OREC America Snow Bull SGW803 Owner's Manual

SNOW BULL

Read this instruction manual carefully before any use of the machine, keep it as a reference.

Also, the engine manual is included as a set with the owner’s manual. Please read both

carefully. For any questions about this manual, please contact your OREC dealer, the distributor

in your country, or go to : http://www.orecamerica.com

Owner’s Manual

SGW803

-1-

Getting Started

Thank you for purchasing this machine. Please read these instructions fully before using this

machine in order to understand the safest, most efficient way of operating it, and the correct way

maintain it. Please keep these instructions in a safe place where they can be easily referred to at

any time. We hope you will use this machine for many years to come. Please understand that

ongoing enhancements in quality and performance, and other possible parts improvements may

cause the actual machine to vary slightly from what is described in these instructions.

Machine Regulations

This is a snow cleaner that has been designed to remove snow. It is not to be used for any other

purpose.

About manual

・ Please read these instructions regarding safety and operation before operating this machine.

・ Please carry this manual all times when using the machine.

・ Please provide this manual to any new operator of the machine.

・ Please ask your dealer for a new manual if this one is lost.

Definitions and Symbols

In these instructions, the following signs and definitions are used to indicate the level of danger

that exists. Please obey the following warnings and have a full understanding of the meaning of the

symbols.

Symbol Definition

Displayed when failure to obey instructions can result in death or

serious injury.

Displayed when there is a danger of death or serious injury.

Displayed when failure to follow instructions can result in injury.

Displayed when it is important to know about operation and

maintenance specific to this machine, or at times when

misunderstanding and mistakes are common.

DANGER

WARNING

CAUTION

NOTICE

Notes for operation-----------------------------------------------------------------------------------3

Important safety points--------------------------------------------------------------------------

-

3

Warning labels--------------------------------------------------------------------------------------

-

6

Parts description and function-------------------------------------------------------------------7

12

How to operate the mach ine----------------------------------------------------------------------14

How to start and stop the engine-------------------------------------------------------------

-

14

How to operate the machine-------------------------------------------------------------------

-

16

Loading------------------------------------------------------------------------------------------------

19

Inspection and maintenance----------------------------------------------------------------------20

Engine & Transmission oil inspection, replacement and lubrication-------------

-

20

How to Inspect, Maintain, and Adjust each part-----------------------------------------

-

22

22

24

Long term storage---------------------------------------------------------------------------------

-

27

Specifications------------------------------------------------------------------------------------------29

Included tools------------------------------------------------------------------------------------------29

Consumable parts------------------------------------------------------------------------------------29

30

Troubleshoot----------------------------------------------------------------------------------------

-

30

When engine won't work properly------------------------------------------------------------

31

Periodic inspection table------------------------------------------------------------------------

-

32

Parts supply-------------------------------------------------------------------------------------------- 34

LIMITED WARRANTY--------------------------------------------------------------------------------35

Contents

Inspection before operation----------------------------------------------------------------------

-

Inspection table---------------------------------------------------------------------------------------

-

Air filter, Spark plug , Sediment cup-----------------------------------------------

-

Tracks, Scraper, Cables, Belt---------------------------------------------------------

-3-

1. Notes for operation

1.1 Notes for the operator of this machine.

・ Do not operate this machine without full understanding this manual.

・ Do not operate if fatigued or if under the influence of alcohol or drugs.

・ Those who are pregnant or too young to understand instructions should never operate this

machine.

・ Always wear appropriate clothing; no loose or hanging clothes, non-slip boots and protective

gear are always recommended to prevent injury from rotating parts.

1.2 Before operation

・ Absolutely do not handle gasoline in the presence of open flame. Be careful not to spill fuel. If

you spill fuel, please clean it up accordance with local laws and regulations. There is a danger

of fire and explosion.

・ When refueling, always stop the engine and allow it to cool down. There is a danger of fire and

burns when refueling a hot engine.

・ Please refuel in a place that is well ventilated.

・ Do not remove any parts from this machine that have been fitted as standard. To prevent

accidents, be sure to use all covers and parts in the same state as they have been fitted.

・ Do not modify the machine as this can cause accidents or explosions. Altering this machine in

any way will void the warranty.

Orec America, Inc. will bear no responsibilities for accidents or problems caused by

alterations or modification.

・ Always work is good visibility. There is possib ility of accident when you can’t see clearly around

you.

・ Use extreme caution around water, such as lakes or rivers. Do not work on steep slope. Please

operate this machine on a flat and safe place.

・ Do not release driving clutch lever on a slope. This may cause loss of control.

・ Do not operate the machine in a situation in which the machine may get very we t.

・ Be sure that there are no people especially children, animals or vehicles close by before

operation.

・ Always work with appropriate safety gear and clothing for the weather.

WARNING

DANGER

WARNING

CAUTION

-4-

1.3 During operation

・ Always work with comfortable posture and take breaks appropriately.

・ Do not allow flammable substances near the engine or the path of the exhaust as this can cause

a fire. Do not touch the engine or muffler as they become extremely hot during operation and

can cause severe burns.

・ Always keep hands and feet clear of the tracks

・ Always operate the machine horizontally on slopes. Use extra caution when turning, the

machine may slip and fall toward you. Do not operate the machine on slopes above 10°.

・ To avoid injury, use caution while turning on slopes.

・ When reversing, check that there are no people or obstacles behind you and that you have a

secure foothold.

・ If you notice any strange noises, smells, heat, or vibrations during the operation of this machine,

switch off the engine immediately. Have the machine inspected for damage and obstructions

and have any damaged parts repaired.

・ Always stop the engine and wear appropriate globes before an inspection of the engine.

・ When inspecting or lifting, take precautions to prevent the machine from falling.

・ Be sure that there are no people especially children, animals or vehicles close by. If children

approach the machine, please turn off the engine immediately.

・ Please release the driving clutch lever and move main clutch lever to “START” position to start

engine.

・ If anything, such as a rock, or branch, gets into the track, stop the engine immediately and

carefully remove the obstruction.

・ When leaving the machine unattended, park on a flat surface with the engine switched off.

WARNING

CAUTION

-5-

1.4 Loading and unloading the machine

・ Use the vehicle of appropriate size to transport the machine.

・ Park on a flat place for loading/unloading.

・ Secure the machine with a strong rope during transport.

Drive safely and avoid sudden starts and stops and sharp turning during transport.

・ Use a ramp designed for the job, be sure it is wide and sturdy enough and that the machine

stays in the middle of the ramp. Always use the lowest forward gear to load, and reverse to

unload.

1.5 Inspection , Maintenance

Periodic inspection is necessary for keeping the quality and performance of the machine. Please

perform an inspection before every operation, and ask your retailer for an annual inspection. Orec

America will bear no responsibilities for any accidents or problems caused by neglecting any

inspections.

To avoid injury, accident, and damage of the machine, be sure to follow all instructions

bellow.

・ To keep the machine safe and in good condition, perform the daily and annual inspections, and

recommended maintenance.

・ When you inspect, adjust or maintain the machine, make sure all any parts have cooled down,

wear appropriate protective gear and use appropriate tools. Work on a flat and open area and

keep the machine balanced to prevent machine tipping.

・ Make sure all parts are at the correct position and are securely tightened after an inspection,

maintenance or replacing. When replacing the driving wheel, replace driving wheel mounting

bolt at the same time.

・ Do not modify this machine or add attachments witch are not OREC option.

・ Be sure to check that the covers of rotating parts are refitted correctly in their original positions

after being removed.

・ When rubber fuel lines become old, they can split and dangerous fuel leaks can occur. Change

rubber parts if they split or every 3 years regardless of damage. At this time, also change the

fastening bands for the new parts.

To avoid machine damage, keep these instructions.

・ When you wash the machine, do not get the engine wet.

・ Inspect and adjust the clutch, throttle and transmission carefully.

・ To avoid burns and fire, cover the machine only after making sure that the engine has cooled

down,

WARNING

WARNING

CAUTION

-6-

1.6 Long-term storage

To avoid damage, please

・ close the fuel valve for safety.

・ store this machine inside for long-term storage.

・ get remove any trash, dust, or s now on and around the machine.

If you don’t follow these instructions, there is a danger of fire.

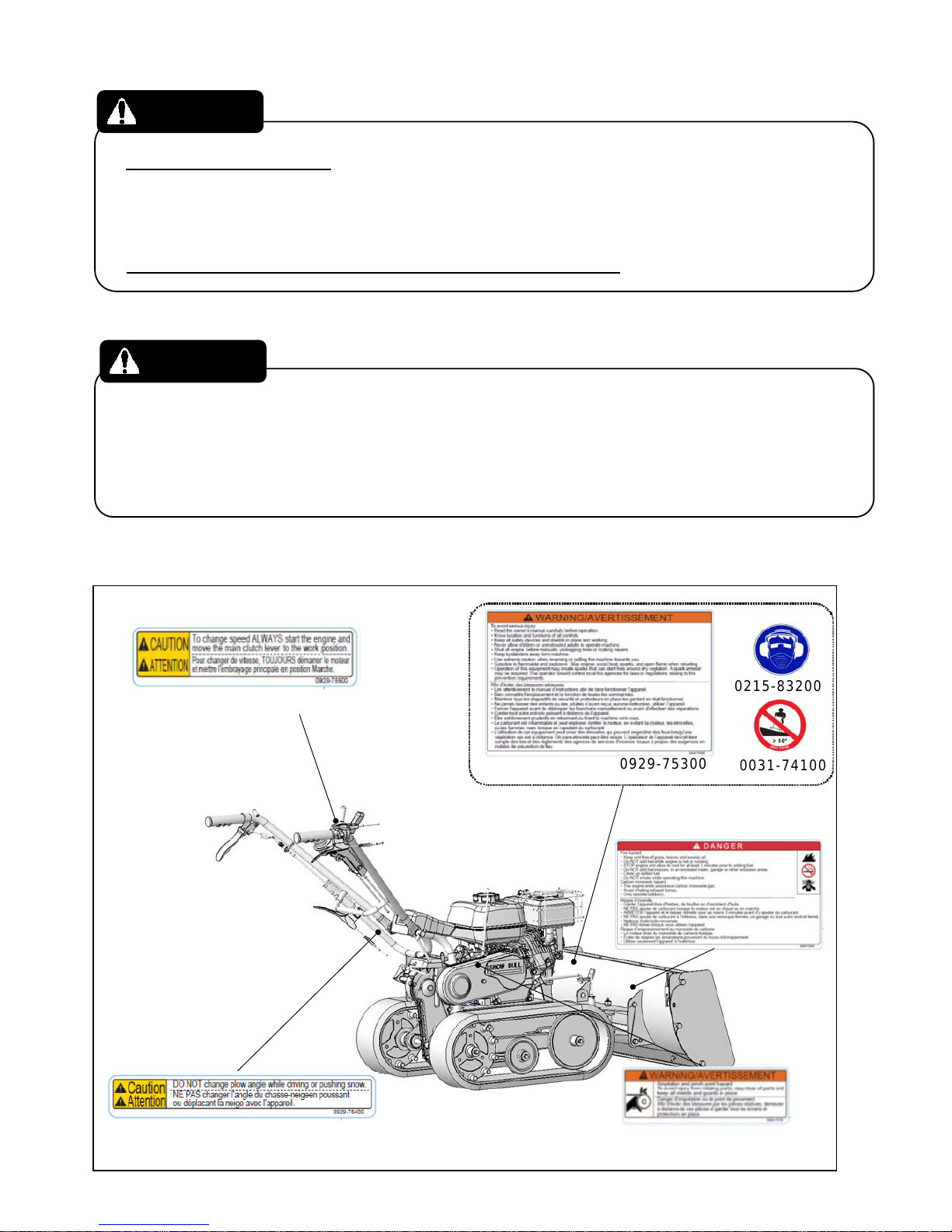

1.7 Warning labels

・ Warning labels are attached to the machine to draw attention to particularly serious dangers.

