Page 1

410-120

1

ORIGINAL INSTRUCTION MANUAL

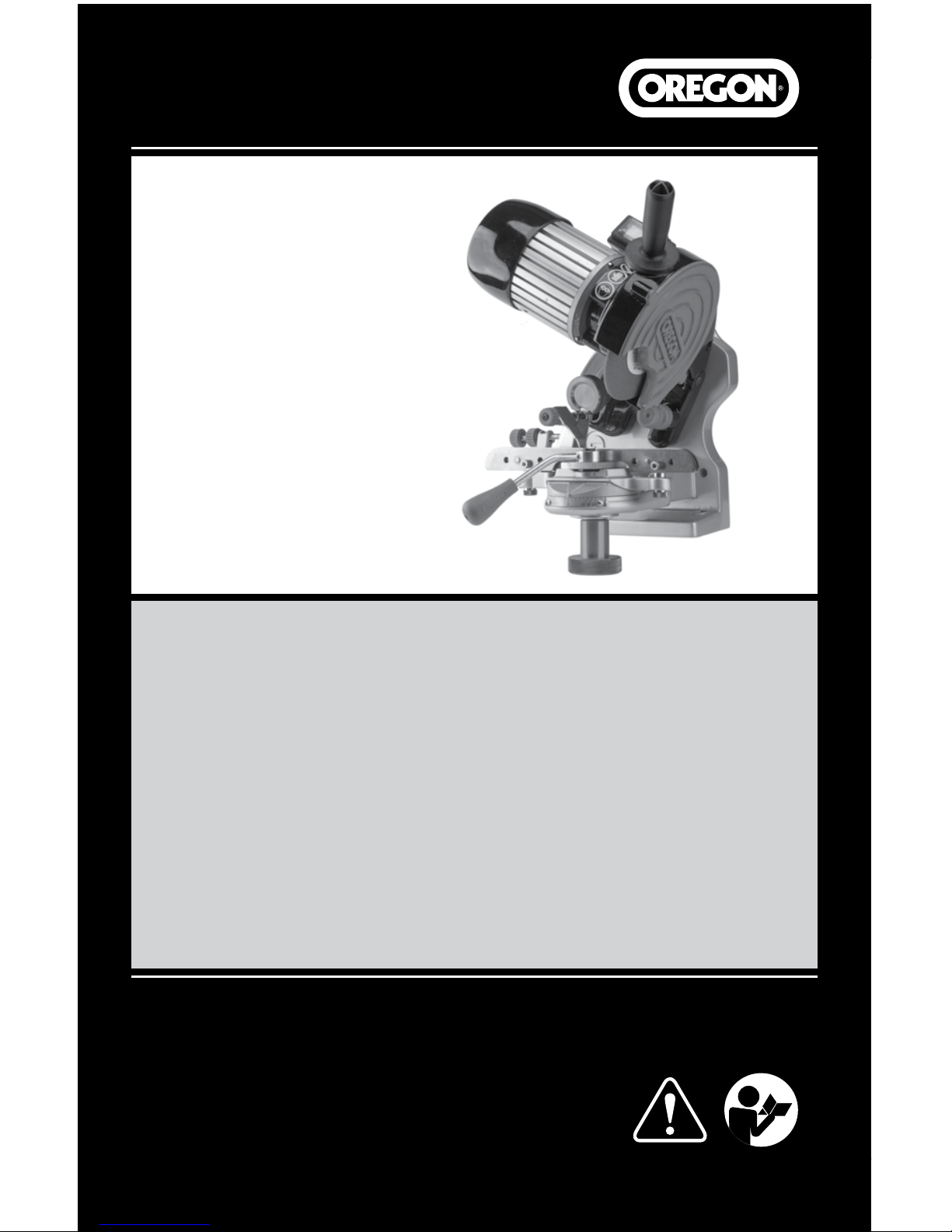

Bench Chain Grinder Model 410-120

MANUEL D’INSTRUCTIONS ORIGINAL

Meuleuse électrique pour chaînes de scie

à moteur modèle 410-120

MANUAL ORIGINAL DE INSTRUCCIONES

Afiladora eléctrica para cadenas

de motosierra modelo 410-120

Page 2

410-120 410-120

2 32

ENGLISH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WARNING: READ AND UNDERSTAND ALL SAFETY WARNINGS AND ALL INSTRUCTIONS. FAILURE TO FOLLOW THE

WARNINGS AND INSTRUCTIONS MAY RESULT IN ELECTRIC SHOCK, FIRE AND/OR SERIOUS INJURY.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

This instruction manual contains translations of a manual drafted in English and are provided to assist those

who do not speak English as their first language. Being a technical writing, some terms may not have a like or

equivalent meaning as translated. Therefore, you should not rely on this translation, and should cross-reference

the English version, where relying on the translated instructions could result in harm to your person or property.

FRANÇAIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

AVERTISSEMENT: VEUILLEZ LIRE ET COMPRENDRE TOUS LES AVERTISSEMENTS DE SÉCURITÉ ET

TOUTES LES INSTRUCTIONS. LE NON-RESPECT DES AVERTISSEMENTS DE SÉCURITÉ ET DES INSTRUCTIONS

PEUT ENTRAÎNER UNE DÉCHARGE ÉLECTRIQUE, UN INCENDIE ET/OU DES BLESSURES GRAVES.

CONSERVEZ L’ENSEMBLE DES AVERTISSEMENTS ET INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

Ce manuel d’instructions est une traduction d’un manuel rédigé en anglais, fournie pour aider ceux dont l’anglais

n’est pas la langue maternelle. Étant donné qu’il s’agit d’un document technique, certains termes peuvent ne pas

avoir de signification similaire ou équivalente lorsqu’ils sont traduits. Par conséquent, vous ne devez pas vous fier à

cette traduction et devriez consulter la version anglaise également, au cas où les instructions traduites pourraient

provoquer des blessures ou des dommages matériels.

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ADVERTENCIA: LEA Y COMPRENDA TODAS LAS ADVERTENCIAS DE SEGURIDAD Y LAS INSTRUCCIONES.

LA OMISIÓN EN SEGUIR ESTAS ADVERTENCIAS E INSTRUCCIONES PODRÍA OCASIONAR UNA DESCARGA

ELÉCTRICA, UN INCENDIO Y/O LESIONES PERSONALES GRAVES.

GUARDE TODAS LAS ADVERTENCIAS E INSTRUCCIONES PARA REFERENCIA FUTURA.

Este manual de instrucciones contiene traducciones de un manual redactado en inglés y se provee para ayudar a

aquellas personas que no hablan inglés como su primer idioma. Dado que el manual es un documento técnico, es

posible que algunos términos no tengan un significado similar o equivalente al traducirlos. Por lo tanto, no debe

confiar en esta traducción y debe consultar la versión en inglés; confiar en las instrucciones traducidas podría

provocar lesiones personales o daños materiales.

Page 3

410-120 410-120

4 5

© Blount, Inc. Pricing and specifications subject to change without notice. All rights reserved.

OREGON® is a registered trademark of Blount, Inc. in the United States and/or in other countries.

NAMES AND TERMS

Skilled Technician: a person who is generally employed by the service center and who is trained to carry

out extraordinary maintenance jobs and repairs on the machine.

