Orcon HRC-300 EcoMax, HRC-300-MaxComfort, HRC-400-MaxComfort, HRC-500-EcoMax, HRC-500-MaxComfort Installation Manual

Installation manual

HRC-EcoMax / HRC-MaxComfort

Balanced ventilation system with heat recovery

This manual is intended for installers of the HRC-EcoMax and HRC-MaxComfort

balanced ventilation system. The manual contains important information

about the installation and configuration of the ventilation unit with heat

recovery. The user manual can be found on the right side of the unit.

This manual concerns the following models:

HRC-300 EcoMax

HRC-300-MaxComfort

HRC-300 EcoMax

HRC-400-MaxComfort

HRC-500-EcoMax

HRC-500-MaxComfort

2

Index

1. Precautions and safety instructions 3

2. Product information 4

3. Product overview 6

4. Installation 10

5. Installation components 19

6. Adjustment 25

7. Maintenance and Service 28

8. Technical specifications 39

9. Installation report 47

10. Product card 48

11. Warranty 50

12. EC declaration 50

1. Precautions and safety instructions

• Only a professional installer may install, connect, commission and carry out

maintenance to the device unless otherwise specified in this document;

• The installation of the unit must be carried out in accordance with the general

and locally applicable construction, safety and installation regulations of the

municipality and electricity company;

• Make sure that the voltage is removed during work on the unit and cannot be

switched on accidentally. Bear in mind that the motor will continue to run for

approx. 20 seconds after switching off;

• The unit is only suitable for a 230V/50 Hz. connection;

• Modification of the unit or specifications stated in this document is not permitted;

• Touching the fans by hand must not be possible, therefore ventilation tubes of at

least 900 mm length must be connected.

3

2. Product information

2.1 General product description

The HRC is a balanced ventilation system with heat recovery. This means that an equal

amount of fresh filtered outside air is supplied to the living room and bedrooms while

polluted air is extracted from the kitchen, bathroom and toilet. The heat of the extract

air from inside is then transferred to the fresh filtered outside air. This results in

significant energy savings.

The Orcon HRC is equipped with an intelligent electronic control circuit that ensures

optimum operation and protection under all circumstances. The unit can be used as

a left or right model. The unit is supplied as standard as a left model with a grounded

plug and can be converted to a perilex model with a perilex power cord (article number: 22915405). For all models it is possible to use a radio remote control 15RF, CO

Roomsensor 15RF or a CO

Controlsensor 15RF; these are available separately.