Please be sure to fully understand the meaning of each warning label before operating this

machine. ※ In the case that these warning labels become difficult to see, please replace them

so that they can be easily seen and understood.(contact your dealer)

The position of warning labels:

WARNING

WARNING

0304-71100

0929-75100

0215-83200

0031-74100

0929-75500

0929-75300

0929-75400

0929-75200

-7-

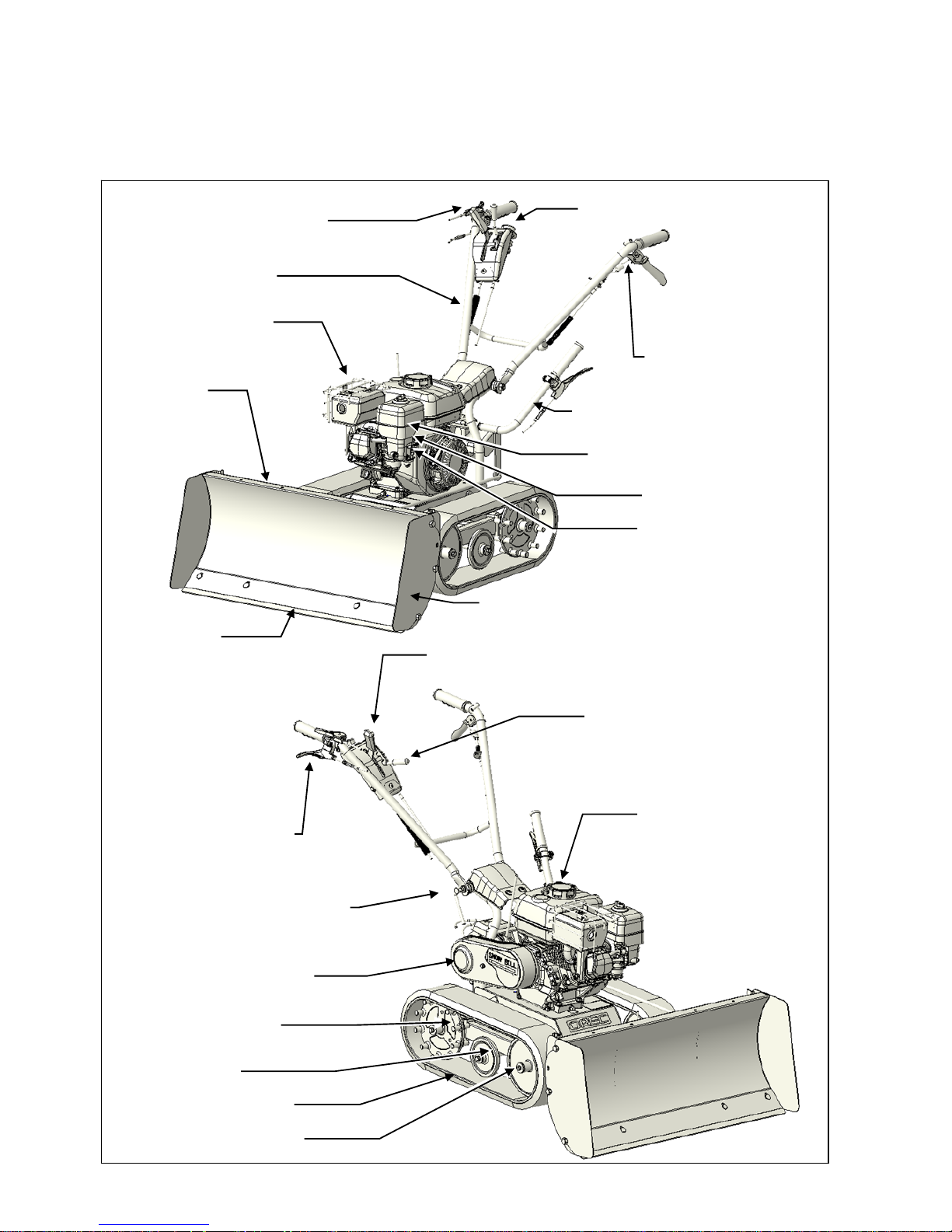

2. Parts description and function

2.1 Parts description

Note: The model in the pictures may vary slightly from the actual machine.

Fuel cap

Track

Belt cover

Handle height adjusting bolt

Main clutch lever

Speed change lever

Plow side plate

Plow angle adjustment lever

Driving clutch lever

Engine stop switch

Throttle lever

Muffler

Plow

Scraper

Plow height

adjustment lever

Handle

Guide wheel

Air cleaner

Fuel valve

Driving wheel

Choke lever

Guide wheel

-8-

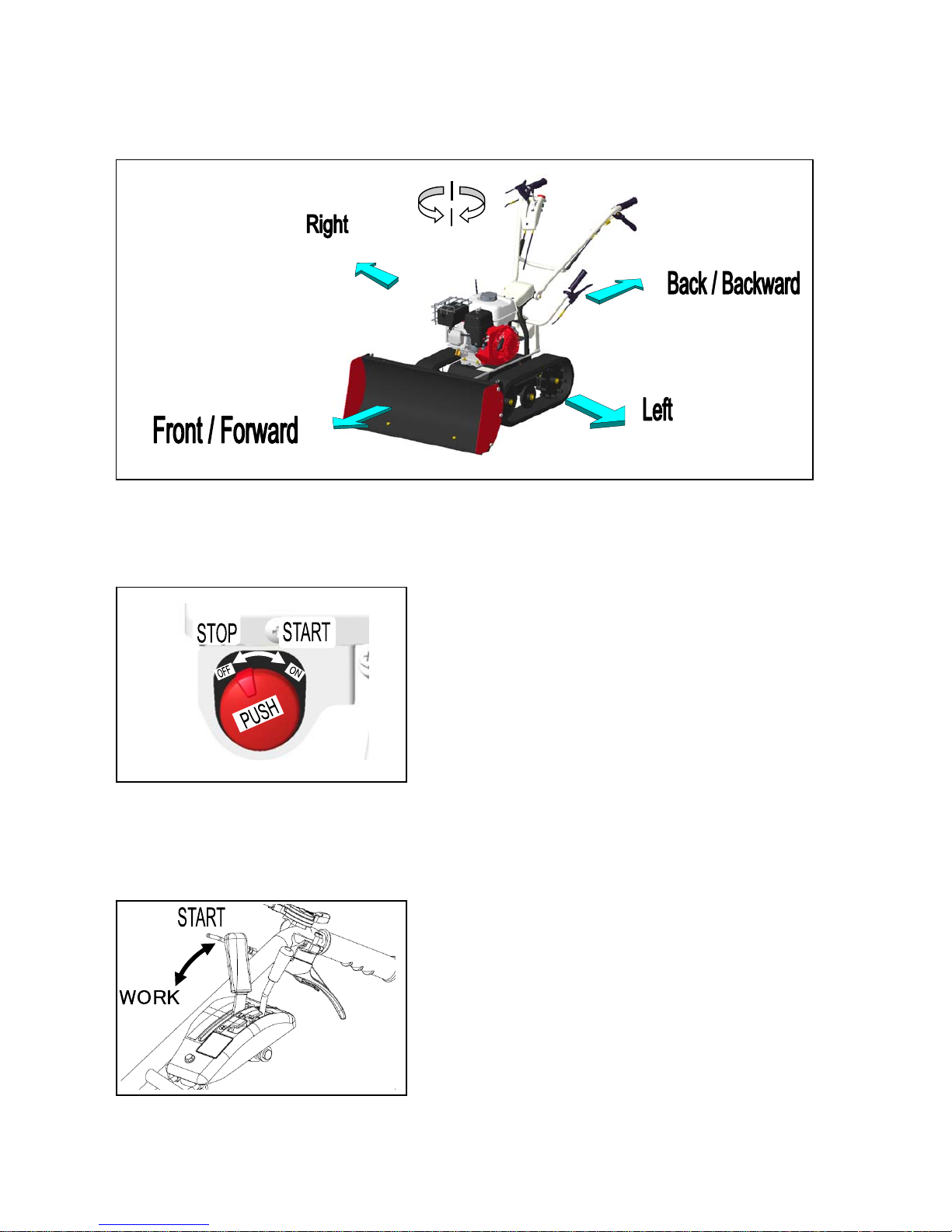

2.2 Machine direction

The machine directions are shown below, from the operator’s perspective behind the machine.

2.3 Function of each part

Engine switch

Use this switch when you start / stop the engine.

“START” … the engine starts.

“STOP” … the engine stops.

・ If you push this switch, the engine will imme diately

stop.

Main clutch lever

Shift the main clutch lever when you start the engine or

when you start work.

“START” … When you start the engine.

“WORK” … When you start working.

Please make sure that the lever is moved to the correct

position when you operate.

-9-

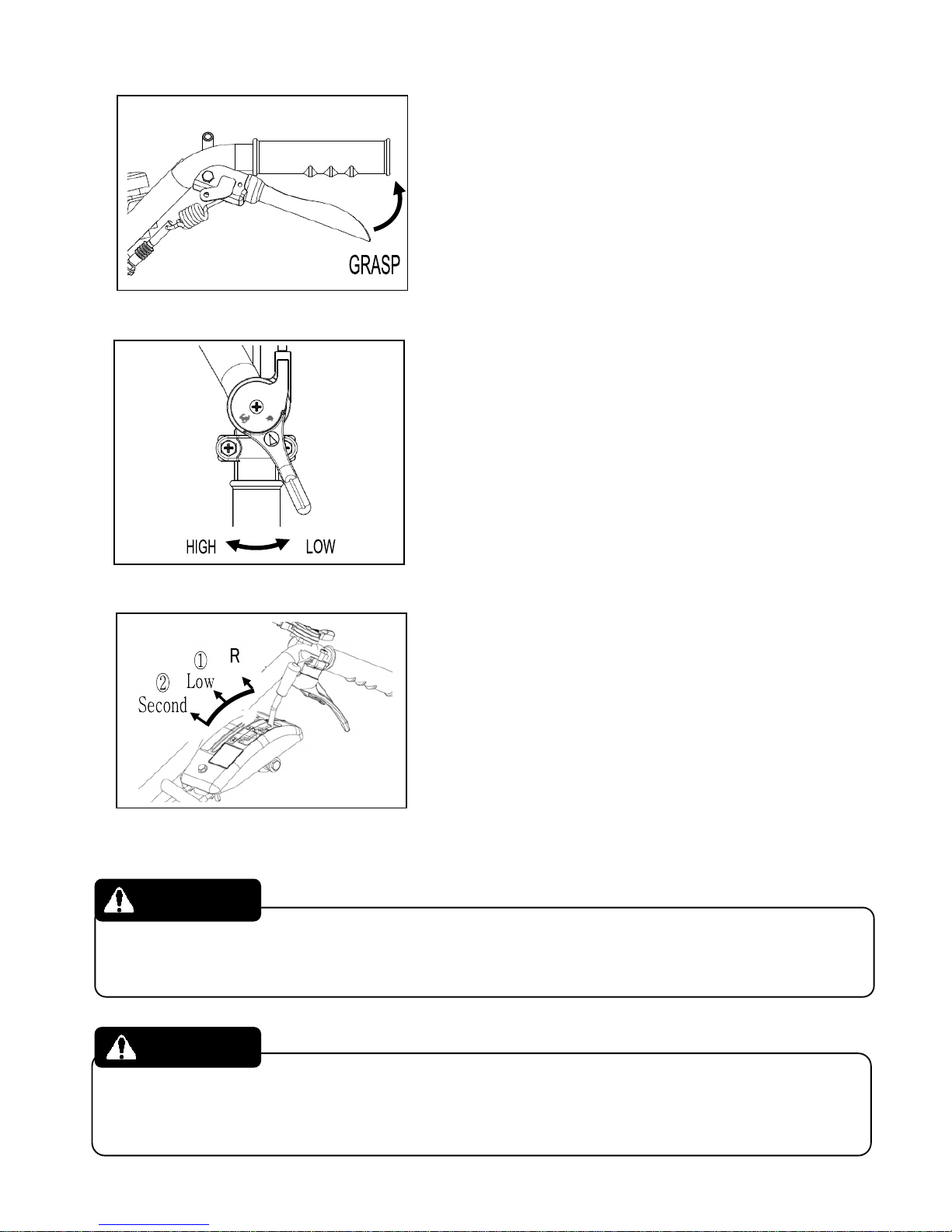

Driving clutch lever

For operation

“GRASP” … Starts moving.