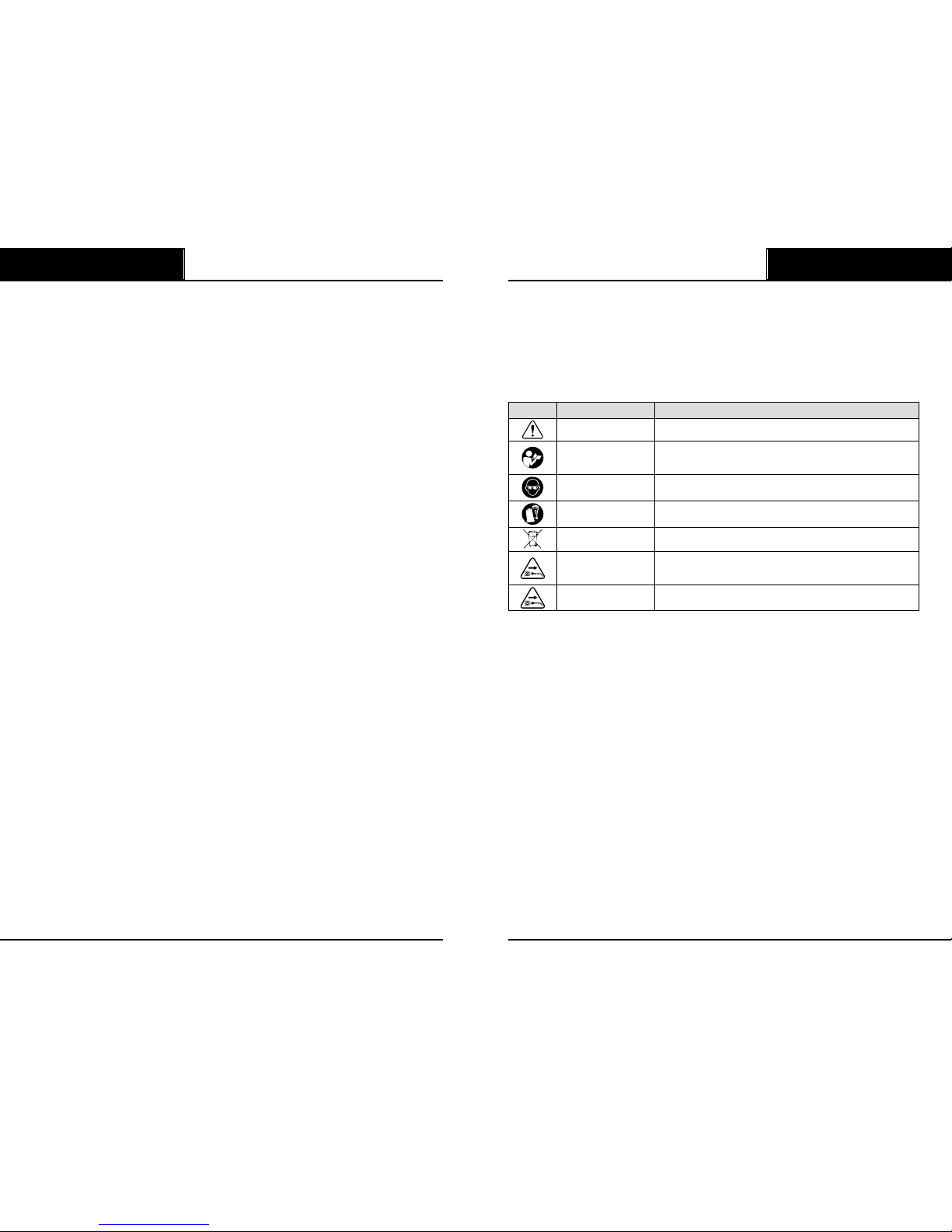

SYMBOLS AND LABELS

These symbols and labels appear on the tool and/or in this manual.

SYMBOL NAME EXPLANATION

SAFETY ALERT

SYMBOL

INDICATES THAT THE TEXT THAT FOLLOWS EXPLAINS A

DANGER, WARNING, OR CAUTION.

READ INSTRUCTIONS

THE ORIGINAL INSTRUCTION MANUAL CONTAINS IMPORTANT

SAFETY AND OPERATING INFORMATION. READ AND FOLLOW

THE INSTRUCTIONS CAREFULLY.

WEAR EYE

PROTECTION

WEAR EYE PROTECTION.

WEAR HAND

PROTECTION

WEAR GLOVES WHEN HANDLING SAW CHAIN.

DO NOT DISPOSE

DO NOT THROW IN HOUSEHOLD WASTE. TAKE TO AN

AUTHORIZED RECYCLER.

DAMAGED CABLE

INSPECT THE POWER CORD REGULARLY FOR DAMAGE.

REMOVE THE PLUG FROM THE MAINS IMMEDIATELY IF THE

CABLE IS DAMAGED OR CUT.

UNPLUG BEFORE

MAINTENANCE

UNPLUG BEFORE PERFORMING ANY MAINTENANCE.

Table of Contents

NAMES AND TERMS ...................................................................... 5

SYMBOLS AND LABELS ................................................................... 5

SAFETY INFORMATION ...................................................................6

SAFETY RULES AND PRECAUTIONS ............................................................6

SETTING UP THE GRINDER .....................................................................8

ELECTRICAL CONNECTION ....................................................................8

GROUNDING INSTRUCTIONS ..................................................................8

GENERAL INFORMATION ......................................................................9

USING AND KEEPING THE OPERATOR’S MANUAL ...............................................9

SAFETY DEVICES ..............................................................................9

INTENDED USE ................................................................................9

TECHNICAL DATA .............................................................................9

PART DESCRIPTION .....................................................................10

GRINDING ANGLES CHART .............................................................. 12

INSTRUMENTAL MEASUREMENTS ........................................................12

PREPARING FOR USE ....................................................................13

MOUNTING THE BASE UNIT - MOTOR UNIT ...................................................13

ASSEMBLY ..................................................................................14

CHOOSING AND INSTALLING THE GRINDING WHEEL .........................................14

SETTING THE SHARPENING ANGLES .....................................................17

FOR RIGHT-HAND CUTTERS WITHOUT A DOWN ANGLE (0°) ...................................18

FOR RIGHT-HAND CUTTERS WITH A DOWN ANGLE ...........................................19

FOR LEFT-HAND CUTTERS WITHOUT A DOWN ANGLE (0°) .................................... 21

FOR LEFT-HAND CUTTERS WITH A DOWN ANGLE ............................................ 22

PLACING THE CHAIN IN THE VISE .........................................................24

OPERATING INSTRUCTIONS ............................................................. 26

SHARPENING THE CHAIN .................................................................... 26

GRINDING WHEEL DRESSING FOR SETTING THE DEPTH GAUGE ............................... 28

SETTING THE DEPTH GAUGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

STOPPING AND SHUTTING DOWN .......................................................30

MAINTENANCE AND CLEANING ..........................................................30

DEMOLITION AND DISPOSAL ............................................................30

WARRANTY AND SERVICE ...............................................................31

TROUBLESHOOTING ....................................................................32

ILLUSTRATED PARTS LIST ...............................................................34

TABLE OF CONTENTS

NAMES AND SYMBOLS

TABLE OF CONTENTS NAMES AND SYMBOLS

Page 4

410-120 410-120

6 7

SAFETY INFORMATION

FOR YOUR OWN SAFETY READ THIS OPERATOR’S

MANUAL BEFORE OPERATING GRINDER

Keep this manual for future reference. To

ensure the correct use of the grinder and to

prevent accidents, do not start working without

having read this manual carefully. The manual

explains how the various components work

and provides instructions for carrying out the

necessary checks and maintenance operations.

SAFETY RULES AND PRECAUTIONS

WARNING The use of accessories or

attachments not recommended by the

manufacturer may result in a risk of injury to

operator or bystander. Any maintenance operation

not described in this manual must only be

carried out by an AUTHORIZED service center.

CAUTION The following instructions

should be carefully followed in order to

reduce the risk of kickback resulting from

improperly sharpened saw chain.

WARNING Replace cracked or

damaged grinding wheel immediately.

Serious injury to operator or bystander

could result from a damaged wheel.

USERS

The grinder must only be used by adults.

Users must be in good physical condition

and familiar with the instructions for use.

KEEP BYSTANDERS AND CHILDREN AWAY

All bystanders should be kept at a

safe distance from work area.

