Page 1

USER’S GUIDE

•IMPORTANT•

SAVE THIS BOOKLET!

COMMERCIAL

XL2000HH

XL2000RH

HIGH SPEED UPRIGHT VACUUM

CLEANER WITH

CLEANING SYSTEM

™

SIMPLY AMAZING™

Includes:

• Safety Warnings

•Warranty

• Operating Instructions

•Trouble Diagnosis

• Accessories

ENGLISH

FRANÇAIS

G

UIDE D’UTILISATION PAGE 8

ESPAÑOL

GUIA DEL USUARIO PAGE 14

75423-02 REV C

Page 2

2

When using an electrical appliance, basic

precautions should always be followed,

including the following:

READ ALL INSTRUCTIONS BEFORE

USING THIS VACUUM CLEANER

WARNING

To reduce the risk of fire,

electric shock, or injury:

IMPORTANT SAFETY

INSTRUCTIONS

• Do not leave appliance unattended when plugged in. Unplug

from outlet when not in use and before servicing.

• Do not use outdoors or on wet surfaces.

• Do not operate the unit while in the upright and locked position.

• Do not let the unit run while in any one stationary position for any

period of time. Keep the unit moving while in operation.

• Do not allow to be used as a toy. Close attention is necessary

when used by or near children.

• Use only as described in this manual. Use only manufacturer’s

recommended attachments.

• Do not use with damaged cord or plug. If appliance is not

working as it should, has been dropped, damaged, left outdoors,

or dropped into water, return it to a service center or call

customer service at

1-800-535-8810 x 7452

• Do not pull or carry by cord, use cord as a handle, close door on

cord, or pull cord around sharp edges or corners. Keep cord

away from heated surfaces.

• Do not run appliance over cord.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not

the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening

blocked; keep free of dust, lint, hair and anything that may reduce

air flow.

• Keep hair, loose clothing, fingers and all parts of body away from

openings and moving parts.

• Do not use to pick up anything that is burning or smoking, such as

cigarettes, matches, or hot ashes.

• Do not use without filter bag assembly in place.

•Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids, such as

gasoline or lighter fluid, or use in areas where they may be

present.

• Do not use appliance in an enclosed space where flammable,

explosive or toxic vapors are given off by oil base paint, paint

thinner, some mothproofing substances, or in an area where

flammable dust is present.

• Do not pick up toxic material such as chlorine bleach, drain

cleaner, gasoline, etc. with this appliance.

SAVE THESE INSTRUCTIONS

For Commercial Use

ENGLISH

Table of C

ontents

BEFORE OPERATING

CLEANER, READ ALL

INSTRUCTIONS IN THIS

MANUAL CAREFULLY.

Maintenance and Customer Service,

Important Safety Instructions . . . . . . . . page 2

Warranty,

Troubleshooting Guide . . . . . . . . . . . page 3

Assembly,

Operating Instructions . . . . . . . . . . . . page 4

Operating Instructions cont.,

To Replace Paper Filter Dust Bag . . . page 5

How to Replace a Worn Belt,

Stuffing or Blockage . . . . . . . . . . . . . page 6

Using a Fresh Air Tab,

Grounding Instructions,

To Adjust or Replace Brush . . . . . . . . page 7

Français Guide D’utilisation . . . . page 8

Españiol Guia Del Usuario . . . . . page 14

Your ORECK vacuum cleaner is a product of precise engineering.

The motor bearings are permanently lubricated and should not be

oiled. If you require additional information or have problems with

your ORECK appliance, you may call ORECK commercial customer

service at:

1-800-535-8810 x 7452

Please specify the model number and serial/code number which

can be found on the data plate on the back of the vacuum.

Save your sales or purchase slip. Should your ORECK appliance

require warranty service in the U.S.A., present this slip to the

Authorized Service Center as your proof of purchase date or, in

Canada, call customer service.

Maintenance and

Customer Service

Accessories

ITEM PART #

1. Dust Bag, 8 Pack, Saniseal™

ACDS Hypo-Allergenic PK20008DW

Dust Bag, 8 Pack, Regular PK20008

2. Belts, 3 Pack 0300604

3. Fresh Air Tabs AIRTABS

Page 3

3

ENGLISH

W

arranty

ORECK MANUFACTURING COMPANY: (ORECK gives you the

following limited warranty for this product only if it was originally

purchased for use, not resale, from ORECK or an ORECK

Authorized Retail Dealer.)