“RELEASE” … Stops moving

・ This action is only when the main clutch lever is in

“WORK” position.

Throttle lever

Move the throttle lever to adjust the engine RPM, and

use to adjust the speed of driving and the pressure of

pushing snow.

“Move right” … Lower the engine RPM

“Move left” … Raise the engine RPM

Speed change lever

Shift the lever when you change the speed.

“ R “ … Reverse

“ 1 “ … Forward slowly

“ 2 “ … Forward fast

・ Make sure that the lever is fixed at the right position.

・ The machine may not move backward if the plow gets

stuck in the snow. If this occurs, lower the handle to

raise the plow higher than snow.

・ When you chose "R" , the machine moves toward your foot. Check around and behind for safety,

then lower the engine speed to keep working.

To change speed ALWAYS start the engine and move the main clutch lever to the work position

and release the driving clutch lever. Shifting speed change lever while you are grasping driving

clutch lever may break the gear inside of the transmission.

WARNING

CAUTION

-10-

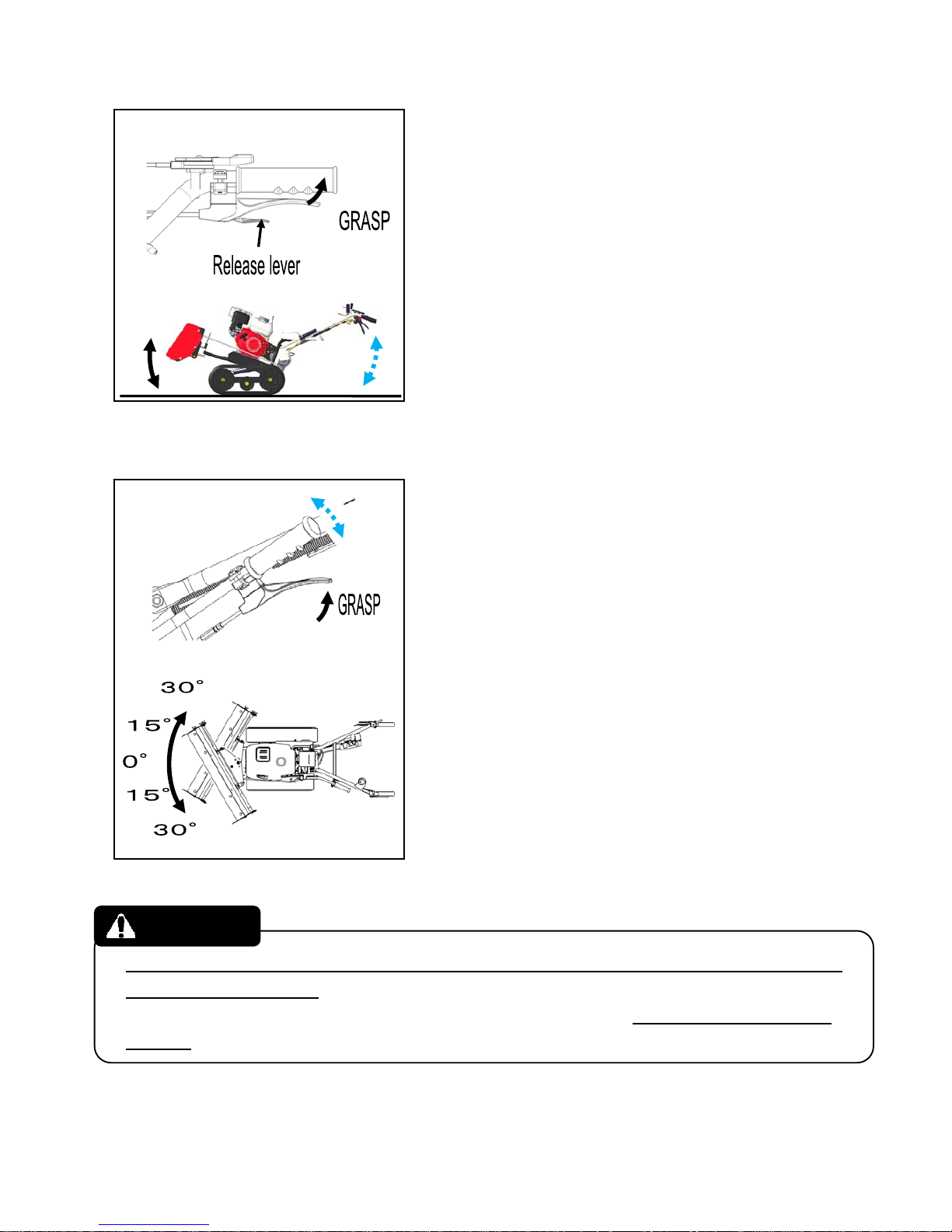

Plow

The plow enables the operator to push and clear the

snow.

Depending on the situation, adjust the angle and height

of plow.

<How to adjust height of plow>

・ To adjust the height of plow, grasp the lever lightly

with your right hand and lower the handle. To set the

height of plow, release the lever. You can set the

plow at any height.

・ Holding the plow height adjustment lever locks the

lever, so you can keep working with the height of the

plow free. To unlock the lever, grasp the release

lever at the bottom of the lever.

・ Depending on the situation, you can chose “fixed

height” or “free height” of plow.

< How to adjust angle of plow>

・ To adjust the angle of plow at th e 15° or 30° position,

hold the angle adjust lever and move it up/down.

When you want to secure the plow angle, release the

plow angle adjustment lever to the position you want

to secure.

Do not change the angle of plow while the machine is moving forward/backward and while

the plow is on the snow. It might be difficult to adjust the angle of plow because of snow

resistance, or impossible to secure the plow at the height you want. It may cause mechanical

failures.

CAUTION

-11-

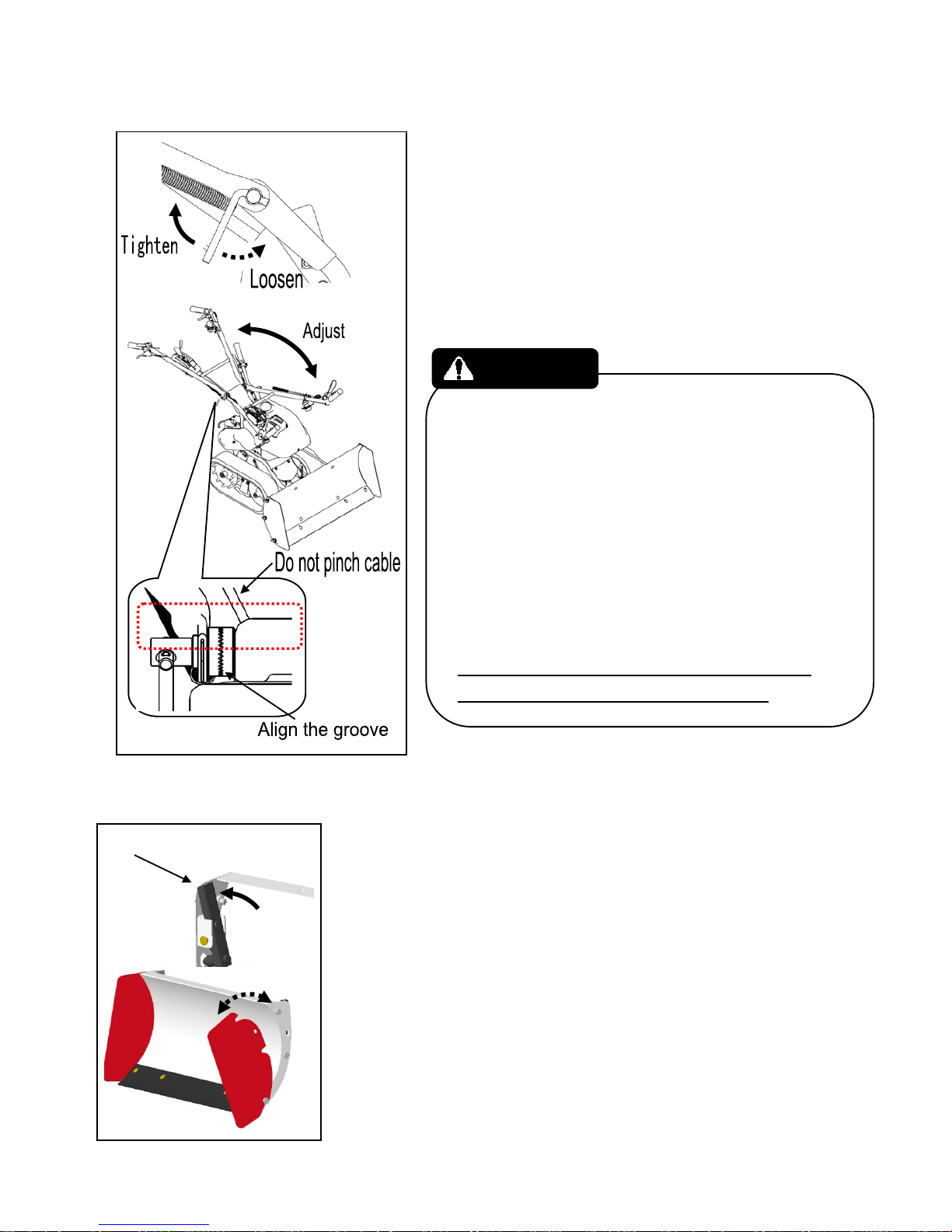

Handle, Handle adjusting bolt

The handle height is adjustable for the operator.

・ To adjust the handle height, stop the engine. Remove

the handle adjust bolt then re-tighten at the proper

position, making sure the grooves are aligned.

・ For storage only, the handle can be folded down.

・ Adjust the handle height holding it tight at the flat

area. If you don’t tighten the adjusting bolt enough,

the handle will fold on its own.

・ When you fold in handle or adjust the handle height,

be sure not to pinch or bend the cable.

・ When you adjust the handle height, tighten the

adjusting bolt firmly aligning the groove at the bottom

of handle.

To avoid injury, accidents, or damage to the

machine, please follow all instructions.