WEAR PROPER APPAREL

Never wear loose clothing, bracelets, neckties, rings

or any other jewelry that could come into contact

or get caught with the grinding wheel or any other

moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

ALWAYS USE SAFETY GLASSES

AND GLOVES

Always wear gloves and protective eyewear

while operating the grinder and while retouching

the grinding wheel using the dressing stone.

Also use face or dust mask if cutting operation

is dusty. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

NEVER STOP THE WHEEL WITH YOUR HANDS

Never attempt to stop the rotation of the

grinding wheel with your hands.

DISCONNECT TOOLS BEFORE SERVICING

Make sure the plug is disconnected when tting

or changing the grinding wheel and during any

other operation of maintenance or transport.

KEEP GUARDS IN PLACE AND

IN WORKING ORDER

Never start the grinder without

the wheel guards in place.

REMOVE ADJUSTING KEYS AND WRENCHES

Make sure that keys and adjusting wrenches

are removed from tool before turning it on.

DON’T FORCE TOOL

It will do the job better and safer at the

rate for which it was designed. Each

grinder has a plate indicating:

– Size of arbor: Ø .866" (22 mm)

– No-load speed in revolutions

per minute: RPM 3150

– Always read operator’s manual

before operating the machine

– Always wear eye and face protection

– Always use the proper grinding wheel

Also make sure that the voltage and frequency

indicated on the plate applied to the grinder

correspond to those of the mains hook-up.

REDUCE THE RISK OF

UNINTENTIONAL STARTING

Always make sure that the start-up

switch is in the “0” (OFF) position before

connecting the plug to the outlet.

NEVER USE CABLES, PLUGS OR

EXTENSION CABLES THAT ARE

DEFECTIVE OR NON-STANDARD

See “Minimum Extension Cord Gauges” table

on page 12 Remove the plug from the mains

immediately if the cable is damaged or cut;

for cable repair or replacement, contact your

authorized dealer or service center. The power

supply cable is complete with terminals – with

protection. The internal electrical connection

consists of inserting the feeding cable terminals

directly in the switch. The electrical connection

to the mains shall be made in such a way as

to prevent damage by people or vehicles

which could endanger both them and you.

KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents.

Make sure that the grinding wheel working

area is free of tools or other objects before

starting up the grinder. Frequently clean

grinding dust from beneath grinder.

DON’T USE IN DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well-lighted.

CHECK THE POSITION OF THE

CABLE DURING OPERATION

Make sure that the cable remains outside

the range of action of the grinding wheel

and is not under tension. Never operate in

the vicinity of other electrical cables.

DIRECTION OF FEED

Feed work into a blade or cutter against

the direction of rotation of the blade or

cutter only. Never advance the chain with

your left hand until the grinding wheel has

moved entirely outside the work area.

MAKE WORKSHOP CHILD PROOF

Use padlocks, master switches. Do not

allow anyone but the user to remain in the

vicinity of the grinder while it is operating

or to touch the grinder supply cable.

ALWAYS KEEP THE HAND GRIPS

CLEAN AND DRY

SECURE GRINDING WHEEL

Make sure the grinding wheel is secured

before starting the grinder. Do not

over-tighten the wheel nut.

SECURE WORK

Make sure that the machine is stable

and rmly secured. Use the vise to hold

chain. This frees both hands for moving

the wheel down to grind the chain.

DON’T OVERREACH

Keep proper footing and balance at all times.

NEVER STAND ON TOOL

Always work in a stable and safe position. Serious

injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

ALWAYS FOLLOW MAINTENANCE

INSTRUCTIONS

CHECK FOR DAMAGED PARTS

Before using the grinder, check to make sure

that all the devices, those for safety and others,

are in good working order. A guard, a wheel or

other part that is damaged should be carefully

checked to determine that it will operate properly

and perform its intended function – check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may aect its operation. A guard,

a wheel or other part that is damaged should

be properly repaired or immediately replaced.

USE RECOMMENDED ACCESSORIES

Consult the operator’s manual for recommended

accessories. The use of improper accessories may

cause risk of injury to persons. Use only anges

furnished with the grinder. To guarantee the

ecient and consistent operation of your grinder,

remember that any worn or broken parts must

only be replaced using ORIGINAL SPARE PARTS.

USE ONLY RECOMMENDED GRINDING WHEELS

CHECK YOUR MACHINE

Never work with a damaged, poorly repaired,

incorrectly tted, or arbitrarily modied grinder. Do

not remove, damage, or disable any safety device.

USE THE RIGHT TOOL

Never use the grinder as a cutter or for

grinding objects other than saw chains.

Don’t force tool or attachment to do a

job for which it was not designed.

EXPERT USERS ONLY

Only lend your grinder to expert users who

are familiar with its operation and correct

use, and always give them the operator’s

manual to read before they start a job.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and

safest performance. Follow instructions for

lubricating and changing accessories.

STORE YOUR GRINDER IN A DRY PLACE

Keep it o the ground and out

of the reach of children.

NEVER LET YOUR GRINDER BE

EXPOSED TO RAIN OR DAMPNESS

NEVER USE THE GRINDER IN AN EXPLOSIVE

OR INFLAMMABLE ATMOSPHERE

TAKE THE GRINDER TO YOUR DEALER

When your grinder is not in working order, do not

abandon it on the work site or elsewhere. Take it to

your dealer who will store or dispose of it correctly.

CONSULT YOUR DEALER

Always consult your dealer for any clarication

or important maintenance or repair operation.

NEVER JERK THE CABLE TO DISCONNECT

IT FROM THE OUTLET

Keep the cable away from heat,

oil, and sharp objects.

USE PROPER EXTENSION CORD

Make sure your extension cord is in good

condition. When using an extension cord, be

sure to use one heavy enough to carry the

current your product will draw. An undersized

cord will cause a drop in line voltage resulting

in loss of power and overheating.

SAFETY INFORMATION SAFETY INFORMATION

Page 5

410-120 410-120

8 9

The table below shows the correct size to use

depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Minimum Extension Cord

Gauges for 410-120 Grinder

Length Gauge, AWG

25 ft. / 7.6 m 18

50 ft. / 15.2 m 16

100 ft. / 30.5 m 16

150 ft. / 45.7 m 14

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power o. Do not leave tool until

it comes to a complete stop.

SETTING UP THE GRINDER

CAUTION The grinder must only be used in a

place that is protected from dust and dampness,

is well-lit, out of the reach of children, and away

from gases or other ammable or explosive liquids.

The grinder must be situated near a

normal grounded electrical outlet. Avoid

using dangerous extension cables.

ELECTRICAL CONNECTION

– Make sure the electrical system power

supply complies with the values

written on the rating nameplate.

– The power supply voltage must not dier

from that written on the nameplate by ±5%.

– The connection to the electric mains must be

prepared subject to current standards in force

in the country in which the machine is used.

– The mains used for the machine must be

grounded, have an adequate fuse, and must be

protected by a ground fault protection device

with tripping sensitivity no higher than 30 mA.

GROUNDING INSTRUCTIONS

A. In the event of malfunction or breakdown,

grounding provides a path of least resistance

for electric current to reduce the risk of electric

shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and

a grounding plug. The plug must be plugged

into a matching outlet that is properly installed

and grounded in accordance with all local

codes and ordinances. Do not modify the plug

provided – if it will not t the outlet, have the

proper outlet installed by a qualied electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

The conductor with insulation having an outer

surface that is green with or without yellow

stripes is the equipment-grounding conductor.

If repair or replacement of the electric cord or

plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualied electrician or service

personnel if the grounding instructions are

not completely understood or if in doubt as

to whether the tool is properly grounded.

Use only 3-wire extension cords that have

3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug. Repair or replace

damaged or worn cord immediately.

