Page 1

SIMPLY AMAZING

Service Parts List

Upright Vacuum

Cleaner Models

®

XL3600HH

XL3600RH

XL3610HH

U3700HH

U3710HH

REV AK. Please disregard all earlier versions.

U3720HG

U3720HR

U3760HH

XL3640HH

U3640RH

XL3800H2B

XL3900H2B

XL3910H2B

U3980H2B

U3990H2B

SILVER SERIES UPRIGHTS

U3770HH

U3771HH

Type 4, 5, 6 & 7

Page 2

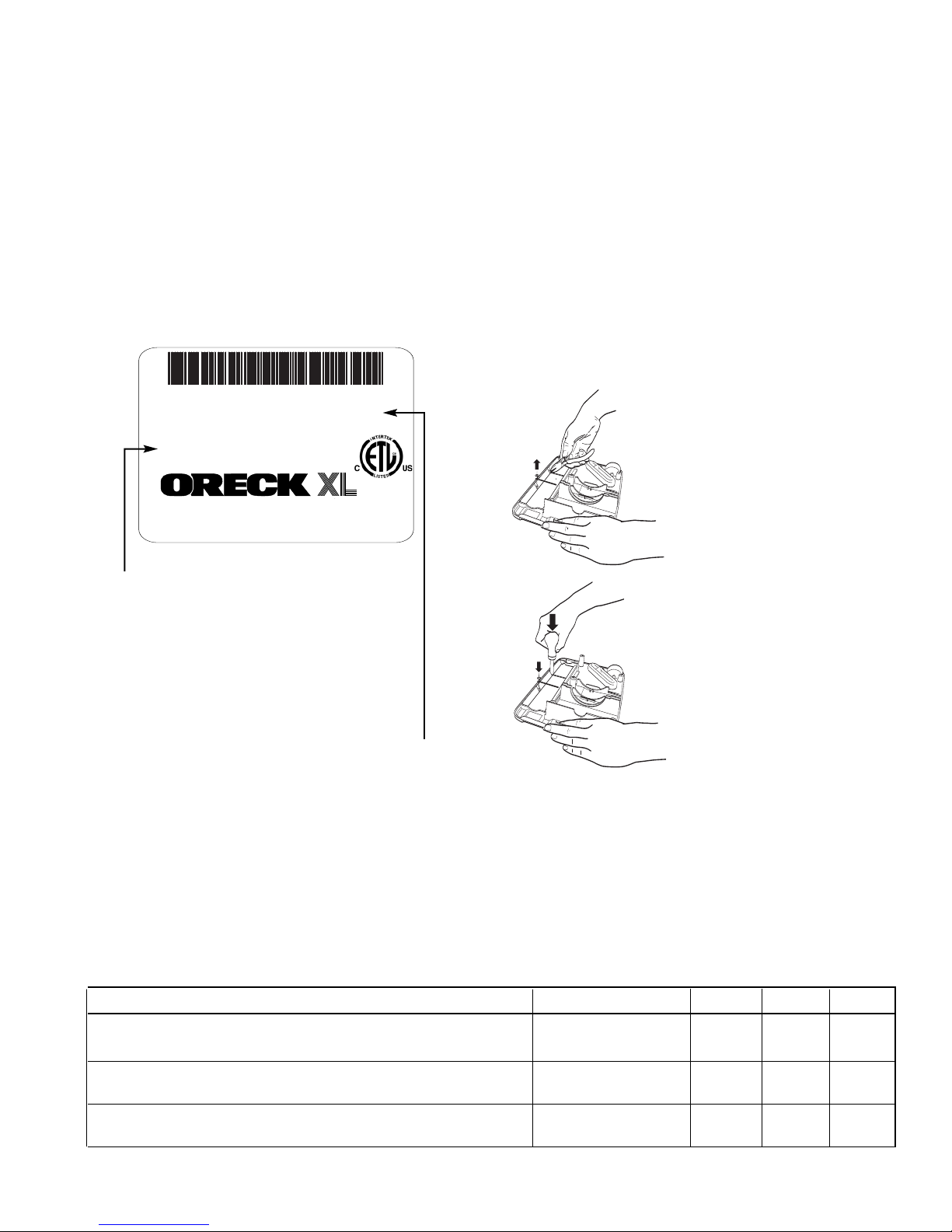

Product Information

SN

3600HH00000672 -

TYPE 7

MODEL:

XL3600HH

120 VOLTS 60 HZ 4.0 AMP

NEW ORLEANS, LA 70123 U.S.A.

FOR HOUSEHOLD USE ONLY

POUR USAGE MENAGER

06095

3076689

®

®

7

CONFORMS TO UL STD 1017

CERTIFIED TO CSA C22.2 NO.243-01

DATE:

W: 3 YR/10HSG

Customer Service US 1-800-989-3535

Canada 1-888-676-7325 www.oreck.com

• Minimum water lift: 9 in. @ nozzle sealed suction

• Power consumption 120V/60Hz: 4.0 amps, 480 watts

• Weight: 8 lbs. without power cord

• Power cord rating - Domestic 18/2 SJT 105°C

Data Label

Service Information

Component configuration on exploded view may differ in

•

ase of specific versions. However, the actual

c

components are distinguished by means of item and

part numbers.

• If a repair has been made, make sure that all functions

f the appliance are working correctly.

o

• Spare parts have been standardized as much as

possible and the part may not be the exact replacement

part.

• Baseplate assemblies with one-piece wireform are

interchangeable on Type 4-6 units.

To remove the retainer clips from the

baseplate, using a pair of side cutting

pliers, carefully cut the retainer clips

away from the posts. Remove the

retainer clips. Be careful not to

damage the posts.

Type Code: Represents product service

revision number.

Type 4: Initial production.

Type 5: Improved lower tube.

Type 6: Hardwire handle.

Type 7: Improved baseplate with

one-piece wireform.

Julian Date Code:

Represents date of manufacture.

06 Represents the year.

095 Represents the day in that year.

TOOLS

Description Order #

Fan Housing Removal Tool (This tool is designed to assist in removing 75377-01

fan housing assembly from the motor

Strain Relief Pliers (This tool is designed to remove the cord retainer, 75383-01

part #33.)

Retainer Clip

to assist in adding retainer clips, part #77, to baseplate.)

ool

T

****Use 7/32” nut driver.(This tool is designed

.)

75485-01

To replace the retainer clips, position

the retainer clips on the posts with

indentation facing downward. Use a

7/32” nut driver to force the retainer

clips down. Retainer clip should fit

firmly against wireform.

NLA

2

Page 3

STANDARD FASTENER HARDWARE LISTING

Fasteners Fit Uprights Listed in Service Manual

# FASTENER FASTENER PART THAT FASTENER QTY TORQUE QTY

DESCRIPTION PART NO. IS USED ON REQ’D RANGE PER

(in/lb) PKG.

