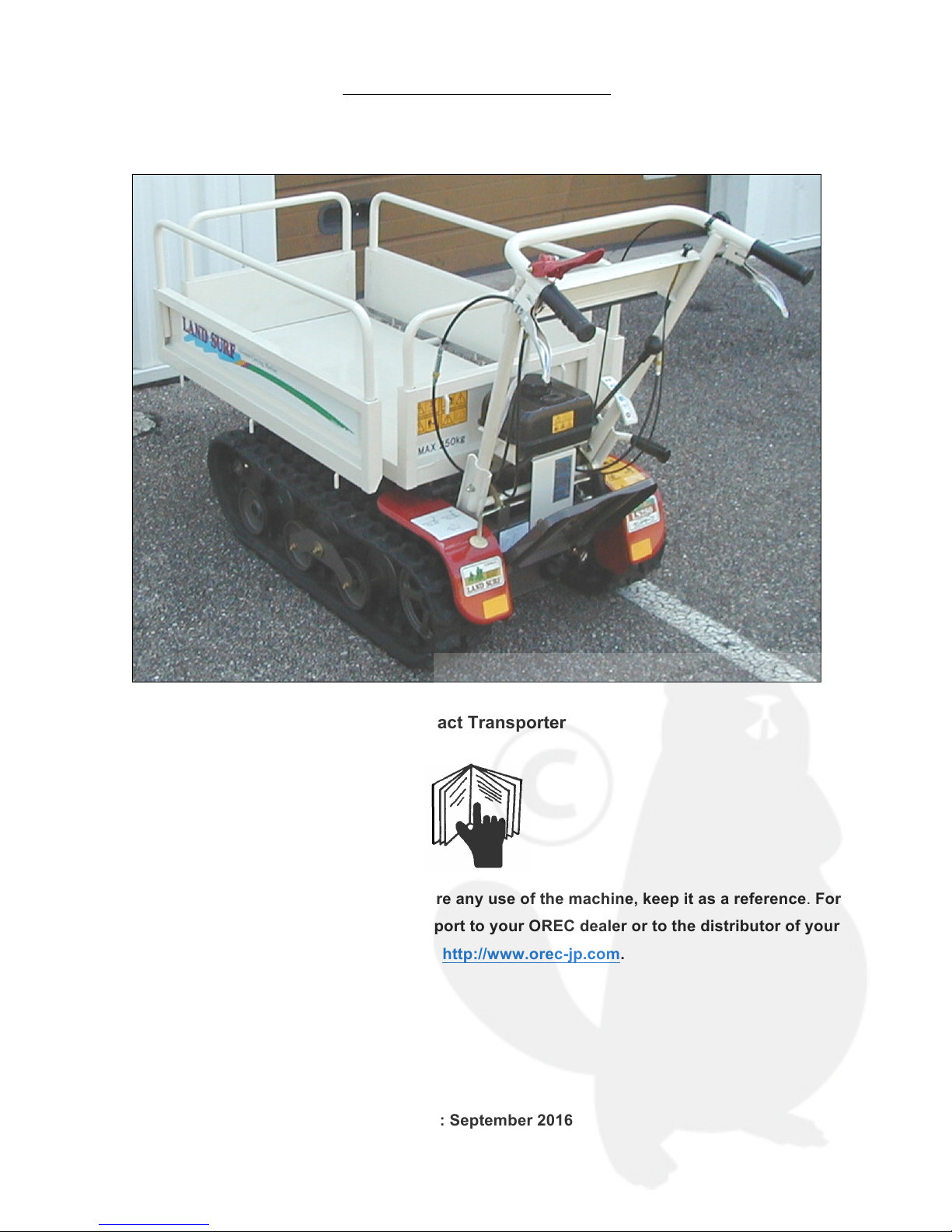

OREC LS 280, LS360, LS461 Owner's Manual

OWNER’S MANUAL

Transporter LS 280 / LS360 / LS461

Compact Transporter

Read this instuction manual carefully before any use of the machine, keep it as a reference. For

any question about this manual, please report to your OREC dealer or to the distributor of your

country or to : http://www.orec-jp.com.

Update : September 2016

© SAT – 09/2006

2

“Only the English version of this manual can be used as a reference.”

INTRODUCTION

Forword to the user

Read this manual before any use of your mower, only the herein instructions shall help you to achieve an

efficient and safe work.

