Oregon Scientific Chain Saw Maintenance Manual

Maintenance &

Safety Manual

www.oregonchain.eu

Advanced Cutting Technology

Introduction

Your chainsaw is only as good as your chain, guide bar, and sprocket.

They function as a team while doing the actual work of cutting wood and,

therefore, must be maintained as a team.

A properly maintained chain, bar, and sprocket will provide excellent

cutting performance. An improperly maintained chain will cause

damage to the bar and sprocket, will cut poorly, and will create potential

Introduction

safety hazards.

®

This manual addresses the maintenance of only OREGON

chains, bars, and sprockets. For information on maintenance and

operation of your saw, refer to your saw’s operator’s manual or contact

your local chainsaw dealer.

manufactured

2.

Introduction

CHAINSAW SAFETY

IMPORTANT SAFETY MESSAGE

SAFETY SYMBOL

This safety symbol is used to highlight safety messages. When you see

this symbol, read and follow the safety message to avoid severe personal

injury.

WARNING

All cutting chain can kick back, which can lead to dangerous loss of

control of the chainsaw and result in serious injury to the saw operator or

by standers. Follow all instructions in your chainsaw operator’s manual

and in this booklet for proper use and maintenance of your saw’s cutting

chain, guide bar, and sprocket.

GUARD AGAINST CHAINSAW KICKBACK

• Know your personal level of chainsaw experience.

• Know your cutting chain.

Introduction

If you do not have experience and specialized training for dealing with

chainsaw kickback, then OREGON

®

urges you to use only low-kickback

saw chains.

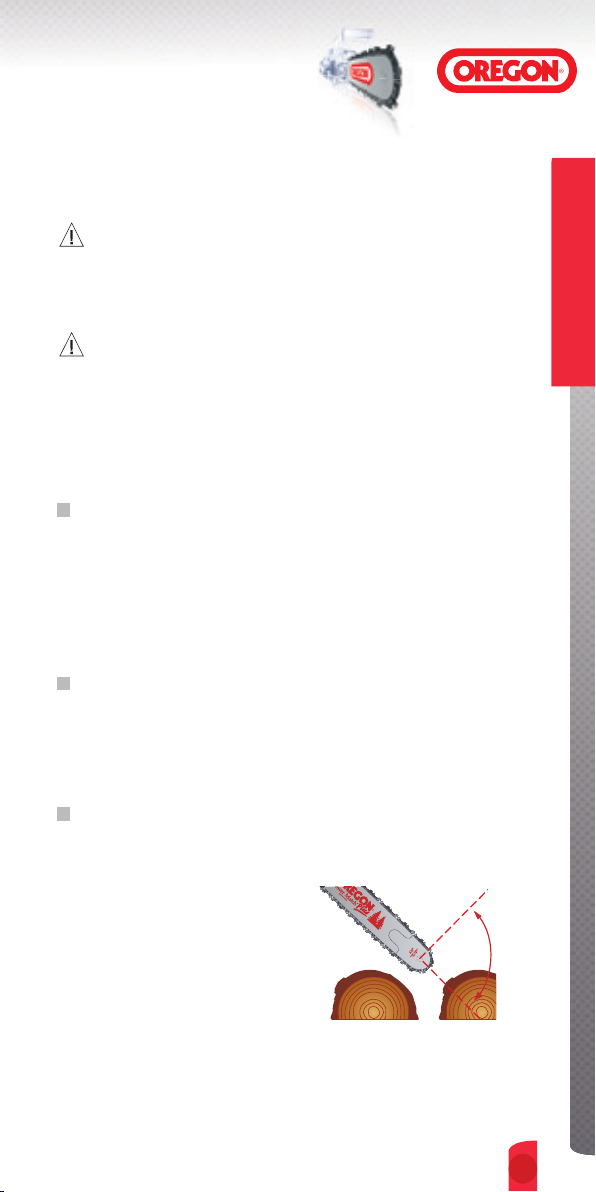

WHAT IS KICKBACK?

Kickback is the violent backward and/or upward motion of the chainsaw

guide bar occurring when the chain near the nose or tip of the guide bar

contacts any object, such as another log or branch, or when the wood

closes in and pinches the saw chain in the cut.

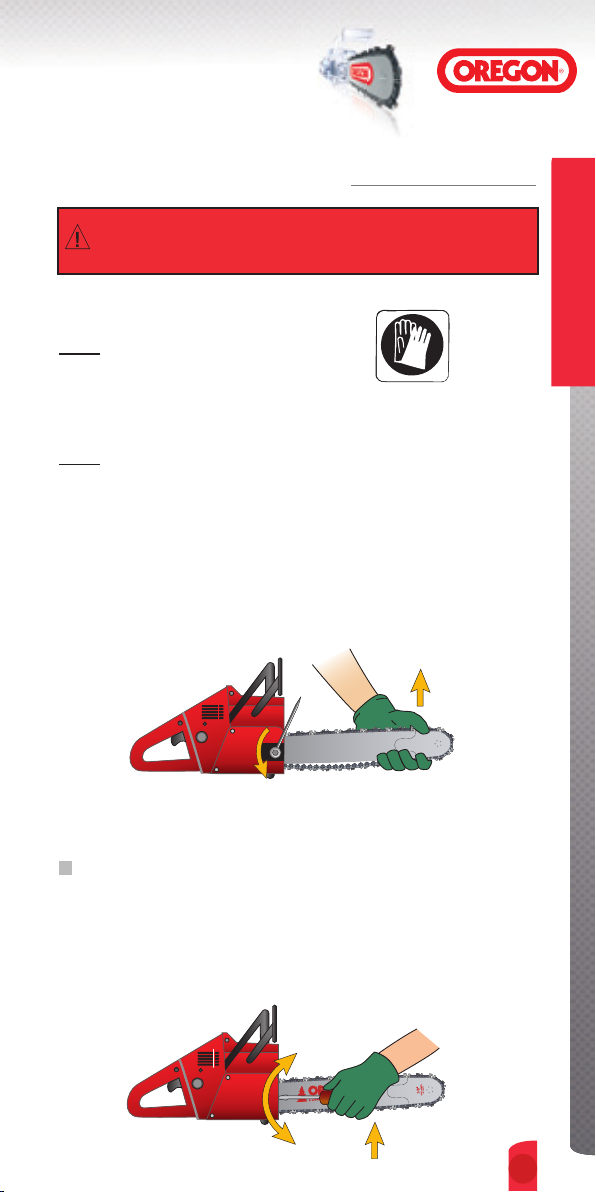

TO HELP AVOID INJURY

Kickback Awareness

➊

Be alert at all times to guard against a possible kickback reaction. Always

be aware of the position of your

bar’s nose.

➋

Different models of cutting

chain are available for most

cutting tasks. Use the

chain, suitable for your

type of cutting, with the

lowest kickback potential.

➌

Narrow-nose bars such as OREGON® Double Guard™ bars are

Potential Kickback Situation

recommended for maximum kickback safety.

3.

Introduction

CHAINSAW SAFETY

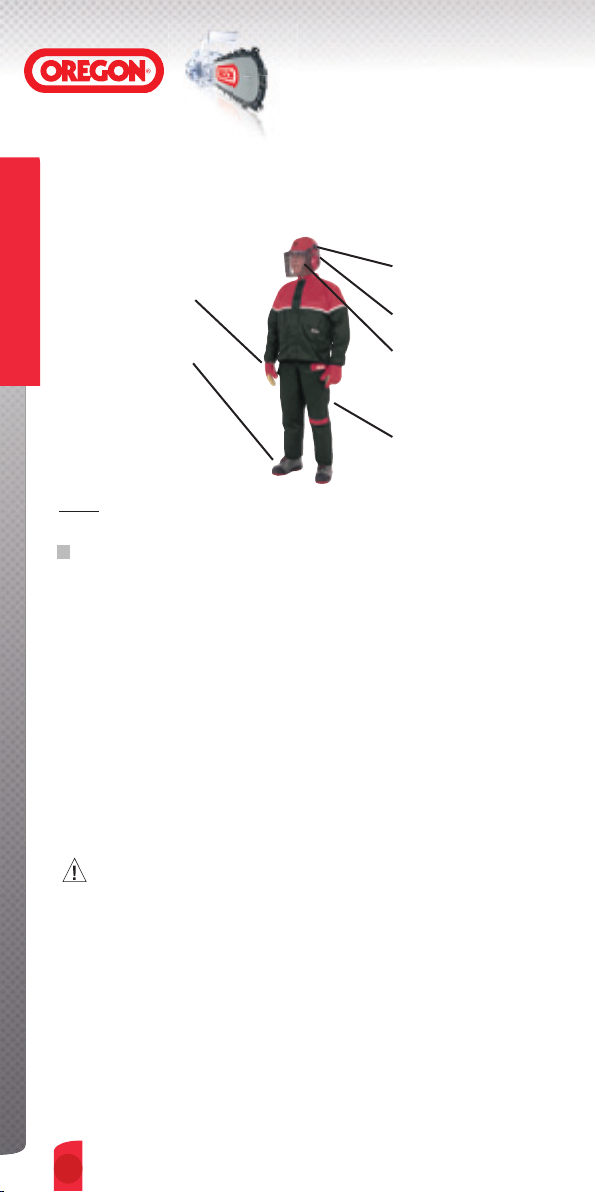

CLOTHING AND PROTECTIVE EQUIPMENT

Wear hard hat to protect

Wear protective gloves to

prevent slippage and to

protect hands.

