Page 1

OWNER’S MANUAL

SF600

Read this instuctio n m an u al carefu lly before any use of the mach i n e, keep it as a reference.

Also, the engine m an ual is included as a set with th e owners man u al . Please read both carefully.

For any questions about this manual, please contact your OREC dealer, the

distributor in your country, or go to : http://www.orecamerica.com

0031-71010

Page 2

Getting Started

y

g

play

DANGER

CAUTION

WARNING

NOTICE

Thank you for purchasing this machine. These instructions explain the correct and easy way

to alwa

Please read these instructions fully before using this machine in order to understand the

safest, most efficient way of operating it, and the correct way maintain it.

Please keep these instructions in a safe place where they can be easily referred to at any

time. We hope you will use this machine for many years to come.

Please understand that ongoing enhancements in quality and performance, and

other possible parts improvements may cause the actual machine to vary slightly from what is

described in these instructions.

s keep this machine in fine working order and operate it safely.

Machine Regulations

This machine is designed to cut overgrown weeds and brush, and is not a lawn mower.

Therefore it can not offer the same quality cut as a finishing mower.

This machine is desi

ned mainly for commercial and agricultural users.

Definitions and Signs

In these instructions, the following signs and definitions are used to indicate the level of

danger that exists. Please adhere to the following warnings and have a full understanding of

the meaning of the signs.

Sign Definition

Displayed when failure to obey instructions can result in death or

serious injury.

Dis

Displayed when failure to follow instruct ions c an result in injury, or

when not attending to the machine and correcting it can also result in

injury.

Displayed when it is important to know about operation and

maintenance specific to this machine, or at times when

misunderstanding and mistakes are common.

ed when there is a danger of death or serious injury.

㻝

Page 3

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Contents

For Safe Operation----------------------------------------------------------------------------------3

Warning Symbols------------------------------------------------------------------------------------Important Safety Points-----------------------------------------------------------------------------

Name of Parts---------------------------------------------------------------------------------------How to Operate the Machine--------------------------------------------------------------------

How to start and stop the engine---------------------------------------------------------------How to drive, turn, change speed, and stop------------------------------------------------Tilling------------------------------------------------------------------------------------------------------

Oiled Parts Inspection, Replacement, and Lubrication--------------------------------

Transmission oil inspection, replacement and lubrication----------------------------Engine oil inspection, replacement, lubrication-------------------------------------------How to Lubricate Each Part-----------------------------------------------------------------------

How to Inspect, Maintain, and Adjust Each Part-----------------------------------------

How to inspect and adjust the spark plug---------------------------------------------------How to clean the air filter--------------------------------------------------------------------------Tire pressure adjustment--------------------------------------------------------------------------Adjusting the Cables--------------------------------------------------------------------------------Belt Inspection----------------------------------------------------------------------------------------Tine Inspection and Replacement--------------------------------------------------------------Inspection and Replacement of EZ Anker----------------------------------------------------

Long-term Storage---------------------------------------------------------------------------------- 26

Specifications Reference values--------------------------------------------------------------- 27

Included Tools--------------------------------------------------------------------------------------Consumable Parts List-----------------------------------------------------------------------------27

Periodic Voluntary Inspection Table--------------------------------------------------------Troubleshoot----------------------------------------------------------------------------------------When engine won't work properly------------------------------------------------------------- 30

Warranty parts--------------------------------------------------------------------------------------LIMITED WARRANTY------------------------------------------------------------------------------

3

5

11

13

13

15

17

18

19

20

21

21

21

22

22

23

24

25

26

27

28

29

31

32

Page 4

For Safe Operation

y

g

Please read these instructions regarding safety and operation before operating this machine.

In order for this machine to satisfactorily demonstrate its tr ue per formance, please preform r egular

maintenance and inspection

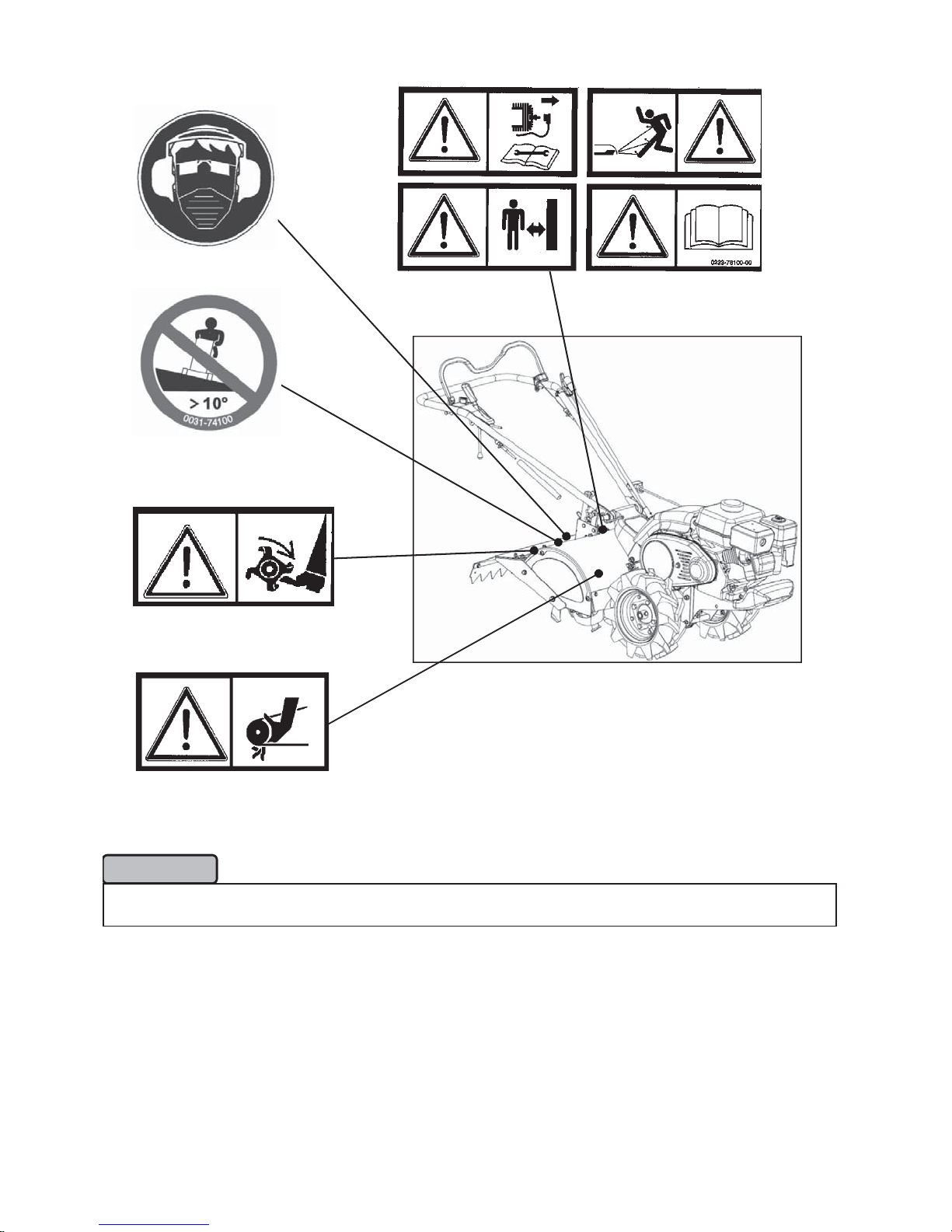

Warning Symbols

The warning symbols are attached to the machine to draw attent ion to particularly serious dangers.

Please be sure to fully understand the meaning of each warning symbol before operating

this machine.

࣭ Read the safety and operating manual.

࣭ Remove all objects that could be thrown by the tines. Beware of

thrownobjects.

࣭ Pinch hazard. Keep bod

Always wear safety glasses and ear protection while operating

䞉

࣭ Do NOT use on slopes of more than 10 de

parts away from rotating parts

rees

࣭ Keep body parts away from rotating tines

࣭ For safety, disconnect the spark plug when performing

inspections and maintenance

࣭

Do not operate the machine near people or animals.

