ORBOT SPRAYBORG Operating Manual

V052015

OPERATING MANUAL (ENG

)

WARRANTY

All Orbot equipment has been carefully tested and inspected at our USA factory. Orbot machines are

guaranteed for one year from the date of original purchase against defects or workmanship made during

manufacture. Within the guarantee period we undertake at our discretion, to repair or replace any part

found to be defective, free of charge to the purchaser with subject to the following conditions:

Claims made under the terms of the guarantee must be supported by the original invoice issued at the

time of sale along with the machine serial number.

For claims under this guarantee contact the supplier from whom you’ve purchased the product who will

arrange the appropriate action. Do not initially return the product as this could lead to transit damage.

Neither Orbot nor its distributors will be held responsible for any incidental or consequential loss.

This guarantee does not cover:

Periodic maintenance, repair, or replacement of parts due to normal wear and tear.

Damage caused by accident, misuse or neglect, re, or the tting of other than genuine Orbot parts.

Defects in other than genuine Orbot parts, repairs, modi cations or adjustments made by other than

a Orbot service engineer or authorized service dealer. Costs and risks of transport relating directly or

indirectly to the guarantee of this product. Consumable items such as brushes, drivers, velcro discs,

gliders, pads, and so forth. Orbot has a policy of continual product development and we reserve the right

to alter speci cations without prior notice.

Model:

Serial:

Date of Purchase:

Dealer:

Address:

Phone Number:

Sales Representative:

Machine Type: Floor Model: Orbot Sprayborg

This Machine is in conformity with the following EU directives:

- Machinery Directive: 2006/42/EC

- Electro Magnetic Compatibility Directive: 2004/108/EC

- In conformity with 2006/95/EC

Applied harmonized standards:

