Orbit Merret OMX 100, OMX 100DC, OMX 100PWR, OMX 100PM, OMX 100RTD Instructions Manual

...

GUARANTEE

YERS

OMX 100

PROGRAMMABLE TRANSMITTER

DC VOLTMETER/AMMETER

AC VOLTMETER/AMMETER

PROCESS MONITOR

THERMOMETER FOR PT 100/500/1 000

THERMOMETER FOR THERMOCOUPLES

DISPLAY INSTR.FOR LIN.POTENTIOMETERS

OHMMETER

THERMOMETER FOR NI 1 000

1

INSTRUCTIONS FOR USE OMX 100

SAFETY INSTRUCTIONS

Please, read the enclosed safety instructions carefully and observe them!

These instruments should be safeguarded by isolated or common fuses (breakers)!

For safety information the EN 61 010-1 + A2 standard must be observed.

This instrument is not explosion-safe!

TECHNICAL DATA

Transmitters of the OMX 100 series conform to European regulation 89/336/EWG and the Ordinance 168/1997

Coll.

They are up to the following European standards:

EN 55 022, class B

EN 61000-4-2, -4, -5, -6, -8, -9, -10, -11

The instruments are applicable for unlimited use in agricultural and industrial areas.

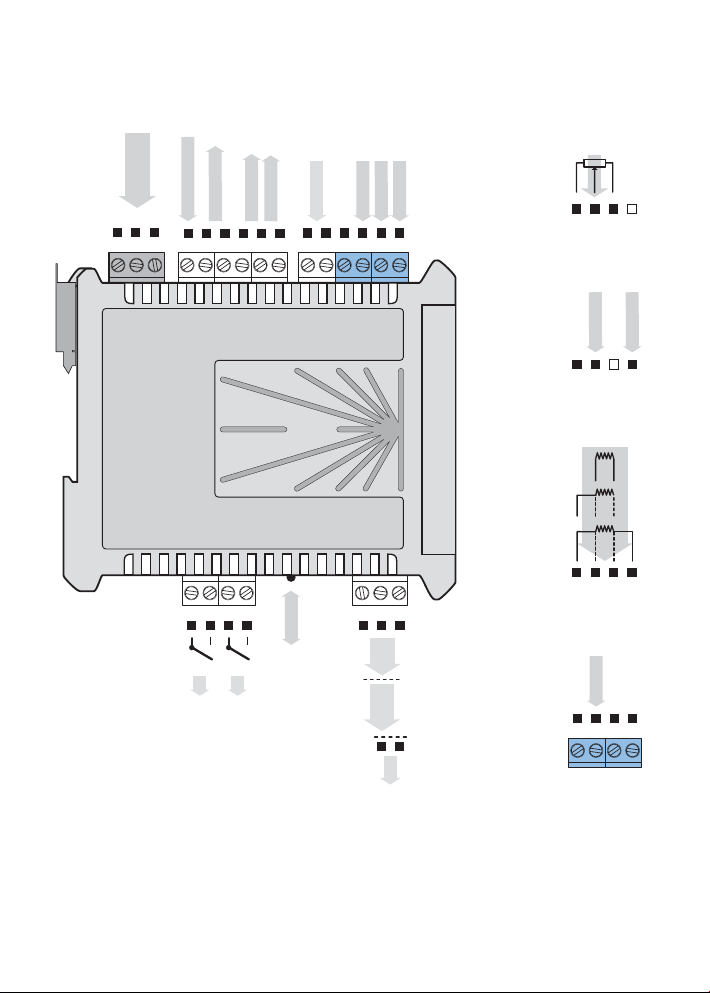

CONNECTION

Supply of energy from the main line has to be isolated from the measuring leads.

ORBIT MERRET, spol. s r.o.

Vodnanská 675/30

198 00 Prague 9

Czech Republic

Tel: +420 - 281 040 200

Fax: +420 - 281 040 299

e-mail: orbit@merret.cz

www.orbit.merret.cz

2

1. CONTENTS

1. CONTENTS

1. Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Instrument description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Instrument setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setting the DP and the (-) sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Access into Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Guide through minimum instrument setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Configuration mode - INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.1.1 Internal values resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.1.2 Counter resetting . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1.3.1 Setting the measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1.3.2 Shifting the beginning of the range . . . . . . . . . .