Introduction

Wear chainsaw protective

boots or safety boots and

gaiters to protect feet.

NOTE: Dress properly - do not wear clothing that is too tight or too loose.

MAKE PROPER WORK PRACTICES A HABIT

• Use only a right-hand grip to hold your saw (right hand on the trigger,

left hand on the front handle).

• Keep your left arm straight for better control.

• Hold saw firmly with both hands. Keep thumb firmly locked around

front handle.

• Stand to the side of the chainsaw, never behind it.

• Run engine at full throttle.

• Use low-kickback saw chain and a reduced-kickback guide bar.

• Keep the chainsaw, cutting chain, guide bar and sprocket properly

maintained.

• Stand with feet well braced and your body balanced.

• Cut only wood with your chainsaw. Do not cut any other material.

head.

Wear ear protection to

protect ears.

Wear safety goggles or

face shield to protect eyes.

Wear protective trousers

or leggings to protect legs

CAUTION

▲

Keep yourself clear of the work. Before cutting :

• Calculate how the object being cut will fall.

• Determine if the saw may be thrown unexpectedly by the movement

of the cut material.

• Position yourself to avoid injury.

▲

Never cut above shoulder level.

▲

Never cut while in a tree, or while on a ladder.

▲

Keep others away from the cutting area.

Do not allow others to hold wood during cutting.

4.

Contents

INTRODUCTION

Introduction .............................

Chainsaw safety ......................

CHAIN

Chain Terms ..........................

Chain Pitch ...........................

Chain Gauge ........................

Parts of a Cutter .....................

Cutter Sequence ....................

Parts of a Saw Chain .............

Maintenance Terms ................

Chain maintenance tools ........

Chain identification chart .....

2

2

2

2

2

3

3

4

5-7

Chain drive-link number

identification .........................

Chain letter identification ........

Four basic rules ..............

How to maintain the chain .....

How to tension chain ......

How to lubricate chain ..........

8

9

10-11

12

13-15

15

How to set depth

gauges ..........................

How to sharpen cutters ....

How to install chain parts

How to break out rivets ...

How to run-in a new chain .....

End-user symbols ...................

Filing specifications ........

Chain troubleshooting .....

16-17

18-19

20-21

22-23

24

25

26-47

48-54

GUIDE BARS

Guide bar terms ...................

55

Guide bar maintenance

tools ....................................

Guide bar maintenance ...

How to replace

Power Match

®

noses .......

55

56-57

58-59

Pro-Lite® noses

sprockets ........................

60-61

Guide bar

troubleshooting ...............

62-64

DRIVE SPROCKETS

Sprocket terms, tools,

and installation .....................

Sprocket maintenance .....

65

66-67

Sprocket

troubleshooting ...............

68-69

USEFUL INFORMATION

Useful information ...........

70-71

Contents

CONTENTS

1.

Saw Chains

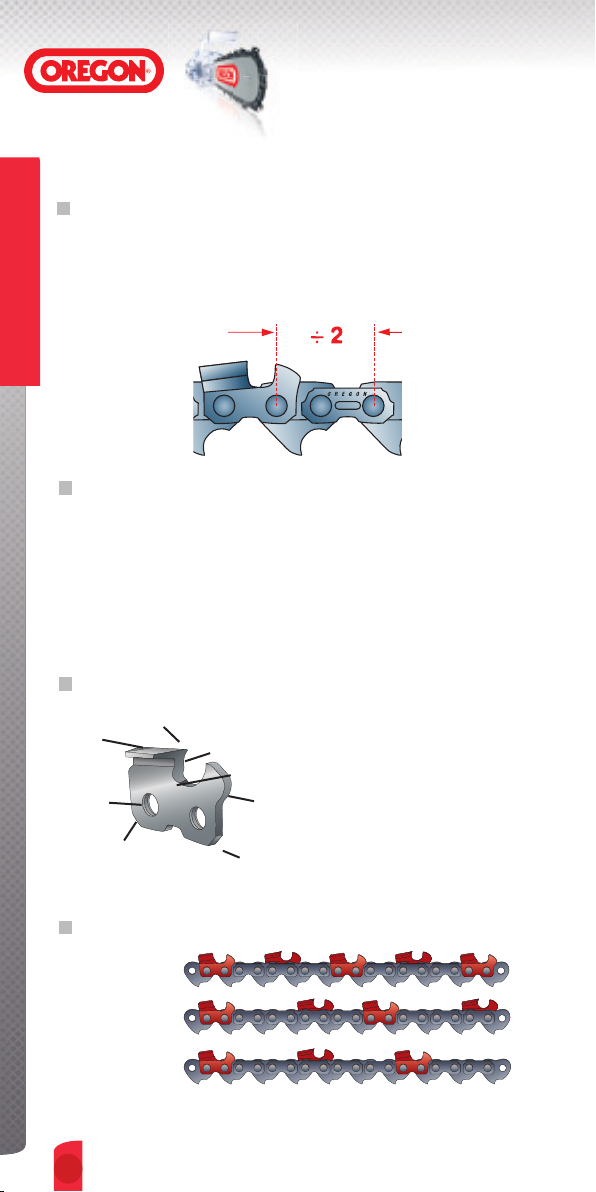

OREGON® CHAIN TERMS

CHAIN PITCH

Chain Pitch is the distance between any three consecutive rivets, divided

by two. OREGON

1/4", .325", 3/8", .404" and 3/4".

Saw Chains

CHAIN GAUGE

Chain gauge is the drive link’s thickness where it fits into the guide-bar

groove. The industry standard for chain gauges are:

.043" (1.1mm), .050" (1.3mm), .058" (1.5mm), .063" (1.6mm)

OREGON

for Harvester applications.

®

chain pitches are:

®

chain gauges of .080" (2mm) and .122" (3.1mm) are used

THE PARTS OF A CUTTER

Top

plate

Rivet

Hole

Cutting corner

Side Plate

Gullet

Heel

CHAIN CUTTER-SEQUENCE TERMS

Standard

Semi-Skip

Skip

Introduction

IntroductionIntroduction

2.

2.

Toe

Depth

Gauge

Saw Chains

OREGON® CHAIN TERMS

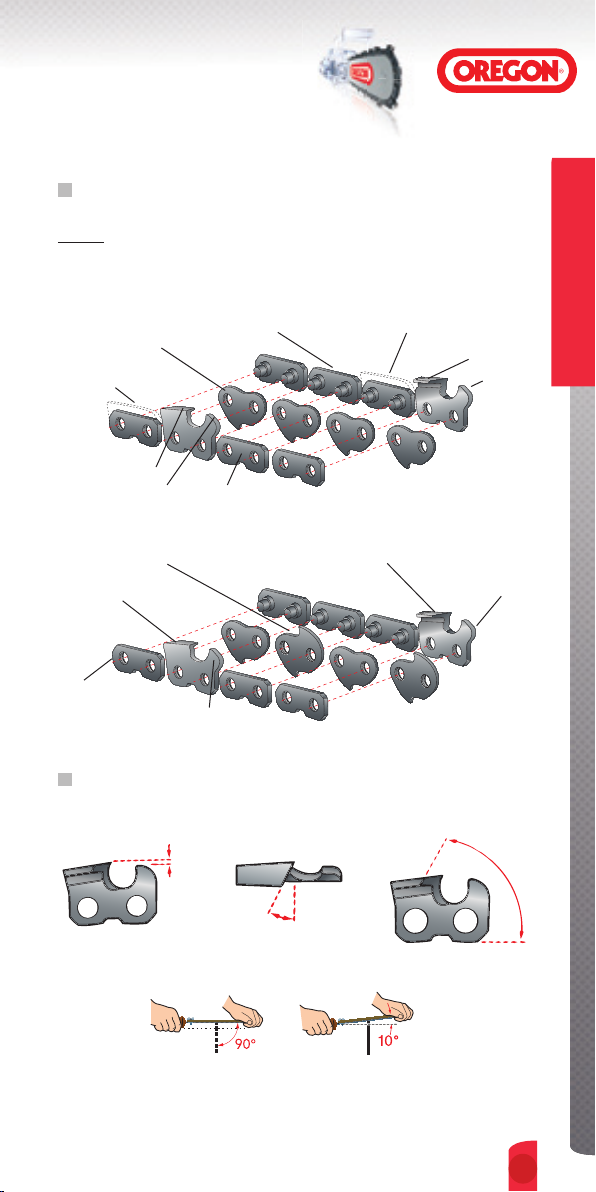

THE PARTS OF A SAW CHAIN

NOTE: Highlighted parts below indicate kickback-reducing “bumper

link" features: bumper tie strap, bumper drive link, and ramped depth

gauge.