EN 60335-1, EN 60335-2-67

MACHINE DATA

EC Declaration of Conformity

HOS GmbH

Hruby Orbital Systems

Kleiststraße 7

10787 Berlin

Date: 02/08/2010

2

Jeffrey Hruby CEO

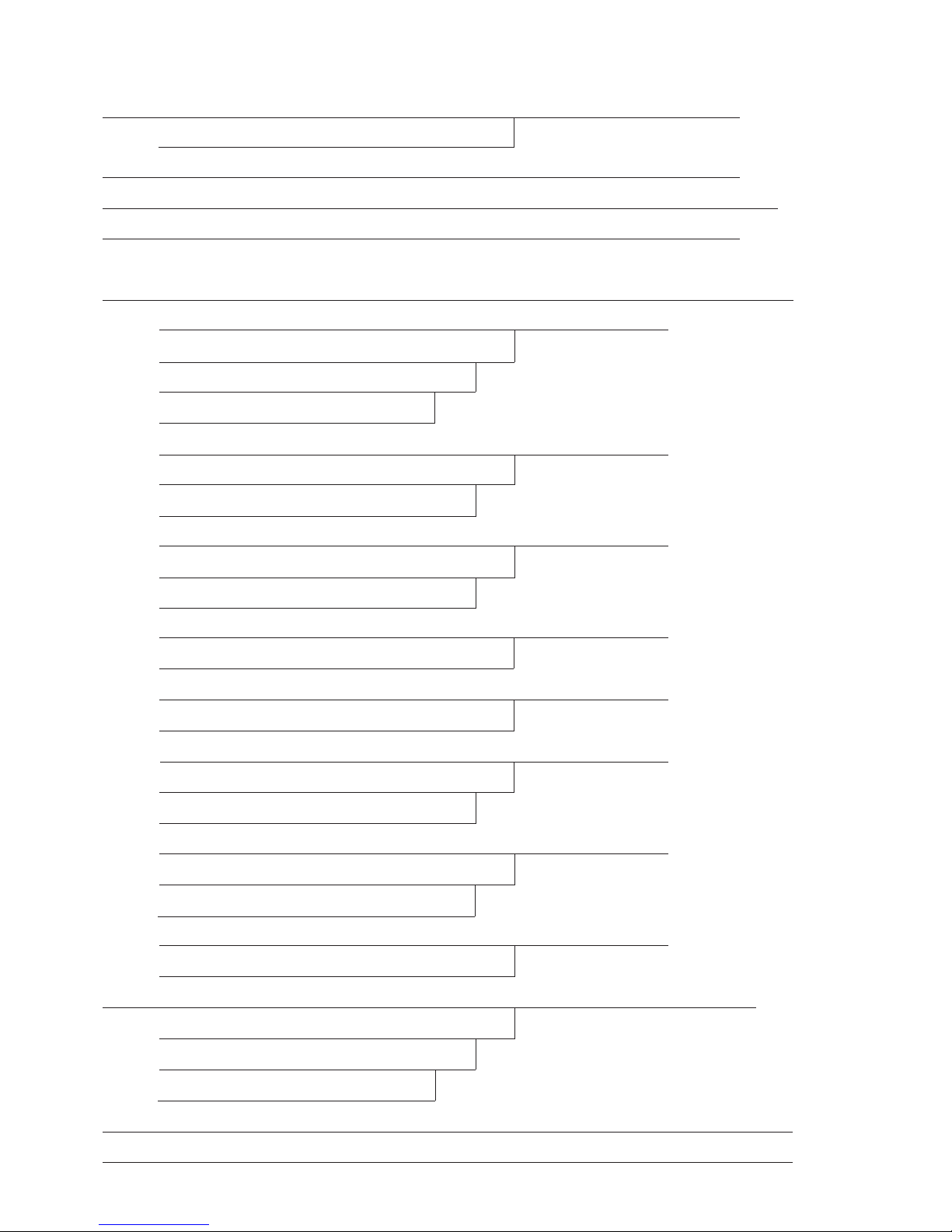

TABLE OF CONTENTS

Warranty

EC Declaration of Conformity

How to use this Manual

Safety

Technical Details

Operation

Unpacking and Initial Operations

Pre-Run Inspection

Power Cable Connection

Spray System Preparation

Spray Jets

Adjusting Height

Process of Cleaning

End of Application

2

4

5 - 7

8

9 - 16

9

10

11

Storage

Lifting and Carrying

Weight Kit Installation

Brush Installation

Attaching and Removing the Driver Plates

Accessories and Applications

Driver Plates

Standard Driver Plates

Carpet Pads

Melamine Pads

AkwaStrip Pads

StoneFlash Pads

Scrub Brush

Concrete Brush

Operation/Maintenance

12

13

14

15

16

17

Application on Different Floor Types

Cleaning the Machine

Changing the driver grip face

Parts Diagram and Parts List

Notes

18 - 38

39

3

HOW TO USE THIS MANUAL

This manual contains the following sections:

• How to Use This Manual

• Safety

• Operations

• Maintenance

• Parts List

The HOW TO USE THIS MANUAL section will tell

you how to nd important information for ordering

correct repair parts.

Parts may be ordered from authorized dealers.

When placing an order for parts, the machine

model and machine serial number are important.

Refer to the MACHINE DATA box which is lled

out during the installation of your machine. The

MACHINE DATA box is located on the inside of the

front cover of this manual.

The model and serial number of your machine

is located on the left side of the handle, from the

operators perspective.

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

• REF – column refers to the reference number on

the parts illustration.

• PART NO. – column lists the part number for the

part.

• PRV NO. – reference number.

• QTY – column lists the quantity of the part used in

that area of the machine.

• DESCRIPTION – column is a brief description of

the part.

• SERIAL NO. FROM – If this column has an (*) and

a Reference number, see the SERIAL NUMBERS

page in the back of your manual. If column has

two asterisk (**), call manufacturer for serial

number. The serial number indicates the rst

machine the part number is applicable to. The

main illustration shows the most current design of

the machine. When a boxed illustration is shown,

it displays the older design.

• NOTES – column for information not noted by the

other columns.

The SAFETY section contains important information

regarding hazardous or unsafe practices of the

machine. Levels of hazards are identied that could

result in product damage, personal injury, or severe

injury resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

• Storage

• Maintenance

• Troubleshooting

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The manual part number is located on the

lower left corner of the front cover.

4

WARNING

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precaution must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of re, electric shock, or injury:

• Use only indoors. Do not use outdoors or expose to rain.

• Use only as described in this manual. Use only manufacturers recommended components and

attachments.

• If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an authorized service center.

• Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airow.

• Machine can cause a re when operating near ammable vapors or materials. Do not operate this

machine near ammable uids, dust or vapors.

• This machine is suitable for commercial use such as: in hotels, schools, hospitals, factories, shops, and

ofces for more than normal housekeeping purposes.

• Maintenance and repairs must be done by qualied personnel.

• During operation, use caution around other persons, especially children.

• The machine shall only be operated by instructed and authorized persons.

• When leaving unattended, unplug the machine.

• Do not handle the plug or machine with wet hands.

• Do not unplug machine by pulling on cord. To unplug, grasp the plug and not the cord.

• Do not use with damaged cord or plug. Follow all instructions in this manual concerning grounding the

machine.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around sharp

edges or corners.

• Do not pull/run machine over cord. Keep cord away from heated surfaces.

• Connect to a properly grounded outlet. See Grounding Instructions.

• If the supply cord is damaged it must be replaced by an authorized service agent.

• Unplug before cleaning or servicing.

• Operational hazard may occur when running the machine over the supply cord.

• This appliance has been designed for use with pads specied by the manufacturer. The tting of other

pads may affect its safety.

• This machine is for dry use only and shall not be used or stored outdoors in wet conditions

• Moving Parts - To reduce the risk of injury, unplug before servicing.

READ AND SAVE THESE INSTRUCTIONS

5

WARNING

CAUTION

SAFETY

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identied by signal words -WARNING, CAUTION, and FOR

SAFETY. The level of hazard intensity is determined by the following denitions:

WARNING - Hazards or unsafe practices CAN result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or

property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. The following is information that signals some potentially dangerous conditions to

the operator or the equipment. Read this information carefully. Know when these conditions can exist.