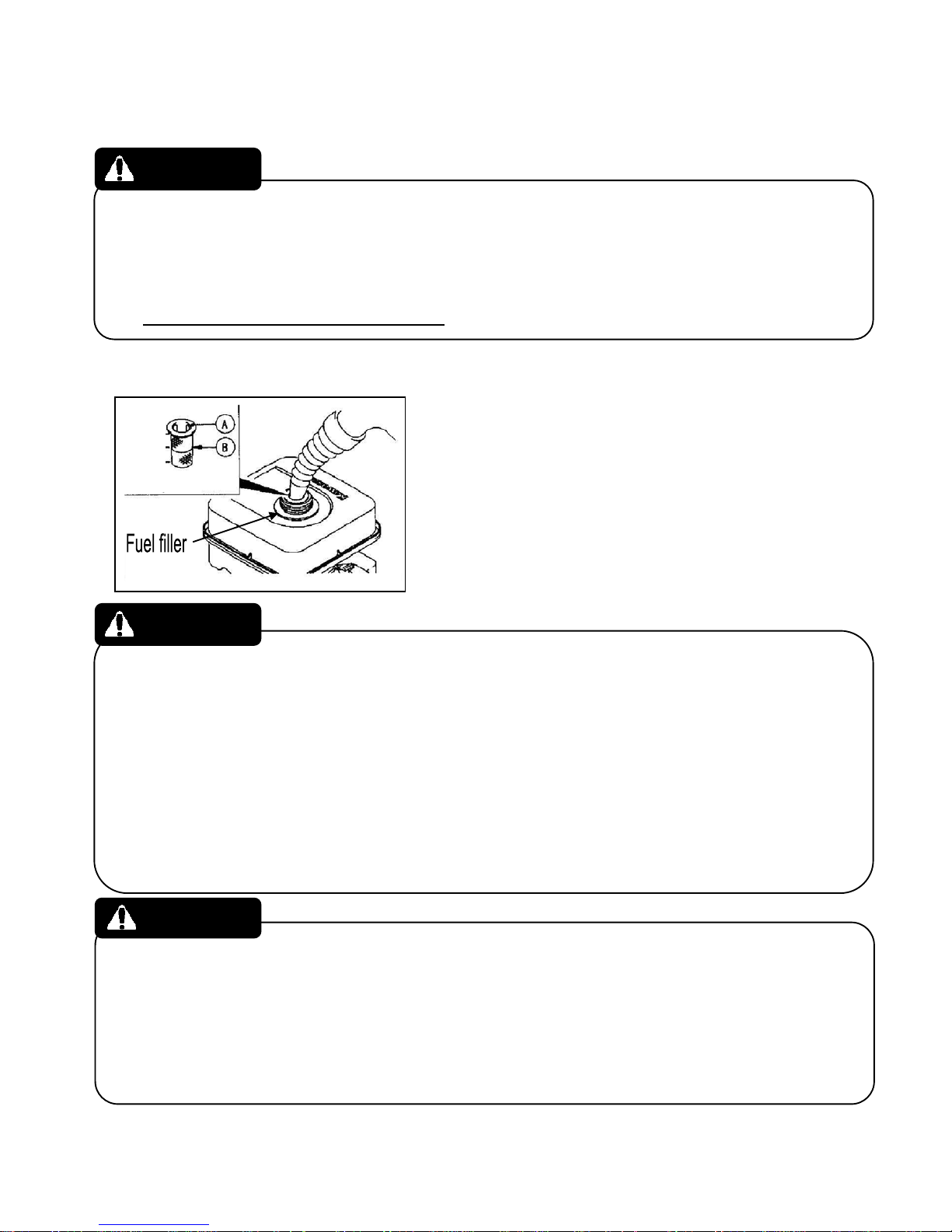

Side Plate

The way to remove and attach the side plates

“Removing” … Grasp the side plate fixing lever, and rotate the

side plate to remove it.

“Attaching” … Align the bottom hole of the side plate with the bolt

slit. Then, grasp the side plate fixing lever to attach

the side plate.

・If you see snow or dusts on bolt slit, please remove them before

attaching the side plate.

CAUTION

Side plate fixing leve r

Grasp

-12-

3. Inspection before operation

To ensure safe operation always do the inspection according to "7.3 periodic inspection table "Page

32 and perform any necessary maintenance.

・ Always stop the engine before inspection, adjustment, and maintenance.

・ Please check the position of levers, and the work area around you when you do the moving test

with engine on.

・ Please carefully read the warning labels on this machine.

Follow all instructions to avoid injury.

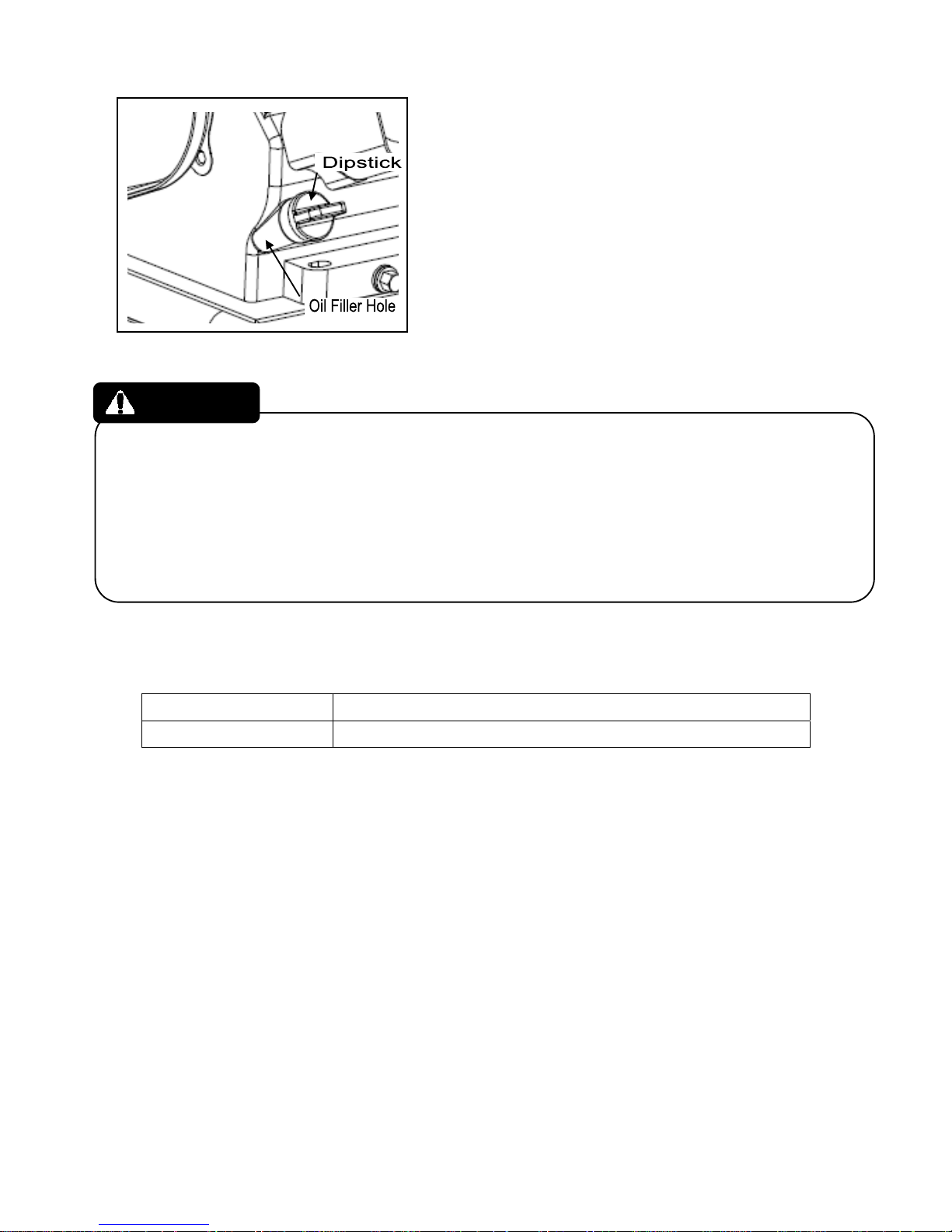

3.1 Inspection of fuel

・ Remove the fuel filler cap after setting the unit in a

horizontal position, then check the amount of gas

from the fuel filler. “B” line is the maximum level. Do

not overfill the fuel tank.

Type of fuel: Regular unleaded gasoline

・ Make sure to close the fuel filler cap after refueling.

When you refuel the gas, please follow these instructions.

・ Please refuel the gas on a flat and well ventilated area.

・ Stop the engine.

・ Keep away from sources of ignition.

・ Do not refuel until the engine cools down

・ Be careful of static electricity. It could cause fire due to vaporized gas.

・ Do not overfill the fuel tank above the maximum level. If you spill gas, clean it in accordance

with local laws and regulations.

・ If you refuel the gas while it’s snowing, make sure that the snow or rain doesn’t get into the fuel

tank. It could cause engine failure.

・ Only use unleaded regular gasoline, as other types could damage the engine.

・ Gas deteriorates when left sitting and can cause damage to engines. Please change to fresh

gasoline if the machine has not been used over 30 days. Do not use gas that is kept in a plastic

container.

WARNING

WARNING

CAUTION

-13-

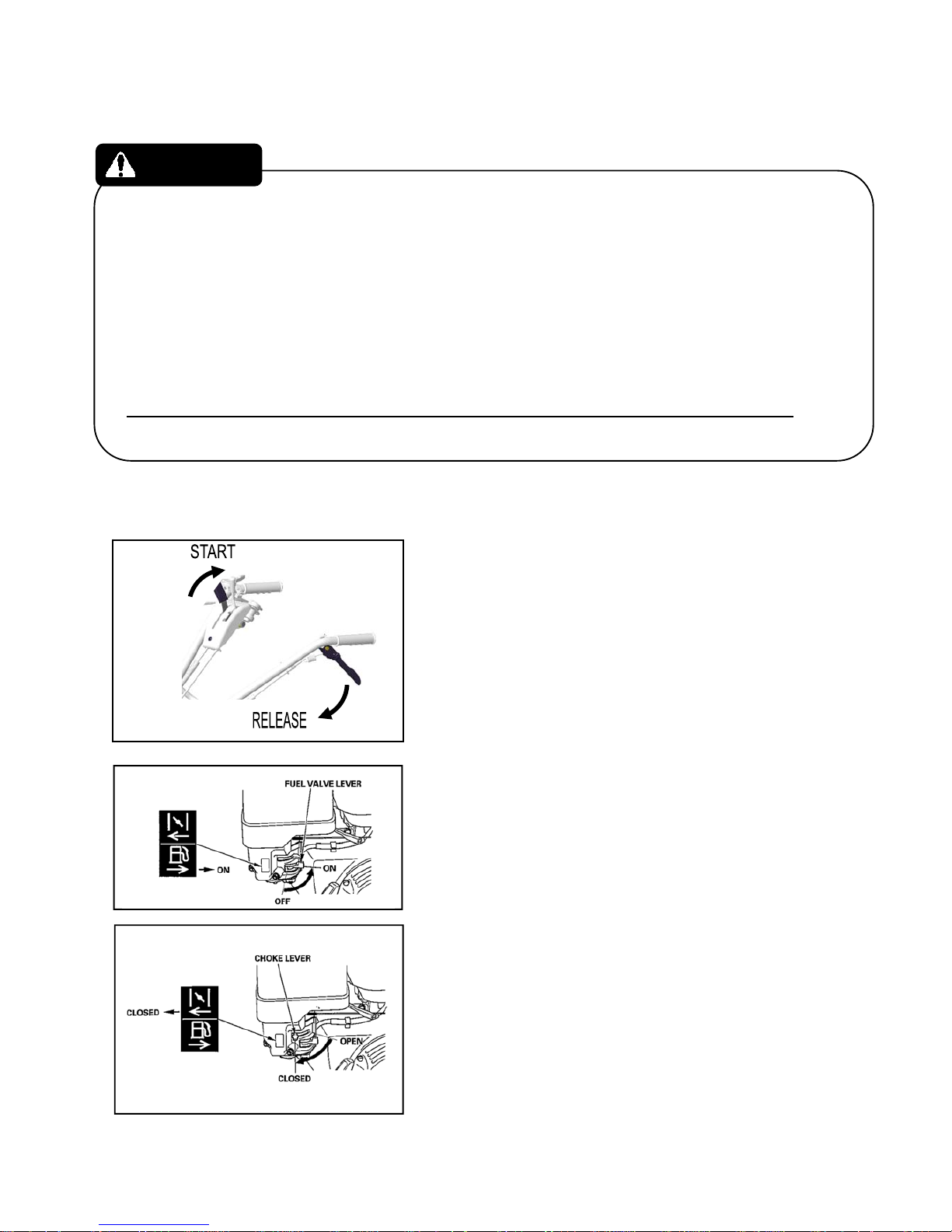

3.2 Inspection of engine oil level

・ To check the oil level, place the machine on a flat

surface. Unscrew the dipstick and inspect, using oil

gauge. Check oil level by inserting and removing the

dipstick without screwing it into the filler hole. If the

oil level is low, add oil to the upper level

・ To avoid injury, make sure the engine has cooled down before checking oil.