2 Cord Clamp 03-00619-01M 1 n/a 100

3 Screw, #8 - 32 x .440 Nylock 03-00478-02M Handle Tube 2 18 - 22 100

Screw, #8 x .811 w/ Int Washer 03-00608-01M Handle Tube w/Through Bolt 1 18 - 22 100

Screw, #8-32 X .545 w/ Washer 03-00504-02M Handle Brace 2 18 - 22 100

Screw, #8 - 32 x 29/32 w/ Washer 03-00605-01M Handle Brace w/Through Bolt 1 18 - 22 100

15 Screw, #8 - 10 x 1.25 Plt 30 03751M Headlight Cover

15 Screw, #8 X .5 Phillips 03752-01M Bulb Holder, Foot Switch, 2/2 13 - 16 100

Cable Clamp 1

30 1/4 X 32 Yellow Chrome 03-00448-01M Fan 1 18 - 20 100

38 Screw, #8 X .75 Phillips 03-00456-01M

Screw, #8 x .75 03-00476-01M D-Handle Type 6 Only 6 17 - 20 100

41 Wire Nut 03-00599-01M as req’d 35 - 55 100

48 Screw, #8 x .75 Phillips 03-00476-01M Baseplate, Belt Door, Intake Pivot, 5 / 1 / 1 13 - 16 100

49 Screw, #7 X .38 Phillips 03-00475-01M Edge Brush Type 4-6 Only, Detent 2 / 2 5 - 8 100

63 Screw, #10 x .5 Phillips 03-00450-01M Cord Bracket 1 13 - 16 100

69 O-Ring 75191-02M Collar 2 n/a 100

72 Washer, Thrust 03-00479-01M Fan 1 n/a 100

73 Washer, Lock External Tooth 03-00480-01M Fan 1 n/a 100

74 1” x 3”, Loop Fastener 75304-01M Bag Support 1 n/a 100

75 1” x 1”, Hook Fastener 75303-01M Bag Dock 2 n/a 100

77 Retainer Clip 03528M Baseplate Type 4-6 Serviceable 2 n/a 100

78 Wireform 75194-03M Baseplate Type 4-6 Serviceable 2 n/a 100

80 Steel Bushing Ring 03-00598-01M D-Handle 1 n/a 100

84 Nut, Square 03-00606-01M Connector 1 n/a 100

, #6-20 x 7/16 Flat Undercut

Screw

85

86 Wireform, One-Piece 75698-01 Baseplate Type 7 Only 1 n/a 1

88 JST Insulator 75679-01M Harness 1 n/a 100

Rivet

89

90 Bag Spring 75015-01M Fan Housing 1 n/a 100

Push Nut

91

03-00626-01M

03-00453-01M

03-00636-01M

D-Handle (small head) 4 17 - 20 100

Motor 2 17 - 20 100

Silver Series Fascia & Bulb Holder 2 / 2 5 - 8 100

Corner Brush, Channel

Fan Housing

Fan Housing 1 n/a 100

ype 7 Only

T

2 / 3

1 n/a 100

6 - 8

100

Kit Number Description

09-75505-01 Kit, Motor

75086-01 Leads, Red

75086-02 Leads, White NLA NLA NLA

75506-01

03-00474-01M 100pc. Edge Brush Axle Kit, Pin, .125 x .5

75338-01 20pc. Edge Brush Wheel Kit

Leads, Green

STANDARD PARTS

3

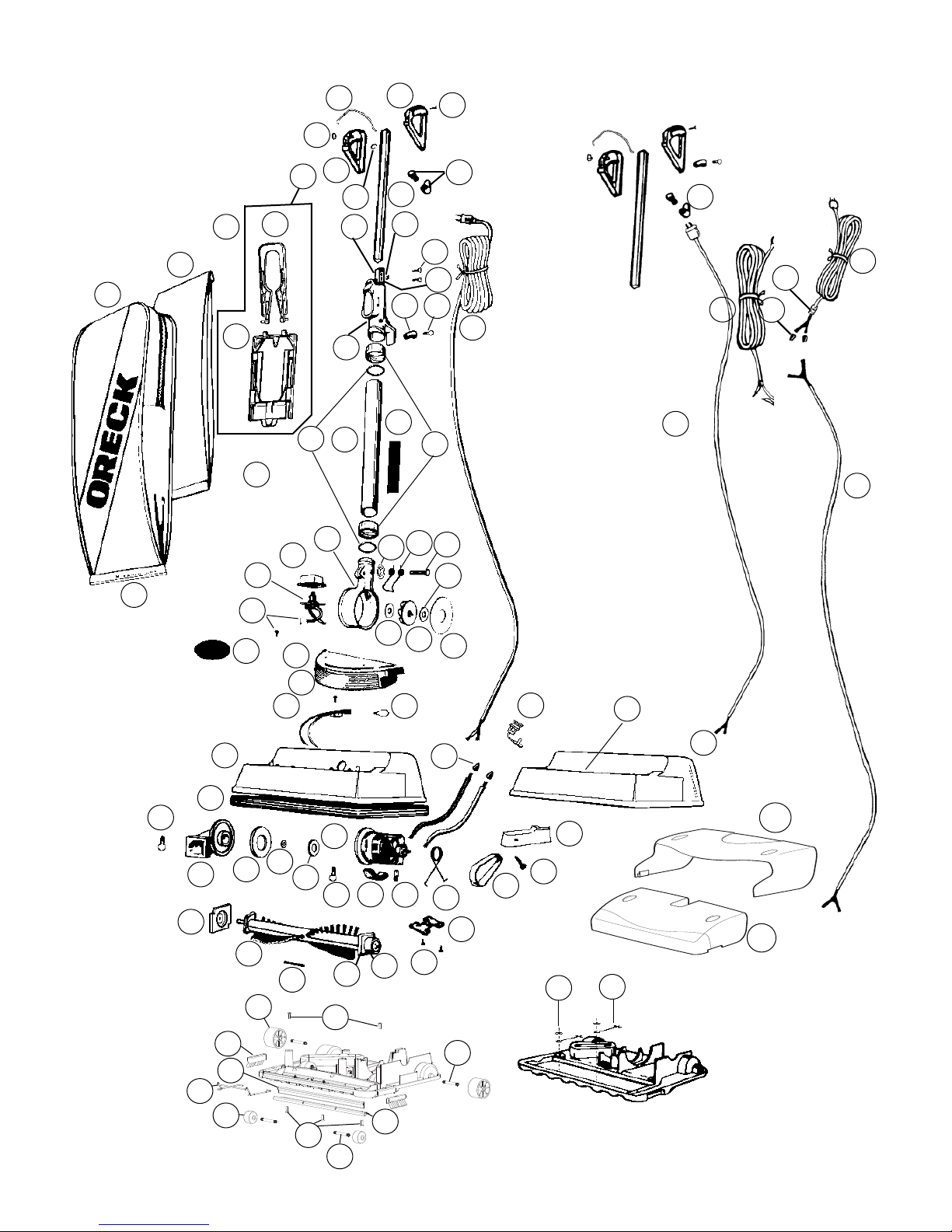

Page 4

Parts

54

53

55

38

Diagram

74

5

6

67

7

RIGHT

15

24

75

14

55

83

57

80

4

13

21

69

79

8

10

12

82

2

61

91

73

90

18

3

84

63

9

89

72

56

19

20

LEFT

58

59

68

41

81

59

Type 6 & 7

Units Only

58

Type 6 & 7

Units Only

48

16

28

86

27

26

50

46

87

29

42

52

25

30

43

22

32

85

34

48

85

51

42a

35

42b

47

23

36

49

41

60

44

51

39

33

40

48

77

Wireforms serviceable

- Baseplate

has posts

65

78

(Type 4-6 Only)

