Page 1

613GC

CUT-OFF SAW

OPERATOR’S MANUAL

ICS, Blount Inc.

4909 SE International Way

Portland, OR 97222

www.icsbestway.com

© Copyright ICS 2003 P/N 70701 May 03

Page 2

613GC OPERATOR’S MANUAL

2

Page 3

613GC OPERATOR’S MANUAL

TABLE OF CONTENTS

SYMBOLS & LABELS 4

SAFETY 5

TECHNICAL SPECIFICATIONS 8

SET-UP 9

OPERATION 11

MAINTENANCE 16

TROUBLESHOOTING 23

REFERENCE 24

3

Page 4

613GC OPERATOR’S MANUAL

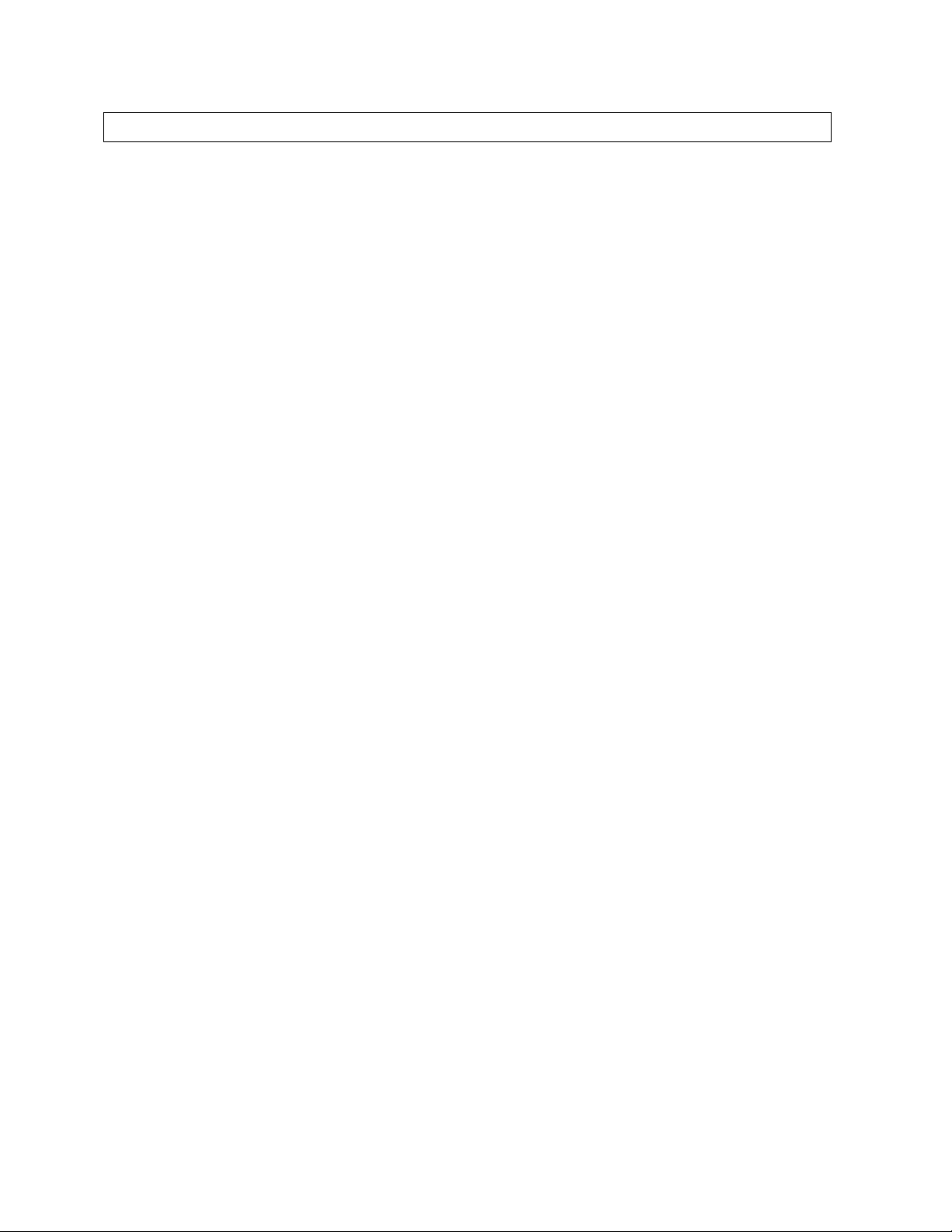

SYMBOLS & LABELS

THE FOLLOWING SYMBOLS & DEFINITIONS ARE FOUND THROUGHOUT THIS MANUAL AND

ARE DESIGNED TO MAKE YOU AWARE OF POTENTIAL HAZARDS OR UNSAFE PRACTICES.

A potentially hazardous situation exists which, if not avoided, could

WARNING

IMPORTANT

THE FOLLOWING SYMBOLS & LABELS MAY BE FOUND IN THIS MANUAL OR ON THE CUT-OFF

SAW

Read the operator’s manual carefully and understand the contents

before you use this equipment.