ORECK will repair or replace, free of charge, to the original

purchaser, any part which is found to be defective in material or

workmanship within one (1) year of the date of purchase.

Drive belts, revolving brushes, bulbs, disposable bags, and other

parts subject to normal wear are not covered by this limited

warranty.

This limited warranty does not apply to any part subjected to

accident, abuse, or alteration, misuse, damage caused by fire or

act of God, the use of voltages other than indicated on the serial

number plate of this product or service of this product by other than

ORECK or an ORECK Factory Authorized Service Center.

ORECK does not authorize any person or representative to assume

or grant any other warranty obligation with the sale of this

product.

ORECK’s limited warranty is valid only if you retain proof of

purchase from ORECK or an ORECK Authorized Retail Dealer for

this product. If you purchase this product from any other source,

your purchase is “AS IS,” which means ORECK grants you no

warranty, and that you, not ORECK, assume the entire risk of the

quality and performance of this product, including the entire cost

of any necessary servicing or repairs of any defects.

ORECK’s liability for damages to you for any costs whatsoever

arising out of this statement of limited warranty shall be limited to

the amount paid for this product at the time of original purchase,

and ORECK shall not be liable for any direct, indirect, consequential or incidental damages arising out of the use or inability to

use this product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion

may not apply to you.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN

DURATION TO THE WARRANTY PERIOD, AND NO

WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY

AFTER THIS PERIOD.

Some states do not allow limitations on the duration of implied

warranties, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

SAVE SERVICE CALLS...CHECK THESE FIRST:

• Is the disposable filter dust bag full?

•Are pores of filter dust bag clogged with powder or fine dust?

•Is anything clogging the revolving brush, lower tube, intake

opening, fan housing or connector assembly opening?

• Is the belt in place and turning the brush?

•Are the brush ends in the proper location?

• Does the brush turn freely? Are hair, string or rug fibers wound

around the brush?

Troubleshooting Guide

CLEANER

WILL NOT RUN

C

LEANER

DOES NOT PICK UP

Not plugged in

properly.

No electricity in

wall outlet.

Plug not firmly in

handle assembly.

Filter bag is full.

Nozzle or intake

pivot clogged.

Belt is broken or

stretched.

Brush is worn.

Bag tube clogged.

Bag pores are

clogged with fine

dust.

Impeller fan is

broken.

Revolving brush is

not even at both

ends.

Be sure cleaner is

firmly plugged

into wall outlet.

Check electrical

source–fuse or

circuit breaker.

Plug firmly in

handle assembly.

Replace filter bag.

See “To Install

Paper Filter Dust

Bag.”

Clear obstruction.

Replace belt.

Replace brush if

bristles do not

extend beyond

base plate.

Clear obstruction.

Change bag.

Return to Service

Center for repair.

Check bearing

seal. Make sure

words “old” or

“new” match at

each end.

PROBLEM P

OSSIBLE SOURCE AREAS TO

CHECK

Whenever calling, please be sure to have your model and

serial number from data plate.

CALL COMMERCIAL CUSTOMER SERVICE HOT LINE

1-800-535-8810 x 7452

ALL OTHER SERVICING SHOULD BE DONE BY AN

ORECK AUTHORIZED SERVICE CENTER.

WARNING: Unplug cord from

electrical outlet before servicing.

Page 4

ENGLISH

4

Operating Instructions

To Operate

Make sure disposable paper filter dust bag is in place. DO NOT

operate the cleaner without a paper filter dust bag. Plug the

power cord into an electrical outlet and press the On (l) - OFF

(O) switch on Helping Handle Assembly, or on top of base for

Straight Handle Models when ready to operate.

General Information

The performance of your new cleaner greatly depends upon care

and maintenance. The instructions in this manual will guide you in

performing basic care and maintenance. To obtain the most satisfying years of service read the instructions and keep them handy

for future reference.

Operating Recommendations

This new ORECK XL High-Speed Upright is one of the finest,

fastest, and strongest units in its class. You’ll love the way it

cleans, gets under things, and it’s SO lightweight and easy to

use.

The following are a few simple suggestions regarding its

operation:

1. When inserting a new disposable paper filter dust bag—

FIRST PUFF OUT and OPEN THE BAG.