・ This machine is shipped WITHOUT engine oil. Fill with engine oil to the correct level before

starting the engine, even if there are traces of residual oil in the engine from factory testing.

・

Please always use the proper quality oil, see below. The proper oil for the outside temperature

will ensure the best performance.

・ After refueling the oil, make sure to tighten the dipstick, to prevent leaking.

Recommend type of oil

Summer [over 50°F]

SAE30, SAE10W-30 , or SAE4 0

Winter [under 10°F]

SAE5W20, or SAE10W-30

CAUTION

-14-

4. How to operate the machine

4.1 Start & Stop

・ Always use the machine in a well ventilated area, and never indoors.

・ Start the engine on a flat surface after verifying the area is free of obstructions.

・ To avoid injury please do not stand next to crawler.

・ If it is difficult to mo ve on the icy ground due to the track slipping, hold the handle firmly to enable

track to grip the snow then move forward slowly.

・ Mark obstacles, grooves, slopes or soft ground so you can avoid those areas.

・ To avoid burns, do not touch the muffler while operating the machine. Let it cool for at least 10

minutes before touching, or covering for storage.

Be sure to avoid injury and accidents by reading and understanding all instructions.

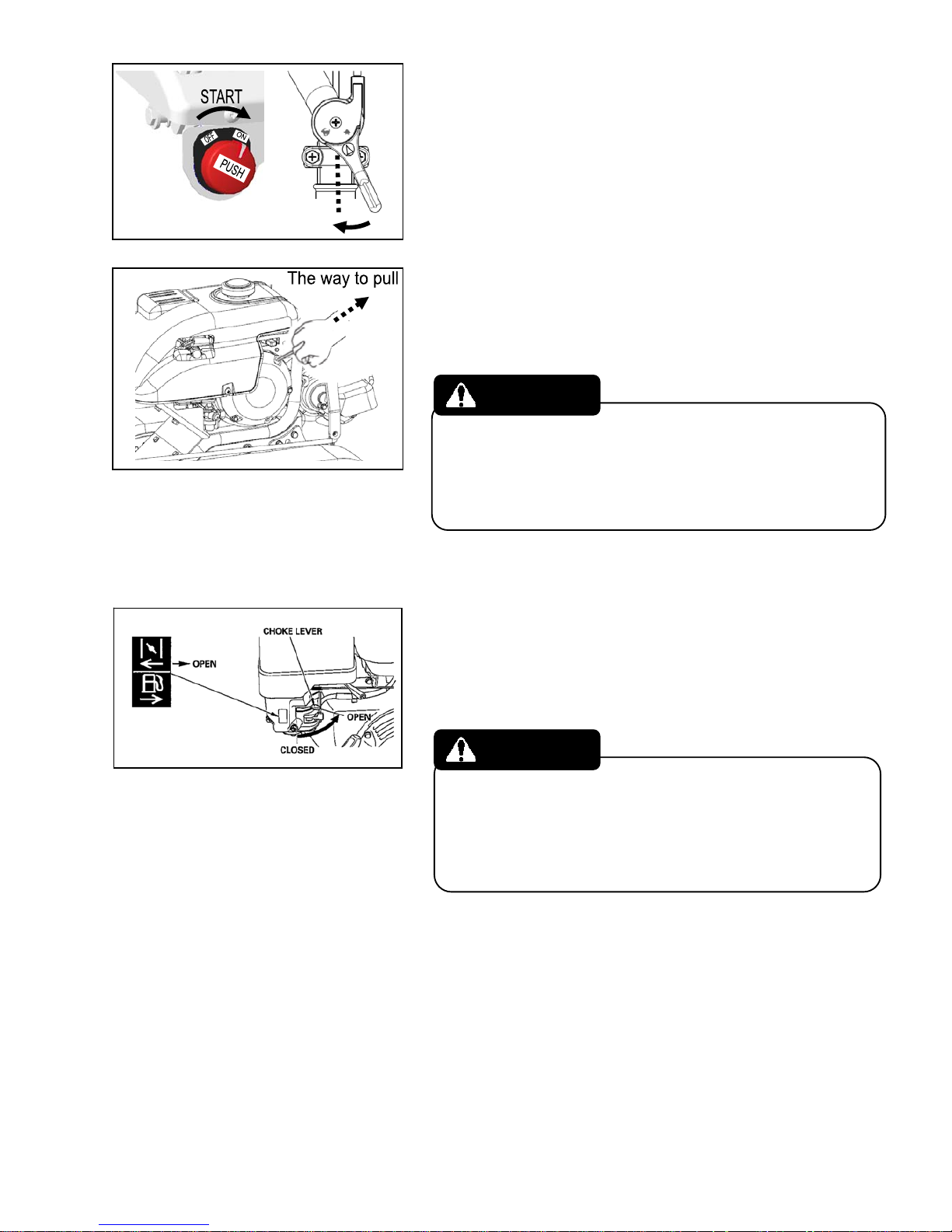

4.1.1 How to start the engine

・ Move the main clutch lever to the “START” position,

and release the driving clutch lever.

・ Move the fuel valve lever to the ON position.

・ To start a cold engine, move the choke lever to the

CLOSED position.

*To restart a warm engine, leave the choke lever in

the OPEN position.

WARNING

-15-

・ Turn the engine switch to the “ON” position, then

move the throttle lever to the middle position.

・ Pull the starter grip lightly until you feel engine

resistance, then pull briskly in the direction of the

arrow as shown in the picture.

・ Return the starter grip gently.

・ Before starting the engine, be sure the area around

you is free from obstacles and other people. Release

the starter grip slowly to avoid damage to the

machine.

・ After starting the eng ine, move the choke lever

gradually to the OPEN position, while checking the

RPM’s, and move the throttle lever to the low position

and let it warm up for 5 minutes.

・ When the RPM’s are stable, move the choke lever all

the way to the right. To prevent damage to the engine,

do not operate with the choke lever in the CLOSED

position.

CAUTION

CAUTION

-16-

4.1.2 Operation (Removing the snow)

・ Always wear appropriate winter wear and shoes, gloves, hats, etc. for safe operation.

・ Always operate the machine from behind the track at the center, and hold firmly.

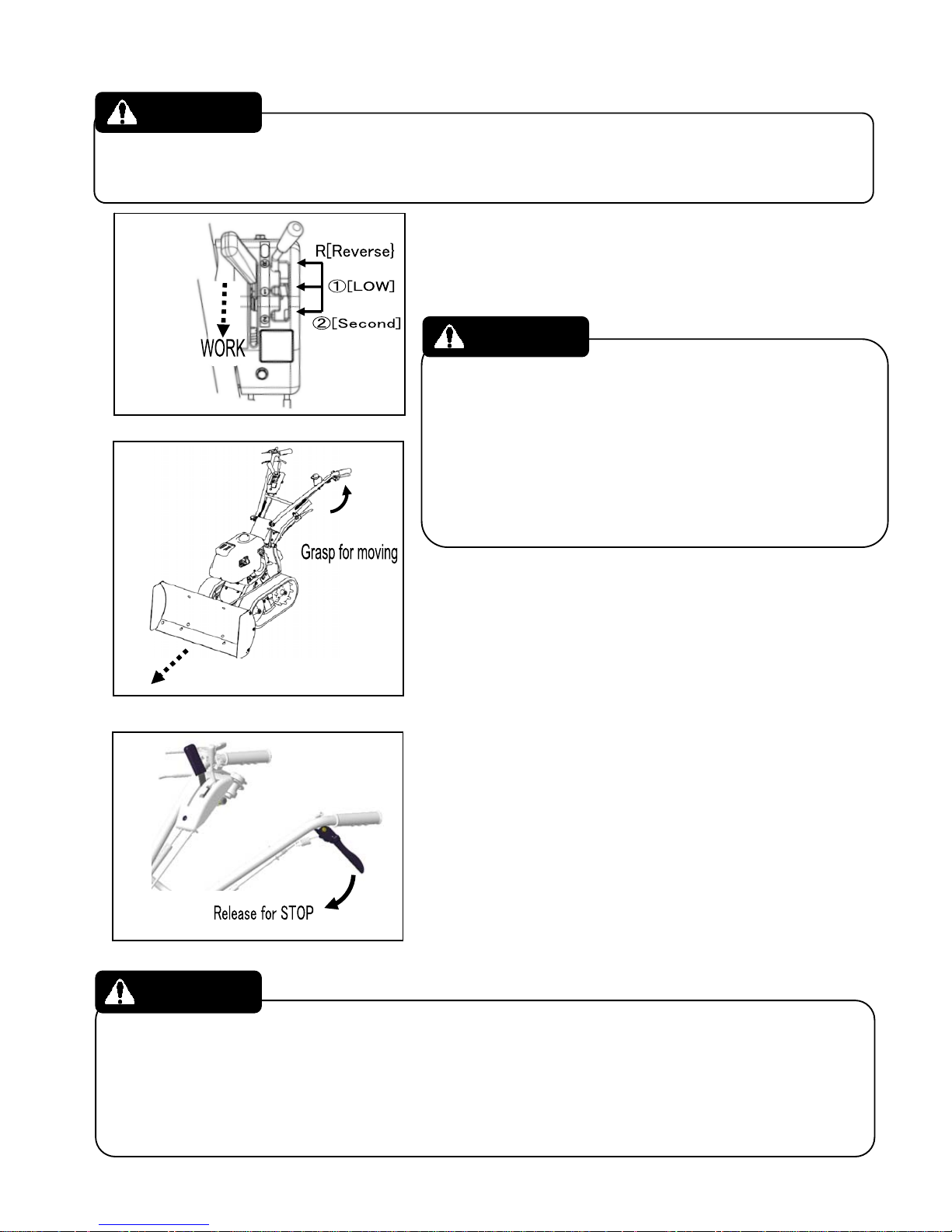

・ Move the main clutch lever to the “WORK” position.

Then shift the speed change lever to change speed.

To change speed ALWAYS start the engine and

move the main clutch lever to the work position. If

the gear won’t move easily, do not force the gear

shifted. Try to move forward or backward or grasp

the driving clutch lever then shift the speed change

lever firmly. If shifting speed is inadequate, there is

a possibility of gear failure, which is dangerous.