4.2.1.3.3 Compensation of 2-wire conduct . . . . . . . . . . .

4.2.1.3.4 Setting the mode of assessment of CJC

4.2.1.3.5 Setting the temperature of CJC . . . . . . . . . . . . .

4.2.1.3.6 Setting the time base . . . . . . . . . . . . . . . . . . . . .

4.2.1.3.7 Setting the input filter parameters . . . . . . . . . . .

4.2.1.3.8 Setting the display status backup . . . . . . . . . . . F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1.3.9 Setting the instrument measuring rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1.3.10 Selection of auto. menu presetting . . . . . . . . .

4.2.1.4 Selection of external input function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1.5 Setting another function of the control key „enter“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 Configuration mode - CHANNELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2.1 Display projection . . . . . . . . . . . . . . . . . . . . . . .

4.2.2.2 Setting the digital filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2.3 Setting the decimal point . . . . . . . . . . . . . . . . . .

4.2.2.4 Setting the measuring units description . . . . . . . DC PM DU

4.2.3 Configuration mode - OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.1.1 Limits - type of relay switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.1.2 Limits - setting the bounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.2.1 Data output - rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.2.2 Data output -address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.3.1 Analog output - type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.3.2 Analog output - range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.3.4 Display projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.4 Configuration mode - SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4.1 Restoration of manufacture setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4.2 Input range calibration . . . . . . . . . . . . . . . . . . . . . . DU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.4.3 Setting new access password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5. Table of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6. Method of measuring of CJC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7. Data protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. Error statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10. Instrument dimensions and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11. Certificate of guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.4.4 Instrument identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

T/C

RTD OHM

RTD OHM

. 15

T/C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DC PM

OHM

F . . . . . . . . . . . . . . . . . . 18

DC PM

DC PM

DU

DU

OHM

OHM

OHM

F . . . . . . . . . . . . . 20

F . . . . . . . . . . . . . 21

F . . . . . . . . . . . . 22

3

INSTRUCTIONS FOR USE OMX 100

2. INSTRUMENT DESCRIPTION

DESCRIPTION

The OMX 100 model series are programmable transmitters to DIN rail manufactured in the following types:

OMX 100DC DC voltmeter/ammeter

OMX 100PWR AC voltmeter/ammeter, wattmetr

OMX 100PM Process monitor

OMX 100RTD Thermometer for Pt 100/500/1 000, Ni 1 000

OMX 100T/C Thermometer for thermocouples

OMX 100DU Display instrument for linear potentiometers

OMX 100OHM Ohmmeter

OMX 100F Frequency meter

The instruments are based on an 8-bit microcontroller with A/D converter, that secures high accuracy, stability and

easy operation of the instrument.

Programmable projection of the display

Calibration projection for the beginning and the end of the input range

setting the input type

Projection -99…999

Digital filters

Exponen. average from 2…100 measurements

Rounding setting the projection step for display

Mathematic functions

Tare* assigned to reset display in case of non-zero input signal

External control

Hold display/instrument blocking

Lock locking the control keys for access into Configuration menu

Tare tare activation

Resetting counter resetting/preset

Output

Analog programmable

0…5 mA, 0…20 mA, 4…20 mA (with error statement evaluation 3 mA)

0…2/5/10 V

0,2…2 200 Hz

4

* only for type DC, PM, DU

2. INSTRUMENT DESCRIPTION

OPERATION

The transmitter is set by two control keys on the front panel or via data line RS 232/485.

A standard equipment is the OM Link interface, through which it is possible to modify and store all settings. The

OM Link program is freely procurable, to be downloaded from the web site. For the connection an OM Link cable

is necessary.

All programmable parameters are stored in the EEPROM memory (they hold even after the instrument is switched

off).

EXTENSION

Excitation is suitable for feeding sensors and converters. It has a galvanic isolation of 12…24 VDC.

Comparators are assigned to control two limit values with relay output. The limits have adjustbale hysteresis as

well as selectable delay of the switch-on. Reaching the preset limits is signalled by LED and simultaneously by the

switch-on of the relevant relay.