Stand clear the machine.

㻟

Page 5

0215-83200

0031-74100

83-1260-909-10

0223-76100

80-1488-928-10

ᵬᵭᵲᵧᵡᵣ

Ɣ

In the case that these warning symbols become difficult to see, please replace them so

that they can be easily seen und understood.

㻠

Page 6

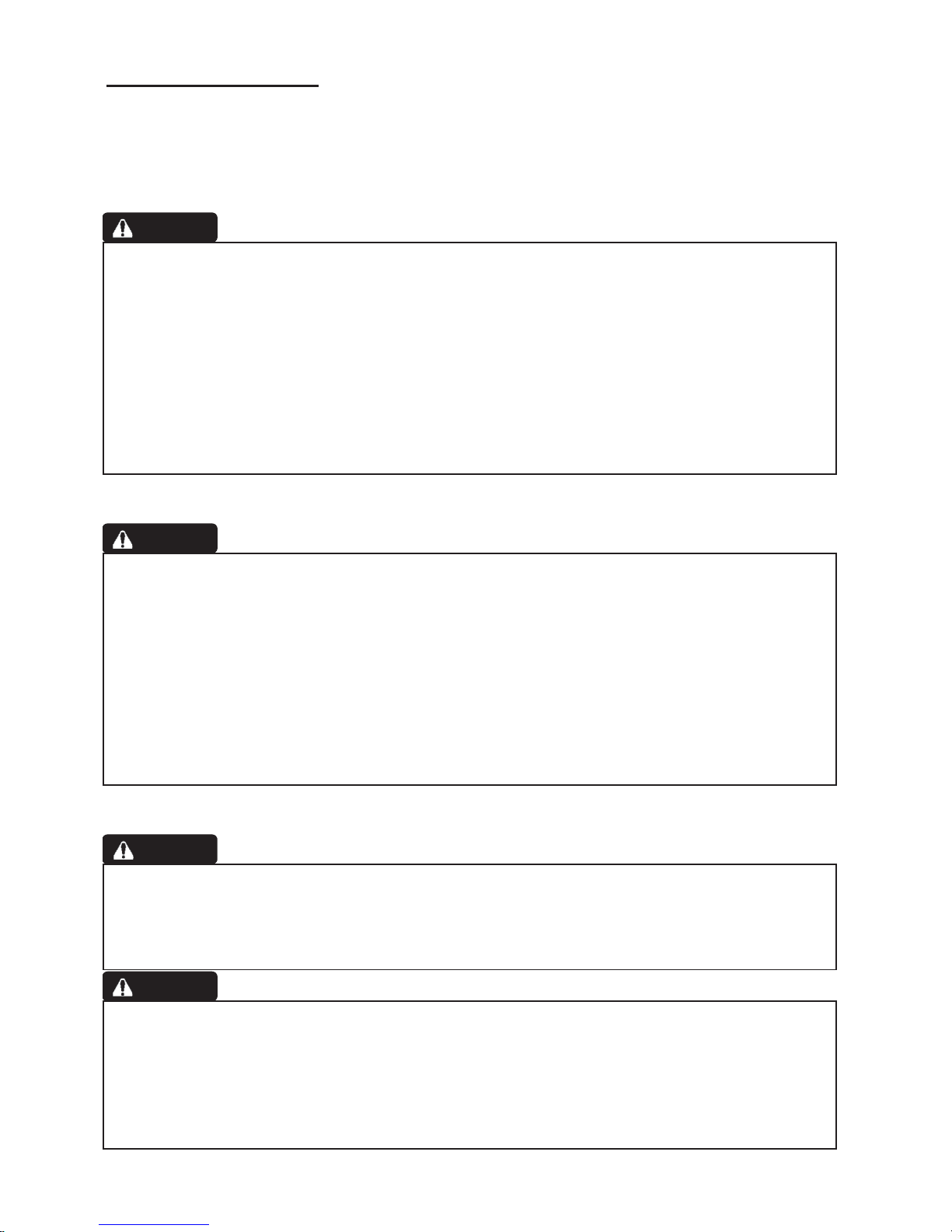

Important Safety Points

ᵥ

ᵥ

ᵥ

This machine is equipped with a high-powered engine and fast moving tines. Misuse of

this machine canresult in serious injury or death. Before using this machine, please be sure to

read these instructions and understand and adhere to the following warnings

ŶNotes for the operator of this machine.

ᵵᵟᵰᵬᵧᵬ

Ɣ

The operator of this machine should fully read these instructions. You can safely use this

machine only after gaining a full understanding of its operat ion and safety use guidelines.

Ɣ

Operate this machine only after fully reading and understanding the included

engine’s instructions.

Ɣ

The operation and maintenance of this machine should only be performed by trained

persons

Ɣ

Do not allow children, expectant mothers or any untrained person to use this m achine,

accident and injury can result. Also, please check and observe local laws which may

place age limits on the operation of machinery.

Ɣ

Do not operate if suffering from overwork or illness or if under the influence of alcohol

or drugs. Accidents and injury can result.

ŶWhen lending this machine to another person

ᵵᵟᵰᵬᵧᵬ

When lending t his m a chine t o another person it is the owner’s responsibility that the following

measures are carried out.

Ɣ

The owner should explain how to operate the machine and require the new operator to fully

read these instructions. The owner should then guide the new operator until t hey have

a comprehensive understanding of the machine’s operation and saf et y guidelines.

The owner should lend these instructions to the new operator with the machine.

Ɣ

When lending this machine to a person who can not read Engl ish, the owner

should take responsibility for fully explaining its safe operation.

Ɣ

The owner holds responsibility for the managem ent of this machine, including checking

that all parts are correctly attached and that all functions are working correct ly bef or e

lending it to anyone.

ŶManaging gasoline safely

ᵢᵟᵬᵥᵣᵰ

Ɣ

Absolutely do not handle gasoline in the presence of lit cig arettes, open flame, or ot her

sources of ignition. Gasoline is an extr em ely flammable liquid and its high volatility means

there is a danger of f ire and explosions.

Ɣ

Do not use a type of gasoline other than that descr ibed. There is a danger of fire and

explosions.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Store gasoline and oil safely away from sources of flame and places where children can easily

reach. Accidents and injury can result.

Ɣ

Please refuel in a place that is well ventilated. As gasoline is a hig hly volatile substance, t here

is a danger that you will feel unwell if you operate the machine in a poorly ventilated place.

Ɣ

Do not open the fuel cap while running the engine.

Ɣ

When refueling, be sure to stop the engine and allow it to cool down. T her e is a danger of

suffering burns.

㻡

Page 7

Ɣ

ᵥ

ᵥ

When refueling, be sure not to f ill t he fuel tank over the maximum level. If you do overfill the fuel

tank, remove fuel until it sits below the maximum level. Over-fueling can cause fire and

other accidents.

Ɣ

After refueling , secur ely close the fuel cap and store the machine in a safe place with no

sources of ignition. Ther e is a danger of fire.

Ɣ

If you spill gasoline, move the machine a safe distance away without starting the engine.

Starting the machine in close proximity to a fuel spill can result in a fire or other accident . Use

a waste cloth to wipe away the spill and dispose of the cloth in accordance with local laws.

Ɣ

Be sure to change your clothes immediately if t hey come int o cont act with gasoline. There is a

danger that any gasoline on your clothes could ignite or cause you to feel unwell.

Ɣ

Do not refuel in places such as inside a car or on a truck , they could move unexpectedly. Refuel

after placing your fuel cont ainer safely on the ground, away from vehicles.

Fuel spills can cause fire and other accidents.

Ɣ

Do not remove the refueling nozzle from the fuel tank until you have finished refueling.

Fuel spills can cause fire and other accidents.

ŶCaution when starting the engine

ᵢᵟᵬᵥᵣᵰ

Ɣ

Do not modify the engine as this can cause accidents or explosions. You will bear responsibilit y

for any accidents or problems caused by modification. Also, trying to claim compensation in

such cases will be ineffective

Ɣ

Do not try to alter the position of the engine governor or change the set r ot ation speeds.