2

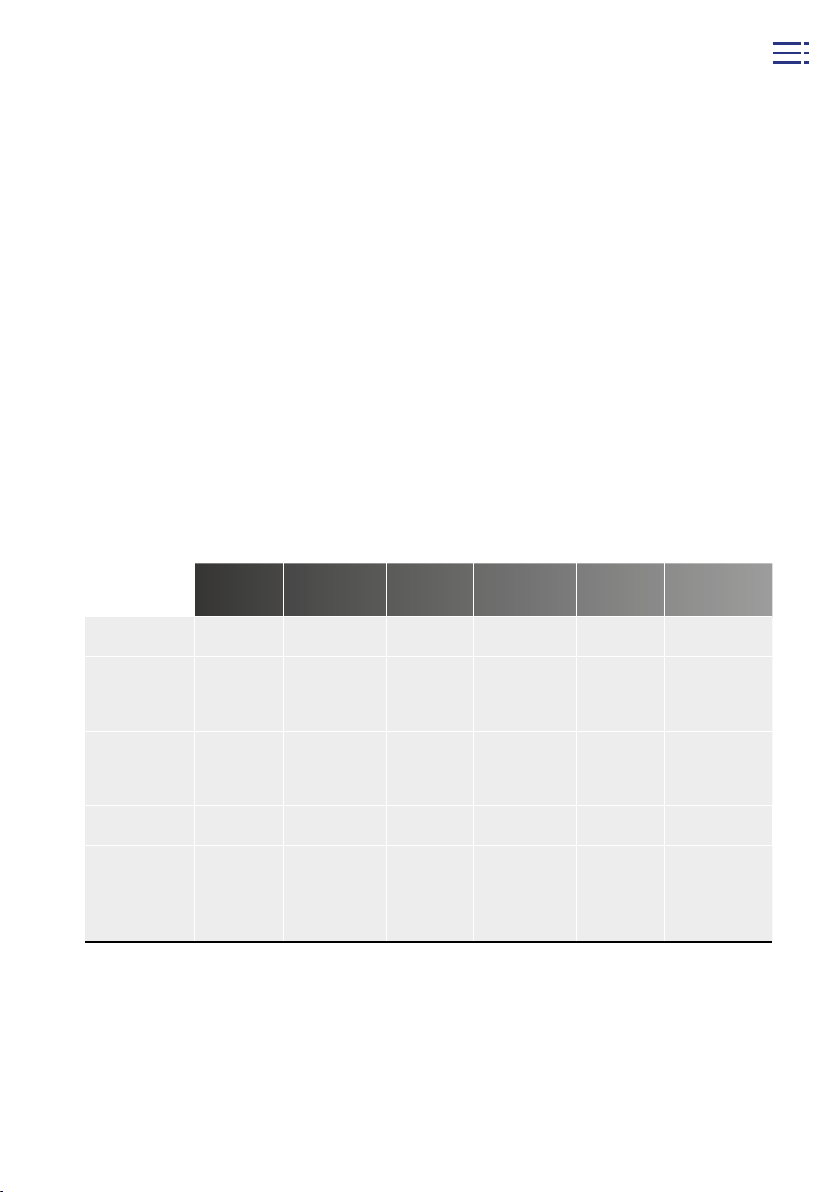

2.2 Unit types

The different models are listed in the table below. Each model is suitable for both left

and right mounting.

2

index

Item no.

Air flow rate

[m³/ h] at

max. 200 Pa

Tube

connection

[mm]

Preheater

Filter class

(ISO16890)

4

HRC-300EcoMax

22000080 22000085 22000090 22000095 22000100 22000105

300 300 400 400 500 500

ø150 ø150 ø180 ø180 ø180 ø180

no yes no yes no yes

2x coarse

65%

HRC-300MaxComfort

supply:

ePM1 70%

extract:

coarse 65%

HRC-400EcoMax

2x coarse

65%

HRC-400MaxComfort

supply:

ePM1 70%

extract:

coarse 65%

HRC-500EcoMax

2x coarse

65%

HRC-500MaxComfort

supply:

ePM1 70%

extract:

coarse 65%

2.3 Scope of delivery

Before installing the HRC, check that it has been delivered complete and undamaged.

It is complete if the following parts are included:

• HRC-EcoMax or HRC-MaxComfort with 230V earthed power cord

• Wall bracket

• Mounting set with 2x M8 bolts, 2x M8 washers and 2x plugs

• Installation manual

• User manual

• Connector piece 32mm / G1¼" for condensation drain

• 2x Orcon Filter (already in unit) (depending on unit model, see Chapter 2.2)

• Optional preheater (depending on unit model, see Chapter 2.2)