Data outputs are for their rate and accuracy suitable for transmission of the measured data for further projection or

directly into the control systems. We offer an isolated RS 232 and RS 485 with the ASCII protocol.

Real time is an internal time control of data collection. It is suitable everywhere where it is neccessary to register

measured values in a given time segment. Up to 65 000 values may be stored in the instrument‘s memory. Data

transmission into PC via serial interface RS232/485

FIRMWARE www.orbit.merret.cz/update

With respect to the continuous development and innovation of our products it is now possible to download the most

recent program version for every instrument directly from the web pages.

After connecting the instrument to PC and running the program the upgrade is performed automatically .

Number of the current program version in your instrument can be found in „Configuration menu - service - identifi-

cation“

5

INSTRUCTIONS FOR USE OMX 100

3. CONNECTION

The lead for feeding the instrument should not be in the proximity of the incoming low-potential signals.

Contactors, motors with larger input power and other efficient elements should not be in the proximity of the instru-

ment.

The lead into the input of the instrument (the measured quantity) should be in sufficient distance from all power leads

and appliances. Provided this cannot be secured it is necessary to use shielded leads with connection to ground.

The instruments are tested in compliance with standards for use in industrial area, yet we recommend to abide by

the above mentioned principles.

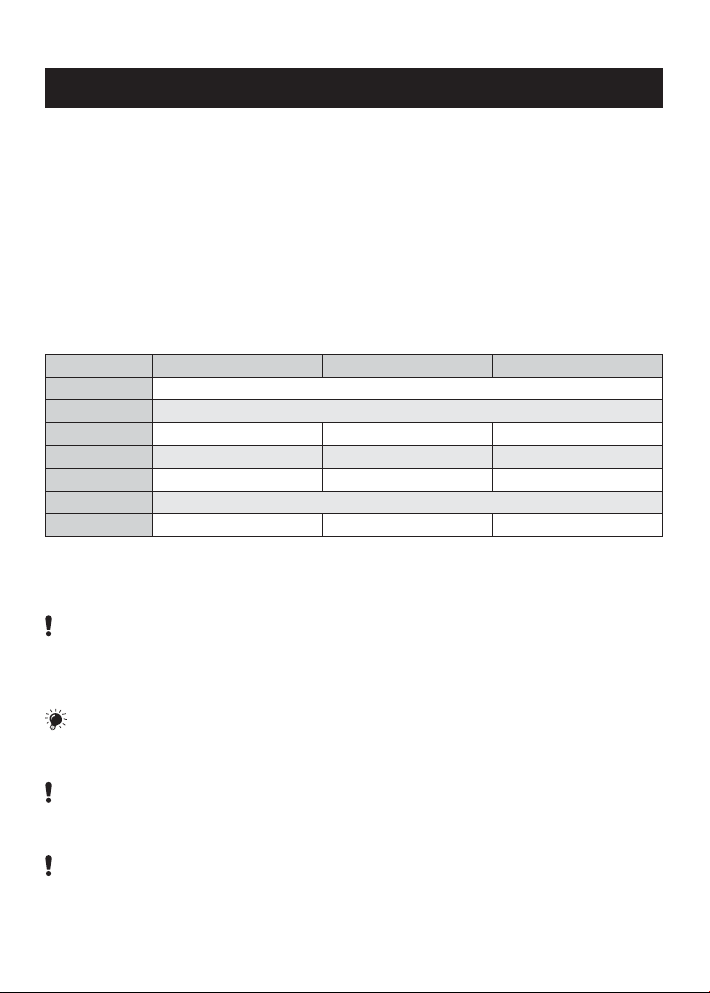

MEASURING RANGES

Type Input 1 Input 2 Input 3

OMX 100 PWR

OMX 100 PWR

OMX 100 DC

OMX 100 DC

OMX 100 PM

OMX 100 OHM

OMX 100 F

Input 1 > 0…60 mV * 0…150 mV * 0…300 mV * 0…1 A * 0…5 A

Input 2 > 0…10 V * 0…100 V * 0…150 V * 0…250 V * 0…450 V

±4/±40 mA ±0,4/±4 V ±40/±400 V

0…1/5 A 0…60/150 mV

0/4…20 mA 0…2 V 0…5/10 V

0…999 Ohm * 0...9,99 kOhm * 0...99,9 kOhm * 5…105 Ohm

< 30 V < 150 V < 300 V

Grounding on terminal „E“ has to be connected at

all times.