26

21a

22a

4

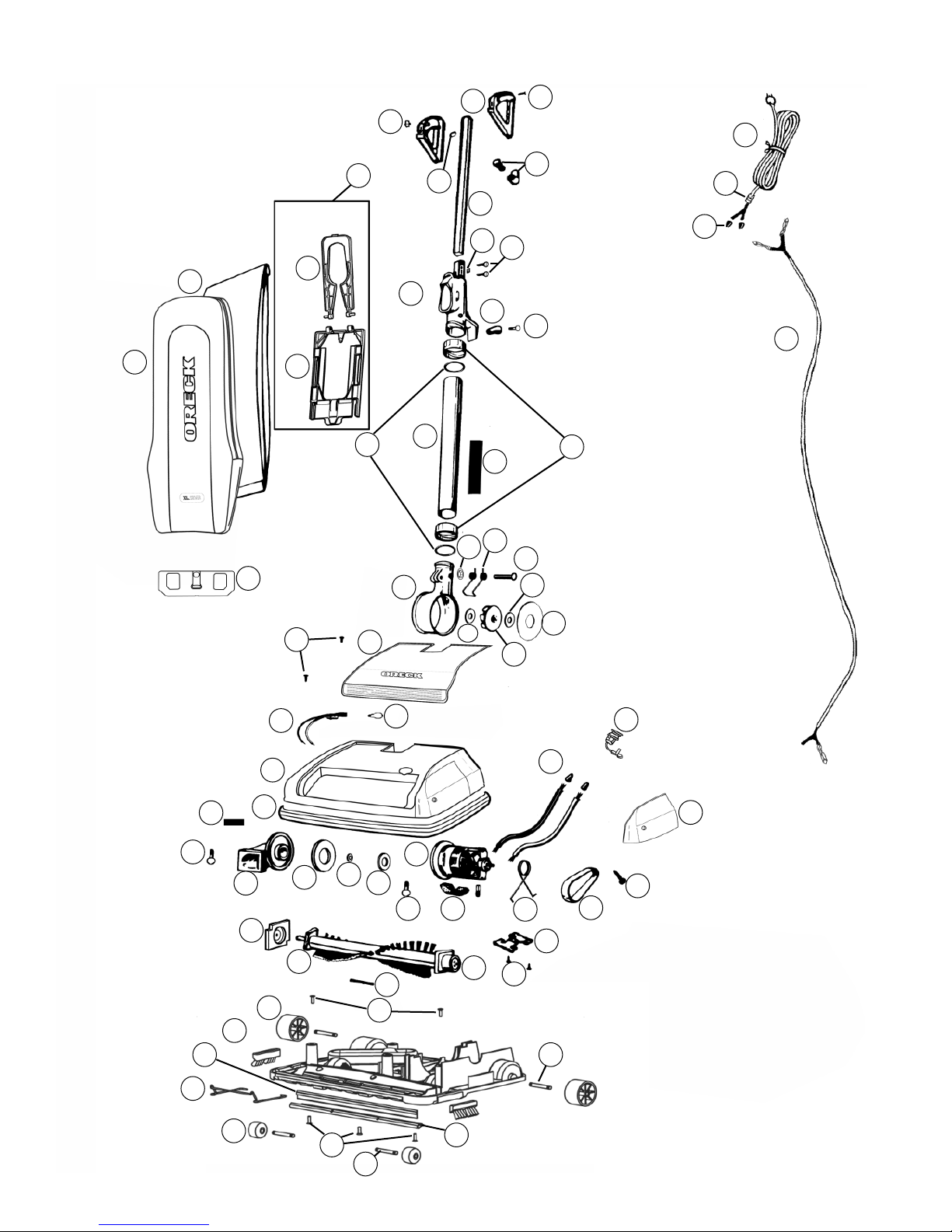

Page 5

Silver Series

54

55

38

59

Parts

Diagram

5

6

94

67

83

4

69

80

57

84

8

10

91

12

56

81

41

3

2

63

58

9

61

90

89

72

48

43

46

50

28

16

27

52

26

25

49

29

42

30

93

32

85

23

34

48 35

43

73

42b

18

49

60

19

33

41

40

48

39

44

51

86

87

85

47

51

5

Page 6

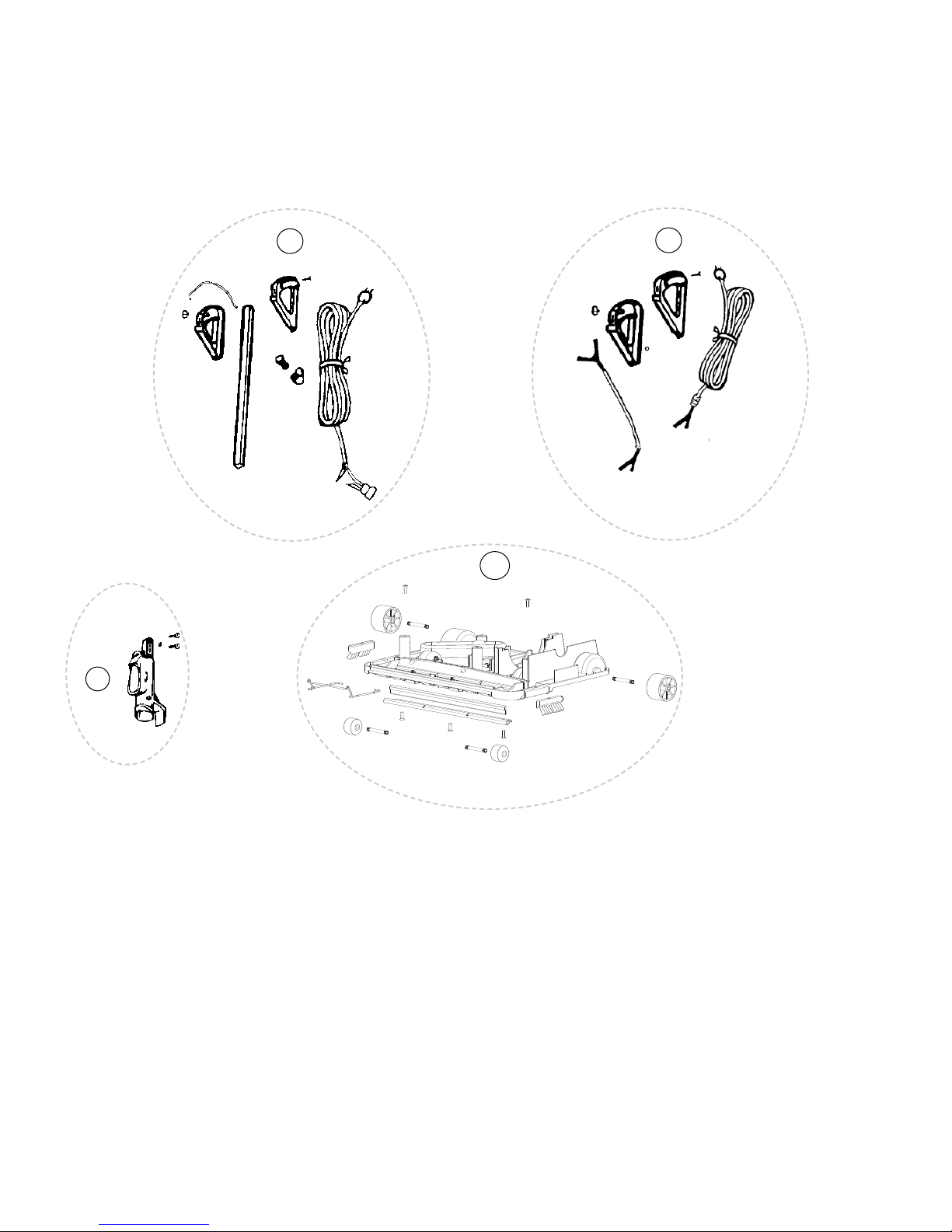

Parts

Assemblies

1

45

8

1b

6

Page 7

Part Numbers Listing: XL3600HH / XL3600RH / XL3610HH / U3700HH / U3710HH

Hypo Bag, Lights, Helping Hand Handle

# Item Order # Qty. Pk.

1 XL3600HH / XL3600RH: Handle Assembly, includes items #38, 09-75288-16 1 1

#53, #54, #55, #56, #57, #59 Type 4 & 5 Units Only

L3610HH:Handle Assembly, includes items #38, #53, #54,

X

#55, #56, #57, #59 Type 4 & 5 Units Only

1b Kit, Retro, Handle Assembly, Residential, White, includes items #38, 09-75612-01 1 1

54, #55, #58, #59, #80, #81

#

Type 4 & 5 Unit s On ly

4 Docking Clip, Rear, Type CC (use w/#67 or order #83) 75583-03-0000 1 1

5 Dust Bag, (8 Pk.) Hypo Allergenic CCPK8DW 1 8

Dust Bag, (25 Pk.) Hypo Allergenic CCPK25DW 1 25

6 XL3600HH / XL3610HH: Outer Bag, Lt. Gray, Black, Dark Gray 75246-10 1 1

XL3600RH: Outer Bag, Dk Gray, Gold Anniversary 75246-29 1 1

U3700HH / U3710HH: Outer Bag, Lt Gray, Blue, Silver Plus 75645-03 1 1

7 XL3600HH / XL3600RH: Bag Clip, White w/Gold 09-75078-17 1 1

XL3610HH: Bag Clip, White w/Black 09-75078-05 1 1

U3700HH: Bag Clip, White w/Blue 09-75078-21 1 1

U3710HH: Bag Clip, White w/Silver 09-75078-22 1 1

8 Connector Assembly Kit, includes items #3 & #84 09-75308-57 1 1

9 Collar 75309-02-0327 2 1

10 Tube Assembly Type 4 Units Only 75188-01 1 1

Tube Assembly Type 5, 6 & 7 Units Only 75198-05 11

12 Fan Housing Assembly includes Rivet & Spring 09-75343-03 1 1

16 XL3600HH / XL3600RH / XL3610HH: End Cap, Plastic Pulley Brush Roll 0134623 1 1

U3700HH / U3710HH: Endcard, Metal Pulley Brush, Rt

18 METAXALLOY™ Fan Kit w/Washers 09-75300-01 1 1

19 Fan Cup Seal 75012-01 1 1

20 Cord Set see #59

21 Lamp Housing, White 75521-01-0431 1 1

22 Lens 75520-02-455 1 1

23 Bulb 00965-0019 2 1

24 XL3600HH / XL3600RH / XL3610HH: Badge Decal, Gold 73020-01 1 1

U3700HH / U3710HH: Badge Decal, Blue 73020-03 1 1

25 Lamp Holder 75539-01 1

26 Housing, White 09-75780-1

27 Bumper, White 75181-03 1 1

28 Intake Pivot Assembly, with Felt Seal 09-75066-02 1 1