A safe use will only result from the manner you will use the machine in accordance with the restrictions

described in this manual. Thus, you must know and follow all the safety measures in this manual and

those relating to the use of your mower.

The mower that you have just bought has been designed and manufactured for your entire satisfaction.

As any other mechanical machine, it requires a proper maintenance and must be kept clean. Grease the

machine like indicated. Follow the rules and safety indications as described in this manual and as showed

on the preventive instruction stickers.

About maintenance, always mind that your OREC dealer has the skills, the genuine parts and the

necessary tools to solve the possible problems.

Use only the OREC original parts : “ non genuine ” parts will not assure you of a correct and safe working

and are likely to make the guarantee null and void. Write the name and the serial number of your

machine hereunder :

MODEL :.......................................................................................

SERIAL NUMBER (refer to the pictures herein) :.........................

Always mention these informations to your dealer in order to obtain the right parts.

Concerned about constant progress, OREC keeps the right to modify the machines without being

compelled to modify those already sold.

The illustrations and characteristics in this manual might lightely differ from your machine because of the

constant improvements made by our production department.

In this manual, the left and the right hand or the rear and the front position are determined according to

the mower handlebar.

All along this manual the word IMPORTANT is used to indicate that a fault might cause damage to the

machine. The words WARNING, CAUTION and DANGER are used with the “ safety/warning ” pictogram

(triangle with an exclamation mark) in order to indicate a hazard for your safety.

This symbol indicates that you must be very attentive because your safety is at stake. It reminds that you

must follow the safety instructions and pay attention to hazardous operations that might cause injuries.

WARNING

Reminds the safety rules that might cause injury if they are not respected

CAUTION

Remembers to pay attention to a real danger that is likely to cause injury or even death if no proper

precaution is taken.

DANGER

Indicates a major hazard that is most likely to cause irremediable injury or death if the right precautions

are not taken.

© SAT – 09/2006

3

CONTENTS

INTRODUCTION ............................................................................................................................................... 2

CONTENTS ...................................................................................................................................................... 3

SPECIFICATIONS ............................................................................................................................................ 3

LOADING CAPACITY ....................................................................................................................................... 3

CHECK LIST ..................................................................................................................................................... 4

SAFETY RULES ............................................................................................................................................... 4

DIFFERENT PARTS OF TRANSPORTER (LS280) ...................................................................................... 6

DIFFERENT PARTS OF TRANSPORTER (LS360) ...................................................................................... 7

DIFFERENT PARTS OF TRANSPORTER (LS461) ...................................................................................... 8

SAFETY INSTRUCTION STICKERS ................................................................................................................ 9

CONTROLS .................................................................................................................................................... 10

OPERATION ................................................................................................................................................... 12

MAINTENANCE OPERATIONS TO BE CARRIED OUT BY THE USER ....................................................... 15

LIST FOR REGULAR SELF-INSPECTION .................................................................................................... 22

HOW TO ASSEMBLE : DEALER INSTRUCTIONS ........................................................................................ 26

EC CONFORMITY DECLARATION ............................................................................................................... 28

MEASUREMENT OF VIBRATIONS ............................................................................................................... 28

EC CONFORMITY DECLARATION ............................................................................................................... 29

MEASUREMENT OF VIBRATIONS ............................................................................................................... 29

EC CONFORMITY DECLARATION ............................................................................................................... 30

MEASUREMENT OF VIBRATIONS ............................................................................................................... 30

EC CONFORMITY DECLARATION ............................................................................................................... 31

MEASUREMENT OF VIBRATIONS ............................................................................................................... 31

TIGHTENING TORQUE (daNm) ..................................................................................................................... 32

LIMITED WARRANTY .................................................................................................................................... 32

NOTES ............................................................................................................................................................ 33