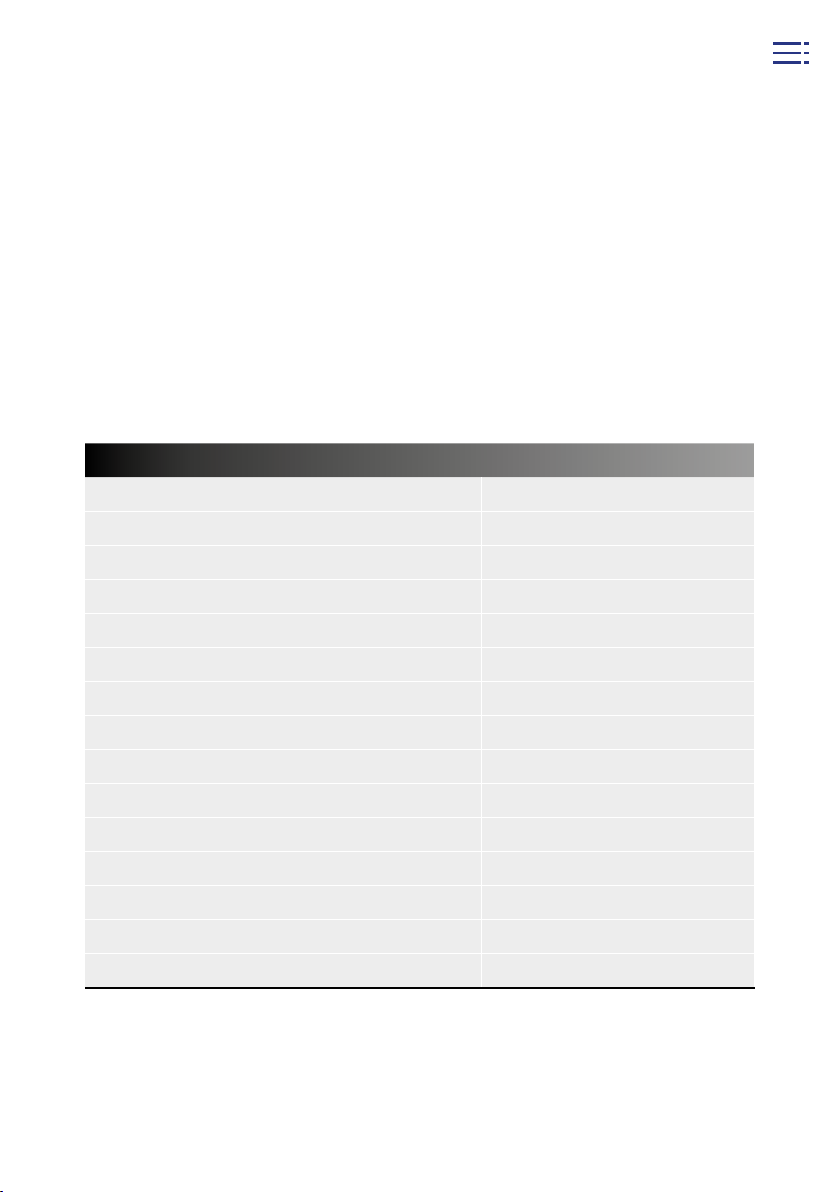

2.4 Optional accessories

Item Article number

HRC chassis

Preheater

EFF ø125 Extractor valve

EFF ø160 Extractor valve

TFF ø125 Supply valve

TFF ø160 Supply valve

Dry condensation drain set

Filter set HRC 2x coarse 65%

Filter set HRC coarse 65% & ePM1 70%

Perilex power cord

CV-3 Perilex socket - surface mounted

CV-3 Perilex power socket - built-in

Remote control 15RF

Roomsensor 15RF

CO

2

Controlsensor 15RF

CO

2

22700080

29190550

23121002

23121003

23121012

23121013

22700065

22700002

22700006

22915405

28000005

28000000

21800000

21800040

21800045

index

2.5 Scope of application

The unit is only suitable for residential buildings and not for industrial use, swimming

pools or saunas. The air flow rate from the unit must match the ventilation requirements

of the home.

5

3. Product overview

index

3.1 Parts

1. Front cover

2. Heat exchanger

3. Filter (2x)

4. Ventilator module (2x)

5. EPP cap (4x)

6. Wall bracket

7. Metal back frame

8. Preheater

(only with HRC-MaxComfort)

9a. Connector flange 150mm (4x)

(HRC-300-EcoMax/MaxComfort)

6

9b. Connector flange 180mm (4x)

(HRC-400-EcoMax/MaxComfort)

9c. Connector flange 180mm (6x)

(HRC-500-EcoMax/MaxComfort)

10. Main circuit board, RF antenna

11. Temperature sensor (2x)

12. Humidity sensor

13. Bypass module

14. Metal front frame

15. Filter cover left & right

3.2 Operation

Bypass

In the summer, or when heat recovery is not desirable, the air is not passed through,

but past the heat exchanger thanks to a bypass module. This makes it possible to

ventilate the home with fresh outside air in the summer situation, during the night,

so that the home is relatively cool again in the morning. The bypass opens when the

inside temperature exceeds the set comfort temperature of 23°C and the outside

temperature exceeds 15°C.

Frost protection

When the outside temperature in winter is around freezing, it is possible for ice to

form in the exchanger. Cold air is blown into your house as a result. To prevent this,

the HRC will heat the exchanger in time using the warm indoor air from your home.

The unit will temporarily create an imbalance to achieve this.

For the MaxComfort models, the built-in preheater switches on and warms up the cold

incoming outside air.

Constant volume

The unit is equipped with a constant volume control. This ensures that deviations

in the air flow rates between the supply and extract air, for example due to weather

conditions or when the filters become contaminated, are corrected automatically.

In this way the unit remains constantly balanced and you are assured of sufficient air

with maximum efficiency.