Feeding of an open collector (OC) for

frequency output max. 40 V, (internal

resistance 5k6)

Relay parameters listed in Technical data apply for resistance

load. Upon connection of induction load we recommend

fitting the leads to relay 1 A with a fuse for protection of

maximum load.

In RTD and OHM inputs it is necessar y in 2 or 3-wire connec-

tion to link the unconnected inputs to terminal board.

6

3. INSTRUMENT CONNECTION

232

485

POWER

LNE

-

+

AO - supply OC

+

+

L1

AO - frequency

-

OMX 100DC, PM, F

INPUT 2

INPUT 1

GND

-

INPUT 3

+

+

+

AO - voltage

+

Hold/Lock

AO - current

+

-

OMX 100DU

E

B

OMX 100PWR

INPUT I

INPUT U

GND

OMX 100RTD

ES-

ES+

S-

ES+

E-

S+

E-

S-

E+

OM Link

GND GND

RxD Rx/Tx+

TxD

L2

232

Rx/Tx-

485

+

Exc.

-

OMX 100T/C

INPUT

GND-CJC

+

7

INSTRUCTIONS FOR USE OMX 100

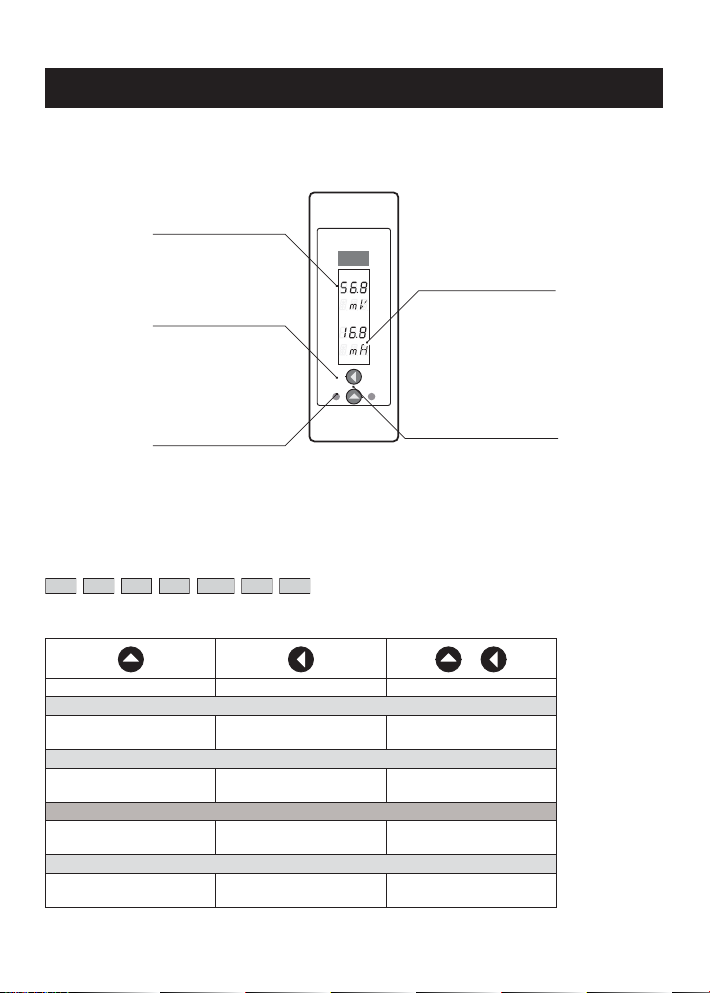

4. INSTRUMENT SETTING

The instrument is set and controlled by 5 control keys located on the front panel. By means of these controls it is

possible to browse through the operating program and to select and set the required values.