29 Felt Seal 75065-01 1 1

Felt Seal, Motor

32

Cord Retainer

33

, Square 03-00655-01 1

34 Motor Assembly Kit 09-75505-01 1 1

35 Motor Seal 75095-01 2 1

36 Kit, Motor Brush / Spring 09-75514-01 2 2

39 Drive Belt, (3 Pk.) 0300604 1 3

39a Drive Belt, Single 75024-01 1 1

40 Door Belt, White 75057-01-0431 1 1

9-75288-17 1 1

0

75704-01 1 1

11

100

1

751

1

17-01M

1

1

7

Page 8

Part Numbers Listing: XL3600HH / XL3600RH / XL3610HH / U3700HH / U3710HH cont.

Hypo Bag, Lights, Helping Hand Handle

# Item Order # Qty. Pk.

42 XL3600RH / XL3610HH: Brush Roll, Plastic Pulley 75202-01 1 1

XL3600HH / U3700HH / U3710HH: Brush Roll, Metal Pulley 75104-02 1 1

42a XL3600HH / U3700HH / U3710HH: Endcard, Metal Pulley Side, Lft 75705-01 1 1

42b

XL3600HH / U3700HH / U3710HH: 75706-01 1 1

Pulley, Metal (For Brushroll)

43 Seal, Baseplate 75008-01 1 1

44 Plastic Detent, (uses 2 #49 screws) 75299-01 1 1

45 Complete Baseplate Assembly includes: #43, #46, #47, 09-75715-01 1 1

#50, #51, #52, #85, #86, #87

46 MICRO SWEEP Blade Type 4, 5 & 6 Units Only 75009-01 1 1

MICRO SWEEP Blade Type 7 Units Only 75700-02 1 1

47 Channel Type 4, 5 & 6 Units Only 75007-02 1 1

Channel Type 7 Units Only 75701-01 1 1

50 Edge Brush w/Wheels, Left Type 4, 5 & 6 Units Only 09-75249-02 1 1

Edge Brush w/Wheels, Right Type 4, 5 & 6 Units Only 09-75250-02 1 1

Edge Brush w/o Wheels, Left & Right 75766-02 2 1

51 Wheel Axle 03-00630-01M 2/4* 100

52 Soft Rear Wheel, Black 75187-02-0327 2 1

53 Static Wire Type 4 & 5 Units Only 75037-01 1 1

54 Lighted 2 position Switch Kit Type 4 & 5 Un its Only 09-75523-01 1 1

Switch, 2 Position Assembly, Lighted Type 6 & 7 Uni ts O nly 75523-03 1 1

55 Grips, White Set Type 4 & 5 Units Only 09-75301-19 1 1

Grips, White Set Type 6 & 7 Units Only 09-75576-19 1 1

56 Cord Wrap Assembly w/Post and Cord Wrap 09-75185-05 1 1

57 XL3600HH / XL3600RH / U3700HH: Handle

XL3610HH / U3710HH: Handle Tube, Black 75190-04 1 1

58 Cord, Harness Assembly, White Type 4 & 5 Units Only 75081-01 1 1

Cord, Harness Assembly, White Type 6 & 7 Units Only 75600-02-328 1 1

59 Cord Set, White Type 4 & 5 Units Only 75522-01-328 1 1

Cord Set, White w/ #81 Type 6 & 7 Units Only 75556-02-328 1 1

Motor Spring

60

61 Tube Label 75087-05 1 1

67 Bag Dock Hinge, Type CC (use w/#4 or order #83) 75582-03-0000 1 1

68 Receptacle Type 4 & 5 Units Only 75524-01 1 1

s Manual 75416-05 1

’