index

7

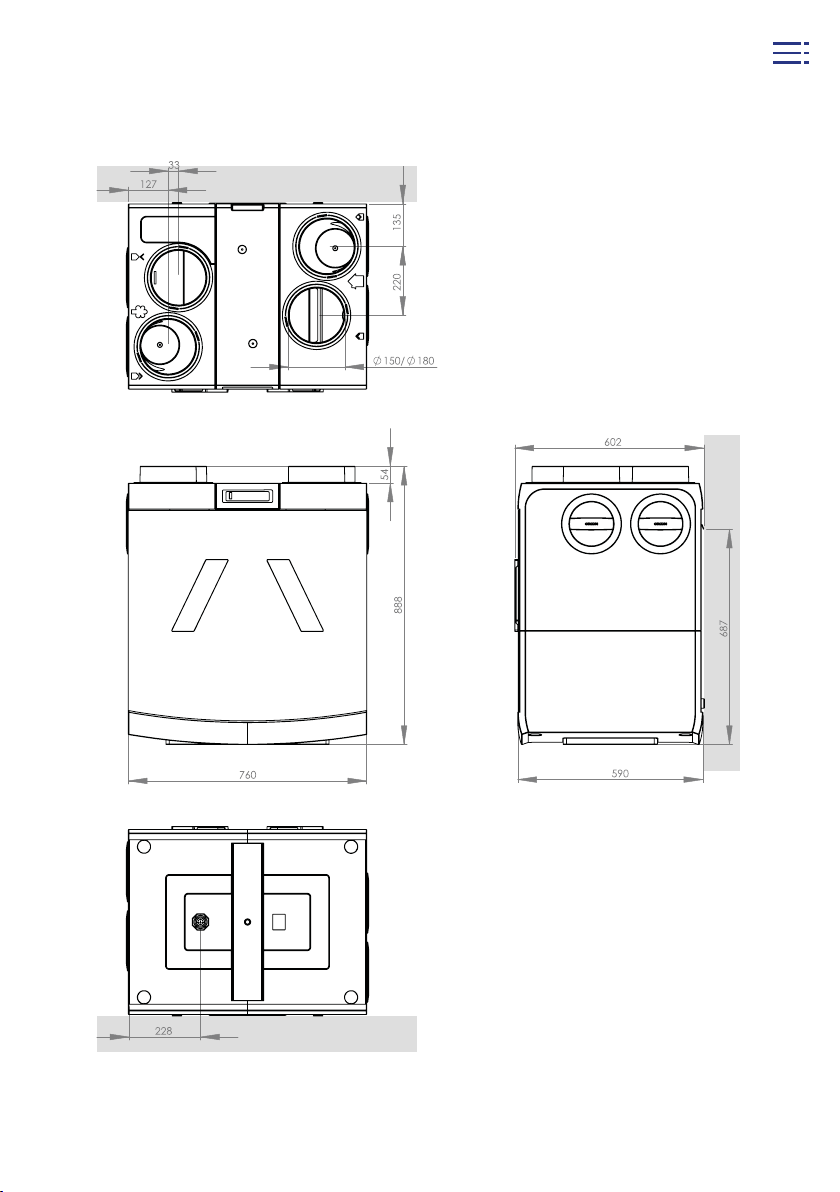

3.3 Dimensional drawing

index

8

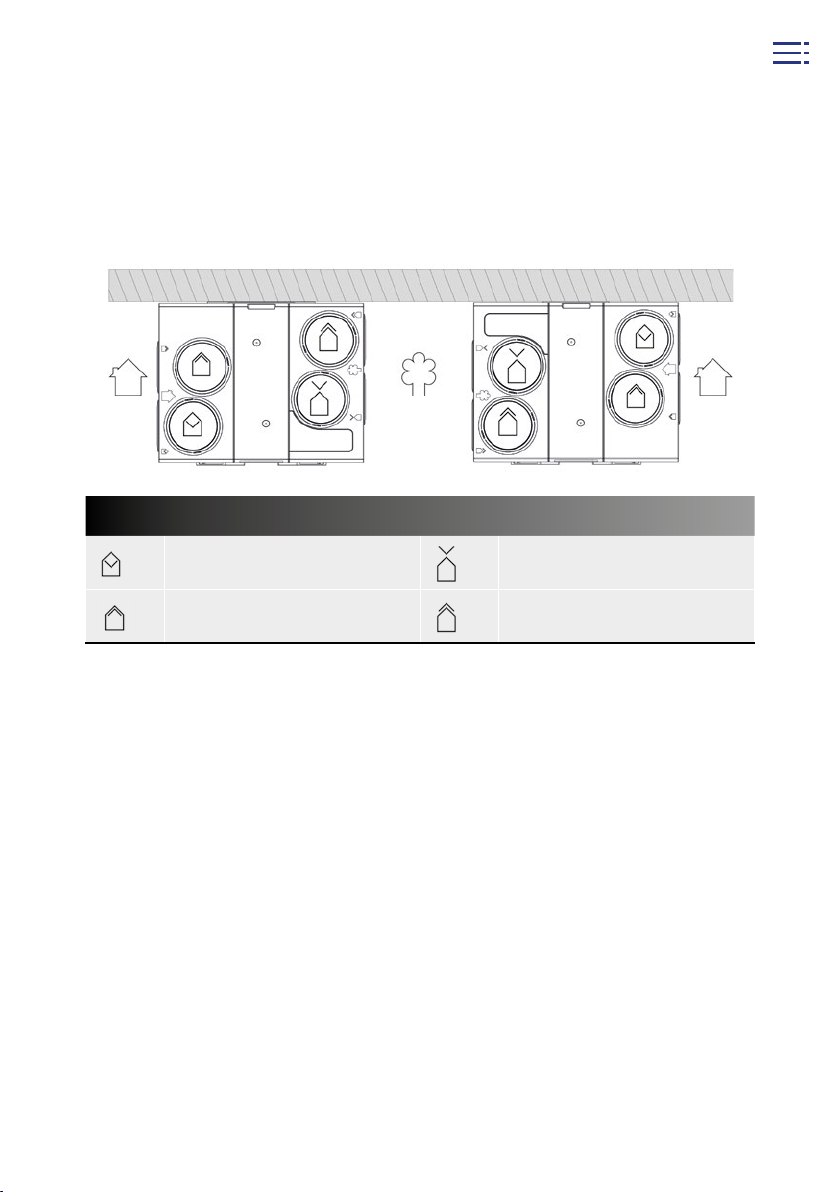

3.4 Duct indicator

When connecting the ducts it is important to take into consideration which

model is being used - left or right mounting. The connections are indicated on the top

of the unit with icons. The unit is supplied as a left model as standard.