2. When the disposable filter dust bag is full, REPLACE IT.

3. If at any time the machine does not pick up properly or

makes an unusual noise, STOP OPERATION and service.

4. Although your upright will pick up pins, paper clips, and

other small objects, it is recommended that these be

removed from the floor before you vacuum. Failure to do so

may result in permanent damage to the motor suction fan

and its housing.

5. WARNING: Do not use your vacuum cleaner on damp or

wet surfaces. This will cause damage to the vacuum cleaner

and is dangerous to the user. Damage caused by use on wet

or damp surfaces is not covered under warranty.

6. REPLACE THE BELT EVERY 6 MONTHS.

7. Change the disposable filter dust bag at least once a

month—even if it is not full! The collected dust in the dust

bag can cause odor, attract moisture, act as a breeding

area and can affect the efficiency of the cleaner.

8. DO NOT run the vacuum cleaner over cord. The revolving

brush could damage the cord.

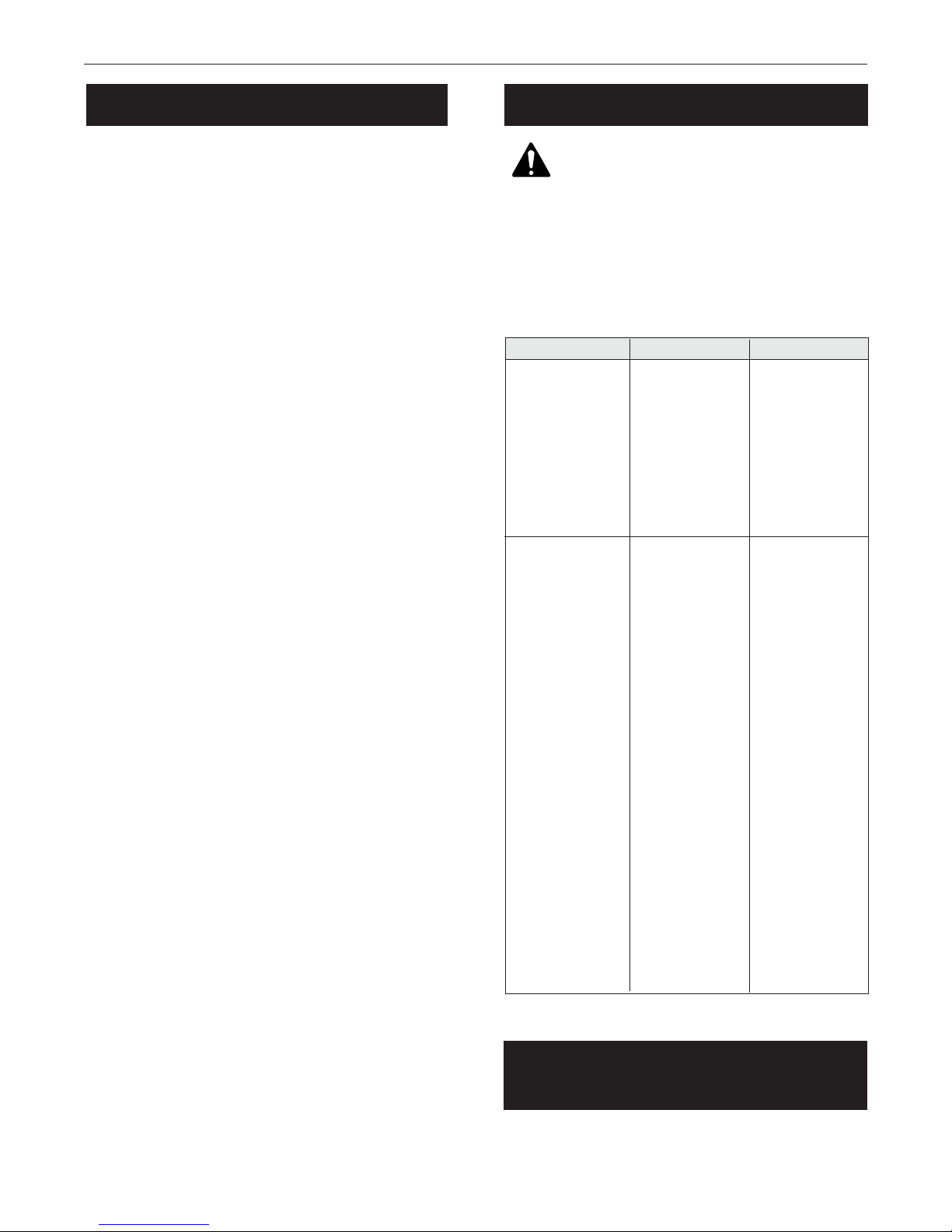

To assist you in identifying

components of your vacuum,

the parts have been numbered

as follows

:

1 Handle section, upper

2Tube, lower

3 Power head

4 Outer bag

5 Paper filter dust bag

6 Power cord

7 Retaining spring

8 Bag tension bar

9 Zip fastener

10 On/off switch

11 Cord hook

12 Plastic loop/

cable clamp

13 Connector assembly

14 Fan housing

15 Cord assembly

Assembly

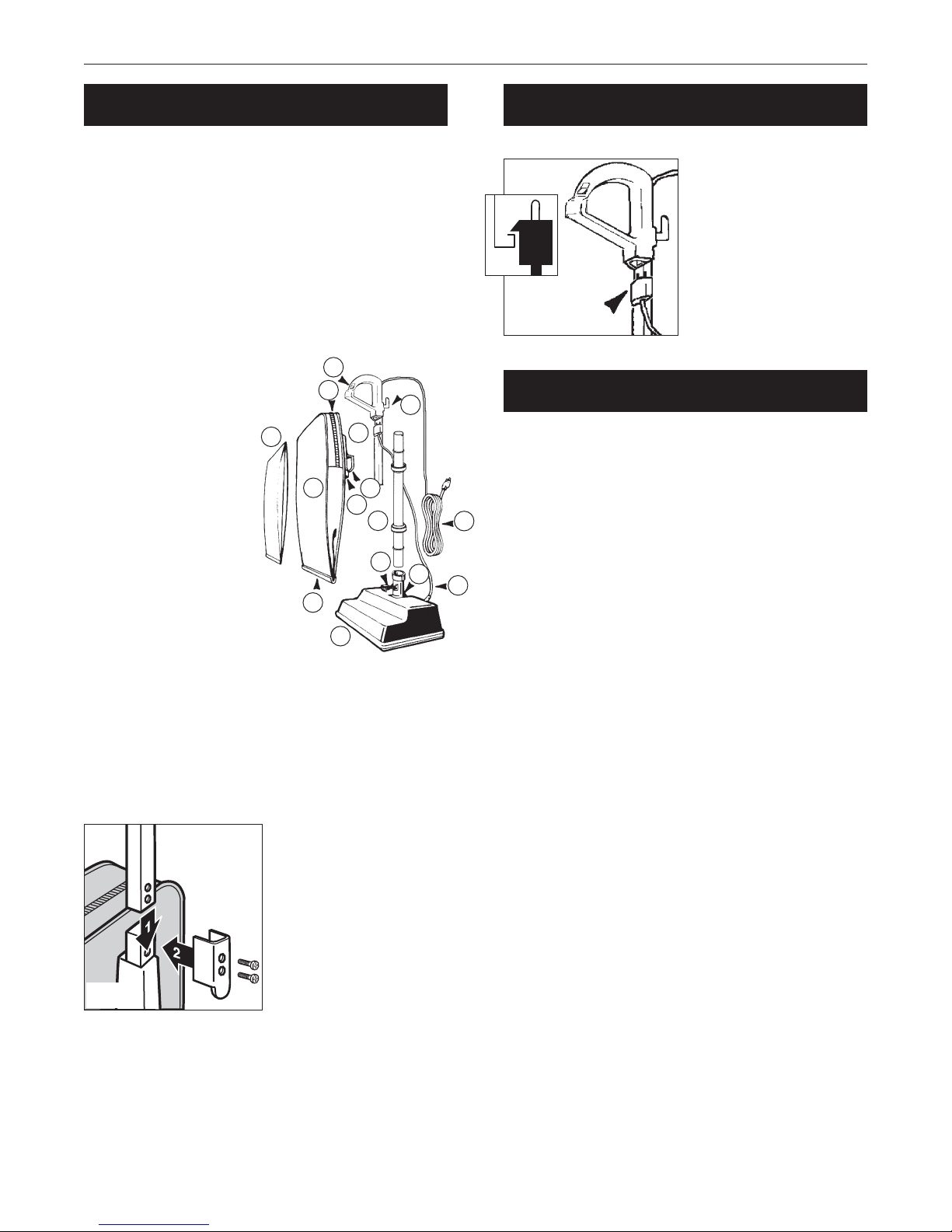

Plug

(Cord

Assembly)

Machine should be in upright

position when inserting cord

assembly into loop.