Locate all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

• Unless trained and authorized.

• Unless Operation Guide is read and understood.

• In ammable or explosive areas.

• In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing, jackets, shirts, or sleeves when working on the machine.

Use only manufacturer approved replacement parts.

6

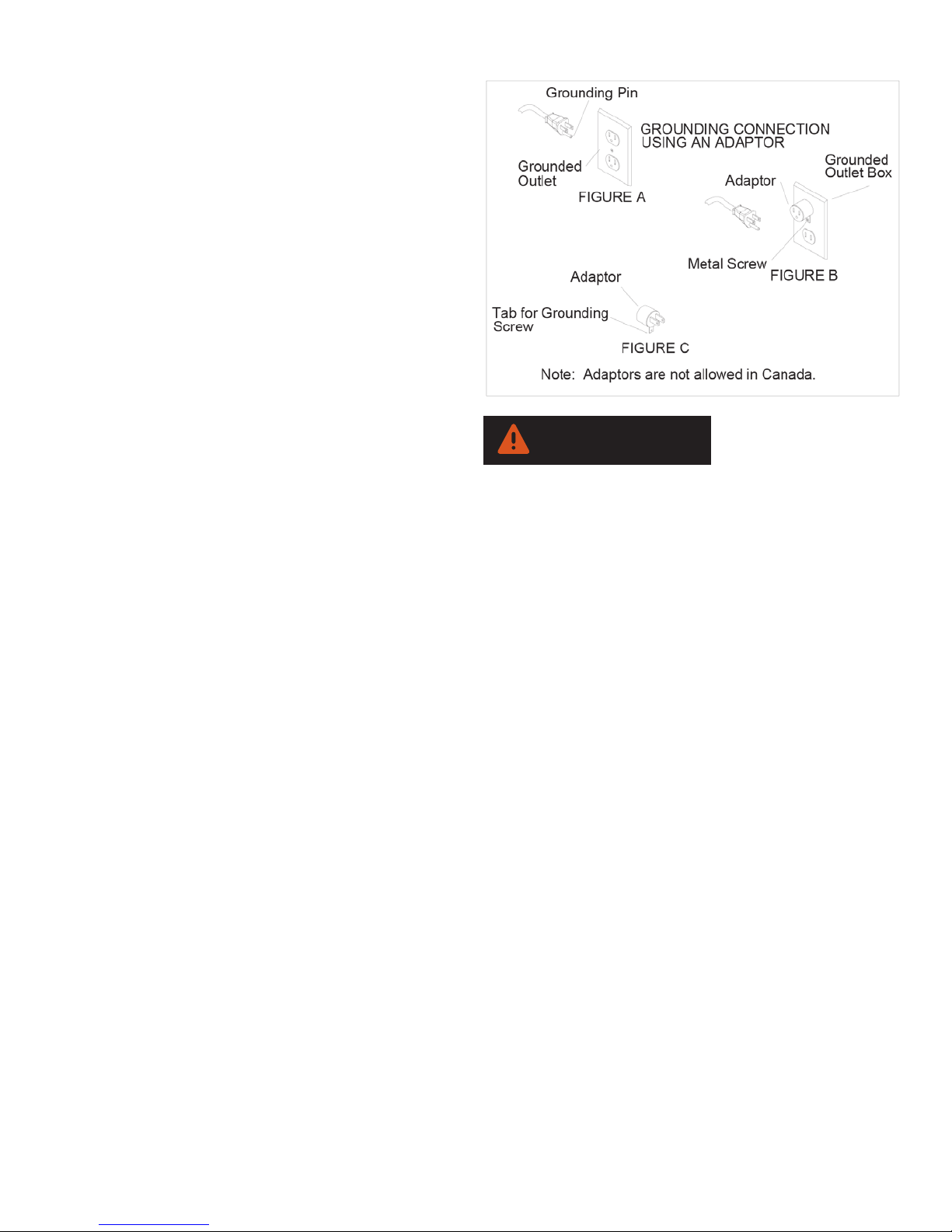

GROUNDING INSTRUCTIONS 120V

WARNING

THIS PRODUCT IS FOR COMMERCIAL USE ONLY

ELECTRICAL:

In the USA this machine operates on a 15 amp

nominal 120V, 60 hz, A.C. power circuit. The

amp, hertz, and voltage are listed on the data label

found on each machine. Using voltages above or

below those indicated on the data label will cause

serious damage to the motors.

GROUNDING INSTRUCTIONS:

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped

with a cord that has an equipment-grounding

conductor and grounding plug. The plug must be

inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like

the plug in “Fig. A”. A temporary adaptor that

looks like the adaptor in “Fig . C” may be used to

connect this plug to a 2-pole receptacle as shown

in “Fig. B”, if a properly grounded outlet is not

available. The temporary adaptor should be used

only until a properly grounded outlet (Fig. A) can

be installed by a quali ed electrician. The green

colored rigid ear, lug, or similar that extends from

the adaptor must be connected to a permanent

ground such as a properly grounded outlet box

cover. Whenever the adaptor is used, it must be

held in place by a metal screw.