Drive Link

Bumper Tie Strap

Right-hand Cutter

Ramped Depth Gauge

Bumper Drive Link

Right-hand Cutter

Tie Strap

Depth Gauge

Preset Tie Strap

Tie Strap

Preset Bumper Tie Strap

Left-hand Cutter

Left-hand Cutter

Depth Gauge

CUTTER MAINTENANCE TERMS

Depth-gauge Setting Top-plate Filing Angle Top-plate Cutting Angle

Ramped

Depth

Gauge

Saw Chains

File-guide Angle

3.

Saw Chains

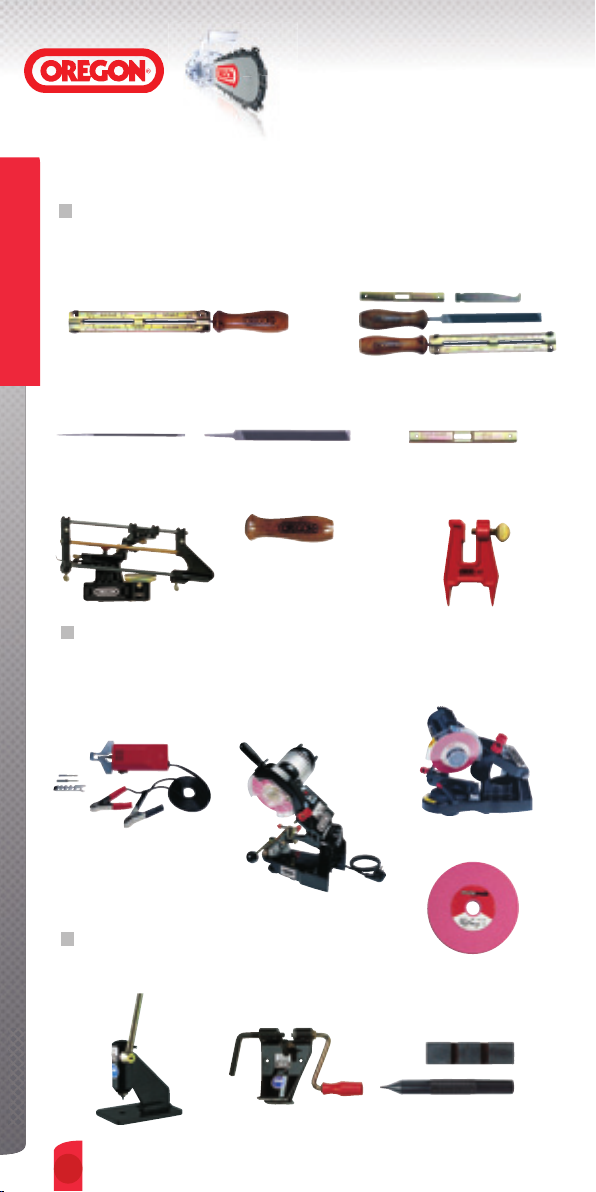

OREGON® CHAIN-MAINTENANCE TOOLS

FILING TOOLS

ASSEMBLED FILE GUIDE

➊

Saw Chains

ROUND FILE

➌

BAR-MOUNTED

➏

FILING GUIDE

GRINDERS

SURE SHARP®

➊

12-VOLT GRINDER

FLAT FILE

➍

FILE HANDLE

➐

BENCH-MODEL

➋

CHAIN GRINDER

SHARPENING KIT

➋

DEPTH-GAUGE TOOL

➎

FILING VISE

➑

MINI GRINDER

➌

GRINDING WHEELS

➍

CHAIN-REPAIR TOOLS

CHAIN BREAKER

➊

Introduction

IntroductionIntroduction

4.

4.

RIVET SPINNER

➋

POCKET-CHAIN

➌

BREAKER

Saw Chains

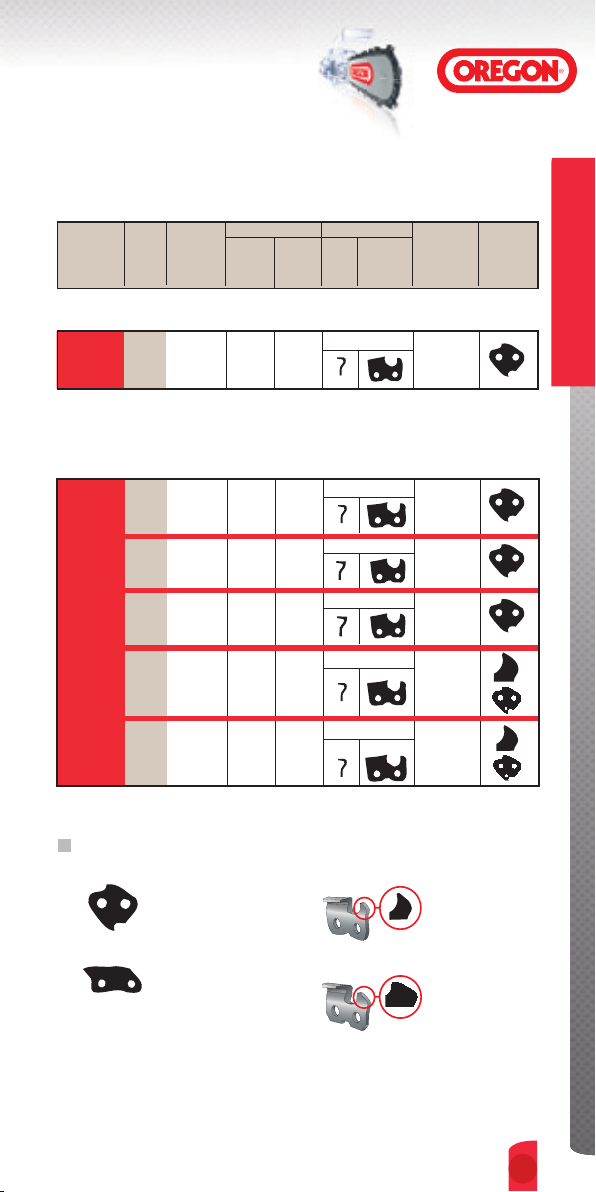

CHAIN IDENTIFICATION

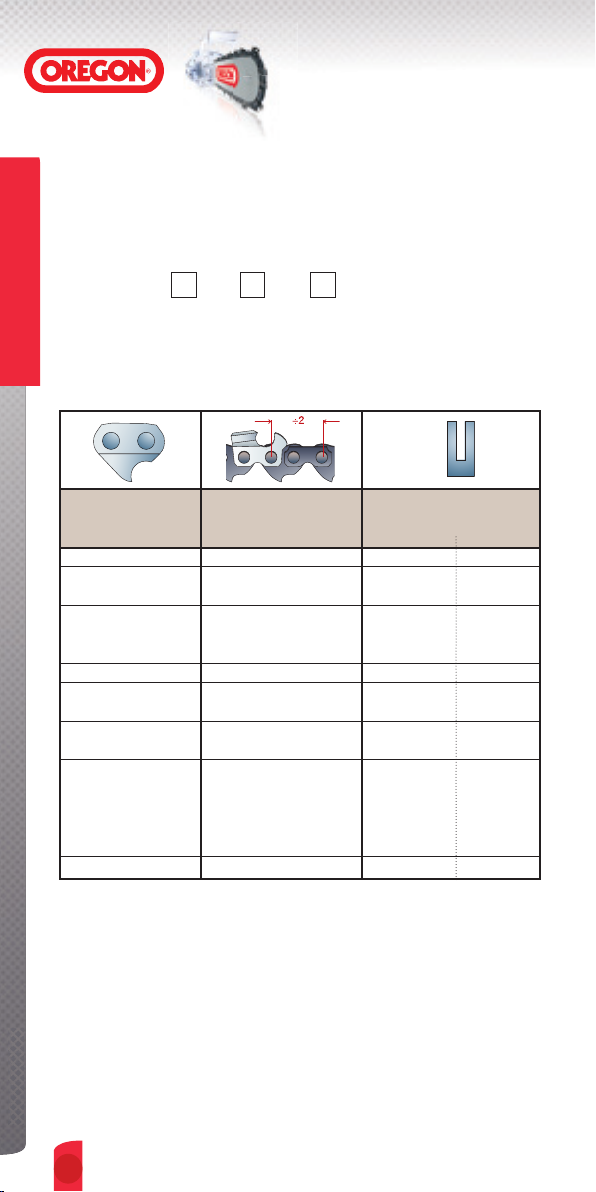

OREGON® FILING OREGON® CHAIN GAUGE CUTTER TYPE CUTTER KICKBACK

CHAIN SPEC’S CHAIN IN. MM END SIDE SEQUENCE REDUCING

PART TYPE VIEW VIEW FEATURES

(IF ANY)*

1/4" PITCH CHAIN

25AP

26

MICRO

CHISEL

050"