User

Magnet Clean Vacuum Protector MC4BK 1 1

79 Stiffener (uses same length screws, notched) 75189-02 1 1

Stiffener, Through Bolt Connector (uses different length screws) 75619-01 1 1

81 Cord Flex Relief T

ype 6 & 7 Units Only

83 Kit, Bag Dock, includes items #4 & #67 09-75657-01 1 1

Front Wheel

87

*Type 7 Units

ype 7 Units Only

T

Tube, Chrome

75190-03 1 1

75283-01

2

03-00600-01 1

75709-01

21

1

1

1

8

Page 9

SILVER SERIES UPRIGHTS

Part Numbers Listing: U3770HH, U3771HH

Hypo Bag, Lights, Helping Hand Handle, Antimicrobial Units

# Item Order # Qty. Pk.

4 Bag Dock Type CC Antimicrobial 75582-02-0327 1 1

5 Dust Bag, (8 Pk.) Hypo Allergenic CCPK8DW 1 8

Dust Bag, (25 Pk.) Hypo Allergenic CCPK25DW 1 25

6 Outer Bag, Antimicrobial 76062-01 1 1

U3771HH: Outer Bag, Antimicrobial 76062-07 1 1

8 Connector Assembly Kit, includes items #3 & #84 09-75308-57 1 1

9 Collar Modified 75199-02-0327 2 1

10 Tube Assembly 75198-05 1 1

12 Fan Housing Assembly 09-75221-12 1 1

16

Endcard, Metal Pulley Brush, Rt

18 METAXALLOY™ Fan Kit w/Washers 09-75300-01 1 1

19 Fan Cup Seal 75012-01 1 1

20 Cord Set see #59

23 Bulb Headlight 77051-01 2 1

25 Lamp Holder 75539-01 1 1

26 Top Cover, Belt Door Assembly, Antimicrobial 09-76032-01 1 1

U3771HH: Top Cover, Belt Door Assembly, Antimicrobial 09-76032-04 1 1

27 Bumper, Clear Antimoicrobial 75765-01 1 1

28 Intake Pivot Assembly, with Felt Seal 09-75066-02 1 1

29 Felt Seal 75065-01 1 1

32 Felt Seal, Motor 75117-01M 1 100

33 Cord Retainer, Square 03-00655-01 1 1

34 Motor Assembly Kit 09-75505-01 1 1

35 Motor Seal 75095-01 2 1

36 Kit, Motor Brush / Spring 09-75514-01 2 2

39 Drive Belt, (3 Pk.) 0300604 1 3

39a Drive Belt, Single 75024-01 1 1

40 Belt Door, Antimicrobial 76002-01-470 1 1

U3771HH: Belt Door, Antimicrobial 76002-01-474 1 1

42 Brushroll, Silver ION

42b Pulley, Metal (For Brushroll) 75706-01 1 1

43 Seal, Baseplate 75008-01 2 1

44 Plastic Detent, (uses 2 #49 screws) 75299-01 1 1

Complete Baseplate

45

#46, #47, #50, #51, #52, #85, #86, #87 Antimicrobial

46 MICRO SWEEP

47 Channel 75701-01 1 1

50 Edge Brush Silver 75766-03 2 1

51 Wheel Axle

Soft Rear Wheel, Black

52

54 Single Speed Switch 75559-01 1 1

55 Grip Set, Lt Gray Antimicrobial 09-75576-38 1 1

U3771HH: Grip Set, Burnt Orange, Antimicrobial 09-75576-40 1 1

Assembly

Blade 75700-02 1 1

includes: #43, 09-75715-07

75704-01 1 1

75202-03

03-00630-01M

75187-02-0327

1

1

2/4* 100

2

1

1

1

9

Page 10

SILVER SERIES UPRIGHTS

Part Numbers Listing: U3770HH, U3771HH

Hypo Bag, Lights, Helping Hand Handle, Antimicrobial Units

# Item Order # Qty. Pk.

56 Cord Wrap Assembly, Lt Gray 09-75185-24 1 1

U3771HH: Cord Wrap Assembly, Burnt Orange 09-75185-25 1 1

57 Handle Tube, Chrome 75190-03 1 1

58 Cord, Harness Assembly, White 75600-02-328 1 1

59 Cord Set 75556-02-328 1 1

60 Motor Spring 75283-01 2 1

61 Tube Label 75087-05 1 1

67 Bag Dock Hinge, Black Antimicrobial 75582-02-0327 1 1

User’s Manual N/A 1 1

81 Cord Flex Relief 03-00600-01 1 1

83 Kit, Bag Dock, includes items #4 & #67 Antimicrobial 09-75657-02 1 1

87 Front Wheel 75709-01 2 1

93 Fascia Delux w/ Logo 76001-01 1 1

U3771HH: Fascia Delux w/Logo 76001-04 1 1

94 Bag Stiffener with Strap 09-76034-01 1 1

10

Page 11

Part Numbers Listing: U3760HH / U3720HG / U3720HR

Hypo Bag, Lights, Helping Hand Handle, Antimicrobial Units

# Item Order # Qty. Pk.

4 Bag Dock Type CC Antimicrobial 75582-02-0327 1 1

5 Dust Bag, (8 Pk.) Hypo Allergenic CCPK8DW 1 8

Dust Bag, (25 Pk.) Hypo Allergenic CCPK25DW 1 25

6 Outer Bag, Blue Antimicrobial 75645-19 1 1

U3720HG: Outer Bag, Gray Antimicrobial 75645-26 1 1

U3720HR: Outer Bag, Red Antimicrobial 75645-27 1 1

7 Bag Clip Curved Antimicrobial 09-75776-01 1 1

U3720HG: Bag clip curved gray 09-75594-11 1 1

U3720HR: Bag clip curved red 09-75594-06 1 1

8 Connector Assembly Kit, includes items #3 & #84 09-75308-57 1 1

9 Collar Modified 75199-02-0327 2 1

10 Tube Assembly 75198-05 1 1

12 Fan Housing Assembly 09-75221-12 1 1

16

Endcard, Metal Pulley Brush, Rt

18 METAXALLOY™ Fan Kit w/Washers 09-75300-01 1 1

19 Fan Cup Seal 75012-01 1 1

20 Cord Set see #59

21 U3720HG: Lamp Housing Gray Antimicrobial 75521-02-0384 1 1

U3720HR: Lamp Housing Red Antimicrobial 75521-02-444 1 1

21a Low Profile Lamp Housing Blue Antimicrobial 75763-01-466 11

22 U3720HG / U3720HG: Lense clear blue 75520-02-455 1 1

22a Lens, Low Profile Light Antimicrobial 75762-01-0329 1 1

23 Bulb Headlight 77051-01 2 1

U3720HG / U3720HG: Bulb Headlight 00965-0019 2 1