Insert plug on cord assembly

into handle.

Wrap power cord (6) around

cord wrap (11) and cord

wrap (13) and secure to “U”

shaped part on plug.

Assembly

6

15

14

7

10

13

11

12

8

9

5

1

2

3

4

Upper

Handle

Connector

Assembly

Before assembling appliance.

Remove two screws from

connector assembly. Slide

upper handle section over

matching section of the

connector assembly. Place

brace against handle and

connector assembly aligning

screw holes. Insert screws in

holes and tighten firmly until

handle is no longer loose.

Brace

Page 5

5

ENGLISH

Disposable Paper Filter Dust Bags

Disposable paper filter dust bags play a very important role in

the efficiency of your ORECK vacuum cleaner. The purpose of

the paper bag is to trap dirt, but at the same time it must be

porous enough to allow air to pass through. If the paper bag

becomes clogged, no air can pass through the cleaner and

cleaning cannot take place, regardless of the cleaner’s power.

Increase the CLEANING POWER of your cleaner by changing

the bag often.

To keep your cleaner operating at maximum efficiency, change

the dust bag frequently. DO NOT FILL ABOVE THE LINE

INDICATED ON THE DUST BAG.

Be sure the disposable paper filter dust bag is installed properly.

All paper dust bags are not the same. Your ORECK disposable

dust bags have been designed to be used with the ORECK

cleaner and using bags other than genuine ORECK disposable

bags will affect the cleaning ability of your cleaner and could

cause damage to it.

The Belt

The belt on your vacuum cleaner controls the speed of the

revolving brush and is very important for the effective operation

of the cleaner. If the belt becomes stretched or cut, it will cause

the revolving brush to stop completely or slow down. See instructions in the manual for replacing belt.

An extra belt is stored in the base plate of your cleaner. When

buying replacement belts, use ONLY ORECK genuine belts. Belts

other than ORECK belts will not operate the revolving brush

correctly and may create undue stress which will cause damage

to the motor and brush bearings. Using belts other than ORECK

belts will void the warranty.

Lubrication

The vacuum cleaner motor bearings are factory lubricated and

seated. Further lubrication is not required.

General Cleaner Care

At least once a month, check for and remove excessive lint,

string or hair from revolving brush.

Wipe the outside of the cleaner with a damp cloth. Also clean

the connector deflector assembly area, base of cleaner and fan

housing area. If there is dust in the outer bag, vacuum it or

shake it out.

A little preventative maintenance will keep your cleaner looking

new and will ensure continued cleaning effectiveness.

CAUTION—Wood Floors, Soft (Vinyl, Asphalt Tile, etc.)

Floor Surfaces and Polished Floor Finishes

Use floor and floor finish manufacturer’s recommended methods of

cleaning. The metal strip on the base of the cleaner could be damaged

if used on concrete or abrasive surfaces, and, therefore, cause

damage to wood floors

, soft (vinyl, asphalt tile, etc.) floor surfaces

and polished floor finishes

. The roller brush may also scuff very soft

finishes. Do not operate the unit while in the upright and locked

position. Do not let the unit run while in any one stationary position for

any period of time. Keep the unit moving while in operation.

Celoc® Hypo-Allergenic Filter System

The CELOC SMMS outer bag of your vacuum cleaner is high

filtration medical material designed to filter the smallest of dust

particles. It is important the inside of the outer bag be cleaned.

Vacuum the inside of the outer bag or hand wash, turned inside

out, with warm water, and air dry. For best results, the CELOC

SMMS outer bag should be replaced once a year. The CELOC

layered disposable inner dust bag must be replaced once a month

even if it is not full. Change it more often if it is used in extremely

dirty areas. Increase the cleaning power of your vacuum by

changing the bag often.

To Replace Filter

Dust

Bag

BAG INSTALLATION :

1. Hook bottom of bag collar

opening under lip “B” of

connector assembly. Pull up

on bag collar and snap over

lip “A” of connector.

2. Press on edges of bag collar

to insure bag is completely

installed.

