a chain

brake, which stops both the motor and the

motion of the chain when kickback occurs (Fig.

). The chain brake can be activated by the

forward motion of the front hand guard as the

saw rotates backward during kickback; it can

also be activated by the inertial forces

generated from a kickback event.

CHAIN

This chainsaw comes equipped with a

saw chain that met the reduced kickback

performance requirements of the American

National Standards Institute (ANSI) and

Canadian Standards Association (CSA), ANSI

B. and CSA Z. respectively, when tested

according to the provisions of the standards.

For replacement chain, see “Specifications and

Components” in this manual.

BAR

This saw comes equipped with a reduced

kickback guide bar that has a small radius nose.

Smaller radius noses have less potential for

kickback than a bar of the same size with a

larger nose radius.

When replacing the bar, only order the bar

listed in this manual to maintain low kickback

performance.

Storage, Transporting, and

Disposal

STORING THE CHAINSAW

• Unplug the chainsaw.

• Inspect the meter cord for cuts or damage.

• Clean chainsaw thoroughly.

• Install the guide bar cover.

• Store in a dry place.

• Keep out of reach of children or pets.

• It is normal for a small amount of oil to seep

from the guide bar when the chainsaw is not

in use. To protect against seepage, install the

guide bar cover and place an absorbent pad

under the bar.

TRANSPORTING THE CHAINSAW

Tools can shift during transport. Ensure the tool

is secure and cannot fall or move into contact

with people or property.

• Unplug the chainsaw.

• Install the guide bar

• If desired, drain the bar and chain oil to reduce

seepage.

CHAINSAW DISPOSAL

This Oregon product is designed and

manufactured with high quality materials and

components which can be recycled and reused.

Upon product end-of-life, and according to

Directive //EC, the electrical appliance

should be disposed of separately from

household waste. In the European Union,

there are separate collection systems for

used electrical and electronic products. Please

dispose of this equipment in an environmentally

correct manner at a local community waste

collection/recycling centre.

FIG. 4

Page 10

10

Chainsaw Model CS1500

Symbols and Labels

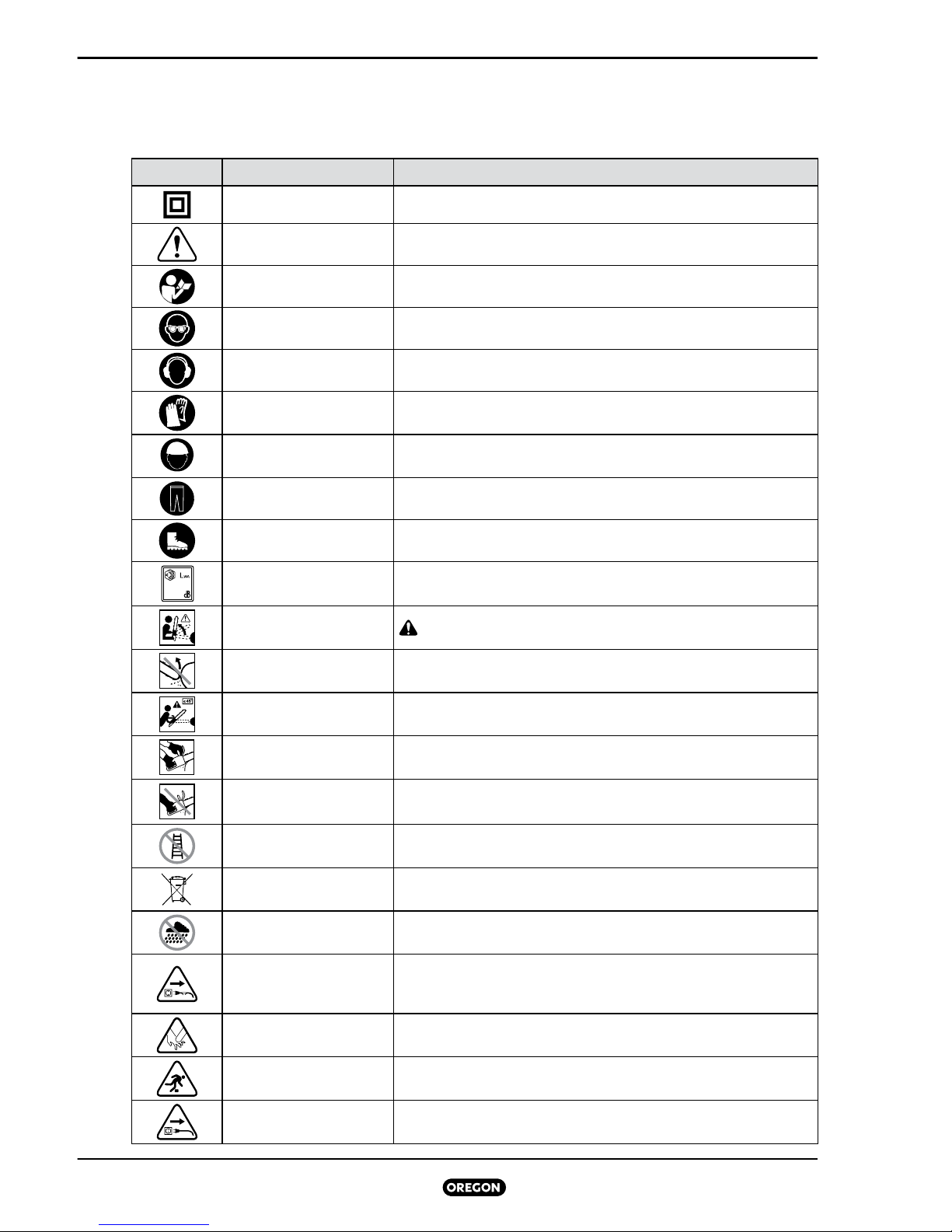

Symbols and Labels

These symbols and labels appear on the chainsaw and/or in this manual.

SYMBOL NAME EXPLANATION

Class II construction Designated double insulated construction tools.

Safety alert symbol

Indicates that the text that follows explains a danger, warning or

caution.