・ Grasp the driving clutch lever. Start working after the

machine moves. Adjust speed using throttle lever.

・ Raise the plow above snow when you turn the

machine.

・ The machine stops moving when you release the

driving clutch lever.

・ Release the driving clutch lever to change the speed.

After the machine stops, you can shift the speed

change lever. Grasp the driving clutch lever to start

moving.

・ Be aware of your surroundings when changing directions, especially forward to reverse, and

reverse to forward. When you are operating in reverse, the machine moves toward your feet –

be sure you have removed any tripping hazards.

・ Raise the plow, by pushing the handle down, to move backward.

・ Always stop the engine if you leave it unattended.

WARNING

CAUTION

CAUTION

-17-

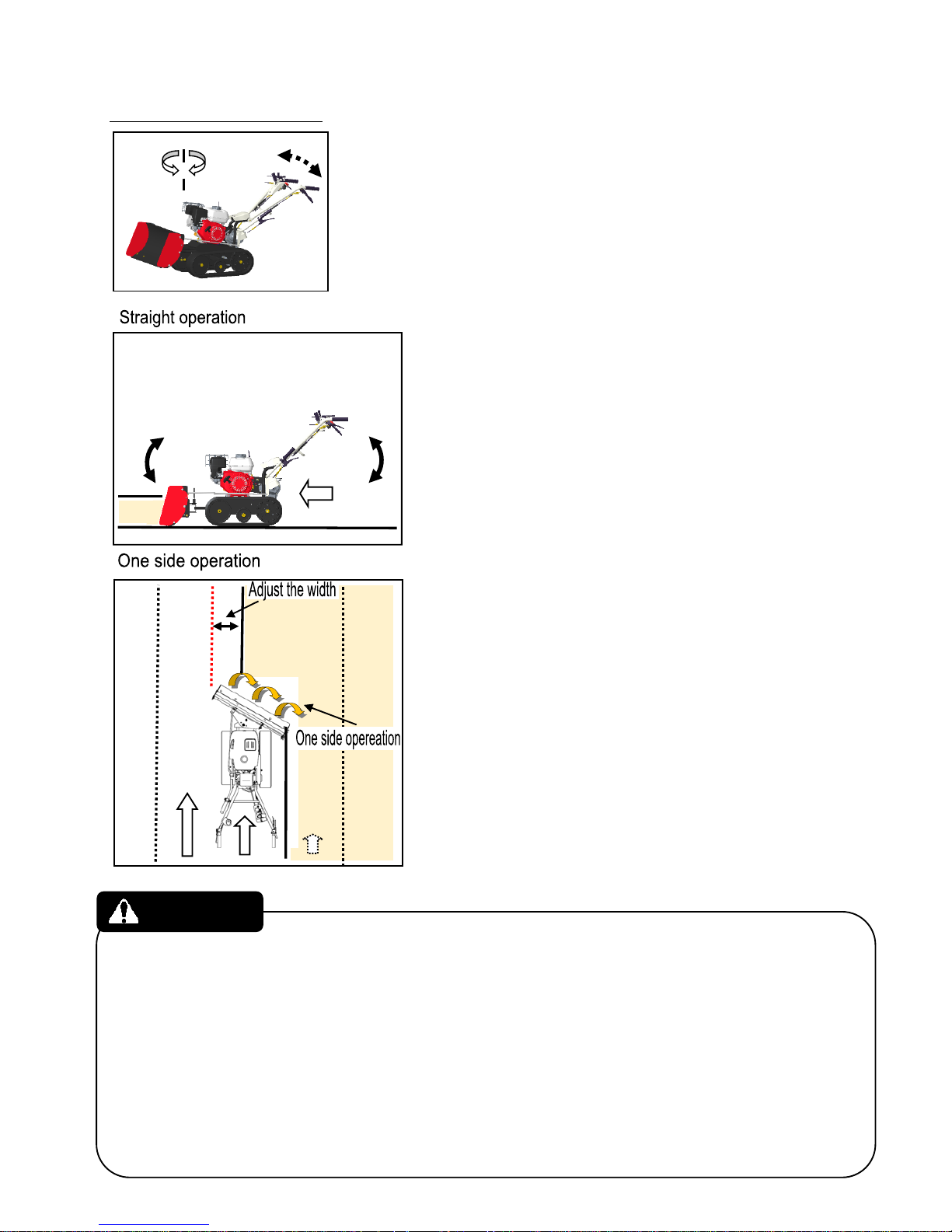

<Tips>

How to turn the machine

1. Push down the handle bar to keep the blade height, and lock it.

2. If you turn the machine around the front part of the track, you

can turn it comfortably.

・ If you experience difficulty pushing snow due to the

amount, or weight of the snow, adjust the height to

remove it.

・ If you feel the tracks slipping, you can increase

power of pushing by pushing down on the handle.

However, if the tracks continue to slip or the engine

loses power, this is due to an excessive weight of

snow. In this case, please clear snow more gradually

or adjust the height of the plow.

・ You can push the snow to one side by removing side

plate of plow. After removing side plate re-tighten the

nut firmly.

・ If the amount of snow is c ausing difficulty, you should

adjust the width (see diagram).

・ You can move the machine without starting the

engine by moving main clutch lever to the “START”

position.

・ If anything , such as a rock, or branch, gets in to the track, stop the machine immediately and

carefully remove the obstruction.

・ Please allow a “breaking-in” period after purchase for about 1 week, or 3-4 hours o operation,

by not overloading the plow.

・ Always start at the lowest speed (1), and increas e as you are sure at the area you are clearing

is safe.

・ If you hit something, always stop the machine immediately and check for damages. Some

unrepaired damages can cause injuries.

・ Clean the machine after operation, to have it safe and ready for the next snow clearing project.

CAUTION

-18-

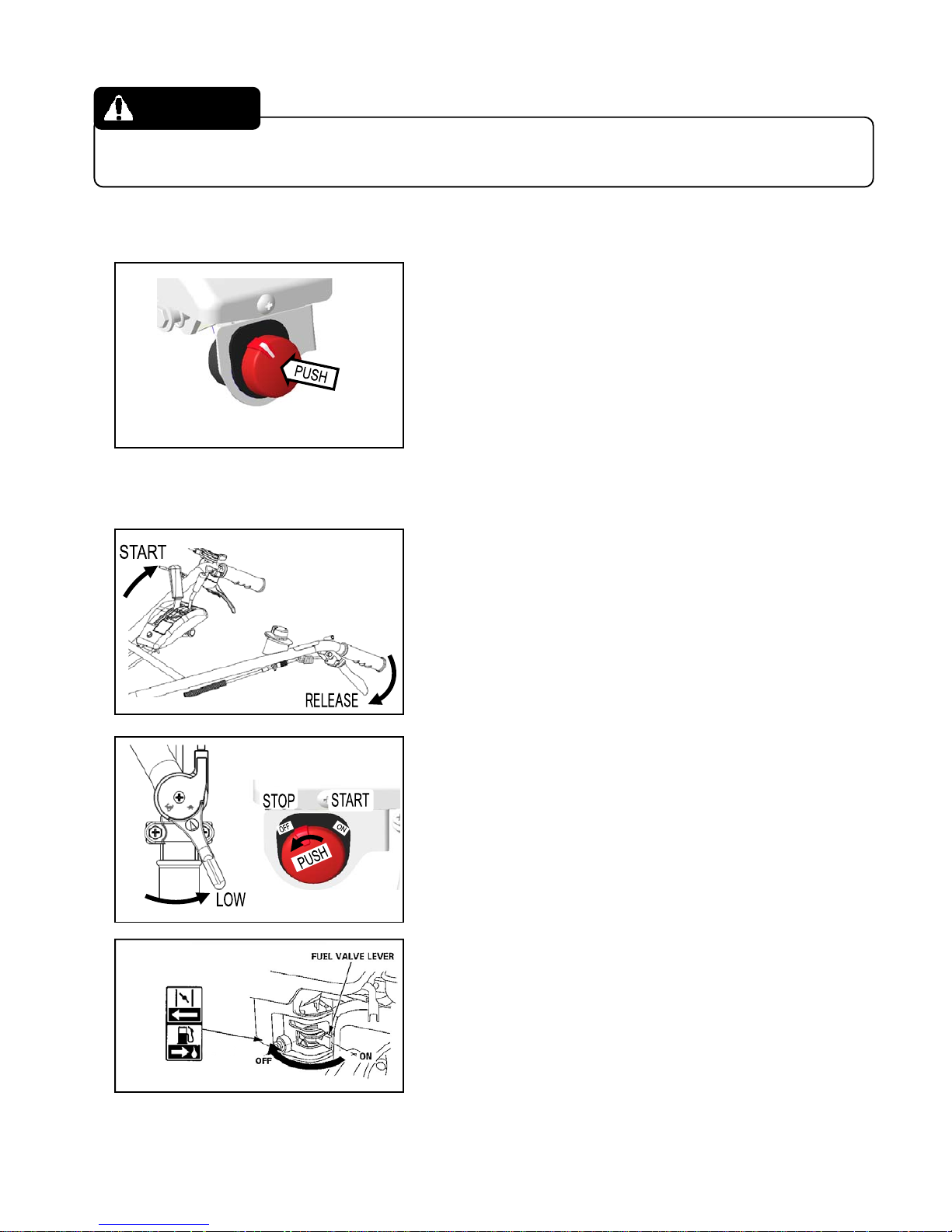

4.1.3 STOP

・ Always stop on a flat area. Stopping on a slope may cause the machine to tip , or loss of control.

・ Please always stop the engine if you must leave it unattended.

[How to stop the engine in emergency]

・ Push the engine stop switch to kill the engine.

・ If you kill the engine, please move each lever to the

correct position. See “How to start the engine” section

for re-start.

[How to stop the machine in normal conditions]

・ Release the driving clutch lever then move the main

clutch lever to “START” position.

・ Move the throttle lever to the low position then push

the engine stop switch to stop the engine.

・ Close the fuel valve.

・ Clean the machine of dirt, snow and water after operation. This helps, ensure safe operation

next time.

WARNING

-19-

4.2 Loading

To avoid damage, accidents, or injury, be sure to follow all instructions below, regarding

loading and unloading the machine.

・ When loading into a vehicle, be sure to check the area around you, and choose a flat surface

for stability.

・ Use a ramp designed for the job, be sure it is wide and sturdy enough and that the machine

stays in the middle of the ramp. Always use the lowest forward gear to load, and reverse to

unload.

・ Do not change speed while you are loading or unloading, and unload slowly.

・ When loading the machine, secure it with rope and take care not to damage cables or plastic

parts of the machine. Do not secure it so tightly that you change the shape of any parts.