Ɣ

Do not run the engine in a place that is poorly ventilated. Eng ine exhaust is odor less and

contains carbon monoxide which can cause death or serious injury.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Do not allow highly flammable substances near the engine or t he path of the exhaust as

this can cause a fire.

Ɣ

Do not touch the engine or muffler as they become extremely hot during operation and can

cause severe burns.

Ɣ

Do not allow weeds and leaves to accumulate in the engine, especially in the recoil cover,

airfilter, and near to the muffler. Overheating and fire can result.

Ɣ

Ensure that the clutch lever is in the [OFF] posit ion, t he speed change

lever is in the [N] position, before star t ing the engine. Not taking precautionswhen starting

the engine can cause injury and accidents.

Ɣ

After starting t he engine with the clutch lever in the [OFF] position, check t he

belt to be absolutely certain that it is not moving . I f the belt is moving even a little,

immediately switch off the engine and adj ust the belt guard and the wire. Not tak ing pr ecautions

can cause injury and accidents.

ŶCaution when loadi ng and unloading

ᵵᵟᵰᵬᵧᵬ

Ɣ

When loading or unloading using a truck, proceed carefully and be certain to park on a

flat and safe surface. A truck moving suddenly could cause injury and accidents.

Ɣ

Attach a gently sloping ramp securely to the t r uck’s loading platform and lower the running of

the engine. The speed change lever should be put in the forward [1] position for loading , and in

the reverse [R] position for unloading . Proceed with caution as injury and accidents can be

caused by the machine tipping over or running out of cont r ol.

㻢

Page 8

ŶBefore operating the machine

)

p

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Absolutely do not try to modify this machine (including m odification of the protect ive cover and

safety cover) as this can cause injury and accidents. You will bear responsibility for any

accidents or problems caused by modification. Or ec America will not bear any responsibility for

modified machines.

Ɣ

Do not change or tamper with the safety apparat us. I nspection should be performed

periodically to ensure the safety apparatus is working cor r ectly.

Ɣ

For safety reasons, use the recommended accessories and att achments that are best suited

to the ground you are working on and the type of work you are per forming

Ɣ

This machine can not be ridden, do not try to ride it or allow children or pets to ride on it. This

can cause injury to people/pets and damage to the machine.

Ɣ

Wear suitable clot hing when operating this machine. Please wear the following items to protect

against injury and reduce the possibility of accidents.

㸫Long sleeves, long pants 㸫Protective glasses

㸫Non-slip shoes 㸫Gloves

㸫Helmet 㸫Ear protection, etc.

Cuffs, hems of loose clothing, and jewelry can become entangled in the

machine. Avoid wearing such items to help prevent injury and accidents. Long hair

should be tied up inside a helmet.

Ɣ

Ensure that no part of your body comes into contact with the m oving t ines of this machine.

There is the possibility of serious injury such as the severing of hands and feet.

Ɣ

Do not remove any parts of this machine that have been f itted as standard. To prevent

accidents, be sure to use all covers and parts in the same state as t hey have been fit t ed.

Ɣ

Be sure that there are no people, animals or vehicles close by. Not taking precautions

can cause injury and accidents.

Ɣ

Before starting, rem ove any rocks or br anches t hat could be thrown and cause injury to

bystanders or damage to the machine

Ɣ

Use this machine during daylight or with sufficient artificial light. Do not operate this machine

at night when poor visibility will not allow you to be completely aware of your surroundings.

Being unable to notice dangerous objects and bystanders is a cause of injury and accidents.

Ɣ

Absolutely do not operate this machine in places where there are dangerous dr ops, dit ches or

embankments. Accidents can be caused by the machine tipping over.

Ɣ

Do not use this machine on wet grass. It is easy to slip on wet grass, causing injury and

accidents.

ŶSpark arrester (optional

Ɣ

This product is NOT equipped with a spark arrester. In some areas, it is illegal to

operate the engine without a spark arrester. Please check local laws and regulations.

An optional USDS approved spark arrester is available through your engine service

dealer.

S

ark arrestor (Honda) item code: 18355-ZL0-000

㻣

Page 9

ŶCaution during operation

Ɣ

During operation, tines and belts are hidden by a cover, be sure to keep hands and feet well

away. Touching these parts can cause serious injury such as the severing of hands and feet.

Ɣ

During operation, the rotating tines come right to the edge of the tine cover. Absolutely

do not put your feet inside the cover. Not taking precautions can cause injury.

Ɣ

Before removing entangled grass or other foreign objects from the tines, be sure to stop

the engine and remove the spark plug cord. Check that the tines have stopped moving

before carefully removing any entangled material.

Ɣ

Be sure that there are no people, animals or vehicles close by. When operating this m achine,

always maintain a distance of 100 FEET between you and bystanders. If people or animals

come near, release the clutch and switch off t he engine. Not taking precautions can cause

injury and accidents.

Ɣ

For safety reasons, do not make sudden star t s/stops or sharp turns.

Ɣ

Take care to move and turn the machine gently, and stop the tines when not tilling

Not taking precautions can cause injury and accidents

Ɣ

The operater should always be behind the machine during use (handlebar side). When this

machine’s engine is running, do not stand in front of the path where you are tilling.

Not taking precautions can cause injury and accidents.

Ɣ

If you notice any strange noises, smells, heat , or vibrations during the operation of this machine,

switch off the engine immediat ely, r emove the spark plug cord and ensure that all m ovable

parts have completely stopped. Be sure to have the machine inspected f or dam age and

obstructions and have any damaged parts repaired.

Ɣ

Watch for holes in the ground and protruding tree roots. Also look out for obstructions

that could be buried in ground. The handlebars can be taken from your control, causing

injury and accidents.

Ɣ

Be careful when approaching blind corners, bushes, and tr ees which block your line of sight.

Such obstructions can hide children and animals from view.

Ɣ

Do not operate this machine in the direction of rivers and drop-offs, people and buildings.

Accidents can be caused by falls and collisions.

Ɣ

When moving the m achine backwards, check that there are no people or obstacles behind

you and that you have a secure foothold. When reversing, there is a danger of being trapped

between the machine and a wall or falling from drop-offs.

Ɣ

Exercise caution when operating the machine alongside fences, buildings and trees.

The machine’s handlebars can be taken fr om your cont r ol if you come into contact with

obstacles, possibly causing injury and accidents.

Ɣ

Do not leave the machine unattended with the engine running. When leaving the machine

unattended, park on a flat sur face with the engine switched off, put t he dr ive clutch lever in

[OFF]. Injury and accidents can be caused if t he machine moves while unattended

ᵡᵟᵳᵲᵧᵭᵬ

Ɣ

When operating the machine close to buildings, or trees, t ake care not to cause

accidents and damage by crashing into them. I f you do hit something, switch off the engine

immediately. Confirm that the tines have stopped moving and then check them for dam age

such as bending and cracking. Check all areas of the machine for damage and have part s

repaired or replaced if necessary

㻤

Page 10

ŶUsing the machine on slopes

ᵥ

ᵥ

ᵥ

ᵵᵟᵰᵬᵧᵬ

When operating on slopes, serious accidents can be caused by you slipping and the machine

rolling over. Be especially careful when working in such areas and stop oper at ing the machine

immediately if you feel in any danger at all.

Ɣ

Do not operate the machine on slopes of more t han 15°.

Ɣ

Till across the face of slopes; never up and down. The handlebar s can be t aken from

your control, or rollover, causing injury and accidents

Ɣ

When changing direction on a slope, do it slowly and carefully. The machine could roll over,

causing injury and accidents.

Ɣ

Do not operate the machine on wet slopes. There is a danger of slipping, causing injury.

Ɣ

Watch for holes in the ground and protruding tree roots. Also look out for obstructions

that could be buried in ground. The handlebars can be taken from your control, causing

injury and accidents.