Read instructions

The original instruction manual contains important safety and

operating information. Read and follow the instructions carefully.

Wear eye protection Wear eye protection when operating the chainsaw.

Wear hearing

protection

Wear hearing protection when operating the chainsaw.

Wear hand protection

Wear gloves when operating the chainsaw and when handling

the saw chain.

Wear head protection Wear head protection when operating the chainsaw.

Wear long pants Wear long pants when operating the chainsaw.

Wear foot protection

Wear appropriate closed-toe work boots when operating the

chainsaw.

XX

Sound power, Lwa Sound power level.

Beware of kickback

Danger: Kickback can cause severe injuries.

Bar nose contact Avoid bar nose contact.

Chainsaw kickback

angle

Designed for use with low kickback saw chain.

Two-handed hold Hold saw with both hands.

One-handed hold Do not hold the saw with one hand.

Do not use a ladder Never stand on a ladder when using the chainsaw.

Do not dispose Do not throw in household waste. Take to an authorised recycler.

Do not expose to rain Do not operate the chainsaw in wet conditions.

Damaged cable

Inspect the 6 meter power cord regularly for damage. Remove

the plug from the mains immediately if the cable is damaged or

cut.

Cutting tool

Cutting tool. Do not touch the chain without first deactivating the

chainsaw by unplugging it.

Trip hazard Know the location of the 6 meter cord at all times.

Unplug before

maintenance

Unplug before performing any maintenance.

Page 11

11

Chainsaw Model CS1500

Chainsaw Names and Terms

Chainsaw Names and Terms

Alignment flange: The protrusion on the bar pad

that fits into the bar slot.

Automatic oiler: The system that automatically

lubricates the guide bar and saw chain.

Bar pad: The mounting pad on the powerhead that

helps ensure proper alignment of the guide bar.

Bar slot: The cut-out portion of the guide bar that

fits on to the alignment flange and mounting stud.

Bystander safety zone: A 6 m (20 ft.) circle

around the operator that must remain free from

bystanders, children and pets.

Chain brake: A device for stopping or locking the

saw chain, activated manually or non-manually

when kickback occurs.

Chain catcher: A device for retaining the saw

chain if it breaks or derails.

Chain gauge: The thickness of the saw chain drive

link, where it fits into the bar groove, indicated by

the part number stamped on the drive links.

Chain pitch: The distance between any three

consecutive rivets on the saw chain divided by two,

indicated by the part number stamped on the drive

links.

Chainsaw powerhead: A chainsaw without the

saw chain or guide bar.

Chain tensioning gear: A gear mounted on the

guide bar that adjusts saw chain tension when

rotated.

Chain tensioning ring: The ring around the

side cover release knob that when turned, adjusts

the saw chain tension.

Drive link: The fin-shaped link of the saw chain

that fits into the groove on the guide bar.

Drive sprocket: The toothed part that drives the

saw chain.

Effective cutting length: The approximate

distance from the root of the spiked bumper to the

outside edge of the cutting link with the tensioner

set to the middle position.

Felling back cut: The final cut in a tree felling

operation made on the opposite side of the tree

from the notching undercut.

Front handle: The support handle located at or

toward the front of the chainsaw intended to be

gripped by the left hand.

Front hand guard: A structural barrier between

the front handle of a chainsaw and the guide bar,

which also serves as an activating mechanism for

the chain brake.

Guide bar: A railed structure that supports and

guides the saw chain. Sometimes simply called

the “bar”.

Guide bar cover: The plastic cover that protects

the guide bar and saw chain when the chainsaw is

not in use.

Kickback: The rapid backward and/or upward

motion of the guide bar, occurring when the saw

chain near the top area of the nose of the guide bar

contacts any object (such as a log or branch),

or when the wood closes in and pinches the

saw chain in the cut.

Low-kickback chain: A chain that complies with

the low kickback performance requirements of

ANSI B175.1 and CSA Z62.3.

Motor housing: The plastic cover of the chainsaw

powerhead.

Mounting stud: The threaded protrusion on the

alignment flange that extends through the bar slot.

Notching undercut: A notch cut in a tree to direct

the tree’s fall.

Rear handle: The support handle located at or

toward the rear of the saw intended to be gripped

by the right hand.

Rear hand guard: A structural barrier at the

bottom right side of the rear handle to protect

the operator in case of rupture or derailing of the

saw chain.

Reduced kickback guide bar: A guide bar with a

maximum nose radius as specified in ANSI B175.1

and CSA Z62.3 and which has been demonstrated

to reduce kickback significantly.

Saw chain: A loop of chain having cutting teeth,

that cuts the wood, that is driven by the powerhead

and is supported by the guide bar. Sometimes

simply called the “chain”.

Side cover: The plastic cover on the powerhead

that covers the drive sprocket and chain tensioning

gear which is removed and installed with the side

cover release knob.

Spiked bumper: A device fitted to the front of the

saw acting as a pivot point when in contact with a

tree or log to make cutting easier. Also known as

“bucking spikes”.

Strain relief bracket: The 6 meter cord can be

looped to the hook on the rear handle to keep it

out of the way and assist in ease of operation.

Trigger lock-out: A movable stop that prevents

the unintentional operation of the trigger switch

until manually actuated.

Trigger switch: A device that turns the chainsaw

on and off.

Wear parts: Parts such as the saw chain and

guide bar that can wear during use and can be

replaced by the user.

Page 12

12

Chainsaw Model CS1500

Product Identification

Product Identification

Know the Chainsaw

NOTE: See “Preparing for Use” for a list of included items.

OIL RESERVOIR CAP

FRONT HANDLE

SPIKED BUMPER

CHAIN CATCHER

REAR HANDLE

REAR HAND GUARD

TRIGGER SWITCH

TRIGGER LOCK-OUT

OIL INSPECTION WINDOW

POWERHEAD

POWER CORD

STRAIN RELIEF BRACKET

GUIDE BAR COVER

SAW CHAIN

GUIDE BAR

CHAIN TENSIONING GEAR

SIDE COVER

RELEASE KNOB

CHAIN TENSIONING RING

SIDE COVER

MOUNTING STUD

DRIVE SPROCKET

SHARPENING STONE

POWERSHARP® LEVER

PRODUCT NAME PLATE FRONT HAND GUARD

Page 13

13

Chainsaw Model CS1500

Preparing for Use

Preparing for Use

DANGER: To avoid serious personal

injury, do not operate the chainsaw

without the guide bar, saw chain and side

cover properly assembled.