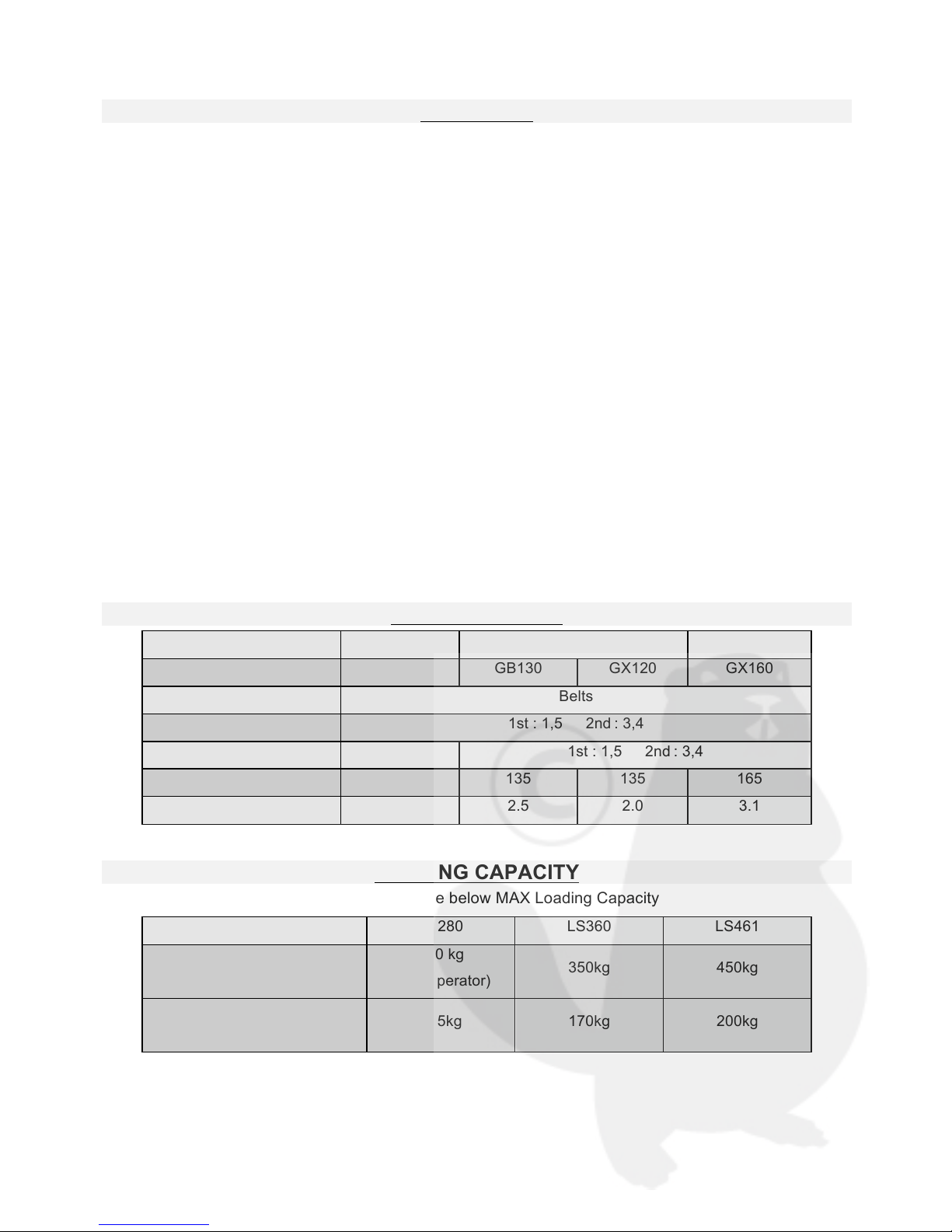

SPECIFICATIONS

Model

LS280

LS360

LS461

Engine

FJ100

GB130

GX120

GX160

Transmission

Belts

Forward speed (km/h)

1st : 1,5 2nd : 3,4

Reverse speed (km/h)

1,5

1st : 1,5 2nd : 3,4

Weight (kg)

140

135

135

165

Fuel tank capacity (L)

2.8

2.5

2.0

3.1

LOADING CAPACITY

Do not carry over the below MAX Loading Capacity

Model

LS280

LS360

LS461

On flat place

(Slope less than 5 degree)

250 kg

(incl. operator)

350kg

450kg

On slope

(Slope between 5~20 degree)

125kg

170kg

200kg

© SAT – 09/2006

4

CHECK LIST

INSTRUCTIONS TO THE DEALER

• The assembling, the installation and the first application of the machine is under the OREC dealer’s

responsability.

• Read the instruction manual as well as the safety measures. Check that all the before delivery and at

delivery check points specified in the following lists have been verified and possibly modified before

delivering the machine to its owner.

CHECKS BEFORE DELIVERY

• Check that all the shields, grids and safety guards are in place and in a good state.