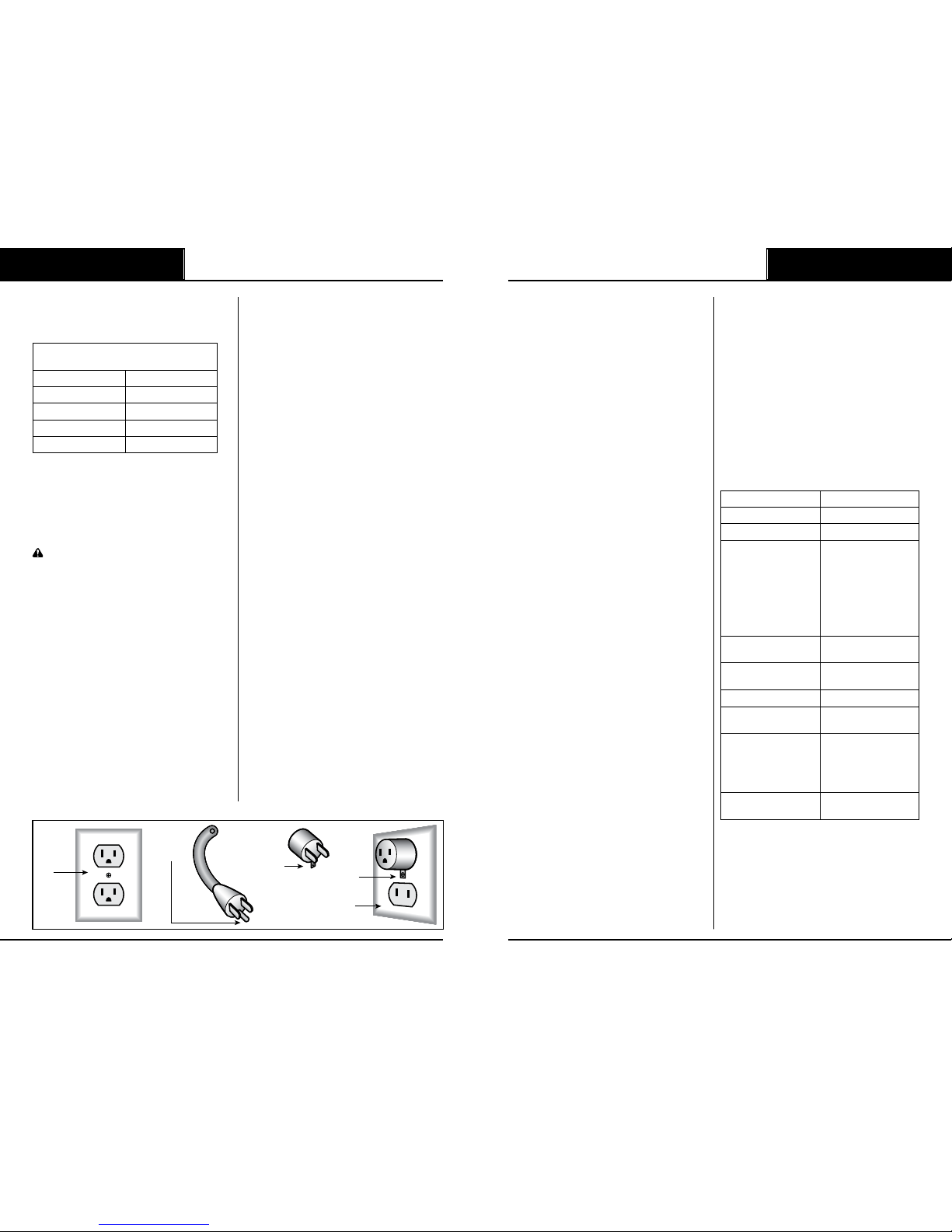

B. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

less than 150V~. This tool is intended for use on

circuit that has an outlet that looks like the one

illustrated in FIG. A. The tool has a grounding

plug that looks like the plug illustrated in FIG. B. A

temporary adapter, which looks like the adapter

illustrated in FIG. C, may be used to connect this

plug to a 2-pole receptacle as shown if a properly

grounded outlet is not available. The temporary

adapter should be used only until a qualied

electrician can install a properly grounded outlet.

The Grounding Means green-colored rigid ear,

lug, and the like, extending from the adapter

must be connected to a permanent ground

such as a properly grounded outlet box.

GENERAL INFORMATION

The manufacturer is not liable for

damages in the following cases:

– Failed observance of the

instructions given herein;

– Use of the machine other than that

described in the “INTENDED USE” section;

– Failure to use in compliance with current

standards on Health & Safety at the workplace;

– Incorrect installation;

– Lack of scheduled maintenance;

– Modications or jobs that are not

authorized by the manufacturer;

– Use of non–original or inadequate spare parts;

– Repairs that are not carried out by a specialist.

USING AND KEEPING THE

OPERATOR’S MANUAL

The characteristics and the information

given in this manual are merely indicative.

The manufacturer reserves the right to add

any modications to the grinder considered

necessary at any time. It is forbidden to

reproduce any part of this document without

authorization on behalf of the manufacturer.

The operator’s manual is an integral part of the

machine and must be kept in a safe place so that

it can be consulted whenever need be. If you

should lose your manual or it should deteriorate,

you can request your dealer or an authorized

service center for another copy. The manual

shall accompany the machine at all times.

SAFETY DEVICES

The grinder is equipped with the safety

devices illustrated on page 10.

– Shield guards: they protect the operator

from parts of the grinding wheel that may

come away during the sharpening process.

These guards must always be tted in place

when the machine is in use. Always make sure

the guards are ecient and tted properly.

Operator safety could be compromised if

the guards are damaged and/or cracked.

– Switch: the machine features a safety switch with

release coil. In the case of a sudden power failure,

the switch trips automatically and disconnects

the machine from the mains. The machine will

not start even if the power supply is suddenly

restored. You need to restart the grinder by

turning the on-o switch to the on position,“l”.

INTENDED USE

This machine is an electrical grinder for

saw chains used on chain saws.

– Use the machine exclusively for the types of

chains stated in the technical data chart.

– Do not use the machine to cut or grind

anything other than the chains envisaged.

– Secure the machine rmly to the bench or wall.

– The machine must not be used in

corrosive or explosive environments.

– Any other use is to be considered improper. The

manufacturer is not liable for damages following

improper or incorrect use of the machine.

TECHNICAL DATA

Model 410-120

Voltage 120V~ 60Hz

Rated power 220W

Grinding wheel

dimensions

Outside Ø :

5 3/4" (145 mm)

Inside Ø:

7/8" (22,2 mm)

Thickness:

1/8"(3.2 mm)

3/16"(4.7 mm)

1/4"(6.3 mm)

Maximum speed of

grinding wheel

3150 min

-1

Maximum power

of lamp

0,5W

Acoustic pressure level 77 dB(A)

Level of vibrations on

operating handle

< 2,5 m/s

2

Types of chains that

can be sharpened

1/4”

.325"

3/8"

.404"

3/4” (*)

Weight

(complete machine)

13.9 lbs/ 6.3 kg

(*) only with specic kit (vise+grinding

wheel) to be ordered separately.