Always use:

• Protective helmet

• Ear protection

• Protective glasses or full face protection

Wear hand protection

result in death or serious injury.

A potentially hazardous situation exists which, if not avoided, may

result in minor or moderate injury or property damage.

A potential situation exists which, if not avoided, may result in

product or property damage.

4

Page 5

613GC OPERATOR’S MANUAL

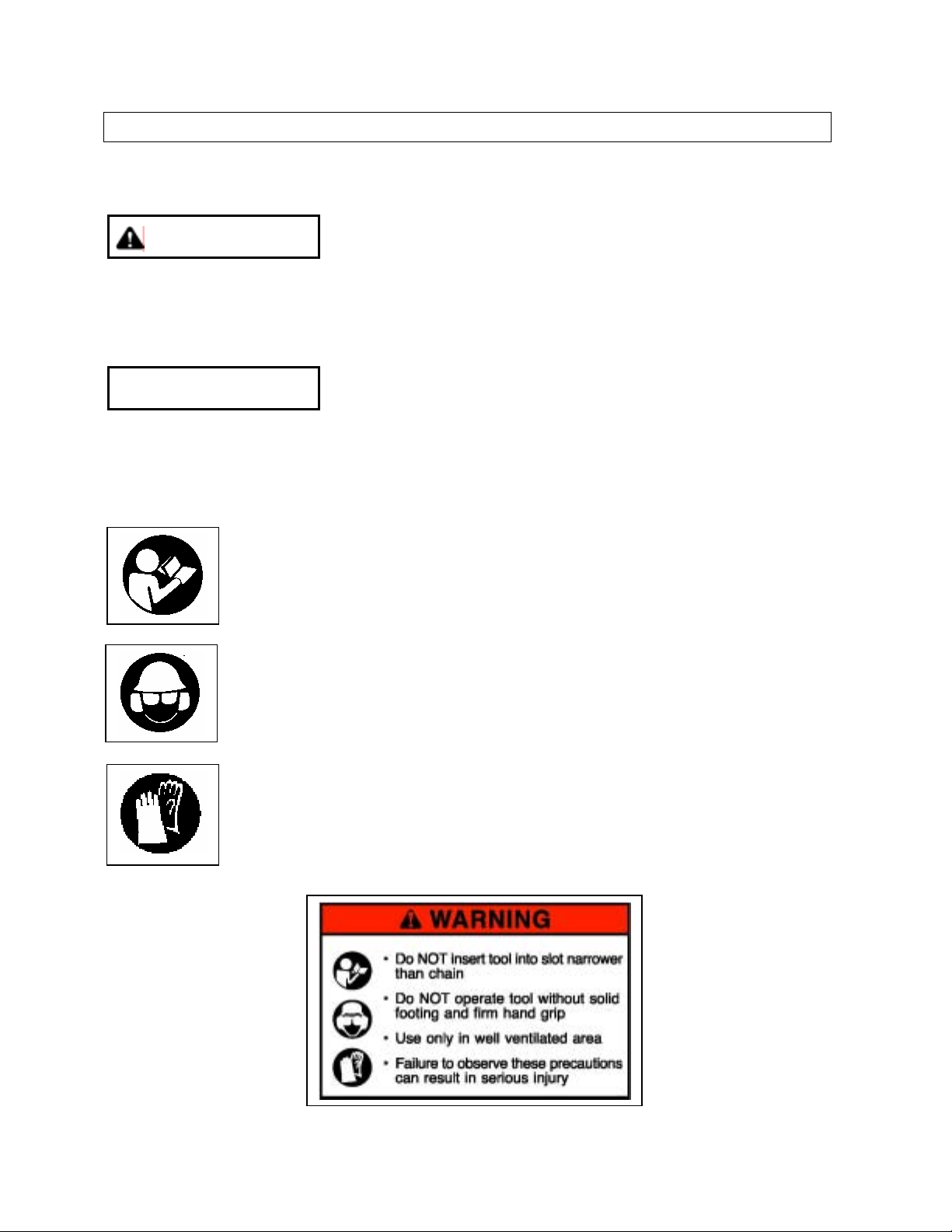

SAFETY

THE FOLLOWING SYMBOL APPLIES TO ALL THE ITEMS LISTED ON THIS PAGE

A potentially hazardous situation exists which, if not avoided, could

WARNING

Diamond chain breakage can result in high-speed ejection of parts, which can result in death or

serious personal injury to operators or bystanders. The items listed below are critical to

minimizing the risk of diamond chain breakage and injury.

• DO NOT operate a chain-based cut off saw with a damaged, modified, broken, or missing side

cover, bottom guard, or guard flap. The side cover, bottom guard, and guard flap provides

protection against contact with moving parts, ejected debris, broken diamond chain, thrown

water and concrete slurry.

• DO NOT install or run the diamond chain backwards. The bumper must lead the segment into

the cut.

• DO NOT insert a chain-based cut off saw into a slot narrower than the diamond chain

segments. Rapid pushback might occur. Reference: Most diamond segments are .225 inches

(5.72 mm) wide.

• DO NOT use damaged, modified or improperly repaired diamond chain.