Ɣ

When operating on slopes, do not leave the machine with its clutch off or t he speed change

lever in neutral. The machine could run out of control, causing injury and accidents.

ŶChildren

ᵵᵟᵰᵬᵧᵬ

When operating this machine, be particularly aware of children. Childr en ar e often interested in

tillers and may be curious. As children may not be concentrating on their surroundings,

accidents can occur if you take your eyes off t hem . Please treat the following points with great car e.

Ɣ

Do not allow children to come into the area where you are working. Make sure that young

children are securely in the care of an adult other t han the operator.

Ɣ

Switch off the engine immediately if children enter the area where you are working.

Ɣ

Do not allow children to operate the machine. Check and obey local laws which

may place age limits on the operation of m achinery

Ɣ

Be careful when approaching blind corners, bushes, and tr ees which block your line of sight.

Such obstructions can hide children from view.

ŶMaintenance

ᵵᵟᵰᵬᵧᵬ

Ɣ

Be sure to switch off the engine and r em ove the spar k plug cord before performing any

inspection, adjustment or maintenance on this machine.

Ɣ

When performing inspection, adjustment or m aintenance, use the correct tools to

work as safely as possible

Ɣ

Perform periodic inspections in order t o work as safely as possible. If you discover any worn or

damaged parts, please replace them with recomm ended par ts only.

Ɣ

When inspecting or handling the machine, do not directly touch the t ines. Exercise caut ion

by wearing gloves and wrapping the tines in cloth. If you notice any abnormalities

in the tines, do not try to repair them, have them r eplaced with OEM parts from Orec.

Not taking this precaution can cause injur y and accidents

Ɣ

Damage to the belt cover, tine cover, or rear guard, could cause injury or

accidents. Be sure to have any damaged parts replaced befor e using the machine again.

Ɣ

Be sure to check that the covers of r otating parts are refit ted correctly in their original positions

after being removed. Poorly f it t ed covers could open dur ing operation and cause serious injury

Ɣ

Check that all nuts and bolts are securely tight ened

Ɣ

Perform comprehensive inspection and adjustment of such parts as drive clutch,

throttle, and gear change.

㻥

Page 11

Ɣ

When rubber fuel lines become old, they can split and dangerous fuel leaks can occur. Change

rubber parts if they split or every 3 years regardless of damage. At this time, also change

the fastening bands for the new parts.

Ɣ

Be sure to check that the bolts in the wheels and blades are tightly fastened.

Ɣ

When replacing the tines, also replace the attached nuts and bolts. There is a possibility of

accidents caused by worn or damaged parts. Never substitute nuts and bolts with those that

are not recommended.

Ɣ

Remove fuel when storing or transporting the machine. Accidents and damage can be caused

by fuel spills or expired fuel.

Ɣ

When storing the machine, place it on a flat surface away from sources of flame. Not taking

precautions can cause accidents and damage.

Ɣ

Before storing the machine, remove such foreign material as weeds and leaves. Clean away

any oil spills or fragments stained with oil.

Ɣ

Make sure that the engine has completely cooled before covering the machine with

a storage cover.

Depending on operating conditions, there may be occasions when incidents arise which are not

covered by the warnings in this manual. The operator should always use common sense and put

safety first when using this machine

㻝㻜

Page 12

䛀

䛁

Name of Parts

Note: the model in the pictures may slight ly different than the actual m achine.

1: Clutch lever

3: Engine stop switch

4: Diff lock lever

5: Adjustable handle

2: Throttle lever

6: Speed change lever

8: Depth adjustment bar

7: Rear guard

㻝㻝

Page 13

1: Clutch lever

r

Operates by turning power transmission [ON] / [ OFF] from the engine to the drive transmission.

Lower the lever and grip it together with the handlebars to t ransfer power to the transmission

and start driving the machine [ON] .

Release your grip on the lever and it will automatically return to its raised position,

power transmission will be cut and the machine will stop moving.

2: Throttle lever

Adjusts the engine rotating speed (RPM)

3: Engine stop switch

Switches the engine ON/OFF.

4: Diff lock lever

When the lever is put int o its forward position, the differential gear lock is [ O N].

Normally, the machine should be operated with this lever [OFF].

When you are operating on a slope or soft ground where the tire on one side m ay slip and it

may be difficult to go in a st r aight line, when unloading from a truck, or when you need to

operate the machine in a straight line, switch the diff lock lever on to stop the t ir es from moving

left and right, to increase the machine's ability to move forward in a straight line.

ᵡᵟᵳᵲᵧᵭᵬ

Ɣ

There is a danger of damage to the gears if the diff lock lever is operated with

the drive clutch lever [ON].

Ɣ

For safety reasons, turn the diff lock lever [ON] when on slopes.

5: Adjustable handle

Handlebar height can be adjusted based on operator's height

6: Speed change lever

Select tilling speed. There are two forward speeds levels and one reverse.

When you select the tilling position[ ], the machine will begin tilling.

There is only one travel speed when tilling.

7: Rear guard

Protects the operator's feet from the tines and thr own object s when tilling .

8: Depth adjustment ba

Adjusts tilling depth.

㻝㻞

Page 14

How to Operate the Machine

䠖

㸸

ᵥ

ᵥ

How to start and stop the engine

(Refer engine manual)

ŶBefore starting the engine

Place the machine on a flat surface and per form the following procedures to check the quantity of

engine oil and fuel.

Prep 1

Ɣ

Ɣ

Check engine oil

ᵵᵟᵰᵬᵧᵬ

Make sure the engine has cooled down before checking oil. There is a danger of burns.

ᵬᵭᵲᵧᵡᵣ

When this machine is shipped, it is l ubricated with oil; however, before operating

the machine,make sure that it is lubricated with the described oil.

1.

Unscrew the dipstick and inspect, using oil gaug e.

Note: Check oil level by inserting and removing

the dipstick wit hout screwing it into

the filler hole.

2.

If the oil does not lie between the upper level and

lower level, replenish to bring the oil to the upper level.

DIPSTICK

Note:

Please make sure not to overfill t he engine oil

Prep 2

Check fuel

ᵢᵟᵬᵥᵣᵰ

Ɣ

Absolutely do not handle gasoline in the presence of lit cig ar et tes, open flame, or other sources

of ignition.Gasoline is an extrem ely flammable liquid and its high volatility means ther e is

a danger of fires and explosions.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Please refuel in a place that is well ventilated. As gasoline is a hig hly volatile substance,

there is a danger that you will feel unwell if you operate the m achine in a poorly ventilated place.

Ɣ

When refueling, be sure to stop the engine and allow it to cool down. T her e is a danger

of suffering bur ns.

Ɣ

When refueling, do not overfill the fuel tank above the maximum level. If you do overfill

the fuel tank, rem o ve fuel until it sits below the maximum level. Over-fueling can cause fire and

other accidents

Ɣ

After refueling , secur ely close the fuel cap and store the machine in a safe place with

no sources of flame.Ther e is a danger of fire.

Ɣ

If you accidentally spill gasoline, move the machine a safe dist ance away without starting

the engine. Starting the machine in close proximity to a fuel spill can result in f ir e or

other accident. Use a cloth to wipe away waste gasoline then dispose of according to local laws.

Refuel the machine with regular unleaded gasoline.

1.

(Refer to fuel tank specifications on quantity)

㻝㻟

Page 15

ŶHow to start the engine

ᵢᵟᵬᵥᵣᵰ

Ɣ

Do not start the engine in a confined space or a place with insufficient ventilation.

Engine exhaust gas is odorless and contains carbon monoxide which can cause death.

Put the speed change lever in the [N] position.

1.

2.

Move the fuel valve lever to the [ON] position

3.

To start a cold engine, move the choke lever to

the [ CLOSED ] position.

Throttle lever

Starter grip

If the engine has been warmed up,

there is no need to use the choke.

Turn the throttle lever between the [ ] and [ ]

4.

positions

Grip the starter knob, pull slowly until you feel tension and

5.

then pull strongly from this position.

Immediately after the eng ine has st arted, slowly return

the startknob to its or iginal position.