FIG. A

Cover of

grounded

outlet box

Cover of grounded

outlet box

Adapter

Grounding

Means

Metal

Screw

FIG. B

Grounding

Pin

FIG. C

SAFETY INFORMATION SAFETY INFORMATION

Page 6

410-120 410-120

10 11

A

17

15

14

13

C

D

E

F

F

G

1

2

3

4

11

5

7

12

6

6

8

9

10

L

O

N

M

H

J

I

K

16

B

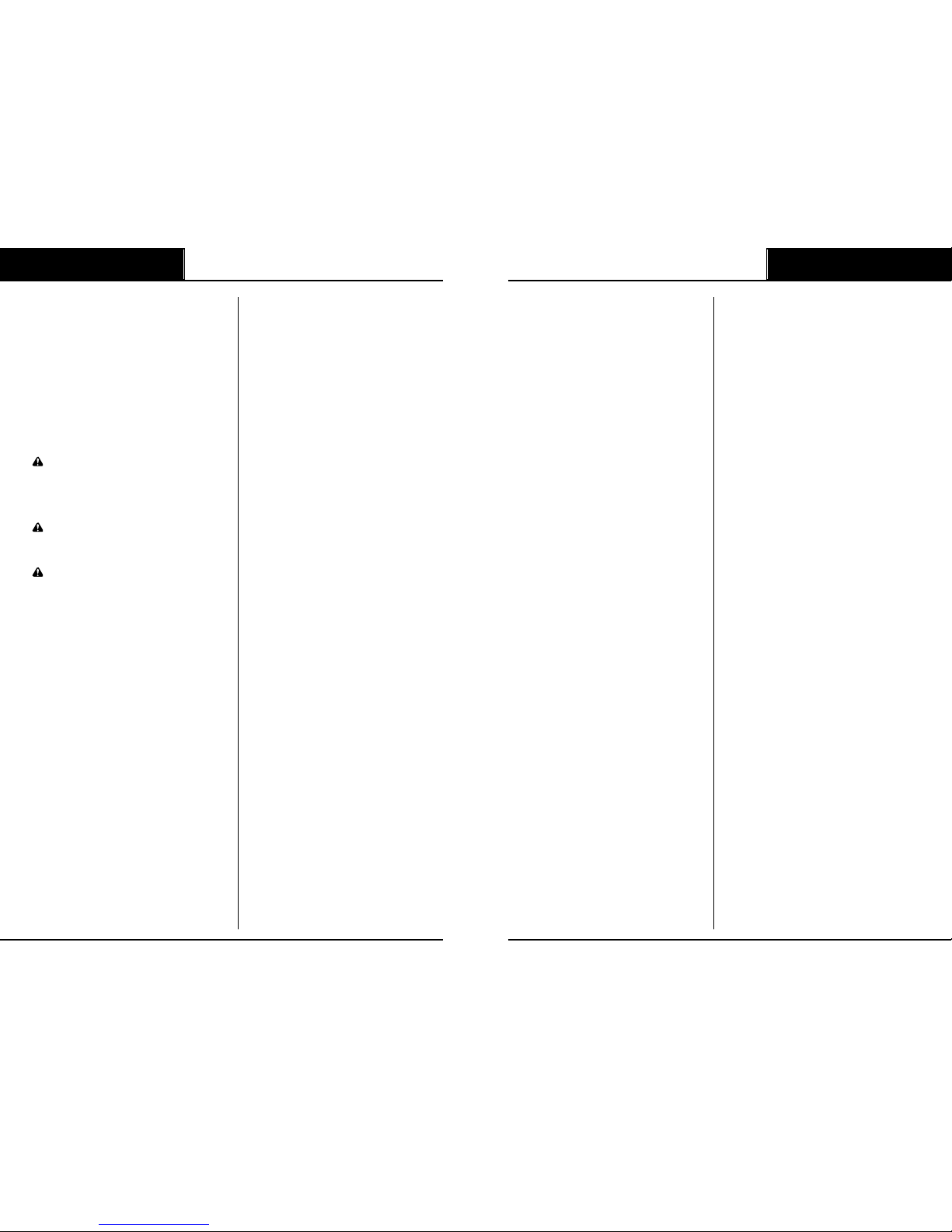

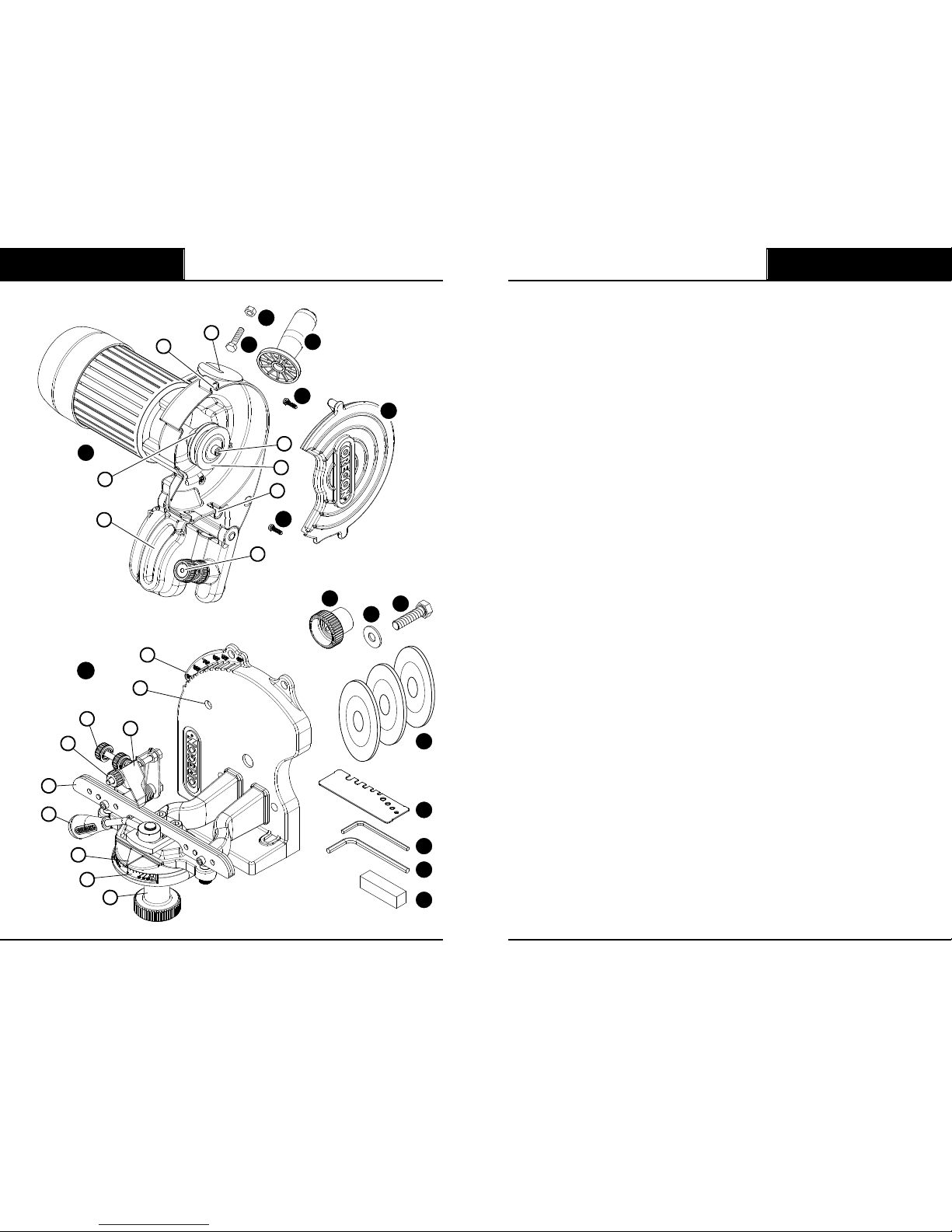

PART DESCRIPTION

The grinder is supplied already partially assembled.

A. Upper housing / motor unit

B. Base unit

C. Operating handle securing bolt

D. Operating handle securing nut

E. Operating handle

F. Guard securing screws (2)

G. Shield guard

H. Upper housing locking knob (for bench-mount only)

I. Upper housing securing bolt

J. Upper housing washer

K. Grinding wheels:

5 3/4" x 1/8"x 7/8" (145 x 3.2 x 22.2 mm)

5 3/4" x 3/16" x 7/8" (145 x 4.7 x 22.2 mm)

5 3/4" x 1/4" x 7/8" (145 x 6,3 x 22.2 mm)

L. Sharpening template

M. 4 mm Allen wrench

N. 5 mm Allen wrench

O. Dressing brick

1. Operating handle mounting slot

2. Grinding wheel hub

3. Grinding wheel ange screw

4. Grinding wheel ange

5. Height adjustment knob

6. Shield guard mounting holes

7. Upper housing / motor unit mounting slot

8. Saw chain cutter adjustment knob

9. Chain stop adjustment knob

10. Chain stop

11. Head tilt angle guide plate

12. Upper housing / motor unit mounting hole

13. Vise handle

14. Vise (chain jaws)

15. Vise rotate angle guide plate

16. Vise adjustment knob

17. Vise reference mark pointers

PART DESCRIPTION PART DESCRIPTION

Page 7

410-120

13

410-120

12

PREPARING FOR USE

ATTENTION Do not install the machine at eye level. You are recommended to install it at a height of no

more than 3.9 to 4.2 feet (1.2 – 1.3 m) from the oor. The machine can be bench mounted or wall mounted.