• DO NOT run a chain-based cut off saw upside-down. Concrete debris can fly back into the

operator’s face.

• DO NOT cut ductile iron pipe with the chain-based cut off saw. Segment loss or diamond

chain breakage may occur.

result in death or serious injury.

Bumper

5

Page 6

613GC OPERATOR’S MANUAL

SAFETY

THE FOLLOWING SYMBOL APPLIES TO ALL ITEMS LISTED ON THIS PAGE

A potentially hazardous situation exists which, if not avoided, may

CAUTION

• Always turn a chain-based cut off saw OFF when performing maintenance on the saw

including diamond chain tensioning.

• Never use equipment that is not functioning properly. Have the cut-off saw repaired by

qualified service personnel.

• Turn engine OFF before refueling. Keep away from open flame. Always provide adequate

ventilation when handling fuel. Move chain-based cut off saw at least 10 feet (3 m) away from

refueling area before starting.

• SealPro

water supply may result in excessive wear to the diamond chain, which can lead to loss of

strength and diamond chain breakage.

• Never start a chain-based cut off saw unless the guide bar, diamond

chain and side cover are properly installed.

GENERAL SAFETY PRECAUTIONS

• Always wear protective clothes, including hard hat, eye protection, hearing protection, and gloves.

• Avoid loose fitting clothing.

• Perform safety checks before starting each day.

• Always operate tool with solid footing and with both hands on cut-off saw.

• Remove or control slurry to prevent slippery conditions while cutting.

• Be sure there are no obstructions (plumbing, electrical conduit, air ducts) and no unnecessary people

present.

• Set up a well-marked safety zone with a roped boundary and clear signs.

• Provide adequate ventilation when working in an enclosed area. Breathing exhaust gases is

dangerous.

• To avoid electrocution, check for live electrical wiring near cutting area.

®

diamond chains require a minimum water pressure of 20 psi (1.4 bar). Insufficient

result in minor or moderate injury or property damage.

6

Page 7

613GC OPERATOR’S MANUAL

SAFETY

THE FOLLOWING SYMBOL APPLIES TO ALL ITEMS LISTED ON THIS PAGE

A potential situation exists which, if not avoided, may result in

IMPORTANT

Note: The chain-based cut off saw is equipped with a two-stroke engine and must always be run

using a mixture of gasoline and ICS

measure the amount of oil to be mixed to ensure that correct mixture is obtained. When mixing

small amounts of fuel, even small inaccuracies can drastically affect the ratio of the mixture.

• This engine is designed to be operate on premium unleaded gasoline.

• Use high quality, unleaded gasoline with a minimum octane rating of 90. If lower octane

gasoline is used, engine temperature will increase which can result in a piston seizure and

damage to the engine.

• Fuel mixture: 25:1 gasoline/oil mixture. Incorrect fuel mixture is the number one cause of

piston seizure.

Use ICS

formulated for air cooled power equipment.

• Never use two-stroke oil formulated for water-cooled two-cycle engines, such as outboard

motor oil.

• Never use motor oil intended for four-stroke engines.

ENGINE BREAK-IN

• It is very important to break-in a new engine to “seat” all moving parts, especially the piston

rings.

• To break-in the engine, run one full tank of 25:1 fuel at idle, cycling the throttle every 5 to 10

minutes to prevent loading.

• Failure to break-in an engine may result in piston seizure.

®

brand two-stroke engine oil, or other high quality 2-stroke oil that has been

product or property damage.