You can change your apparatus into a right mounted model (see Section 4.3).

index

Left model

Home HomeOutside

Right model

Air ducts on the home side Air ducts on the outside

Supply air from the unit to

the home

Return air from the home to

the unit

Supply air from outside to

the unit

Extractor air from the unit to

the outside

9

4. Installation

4.1 Brief installation instructions

Step-by-step assembly:

1. Mount the wall bracket level on a wall with sufficient mass (200 kg/m2) with the

supplied bolts and plugs, or mount the unit on the optional base in the case of

floor mounting

2. Mount the Orcon extractor and supply valves in the various rooms

3. Configure the unit in the desired direction (see Chapter 4.3)

4. If desired, replace the earthed power cord with a perilex power cord

5. Set the required flow rate with the help of the DIP switches on the main circuit

board (see Chapter 6)

6. Hang the unit on the wall bracket, or position the unit with the base in the

desired location

7. Adjust the levelling feet so that the unit is hanging (wall mounting) or standing

(floor mounting) level

8. Install 2 silencers of at least 1 metre (ducts to and from interior spaces)

9. Mount the ventilation ducts and conduits with as little air resistance as possible

and free from leaks. Make sure no residual material from the pipes is able to reach

the device.

10. Mount the condensation extractor (preferably dry siphon) under the unit

11. Mount the desired remote controls, CV-3 switch (for perilex) and/or CO

(see Chapter 5)

12. Switch on the voltage of the HRC-EcoMax or HRC-MaxComfort unit

13. Report separately supplied remote controls and/or CO

sensors on

2

(see Chapter 5), the supplied remote control is already registered to the unit as

standard

sensors

2

index

4.2 Installation instructions

The HRC must be installed in compliance with:

• Quality requirements for residential ventilation systems, ISSO 61 quality requirements

for balanced ventilation in homes, ISSO 62

• The capacity calculation in compliance with the Netherlands Building Decree

• Requirements for ventilation of buildings - determination methods for new buildings

NEN 1087:2018

• The safety provisions for low-voltage installations, NEN 1010

• The requirements for connection to indoor drainage - design and implementation

guidelines, NTR 3216:2012. Any additional requirements from the local energy

companies

• The installation instructions for the HRC-EcoMax and/or HRC-MaxComfort

10

4.3 Changing the unit direction

The HRC is available in a left or right model. The HRC is by default supplied as a left

model. The ducts are therefore are connected to the home on the left side of the unit,

and the ducts on the right side of the unit go outside. If you wish to use the HRC as a

right model, it can be configured as follows:

1. Remove the plug from the socket

2. Place the device on a flat surface if the device is already suspended

3. Remove both filter covers

4. Remove the plastic front plate

5. Remove the metal front plate of the device by removing the 5 screws

(wrench size T25)

6. Take the power cord out of the cable clamp on the metal back plate

7. Remove the metal back plate of the device by removing the 5 screws.

8. Move the metal front plate to the other side of the device and fasten the 5 screws

9. Move the metal back plate to the back of the device and fasten the 5 screws

10. Remove the circuit board cover on the top. Keep an eye on the length of the display

cable when removing the circuit board cover. If necessary, temporarily separate it

from the connector on the circuit board

11. Move the earthing cable to the new back of the device. Move the strain relief

towards the recesses at the other wide of the circuit board as well

12. Reinstall the top cover such that the display is located at the front and fasten the 2

screws.

13. Return the earthing cable to the cable clamp on the metal back plate

14. Place the plastic front plate back to cover the metal front plate. Secure the front

plate by pressing on the four outer corners

15. Reinstall the filter covers.

index

The device is now suitable for installation in a right-handed setup.