MOUNTING THE BASE UNIT - MOTOR UNIT

SECURING THE UPPER HOUSING / MOTOR UNIT

Insert the bolt (I) in the dedicated slot (7) in the motor unit (A) and through the mounting hole(12)

in the support unit (B). Insert the washer (J ) at the front and tighten the locking knob (H).

NOTE: you may need to depress the upper housing to ensure correct alignment.

A

I

7

12

B

J

H

BENCH-MOUNTING

Use two (2) appropriate bolts complete

with washers and nuts (not supplied),

inserted in the securing holes. Make sure

you position the base unit hanging over the

edge of the bench as shown in the detail.

WALL-MOUNTING

NOTE: assemble the upper housing / motor unit (A)

to the base unit (B) before mounting to your wall.

Use four (4) appropriate bolts

complete with washers (not supplied),

inserted in the securing holes.

B

B

GRINDING ANGLES CHART

|X|

Wheel Width

A

Vise Rotate AngleBDown AngleCHead Tilt AngleDDepth Gauge

X A B C D

MICRO

CHISEL®

20-21-22BPX 3/16" 30° 10° 55° .025" .65 mm

25AP, 25A, 25F 1/8" 30° 0° 55° .025" .65 mm

27A, 27AX 3/16" 30° 10° 55° .030" .75 mm

95VPX

3/16" 30° 10° 55° .025" .65 mm

ROUND

GROUND

CHISEL

20-21-22LPX

M20-21-22LPX

3/16" 25° 10° 55° .025" .65 mm

58, 59L, J 3/16" 25° 10° 55° .025" .65 mm

68JX, LX 3/16" 25° 10° 55° .030" .75 mm

68CJ, CL 45° 45° - .030” .75 mm

72-73-75JGX,

JPX, LGX, LPX,

M72-73-75LPX

3/16" 25° 10° 55° .025" .65 mm

72-73-75V 3/16" 25° 10° 55° .025" .65 mm

SEMI

CHISEL

72APX/72-73-75DPX 3/16" 35° 10° 55° .025" .65 mm

91PXL, 91VXL,

M91VLX

1/8" 30° 0° 55° .025" .65 mm

RIPPING

CHAIN

27R, RA 3/16" 10° 10° 50° .030" .75 mm

72-73-75RD 3/16" 10° 10° 50° .025" .65 mm

CHAMFER

CHISEL™

90PX, 90S, 90SG

1/8" 30° 0° 55° .025" .65 mm

91P, 91PX, 91VG,

91VX, M91VX

1/8" 30° 0° 55° .025" .65 mm

INSTRUMENTAL MEASUREMENTS

A Measure the gauge

depth using the

suitable shape.

B Measure the

cutter length.

C Measure the

chain pitch.

A

B

A

B

C

GRINDING ANGLES CHART

INSTRUMENTAL MEASUREMENTS

PREPARING FOR USE

Page 8

410-120 410-120

14 15

REMOVE FLANGE

Using the 5 mm Allen wrench (N), remove

the grinding wheel ange screw (3) and the

grinding wheel ange (4) from the hub.

INSTALL GRINDING WHEEL

Insert and perfectly center the grinding wheel

(K) in the dedicated seat on the hub (2).

REINSTALL FLANGE

Using the 5 mm Allen wrench (N), insert

the ange (4) and tighten the screw (3).

Make sure you t the ange as illustrated. If the

grinding wheel is tted with the ange too tight,

it could break during use and put the operator at

risk. To avoid such risk, tighten screw (3) to 62 inlbs. (7 Nm). If possible, check with a torque wrench.

REINSTALL WHEEL GUARD

Reinstall wheel guard (G) with guard

securing screw (F) in holes(6) using

screwdriver (not included).

A

4

3

N

A

2

K

A

4

3

N

G

A

6

F

F

ASSEMBLY

SECURING THE OPERATING HANDLE

– insert the nut (D) into the handle (E).

– insert the bolt (C) into the slot (1).

– Completely screw the operating

handle (E) onto the bolt (C).

CHOOSING AND INSTALLING THE GRINDING WHEEL

WARNING

– Do not force the grinding wheel (K) on the hub (2) and do not alter the center hole

diameter. Do not use grinding wheels that do not t perfectly in place.

– Ensure hub (2) and ange (4) are clean and intact.

CHOOSE THE GRINDING WHEEL

Choose the correct size grinding wheel

based on the type of chain to be sharpened

(see the chain chart on page 12).

TESTING THE GRINDING WHEEL

Hold the grinding wheel (K) up by its center

hole. Knock the edge of the grinding wheel

gently with a non-metallic object. If it makes

a dull, non-metallic noise it means that the

wheel could be damaged: DO NOT USE IT!

REMOVE WHEEL GUARD

Remove wheel guard (G) by removing the

guard securing screw (F) from holes(6)

using screwdriver (not included).

A

E

D

C

K

G

A

6

F

F

PREPARING FOR USE PREPARING FOR USE

Page 9

410-120

17

410-120

16

CHECKING THE ASSEMBLY OF

THE GRINDING WHEEL

Stand at the side of the grinding wheel.

Start the grinder by turning the

switch to position “l”.

Once started, the lamp lights up to

illuminate the sharpening area.

Visually make sure the grinding wheel

does not oscillate sideways or crosswise,

consequently causing abnormal vibrations.

If this should be the case, stop the machine

immediately and check if the grinding wheel

has been tted correctly. If necessary, replace

the grinding wheel with another original one.

Always check a freshly tted grinding

wheel at working speed for at least one minute

before you start grinding, standing at a safe

distance to the side of the grinder, making

sure no one else approaches the machine.

CHECKING THE GRINDING WHEEL SHAPE

With the machine turned o, check the

grinding wheel (K) prole using the

measuring template (L); if necessary, dress

the wheel to restore the correct prole.

GRINDING WHEEL DRESSING

Wear personal protection equipment.

Start the grinder by turning the

switch to position “l”.

Prole the grinding wheel (K) with the dressing

brick (O), always working with extreme caution,

holding it with two hands rmly and eectively.

WARNING Contact with the grinding

wheel while it spins at high speed may

cause burning and abrasions.

Stop the grinder by turning the

switch to position “O”.

Check if the grinding wheel (K) prole is

correct using the template (L). Continue to

dress wheel until prole matches template.

A

L

K

K

O

L

K

SETTING THE SHARPENING ANGLES

WARNING

– Wear personal protection equipment when sharpening.

– All adjustments must be made with the motor switched o and the grinding wheel completely stopped.

– In the case of accidental impact or collision of the grinding wheel during the sharpening process, follow

the instructions given in the “CHOOSING AND INSTALLING THE GRINDING WHEEL – WARNINGS” section.

– Clean the chain before sharpening it.

– To avoid overloading the motor excessively and to avoid damaging the chain cutters, grind minimum

quantities of material and do not stop along the same cutter as this could burn the cutting edge.

– Do not use cooling liquids during the sharpening process.

WARNING Grinding creates sparks which

could ignite ammable materials. Do not

operate grinder in presence of ammable

materials or explosive atmospheres.

PREPARING FOR USE SETTING THE SHARPENING ANGLES

Page 10

410-120 410-120

18 19

FOR RIGHT-HAND CUTTERS WITHOUT A DOWN ANGLE (0°)

Once you have established the type of chain to be sharpened, look up the adjustment angles

(vise, down and head tilt angles) in the “Grinding Angles Chart” on page 12 (columns A/B/C).