Loading

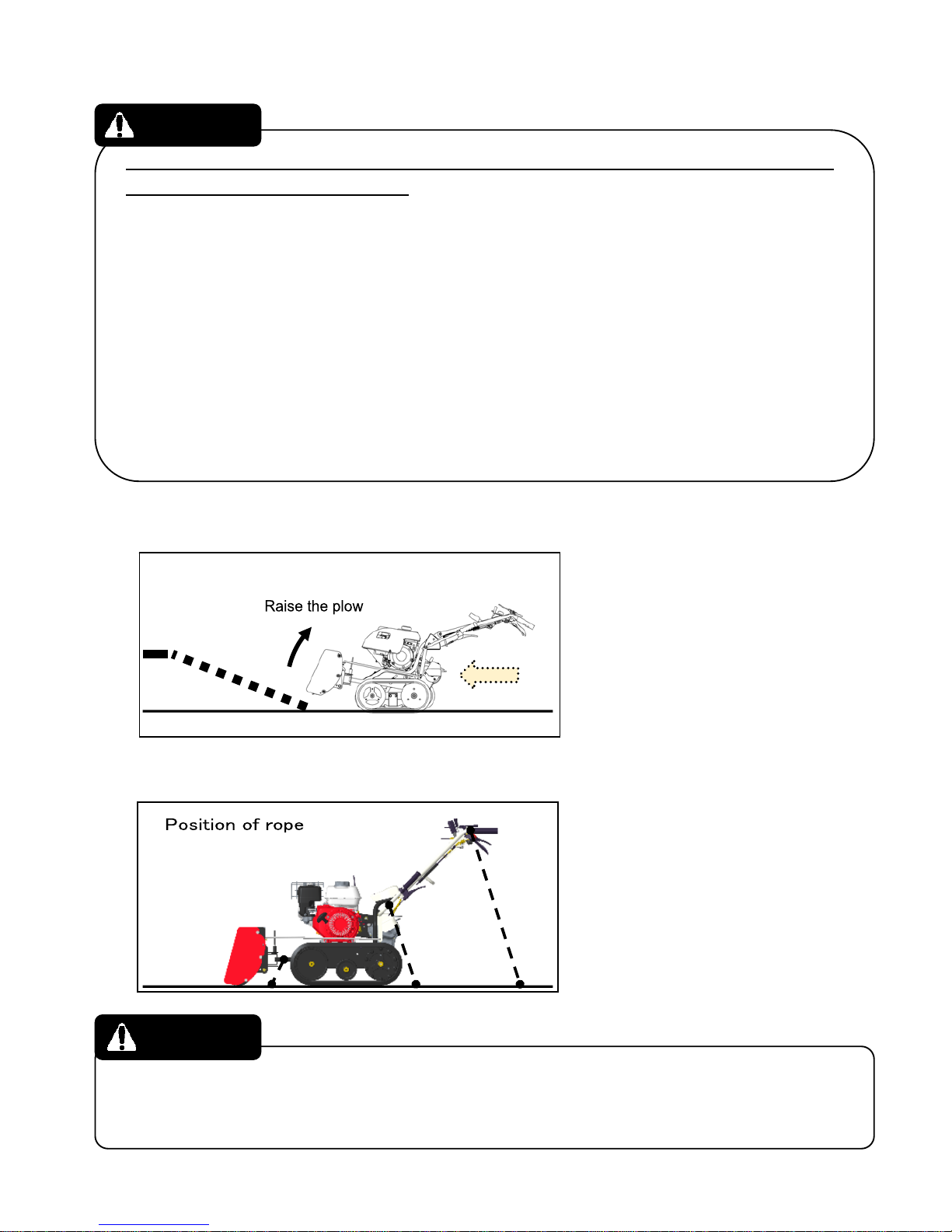

・ While loading, raise the plow so

that it doesn’t touch the ground.

・ Be sure your ramp is wide

enough to accommodate the

change in the center of gravity as

you move up the ramp. Stay to

the center.

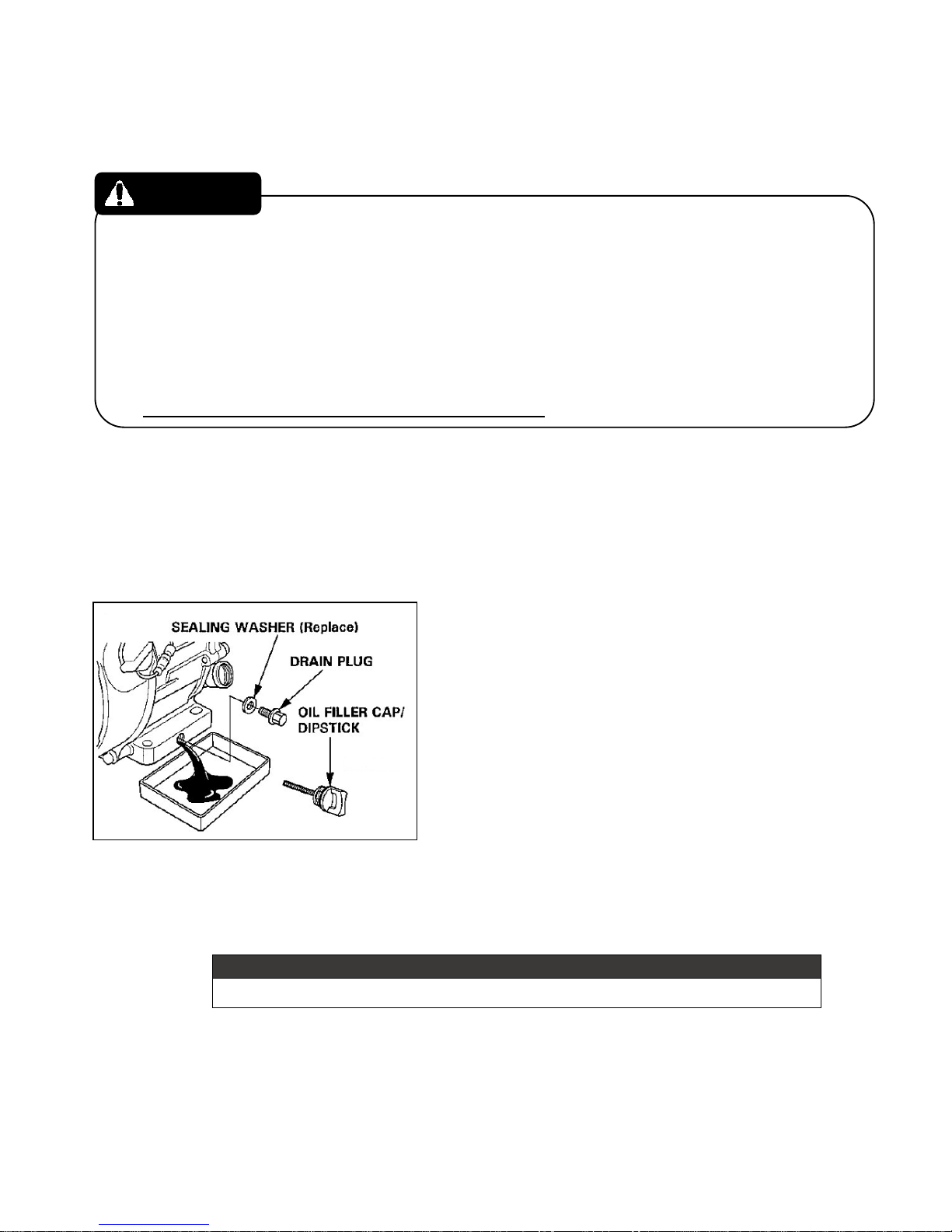

Secure with Rope

・ Secure with a rope that is strong

enough to hold the machine

during transportation. Be sure the

machine doesn’t move.

・ Always stop the engine and close the fuel valve when you transport by vehicle. Leaking fuel can

ignite.

・ Also please do not tilt the machine more than necessary. There is a risk of leaking fuel.

WARNING

DANGER

-20-

5. Inspection and maintenance

Please inspect the machine using the “Periodic inspection table” ( Page 32) and “Inspection

before operation” (Page 30) section for safe and comfortable operation. Perform any maintenance

before working.

・ Please inspect the machine in an open and flat area with the engine off.

・ Keep open flame away from the unit. Also be careful of static electricity and lightning during

operation.

・ Please do not start the engine in poor ventilation or indoors.

・ Engine and oil are at high temperatures immediately after engine stops. Make sure that any

parts cool down before any inspection, maintenance or lubrication.

Follow all instructions to avoid injury and damage.

5.1 Inspection and Changing oil

・ This machine is shipped WITHOUT engine oil. Fill with the recommended engine oil to the correct

level before starting the engine.

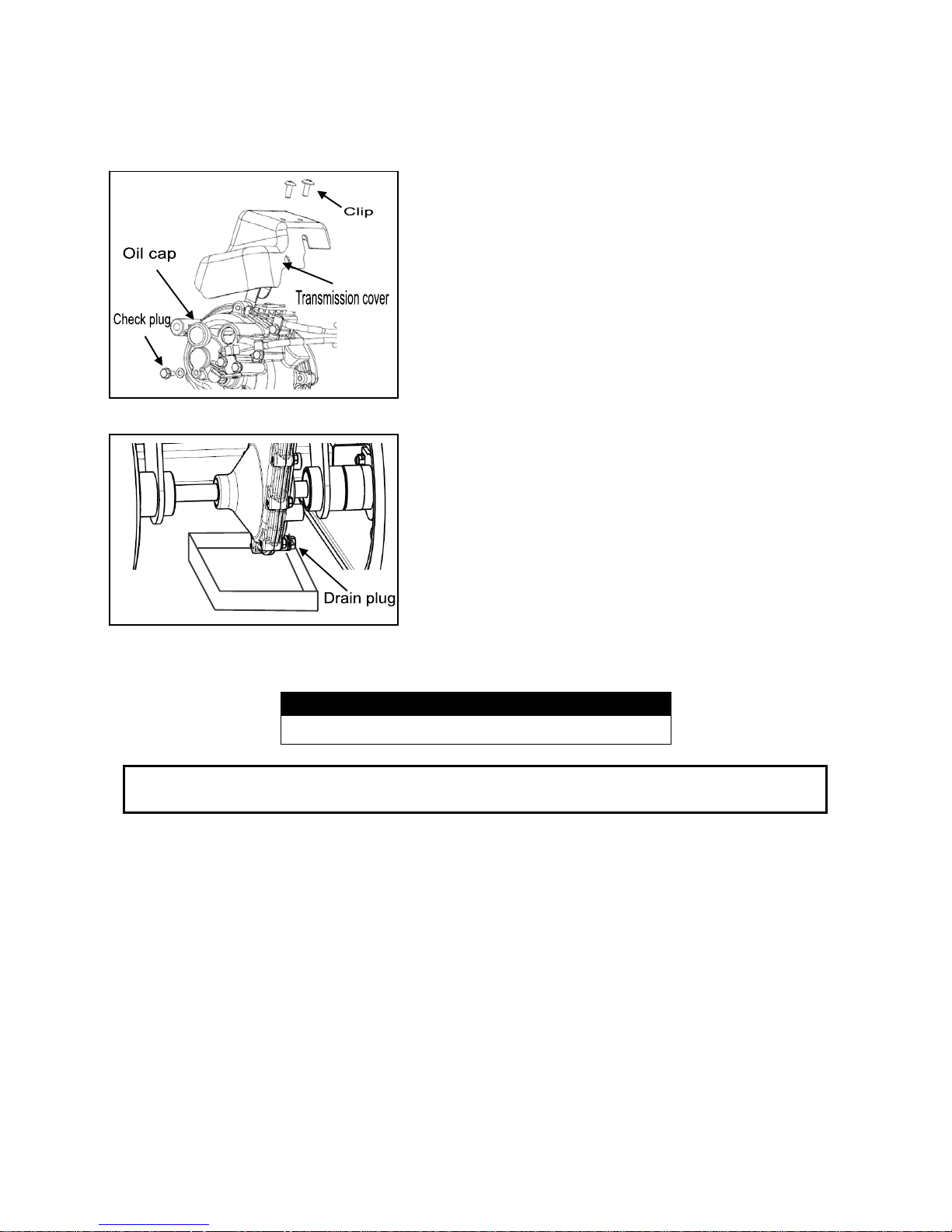

5.1.1 How to change the engine oil

1.Place an oil pan under the transmission.