®

two-stroke engine oil. Its is important to accurately

7

Page 8

613GC OPERATOR’S MANUAL

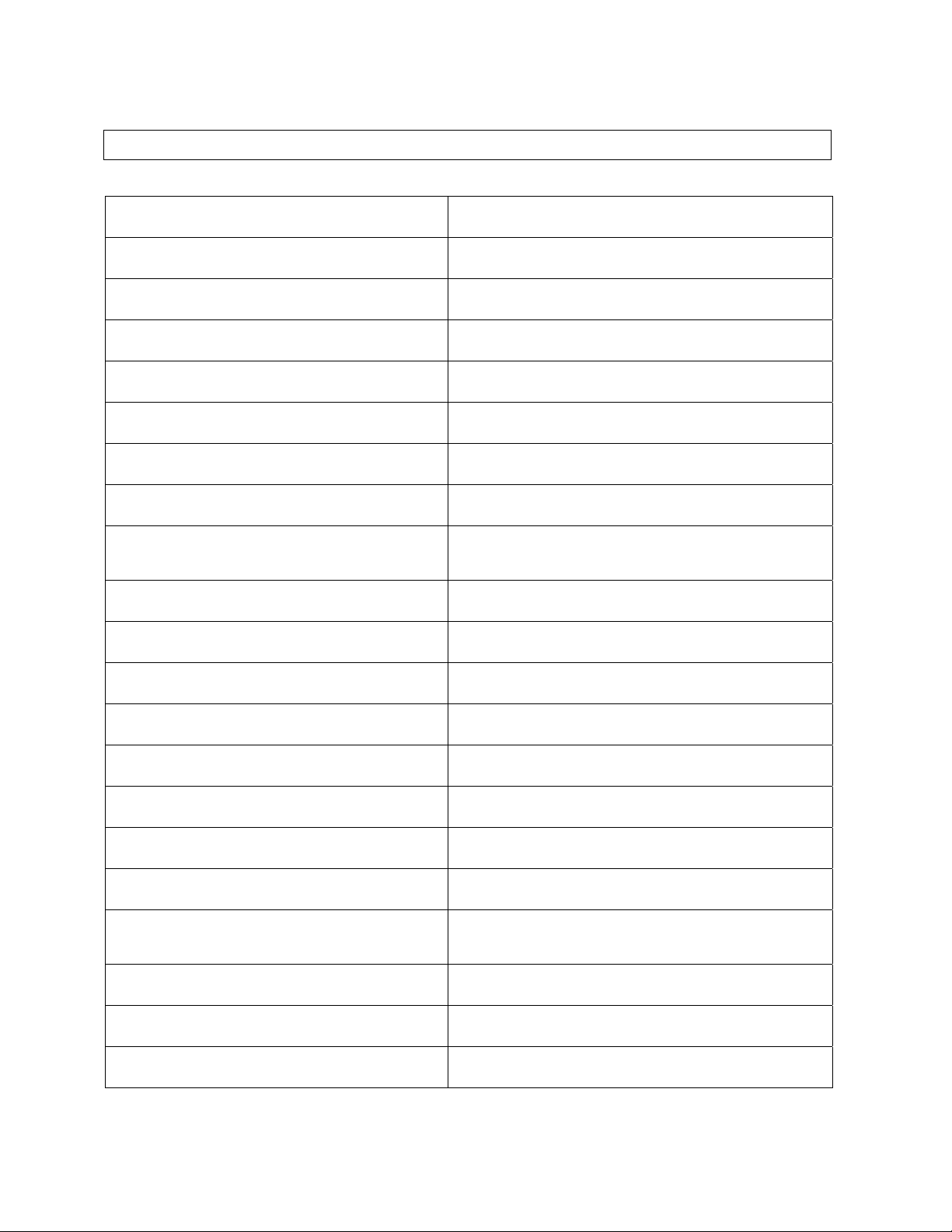

TECHNICAL SPECIFICATIONS

Engine Type 2-stroke Single Cylinder Air Cooled

Displacement 4.88 cu-in (80cc)

Horsepower 5.6 HP (4.6 kw) @ 9,000 RPM

Torque 37.2 in-lbs (4.2 Nm)

Engine Speed

Diamond Chain Speed

Weight 20 lbs (9.1 kg) with guide bar and diamond chain

Cut Depth

Dimensions

Air Filter Washable dry nylon

Carburetor

Starter Dust and water shielded

Ignition Special water resistant electronic ignition

Clutch Three-weight, single spring

Fuel ratio 25:1 gasoline-to-oil

Walbro WJ85B, throttle shaft sealed,

12,000 +/- 500 rpm

2,800-3,200 rpm idle

In cut = 4,000 sfm

No load = 5,300 sfm

Up to 12 inches (30.5cm)

10 inches square (25.4cm)

18 inches (46cm) length

11.5 inches (29cm) height

10 inches (25cm) width

pressure compensating

Fuel Capacity

Water Supply Minimum 20psi (1.5 bar)

Noise Level

Vibration Level 10.5 m/s2 (front handle)

Engine Break-in Period One tank, without cutting, cycling throttle

Spark Plug Champion CJ7Y or Bosch BWS7F

8

15-18 minutes run time per tank

34 oz (1 Liter)

100dB at 3 ft (1m)

Page 9

613GC OPERATOR’S MANUAL

SET-UP

GUIDE BAR AND DIAMOND CHAIN INSTALLATION

STEP 1

Loosen side cover nuts and remove side

cover.

STEP 2

Place bar onto studs and chain adjustment pin.

STEP 3

Move chain adjuster pin back towards drive

sprocket by turning chain-tensioning screw

counter clockwise.

9

STEP 4

Mount the diamond chain on the guide bar

starting at the drive sprocket & continue over

the guide bar nose.

Install the diamond chain correctly. The

bumper must always lead the segment into

the cut as shown here.

STEP 5

Make sure all the drive links are inside the

guide bar groove then pre-tension the chain.

Page 10

613GC OPERATOR’S MANUAL

SET-UP

GUIDE BAR AND DIAMOND CHAIN INSTALLATION

STEP 6

Install side cover and thread the side cover

nuts on finger tight.

STEP 7

Manually pull the chain across the top of the

guide bar away from the Wallwalker®. It is

normal for the chain hanging under the guide

bar to alternately tighten and loosen as the

chain rotates. See Note 1.

Note 1: Be aware that the guide bar rails may develop sharp edges over time so always pull the diamond

chain by the diamond segments.

Note 2: Do not “over tension” the diamond chain. Loss of power will result. It is normal for the drivelinks to

hang underneath the guide bar. The diamond chain should be tight but be able to be pulled arou nd the

guide bar by hand.

Note 3: To prevent chain tensioner breakage, be sure the side cover nuts are tightened to approximately

20 ft-lbs (27Nm).