If the choke lever to moved to t he [CLOSED] position

6.

to start the engine, g radually move it to the [OPEN] position

as the engine warms up

ᵬᵭᵲᵧᵡᵣ

Ɣ

Please warm up the engine by leaving it engaged,

with the throttle in [ LOW ] for approximately 2 minutes.

㻝㻠

Page 16

ŶHow to stop the engine

ᵥ

ᵥ

Turn the throttle lever to t he [ ] position, then move

Throttle lever

How to drive, turn, change speed, and stop

ᵵᵟᵰᵬᵧᵬ

Ɣ

Confirm that all around you is safe before proceeding to drive the machine.

ʊ If driving the machine alongside ditches or the edg es of paths, there is a danger that the

weight of the machine could cause the ground t o collapse. Exercise sufficient caution when

operating the machine on soft ground.

ʊ Do not operate the machine on slopes of more than 10° or on slippery gr ound. There is a

danger of the machine rolling over or r unning out of control.

1.

the engine stop switch to the [ OFF ] position t o st op

the engine.

Shift the fuel valve to the [CLOSED] position

2.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Do not touch the hot engine immediately after

switching off. Allow time f or it to cool down as

there is a danger of burns

ŶHow to dri ve

Start the engine.

1.

Be sure to shift the speed change lever securely in the

2.

necessary position, [ 1 ], [ 2 ] or [ R ]

Do not shift in the [ ] position.

Ɣ

If the speed change lever is not securely in place,

there is a real danger that gear s could be r eleased

while driving the machine. If a gear is difficult to engag e,

do not force it. Press the clut ch lever t o t he [ON]

position and be certain tocheck the gear change

clutch lever

3.

ᵬᵭᵲᵧᵡᵣ

Ɣ

Place the machine on a flat surface and r elease t he diff lock lever [OFF].

Ɣ

When you are operating on a slope where the tires may slip and it may be difficult t o go in a

straight line, switch the diff lock lever [ON] to help your progr ess.

one more time.

Ɣ

Turn the throttle lever to [ ] position. [ ] position

will increase the risk of sudden start.

Adjust throttle speed using the thr ot tle lever after

operating the clutch lever

The machine will start moving, when the clutch lever is

pushed down.

㻝㻡

Page 17

ŶHow to turn

ᵥ

ᵥ

ŶHow to change speed

clutch lever

Steer the machine by lifting the handle bar so that

the tines come to the ground surface.

Ɣ

Do not shift the speed change lever to [ ] position.

Rotating tines may cause serious injury and accident.

ᵬᵭᵲᵧᵡᵣ

Ɣ

Release the diff lock lever [O FF] when turning. Release

the drive clutch lever [OFF] to operate the diff lock lever.

Locking the differential makes both tires rotat e at

the same speedso that it helps to drive straight forward,

however it creates a larger turning radius as well as

a greater work-load on the transmission.

Release the clutch lever [OFF] and allow the machine

1.

to stop

ᵵᵟᵰᵬᵧᵬ

Ɣ

Do not try to change speed with the drive clutch

lever [ON].This can cause accidents and

transmission damage.

ŶHow to stop

clutch lever

Please be sure to securely shift it to the necessar y position.

2.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Do not shift the speed change lever to [ ] position.

Rotating tines may cause serious injury and accident.

Release the drive clutch lever [OFF] and allow the machine

1.

to stop.

2.

Shift the speed change lever to [ N ] position and

stop the engine.

Ɣ

Please park the machine on flat, open ground with

no obstacles nearby .The machine may accidentally

move if it's on a slope.

Ɣ

Please turn off the eng ine when unattended.

㻝㻢

Page 18

Tilling

ᵥ

Please carefully read and understand the following im por t ant safety points.

Ɣ

Please clean inside the tine cover ONLY AFTER turning off the engine.

Doing so without turning off the engine may cause serious injury.

Ɣ

Please remove objects, such as big rocks, in advance, when

operating this machine on rocky soil to prot ect the machine from damage.

Ɣ

Do not push the handle bar down when operating but support lightly, as it causes extr a st r ain

to the machine, and the machine may move forward due to t he r ot ational reaction force

Ɣ

When working on har d com pacted soil, till several times using a shallow depth setting.

Ɣ

This machine will stop when the clutch lever is off. Please stop m achine r eleasing

the clutch lever in an emergency.

Ɣ

Always use your hands to operate the clutch lever. Never use string or steel wire to hold

the handle, as it may cause serious injury, because the turn off action will be delayed.

Shift the speed change lever into [ ] posit ion.

1.

Difflocklever

Clutch lever

ᵵᵟᵰᵬᵧᵬ

Ɣ

Start tilling after checking that the rear g uar d is attached

in the correct position. Tilling without t he r ear guard

may throw outobjects and cause accidents.

Pressing the clutch lever will start the tines and wheels

2.

rotating

Ɣ

Please be careful of the rotating tines.

Use the diff lock lever set t o [ ON ] when necessary.

3.

Note:

Put the diff lock lever [ OFF ] when flat and soil is

in good condition.Use [ ON ], when working on

slopes and loose ground.

㻝㻣

Page 19

ŶHow to stop

䛀

䛁

ᵥ

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Please park the machine on flat open g r ound.

If the machine moves when unattended it may cause accidents or machine damage.

Please turn off the eng ine when unattended.

Release the clutch lever

1.

Turn the throttle lever [ ] position then turn the engine

2.

stop switch [ OFF ] position.

Clutch lever

ŶHow to adjust the depth.

Pull the depth adjustment bar to unlock then move up and

1.

down to set and lock it at desired depth. Ther e ar e

6 depth positions.

Move the depth adjustment bar up when tilling deeper.

Depthadjustmentbar

Move the depth adjustment bar down when tilling

2.

more shallow

Note:

If the depth adjustment bar becomes hard to move,

remove any objects such as clogged mud, and

lubricate with engine oil.

Depthadjustmentbar

Ŷ How to adjust the handle height.

The handle height is adjustable for operator.

Remove the handle adjust bolt then re-tig ht en at

the proper position, with both tooth are biting each other.

Handleadjustbolt

Oiled Parts Inspection, Replacement, and Lubr i cation

ᵵᵟᵰᵬᵧᵬ

Ɣ

When this machine is shipped, it is lubricated with oil;however, before operating t he machine,

make sure that it is lubricated with the described oil.

Ɣ

Before operating the ma chine, m akesure that it is lubricated with the described oil,

in the described parts, and in the described quant it ies.

Ɣ

To always operate this machine in good condition, perf orm oil changes periodically

㻝㻤

Page 20

Ɣ

When performing inspection, replacement, or lubr ication of oiled parts, place the machine on a

flat, open surface. Switch on t he engine and warm it up to confirm it is work ing properly. Then

switch off the engine, allow it to cool down and remove the spark plug cord.

After switching off, please wait at least 10 minutes for all parts to cool down sufficiently before

you touch the machine.

Immediately after the engine has stopped, the body will be very hot and

can cause burns if touched. Also the oil will still be in the engine and transmission

so the quantity of oil remaining will not be accurately displayed.

Ɣ

After changing the oil, please dispose of waste oil appropriately.

Transmission oil inspection, replacement and lubrication

Inspection

Inspect around the oil inlet at the lef t side of the transmission,

after removing the oil plug If the oil level surface can be seen

from there, ther e is a sufficient amount of oil.

Oil plug

Replacement

Place an oil pan under the transmission, then remove the

drain plug at the left bottom of the transmission near drive shaft

and drain old oil.

Drain plug

Change the gear oil after t he first 20 hours of

operation and every 100 hours thereafter

Lubrication

After reattaching t he drain plug, fill with 3.2 qt ( 3 L ) of gear oil

(#90) by pouring through the oil inlet .

㻝㻥

Page 21

Engine oil inspection, replacement, lubrication

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Before changing oil, please switch on the eng ine and warm it up. Allow at least 10 min for

all parts to cool down after switched off in or der to prevent burns.