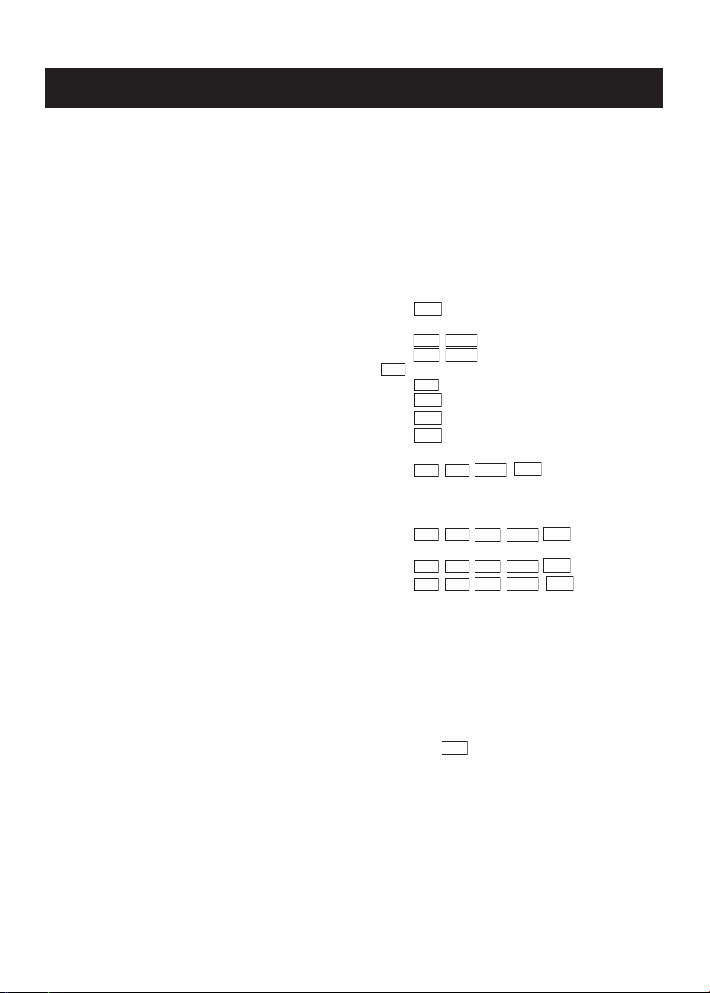

Input value

+ 3 digit optional

projection of meas.unit

Relay status - red LED

ON number is alight

OFF number is not alight

OFF number is flashing

limits w/restriction

(hysteresis, delay)