STEP 8

Hold the guide bar nose up and tension the

chain. The chain should be tight but able to be

pulled around the guide bar by hand.

See Note 2

STEP 9

Continue to lift up on the nose of the guide bar

and firmly

See Note 3.

tighten the side cover nuts.

10

Page 11

613GC OPERATOR’S MANUAL

OPERATION

FUEL HANDLING

CAUTION

GASOLINE

US

Gallon

1 5.2

2 ½ 12.8

5 25.6

• Use premium unleaded gasoline with a minimum octane rating of 90. If lower octane gasoline is

used, engine temperature will increase which can result in a piston seizure and damage to the

engine.

• Always provide adequate ventilation when handling fuel.

• Use caution when handling gasoline. Avoid direct contact with skin or inhaling fuel vapor.

FUEL MIXING

• Always mix gasoline and oil in a clean container intended for use with fuel.

• Keep fuel container closed tightly to prevent moisture from getting into the fuel.

• Always begin mixing fuel by adding half the amount of gasoline to be used. Then add the correct

amount of two-stroke oil for 25:1 mixture and finish filling the container with gasoline.

• Do not mix more than one month’s supply of fuel. This helps prevent the separation of the two stroke

oil from the gasoline (varnishing).

• If the cut-off saw is not used for an extended period of time (3 months) the fuel tank should be

emptied and cleaned.

FUELING

• Always shut off the cut-off saw before fueling.

• Before fueling, clean the area around fuel cap to prevent dirt from contaminating the fuel.

Contamination of the fuel tank can lead to cut-off saw malfunction.

• Thoroughly mix the fuel in it’s container before fueling.

• Slowly open the fuel cap to release any pressure that may have built-up in the tank.

• After adding fuel, tighten the fuel cap carefully and secure with a wrench.

• FUEL MIXTURE: 25:1 gasoline/oil mixture.

OIL

US

Fl oz

GASOLINE

Liters

1 40

5 200

10 400

20 800

OIL

ml

11

Page 12

613GC OPERATOR’S MANUAL

OPERATION

STARTING AND STOPPING A CHAIN-BASED CUT OFF SAW

Never start a chain-based cut off saw without the guide bar,

WARNING

CAUTION

CAUTION

IMPORTANT

COLD ENGINE STARTING PROCEDURE

1. Toggle the ignition switch to the "ON" position and pull the

choke lever out.

2. Lock the throttle in the start position by depressing the trigger

(A) and trigger interlock (B) at the same time.

3. Depress and hold throttle lock button (C) while releasing the

trigger and trigger interlock in succession.

4. Press decompression valve (D).

5. Open the water valve ¼ turn.

6. Place the 613GC Cut-Off Saw on the ground making sure the

chain is free of any obstructions.

7. Place right foot on the base of the rear handle.

8. Place left hand on front handle.

9. With right hand, slowly pull starter handle until the starter

pawls engage.

10. Pull the starter cord (hard, fast, short pulls) until engine fires or

"pops" - should be 1 to 7 pulls.

11. Push the choke lever in.

12. Check decompression valve. Press if necessary.

13. Pull the starter cord until engine starts - should be 1 to 2 pulls.

14. When the engine starts, allow the engine to idle. Pull on the

throttle trigger several times to help warm up the engine.

15. Open the water valve completely.

Warm Engine Starting Procedure

diamond chain and side cover properly assembled. The clutch may

come loose and cause personal injury.

Always move a chain-based cut off saw at least 10 feet (3 m) away

from the fueling area before starting.

Place the chain-based cut off saw on clear ground. Ensure that

secure footing is established and diamond chain is not contacting

any objects.

C

B

A

Figure 1: Trigger, trigger interlock,

throttle lock

D

Figure 2: Decompression valve

1. Use the same procedure as starting cold engine, but DO NOT pull choke lever out. If choke is

used, the carburetor will flood with gas.

2. If the engine does not start in 3 hard, fast pulls with the throttle locked, unlock the throttle and pull

the starter cord 3 more times.

Note: To hold the trigger fully

and twist.

open it may be necessary to insert right foot into rear handle opening

12

Page 13

613GC OPERATOR’S MANUAL

OPERATION

PRE-CUT CHECKLIST

• Proper Diamond Chain Installation: The bumper should lead the segment into the cut.

• Proper Diamond Chain Tension: The diamond chain should be tight but easily pulled around the

guide bar by hand.

• Ensure all safety devices are properly mounted and functional; and that all controls are in proper

working order.

• Be sure there are no obstructions (plumbing, electrical conduit, air ducts) and no unnecessary people

present.

• Always wear protective clothes, including hard hat, eye protection, hearing protection, non-slip safety

boots, gloves, and avoid wearing loose fitting clothing.

• Diamond chains with SealPro

PLANNING THE CUT

• Outline the cut with a permanent marker for a visual cutting guide.

• Avoid pinching the guide bar and diamond chain. Always cut the bottom of an opening first, then top,

and then the sides. Save the easiest cut for last.