WARNING: Do not attempt to operate

the chainsaw if any part is damaged or

missing.

WARNING: An electric power tool that

is plugged in can start accidentally. Unplug

the chainsaw before preparing for use or

performing maintenance.

What’s in the box?

These items ship with the chainsaw:

• Chainsaw powerhead with saw chain and

guide bar attached

• Guide bar cover

• Bar and chain oil

After removing the chainsaw from the box,

inspect it carefully to ensure no damage has

occurred during shipping, and that no parts are

missing. If any parts are damaged or missing,

do not use the chainsaw. Contact Oregon® to

obtain replacement parts.

Checking the Front Hand

Guard Position

After unpacking the chainsaw, check the

position of the front hand guard. The chainsaw

will not run with the chain brake engaged. Pull

the front hand guard back towards the front

handle before operation (Fig. ).

FRONT HAND GUARD IN

OPERATING POSITION

FRONT HAND GUARD

IN BRAKE POSITION

FIG. 5

Page 14

14

Chainsaw Model CS1500

Preparing for Use

Filling the Bar and

Chain Oil Reservoir

IMPORTANT: Bar and chain oil prevents

premature wear. Never operate the

chainsaw if oil is not visible in the

inspection window. Check oil level

frequently and fill as needed.

Bar and chain oil is required to properly

lubricate the guide bar and saw chain. The

chainsaw is equipped with an automatic oiler

that deposits oil on the bar and chain when

running, keeping them properly lubricated. Use

Oregon bar and chain oil for best results. It is

specially designed to provide low friction and

faster cuts. NEVER use oil or other lubricants

not specifically designed for use on the bar and

chain. This can lead to a clogged oil system

which may cause premature wear of the bar

and chain.

Place the chainsaw on a firm, flat surface so

that the oil cap is on top (Fig. ).

• Clean any debris from the cap area.

• Remove the cap.

• Carefully pour the bar and chain oil into the

reservoir.

• Replace the cap and make sure oil is visible in

the reservoir.

PRIMING THE OILER

WARNING: To reduce the risk of injury,

never run the chainsaw without the side

cover.

CAUTION: Keep hands, clothing, and

hair away from the drive sprocket when

priming the oiler.

If this is the first time filling the bar and chain

oil reservoir, or if the chainsaw has been stored

for a long period of time without use, prime the

oiler.

Wear Gloves

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the guide bar and saw chain.

• Plug in the chainsaw.

• Install the side cover, then lightly tighten the

side cover release knob.

• Run the chainsaw for about two minutes.

• Unplug the chainsaw, remove the side cover

and check for oil on the bar pad (Fig ).

• If no oil is present on the bar pad, replace the

side cover and run for another seconds.

FIG. 6

FIG. 7

Page 15

15

Chainsaw Model CS1500

Preparing for Use

• When oil begins to seep from the hole, unplug

the chainsaw and replace the bar and chain as

described in “Maintaining the Guide Bar”.

If oil is not visible in the reservoir, additional bar

and chain oil is necessary.

Tensioning the Saw Chain

WARNING: An electric power tool that

is plugged in can start accidentally. Unplug

the chainsaw before preparing for use or

performing maintenance.

WARNING: If the chain is still loose

when the saw is at maximum tension,

replace the chain.

IMPORTANT: Only tension the saw chain

when the chain is cool. A hot chain may

contract and damage the guide bar or

chain as it cools.

Wear Gloves

• Unplug the chainsaw before tensioning.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Hold up the nose of the guide bar (Fig. ) and

turn the chain tensioning ring clockwise.

• Tighten the chain tensioning ring until the

lowest cutters underneath the bar solidly

contact the bar (Fig. ).

• Saw chain tension is correct when, with some

effort, a gloved hand can pull the chain

smoothly around the bar. The chain should

touch the underside of the bar rail (Fig. ).

• Tighten the side cover release knob.

• After a short period of use, allow the chain

to cool, unplug the chainsaw and check the

tension again. Watch tension carefully for

the first half-hour of use and periodically

throughout the life of the chain readjusting as

required when the chain and bar are cool to

the touch. Never tension chain when it is hot.

Chain will stretch as a result of normal use,

however, insufficient oil, aggressive use or

failure to perform recommended maintenance

can lead to premature stretching.

FIG. 8

FIG. 9

INCORRECT

CORRECT

FIG. 10

Page 16

16

Chainsaw Model CS1500

Operating the Chainsaw

Operating the Chainsaw

General Operation

DANGER: To avoid serious personal

injury, do not overreach and do not stand

on a ladder, stepstool or any raised

position that is not fully secured. Never cut

above shoulder height.

WARNING: To reduce the risk of injury,

always wear proper boots, gloves, head,

ear and eye protection.

GRIP

Always grip the tool with both hands. Grasp

the front handle with the left hand and the

rear handle with the right (Fig. ). Wrap the

fingers over the top of the handle with the

thumb below the handle.

FOOTING

Stand with both feet on solid ground with

weight evenly spread between them (Fig. ).

FIG. 11

GRIP WITH THUMB

BELOW HANDLE

FIG. 12

Page 17

17

Chainsaw Model CS1500

Operating the Chainsaw

STOPPING THE CHAINSAW

Release the trigger switch to stop the

chainsaw.

STARTING THE CHAINSAW

WARNING: To reduce the risk of injury,

never defeat the interlock by taping, wiring

or tying down the trigger lock-out.

Make sure the chain brake is not engaged.

Grasp the front and rear handles firmly. Press

and hold the trigger lock-out with the thumb

(). To start the saw, squeeze the trigger switch

() (Fig. ). There is no need to continue to

press the trigger lock-out. It will remain

disengaged until the trigger is released.