Inspection

Perform this inspection bef or e every use, and check oil quantity and quality using the dipstick

Make sure the engine oil is always at the maximum level on the

level gauge. Inspect with the engine horizontal and do not screw

in the dipstick.

Replacement

Remove the oil filler cap and the drain plug. Dr ain all old oil.

Replace engine oil after the f ir s t 5 hour s of operation and roughly

every 25 hours thereafter.

Lubrication

Remove the oil filler cap then put in the new engine oil (SAE10W-30) with 0.6qt (0.6L)

(Refer to the engine manual )

After the oil has been removed, securely ret u r n t he drain plug to its original position.

1.

Fill with new engine oil from the oil filler.

After filling with eng ine oil, secur e ly reat t a ch t he oil inlet plug so that oil does not leak out

2.

Note:

The oil may bleed when the oil filler cap and the drain plug has not been t ightened enough.

㻞㻜

Page 22

How to Lubricate Each Part

r

䛀

䛁

䠝

䠝

䠝

䠝

䠝

ᵡᵟᵳᵲᵧᵭᵬ

Ɣ

Be sure to lubricate each part with grease or lubricat ing oil (#30) every 30 hours.

Operation will become heavy and the machine could be damaged if you neglect lubrication and

allow oil to run out

Lubricate all parts indicated by "A" in the pictures below

The clutch cable and the clutch lever The diff lock cable and clut ch lever

pivoting point. pivoting point

The depth adjustment ba

How to Inspect, Maintain, and Adjust Each Part

How to inspect and adjust the spark plug

Remove the spark plug with a plug wrench and clean away

1.

any carbon deposits on the electrode with a wire brush

and wipe away any moisture if present.

Replace the spark plug with a new one if the ceramic part

2.

has cracked or the electrode has suffered extensive wear

and tear.

Plug: Honda GX200 ---- BPR6ES㸦NGK㸧

Please adjust the spark plug electr ode clear ance t o

3.

0.028-0.031in (0.7-0.8mm)

ᵬᵭᵲᵧᵡᵣ

Ɣ

When attaching a spark plug onto the engine, scr ew by hand at fir st before tightening with

a plug wrench. If you start by using a plug wrench to screw in the spark plug, there is

a danger of cross-threading it

㻞㻝

Page 23

How to clean the air filter

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Be sure to periodically clean the air filters. I f you continue to use the machine with

the air filter and recoil starter clogged with weeds, etc., exhaust temperatur e will increase and

could ignite fuel, resulting in a fire.

Cleaning, replacement time (approx.)

Replacement

Every 200 hours or 1 year

Every 200 hours or 1 year

Foam element

Paper element

Cleaning

Every 25 hours

Every 50 hours

Take care to clean the f ilt er more frequently when operating in an environm ent with a lot of

dust or grime.

Release the wing nut and air cleaner cover

1.

Remove the paper and foam elements and check

2.

for damage

Note:

Wash the foam element with a pH neutral

3.

Replace with new parts if damaged

detergent. After washing, be sure to squeeze out all the

water and allow it to dry. Then soak it in

new engine oil (SAE10W-30 equivalent), wring it out hard,

and shake to remove any surplus oil.

Lightly tap the paper element several times to r em ove any

4.

waste. Blow any dirt from the inside of the filter in an

outward direction

Wipe any dirt f r om the inside of the case and reassemble

5.

back to its original position

ᵬᵭᵲᵧᵡᵣ

Ɣ

Replace the paper element with a new one if it is very dirty.

Ɣ

Take care when tapping the paper element so as not to cause any damage to the filter.

Ɣ

Do not use a brush as this could scrape the filter.

Tire pressure adjustment

Tire pressure

Please adjust tire pressure to 17.4 psi (0.12 MPa)

If the air pressure of the left and right tires is not equal, there is

a danger of losing control of the handlebars.

㻞㻞

Page 24

Adjusting the Cables

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Check that you are taking suf ficient safety precautions when adjusting each cable by

placing the machine on a flat, open surface with the engine switched off and the spark plug

cord removed.

Clutch cable

If the V-belt slips and the machine becomes over- loaded

even when you grip the handlebar with the clutch lever

-Loosen the lock nut and move the adjust nut

Clutch wire

Lock nut

Adjust nut

in the direction B

If the machine still moves when the drive clutch lever is

released.

-Loosen the lock nut and move the adjust nut

in the direction A

Please securely tighten the lock nut after the adjustment.

Lock nut

Differential locking

Adjust nut

Diff lock cable

If the machine does not function even when diff lock lever

is ON.

-Loosen the lock nut and move the adjust nut

in the direction B

If the machine still functions even when diff lock lever

is OFF.

-Loosen the lock nut and move the adjust nut

in the direction A

Please securely tighten the lock nut after the adjustment.

㻞㻟

Page 25

Belt Inspection

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

Before working on the machine, st op the engine and remove the spark plug cord. Not taking this

precaution could lead to serious injury and accident

Please check the belt regularly as it is a consumable part s and subject to wear and tear.

If you notice wear or cracks in any of these par t s , please r eplace immediately

Cog belt: Size----- HP-2 SB33 x 1

Ɣ

Inspection time:

After the first 2- 3 hour s of operation and then every 30 hours of operation ther eafter

Adjustment

Depress the clutch lever to [ON], and make sure the belt

has about 1/4" deflection when it is pressed with 6 lbs force.

If the adjuster at t he clut ch cable doesn't allow you to set it

within the range, you can also adjust by loosening

the engine mounts bolt to move the engine position.

Replacement

After changing or adj ust the belt, please adjust belt holder's

position.

When the clutch lever is in [ ON ] position, the gap between

the belt and the belt holder is 3/16" (4mm ) on the upper side,

and 1/8" (3mm) on the lower side.

Confirming the attachment of the belt af t er replacing

Return the spark plug cord t o it s or iginal position and run the engine for ar ound 2 minutes with the

blade clutch lever and drive clutch lever in both the [ON] and [OFF] positions to confirm that the belt

is operating normally. Afte r confirming, set nuts, bolts, and covers securely to their original positions

㻞㻠

Page 26

Tine Inspection and Replacement

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

When inspecting or r eplacing the tines, place the machine on a flat, open ar ea.

Always be sure to switch off the engine as there is a danger of injury.

Ɣ

When replacing or r epair ing tines, always have the work performed by someone with

the correct tools and experience.

Ɣ

The inspection or replacement of blades should be performed by 2 people. The handlebars

should be held firmly to stop the rear of the machine from f alling down. Not taking this precaution

can cause injury.

Ɣ

To avoid injury, wear safety gloves when performing inspection or r eplacem ent and wrap the tips

of the tines in cloth.

Ɣ

Replace the tines if you detect any abnormalities. If you ignore wear and tear, cracks, and

bending, there is a danger that the tines could break and fly out of the m achine, severely

injuring the operator or any bystanders.

Ɣ

When replacing t he t ines, be sur e t o also r eplace the nuts and bolts which tighten the tines.

This prevents accidents caused by wear and tear on the nuts and bolts. Never use nuts and bolts

that are not recommended for this specified purpose.

Stop the engine and move the fuel valve to [ CLOSE] position

1.

and remove the spark plug cap

Lift the machine's handlebars up to raise the rotor part

2.

of the machine.

ᵬᵭᵲᵧᵡᵣ

Ɣ

Do not leave the machine in a tilted position, as

the fluids may shift and prevent the eng ine from

starting properly.

Inspect for any cracks, bending and wear.

3.

Inspect all the tine setting bolts to be sur e t hey are secur ely tig ht ened

4.

Replacing Tines

Place the rotor on flat surf ace and check from behind. When each tine's edge has no overlap,

it's time to replace.

Tine distributions

Remove the tine setting bolts when replacing

tines.

Please refer to the picture on t he left, when

attaching new tines.

Please check the curb directions and position

of offset tines. Securely tighten with the tine

setting bolts.

䈜The picture shown is the view from behind

the machine.

ᵬᵭᵲᵧᵡᵣ

Ɣ

We recomm end pur chasing a replacement set in advance.

