GUARANTEE

YERS

OMX 100

PROGRAMMABLE TRANSMITTER

DC VOLTMETER/AMMETER

AC VOLTMETER/AMMETER

PROCESS MONITOR

THERMOMETER FOR PT 100/500/1 000

THERMOMETER FOR THERMOCOUPLES

DISPLAY INSTR.FOR LIN.POTENTIOMETERS

OHMMETER

THERMOMETER FOR NI 1 000

1

INSTRUCTIONS FOR USE OMX 100

SAFETY INSTRUCTIONS

Please, read the enclosed safety instructions carefully and observe them!

These instruments should be safeguarded by isolated or common fuses (breakers)!

For safety information the EN 61 010-1 + A2 standard must be observed.

This instrument is not explosion-safe!

TECHNICAL DATA

Transmitters of the OMX 100 series conform to European regulation 89/336/EWG and the Ordinance 168/1997

Coll.

They are up to the following European standards:

EN 55 022, class B

EN 61000-4-2, -4, -5, -6, -8, -9, -10, -11

The instruments are applicable for unlimited use in agricultural and industrial areas.

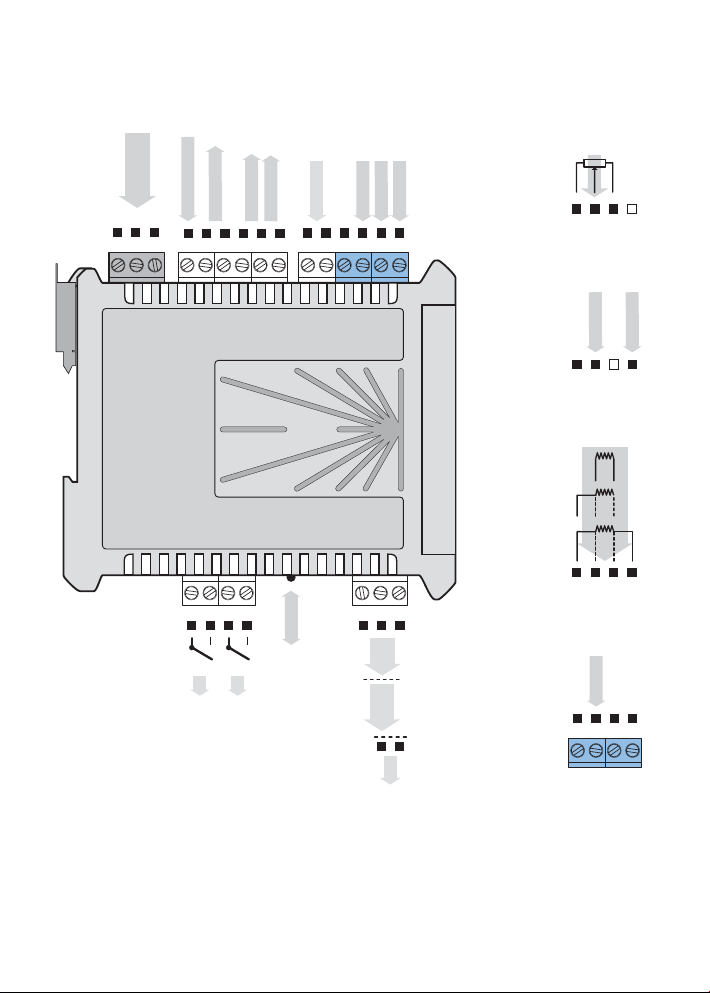

CONNECTION

Supply of energy from the main line has to be isolated from the measuring leads.

ORBIT MERRET, spol. s r.o.

Vodnanská 675/30

198 00 Prague 9

Czech Republic

Tel: +420 - 281 040 200

Fax: +420 - 281 040 299

e-mail: orbit@merret.cz

www.orbit.merret.cz

2

1. CONTENTS

1. CONTENTS

1. Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Instrument description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Instrument setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setting the DP and the (-) sign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Access into Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Guide through minimum instrument setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Configuration mode - INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.1.1 Internal values resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2.1.2 Counter resetting . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1.3.1 Setting the measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1.3.2 Shifting the beginning of the range . . . . . . . . . .

4.2.1.3.3 Compensation of 2-wire conduct . . . . . . . . . . .

4.2.1.3.4 Setting the mode of assessment of CJC

4.2.1.3.5 Setting the temperature of CJC . . . . . . . . . . . . .

4.2.1.3.6 Setting the time base . . . . . . . . . . . . . . . . . . . . .

4.2.1.3.7 Setting the input filter parameters . . . . . . . . . . .

4.2.1.3.8 Setting the display status backup . . . . . . . . . . . F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1.3.9 Setting the instrument measuring rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1.3.10 Selection of auto. menu presetting . . . . . . . . .