• For the straightest cuts use the “Step Cut” method. First score the entire cut line approximately a

half-inch deep using the nose of the guide bar. Next deepen the cut by about two inches. Then

plunge all the way through and complete the cut using the Wallwalker

• Be sure cut concrete cannot fall and injure operator or bystanders. Concrete is very heavy, one cubic

foot = 12”x12”x12” = 150 lbs. (30cm x 30cm x 30cm = 68kg).

• Check for live electrical wiring near the cutting area or in the concrete to avoid electrocution.

®

require a minimum water pressure of 20 psi (1.4 bar).

®

.

13

Page 14

613GC OPERATOR’S MANUAL

®

OPERATION

CUTTING WITH THE 613GC CUT-OFF SAW

To start a cut, hold trigger on full throttle and slowly plunge the nose of the guide bar straight into the wall.

Lengthen the cut and engage the point of the fixed Wallwalker

®

. Use the fixed Wallwalker® as a pivot

point and pull up on the rear handle to rotate the guide bar into the cut.

CUTTING TIPS

• Always operate the chain-based cut off saw at full throttle. Apply enough feed force so that the free

running RPM drops 20 to 30%. If too much force is applied, the cut-off saw will lug or stall. The

diamond chain will not have enough speed to cut effectively. If too little feed force is applied, the

diamonds will skid and glaze over.

• For straighter cuts use the “step cut” method. First score the entire cut line with the nose of the guide

bar approximately ½ inch (12mm) to 1 inch (25mm) deep. Next, deepen the cut by about 2 inches

(50 mm). This groove will help guide the guide bar for a straight cut. Then plunge all the way through

and complete the cut using the fixed Wallwalker

®

.

• Plunge cut instead of starting at the top of the wall. This will reduce chatter, extend diamond life,

create a straighter cut and more quickly enable the use of the fixed Wallwalker

• Use the fixed Wallwalker

fulcrum that can be used to apply additional force when cutting. To use correctly, plunge into the wall

and simply engage the point of the fixed Wallwalker

®

to cut efficiently and reduce user fatigue. The fixed Wallwalker® is a

®

into the cut and pry upward with the rear handle.

®

.

Wallwalker

point

• As the cut-off saw begins to rotate up, feed force is developed down the line of the intended cut.

Once the cut-off saw is fully rotated upwards, pull the cut-off saw out of the cut a few inches and reengage the pick into the cut and repeat.

• When cutting heavy rebar, slowly ”rock” the cut-off saw so that you’re always cutting concrete as well

as steel. This will help keep the diamonds exposed. Also, expect less diamond chain life when

cutting heavy rebar.

• Expect more diamond chain stretch when making nose buried cuts for extended periods of time, as

the diamond chain does not have a chance to “throw” the slurry away from the nose of the guide bar.

• If the cut-off saw begins to cut consistently crooked, turn the guide bar over and use the other side.

Dress worn rails with belt grinder. Note: The normal life of a guide bar is 2 to 3 diamond chains.

Heavy rebar can shorten guide bar life.

• When using a new diamond chain, you can increase the cutting speed by “opening up the diamonds”.

Make a few cuts in an abrasive material such as a cinder block.

14

Page 15

613GC OPERATOR’S MANUAL

OPERATION

SYSTEM CLEAN-UP

• After cutting, run the cut-off saw for at least 15 seconds with the water on to flush slurry and debris

from diamond chain, guide bar and drive sprocket.

• Wash concrete slurry from cut-off saw assembly.

• Avoid getting any water in the carburetor or exhaust system. If water enters exhaust port, point the

guide bar tip down and pull the starter handle several times to expel water from muffler.

• Remove guide bar and diamond chain. Flush out the chain tensioner with high water pressure and

lube with grease.

• After cleaning the cut-off saw, spray the entire saw body, diamond chain, guide bar, and drive

sprocket with a lightweight oil. Using lightweight oil on the cut-off saw will minimize rust and help

reduce slurry build up.

15

Page 16

613GC OPERATOR’S MANUAL

MAINTENANCE

AFTER EACH USE

1. Rinse the saw, guide bar and diamond chain with water.

2. Follow instructions on the Daily Maintenance Label, located on the air filter cover.

3. Inspect and tighten all fasteners as necessary.

4. Inspect drive sprocket for tooth wear and replace if tooth tips are pointed.

5. Inspect the starter cord. Replace if frayed.

6. Clean air filter with solvent. Inspect the air filter for holes. Replace as necessary.

7. Spray saw, guide bar, and chain with lightweight oil.

8. Grease the chain tensioner.

AFTER 10 HOURS OF USE

1. Remove the starter cover and lubricate the starter recoil spring. Clean the flywheel fins and the

starter pawls with a wire brush, then grease the starter pawls.

2. Remove the spark plug and clean with a wire brush. Check the electrode gap.

The correct gap is 0.020 inches (0.5mm).

AFTER 40 HOURS OF USE

1. Change the spark plug. Adjust the electrode to 0.020 inches (0.5mm).

2. Check the fuel filter located inside the fuel tank. Clean or replace if clogged

and the 613GC Cut-Off Saw will keep running at its very best.