SAFETY

Improper connection of the equipment-grounding

conductor can result in electric shock. Check with a

quali ed electrician or service person if you are in

doubt as to whether the outlet is properly grounded.

Do not modify the plug provided with the appliance

- if it will not t the outlet, have a proper outlet

installed by a quali ed electrician.

SAFETY LABEL LOCATION

These drawings indicate the location of safety labels

on the Machine. If at any time the labels become

illegible, contact your authorized representative for

prompt replacement.

7

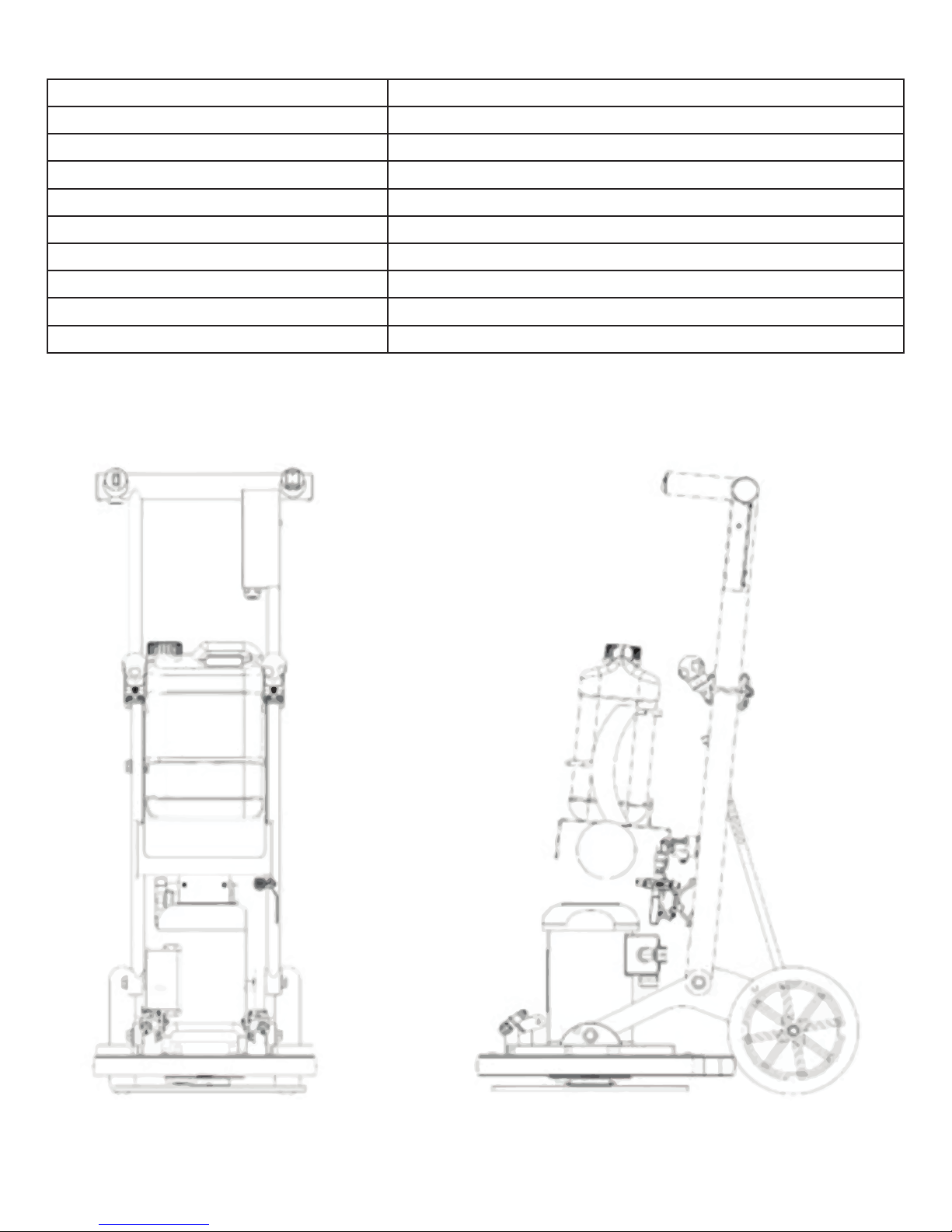

TECHNICAL DETAILS

ITEM MEASURE

Motor 1HP, 100-240V/50-60Hz, 6 amps (50Hz)/11amp (60Hz)

RPM 1725 (60Hz)/1400 (50Hz)

Base Diameter 17“/43 cm

Orbital Diameter 3/8” (9.5 mm)

Weight 102 Lbs./46.7 kg

Height 48” (122 cm)

Length 29” (75 cm)

Wheels 10”/25 cm Diameter, resistant to chemicals

Decibel Rating 59 dB

8

Unpacking and Initial Operations

CAUTION

WARNING

Open the shipping box on both sides, remove the

packaging material and roll the machine out of the box.