• Check that the hydraulic hoses are in place and in a good state. Replace them if necessary.

• Check that there is no oil leak, repair if necessary.

• Check that the safety instruction stickers are in place and in a good state. Replace them if necessary.

• Check that all the bolts and screws are properly tightened with the right torque (refer to page 16).

• Protect the grease nipples by coating them with grease and lubricate the machine.

• Check that the machine can work properly.

Especially Braking system ,Driving system is important to check.

CHECKS ON DELIVERY

• Show the user how to perform the adjustments.

• Explain to the user the importance of the lubrication and show him the different greasing points on the

machine.

• Show him the safety devices, grids, guards and the optional equipments.

• Give the instruction manual to the customer, ask him to read it carefully.

SAFETY RULES

CAUTION

Some of the illustrations show the machine with no guard, no shield. Never use the machine

without these devices.

• Learn to stop the machine in case emergency.

• Read this manual.

• Do not let anybody use the machine before having read and understood this manual.

• Do not let children use the machine.

• Do not wear loose clothes. They might be grasped by moving parts.

• Always wear protection equipments for when using the machine.

• Only work during daylight or with a good artificial light.

• Check that the safety instruction stickers are in place and in a good condition.

• Keep the machine free from debris or mud.

• Check that the machine can work properly before any use.

• Check that all the shields, grids and safety guards are in place and in a good state.

• It is strictly forbidden to carry persons or animals onto the machine during the work or during the

transportation.

© SAT – 09/2006

5

• Never stop or start roughly when working on a slope. Never use the machine to work on a stepping

terrain.

• Reduce the ground speed when driving on a slope and when turning straight

in order to prevent from any risk of losing control.

• Be very careful when bordering ditches.

• Stop the engine, and remove the sparking plug ignition cover before any

intervention on the machine.

• Never work under the machine or its parts when lifted, unless they are

blocked and maintained into position with sufficient security.

• When driving on a slope, always work going up or down but never across the

slope.

• Stay clear of unsteady embankments, holes or rocks. They might be dangerous during work or

transport.

• Keep away from electric wires and obstacles. A contact with electric wires cause electrocution and

death.

• Stop the machine progressively when lifting or lowering the machine.

• When stopping the work, stop the engine and remove the sparking plug ignition cover before leaving

the mower.

• Engage all the safety equipments.

Move the controls only when correctly sat down in the mower

• Visually check hydraulic leaks and if some parts are faulty or missing. Repair before use.

Never change the adjustment of the regulator, it is set in the factory. Unsetting the regulator would cause

failures.

• Ensure that the user of the machine has already read and understood this

manual and that he is aware of all the safety instructions before any use.

• Always use a chuck and bronze hammer when replacing or intervening

on the pins and bolts at the end of rams, rod … etc in order to avoid the

projection of metal fragments.