Signalization - green LED

ON LED is alight

ON LED is flashing

error statement

OFF LED is not alight

SYMBOLS USED IN THE INSTRUCTIONS

DC AC PM DU OHM RTD T/C

INPUT

OUTPUT

12

Output value

+ 3 digit optional

projection of meas.unit

Control keys

Indicates the setting for given type of instrument

CONTROL KEYS FUNCTIONS

+

Measuring mode

UP* LEFT* UP + LEFT

tare/resetting tare projection access into menu

Moving around in the menu

move to next item return to previous level confirm selected item

Setting/selection - items

move up move down confirm selected item

Setting - numbers

change of current figure - up - move to higher decade confirm selected number

* control keys react after being released

8

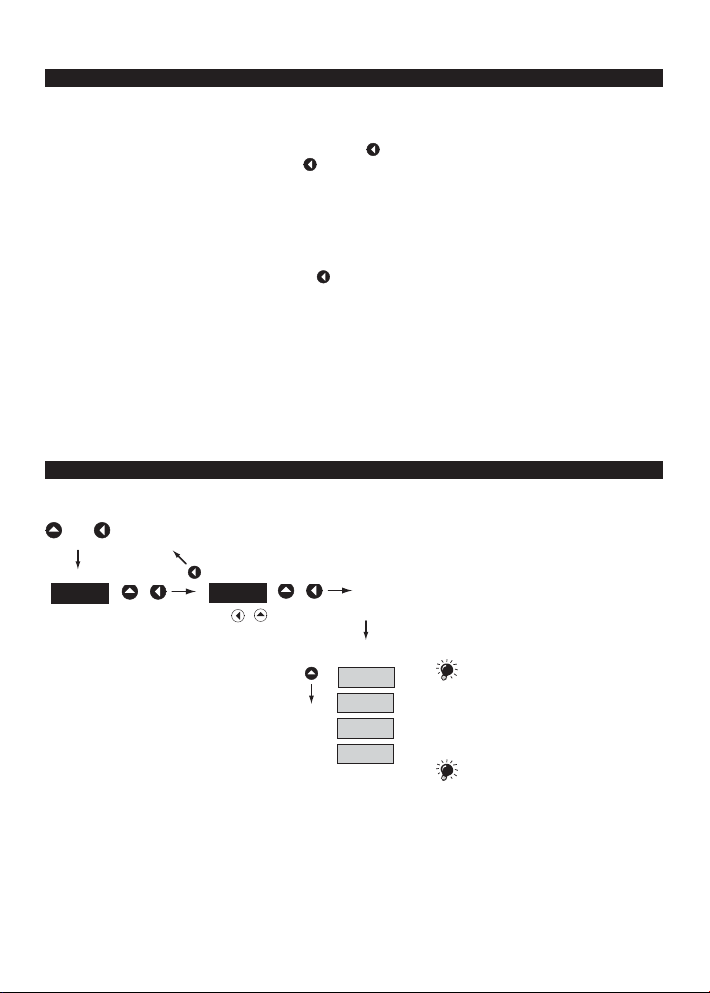

4. INSTRUMENT SETTING

SETTING THE DECIMAL POINT AND THE (-) SIGN

DECIMAL POINT

Its selection in the setting mode is performed by control key with transition behind the highest decade, when the

data starts flashing. Positioning is performed by

For projection of value exceeding 999 the „k“ suffix may be set up (display value is multiplied by 1000, only for

frequency output).

MINUS SIGN

Setting the minus sign is performed by control key on the higher decade. When editing the item, figures change

in numeric row 0,1…9,-,0,1

ACCESS INTO THE CONFIGURATION MODE

.

+

PAS

w/o saving

+

000

shift left

+

9,8,7…

OK

CHA .

INP .

The code from manufacture is always

preset to 000. In case of loss of access

password it is possible to use the universal access

code "177"

OUT.

SER.

If the code is preset to 000 the access

into the menu is free, i.e. without call for

its setting

9

INSTRUCTIONS FOR USE OMX 100

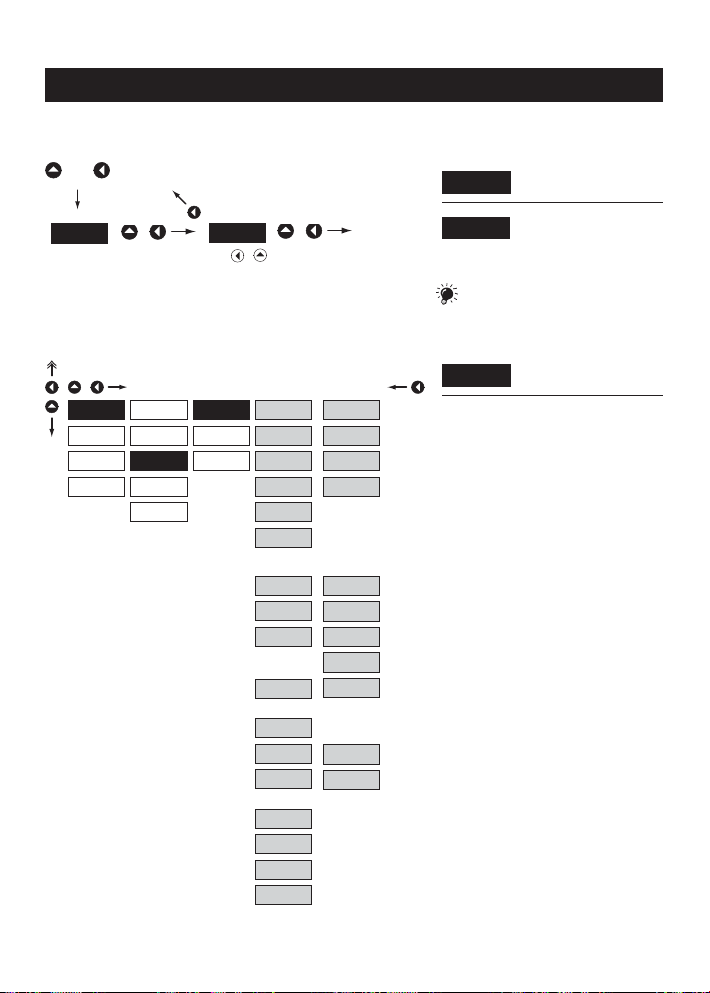

4.1 GUIDE THROUGH MINIMUM INSTRUMENT SETTING

Access into the „Configuration menu““

+

PAS

Selection of the measuring range/input type

+

INP.