IMPORTANT: Check to

make sure bag collar is

behind lips “A” and “B”. If it

is not, dust will leak into

outer bag. When filter bag

is in place, close outer bag

with zipper fastener.

WARNING: Unplug cord from

electrical outlet before servicing.

A

B

Page 6

6

ENGLISH

WARNING: Unplug cord from

electrical outlet before servicing.

Remove the replacement

belt from the storage

channel.

Remove the door by

removing the hold down

screw located on side of

power head.

Slide the door forward

by prying open with a

screwdriver or coin.

Remove the belt from the

brush roll pulley and the

motor drive shaft.

Loop the new belt over

the motor drive shaft.

Place the opposite end of

the belt on the top of the

brush pulley and roll the

belt around the pulley.

Using your thumb and

finger, rotate the belt on

the pulley, ensuring that

the belt encircles the

entire circumference of

the pulley.

Replace the door by

sliding it into the groove

at the bottom of the

housing. Replace the

hold down screw.

WARNING: Unplug cord from electrical

outlet before servicing.

Stuffing or

Blockage

Under certain conditions it is possible to stuff or block the intake

tube and the lower tube assembly. If your vacuum cleaner does

not pick up properly, or makes unusual noise and the outer bag

does not fluff up or balloon open, follow the following steps:

How to Replace a Worn Belt

➧

Intake Opening

D

O-ring

Fan

Housing

1. Check for blockage at the

mouth of the intake

opening. See illustration A.

If there is blockage, remove

it with long-nose pliers, a

screwdriver or coat hanger.

If you can not reach the

blockage, remove base

plate. See illustration B.

2. If the blockage is not at the

base, remove lower tube.

See illustration C. Unhook

retainer spring, releasing

bottom of bag. Twist lower

collar counter clockwise to

slide up. Pull tube out of

base. Check for blockage. If

blockage is in the tube,

remove with a coat hanger.

3. If tube is not blocked, look

into fan housing. See illustration D. Remove debris

with long-nose pliers, a

screwdriver or coat hanger.

4. To reassemble, check O-ring

on tube, and replace if

damaged. Vacuum will not

operate properly without the

tube O-ring. Slide O-ring to

approximately 2" from base

of tube. Replace tube by

first lining up slot at base of

tube with inner tab inside

fan housing. Then reinsert

tube and push down until

the tube is seated. Make

sure O-ring is in place

against fan housing

opening. Replace and

tighten collar until collar

locking tabs are locked in

place. See illustration E.

Make sure collar is not cross

threaded on housing.

E

Intake Opening

B

A

C

Retainer

Spring

➧

Page 7

Rotate and match bearing

assemblies

7

IMPORTANT: On plush and new carpets, stuffing may occur

due to excessive fuzz and loose cuttings in the carpet.

Stuffing could occur for the first few cleanings until all the

loose material is removed. Due to the high efficiency of the

cleaner, many older carpets will cause stuffing when the

cleaner is first used on them.

NOTE: If the above actions do not correct the problem, contact

an ORECK authorized service center or call the commercial

customer service center.

1-800-535-8810 x 7452

Your ORECK XL vacuum cleaner has a

special FRESH AIR tab pocket. This

light-colored pocket is located inside

the vinyl bag in the area where the

paper disposable bag attaches to the

intake tube. Insert tablet in pocket.

Using AFresh Air™ Tab

5. Many times blockage occurs

due to a full dust bag

causing dirt to back down

the air flow system. When

that happens, the blockage

will be at the top of the

system, starting in the area

where the dust bag connects

to the connector assembly.

See illustration F.

WARNING: Unplug cord from

electrical outlet before servicing.

To determine if the brush is

worn, place a firm straight

edge across the nozzle

opening. If brush bristles

do not extend beyond

base plate, brush should

be adjusted.

Remove the base plate by

removing 5 screws. Then,

remove the belt and brush

roll from the housing.

Rotate both bearing assemblies at ends of brush roll

to show “old” and replace

in the holding channels in

the housing.

NOTE: The bearing

assembly setting marked

“OLD” has two bars ( l l )

on the top of the assembly.

The one marked “NEW”

has one bar ( l ). When

rotating bearings, make

sure both bearing

assembly settings are the

same and face up when

replacing the brush roll.

Reassemble the belt and

the base plate and check

bristle height above base

plate at each end of

brush.

If a previous adjustment

has already been made

and bristle height does not

extend above base plate,

a new brush assembly

should be ordered.