24 Label, XL Dome Blue on Silver 75772-02 1 1

U3720HG / U3720HG: Label Badge Black on Silver 73020-04 1 1

25 Lamp Holder 75539-01 1 1

26 U3760HH:

Top Cover, Blue, Antimicrobial 09-75780-30 1 1

U3720HG: Top Cover, Gray, Antimicrobial 09-75780-38 1 1

U3720HR: Top Cover, Red, Antimicrobial 09-75780-31 1 1

27 Bumper, Clear Antimoicrobial 75765-01 1 1

U3720HG / U3720HG: Bumper Clear with Blue Tint 75181-04 1 1

28 Intake Pivot Assembly, with Felt Seal 09-75066-02 1 1

29 Felt Seal 75065-01 1 1

32 Felt Seal, Motor 75117-01M 1 100

Cord Retainer

33

, Square 03-00655-01 1 1

34 Motor Assembly Kit 09-75505-01 1 1

35 Motor Seal 75095-01 2 1

Kit, Motor Brush / Spring

36

Drive Belt, (3 Pk.)

39

39a Drive Belt, Single 75024-01 1 1

40 U3760HH: Belt Door Blue, Antimicrobial 75057-03-466 1 1

Antimicrobial

,

U3720HG: Belt Door

U3720HR: Belt Door

, Gray

, Red,

Antimicrobial

75704-01 1 1

09-75514-01

0300604

75057-03-0384

75057-02-444

22

13

1

1

1

1

1

1

Page 12

Part Numbers Listing: U3760HH / U3720HG / U3720HR

Hypo Bag, Lights, Helping Hand Handle, Antimicrobial Units

# Item Order # Qty. Pk.

42 Brushroll, Silver ION 75202-03 1 1

U3720HG / U3720HR: Brushroll 75104-02 1 1

2b Pulley, Metal (For Brushroll) 75706-01 1 1

4

43 Seal, Baseplate 75008-01 1 1

44 Plastic Detent, (uses 2 #49 screws) 75299-01 1 1

45 Complete Baseplate Assembly

#46, #47, #50, #51, #52, #85, #86, #87 Antimicrobial

46 MICRO SWEEP Blade 75700-02 1 1

47 Channel 75701-01 1 1

50 Edge Brush Silver ION 75766-01 2 1

U3720HG / U3720HR: Edge Brush 75766-02 2 1

51 Wheel Axle 03-00630-01M 2/4* 100

52 Soft Rear Wheel, Black 75187-02-0327 2 1

54 Switch, 2 Position Assembly, Lighted 75523-03 1 1

U3720HG / U3720HR:Single Speed Switch 75559-01 1 1

55 U3760HH: Grip Set, Blue Antimicrobial 09-75576-37 1 1

U3720HG: Grip Set Gray Antimicrobial 09-75562-62 1 1

U3720HR: Grip Set Red Antimicrobial 09-75562-63 1 1

56 U3760HH: Cord Wrap Assembly, Black 09-75185-15 1 1

U3720HG:Cord Wrap Assembly, Gray 09-75185-21 1 1

U3720HR: Cord Wrap Assembly, Red 09-75185-18 1 1

57 Handle Tube, Chrome 75190-03 1 1

58 Cord, Harness Assembly, White 75600-02-328 1 1

59 U3760HH: Cord Set, White w/ #81 75556-02-328 1 1

U3720HG / U3720HR:Cord, Harness Assembly, White 75556-03-328 1 1

60 Motor Spring 75283-01 2 1

61 Tube Label 75087-05 1 1

67 Bag Dock Hinge, Black Antimicrobial 75582-02-0327 1 1

s Manual

User’

Magnet Clean V

acuum Protector

79 Stiffener, Through Bolt Connector (uses different length screws) 75619-01 1 1

81 Cord Flex Relief 03-00600-01 11

83 Kit, Bag Dock, includes items #4 & #67 Antimicrobial 09-75657-02 1 1

Front Wheel

87

92 Odorfighter Patch 3 pack (not shown) ODOR3PK 3 1

Odorfighter Patch 25 pack (not shown) ODOR25PK 25 1

*Type 7 Units

includes: #43, 09-75715-56 1 1

75416-05

MC4BK

11

1

75709-01 2 1

1

12

Page 13

Part Numbers Listing: XL3640HH / U3640RH / XL3800H2B / XL3900H2B / XL3910H2B / U3980H2B / U3990H2B

Hypo Bag, Lights, Helping Hand Handle

#Item Order # Qty.Pk.

1Handle Assembly, Includes items #38, #53, #54, #55, #56, #57, #59 09-75288-02 1 1

Type 4 & 5 Units Only

1b Kit, Retro, Handle Assembly, Residential, White, includes items #38, 09-75612-01 1 1

#54, #55, #58, #59, #80, #81 Type 4 & 5 Units Only

4 Docking Clip, Rear, Type CC (use w/#67 or order #83) 75583-03-0000 1 1

5Dust Bag, (8 Pk.) Hypo Allergenic CCPK8DW 18

Dust Bag, (25 Pk.) Hypo Allergenic CCPK25DW 1 25

6 XL3640HH / XL3910H2B / U3990H2B: Outer Bag, Lt. Gray, Black, 75645-01 1 1

White Plus

U3640RH: Outer Bag, Dark Gray, Black, Dark Gray 75246-11 1 1

XL3800H2B: Outer Bag, Lt. Gray, Blk, Dark Gray 75246-10 1 1

XL3900H2B / U3980H2B: Outer Bag, Lt. Gray, Gold XL2Ultra 75246-31 1 1

7 XL3640HH / U3640RH: Bag Clip, Curved, Black w/White, Front 09-75594-02 1 1

XL3800H2B: Bag Clip, Black w/Silver 09-75078-06 1 1

XL3900H2B / XL3910H2B / U3980H2B / U3990H2B: Bag Clip, 09-75078-19 1 1

Black w/Gold

XL3900H2B / XL3910H2B / U3980H2B / U3990H2B: Bag Clip, 09-75594-01 1 1

Curved, Black w/Gold, Front

XL3640HH / U3640RH / XL3900H2B / XL3910H2B

U3990H2B

: Bag Clip, Curved, Black, Rear

8 Connector Assembly Kit, includes items #3 & #84 09-75308-57 1 1

9Collar 75309-02-0327 21

10 Tube Assembly Type 4 Units Only 75188-01 1 1

Tube Assembly Type 5, 6 & 7 Units Only 75198-05 1 1

12 Fan Housing Assembly includes Rivet & Spring 09-75343-03 1 1

16 XL3800H2B / XL3900H2B / U3980H2B: End Cap, Plastic Pulley Brush Roll 0134623 1 1

XL3640HH / U3640RH / XL3910H2B / U3990H2B:

Metal Pulley Brush, Rt

18 METAXALLOY™ Fan Kit w/Washers 09-75300-01 1 1

19 Fan Cup Seal 75012-01 1 1

20 Cord Set see #59

Lamp Housing, Black 75521-01-0327 1 1

21

22 Lens 75520-02-455 1 1

Bulb 00965-0019 2 1

23

24 XL3640HH / U3640RH / XL3800H2B: Badge Decal, Silver 73020-02 1 1

XL3900H2B / XL3910H2B / U3980H2B / U3990H2B: 73020-01 1 1

Badge Decal, Gold

25 Lamp Holder 75539-01 1 1

26 Housing, Black 09-75780-17 1 1

27 XL3800H2B: Bumper, White 75181-03 1 1

XL3640HH / U3640RH / XL3900H2B / XL3910H2B / U3980H2B / 75181-04 1 1

U3990H2B: Bumper

, Clear

28 Intake Pivot Assembly with Felt Seal 09-75066-02 1 1

29 Felt Seal 75065-01 1 1

Felt Seal, Motor

32

33 Cord Retainer, Square 03-00655-01 1 1

Assembly Kit

Motor

34

Motor Seal

35

/ U3980H2B / 75593-01-0327 1 1

Endcard, 75704-01 1 1

100

17-01M

751

09-75505-01

1

11

75095-01 2 1

13

Page 14

Part Numbers Listing: XL3640HH / U3640RH / XL3800H2B / XL3900H2B / XL3910H2B / U3980H2B / U3990H2B cont.

Hypo bag, lights, Helping Hand handle

# Item Order # Qty. Pk.

36 Kit, Motor Brush / Spring 09-75514-01 2 2

9Drive Belt, (3 Pk.) 0300604 1 3

3

39a Drive Belt, Single 75024-01 1 1

0Door Belt, Black 75057-01-0327 1 1

4

42 XL3800H2B / XL3900H2B: Brush Roll, Plastic Pulley 75202-01 1 1

XL3640HH / U3640RH / XL3910H2B / U3980H2B / U3990H2B: 75104-02 1 1

Brush Roll, Metal Pulley

XL3640HH / U3640RH / XL3910H2B / U3980H2B / U3990H2B: 75705-01 1 1

42a

Endcard, Metal Pulley Side, Lft

42b XL3640HH / U3640RH / XL3910H2B / U3980H2B / U3990H2B: 75706-01 1 1

Brush Roll Pulley, Metal

43 Seal, Baseplate 75008-01 1 1

44 Plastic Detent, (uses 2 #49 screws) 75299-01 1 1

45 Complete Baseplate Assembly includes: #43, #46, #47, 09-75715-01 1 1

#50, #51, #52, #85, #86, #87

46 MICRO SWEEP Blade Type 4, 5 & 6 Units Only 75009-01 1 1

MICRO SWEEP Blade Type 7 Units Only 75700-02 1 1

47 Channel Type 4, 5 & 6 Units Only 75007-02 1 1

Channel Type 7 Units Only 75701-01 11

50 Edge Brush w/Wheels, Left Type 4, 5 & 6 Units Only 09-75249-02 1 1

Edge Brush w/Wheels, Right Type 4, 5 & 6 Units Only 09-75250-02 1 1

Edge Brush w/o Wheels, Left & Right 75766-02 2 1

51 Wheel Axle 03-00630-01M 2/4* 100

52 Soft Rear Wheel, Black 75187-02-0327 2 1

53 Static Wire Type 4 & 5 Unit s On ly 75037-01 1 1

54 XL3640HH / U3640RH: Switch, 2 Position Assembly, Lighted 75523-03 1 1

Switch, 3 Position Assembly w/Diode Type 4 & 5 Units Only 75320-01 11

Switch, 3 Position Assembly w/Diode Type 6 & 7 Units Only 75585-01 1 1

55 Grips, Black Set Type 4 & 5 Units Only 09-75301-02 1 1

Grips, Black Set Type 6 & 7 Units Only 09-75576-02 1 1

56 Cord Wrap Assembly w/Post and Cord Wrap 09-75185-01 1 1

57 XL3640HH / U3640RH / XL3800H2B / XL3900H2B / 75190-03 1 1

U3980H2B: Handle Tube, Chrome

ube, Black

XL3910H2B / U3990H2B: Handle

T

75190-04

58 XL3640HH / U3640RH: Cord, Harness Assembly, Black 75600-02-327 1 1

Cord, Harness Assembly, Black T

ype 4 & 5 Units Only

75081-02 11

Cord, Harness Assembly, Black Type 6 & 7 Units Only 75552-02-327 1 1

59 Cord Set, Black Type 4 & 5 Units Only 75292-01-327 1 1

Cord Set, Black w/ #81 Type 6 & 7 Units Only 75556-02-327 1 1

60 Motor Spring 75283-01 2 1

61 Tube Label 75087-05 1 1

67 Bag Dock Hinge, Type CC (use w/#4 or order #83) 75582-03-0000 1 1

s Manual 75416-05 1 1

’