®

1.3

Page

.325" PITCH CHAINS

050"

20BPX

21BPX

22BPX

20LPX

21LPX

22LPX

M21LPX

M22LPX

95VPX

95R

Page

27

Page

28

Page

31

Page

30

Page

43

MICRO

CHISEL

SUPER

20

MULTICUT

MICRO-

LITE™

RIPPING

CHAIN

®

058"

063"

050"

058"

063"

058"

063"

050"

050"

1.3

1.5

1.6

1.3

1.5

1.6

1.5

1.6

1.3

1.3

KICKBACK REDUCING FEATURES

➊

DRIVE LINK

BUMPER

CHISEL

CHISEL

®

STANDARD

®

STANDARD

STANDARD

STANDARD

®

STANDARD

®

STANDARD

RAMPED

MICRO CHISEL

MICRO CHISEL

MICRO CHISEL

MICRO CHISEL

➌

DEPTH GAUGE

Saw Chains

➋

TIE STRAP

BUMPER

➍

RAMPED

DEPTH GAUGE

LOW-PROFILE

5.

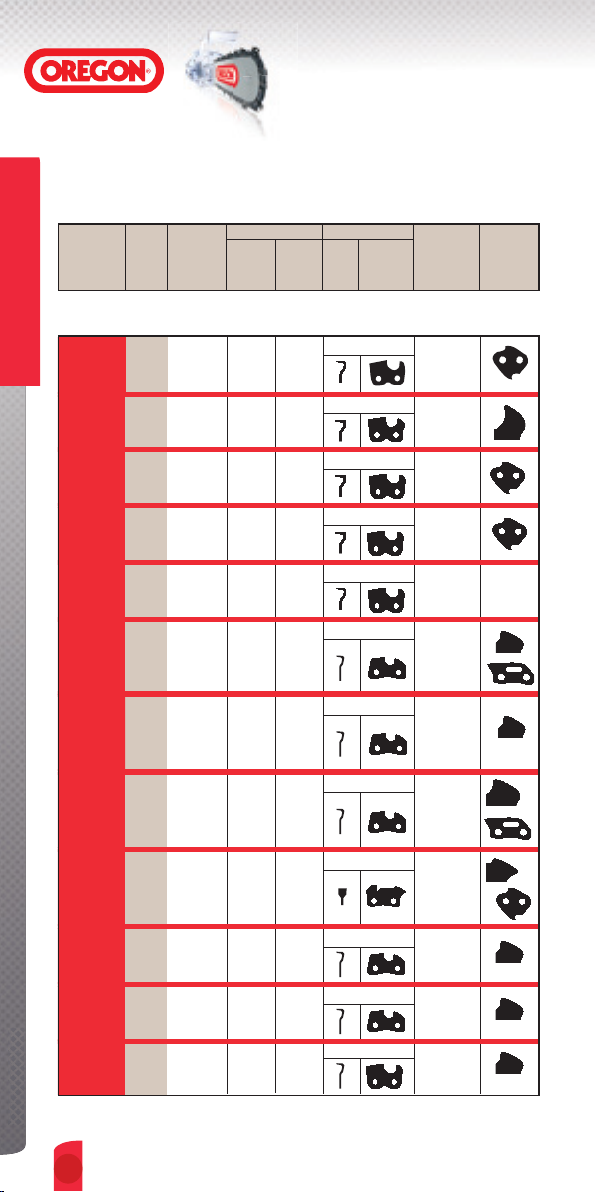

Saw Chains

CHAIN IDENTIFICATION

OREGON® FILING OREGON® CHAIN GAUGE CUTTER TYPE CUTTER KICKBACK

CHAIN SPEC’S CHAIN IN. MM END SIDE SEQUENCE REDUCING

PART TYPE VIEW VIEW FEATURES

(IF ANY)*

3/8" PITCH CHAINS

Saw Chains

72DX/DPX

73DX/DPX

75DX/DPX

72LGX

73LGX

75LGX

72LPX

73LPX

75LPX

M73LPX

M75LPX

72RD

73RD

75RD

90SG

91VX

91VG

91LX

Page

33

Page

34

Page

35

Page

32

Page

36

Page

38

Page

39

Page

40

-

S-70

SUPER

GUARD

SUPER 70

Low

vibration

MULTICUT

RIPPING

CHAIN

MICRO-

LITE™

Low

vibration

Low

vibration

Low

profile

Low

vibration

XTRA

GUARD

POWER

SHARP

050"

058"

063"

050"

058"

™

063"

050"

058"

063"

058"

063"

050"

058"

063"

043"

050"

050"

™

050"

®

SEMI-CHISEL

1.3

1.5

1.6

1.3

1.5

1.6

1.3

1.5

1.6

1.5

1.6

1.3

1.5

1.6

1.1

1.3

1.3

1.3

CHISEL

CHISEL

CHISEL

SEMI-CHISEL STANDARD

CHAMFER-CHISEL

CHAMFER-CHISEL

CHAMFER-CHISEL

SPECIALIZED

STANDARD

(LG)

STANDARD

(LP)

STANDARD

STANDARD

(SG)

STANDARD

STANDARD

STANDARD

STANDARD

91R

M91VX

91VXL

Introduction

IntroductionIntroduction

6.

6.

Page

37

Page

39

Page

29

RIPPING

CHAIN

MULTICUT

SEMI-

CHISEL

050"

050"

050"

CHAMFER-CHISEL

1.3

CHAMFER-CHISEL

1.3

1.3

SEMI-CHISEL

STANDARD

STANDARD

STANDARD

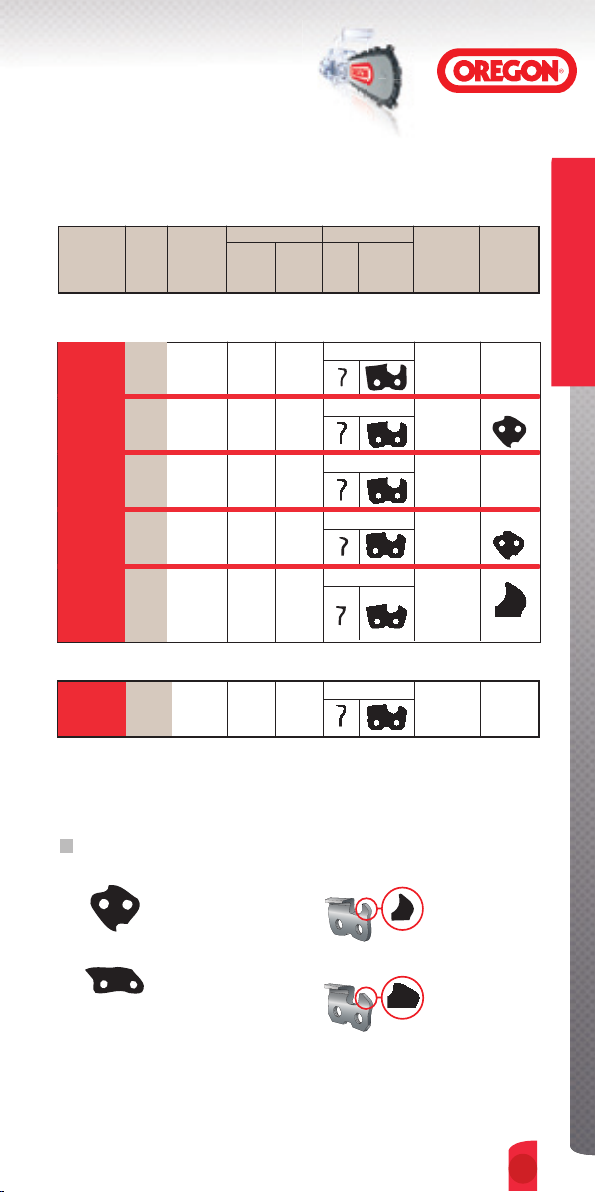

Saw Chains

CHAIN IDENTIFICATION

OREGON® FILING OREGON® CHAIN GAUGE CUTTER TYPE CUTTER KICKBACK

CHAIN SPEC’S CHAIN IN. MM END SIDE SEQUENCE REDUCING

PART TYPE VIEW VIEW FEATURES

(IF ANY)*

.404" PITCH CHAINS

16H

18HX

26

27, 27P

27R

59AC

58L

59L

Page

47

Page

41

Page

42

Page

44

Page

45

HARVESTER

MICRO-

CHISEL

RIPPING

MICROBIT

GUARD

CHAIN

SUPER

063"

080"

058"

®

063"

063" 1.6

®

063"

058"

063"

™

1.6

2.0

1.5

1.6

1.6

1.5

1.6

3/4" PITCH CHAINS

Page

SEMI-

122"

11H

46

CHISEL

3.1

KICKBACK REDUCING FEATURES

➊

DRIVE LINK

BUMPER

MICRO CHISEL

MICRO CHISEL

MICRO CHISEL

➌

DEPTH GAUGE

®

STANDARD

®

STANDARD

®

(R)

STANDARD

CHIPPER STANDARD

CHISEL

SEMI-CHISEL

STANDARD

STANDARD

RAMPED

P ONLY

CP ONLY

Saw Chains

➋

TIE STRAP

BUMPER

➍

RAMPED

DEPTH GAUGE

LOW-PROFILE

7.