Pre-Run Inspection

Before each use, inspect the accessory such as the pad

driver for cracks, tears, or excess wear. If the machine or

accessory is dropped, inspect for damage to install an

undamaged accessory.

Repair the damaged machine before the next application.

Tilt the head back and place the foot of the bumper on the

ground.

Choose a pad for the appropriate application. Center the

pad on the driver plate.

Position the handle in a lower position.and push slowly

forward until the machine base tilts towards the ground.

OPERATION

Make sure to put the wheels back on the ground in time to

avoid the base from falling on the ground. This might cause

damage!

Check to make sure the power switch is in the “off” position.

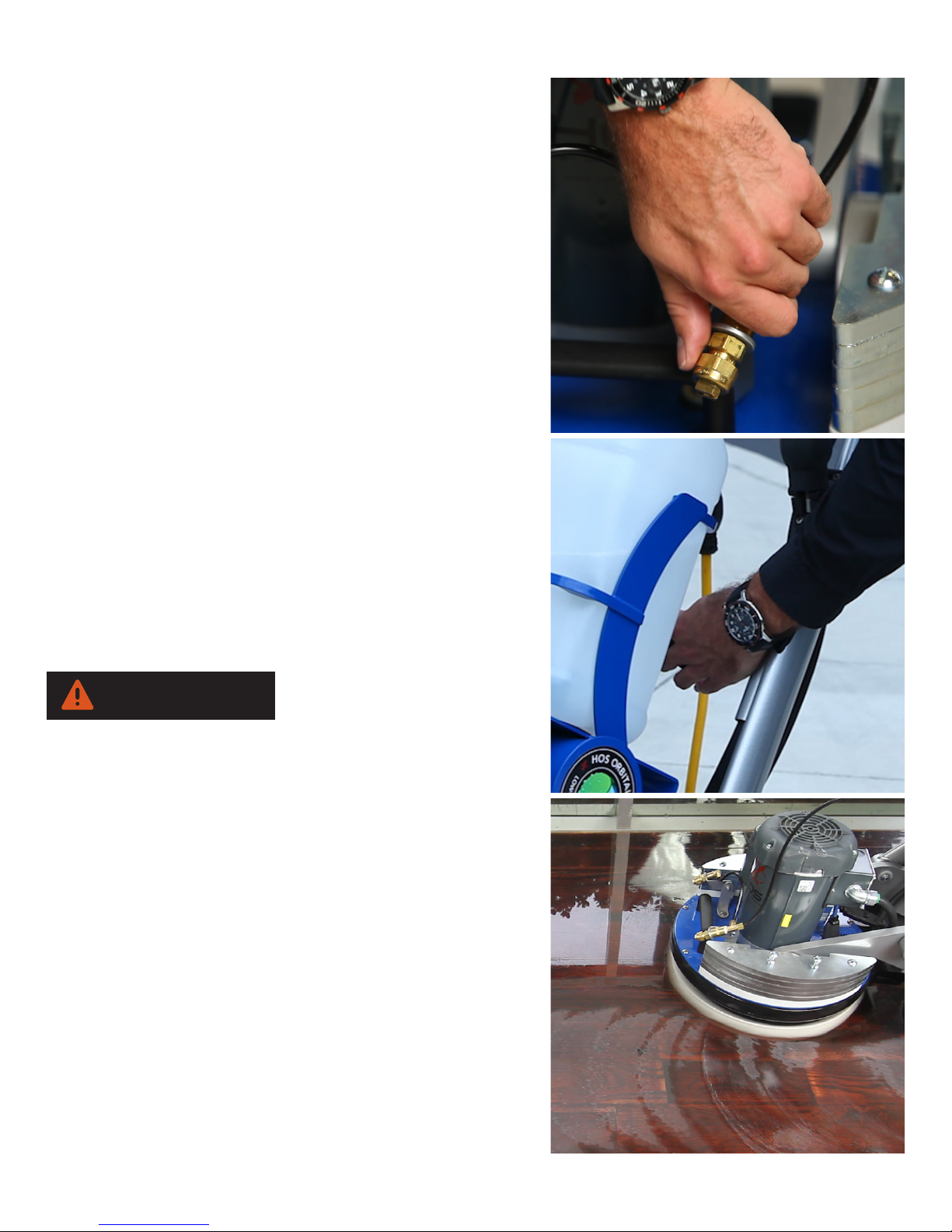

Power Cable / Quick Disconnect

Take provided power cable and connect to machine quick

disconnect located on machine. Push and twist to lock

cables together. You can now plug power cord into outlet.