NOTE: if your chain has a down angle in column B on the “Grinding Angles Chart,”

please see the “For Right-Hand Cutters with a Down Angle” section on page 19.

SETTING THE VISE ROTATE ANGLE

Loosen the vise adjustment knob (16).

Turn the vise clockwise.

Position the reference mark pointer (17) on

the vise by the desired vise rotate angle.

Tighten the vise adjustment knob (16) .

SETTING THE HEAD TILT ANGLE

Loosen the arm locking knob (H) at

the back of the motor unit (A).

Rotate the entire motor unit (A) until the

reference mark on the edge of the arm is

positioned at the desired head tilt angle (11).

Tighten the locking knob (H) at

the back of motor unit (A).

RIGHT-HAND CUTTERS

16

17

16

A

H

A

11

A

H

FOR RIGHT-HAND CUTTERS WITH A DOWN ANGLE

This section describes how to adjust the grinder for those chain types that require a down angle setting.

Tond out which chains require this setting, consult column B in the “Grinding Angles Chart” on page 12.

SETTING THE DOWN ANGLE

Find the correct angle using the “Grinding

Angles Chart” chart on page 12.

Loosen the vise adjustment knob (16).

Push the vise adjustment knob (16) away from

you and up as far as it will go to rotate vise.

SETTING THE VISE ROTATE ANGLE

Turn the vise clockwise.

Position the reference mark pointer (17) on

the vise by the desired vise rotate angle.

Tighten the vise adjustment knob (16).

RIGHT-HAND CUTTERS

16

16

17

16

SETTING THE SHARPENING ANGLES SETTING THE SHARPENING ANGLES

Page 11

410-120

21

410-120

20

SETTING THE HEAD TILT ANGLE

Loosen the locking knob (H) at the

back of the motor unit (A).

Rotate the entire motor unit (A) until the

reference mark on the edge of the arm is

positioned at the desired head tilt angle (11).

Tighten arm locking knob (H) at the

back of the motor unit (A).

A

H

A

11

A

H

FOR LEFT-HAND CUTTERS WITHOUT A DOWN ANGLE (0°)

Once you have established the type of chain to be sharpened, look up the adjustment angles

(vise, down and head tilt angles) in the “Grinding Angles Chart” on page 12. (columns A/B/C).

NOTE: if your chain has a down angle in column B on the “Grinding Angles Chart,”

please see the “For Left-Hand Cutters with a Down Angle” section on page 22.

SETTING THE VISE ROTATE ANGLE

Loosen the vise adjustment knob (16).

Turn the vise counter-clockwise.

Position the reference mark pointer (17) on

the vise by the desired vise rotate angle.

Tighten the vise adjustment knob (18).

SETTING THE HEAD TILT ANGLE

Loosen the locking knob (H) at the

back of the motor unit (A).

Rotate the entire motor unit (A) until the

reference mark on the edge of the motor unit is

positioned at the desired head tilt angle (11).

Tighten the locking knob (H) at the

back of the motor unit (A).

LEFT-HAND CUTTERS

16

17

16

A

H

A

11

A

H

SETTING THE SHARPENING ANGLES SETTING THE SHARPENING ANGLES

Page 12

410-120

23

410-120

22

FOR LEFT-HAND CUTTERS WITH A DOWN ANGLE

This section describes how to adjust the grinder for those chain types that require a down angle

setting. To nd out which chains require this setting, consult column B in the chain chart on page 12.

SETTING THE DOWN ANGLE

Find the correct angle using the

“Grinding Angles Chart” on page 12.

Loosen the vise adjustment knob (16).

Pull the vise adjustment knob (16) towards

you and up as far as it will go to rotate vise.

SETTING THE VISE ROTATE ANGLE

Turn the vise counter-clockwise.

Position the reference mark pointer (17) on

the vise by the desired vise rotate angle.

Tighten the vise adjustment knob (16).

LEFT-HAND CUTTERS

16

16

17

16

SETTING THE HEAD TILT ANGLE

Loosen the locking knob (H) at the

back of the motor unit (A).

Rotate the entire motor unit (A) until the

reference mark on the edge of the arm is

positioned at the desired head tilt angle (11).

Tighten locking knob (H) at the

back of the motor unit (A).

A

H

A

11

A

H

SETTING THE SHARPENING ANGLES SETTING THE SHARPENING ANGLES

Page 13

410-120 410-120

24 25

PLACING THE CHAIN IN THE VISE

– Clean the chain before sharpening it.

– Check the cutters and nd the one with the most damage, you will want to start with this cutter.

– Ensure chain is placed in vise as shown, cutter direction heading toward right.

SETTING THE CHAIN STOP

Put the chain in the vise (14).

Slide a chain cutter up against the chain stop (10).

Turn the adjustment knob (9) to position the chain

stop (10) laterally to the center of the cutter.

POSITIONING THE CUTTER

Move the grinding wheel onto the cutter

to be sharpened by pulling the motor

unit (A) downwards using handle (E).

Turn the cutter adjustment knob (8) to move

the chain so that the cutter cutting edge

skims the grinding wheel (K). The chain should

run freely over the vise (14) throughout this

procedure but without any clearance.

14

10

14

9

10

E

A

14

8

K

Raise the motor unit (A) using handle (E).

Turn the cutter adjustment knob (8)

clockwise, to slightly move the cutter

to be sharpened further forwards.

This forward movement corresponds to

the quantity of material to be ground from

the cutter. The more dull or damaged the

cutters, the greater this forward movement

should be. For cutters that are not too dull,

simply grind a slight amount of material.

It is also important not to grind too much material

in one pass. This could result in “burning” the cutter,

reducing its hardness, and causing excessive burrs.

Turn cutter sharpening depth adjustment

knob (5) to adjust the cutter sharpening

depth. The grinding wheel (K) should skim

the bottom of the cutter vertically.

Once you have found the exact position of

the cutter, pull the vise handle (13) to the

right to tighten the vise jaws (14). You are

now ready to begin sharpening your chain.

E

A

8

K

K

5

13

14

PLACING THE CHAIN IN THE VISE PLACING THE CHAIN IN THE VISE

Page 14

410-120 410-120

26 27

OPERATING INSTRUCTIONS

SHARPENING THE CHAIN

– Wear personal protection equipment.

– Sharpen all the cutters on the same side and then adjust the vise as explained in

the previous sections, and sharpen the cutters on the opposite side.

– When grinding is complete, ensure all cutter top plates equal length.

Make sure the vise handle (13) has been pulled

to the right and the vise jaws (14) are tight,

and the cutter is blocked (10) properly.

Start the grinder by turning the

switch to position “l”.

Sharpen the cutter by lowering the

grinding wheel with handle (E).

A

A=B

B

13

14

10

E

Once you have sharpened the rst cutter,

raise the motor unit with handle (E).

Loosen the vise handle (13).

Advance the chain forward to position

the next cutter to be sharpened, assuring

that the chain stop (10) is seated rmly

against the rear of the cutter.

Clamp chain again with the vise handle(13)

and sharpen the next cutter.

E

A

13

14

10

13

14

OPERATING INSTRUCTIONS OPERATING INSTRUCTIONS

Page 15

410-120 410-120

28 29

GRINDING WHEEL DRESSING FOR SETTING THE DEPTH GAUGE

Fit the 1/4" (6,3 mm) thick grinding wheel, following the instructions given on pages 14–16.

DO NOT check the grinding wheel shape or dress the grinding wheel as shown on page 16.

Turn the vise so that the reference

mark (17) is on 0°.

Turn the motor unit (A) to take the reference mark

to 80°-75° on the head tilt angle guide plate (11).

Position the dressing brick (O) on the vise

jaws(14) and against the chain stop (10). Hold

the dressing brick rmly with one hand, keeping

ngers / hands clear of the grinding wheel.

Start the grinder by turning the

switch to position “l”.