TESTING THE CHAIN BRAKE

Make sure the chain brake is working before

using the chainsaw. To check brake operation:

• Place the saw on a firm, flat surface.

• Start the saw briefly.

• Keep the left hand on the front handle and roll

the left wrist to move the front hand guard

forward to manually activate the chain brake

(Fig. ).

• Release the trigger switch.

A properly functioning chain brake stops the

motor and saw chain immediately. If the motor

and saw chain do not stop immediately, have

the chain brake checked at an approved service

location.

• Return the front hand guard to operating

position.

FIG. 13

(1) TRIGGER LOCK-OUT

(2) TRIGGER

SWITCH

FIG. 14

Page 18

18

Chainsaw Model CS1500

Operating the Chainsaw

6 Meter Power Cord Use and Care

The CS comes with an attached meter

power cord. Prior to every use, make sure the

cord insulation is free of cracks and the plug is

undamaged.

Only use extension cords as approved for safe

use in your region and for this application. If

use of an extension cord is acceptable in your

region, please use the selection criteria shown

below in “Selecting an Extension Cord.”

SELECTING AN EXTENSION CORD

Select an extension cord that is:

• Specifically labelled for outdoor use

• Of a wire size (AWG) heavy enough to carry

the current the full length of the cable

according to the table below

Select the gauge of extension cord based

on the desired length and the electrical

specifications found on the product label.

These are the recommended gauges based on

the length of cord.

CORD LENGTH (M) MINIMUM WIRE SIZE

0–15 14 AWG (1.5 mm2)

16–30 12 AWG (3.0 mm2)

Make sure the insulation is free of cracks and

that the plugs on both ends are undamaged.

USING THE STRAIN RELIEF BRACKET

It is important to use the strain relief bracket as

it saves wear on the power cord.

To use the strain relief bracket, bend the

meter cord into a U-shape and put it through

the hole in the rear handle. Slide the loop of

cord over the hook and tug lightly until snug

(Fig. ).

Cutting

WARNING: To reduce the risk of injury,

wear proper boots, gloves, head, ear and

eye protection.

WARNING: To reduce the risk of

electric shock, make sure the 6 meter cord

insulation is intact and that the

6 meter cord is in a dry location where

there is no danger of it being cut or tripped

over.

WARNING: To reduce the risk of injury,

always be sure of footing and hold the

chainsaw firmly with both hands while the

motor is running.

WARNING: To reduce the risk of injury,

plan ahead and plan multiple escape paths

before beginning work.

CAUTION: Establish a bystander safety

zone of 6 m (20 ft) prior to operation of

this equipment. Bystander safety zone is a

minimum 6 m (20 ft) circle around the

operator that must remain free from

bystanders, children and pets (Fig. 16).

Felling operations require a larger safety

zone according to the size of the tree, see

“Felling a Tree” section.

IMPORTANT: Practice cutting logs on

a sawhorse or cradle until you become

comfortable operating the saw.

FIG. 15

6 m (20 ft)

FIG. 16

Page 19

19

Chainsaw Model CS1500

Operating the Chainsaw

To get the best performance and operate the

saw safely, follow these instructions:

• Observe all applicable national and municipal

rules and regulations for cutting.

• Take frequent breaks to reduce the risk of

injury.

• Before beginning to cut, make sure the saw

chain is properly tensioned and the chain is

sharp.

Saw chains are made to cut wood only. Do not

use the chainsaw to cut any other materials,

and do not allow the chain to come into contact

with dirt, stones, nails, staples or wire. These

materials are extremely abrasive and will wear

away protective plating from the chain in a very

short time.

Sharpen or replace the saw chain if any of these

conditions occur:

• The pressure required to make cuts increases

noticeably.

• Wood chips coming off of the chain are very

fine or dust-like.

Do not work with a dull chain as it will increase

the effort required to cut, cause jagged cuts,

increase wear on the chainsaw and increase the

risk of kickback. Never force a dull chain to cut.

• Assume the proper cutting grip and stance

in front of the wood with the saw turned off.

Press the trigger lock-out and squeeze the

trigger switch. Let the chain reach full speed

before beginning the cut.

• Begin cutting by lightly pressing the guide bar

against the wood. Use only light pressure and

let the saw do the work.

• Maintain a steady speed throughout the cut

releasing pressure just before the end of the

cut.

• Know the location of the meter cord at all

times to avoid trip hazards and avoid cutting

the meter cord.

• Know the location of the tip of the bar at all

times and avoid contact with other objects.

• If the saw stops suddenly when cutting, remove

the saw from the cut, then resume cutting using

lighter pressure on the work piece.

PRUNING

CAUTION: Falling limbs may bounce or

“spring back” after they hit the ground so

it is essential to keep the ground clear to

provide multiple retreat paths. Clear the

work area and wear head protection.

Pruning is removing dead or overgrown

branches to maintain plant health.

• Plan retreat paths before beginning to cut,

and make sure there are no obstructions.

Always know how to get out of the way of

falling branches.

• Make sure bystanders or helpers are a safe

distance from falling branches. Bystanders or

helpers should not stand directly in front of or

behind the operator. See Fig. .

• Maintain solid footing and hold the chainsaw

firmly with both hands. Do not overreach.

Never climb a tree or ladder to reach high

limbs.

• Secure any branches that might be hazardous.

• Use proper auxiliary equipment.

• Prune lower limbs before pruning higher ones.

• Allow the saw chain to achieve full speed

before cutting.

• Apply light pressure to the branch.

• For long limbs (Fig. ), cut the end of the limb

first () to relieve pressure from the limb, then

prune closer to the trunk ().

FIG. 17

(1)

(2)

Page 20

20

Chainsaw Model CS1500

Operating the Chainsaw

• Thick limbs (greater than cm ( inch) in

diameter) can splinter or pinch the chain when

making a single cut from the top. To avoid

pinching or splintering, first make one shallow

relief cut on the bottom surface of the limb (),

then cut the limb all of the way through from

the top of the limb () to match the bottom

cut (Fig. ).