Follow these simple maintenance guidelines

MAINTENANCE

16

Page 17

613GC OPERATOR’S MANUAL

MAINTENANCE

AIR FILTER

IMPORTANT

• The air filter (Figure 1) should be free of holes and white in color.

• Replace air filter when dirty.

STARTER HOUSING ASSEMBLY

IMPORTANT

• After each usage, thoroughly flush the starter housing

assembly with water. (Figure 2)

• Lubricate the starter pawls by spraying light weight oil

into the starter housing through the vents. (Figure 2)

• Check the starter cord for fraying, replace if necessary.

STARTER CORD REPLACEMENT

• Remove the 4 screws that attach the starter assembly to the

crankcase.

• Pull the cord out approximately 8” and lift the cord up into

the notch in the pulley (Figure 3). Relax the recoil spring by

placing thumb on pulley and gently allow the pulley to unwind

entirely. Undo the screw in the center of the pulley and

remove the pulley.

• Thread the new cord through the starter cover and fasten it

to the pulley. Wind 4 turns of the starter cord on to the pulley.

Assemble the starter pulley against the recoil spring so the

end of the spring engages into the backside of the pulley.

Install the retaining screw in the center of the pulley

The air filter is made from a nylon micro mesh. It must be kept clean

for the engine to operate properly. If the cut-off saw is not reaching

full RPM, most likely the air filter is dirty.

It is common for concrete slurry to get inside the starter housing

assembly during cutting. This can cause the starter pawls to stick

and not engage when the rope is pulled.

Figure 3

Figure 1

Figure 2

17

Page 18

613GC OPERATOR’S MANUAL

MAINTENANCE

TENSIONING THE RECOIL SPRING

• Lift the starter cord up into the notch on the starter pulley

(Figure 4) and wind the pulley clockwise 5 full turns.

Remove the cord from the pulley notch while pinching the

pulley. Release the pulley slowly allowing it to wind the rope

counterclockwise onto the pulley.

• When completed, the starter handle should be pulled back

in the starter housing under it’s own tension.

• To check that the starter pulley was assembled correctly,

pull the cord completely out of the housing, grip the pulley

and turn clockwise another ½ turn. If the pulley turns another

½ turn it is correctly assembled.

STARTER HOUSING ASSEMBLY

• To reattach the starter housing, first pull the starter cord

out, then hold the starter housing against the crankcase

(Figure 5). Slowly release the starter cord to enable the

pulley to fit between the pawls.

• Insert and tighten the screws. Use blue Loctite # 242.

Figure 4

Figure 5

18

Page 19

613GC OPERATOR’S MANUAL

p

MAINTENANCE

CHAIN TENSIONER

The chain tensioner (Figure 1) can become clogged with concrete

IMPORTANT

Most Common Causes of Tensioner Damage:

• Side cover nuts are not tight enough. Side cover nuts

should be torqued to 20 ft-lbs (27Nm).

• Chain tensioning is attempted without loosening the

side cover nuts.

• Concrete debris in tensioner pocket.

DRIVE SPROCKET

IMPORTANT

IMPORTANT

A rim sprocket system (Figure 2) consists of a clutch cup w/

splined adapter and a rim sprocket. When the rim sprocket

wears out, it is the only part that needs to be replaced. The

clutch cup w/ splined adapter is a wear item that needs

replacement after 3 to 5 rim sprockets have been used.

• Inspect the rim the rim sprocket for wear. Replace the rim

sprocket if the drive teeth become pointed.

• Check the drive sprocket bearing by spinning clutch cup.

Replace the bearing if it is worn out.

• The needle bearing on the drive shaft must be greased

regularly, use high quality water-resistant bearing grease.

slurry during cutting. After each use thoroughly flush the chain

tensioner with water. Then apply a liberal amount of grease.

The drive sprocket (rim sprocket) is a wear item and should be

replaced every 2-3 diamond chains.

The needle bearing inside the splined adapter should be greased

regularly and should be replaced with each new clutch cup.

Figure 1

Clutch

Cu

Figure 2

Chain

Tensioner

Splined

Adapter

Rim

Sprocket

19

Page 20

613GC OPERATOR’S MANUAL

MAINTENANCE

DRIVE SPROCKET REMOVAL

• Remove the side cover, guide bar, diamond chain, and

clutch slurry shield.

• Remove the spark plug and insert the piston stop (supplied

with each cut-off saw) into the spark plug hole. Pull the starter

cord slowly until the piston stops. (Figure 1) Use a 19mm

wrench to turn the clutch clockwise and remove.

• Slide the clutch cup/drive sprocket assembly off the shaft.

Remove the needle bearing and inspect for heavy wear

or damage.

DRIVE SPROCKET INSTALLATION

• Slide the rim sprocket onto the splined adapter,

either side out.

• Apply a liberal amount of grease to the needle bearing.

• Place the thin metal washer onto drive shaft. Slide the

needle bearing and clutch cup w/rim sprocket onto shaft

(Figure 2).

• Install the clutch by turning it counter clockwise on the

drive shaft and firmly tighten. Replace the clutch slurry shield.

Installation of drive sprocket assembly is now complete.