User

Magnet Clean V

79

Stiffener (uses same length screws, notched) 75189-02 1 1

acuum Protector MC4BK 1 1

Stiffener, Through Bolt Connector (uses different length screws) 75619-01 1 1

Cord Flex Relief

81

83

Kit, Bag Dock, includes items #4 & #67 09-75657-01 1 1

87

Front Wheel

*Type 7 Units

ype 6 & 7 Units Only

T

T

ype 7 Units Only

03-00600-01

75709-01

1

1

1

1

21

14

Page 15

HARDWIRE IN HANDLE

RESIDENTIAL SWITCH

IN HANDLE

W/O LIGHTS

SEE MOTOR

DETAIL A & B

RESIDENTAIL

SWITCH IN BASE

W/O LIGHTS

SEE MOTOR

DETAIL A & B

RESIDENTIAL

SWITCH IN BASE

W/LIGHTS

1 PARALLEL

LIGHT HARNESS

SEE MOTOR

DETAIL C & D

HARDWIRE

IN HANDLE

RESIDENTIAL

SWITCH IN HANDLE

W/LIGHTS

1 PARALLEL

LIGHT HARNESS

SEE MOTOR

DETAIL C & D

D-PLUG IN HANDLE

RESIDENTIAL

SWITCH IN HANDLE

W/O LIGHTS

SEE MOTOR

DETAIL A & B

D-PLUG IN HANDLE

RESIDENTIAL

SWITCH IN HANDLE

W/LIGHTS

SEE MOTOR

BLACK BLACK

WHITE WHITE

WIRE NUT

SWITCH

TERMINAL

MOTOR

BLACK BLACK BLACK

WHITE

WIRE NUT

MOTOR

BLACK BLACK BLACK

BLACK

WHITE

WHITE

WIRE NUT

MOTOR

LIGHTLIGHT

TERMINAL

BLACK BLACK

BLACK

WHITE WHITE

WHITE

WIRE NUT

MOTOR

LIGHTLIGHT

WHITE

WHITE

PLUG

MOTOR

BROWN BROWN

BLACK

BLACK

RECEPTACLE

TERMINAL

WHITE

WHITE

PLUG

MOTOR

BROWN BROWN

BLACK

BLACK

RECEPTACLE

TERMINAL

WHITE

WHITE

MOTOR

BROWN BROWN

BLACK

BLACK

TERMINAL

L I

GH

T E

D

S

W

I TC

H

I

N

H

A

ND

L E

W

H

I TE

BLA CK

S

W

I TC

H

33

R

ECE PTAC LE

22

PI

GG

Y B ACK

TE

R

MI

N

AL

11

W

H

I TE

B

RO

W

N

L I

GH

T E

D

S

W

I TC

H

I

N

H

A

ND

L E

W

H

I TE

T

O

M

O

T

OR

BLA CK

S

W

I TC

H

33

R

ECE PTAC LE

22

W

I

R

E

NU

T

11

W

H

I TE

BLA CK T

O

M

O

T

OR

DETAIL A

AMETEK MOTOR

RESIDENTIAL

W/O LIGHTS

DETAIL B

JOHNSON MOTOR

RESIDENTIAL

W/O LIGHTS

WHITE

FROM CORD

BLACK

FROM CORD

OR SWITCH

BLACK

FROM CORD

OR SWITCH

WHITE

FROM CORD

DETAIL C

AMETEK MOTOR

RESIDENTIAL

W/LIGHTS

1 PARALLEL HARNESS

LAMP

PIGGY-BACK

TERMINAL

BLACK

WHITE

WHITE

FROM CORD

LAMP

BLACK

FROM CORD

OR SWITCH

DETAIL D

JOHNSON MOTOR

RESIDENTIAL

W/LIGHTS

1 PARALLEL HARNESS

LAMP

BLACK

WHITE

LAMP

WHITE

FROM CORD

BLACK

FROM CORD

OR SWITCH

WHITE

FROM CORD

PIGGY-BACK

TERMINAL

PIGGY-BACK

TERMINAL

BLACK

FROM

CORD

OR

SWITCH

LAMP

W

HITE

BLACK

75516-04 REV D 05/04 ECN# R-7618

15

Page 16

D-PLUG IN HANDLE

RESIDENTIAL

SWITCH IN HANDLE

W/LIGHTS

SEE MOTOR

DETAIL E & F

D-PLUG IN HANDLE

RESIDENTIAL

SWITCH IN BASE

W/LIGHTS

2 LIGHT HARNESS

SEE MOTOR

DETAIL E & F

HARDWIRE IN

HANDLE

COMMERCIAL

SWITCH IN HANDLE

SEE MOTOR

DETAIL G & H

COMMERCIAL

SWITCH IN BASE

SEE MOTOR

DETAIL G & H

D-PLUG IN HANDLE

COMMERCIAL

SWITCH IN HANDLE

SEE MOTOR

DETAIL G & H

WHITE WHITE

MOTOR

GREEN

BROWN

BROWN

BLACKBLACK

GREEN

TERMINAL

WHITE

WHITE

MOTOR

BROWN BROWN

BLACK

BLACK

TERMINAL

LIGHT

LIGHT

WHITE

MOTOR

BLACKBLACK

BLACK

LIGHT

LIGHT

WIRE NUT

WHITE WHITE

MOTOR

GREEN

BLACKBLACK

GREEN

TERMINAL

WIRE NUT

WHITE

MOTOR

GREEN

GREEN

BLACKBLACK

WIRE NUT

JUMPER WIRE

75506-01

BLACK

FROM CORD

OR SWITCH

DETAIL E

AMETEK MOTOR

RESIDENTIAL

W/LIGHTS

2 LIGHT HARNESS

WHITE

FROM CORD

LAMP

PIGGY-BACK

TERMINAL

PIGGY-BACK

TERMINAL

BLACK

WHITE

LAMP

WHITE

BLACK

DETAIL F

JOHNSON MOTOR

RESIDENTIAL

W/LIGHTS

2 LIGHT HARNESS

PIGGY-BACK

TERMINAL

PIGGY-BACK

TERMINAL

LAMP

BLACK

FROM

CORD

OR

SWITCH

WHITE

FROM

CORD

WHITE

BLACK

LAMP

WHITE

BLACK

DETAIL G

AMETEK MOTOR

FOR COMMERCIAL

WHITE

FROM CORD

BLACK

FROM CORD

OR SWITCH

JUMPER WIRE

75506-01 OR

GREEN FROM CORD

DETAIL H

JOHNSON MOTOR

FOR COMMERCIAL

BLACK

FROM

CORDORSWITCH

WHITE

FROM

CORD

GREEN

®2004 Oreck Holdings, LLC. All rights reserved. All trademarks are owned and used under the authority of Oreck Holdings, LLC.

16

Page 17

Troubleshooting

Notice: Make sure the unit is unplugged before removing any part off the unit.

roblem Being Checked:

1. P

a. Solution

Dust Blowing from Bottom of Unit:

1.

a. Change bag ensuring it’s properly installed on connector deflector.

b. Remove lower tube and check for clog. Remove any debris.

c. Remove baseplate and check inlet for clog. Remove any debris.

d. Check for cracked fan housing. Replace fan housing.

2. Unit not picking up:

a. Remove lower tube and check for clog.

b. Remove baseplate and check inlet for clog.

c. Change bag ensuring it’s properly installed on connector deflector.

d. Make sure belt is installed properly.

Brush Roll Not Spinning / Belt Breaks:

3.

a. Belt is older than six months and slipping or may not be installed properly. Install new belt.

b. Bearings in brush roll worn, change brush roll.

4. Sparking from Plug to Handle (non-hardwire units):

a. Make sure plug fits firmly into handle.

5. Unit Dead:

a. Make sure unit is plugged into working outlet.

b. Check switch for failure. If bad, replace switch.

c. Check to see if motor wires are plugged and not loose.

d. Check motor brushes and motor brush springs to make sure they have good contact.

e. Check motor for failure. If bad, replace motor.

f. Check cord for failure. If bad, replace cord.

Parts Falling off Baseplate:

6.

a If wheels come off, replace wheels.

b. If channel, micro sweep blade, or wireform come off, replace baseplate.

7. Noisy Unit:

a. Check to see if brush roll has bad bearings. If so replace brush roll.

b. Check to see if an object is stuck in the fan housing.

c. Check fan in fan housing. Make sure there are no broken blades. Replace if broken.

8. Unit Will Not Stand Up:

a. Broken or missing detent.

An Oreck Authorized Service Center should do all technical servicing.

17

Page 18

2009 Oreck Holdings, LLC.

©

All rights reserved.

All trademarks are owned and used under the authority of Oreck Holdings, LLC.

75545-01 REV

AK 04/09

ECN# R-9350

Loading...

Loading...