2.Remove the drain plug at the bottom of the engine

and drain old oil.

Note

;

・ Removing the dipstick at the same time makes it easy

to drain the old oil.

3.After draining old oil, make sure to screw the drain

plug securely, and replace the dipstick

4.Add the recommended oil regarding “3.2 Inspection of

engine oil”( Page 13 ).

・ If you use continuously under high-load or high temperature, change the oil before

recommended period of changing oil.

・ After changing oil, make sure to put t he cover and oil filler cap securely.

Period of changing oil

First time: 5 hours / From the second time: Every 25 hours

WARNING

-21-

■ After chan ging the oil, please dispose o f waste oil in accord ance with loc al laws and r egulations.

5.1.2 Inspection of transmission oil, How to change

・ To mainta in optimum performance, change oil as recomme nded

・ To prevent overfilling, pour oil slowly.

< Inspection>

1. Remove 2 clips on transmission cover, and lift the

cover.

2. Loosen check plug (M6 bolt) as shown in the picture.

There is enough gear oil if the oil comes out through

that hole.

3. Check oil level and quality. Replace if necessary.

< Oil Change>

Replace oil after the first 20 hours of operation and

roughly every 100 hours thereafter. Use an approved

container for the old oil. Remove the drain plug from

the bottom right side of the transmission case. Drain old

oil and replace the drain plug securely. Fill with 0 .8 US qt

(0.75L) of transmission oil (SAE 90 or SAE 80W-90) by

pouring through the oil inlet.

Recommendation

1st time: after 20Hrs, thereafter: every 100Hrs

-22-

5.2 How to inspect, maintain, and adjust each part

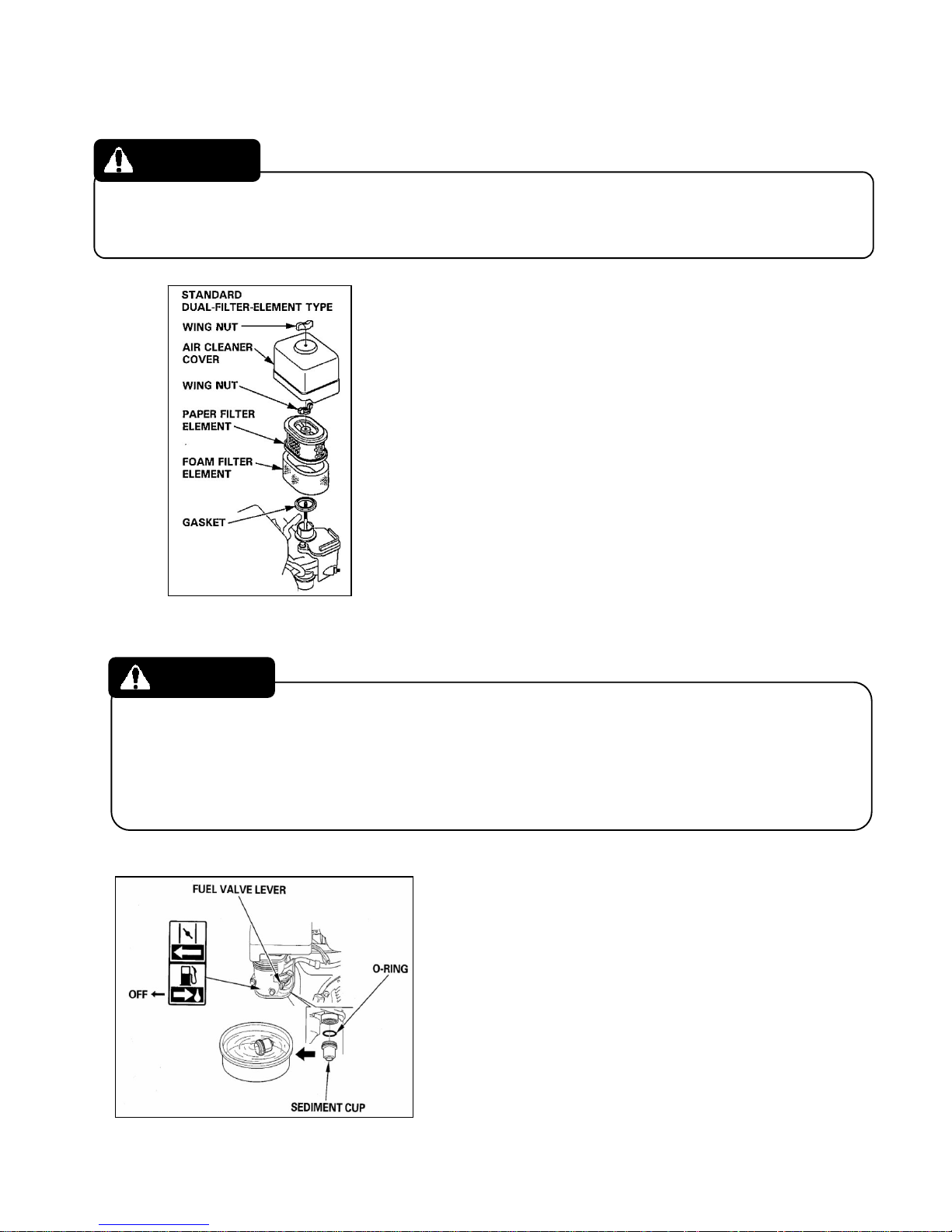

5.2.1 How to clean the air filter

- To avoid fire and da mage to the machine, always keep the air filter and recoil starter fre e of debris.

- Do not start the engine with the air filter removed. Dir t and du st will be sucked into the engine , causing

engine trouble and abnormal wear and tear.

1. Unscrew the wing nut and remove air cleaner cover.

2. Remove the paper and foam elements and check for da mage.

Note; Replace with new parts if damaged.

3. Wash the foam element with a pH neutral deterg ent. After

washing, be sure to squeeze out all the water and allow it to dr y.

After that, soak it in new engine oil (SAE10W-30 equivalent),

wring it out thoroughly, and then shake to remove any surplus oil.

4. Lightly tap the paper element several times to remove any

waste. Blow any dirt from the inside of the filter in an outward

direction

5. Wipe any dirt from the inside of the case and reassemble back

to its original position.

・ When washing the foam element, remove gently to avoid tearing.

Cleaning and replacement time s of the foam eleme nt (appro x)

Cleaning Every time after operation

Replacement Every 100 hours

・ Take care to clean the filter mor e frequently when operating in an environment with a lot of dust or grime.

5.2.2 How to clean sediment cup

・ Clean inside th e sediment cup after e very 50 hours of

operation.

・ Be sure yo u are working in a clean ar ea to prevent dusts

from entering the machine and causing dam age.

1. Move the fuel valve to the OFF position, and th en

remove the fuel sediment cup and O-ring.

2. Wash the sediment cup in non-flammable solvent,

and dry it thoroughly.

3. Place the O-ring in the fuel valve, and install the

sediment cup. Tighten the sediment cup securely.

4. Move the fuel valve to the ON position, and check

for leaks. Replace the O-ring if th ere is an y

leakage.

WARNING

CAUTION

-23-

・ Never use gasoline or thinner as it is highly flammable .

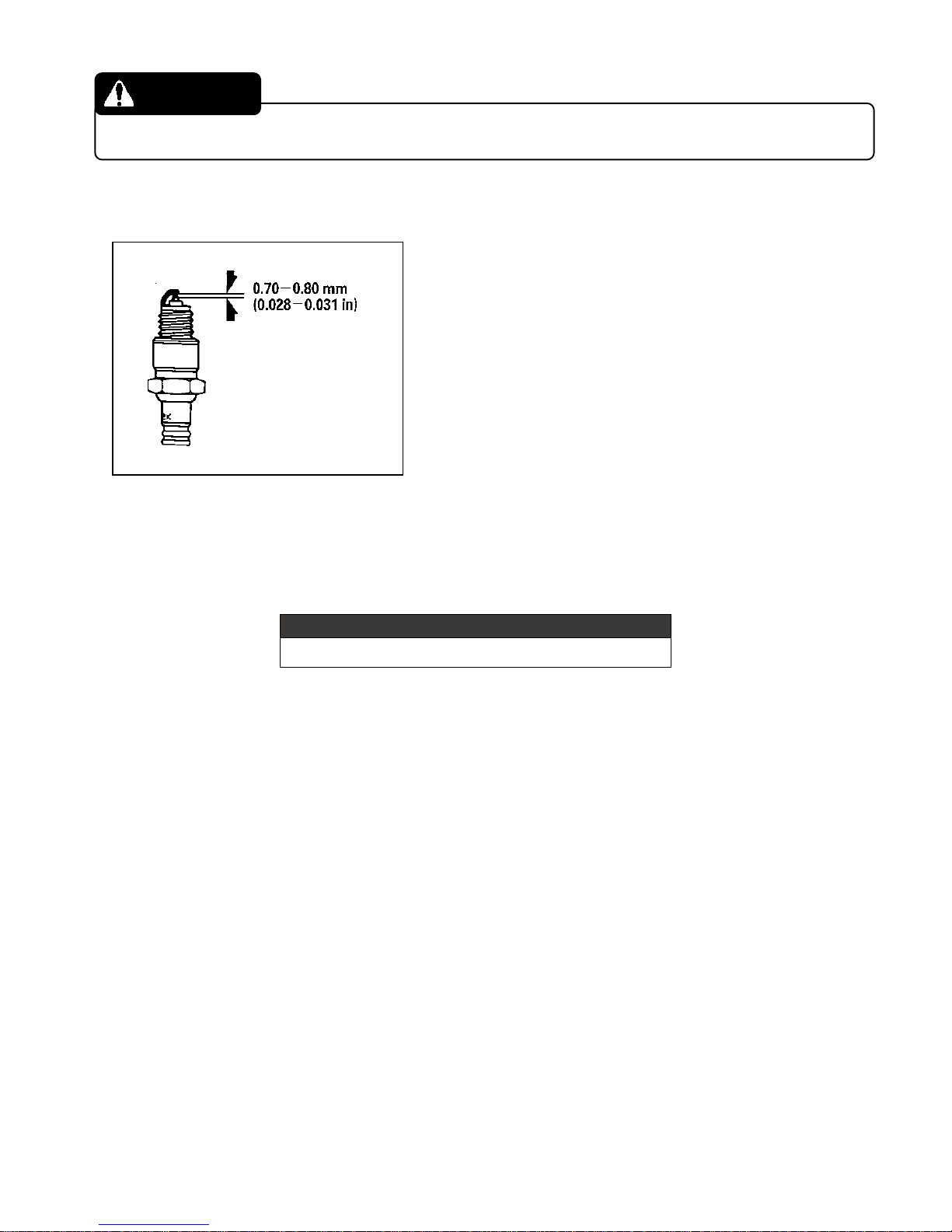

5.2.3 How to inspect and adjust the spark plug

Remo ve th e spark plug with a plug wrench and c lean away

any carbon deposits on the electrode with a wire b rush and

wipe away any moisture if present.

Replace the spark plug with a new one if the cera mic part

has cracked or the electrode shows extensive wear and

tear.

Please adjust the spark plug electrode clearance to 0.028-

0.031in (0.7-0.8mm).

When attaching a spark plug onto the engine, screw b y hand at first be fore tightenin g with a p lug wrench. If you

start by using a plug wrench to screw in the spar k plug, there is a risk o f cross-threading it.

Spark plug

W20EPR-U (DENSO)

WARNING

Loading...

Loading...