© SAT – 09/2006

6

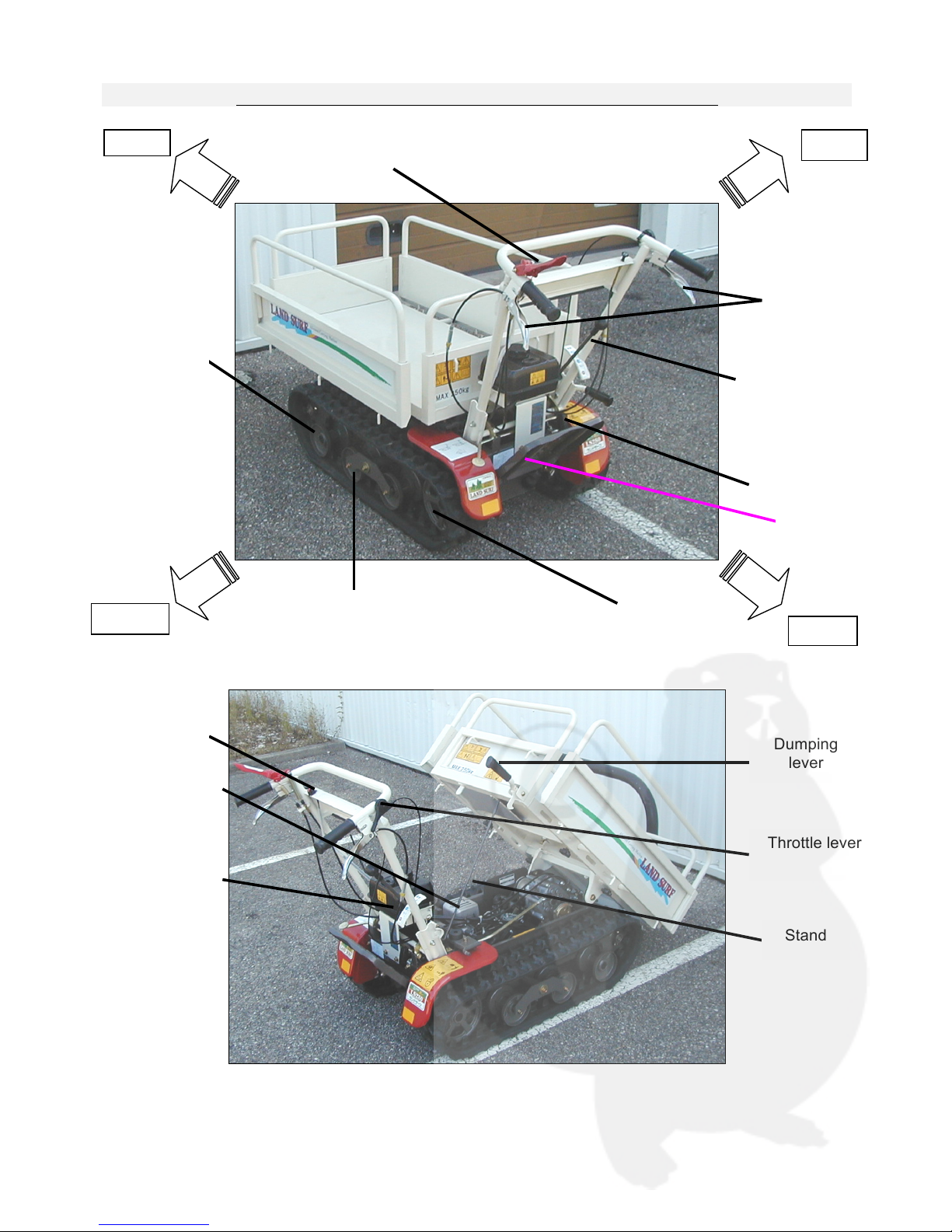

DIFFERENT PARTS OF TRANSPORTER (LS280)

Front

Right

rear

left

Side Clutch

Lever

Travel Lever

Throttle lever

Idle Wheel

Driving Sprocket

Turning Wheel

Recoil Starter

Speed change

Lever

Fuel tank

Exhaust

silencer

Dumping

lever

Stand

On/off engine

switch

Foot Rest

(LS280)