• After most of the limb has been removed,

make one smooth cut near the trunk

(Fig. ).

FELLING A TREE

CAUTION: A tree is likely to roll or slide

downhill after it is felled. Plan and clear a

retreat path before cuts are started. The

retreat path should extend back and

diagonally to the rear of the expected line of

fall (Fig. 20).

Felling is cutting down a tree.

• Before felling is started, consider the natural

lean of the tree, the location of larger

branches and the wind direction to judge

which way the tree will fall.

• Remove dirt, stones, loose bark, nails, staples

and wire from the tree where felling cuts are

to be made.

• When bucking and felling operations are being

performed by two or more persons at the

same time, separate the felling operation from

the bucking operation by a distance of at least

twice the height of the tree being felled.

• Trees should not be felled in a manner that

would endanger any person, strike any utility

line or cause any property damage. If the tree

contacts any utility line, immediately leave

the area and notify the utility company.

• Use the metal spikes on the front of the saw

to support the saw on the wood. Set metal

spiked bumper into the wood and use as a

leverage point to increase stability when

cutting large diameter wood.

(1)

(2)

FIG. 18

FIG. 19

RETREAT PATH OPTIONS

DIRECTION

OF FALL

RETREAT

RETREAT

FIG. 20

45°

Page 21

21

Chainsaw Model CS1500

Operating the Chainsaw

Notching Undercut

• First, make the notch / the diameter of the

tree perpendicular to the direction of fall.

Make the lower horizontal notching undercut

first (). This will help to avoid pinching of

either the saw chain or the guide bar when the

second cut () is being made (Fig. ).

Felling Back Cut

• Second, make the felling back cut at least

mm ( in.) higher than the horizontal

notching undercut (Fig. ). Keep the felling

back cut parallel to the horizontal notching

undercut.

• Make the felling back cut so enough wood is

left to act as a hinge. The hinge wood keeps

the tree from twisting and falling in the wrong

direction. Do not cut through the hinge.

• As the felling cut gets close to the hinge, the

tree should begin to fall.

• If there is any chance that the tree may not

fall in the desired direction or it may rock back

and bind the saw chain, stop cutting before

the felling back cut is complete and use

wedges of wood, plastic or aluminium to open

the cut and drop the tree along the desired

line of fall.

• When the tree begins to fall, remove the

chainsaw from the cut, stop the motor, put

the chainsaw down, then use the retreat path

planned.

• Be alert for overhead limbs falling and watch

footing.

Limbing a Tree

CAUTION: Limbs under tension can

“spring back” and contact the operator or

throw the chainsaw out of control resulting

in personal injury. Always be alert for wood

under tension which may strike the operator

or chainsaw when cut.

Limbing is removing the branches from a fallen

tree.

• When limbing, leave larger lower limbs to

support the log off the ground.

• Remove the small limbs in one cut.

• Branches under tension should be cut from

the bottom up to avoid binding the chainsaw

(Fig. ).

NOTCHING UNDERCUT

DIRECTION

OF FALL

NOTCH

(1)

(2)

FIG. 21

FELLING BACK CUT

FELLING

BACK CUT

HINGE

DIRECTION

OF FALL

NOTCH

50 MM

(2 IN.)

50 MM

(2 IN.)

FIG. 22

TREE LIMBING

LIMB CUT

KEEP WORK OFF GROUND

LEAVE SUPPORT LIMBS UNTIL LOG IS CUT

FIG. 23

Page 22

22

Chainsaw Model CS1500

Operating the Chainsaw

BUCKING A LOG

CAUTION: Bucking logs under tension

increases the chance of kickback. Use one

of the methods below to support the log

when bucking.

Bucking is cutting a log into lengths. It is

important to make sure footing is firm and

weight is evenly distributed on both feet.

When possible, the log should be raised and

supported by the use of limbs, logs or chocks.

• When the log is supported along its entire

length, cut from the top (overbuck) (Fig. ).

• When the log is supported on one end, cut

/ the diameter from the underside

(underbuck), then make the finished cut by

overbucking to meet the first cut (Fig. ).

• When the log is supported on both ends, cut

/ of that diameter from the top overbuck,

then make the finished cut by underbucking

the lower / to meet the first cut (Fig. ).

• When bucking on a slope, always stand on the

uphill side of the log (Fig. ).

• To maintain complete control when cutting

through, release the cutting pressure near the

end of the cut without relaxing the grip on the

chainsaw handles.

• Don’t let the chain contact the ground.

• After completing the cut, wait for the saw

chain to stop before you move the chain saw.

• Always stop the motor before moving from

tree to tree.

LOG IS SUPPORTED

ALONG ITS ENTIRE LENGTH

CUT FROM TOP (OVERBUCK)

AVOID CUTTING EARTH

FIG. 24

LOG IS SUPPORTED ONE END

1ST CUT UNDERBUCK (1/3 DIAMETER)

TO AVOID SPLINTERING

2ND CUT OVERBUCK (2/3 DIAMETER)

TO MEET 1ST CUT (TO AVOID PINCHING)

FIG. 25

BUCKING A LOG

1ST CUT OVERBUCK (1/3 DIAMETER)

TO AVOID SPLINTERING

2ND CUT UNDERBUCK (2/3 DIAMETER)

TO MEET 1ST CUT (TO AVOID PINCHING)

FIG. 26

BUCKING ON A SLOPE

STAND ON UPHILL SIDE

WHEN CUTTING BECAUSE

LOG MAY ROLL

FIG. 27

Page 23

23

Chainsaw Model CS1500

Operating the Chainsaw

Sharpening with PowerSharp®

WARNING: PowerSharp should not be

used in the presence of exposed, extremely

flammable materials such as gasoline and

acetylene.

CAUTION: Sharpening with the

PowerSharp system produces low energy

sparks.

CAUTION: the PowerSharp integrated

sharpening system is for use only with

PowerSharp chain. Never attempt to

sharpen other chain with the integrated

sharpener. Damage to the chain and

sharpener will occur.