Please check the rotating direction as well.

When you replace, go from the left t o r ig ht,

one by one this will help you complete correctly.

If the direction or positon is incorrect, there

may beclumping and uneven tilling.

㻞㻡

Page 27

Inspection and Replacement of EZ Anke

r

䛀

䛁

ᵥ

ᵥ

ᵵᵟᵰᵬᵧᵬ

Ɣ

EZ Anker is a consumable part. Using worn EZ Ank er will prevent proper r esist ance,

and the machine may run rapidly on the ground, which may cause accidents.

If the length of t he EZ Anker has become shorter than

1.

the rotor's rotating r adius, it 's time for replacement.

When the machine r uns r apidly on the ground surface,

please check the EZ Anker for wear.

Please attach in the same direction when replacing.

2.

Long-term Storage

If you do not plan to use the machine for m or e than 30 days, please follow these procedures for

proper storage.

If the machine is not stored pr oper ly, t here is a danger of fuel spoilag e, the machine failing to

start, ordifficulty in running the machine.

ᵵᵟᵰᵬᵧᵬ

Ɣ

Please work on the machine in a place that is well ventilated. Gas fum es can fill a room and

cause accidents.

Ɣ

Before working on the machine, switch off the engine and remove the spark plug cord.

Ɣ

Store the machine on a flat surface in a place protected from the elem ents that is well ventilated

and cool.

Ɣ

When removing fuel, do not work near lit cigaret t es or other sources of open flame

Also, keep fireworks and fir ear m s away as there is a danger of the machine catching fire.

Ɣ

When removing fuel, be sure that the engine and muffler have cooled before touching the

machine. There is a danger of bur ns. Take care to dispose of f uel in accor dance with

local laws and regulations.

Empty fuel from inside the fuel tank and the carburetor.

1.

To remove fuel from inside the carburetor, remove the

drain screw from underneath and allow any fuel to

flow out.

Wash all part s well.

4.

࣭ Clean the recoil starter, air filter , m uffler, around the carbur etor, and inside the belt cover by

blowing air through them to remo ve dirt and dust .

࣭ Remove rust from affected ar eas and apply anti- cor r osion paint.

࣭ If you continue to operate with an accumulation of grass and dust in t he m achine, the engine

can become clogged, causing it to overheat and possibly catch fire.

Refuel and lubricate the necessary parts and have any defective parts r epair ed

5.

Put a cover over the machine to keep dust out.

6.

ᵬᵭᵲᵧᵡᵣ

Ɣ

During storage, check t he t ir e pr essur e per iodically and add air as necessar y

Clean away any fuel on the outside of the engine or

2.

machinewith a rag.

Please replace the engine oil.

3.

Refer to [ Replacing Eng ine O il ]

㻞㻢

Page 28

䛀

䛁

䛀

䛁

䛀

䛁

g

Specifications Reference values

Name

Model

Tilling width

Tines

Size of Cog belt

Weight

Size of tire

Clutch

Speeds

Engine

Included Tools

No Name of Tool

Dual head wrench

Dual head wrench

Spark plug wrench

Forward (MPH)

Reverse (MPH)

Name

Type

Power

Oil

Fuel tank

Mighty

SF600

67"x 23"x 38" (1690×590×970mm)Total length × Total width × Total height

19.7in (500mm)

12

HP-ϩSB33 x 1

185 lbs.( 84kg )

3.50-7 (ij350㹫㹫)

Belt tightener

[1] 0.72 [2] 2.78

[R] 0.72

HONDA GX200

UT2-SAR

4.8 kW (6.5HP)

0.6 qt (0.6L)

0.8 gallon (3.1L)

Specification Qty

10-12 (mm) 1

14-17 (mm)

Remarks

1

1 Engine tool

Consumable Parts List

No

1

2

3

4

5

6

7

8

9

10

11

12

Name of the Parts Parts No

Belt 89-6133-003301

Regular tine 㹊 80-1310-821-00

Re

ular tine R 80-1310-822-00

Offset tine 㹊 80-1310-826-00

Offset tine 㹐 80-1310-827-00

Tine attaching bolt

&nut set

Cable, clutch 83-1260-932-00

Throttle cable assy 0023-72400

Cable, diff lock 0016-73100

EZ Anker 0031-02100

Qty/Unit

1

4

4

2 Marked as A㹐50S㹊

2

85-1321-835-00 12

1

1

1

1

Remarks

HP-2 SB33

Marked as A㹐50㹊

Marked as A㹐50R

Marked as A㹐50SR

M10(round head

square neck bolt )

㻞㻣

Page 29

䛀

䛁

Periodic Voluntary Inspection Table

Neglecting inspection and maintenance is a cause of accidents and damage. Perform inspection

referring to [Periodic voluntary inspection table] in order to always keep the machine functioning

correctly

Perform annual inspection once a year and monthly inspection once a month, and starting checks

every time you use the machine

D: Daily M: Monthly Y: Yearly

Inspection Content

Main Body

Engine

Lubrication

Fuel

Electrics

Purity

Cooling

Transmitter

Belt

Transmission

Body Drive

Body

Cover

Lever&Cables

Tires

(Wheel)

Labels

Condition at startup, abnormal noise Machine starts up easily.

Revolution and acceleration

exhaust and gas leakage Exhaust color, smell, and sound are normal

Air filter damage, loosening, cleanlinessNo damage, loosening, or noticeably dirty.

Loosening of the attachment Gas leak, cracking, noticeable corrosion.

of cylinder head and manifolds (Tightened to the correct torque, not loose)

Valve clearance Clearance looks right range

Compressive pressure Compressive pressure looks straight

Engine base cracking or deformity, The engine base is not cracked or deformed

loosening of nuts and bolts and the nuts and bolts are not loose.

Quantity, cleanliness

Oil leakage Oil seal and gasket are not leaking oil.

Fuel leakage Fuel is not leaking

Fuel filter blockage Not noticeably dirty, deformed, or clogged

Fuel quantity/quality

Loosening. damage to electrical

wire connections

Spark Plug

Dirtying of air filter element Air filter element is not dirty.

Element breakage Element is not torn or worn out.

Grass etc. clogged in the

recoil cover

Accumulation of grass in the muffler There is no accumulation of grass around the muffler

Loosening There is suitable tension on the belt

Damage, cleanliness Belt is not cracked, damaged or noticeably dirty

Abnormal noise, strange

heat movement

Oil quantity, cleanliness

Oil leakage Oil seal and packing parts are not leaking oil.

Cracking or deformity, Mounting nuts

and bolts are loose or have fallen off

Cracking, deformity, corrosion No cracking, deformity or corrosion

Damage, loosening, rattling

of levers and cables, loss of split pins

Air pressure and tread depth Standard values are observed

Cracking, damage, wear and tear No cracks, damage or wear and tear.

Metal, stones, etc., stuck in the tires There is no debris in the tires

Loose or missing nuts and bolts Nuts and bolts are not loose or missing

Rattling, strange noise Mounted parts do not rattle or are missing.

Damage Warning labels and nameplate are attached and not damaged

Revolution speed increases gradually and smoothly

Oil quantity is suitable, not dirty or

mixed with any water or metals.

There is fuel in the engine and it is of good quality.

Harness connections are suitable, not loose or damaged

There are no cracks in the ceramic, the electrodes

are not worn, and there are no carbon deposits

Recoil cover is not clogged with grass

There are no abnormalities, strange noises or heat,

when running the machine

There is a suitable quantity of oi l and i t is not dirty.

Frame is not cracked or deformed. Nuts and

bolts have not fallen off.

When moving or loading there is no damage,

loosening, rattling and nothing has fallen off.

nspection

Freq.

DMY

If you do not understand any of these points, please consult with the retailer where you

purchased this machine.

㻞㻤

Page 30

䛀

䛁

Troubleshoot

If any of the following effects occur, refer to the instruction manual and take the appropriate action

Effect

Clumping tillage

Tiller jumps forward and

away

Does not till evenly

Belt slips

Wheel slips

Diff. is not locked

Engine bog

Can't move the depth

adjustment bar

Cause

Tines are worn out, Replace whole set of tines.