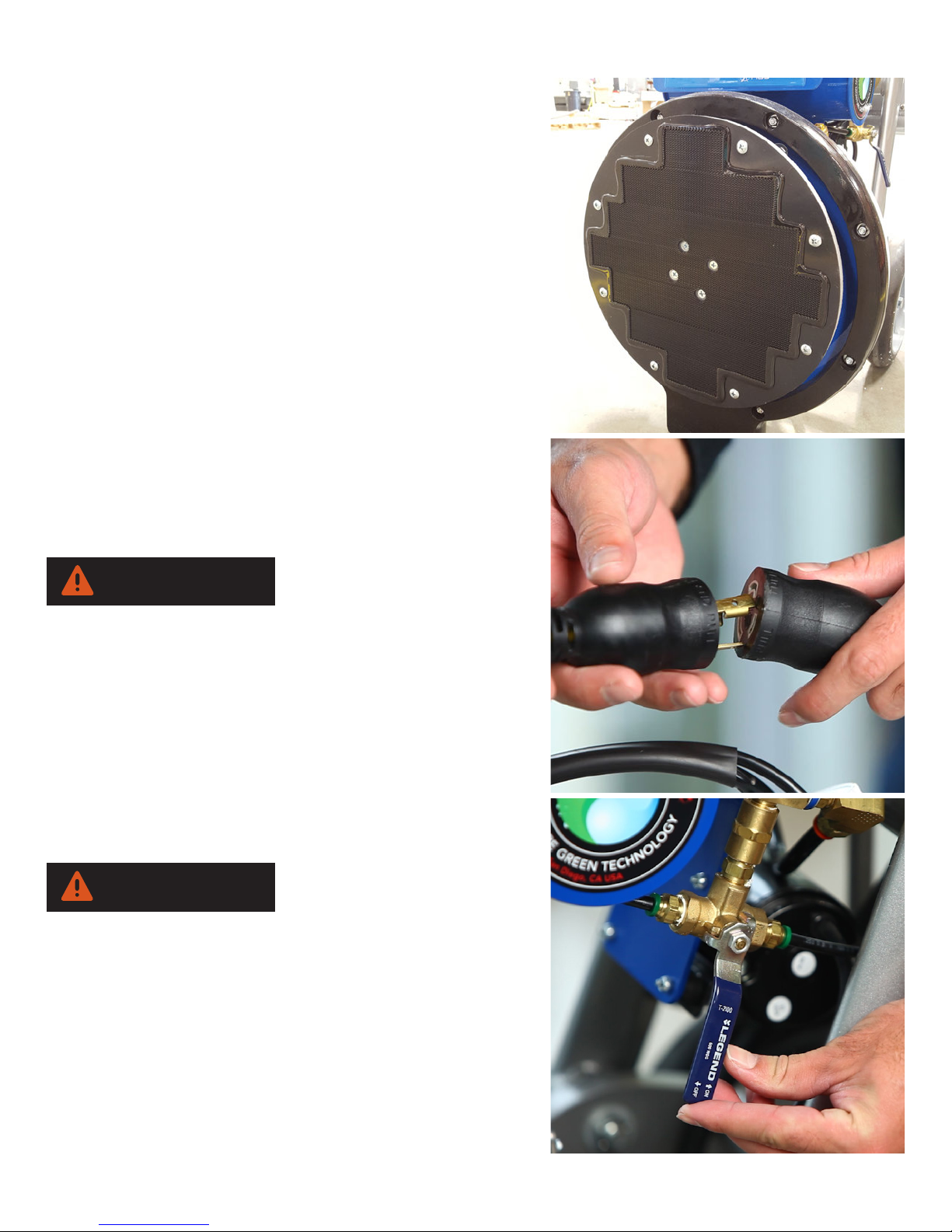

Spray System Preparation

Fill the bottle cartridge with recommended cleaning solution.

For priming the pump system for the rst system, move the

valve lever to the vertical position and depress spray switch

for 30 seconds. For standard priming, 10 seconds is usually

sufcient.

By adjusting the valve lever you can vary the spray

9

OPERATION

CAUTION

pressure. The further you move the lever counterclockwise

upwards, the higher the water pressure. A horizontal

position means maximum water output at maximum

pressure.