IMPORTANT: Unless

the brush is worn as

indicated above,

both bearings must

be in the new

position. When

rotating, both

bearings must be in

the old position.

Unmatched settings

will cause damage

to your machine.

ENGLISH

To Adjust or Replace Brush

This appliance must be grounded. If it should malfunction or

break down, grounding provides a safe path of least resistance

for electrical current, reducing the risk of electric shock. The cord

for this appliance has an equipment-grounding conductor and a

grounding plug. It must only be plugged into an electrical outlet

that is properly installed and grounded in accordance with all

local codes and ordinances.

DANGER: Improper connection of the equipment-grounding

conductor can result in a risk of electrical stock. Check with a

qualified electrician or service person if you are in doubt as to

whether the outlet is grounded. If not, have a proper outlet

installed by a qualified electrician.

This appliance is for use on a nominal 120-volt circuit. It has a

grounding plug similar to the example shown. Make sure the

appliance is connected to an outlet with the same configuration

as the plug. No adapter should be used with this appliance.

Grounding Pin

Grounded Outlet

Grounding Instructions

F

Connector

Deflector

Opening

Page 8

U2000 PARTS LIST

7

Advance Filtration Disposable Dust Bag (Pack of 25) Case 250 bags

8000.25DW

22

Fan Nut 1/4 X32 Yellow Chrome Left Hand

03-00448-01

8 Lbs. Upright

100 Armstrong Road, Suite 101 Plymouth, MA 02360

(800) 242 - 1378 (888) 23-ORECK Fax (877) 672 - 4566

Diagram Part Description Part Number

1 Handle Grip 2000RSB- STRAIGHT HANDLE 75272-02

2 Bent Handle Assembly 75575-04

3 Cord Bracket 75245-02

4 Screw #10X.5 w/Intrigle Washer, Handle Tube 03-00478-02

4 Short Screw Handle Bracket 03-00504-01

4 Long Screw Handle Bracket 03-00605-01

4 Handle Bracket Square Nut 03-00606-01

5 Cord Clamp 03-00449-01

6 Screw #10X.5 Phillips, Cord Bracket/Clamp 03-00450-01

7 Filter Disposable Dust Bag (Pack of 25) Case 250 bags 8000.25

7 Filter Disposable Dust Bag (Pack of 9) 8000.9

7 Advance Filtration Disposable Dust Bag (Pack of 9) 8000.9DW

7 Permanent Cloth Bag PCB9300

8 Outer Cloth Bag (RHB) 75246-16N

8 Advance Filtration Outer Cloth Bag (HHB) 75246-15N

9 Connector/Deflector Assembly w/Stiffener 09-75308-05N

9 Deflector 75220-01-327

10 Collar 75309-02-327

12 Tube Assembly 75188-01

12 Tube Assembly for 9300 Upright 75017-01

13 Stiffener (use same length screws) 75189-02

13 Stiffener Through Bolt Connector (use different length screws) 75619-01

14 Fan Housing w/Spring & rivet 09-75343-03N

15 METAXALLOY Fan Kit w/Washer 09-75300-01N

15 Metal Fan Kit 75013-01

16 Metal Fan Seal 75012-01

17 End Cap (Left) 013.4623

18 Motor Kit includes: Jumper Wire, Wire Nut & Felt 09-75505-01

18 Motor Kit includes: Jumper Wire, Wire Nut & Felt (U2000EB & U2000RB) 09-75505-02

19 Motor Brush 2 Pack. 09-75514-01

20 Motor Seal 75095-01

21 Felt Motor Seal 75117-01

-

-

Page 9

U2000 PARTS LIST

33

Belt Drive 3 pack

030.0604

51

Screw #8X .62 Phillips, Intake Pivot

03796

8 Lbs. Upright

100 Armstrong Road, Suite 101 Plymouth, MA 02360

(800) 242 - 1378 (888) 23-ORECK Fax (877) 672 - 4566

Diagram Part Description Part Number

23 Foot Switch Cover 09-75266-01