Saw Chains

CHAIN DRIVE-LINK NUMBER IDENTIFICATION

Nearly all OREGON® chains are named by a part number made up of a

number (see below), followed by one or two letters (see page 9).

OREGON

The Numbers: 18 HX, 72 LPX, 91 VG

The numbers are stamped on the chain’s drive links and indicate the

Saw Chains

physical size of the chain (pitch and gauge).

®

Part-number Examples: 18 HX, 72LPX, 91VG

CHAIN

NUMBER

11 3/4" .122" 3.1

16 .404" .063" 1.6

18 .404" .080" 2.0

20 .325" .050" 1.3

21 .325" .058" 1.5

22 .325" .063" 1.6

25 1/4" .050" 1.3

26 .404" .058" 1.5

27 .404" .063" 1.6

58 .404" .058" 1.5

59 .404" .063" 1.6

72 3/8" .050" 1.3

73 3/8" .058" 1.5

75 3/8" .063" 1.6

90 3/8" .043" 1.1

91 3/8" .050" 1.3

95 .325" .050" 1.3

GAUGE

PITCH

MM

IN

Introduction

IntroductionIntroduction

8.

8.

Saw Chains

CHAIN LETTER IDENTIFICATION

The letters: 18 HX , 72 LPX , 91 VG

The letters represent cutter type and sequence, safety features, or other

physical traits of the chain.

AC Chipper Cutter,

Standard Sequence

AP Micro Chisel

®

Cutter,

Bumper Drive Link,

Standard Sequence

BC Chipper cutter with standard

sequence (11BC only)

®

BPX Low vibration Micro Chisel

Cutter, Bumper Drive Link,

Standard Sequence

DX Semi-chisel Cutter, Standard

Sequence

DPX Semi-chisel Cutter, Bumper

Drive Link, Standard

Sequence

H Modified for Harvester

applications, Micro Chisel

®

or Semi-chisel cutters

with Standard Sequence

L Round-ground chisel cutters

with standard sequence (.404"

58L & 59L)

LGX Round-ground Chisel

Cutter, Ramped Depth

Gauge, Standard

Sequence.

LPX Low vibration Round-ground

Chisel Cutter, Bumper Drive

Link, Standard Sequence

®

LX Power Sharp

Chain,

Ramped Depth Gauge,

Bumper Drive Link,

Standard Sequence

(no hand maintenance

required)

M Specially built chain with

round-ground chisel cutters

(M73, 75LPX, M21,22LPX)

and Bumper Drive Link or

chamfer-chisel cutter (M91VX)

and ramped depth gauge for

effective cutting in extremely

dirty or abrasive conditions

R Ripping Chain, Chamfer-chisel

(91R) or Micro-chisel

(95R,27R) Cutter,

Standard Sequence

RA Ripping Chain, Micro-chisel

Cutter, Skip Sequence

RD Ripping chain with semi-

chisel cutters and standard

sequence

SG Low vibration chamfer-chisel

cutters, ramped depth gauge,

bumper tie strap, standard

sequence, narrow kerf design.

VG Low-vibration Chamfer-chisel

cutter, ramped depth gauge,

bumper tie strap, standard

sequence

VPX Low-vibration Micro Chisel™

cutter, ramped depth gauge,

bumper drive link, narrow-kerf

design (95VPX only)

VX Low-vibration Chamfer-chisel

cutters, ramped depth gauge,

standard sequence

VXL Low-vibration Semi-chisel

cutters with long top plate,

ramped depth gauge,

standard sequence

Saw Chains

9.

Saw Chains

THE FOUR BASIC SAW-CHAIN RULES

ATTENTION CHAINSAW USERS:

®

OREGON

rules. Users who know and follow these rules can count on superior

performance from their chain, bar, and sprocket, - and reduce safety

hazards at the same time.

Saw Chains

Your chain must be correctly tensioned.

More chain and bar problems are caused by incorrect chain tension

than by any other single factor. See pages13 and 14 on how to tension

your chain.

urges you to become familiar with the four basic saw-chain

RULE NUMBER 1

RULE NUMBER 2

Your chain must be well lubricated

A constant supply of oil to your saw’s bar, chain and sprocket is vital.

Without it, excessive friction, wear, and damage will occur.

See page 15 for instructions on how to lubricate your chain.

Introduction

IntroductionIntroduction

10.

10.

Saw Chains

THE FOUR BASIC SAW-CHAIN RULES

RULE NUMBER 3

Your chain’s depth gauges must be set correctly

Depth-gauge setting and depth-gauge shape are critical to performance

and safety. See pages 16-17 for instructions on how to set your chain’s

depth gauges.

Saw Chains

RULE NUMBER 4

Your chain must be sharp

When your chain is sharp, it does the work. When it’s not, you do the work

- and your cutting attachments will wear more rapidly. See pages 18 and 19

for instructions on how to sharpen your chain. See pages 26 to 47 to find

maintenance specifications for each OREGON

®

chain type.

11.

Saw Chains

HOW TO MAINTAIN CHAIN

ATTENTION: DEALERS, CHAINSAW USERS, AND ANYONE WHO

SERVICES SAW CHAIN - IMPORTANT SAFETY INFORMATION.

®

OREGON

Saw Chains

techniques, and the possible dangers which can result if chain is not

properly maintained.

Always turn off your saw’s engine before handling the chain,

urges you to become familiar with proper chain-maintenance

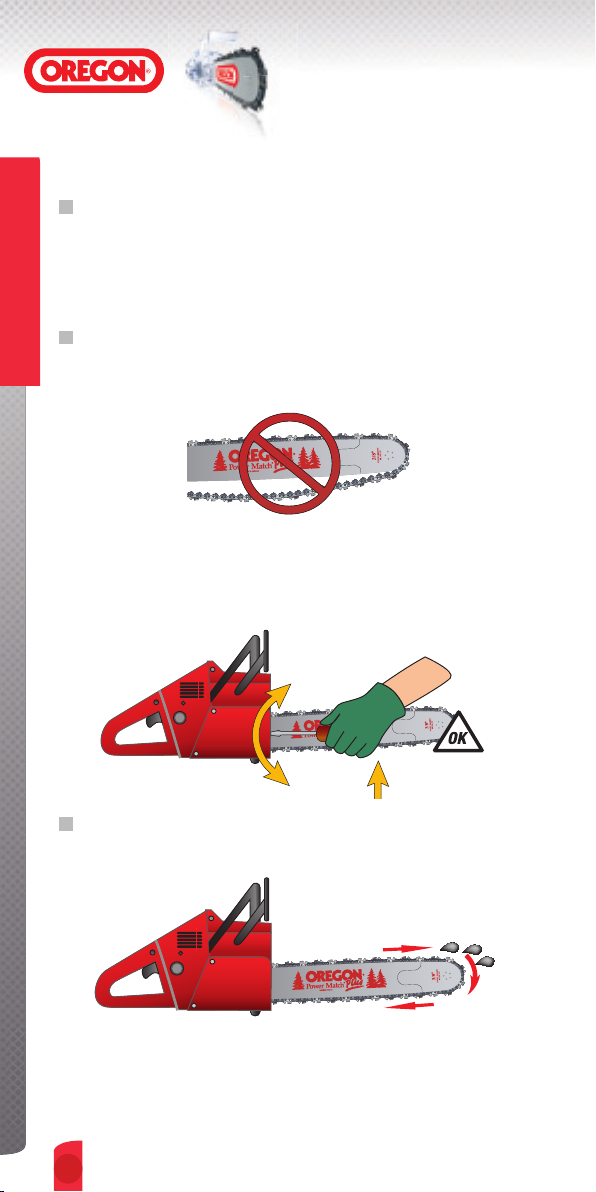

WARNING

Failure to follow the instructions below can result in severe

injury to the saw operator, bystanders, or the person

performing maintenance.

guide bar or sprocket.