Lower the motor unit (A) with handle (E).

Grind the wheel against the dressing brick until

you obtain a prole like the one illustrated.

WARNING Contact with the grinding

wheel while it spins at high speed may

cause burning and abrasions.

17

A

11

80°-75°

14

O

10

E

O

A

O

10

K

Raise the motor unit (A) with handle (E).

Stop the grinder by turning the switch to position

“O” and remove the dressing brick (O) from the vise.

SETTING THE DEPTH GAUGE

Put the chain in the vise jaws (14), with a

cutter up against the chain stop (10).

With the motor unit (A) pulled down, turn

the cutter adjustment knob (8) to move

the chain so that the cutter’s depth gauge

is below the grinding wheel (K).

Turn the adjustment knob (9) to position the chain

stop (10) laterally to the center of the cutter.

With the motor unit (A) pulled down, adjust the

grinding depth on the gauge by turning knob (5).

Set the depth gauge following the instructions

given in the “OPERATING INSTRUCTIONS,

SHARPENING THE CHAIN” section on

pages26–27 . For this type of sharpening

procedure, there is no dierence between

the right and left cutters, therefore sharpen

all the gauges one after the other.

Check if the gauge depth is correct, using

the template with the shape related to

the type of chain used. Also consult the

chain table on page 12., column D.

E

O

A

10

14

K

10

8

9

K

5

OPERATING INSTRUCTIONS OPERATING INSTRUCTIONS

Page 16

410-120

31

410-120

30

STOPPING AND SHUTTING DOWN

STOPPING

Turn the machine o by turning the

switch to position “0” and unplug the

power cable from the mains.

SHUTTING DOWN

Once you have nished using the machine,

disconnect it and clean it thoroughly.

Store it in a dry, safe place, protected

against dust and dampness.

MAINTENANCE AND CLEANING

WARNING Grinder must be tur ned o and

the power cable unplugged from the mains

before any maintenance is performed.

Inspect the power cord regularly for

damage. Remove the plug from the mains

immediately if the cable is damaged or cut.

When the grinding wheel reaches a

minimum diameter of approximately

105mm, replace the grinding wheel.

After 40 hours of use:

– Clean the lamp carefully using a rag or a

cleaning brush. Do not use compressed air.

– Clean the grinder carefully using a rag

or a cleaning brush. Clean the electric

motor and the sliding guides with

caution. Do not use compressed air.

DEMOLITION AND DISPOSAL

The machine is to be demolished by qualied

personnel in compliance with current laws in

force in the country in which it is installed. The

symbol (on the rating nameplate) points out

that the product must not be disposed of with

normal household garbage. Contact an authorized

shop or your dealer for disposal instructions.

Before you scrap the machine, make it

unusable by cutting the power supply cable,

for example, and make the parts safe, which

could cause a source of danger for children

if they should play with the machine.

WARRANTY AND SERVICE

The warranty validity is that acknowledged in the country of sale. Claims

under warranty will only be accepted if they are backed up by the copy of the

purchase document (bill or receipt). The guarantee becomes void if:

– The machine has been tampered with;

– The machine has not been used according to this manual;

– Non-original parts, machines or grinding wheels have been tted on the

grinder or other parts that are not authorized by the manufacturer;

– The machine has been powered at a voltage or frequency dierent

from that written in the rating nameplate.

THE OREGON® CUSTOMER-SATISFACTION POLICY

LIMITED WARRANTY

OREGON® | Blount, Inc. warrants its products to be free from defects in materials and

workmanship for as long as they are owned by the original retail purchaser.

If you like our products, please tell your friends. If you are not satised with our products,

for any reason, please tell us. OREGON® wants to provide you with products that perform

to your full satisfaction. We welcome you to contact us as shown below.

LIABILITY UNDER THIS WARRANTY IS LIMITED TO REPLACEMENT PARTS, AT THE OPTION

OF YOUR OREGON® DISTRIBUTOR AND OREGON®. PLEASE CONTACT YOUR OREGON®

DISTRIBUTOR OR US DIRECTLY. OREGON® PRODUCTS ARE NOT WARRANTED AGAINST NORMAL

WEAR AND TEAR, USER ABUSE, IMPROPER MAINTENANCE OR IMPROPER REPAIR.

REPLACEMENT OF DEFECTIVE PRODUCT IS THE EXCLUSIVE REMEDY UNDER THIS WARRANTY AND

ANY APPLICABLE IMPLIED WARRANTY. THE REPLACEMENT WILL BE UNDERTAKEN AS SOON AS

REASONABLY POSSIBLE AFTER RECEIPT OF THE DEFECTIVE PRODUCT. TO THE EXTENT PERMITTED

BY LAW, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

APPLICABLE TO THIS PRODUCT IS LIMITED TO THE DURATION AND SCOPE OF THIS EXPRESS

WARRANTY. OREGON® SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR

DO NOT ALLOW THE EXCLUSION OF CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES THE ORIGINAL OWNER SPECIFIC

LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

If you have questions regarding OREGON® products in the U.S.A. or Canada, our Technical Services

Department welcomes all calls between the hours of 6:30 a.m. and 4:00 p.m. (Pacic Time), Monday

through Friday, at 800-223-5168. Alternatively, you can write to: Technical Services Department,

OREGON® | Blount, Inc., P.O. Box 22127, Portland, Oregon 97269-2127, visit our website at

www.oregonproducts.com (look for the “Contact Us” link under the “Customer Service” menu),

or email us directly at technicalservices@oregonproducts.com.

STOPPING, MAINTENANCE, DISPOSAL WARRANTY AND SERVICE

Page 17

410-120 410-120

32 33

TROUBLESHOOTING

Turn the machine o by turning the switch to position “0” and unplug the power

cable from the mains before you start to work on the machine.

Problem Probable Cause Solution

The machine fails to start

when you switch on

(switch in position “I”).

One of the safety devices of the

system to which the machine

is connected has tripped

(fuse, circuit breaker, etc.).

Reset the safety device.

If the safety switch trips again,

do not use the machine, and

contact a Skilled Technician.

The machine is not plugged

into the mains properly.

Unplug and plug in

again properly.

The lamp fails to switch

on when the switch is

turned to position “I”.

The lamp has blown. R eplace the lamp.

The wheel is broken

or damaged.

Replace wheel.

The machine vibrates

abnormally.

STOP USING IMMEDIATELY

The grinder is not

secured correctly.

Check its attachment and,

if necessary, tighten the

securing screws correctly.

The motor unit is not secured

correctly to the base unit.

Tighten the related locking

handle correctly.

The vise assembly is not secured

correctly to the base unit.

Tighten the related vise

adjustment knob correctly.

The grinding wheel is not tted

correctly in its seat on the hub.

Dismantle the grinding

wheel, check its integrity

and t again correctly.

Contact a Skilled Technician if you are still unable to restore the correct operation

of the machine following the instructions given in the chart.

TROUBLESHOOTING

Page 18

410-120 410-120

34 35

NO. DE SCRIPTION

1 572 119 Complete vise assembly

2 537 411 Cha in stop vise ass embly

3 522688 Chain stop

4 32677 Chain sto p (5 pack)

5 32681 Pawl cent er spring kit (5 pa ck)

6 572522 Adjustment knobs kit

7 572202 Lever vise assembly chain locking

8 572203 Vise jaws

9 572524 Vise locking kit

10 35590 Spring

11 572525 Scales

12 32678 Spri ng and ball kit (2 p ack)

13 572526 End motor cap

14 109879 Switch

15 572527 Spring arm return

16 572529 Bracket arm supp ort

17 105538 Handle kit

18 537409 Motor flange kit

19 572528 Plastic shield

1

13

14

15

16

12

9

10

17

11

18

19

2

5

6

7

8

6

3

4

ILLUSTRATED PARTS LIST

ILLUSTRATED PARTS LIST ILLUSTRATED PARTS LIST

Loading...

Loading...