24 Foot Switch Assembly (Includes Plate) 75084-05

25 Screw #8X.5 Phillips, Foot Switch 03752

26 ORECK Commercial Name Plate Label 75599-02

27 Housing 09-75430-03N

27 Housing with Belt Door Assembly (U2000EB & U2000RB) 09-75430-19

28 Bumper, Clear 75181-04N

29 Intake Pivot w/Felt Seal (Includes 30) 09-75066-02

30 Felt Pivot Seal 75065-01

32 Wire Nut 03-00444-01

33 Belt Drive 75024-01

33 Belt Drive (U2000EB & U2000RB) 75855-01

34 Heyco Cord Retainer Strain Relief (round) 03-00455-01

34 Heyco Cord Retainer Strain Relief (square) 03-00494-01

35 Screw #8X.75 Phillips, Base Plate, Belt Door, Motor 03-00476-01

36 Brush Roll, Pulley & Bearing Assembly, Red 75202-01N

36 Brush Roll with Grooved Pulley (U2000EB & U2000RB) 75881-01

37 Belt Door 75057-01-441

37 Belt Door Vented (U2000EB & U2000RB) 75894-04-441

38 Screw #7 X.38 Phillips, Detent & Corner Brush 03-00475-01

40 Base Plate Seal 75008-01

41 Complete Baseplate 09-75715-03

41 Complete Baseplate (U2000EB & U2000RB) 09-75715-05

42 Channel Old Style 75007-02N

43 Soft Rear Wheel, Black 75187-01-327

44 Rear Wheel Axle 03-00630-01

45 Edge Brush (each) 75766-04

46 Washer, Trust Fan 03-00479-01

48 Bag Retainer Spring 75035-02

49 Bag Clip (Gray) 09-75078-07

49 Bag Clip (Red) 09-75078-08

50 Plastic Detent 75299-01

Page 10

U2000 PARTS LIST

56

Lower Cord Harness Assembly (U2000EB & U2000RB)

75877-01-441

96

Wire Harness (U2000EB & U2000RB)

75877-01-447

8 Lbs. Upright

100 Armstrong Road, Suite 101 Plymouth, MA 02360

(800) 242 - 1378 (888) 23-ORECK Fax (877) 672 - 4566

Diagram Part Description Part Number

52 Micro Sweep Blade 75009-01N

53 Power Cord, Foot Switch Model 75080-04

53 D-Handle 35' Red Power Cord post 01/03 75558-02-441

53 D-Handle 35' Black Power Cord post 01/03 75558-02-441B

54 Handle Switch Assembly prior to 01/03 75110-02N

54 Handle Switch Assembly TWO SPEED 75585-01

54 Switch reffer to #54-A TWO SPEED SWITCH 75585-01

54 Switch Purchased after 01/03 75559-01

55 D-Handle Power Cord prior to 1/03 75294-01-327

56 Lower Cord Harness prior to 1/03 75082-02

56 Lower Cord Harness after 1/03 75557-03-441

57 Static Wire 75037-01

58 Handle Grip set prior to 1/03 09-75301-08

58 Handle Grip set after 1/03 (5 Screws) 09-75576-08

59 Screw #8 X.75 Phillips w/Small Heads, Handle Grips 03-00456-01

60 Cord Wrap Assemble includes: Post & Cord Wraps 09-75185-07

61 Handle Tube Black 75190-04

61 Handle Tube Chrome 75190-03

62 Collar O'ring 75191-02

63 Screw #6-20 X 1/4" Collar Set 03-00482-01

64 Motor Spring 75283-01

66 Handle Brace Kit (use is highly recommended) 75435-01

69 Soft Front Wheels, Black 75709-01

70 Hardwire kit includes # 54, 55, 56, 58 & 61 09-75562-09

71 Fan Housing Push Nut 03-00636-01N

72 Bag Spring 75015-01

73 Rivet 03-00453-01

73 Washer Lock External Tooth 03-00480-01

80 Housing 2000RS 09-75430-04

93 PCB Bracket (U2000EB & U2000RB) 75880-01-0327

94 Main Circuit Board (U2000EB & U2000RB) 75879-01

95 Circuit Board Harness (U2000EB & U2000RB) 75878-01

-

-

Page 11

U2000 PARTS LIST

8 Lbs. Upright

100 Armstrong Road, Suite 101 Plymouth, MA 02360

(800) 242 - 1378 (888) 23-ORECK Fax (877) 672 - 4566

Diagram Part Description Part Number

* Soft Vacuum Cover VACCOVER

* Scent Tabs SCENT

* Bag Docking Kit 09-75657-01

* Magnet Bar MC4BK

Loading...

Loading...