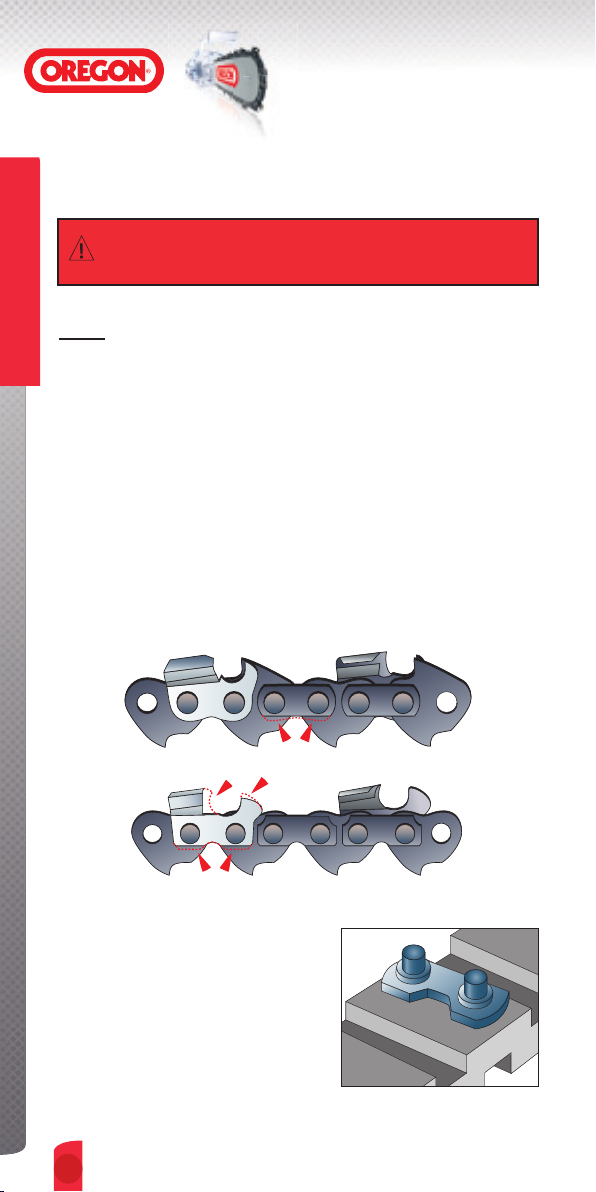

Any one of the following conditions can increase a chain’s

potential kickback energy, increase the risk of a chain throwing

itself off the bar, or increase the risk of other hazards associated

with chainsaw use.

1. Incorrect sharpening of chain angles.

2. Dull chain.

3. Alteration of kickback-reducing chain features.

4. Excessive chain depth-gauge settings.

5. Incorrect chain depth-gauge shapes.

6. Loose chain tension.

7. Incorrectly installed chain parts.

8. Loose rivets, or cracks or breaks in any chain component.

When performing maintenance on saw chain, follow all instructions

on pages 12 through 54. Doing so can minimize the risk of injury.

Introduction

IntroductionIntroduction

12.

12.

Saw Chains

HOW TO TENSION YOUR CHAIN WITHOUT INTENZ™

Read the warnings on page 12.

NOTE: Always wear protective gloves.

➊

Turn the engine off.

NOTE: Never tension your chain right after cutting. Chain tensioned

while hot can cool and contract, causing tension to be much too tight.

Let chain cool first.

➋

Loosen bar-mounting nuts on the side of your saw.

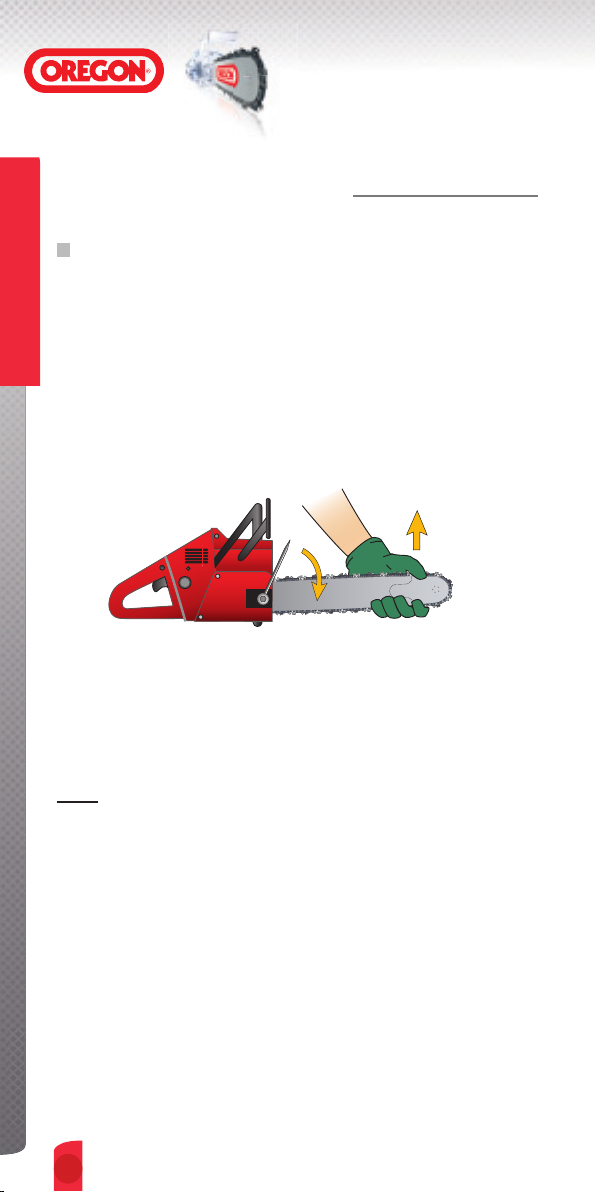

➌

Pull the bar nose up, and keep it up as you adjust tension.

Saw Chains

➍

Adjust tension as follows:

If you have a solid-nose bar

Turn your saw’s tension-adjustment screw until the bottoms of the

➞

lowest tie straps and cutters come up and just touch the bottom of

the bar rail.

13.

Saw Chains

HOW TO TENSION YOUR CHAIN WITHOUT INTENZ™

If you have a sprocket-nose bar

Tension must be tighter than on a solid-nose bar. Turn your saw’s

➞

Saw Chains

tension-adjustment screw until the bottoms of the lowest tie straps

and cutters come up and solidly contact the bottom of the bar rail.

➎

With either type of bar, hold the nose up and tighten your saw’s rear

bar-mounting nut first, then tighten the front nut.

➏

Pull the chain by hand along the top of the bar several times,

from the engine to the bar’s tip. Chain should feel snug but still pull

freely.

NOTE: If you have a sprocket-nose bar you should now perform the snap

test. Grasp the chain along the bottom of the bar, pull down, and let go.

Chain should snap back to its original position, solidly contacting the

bottom of the bar.

➐

Check tension often during operation, especially during the first

half-hour. If chain loosens: stop, let chain cool, and readjust tension.

Introduction

IntroductionIntroduction

14.

14.

Saw Chains

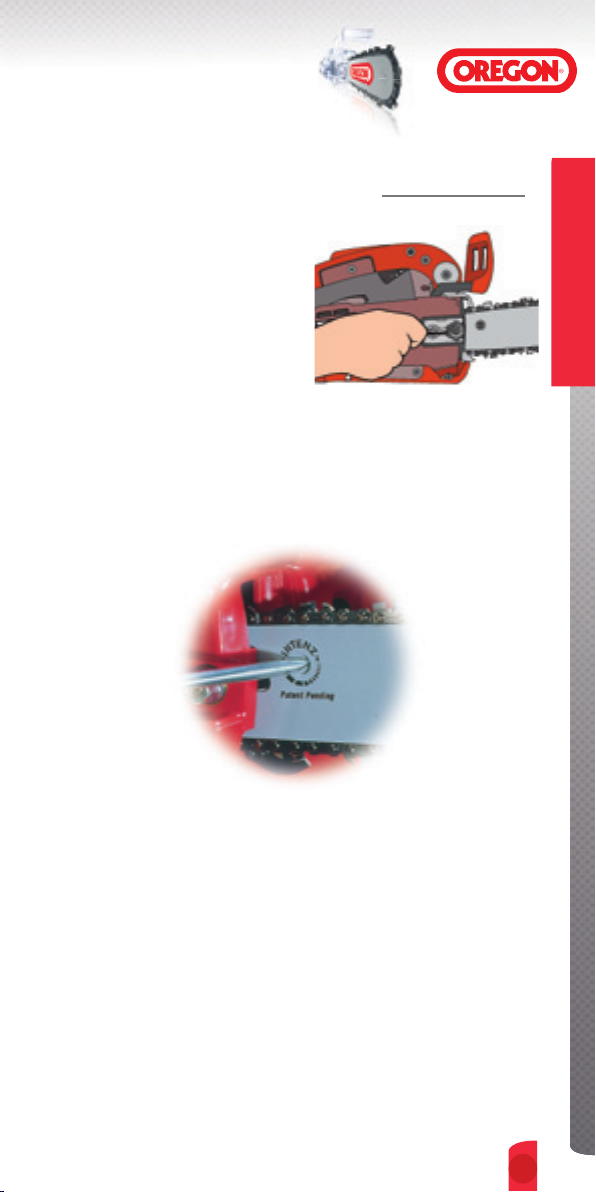

HOW TO TENSION YOUR CHAIN WITH INTENZ™

➊

Turn the engine off.