INTRODUCTION TO POWERSHARP

This chainsaw is equipped with the PowerSharp

integrated sharpening system, a fast and easy

way to sharpen chain on the saw. It is time to

sharpen the saw chain when cuts take longer

or the wood chips become smaller, turning the

saw to dust in extreme cases.

SHARPENING THE CHAIN

IMPORTANT: PowerSharp chain uses

unique top-sharpening cutters and

can only be sharpened with a genuine

PowerSharp sharpener.

• With the saw at full speed, lightly lift the

PowerSharp lever for – seconds (Fig. ).

Sparks will be visible when the cutters are in

contact with the sharpening stone.

• Make a test cut to determine if the chain has

been sufficiently sharpened. If not, repeat

the sharpening procedure until the chain is

sufficiently sharp.

IMPORTANT: Do not apply too much force

when sharpening. Excessive force can

reduce the performance of the sharpening

stone.

IMPORTANT: It is normal to see a small

amount of sparks and smoke during

sharpening as the cutters contact the

stone and friction heats the chain.

WHEN TO REPLACE THE

SHARPENING STONE

The sharpening stone is designed to wear at

the same rate as the chain. Always replace

the stone when replacing the chain even if it

appears to have more life. See “Replacing a

Worn Saw Chain and Sharpening Stone” in this

manual.

FIG. 28

Page 24

24

Chainsaw Model CS1500

Maintenance and Cleaning

Maintenance and Cleaning

WARNING: Failure to identify and

replace damaged or worn parts can

cause serious personal injury. Inspect the

chainsaw regularly. Regular inspection

is the first step to proper maintenance.

Follow the guidelines below to maximise

safety and satisfaction. Have any damaged

or excessively worn parts replaced

immediately.

WARNING: An electric power tool that

is plugged in can start accidentally. Unplug

the chainsaw before preparing for use or

performing maintenance.

CAUTION: When cleaning the chain saw,

do not immerse in water or other liquids.

Inspection

Before each use and if the chainsaw has been

dropped, inspect these parts:

• Meter Cord: Ensure the plug is in good

condition and not bent or corroded, and that

the insulation is intact. If the meter cord is

damaged, do not use. Contact an authorised

service dealer.

• Handles: Front and rear handles should not

have cracks or other damage. They should be

clean and dry.

• Front Hand Guard: The front hand guard

should be free of damage and able to move

easily back and forth. When moved, the front

hand guard should activate the chain brake.

• Guide Bar: The bar should be straight and free

of chips, cracks or excessive wear.

• Saw Chain: The chain should be properly

tensioned and sharp and all components free

of cracks, chips, broken teeth or excessive

wear. See “Tensioning the Saw Chain” and

“Sharpening with PowerSharp®”.

• Side Cover: The side cover should be free of

cracks or other damage. It should fit tightly to

the saw body with no warping. Make sure the

chain catcher is free of cracks.

• Chain Brake: Test the chain brake to make

sure it is functioning properly. See “Testing the

Chain Brake” under “General Operation.”

• Oil Level: Make sure the oil reservoir is full

before use.

• Motor Housing: Check for cracks in the cover

and debris in the air intake vents.

Periodically inspect these parts:

• Drive Sprocket: Look for deep grooves, broken

teeth or burrs.

• Chain Tensioning Gear: Inspect the gear for

cracks, chips, loose screw, warping or other

damage.

• Bar-Mounting Area Underneath Side Cover:

Make sure the bar mounting stud is not bent,

stripped or cross-threaded and that the bar

pad and alignment flange are free of debris

and intact.

Cleaning

CAUTION: When cleaning the chainsaw

powerhead, do not immerse in water or

other liquids.

• Wear gloves.

• Unplug the chainsaw.

• Remove wood chips and other debris from the

motor housing and the vents.

• Always clean out wood chips, saw dust and

dirt from the bar groove when replacing the

chain.

• Make sure the meter cord and plug are dry

before connecting to an outlet.

Page 25

25

Chainsaw Model CS1500

Maintenance and Cleaning

Maintaining the Guide Bar

CAUTION: The guide bar can be hot

after cutting. Wear gloves to avoid burns.

To even bar wear and maximise bar life, flip the

bar occasionally.

• Wear gloves.

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the bar and chain and inspect for

damage and wear.

• Remove the screw from the back side of the

chain tensioning gear and remove the chain

tensioning gear from the guide bar (Fig. ).

• Flip the bar (Fig. ).

• There is a rubber washer that is important to

the function of the saw. The rubber washer

must be in place around the pin on the

tensioner before the tensioner is screwed onto

the bar (Fig. ).

• Place the chain tensioning gear on the side

of the guide bar facing you such that the

rectangular piece does not protrude past the

edges of the guide bar and replace the screw.

• Place the guide bar on the bar pad by

sliding the bar slot over the alignment

flange (Fig. ).

• Replace the saw chain as described in

“Replacing a Worn Saw Chain and Sharpening

Stone”.

• Tension the chain as described in “Tensioning

the Saw Chain” in the “Preparing for Use”

section of the manual.

FIG. 29

FIG. 30

FIG. 31

FIG. 32

BAR PAD

ALIGNMENT FLANGE

MOUNTING STUD

Page 26

26

Chainsaw Model CS1500

Maintenance and Cleaning

Replacing a Worn Saw Chain

and Sharpening Stone

CAUTION: Replace PowerSharp®

saw chain and the sharpening stone at the

same time. Failure to do so could result in

decreased performance or damage to the

chain and/or sharpening stone.

CAUTION: The PowerSharp integrated

sharpening system is for use only with

PowerSharp chain. Remove the sharpening

stone when using saw chain other than

PowerSharp. Failure to do so may result

in damage to the saw chain, sharpening

system and/or chainsaw.

When the saw chain becomes cracked or has

broken teeth, is stretched to the point that

it cannot be kept at proper tension or simply

cannot be sharpened, it must be replaced.

• Wear gloves.

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the saw chain.

• Remove the two screws holding the

sharpening stone (Fig. ).

• Remove the stone.

• Make sure the PowerSharp lever and

surrounding area are free of debris.