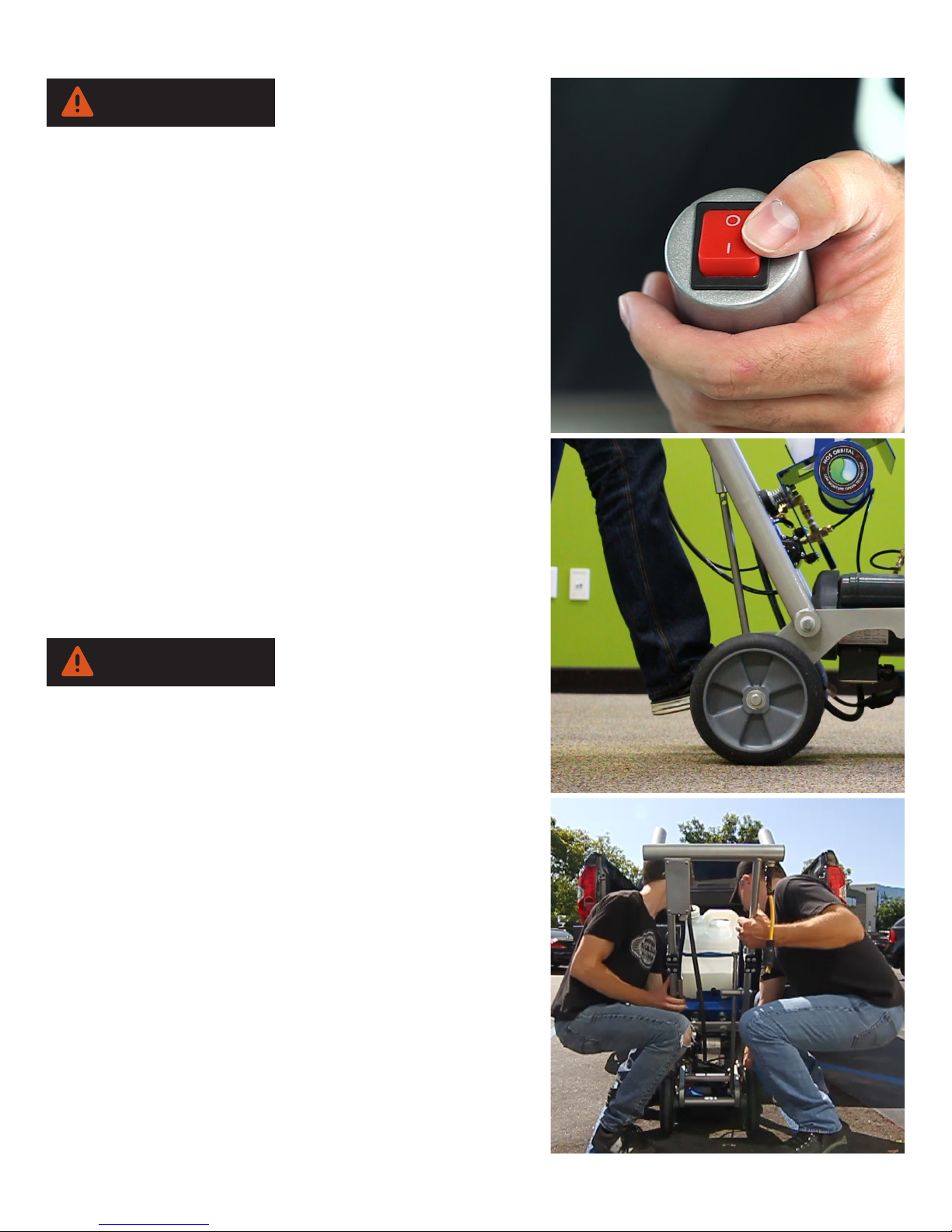

To turn the machine on, press the power button on the end

of the left handle.

Spray Jets

Adjust the spray jets on the machine base to the desired

position. For most oor cleaning applications adjust the

spray jets so that they spray about 6 inches (15 cm) in front

of the base.

Adjusting Height

Set the handle position to the desired height by pulling and

releasing the black knob with the left hand.

While holding the black knob out, raise or lower the handle

frame with your right hand.

To x the handle frame into place, release the black knob so

that it locks rmly into one of the holes provided.

Position “0” is off and position “I” is on.

Make sure a suitable pad or brush is mounted before

starting the machine. The immediate contact of the oor and

driver plate without a pad can lead to serious damage of

the oor and/or the machine.

Process of Cleaning

For effective oor cleaning, move the machine forward and

backwards. It is recommended to wet the oor as you move

the machine forward, releasing the solution button when

you move the machine backwards.

To increase the pressure and cleaning effect on certain oor

types like tile and grout, you can lift the machine frame up,

raising the wheels off the ground. When lifting the wheels

off the ground the full weight of the machine lies on the

machine base.

10

CAUTION

Make sure the surface to be cleaned is not damaged by the

CAUTION

increase in pressure.

Omit this measure on very sensitive oors.

End of the Application

Turn off the machine by putting the on/off switch to “O”. If

a cleaning solution was used, ll bottle cartridge with water

and spray out system for 30 seconds.

Make sure to not let solution come in contact with the motor.

Storage

To avoid damage to the handle frame, DO NOT lay the

machine frame on the oor as done with other traditional

cleaning equipment. Remove the pad from the driver plate

by pulling it down rmly. Put the machine frame in an

upright position by pulling the black knob with the left hand

and move the handle frame upwards with the right hand.

OPERATION

The black knob should lock rmly in the top hole.

To allow an easy transportation of the machine, remove the

weight kit if used.

To easily roll the machine, push your foot on the back wheel

axle to create leverage and pull the handle towards your

body. The machine can be moved similar to a dolly now.

Always store with the base in the upright position.

Lifting and Carrying

If you do not have a ramp, we recommend two people to

life machine in and out of a vehicle. Put the rmly locked

handle into a lowered position. Make sure that the machine

base rests on a pad, so that the grip surface of the driver

plate does not get damaged or hooked onto a carpeted

surface.

Grip the machine from each side as shown.