Tines are attached in the wrong direction Reattach tines in the right direction

Too much work load Till at a shallow depth setting.

Ground is too compacted, hard Divide area into smaller sections

Tines are attached in the wrong direction Attach tines in the right directions

Belt tension is too low. Adjust belt tension

Entangled grass or other foreign objects in the

tine cover

Ground is wet Wait until ground dries

Belt worn Change belt

Too much work load Till with shallow depth.

Tine cover is clogged with mud etc. Clean them up

Ground is wet Wait until ground dries

The diff lock lever is [ OFF ] position Switch the diff lock lever [ ON ] position

Cable is stretched Adjust cable

Engine rotation speed is low Raise throttle

Mud and grasses are clogged up.

Clean them up

Take them out

Treatment

If you do not understand any of these points, please consult with the retailer where you purchased

this machine

㻞㻥

Page 31

䛀

䛁

t

When engine won't work properly

If the engine malfunctions, perform diagnosis by referring to the following table and then taking the appropriate ac

Effect Cause

trouble

starting the engine

(Engine won't start)

Output shortage

Treatment

Engine stop switch is not in the [ ON] position. Put the safety switch to the [ ON ]

Choke lever has not been turned to [ CLOSE ].

Fuel is not flowing properly.

There is air or water mixed in the fuel

delivery system.

In cold weather, oil becomes thick, and the engine

rotation is sluggish

Ignition coil or unit is defective Replace the ignition coil or unit.

Defective spark plug.

Fuel shortage. Refuel the machine.

Clogged air filter. Clean the element.

Poor quality fuel. Replace with good quality fuel.

Choke has not been fully opened. Return the choke bar to [ OPEN ] completely

When cooling the engine, put the choke bar [CLOSE ]

position

Inspect fuel tank, remove impure deposits

or water. Remove the fuel valve strainer and clean

out any sediment deposited inside the cap

together with any other attached dirt.

Remove foreign objects, inspect fastening bands,

replace damaged parts with new ones.

Use the correct oil depending on the outside

temperature.

Inspect the gap between spark plug electrodes and

adjust

Replace with a new spark plug

Cooling system is clogged. Clean around the recoil starter

The engine stalls

suddenly.

Exhaust is

abnormally black

Muffler emits black

smoke and power

output falls.

Muffler emits gray

smoke.

Engine revolution is

Fuel shortage. Refuel the machine.

Fuel valve is closed. Open the fuel valve.

Poor quality fuel. Replace with good quality fuel.

Overfilled with engine oil. Adjust to correct fuel level

Air filter element is clogged. Clean the elements

Choke has not been fully opened

Overfilled with engine oil. Adjust to correct fuel level

Cylinder or piston ring is worn out Replace the ring.

Choke has not been fully opened Return the choke bar to [ OPEN ] completely

Return the choke bar to [ OPEN ] completely

not stable (does

not increase).

Poor quality fuel Replace with good quality fuel.

Defective ignition coil. Replace the ignition coil.

Momentary stall.

Fuel filter is clogged. Clean the fuel filter.

Exhaust has an

unusual smell

Poor quality fuel Replace with good quality fuel.

If you do not understand any of these points, please consult with the retailer where you purchased

this machine

㻟㻜

Page 32

䕔

m

m

Warranty parts

The supply term (period) during which replacement parts will be supplied is 9 years from the ti

last OREC product is produced. However, even during the supply period, it may be necessary

consult with OREC when seeking to purchase specific parts. If you have a request for replace

parts after this period has passed, please consult with OREC for prices and availability.

If you have any questions please talk to staff at the point of purchase or at our head office. At

time, please inform us of your machine’s [model type, serial number, and engine type].

㻟㻝

Page 33

LIMITED WARRANTY

s

Terms and Conditions

• Orec America, Inc. provides a limited warranty of two (2) years for residential users, one

one (1) year for commercial users, and one (1) year for rental companies, of its products against

defects in workmanship and materials when said products are put to ordinary and normal use.

The terms and conditions of the limited warranty are as set forth herein.

• The second year of the residential warranty shall cover only parts and NOT service.

• Crawlers are guaranteed for one hundred eighty (180) days after initial purchase.

This warranty covers defects in materials or workmanship only, and does not include damage to

crawlers from normal use and other external factors.

• The warranty shall commence from the date of purchase.

This warranty is available only to the original purchaser, and is not transferable.

• OREC reserves the right to inspect covered machines and parts in order to determine the

validity of warranty claims

• For the purposes of the above warranties “ordinary and normal use” does not include misuse,

accidents, or damage due to inadequate maintenance.

• Under this warranty, the responsibility of Orec America is limited to replacement or repair

of defective parts at Orec America, or at an authorized Orec dealer.

• Routine maintenance and adjustments, as defined by the manufacturer’s owner's manuals,

are the responsibility of the user and are not covered by the warranty.

•Degradation or deterioration of the product due to everyday use are excluded from the warranty

•Expendable components including but not limited to such as belts, blades, filters, spark plugs,

bags, wheels hoses, cables, wires, brake pads and flappers, are excluded from the warranty.

This warranty does NOT cover tire replacement or repair caused by punctures from outside

objects, such as nails, thorns, stumps or glass.

• During the warranty period, the warranty holder is responsible for equipment transportation

charges, and transportation expenses needed to process the claim will not be reimbursed.

• The following are excluded from the warranty:

࣭Repairs necessary due to inappropriate use or abuse including, but not limited to, damage

caused by towing objects or overspeeding the engine.

࣭Paint peeling or rust that occur through exposure to the elements or through everyday use

shall not be covered by the warranty.

࣭Repairs necessary because of operator negligence, including but not limited to, electrical and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oil, failure to keep the mowing deck clear of flammable debris, or the failure to

maintain the equipment according to the instructions contained in the owner’s manual.

࣭Repairs necessary because of accidents.

࣭Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or

oxidized (stale). In general, fuel should be used within thirty (30) days of its purchase date.

࣭Claims made after expiration of the warranty.

࣭Claims that are NOT specifically covered by warranty.

• Repairs, maintenance and/or modifications performed by unauthorized persons or dealers, as well a

the use of unauthorized parts or accessories will lead to the immediate forfeiture

of the warranty.

• Under NO circumstances shall Orec America be liable for damages or expenses of any kind resulting

from inappropriate use of its products.

• Orec America shall NOT be responsible for incidental or consequential costs or damages resulting

from defects in its machinery.

Such excluded costs and damages may include 1) Labor 2) Lost sales 3) Cost of replacement parts.

• This warranty shall apply only to models sold within the United States and purchased from

authorized dealers.

㻟㻞

Page 34

Note: to request warranty service, please contact an authorized Orec dealer or refer to your

owner’s manual for the proper procedure

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY HAVE

OTHER RIGHTS WHICH MAY VARY FROM STATE TO STATE. SOME STATES DO

NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Warranty Registration

Register your information within 30 days of purchase at http://www.orecamerica.com/warranty

Warranty Claim Procedure

Should this Orec product fail due to a defect in materials and/or workmanship, the owner should use

the following procedure to make a warranty claim:

1) The owner must take the machine to the dealer from whom they purchased the machine or to

an authorized Orec America dealer.

2) The owner must present the warranty registration sheet or the invoice or receipt received at

time of purchase.

3) The warranty claim will be taken and verified by the Orec Dealer or distributor service manager

and submitted to an Orec distributor. The dealer or distributors service managerwill make a report

and submit it to Orec America for consideration of Warranty.

4) Orec will research the claim and may request that parts be returned for further examination.

Orec will report their decision to the distributor service manager or dealer from whom the claim

was received.

5) In the event that OREC approves the claim, parts will be exchanged free of charge and repairs

performed by the dealer.

6) The decision by the Quality/Service department to approve or reject a warranty is final and

binding.

Note: to process a warranty claim, it is necessary to include the model, and serial number

㻟㻟

Loading...

Loading...