11

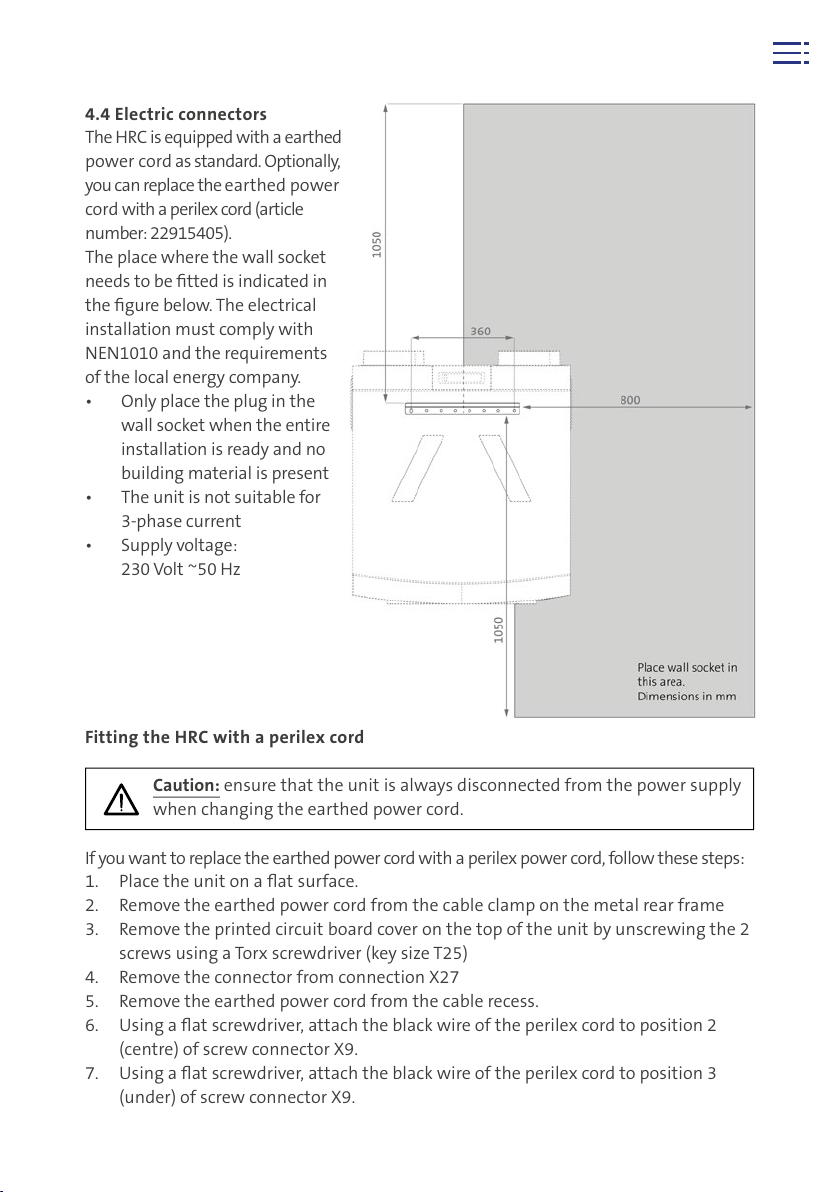

4.4 Electric connectors

The HRC is equipped with a earthed

power cord as standard. Optionally,

you can replace the earthed power

cord with a perilex cord (article

number: 22915405).

The place where the wall socket

needs to be fitted is indicated in

the figure below. The electrical

installation must comply with

NEN1010 and the requirements

of the local energy company.

• Only place the plug in the

wall socket when the entire

installation is ready and no

building material is present

• The unit is not suitable for

3-phase current

• Supply voltage:

230 Volt ~50 Hz

Fitting the HRC with a perilex cord

Caution: ensure that the unit is always disconnected from the power supply

when changing the earthed power cord.

If you want to replace the earthed power cord with a perilex power cord, follow these steps:

1. Place the unit on a flat surface.

2. Remove the earthed power cord from the cable clamp on the metal rear frame

3. Remove the printed circuit board cover on the top of the unit by unscrewing the 2

screws using a Torx screwdriver (key size T25)

4. Remove the connector from connection X27

5. Remove the earthed power cord from the cable recess.

6. Using a flat screwdriver, attach the black wire of the perilex cord to position 2

(centre) of screw connector X9.

7. Using a flat screwdriver, attach the black wire of the perilex cord to position 3

(under) of screw connector X9.

index

Location of socket

outlet relative to

wall bracket

12

8. Place the white connector of the perilex cord on connection X27.

9. Feed the perilex cord through the cable recess. Place the strain relief in the

appropriate recess.

10. Screw the strain relief hand tight using a Torx screwdriver (key size T20)

11. Replace the top cover and re-tighten the 2 screws

12. Reinsert the earthed perilex cord into the cable clamp on the metal back frame

13. Place the plug in a perilex wall socket which is connected as shown in the

diagram below.