➋

Loosen the bar mounting

nuts on the side of the saw.

➌

Insert a combination tool blade in the Intenz™ slot of the guide bar.

➍

Turn the combination tool to move the guide bar forwards, away

from the saw as far as possible.

Saw Chains

➎

Tighten the back bar mounting nut, then tighten the front nut

HOW TO LUBRICATE YOUR CHAIN

➊

Keep your saw’s chain-oiling system filled with clean bar-and-chain

oil.

➋

Never put used oil, or old motor oil in your saw or on your chain.

➌

Be sure your chain, bar, and sprocket are always receiving oil from

the saw during operation.

➍

Fill your oil reservoir each time you fill your gas tank.

15.

Saw Chains

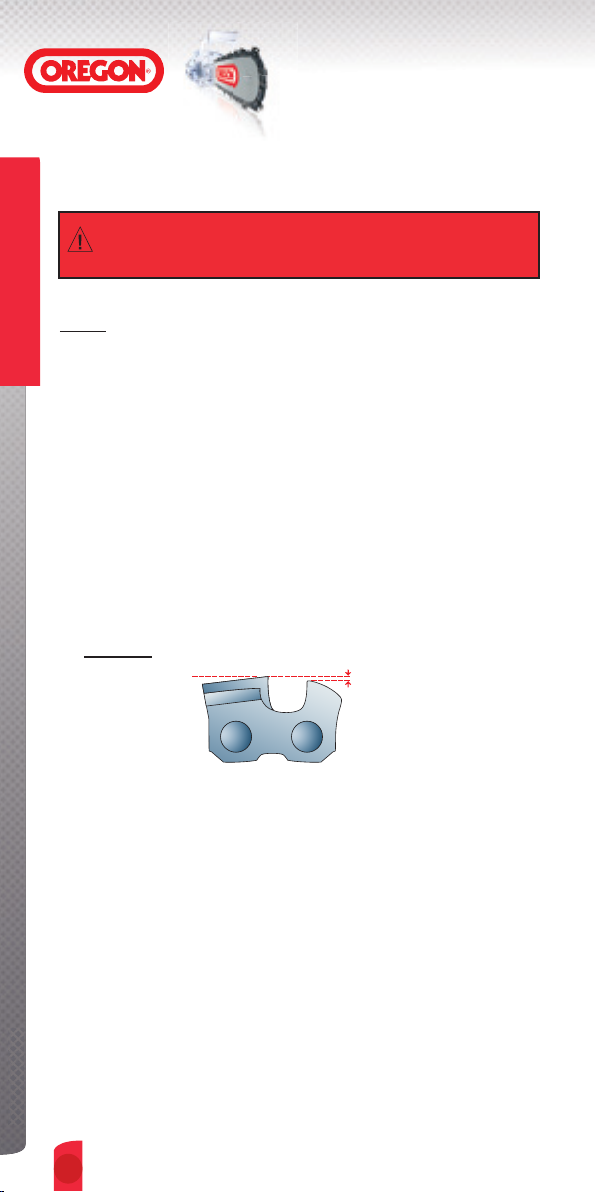

HOW TO SET DEPTH GAUGES

Read the warnings on page 12.

Saw Chains

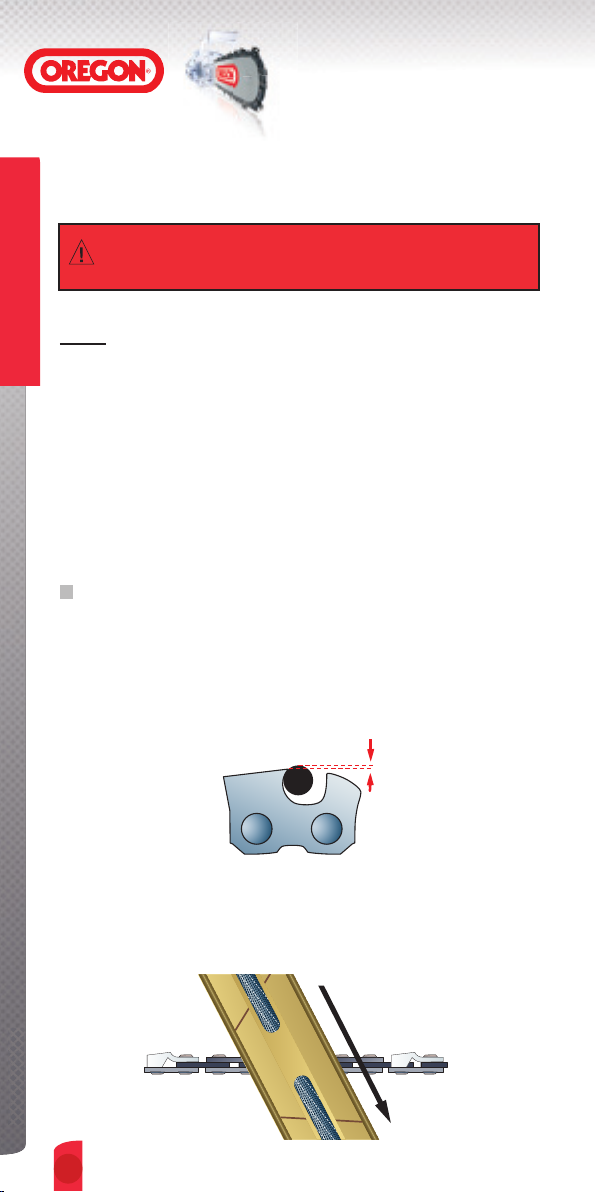

NOTE:

• On saw depth-gauge setting requires proper chain tension, as shown

on pages 13-14,prior to filing.

• Pages 26 through 47 show the correct depth-gauge setting and the

part number of the correct depth-gauge tool for each of the different

OREGON

• Find the page (26-47), which gives the correct filing specifications

for your OREGON

chart on pages 5, 6 and 7.

• If unsure of your OREGON

OREGON

• Most OREGON

gauge indicating the correct depth-gauge setting.

EXAMPLE: .025" (0.64mm)

®

chain types.

®

chain type. To do so, use the Chain identification

®

®

saw chain dealer.

®

chains have a number stamped on each depth

chain’s type, or part number, ask your

.025" (0.64mm) Depth-gauge Setting

➊

Use a depth-gauge tool with the correct built-in setting for your

chain and check your depth gauges every 3 or 4 sharpenings.

➋

Place the tool on top of your chain so one depth gauge protrudes

through the slot in the tool.

➌

If the depth gauge extends above the slot, file the depth gauge

down level with the top of the tool using a flat file.

Never file the depth gauge down enough to exceed the depth-gauge

setting specified in this manual for your OREGON

Introduction

IntroductionIntroduction

16.

16.

®

chain.