SPARK PLUG

• A worn or fouled spark plug can cause a loss of power,

difficulty starting or rough idle (Figure 3).

• If the spark plug is dirty clean it with a wire brush and

check the electrode gap. Readjust if necessary. The correct

gap is (020” (0.50mm)

• The spark plug should be replaced after 40 hours of

operation or earlier if the electrode is badly corroded.

• Always use the recommended spark plug type,

Using the wrong spark plug can severely damage the

piston and cylinder. (Champion RCJ7Y).

Figure 1

Figure 2

Figure 3

20

Page 21

613GC OPERATOR’S MANUAL

MAINTENANCE

CARBURETOR

• The function of the carburetor is to mix fuel with air.

Adjustments other than Idle speed should be made by

a servicing dealer.

• Before adjusting the engine idle speed, make sure the air

filter is clean and the engine is warmed up.

T – Idle Screw is adjusted so that the engine idles smoothly

but the clutch does not engage.

• If cut-off saw has been running satisfactorily and there is a gradual decrease in power

and drop in RPM at full throttle, the filter may have become dirty or saturated with

water. .

T

21

Page 22

613GC OPERATOR’S MANUAL

MAINTENANCE

GUIDE BARS

• The guide bar is designed to be used on both sides. If the cut is consistently leading to one side, turn

the guide bar over to expose a new set of guide rails.

• A table mounted belt or disc sander can be used to square the rails of a worn guide bar. A badly worn

guide bar can quickly damage an expensive diamond chain. If the diamond chain is touching the

bottom of the guide bar groove, replace the guide bar.

• Check the guide bar for straightness. Minor adjustments can be made by bendi ng the guide bar

slightly.

• Proper diamond chain tension will extend guide bar life. See page 9.

• Under some circumstances, especially low water pressure, the sprocket nose can wear out before the

guide bar body. Sprocket nose replacement kits may be purchased from an Authorized Dealer

(part #70249).

• Spray the diamond chain and guide bar with lightweight oil for storage.

• Store guide bar with the sprocket nose up.

• Periodically clean the water ports inside the groove of the guide bar using a small diameter piece of

wire.

• The guide bar is solely a guide track for the diamond chain. Never use the guide bar to lift, twist or pry

concrete material.

22

Page 23

613GC OPERATOR’S MANUAL

TROUBLESHOOTING

• CUT-OFF SAW WON’T REACH FULL RPM - Air filter or pre filter may be dirty.

• SLOW DIAMOND CHAIN SPEED – Diamond chain tension too tight. Diamond chain sh ould always

be able to be pulled around the guide bar by hand. It is normal for the diamond chain drive links to

hang below the guide bar.

• POOR CUTTING SPEED - Diamonds may be “glazed over”. Make a few cuts in an abrasive material

such as a cinder block to expose the diamonds.

• CHAIN TENSIONER BREAKAGE - Side cover nuts are not tight enough. Torque to 20 ft-lbs

(27Nm).

• WATER NOT FLOWING - Water hose is kinked or supply is not turned on.

• WON’T START – Turn ignition switch on or possible defective spark plug.

• WON’T START – Low compression, less than 120 psi (8 bar). Possible incorre ct fuel mixture.

Reference: new = 150 to 180 psi (10 to 12 bar)

used = 140 to 160 psi (9 to 11 bar)

• DIFFICULT TO START – Possible flooded engine. Turn ignition switch on, push choke in, hold

throttle on full with foot and pull starter cord until engine starts.

• DIFFICULT TO START – Possible fouled spark plug. Remove spark plug, clean with wire brush and

re-gap.

• DIAMOND CHAIN BREAKAGE – Diamond chain installed ba ckwards. Bumpers should lead

segments into the cut.

• DIAMOND CHAIN BREAKAGE – Not enough feed pre ssure whil e cutting. Avoid letting the cut-off

saw bounce and chatter.

visit our website at www.icsbestway.com.

Further questions?

Call 1-800-321-1240 or

23

Page 24

613GC OPERATOR’S MANUAL

REFERENCE

APPROXIMATE CUTTING RATES

Material Cutting Rate

Hard aggregate & Steel 15-25 sq-in/min (90-160 sq-cm/min)

Medium aggregates 20-30 sq-in/min (160-190 sq-cm/min)

Masonry, Soft aggregates 30-50 sq-in/min (190-320 sq-cm/min)

INCH-FOOT DEFINITION

An in-ft is a measure of how much material is to be cut.

An in-ft is defined as: depth in inches times length in feet.

Note: 129 in-ft = 1m

Example: How many in-ft are in this doorway?

1. Determine the depth of the cut in inches.

For this example, 8 inches.

2. Determine the length of the cut in feet.

3+7+3+7=20 feet

3. Multiply the two numbers

8 in x 20 ft = 160 in-ft

2

24

Page 25

613GC OPERATOR’S MANUAL

NOTES

25

Page 26

613GC OPERATOR’S MANUAL

ICS, Blount Inc. 4909 SE International Way

Portland, Oregon 97222

TEL 800-321-1240 FAX 503-653-4393

www.icsbestway.com

26

Loading...

Loading...