When lifting the machine in or out of the vehicle, set the

11

OPERATION

WARNING

wheels down rst, followed by the machine base.

Make sure not to grip too close to the machine base. If the

base should ip upwards it can cause serious hand injuries.

Make sure you lift the machine with a back-friendly posture.

Secure machine rmly so it will not move.

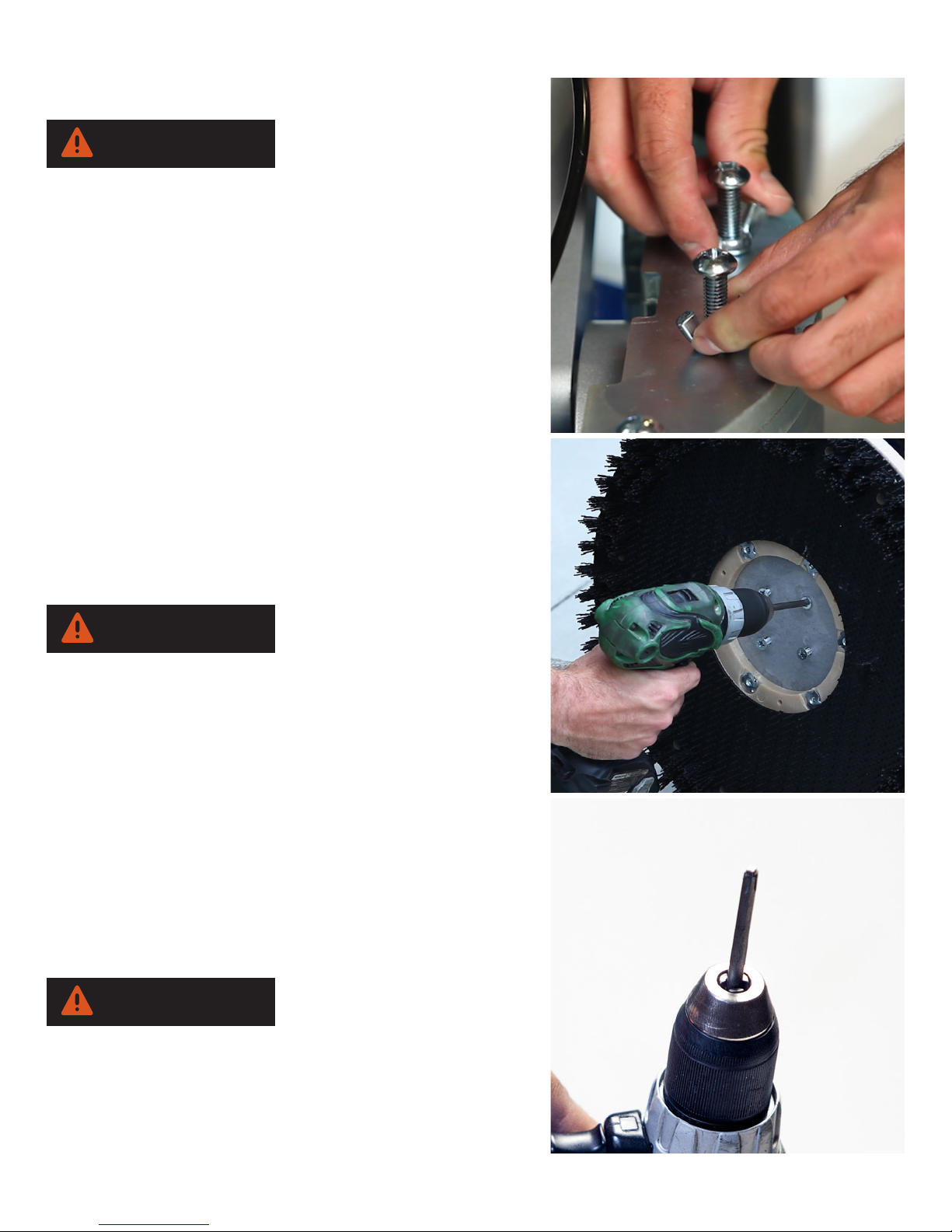

Weight Kit Installation

The total weight of the weight kit is 40 lbs.

Put the weights on top of the mounting plates located on the

sides of the machine base.

Put the four screws into the holes provided on the weight

plates and fasten by turning clockwise.

Once the screws have threaded at least 5 full turns, tighten

the wing nuts by turning them clockwise, until the weights t

securely to the base.

CAUTION

Make sure that the weights are securely attached to the

base. Loose weights can cause serious damage.

For storage and transport we recommend removing the

weight kit. The machine can be transported more easily

without the weights.

Brush Installation

Put the machine base in an upright position, sitting on the

foot of the bumper.

Remove the driver plate by removing the four countersink

screws in the center of the plate using an electric

screwdriver.

WARNING

It is important to only use a Number 3 Phillips head

screwdriver bit. Smaller bit sizes can damage the screw

heads and leave sharp edges, which can tear or snag the

pads. Damaged screws can cause further damage.

12

Loading...

Loading...