Saw Chains

HOW TO SET DEPTH GAUGES

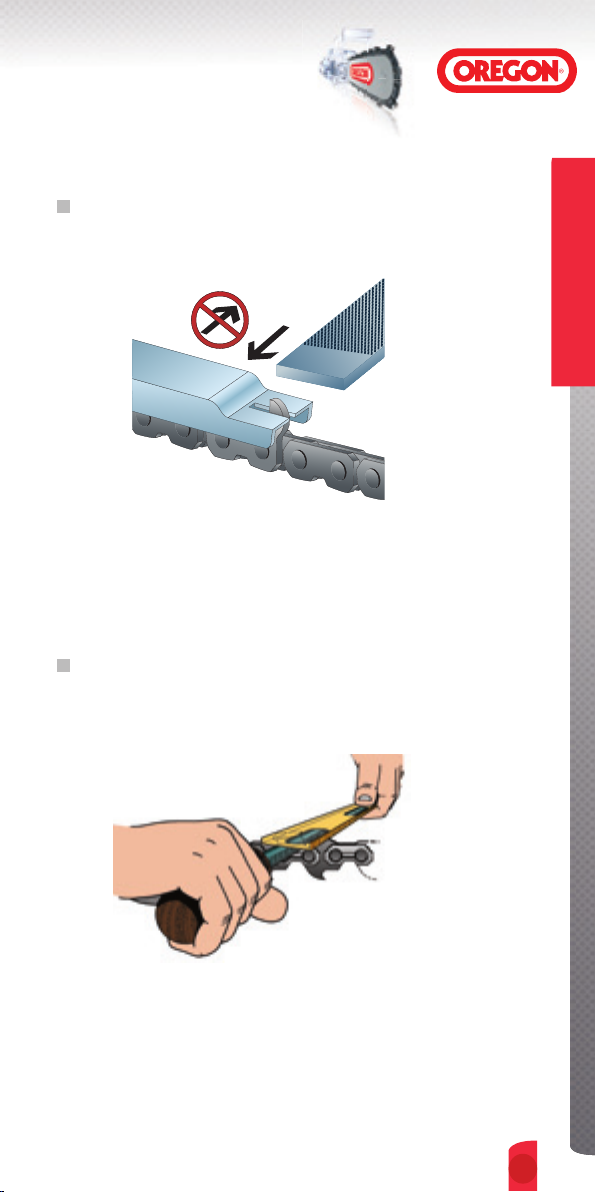

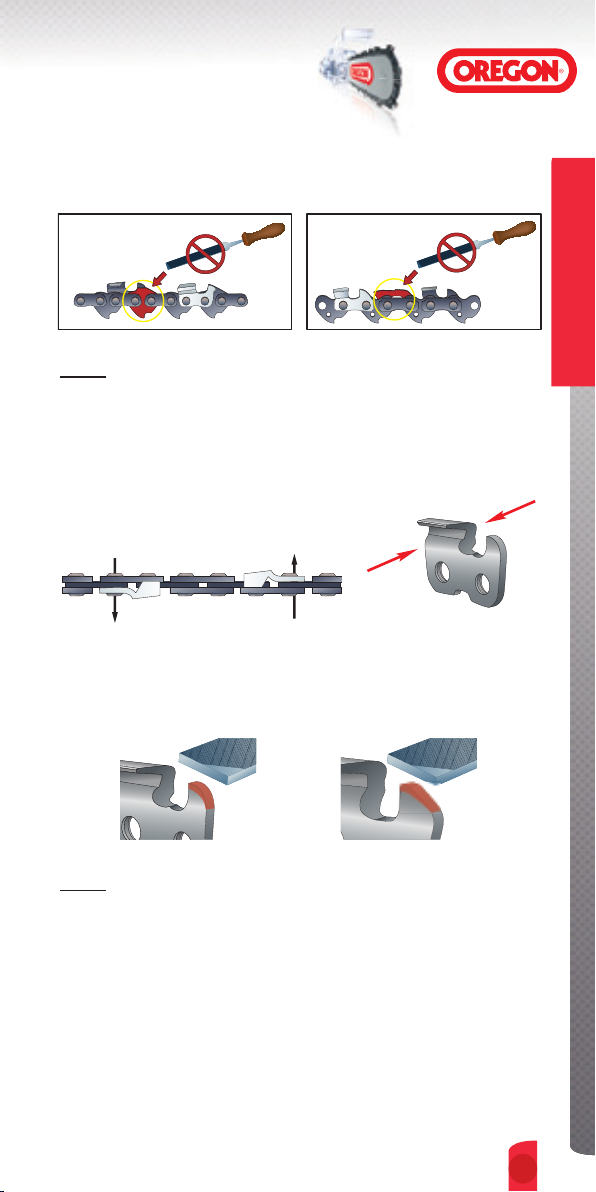

NOTE: Do not file or alter the tops of kickback-reducing bumper tie

straps or bumper drive links.

➍

File from the inside of the cutter to the outside

outside

inside

➎

After lowering, always file off the front corner of each depth gauge

parallel to its original rounded or ramped shape.

Saw Chains

NOTE: On many chains, it may be helpful to tip the depth gauge tool on

end and place it in front of the working corner in order to protect

the cutting surfaces when re-shaping depth gauges.

17.

Saw Chains

HOW TO SHARPEN CUTTERS

Read the warnings on page 12.

Saw Chains

NOTE:

• On-saw sharpening requires proper chain tension.

• Pages 26 through 47 show the correct maintenance specifications

and the correct maintenance-tool part numbers for each of the

OREGON

• Find the correct filing specifications for your OREGON

• If unsure of your OREGON

specification, ask your OREGON

• Check and adjust depth gauges.

ROUND-FILE CUTTER SHARPENING

➊

Be sure 1/5th, or 20%, of the file’s diameter is always held above

the cutter’s top plate. Using the correct file guide is the easiest way

to hold the file in this position.

®

chain types.

®

®

chain’s type, part number or filing

®

saw chain dealer.

chain type.

➋

Keep the correct Top-plate Filing Angle line on your file guide

parallel with your chain.

File holder

Introduction

IntroductionIntroduction

18.

18.

=1/5th or 20%

above top plate

Direction

of stroke

Saw Chains

HOW TO SHARPEN CUTTERS

➌

Sharpen cutters on one side of the chain first. File from the inside of

each cutter to the outside. Then turn your saw around and repeat

the process for cutters on the other side of the chain.

inside

➍

If damage is present on the chrome surface of top plates or side

plates, file back until such damage is removed.

➎

Keep all cutter lengths equal.

A

A=B

B

outside

Saw Chains

➏

Re-check depth gauges. If re-setting of the depth gauges is necessary,

follow instructions on pages 16 and 17.

NOTE: Do not file or alter the tops of kickback-reducing bumper

tie straps or bumper drive links.

19.

Saw Chains

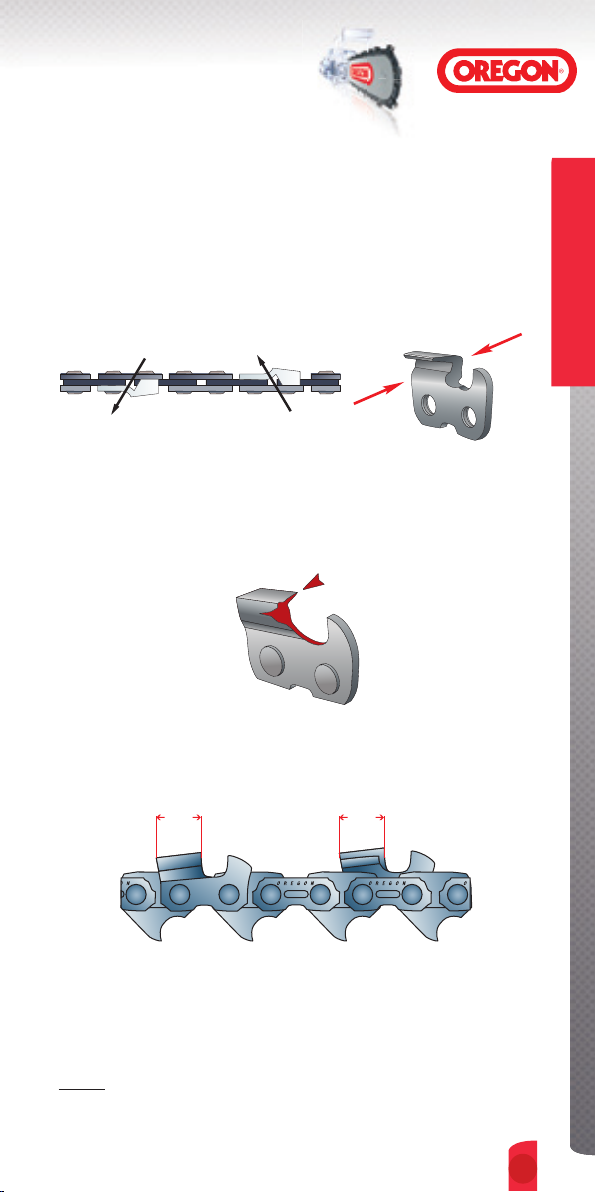

HOW TO INSTALL NEW CHAIN PARTS

Read the warnings on page 12.

Saw Chains

NOTE:

®

• Use only OREGON

parts which are the correct size and type for your chain.

➊

Remove rivets, and parts to be replaced, as shown under “How to

Break Out Rivets," pages 22 to 23. Never reassemble a chain with

old preset tie straps - always use new preset tie straps.

➋

If needed, file off bottom of new parts to match existing worn parts.

File new cutters back to match worn cutters. Do not file the tops of

kickback-reducing bumper tie straps or bumper drive links.

parts to repair OREGON® chain. And only use

➌

Place the preset tie strap on a flat outer

surface of a chain-breaker anvil. Be

sure the rivets are pointing up.

Introduction

IntroductionIntroduction

20.

Loading...

Loading...