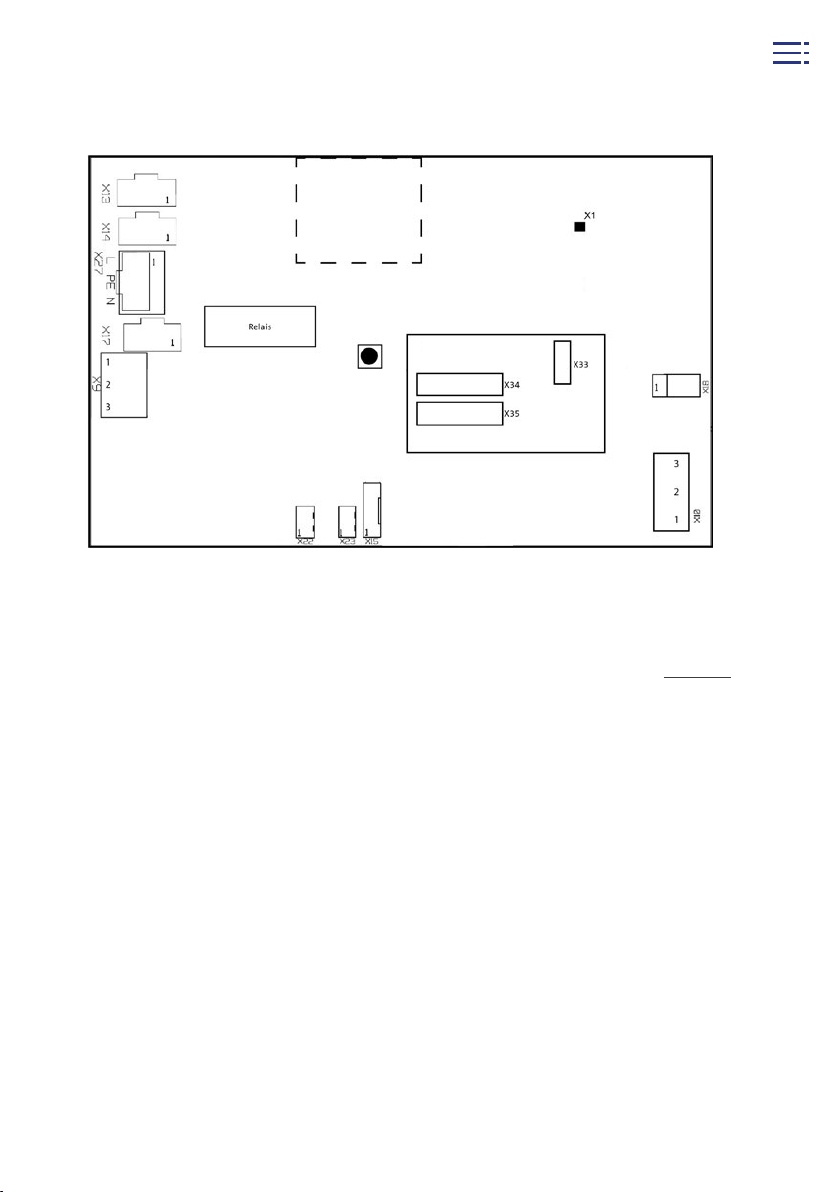

Speed control for perilex connection

A 230 Volt power supply (terminals L3 and N) must be

connected to the perilex wall socket. The speed is controlled by means of a 3-position switch, which receives

power (L3) from the perilex socket (wire diameter 1.5

2

mm)

). A black (L2) and grey (L1) wire leads from the

switch back to the perilex wall socket. It is important

that terminal L3 is always supplied with voltage. For

the correct way to connect the cabling, see the wiring

diagram below. Optionally, an RF Remote Control, CO

Controlsensor or a CO

Roomsensor can be combined

2

2

with the CV-3 switch. If several switches or controls are

used in the home, the last selected ventilation position

always takes precedence.

index

Explanation of 3 ventilation settings

Setting 1

Setting 2

Position 3

Low Absent setting

Medium Present setting

High High setting

For use during absence during a long

period

For daily use with normal use within

the home

For use during cooking, showering

or parties

13

Connections to printed circuit board

No. Function Pin function

X1 RF antenna connection

L – 230V

X9 Perilex input

2 – L2 (black, 230V) Medium setting

3 – L1 (grey, 230V) High setting

1- RSA (2x White)

2- RSB (2x Brown)

3- GND (2x green)

X10

Modbus Communication duct to

ventilators

X13 Supply ventilator power supply 1 – L2 – PE3 – N

X14 Extractor ventilator power supply 1 – L2 – PE3 – N

X15 Bypass stepper motor control

X18 Humidity sensor input

index

X22

X23

Temperature sensor 1 input

(return air from inside)

Temperature sensor 2 input

(supply air from outside)

1 – Earth

2 – Sensor

1 – Earth

2 – Sensor

X27 230V mains 1 – L(3)2 – PE3 – N

X33* Display connection Flat cable

X34* DIP switches extractor 8 dip switches

X35* DIP switches supply 8 dip switches

*on top board

14

4.5 Installing the unit

Transformer

Add-on PCB

Menu

button

Wall mounting

The unit can be hung on the supplied wall bracket. But only if the wall has a minimum

mass of 200 kg/m

2

is available.

1. Attach the wall bracket to the wall using the bolts and plugs supplied. Caution:

mount the wall bracket using a spirit level before you connect the ducts!

Sufficient space must be left underneath the wall bracket for the condensation

extractor (see chapter 4.7).

2. Place the HRC in the left or right configuration over the wall bracket, by hooking

the hook on the back of the unit over the wall bracket.