CHA .

OUT.

SER.

w/o saving

+

CL. T.

CL. C.

CFG

AUX.

KEY

000

shift left

MOD

M.P.S.

CH.S.

+

9,8,7…

DC - 1

U 0.4

U 4

U 40

400

I 4

I 40

RTD

2-W

3-W

4-W

T/C

OK

DC - 2

60 m

150

I 1

I 5

PM

U 2

U 5

U 10

I 0

I 4

B

R

S

T

E

J

K

N

F

FRE .

COU .

password

its setting

DC Input

- setting the input range is dependant on the

ordered measuring range

PM Input

- setting the input range

RTD Input

- setting the type of connection

- in 2 or 3-wire connection it is necessary to link

the unconnected inputs (see the connection)

T/C Input

- setting the type of thermocouple is dependant

on the ordered measuring range

- B type B Range 1

R type R Range 2

S type S

T type T

E type E Range 3

J type J

K type K

N type N

Input F

- setting the measuring mode

- FRE. Frequency measurement

COU. Impulse counter

Entering the introductory

PAS

access password

Standard manufacture

000

setting of the access

If the code is preset to 000 the access

into „CM“ is free, i.e. without call for

Setting the instrument

MOD

measuring range

10

Setting the display projection

+

C. A.

A. O.

SET

FIL.

FOR .

DES .

TYP

MIN

MAX

MIN

MAX

I 5

I 4

E 4

I 20

U 2

U1 0

FRE .

OFF

INP.

CHA .

OUT.

SER.

Setting the analog output type - U/I

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

DI S .

4. GUIDE THROUGH MINIMUM INSTRUMENT SETTING

Setting the display

MIN .

projection for minimum value

of the input signal

- range of the setting is -99…999

value of the input signal

- range of the setting is -99…999

DEF

Setting the display

MAX

projection for maximum

For type „F“ the items „SCA“ and „OFF“

will be displayed

Type - 0…5 mA

I 5

Type - 4…20 mA

I 4

Type - 4…20 mA with error

E 4

statement (3,0 mA)

Type - 0…20 mA

I 20

Type - 0…2 V

U 2

Type - 0…10 V

U1 0

Type - 0,2…2 200 Hz

FRE .

The output is off

OFF

Setting the analog output range - frequency

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

DI S . MIN

A. O.

TYP

F. MI

F. MA

MAX

Setting the beginning of the

F. MI

frequency range for item

„MIN“

- range of the setting is 0,2…2 200 Hz

„MAX“

- range of the setting is 0,2…2 200 Hz

range

- range of the setting is -99…999

- range of the setting is -99…999

Setting the end of the

F. MA

frequency range for item

Assigning the display value

MIN

to the beginning of the AO

Assigning the display value

MAX

to the end of the AO range

11

INSTRUCTIONS FOR USE OMX 100

4.2 CONFIGURATION MENU

• designated for professional service and maintenance

• complete instrument setting

• access is protected by password or a shorting link on the input connector

23 .6

+

Upon delay longer than 30 s the programming mode is automatically discontinued and the instrument itself switches back to measuring mode

PAS

000

INP .

CHA .

CL. T. CFG .

Resetting internal values

SET FOR .

Setting

projection for

min/max input

signal

Entering the access password

CL. C

Counter

resetting

Auxiliary input

function

FIL.

Setting the

digital filters

Setting the

decimal point

OUT. LIM . DA T. A. O .

Setting

the limits,

hysteresis and

delay

Setting the

data output

Setting the

analog output

SER. RES. CA L N. PA.

Restoring

manufacture

setting/calibration

Instrument

calibration

Setting

new access

password

AUX.

Auxiliary input

function

DI S .

Mode of

display

projection

ID. .

Instrument

identification

KEY

Control key

function

Instrument setting

INP .

CHA

Instrument setting, calibration

OUT.

Setting the outputs

SER.

Service functions, authorization,

calibration

12

Loading...

Loading...