• Place the new stone on the lever and replace

the screws.

• Loop the new saw chain onto the drive

sprocket so that the cutting edges of the

teeth along the top of the bar face away from

the powerhead (Fig. ).

• Feed the chain into the groove of the bar and

slide the bar away from the motor to remove

slack from the chain (Fig. ).

FIG. 33

FIG. 34

FIG. 35

Page 27

27

Chainsaw Model CS1500

Maintenance and Cleaning

• Install the side cover, making sure the chain

catcher is properly seated in its hole, then

lightly tighten the side cover release knob

(Fig. ).

• Tension the chain as described in “Tensioning

the Saw Chain” in the “Preparing for Use”

section of the manual.

IMPORTANT: The saw chain must be

properly tensioned before using. See

“tensioning the saw chain” in the

“preparing for use” section of the manual.

Replacing a Worn Guide Bar

WARNING: The edges of a worn guide

bar, particularly the edges of the groove

where the chain touches the bar, can be

extremely sharp. Use appropriate hand

protection.

When the guide bar becomes cracked or has

excessive wear around the edges, particularly

in the groove where the saw chain touches

the bar, it must be replaced. Also, if the nose

sprocket is worn, has teeth missing or does not

turn smoothly, the bar must be replaced.

• Wear gloves.

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the bar and chain.

• Remove and the screw from the back side

of the chain tensioning gear and remove the

chain tensioning gear from the guide bar as

described in “Maintaining the Guide Bar”.

• Place the chain tensioning gear on the new

guide bar and replace the screw.

• Replace the guide bar as described in

“Maintaining the Guide Bar”.

• Replace the chain as described in “Replacing a

Worn Saw Chain and Sharpening Stone”.

• Tension the chain as described in “Tensioning

the Saw Chain”.

Replacing a Worn Chain

Tensioning Gear

Replace the chain tensioning gear if it will not

hold the bar and chain at proper tension or if it

is otherwise damaged.

• Wear gloves.

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the bar and chain.

• Remove the screw from the back side of

the chain tensioning gear and remove the

chain tensioning gear from the guide bar as

described in “Maintaining the Guide Bar”.

• Place the new chain tensioning gear on the

side of the guide bar facing you, and replace

the screw.

• Place the guide bar on the bar pad by sliding

the bar slot over the alignment flange as

described in “Maintaining the Guide Bar”.

• Replace the saw chain as described in

“Replacing a Worn Saw Chain and Sharpening

Stone”.

• Tension the chain as described in “Tensioning

the Saw Chain” in the “Preparing for Use”

section of the manual.

FIG. 36

Page 28

28

Chainsaw Model CS1500

Maintenance and Cleaning

Replacing the Drive Sprocket

Replace the drive sprocket after every two saw

chain replacements or when the sprocket is

damaged.

• Wear gloves.

• Unplug the chainsaw.

• Loosen the side cover release knob slightly,

but do not remove the side cover.

• Loosen the chain tensioning ring (turn it

counter clockwise) as far as it will go.

• Loosen the side cover release knob and

remove the side cover.

• Remove the bar and chain.

• Use a small flat screwdriver to pry open and

remove the e-clip, then remove the drive

sprocket and spring (Fig. ).

• Insert the new spring and drive sprocket, and

install the new e-clip (Fig. ).

• Replace the bar and chain as described in

“Replacing a Worn Saw Chain and Sharpening

Stone”.

• Tension the chain as described in “Tensioning

the Saw Chain” in the “Preparing for Use”

section of the manual.

Tensioning the Saw Chain

IMPORTANT: Only tension the saw chain

when the chain is cool. A hot chain may

contract and damage the guide bar or

chain as it cools.

If the chain does not touch the underside of the

bar when the chainsaw is off and cool, it should

be tensioned.

Tension the chain as described in “Tensioning

the Saw Chain” in the “Preparing for Use”

section of the manual.

Additional Maintenance

Information

For further information on maintaining the saw

chain, guide bar and drive sprocket, consult

the Oregon Maintenance and Safety Manual

at http://OregonProducts.com/maintenance/

manual.htm.

FIG. 37

FIG. 38

Page 29

29

Chainsaw Model CS1500

Troubleshooting

Troubleshooting

Use this table to see possible solutions for problems with the chainsaw. If these suggestions do not

solve the problem, see “Warranty and Service”.

SYMPTOM POSSIBLE CAUSE RECOMMENDED ACTIONS

Motor stops while

cutting

Chain pinched in cut

Undercut limb to relieve pressure on limb. See

“Cutting”.

Cord is damaged or

severed

If extension cord is damaged, do not use and replace

it. If chainsaw cord is damaged, do not use and

contact an approved service location.

Chain brake is engaged

Set the front hand guard to the operating position

as described in “Checking the Front Hand Guard

Position”.

Motor does

not run or runs

intermittently

Saw is not plugged in Plug in the saw.

Cord is damaged or

severed

If extension cord is damaged, do not use and replace

it. If chainsaw cord is damaged, do not use and

contact an approved service location.

GFCI outlet is tripped

Unplug extension cord, reset GFCI and plug the

extension cord back in.

Bad electrical outlet Plug extension cord into a different outlet.

Chain brake engaged

Set the front hand guard to the operating position

as described in “Checking the Front Hand Guard

Position”.

Trigger lock-out not

pressed

Press the trigger lock-out before squeezing the

trigger switch. See “General Operation”.

Debris in side cover

Unplug the chainsaw, then remove side cover and

clean out debris.

Motor does not

stop when chain

brake is engaged

Debris preventing full

movement of front

hand guard

Clean debris from external chain brake mechanism.

Possible chain brake

malfunction

WARNING: Operating a chainsaw without a

functioning chain brake could lead to serious

personal injury. Contact an approved service

location before using.

Motor runs, but

saw chain does not

rotate

Chain not engaging

drive sprocket

Reinstall the chain, making sure the drive links on

the chain are fully seated on the drive sprocket. See

“Replacing a Worn Saw Chain and Sharpening Stone”.