3. Turn the levelling feet on the back of the unit so that it hangs level against the

wall. This ensures that the condensation extractor works optimally.

index

15

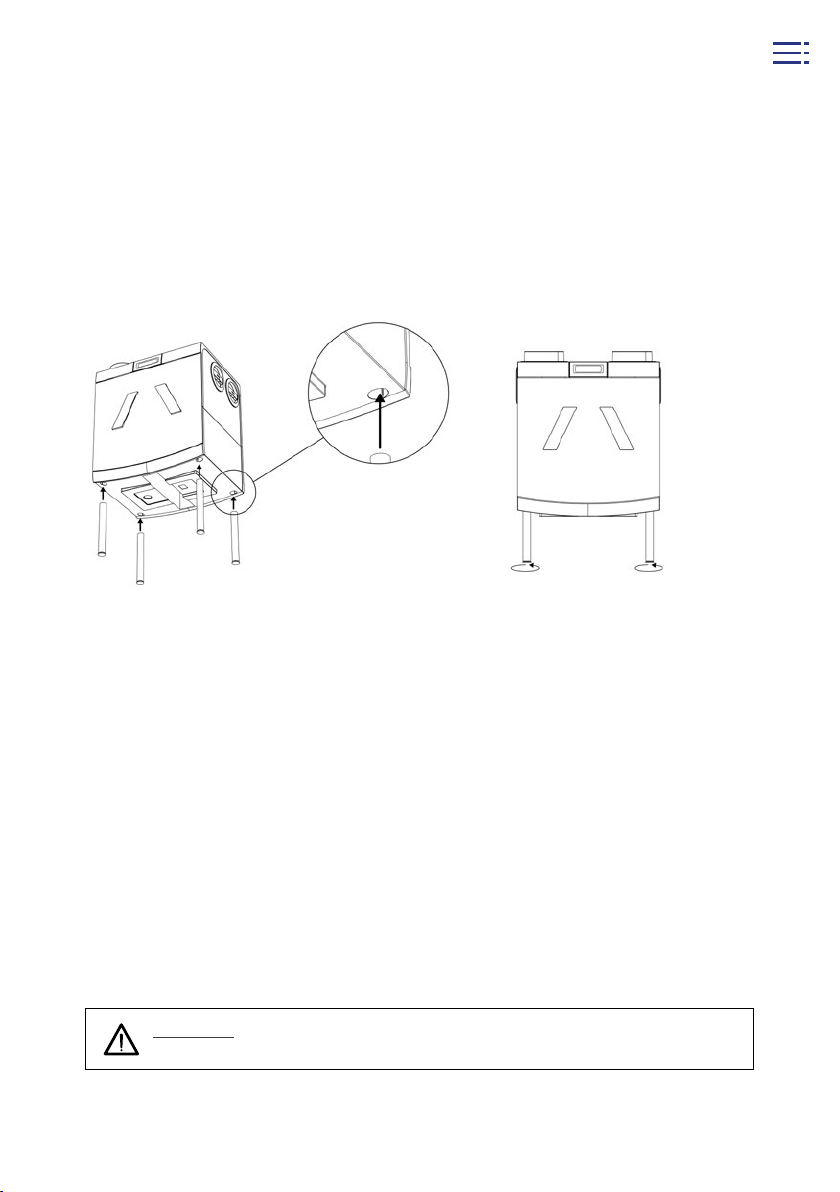

Floor mounting

If there is no wall that is suitable for wall mounting, the HRC can also be placed on

a concrete floor using the optional Orcon base (article number: 22700080) for floor

mounting.

1. Place the legs in the recesses on the bottom of the unit (Figure A). This works best

when the unit is on its side.

2. If necessary, use a spirit level to adjust the levelling feet so that the unit is level on

the floor (Figure B).

A. B.

4.6 Connecting ducts to the unit

Once the unit is fitted, the ducts can be mounted. The ducts (return) from and to

the home (supply) are on one side of the unit, and the ducts from and to the outside

are on the other side. In order to prevent condensation on the ducts from and to the

outside, these must always be insulated externally to ensure that they are dampproof. It is preferable to use preinsulated plastic ducts made of PE or PUR. Try to keep

these ducts as short as possible.

It is advisable to connect the ducts to and from the home to the unit using sound

dampers with a minimum length of 100 cm. When measuring the ducts, bear in mind

that not too much energy is lost when transporting the air through ducts that are

too narrow. It is preferable not to have the total resistance of both the supply system

and the discharge system exceed 100 Pascals. The supply duct system must be fitted

in such a way that NEN 1070, table 4 is complied with in the nominal setting. Think

of crosstalk and installation noise, also with underfloor ducts. Ensure that the supply

ducts are insulated if necessary, e.g. if they are installed outside the insulated skin.

index

16

Attention: make sure no residual material is able to reach the device while

installing the pipes to prevent it from damaging the device.

Loading...

Loading...