© SAT – 09/2006

7

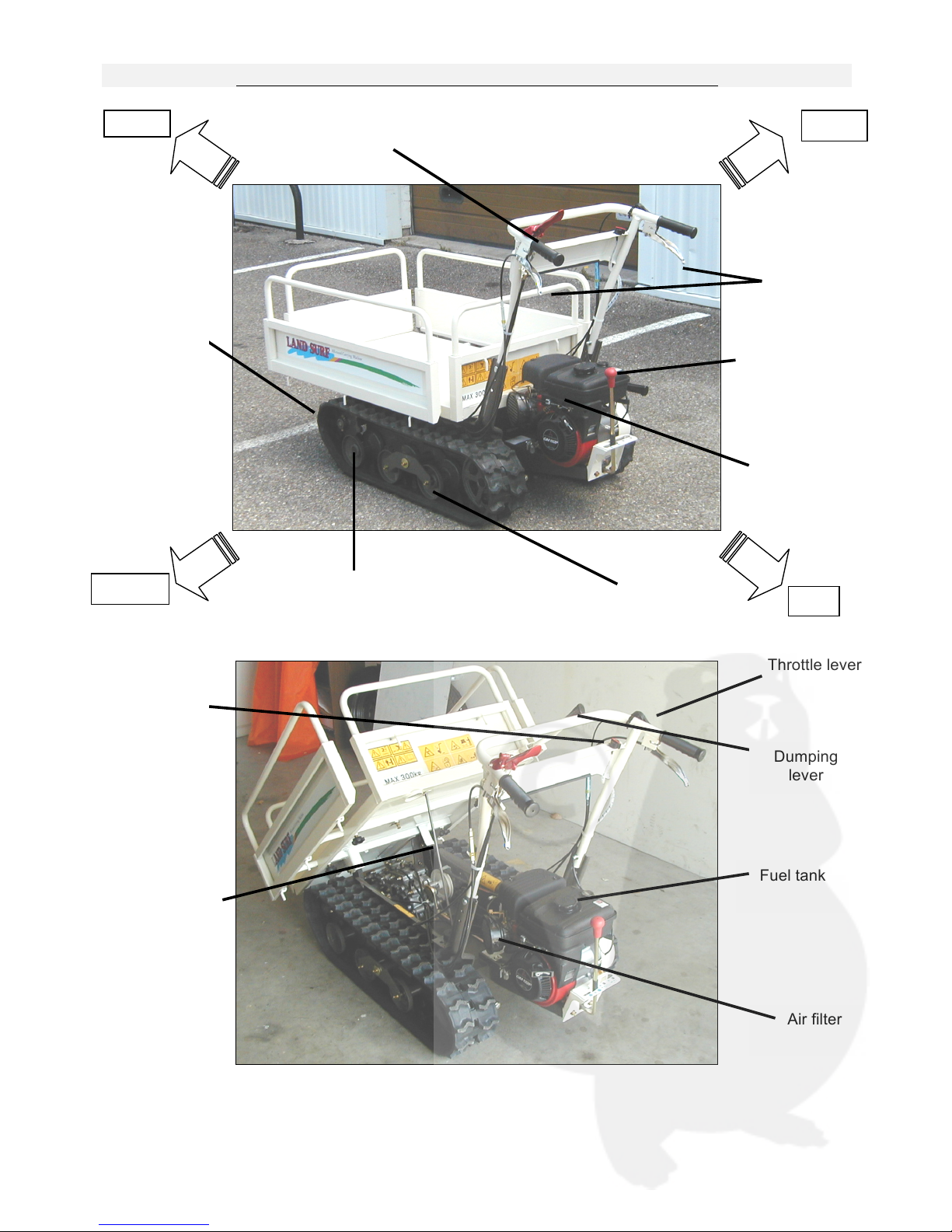

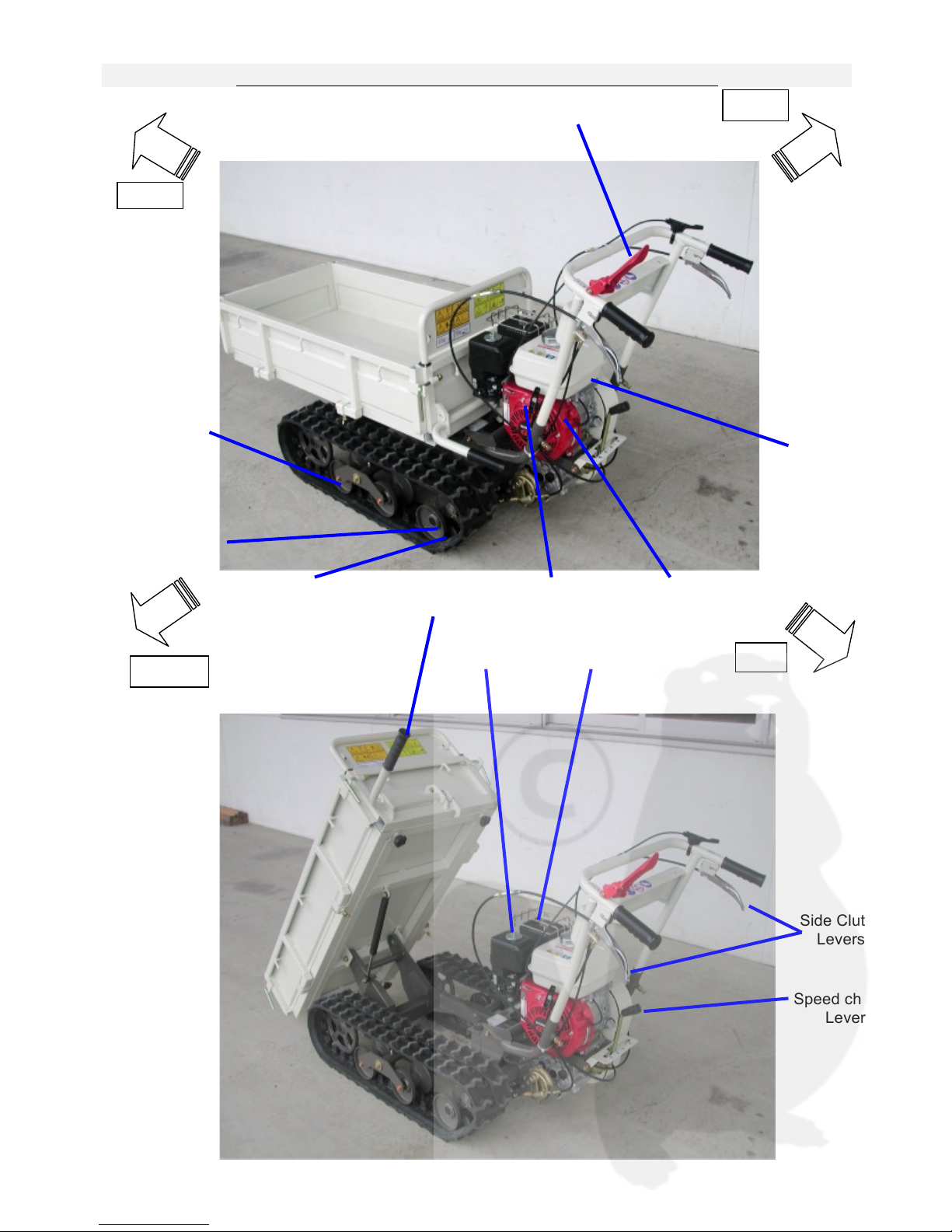

DIFFERENT PARTS OF TRANSPORTER (LS360)

Right

rear

left

Side Clutch

Levers

Travel Lever

Throttle lever

Idle Wheel

Driving Sprocket

Turning Wheel

Recoil Starter

Speed change

Lever

Fuel tank

Air filter

Dumping

lever

Stand

On/off engine

switch

© SAT – 09/2006

8

DIFFERENT PARTS OF TRANSPORTER (LS461)

Front

Right

rear

left

Travel Lever

Throttle lever

Driving Sprocket

Turning Wheel

Recoil Starter

Speed change

Lever

Fuel tank

Air filter

Dumping

lever

On/off engine

switch

Idle Wheel

Side Clutch

Levers

muffler

© SAT – 09/2006

9

SAFETY INSTRUCTION STICKERS

Note their location and replace them immediately in case of damage or when missing

Beware of hot surfaces exhaust gases and burnt read owner’s manual

Before doing maintenance

remove the spark plug

Stand clear of the machine

read owner’s manual

Beware of the rotating parts

under the shield.

Do not load in height

Always use the stand to

secure the folded bucket

・ Always wear protective equipment.

・ Do not opearte in slope more than 20°

・ Always wera safty shoes during the operation

Do not change of gear on slopes

Pay Attention for Backgear

(only LS280)

Do not Ride on the Sloop operation

© SAT – 09/2006

10

CONTROLS

Travel lever(A, figure1)

This lever transmits the power

from the engine to the

transmission. Grip the lever with

the handlebar and it will be in