Guide bar nose sprocket

is not turning

Replace the guide bar. See “Replacing a Worn Guide

Bar”.

Page 30

30

Chainsaw Model CS1500

Troubleshooting

SYMPTOM POSSIBLE CAUSE RECOMMENDED ACTIONS

Chainsaw does not

cut properly

Insufficient chain tension

Tension the chain. See “Tensioning the Saw Chain” in

the “Preparing for Use” section of the manual.

Dull chain See “Sharpening with PowerSharp®”.

Chain installed

backwards

Install the chain with the teeth facing the correct

direction. See “Replacing a Worn Saw Chain and

Sharpening Stone”.

Worn chain

Replace the chain. See “Replacing a Worn Saw Chain

and Sharpening Stone”.

Dry or excessively

stretched chain

Check the oil level. Refill oil reservoir if necessary. See

“Filling the Bar and Chain Oil Reservoir”.

Chain not in bar groove

Reseat chain onto groove. See “Replacing a Worn

Saw Chain and Sharpening Stone”.

Chain loosening

or coming off of

guide bar

Side cover not

installed correctly

Properly install side cover ensuring the tab at rear of

side cover is tucked into saw body.

Bar and chain

excessively hot and

/ or smoking

Chain is under-lubricated

Check the oil level. Refill oil reservoir if necessary. See

“Filling the Bar and Chain Oil Reservoir”.

Page 31

31

Chainsaw Model CS1500

Specifications and Components

Specifications and Components

WARNING: Using replacement parts other than those specified in this instruction

manual increases the risk of injury. Never use cutting attachments other than those

described in this manual. Serious or even fatal injuries could result if the wrong cutting

attachments are used.

REPLACEMENT COMPONENTS PART NUMBER

Guide bar 180SDEA041

91PS062X saw chain and stone, PowerSharp® 571037

Drive sprocket 570964

Chain tensioning gear 570963

CHAINSAW SPECIFICATIONS

Voltage 230 VAC ~50 Hz

Amperage 10.4 amps

Power 2400 watts

Oil capacity 140 ml (4.7 oz)

Bar and chain oil Oregon® brand

Dry weight assembled 5.7 kg (12.6 lb)

Dry weight without bar and chain 4.8 kg (10.6 lb)

Guaranteed sound power level Lwa (1) (2) 110 dBA (Kwa=2.5 dBA)

Vibration 4.35 m / s2 (k=1.5 m / s2)

Max bar length 450 mm (18 inches)

Effective cutting length 43 cm (17 inches)

Chain pitch 3/8" Low profile™

Chain gauge .050"

Drive sprocket teeth 6

No load chain speed 14.7 m / s (48.1 ft / s)

() According to Noise Directive //EC, amended by //EC

() Measured according to EN -:+A: and EN--:+A:;

Sound Pressure level, LpA, is dB(A) with an uncertainty KpA of .dB(A)

Page 32

32

Chainsaw Model CS1500

Warranty and Service

Warranty and Service

Warranty

Blount, Inc. warrants all registered Oregon®

CS chainsaws for a period of three ()

years. This warranty is valid only for units that

have been used for personal use that have not

been hired or rented, or used for commercial

or industrial use. During the warranty period,

Blount will replace or, at its option, repair for

the original purchaser only, free of charge,

any product or part which is found upon

examination by Blount to be defective in

material and/or workmanship. The purchaser

shall be responsible for all transportation

charges and any cost of removing any part

submitted for replacement under this warranty.

Keep Original Receipt

Please attach original receipt from initial

purchase to this manual and file. For warranty

service, please bring product and receipt to

the dealer where product was purchased. Or

contact Oregon by telephone.

Service and Support Information

Visit us on the web at OregonProducts.com

for service centre information, or contact our

customer service department for assistance,

additional technical advice, repair, or

replacement parts.

For safety, use only genuine factory

replacement parts on the chainsaw. Our service

centre is staffed with trained personnel to

efficiently provide support and assistance

with adjustment, repair, or replacement of all

Oregon products.

Page 33

33

Chainsaw Model CS1500

EC – Declaration of Conformity

EC – Declaration of Conformity

Blount International Inc.

SE International Way

Portland Oregon, USA

Blount International Inc. declares under our sole responsibility that the following products:

Brand: Oregon®

Product Type: Chainsaw

Model: CS

Are compliant with the following applicable European directives and standards:

Machinery Directive //EC; based on EC type examination carried out by:

TÜV Rheinland LGA Products GmbH (NB 0197)

Tillystraße 2 D - 90431 Nürnberg, Germany; 0197

Safety standards: EN 60745-1:2009+A11:2010, EN 60745-2-13:2009+A1:2010

EC type-examination certificate number: BM 50284318

Electromagnetic Compatibility (EMC) //EU

EN 55014-1:2006 +A1 +A2

EN 55014-2:1997 +A1 +A2

EN 61000-3-2:2006 +A1 +A2

EN 61000-3-11:2000

Restriction of Hazardous Substances (RoHS) //EU

Waste Electrical and Electronic Equipment (WEEE) //EU

Noise Directive (ODN) //EC according to ANNEX V

Measured Sound Power = 107 dB(A)

Uncertainty, KWA = 2.5 dB(A)

Guaranteed Sound Power, LWA = 110 dB(A)

Technical documentation file, locaton and contact:

Chris Seward

Director – Product Safety and Compliance

Blount International Inc.

Portland Or. USA

Date / Place:

DEC, Portland OR. USA

Michael Winkler

Blount International-Europe-S.A.

Rue Emile Francqui,

Mont-Saint-Guilbert

Belgium

Page 34

34

Chainsaw Model CS1500

Customer Service

Customer Service

UK 0-800-098-8536 info@blount.be

Imported by

Blount Europe SA

Rue Emile Francqui, 5

B 1435 Mont-Saint-Guibert, Belgium

+32 10 30 11 11

Page 35

35

Chainsaw Model CS1500

NOTES

Page 36

OregonProducts.com

Blount International Inc.

Southeast International Way

Portland, OR - USA

Rev. AC /

Loading...

Loading...