"driving" position. Release the

handlebar and it will be in "stop"

position.

The driving clutch lever is

connected with the brake. When

the lever is in "stop" position, the

parking brake is led to "on"

condition.

WARNING

Do not fix the driving clutch lever with wires or strings or straps, which is very dangerous.

.

Speed lever (F, figure1)

This lever decides the speed of the machine. There are two steps for driving forward ("1" & ‘'2") and one

step for driving backward ("R'). Before changing speed, shift the driving clutch lever to "stop" position and

stop the machine.

WARNING

Only allowed to change travel speed when machine is stopped.

Side Clutch Lever (C, figure1)

It is to change directions of the machine. Grip either lever and the machine turns to that direction. When

you grip both levers at the same time, the machine stops on the spot.

WARNING

Handle the side clutch lever with a low speed, or the machine will turn fast, which is very

dangerous.

ON/OFF engine switch (D, figure 1)

Turn the switch « ON » to start the engine. Turn the switch « OFF » to

stop the engine.

Dumping Lever (G, figure 1)

It is necessary when the platform is dumping. Grip the lever and pull it

up.

Choke lever (E figure 1)

Pull the choke knob to start the engine when it is cold. Push the knob

when the engine has started.

Throttle lever

(Figure 3)

It is to adjust the rotation of the engine.

Figure 1

Figure 3

G

Loading...

Loading...