4.2.1.4 Selection of external input function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.1.5 Setting another function of the control key „enter“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.2.2 Configuration mode - CHANNELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.2.1 Display projection . . . . . . . . . . . . . . . . . . . . . . .

4.2.2.2 Setting the digital filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.2.3 Setting the decimal point . . . . . . . . . . . . . . . . . .

4.2.2.4 Setting the measuring units description . . . . . . . DC PM DU

4.2.3 Configuration mode - OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.1.1 Limits - type of relay switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.1.2 Limits - setting the bounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.3.2.1 Data output - rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.2.2 Data output -address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.3.1 Analog output - type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3.3.2 Analog output - range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.3.4 Display projection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.4 Configuration mode - SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4.1 Restoration of manufacture setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2.4.2 Input range calibration . . . . . . . . . . . . . . . . . . . . . . DU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.4.3 Setting new access password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5. Table of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6. Method of measuring of CJC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7. Data protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. Error statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10. Instrument dimensions and installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11. Certificate of guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2.4.4 Instrument identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

T/C

RTD OHM

RTD OHM

. 15

T/C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

F

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DC PM

OHM

F . . . . . . . . . . . . . . . . . . 18

DC PM

DC PM

DU

DU

OHM

OHM

OHM

F . . . . . . . . . . . . . 20

F . . . . . . . . . . . . . 21

F . . . . . . . . . . . . 22

3

INSTRUCTIONS FOR USE OMX 100

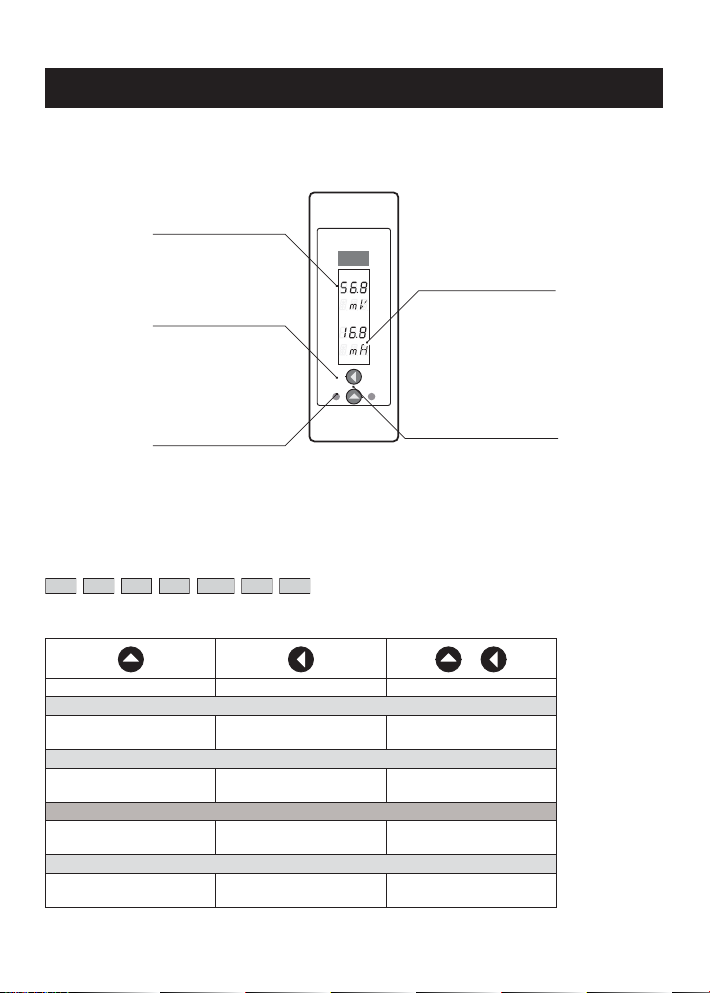

2. INSTRUMENT DESCRIPTION

DESCRIPTION

The OMX 100 model series are programmable transmitters to DIN rail manufactured in the following types:

OMX 100DC DC voltmeter/ammeter

OMX 100PWR AC voltmeter/ammeter, wattmetr

OMX 100PM Process monitor

OMX 100RTD Thermometer for Pt 100/500/1 000, Ni 1 000

OMX 100T/C Thermometer for thermocouples

OMX 100DU Display instrument for linear potentiometers

OMX 100OHM Ohmmeter

OMX 100F Frequency meter

The instruments are based on an 8-bit microcontroller with A/D converter, that secures high accuracy, stability and

easy operation of the instrument.

Programmable projection of the display

Calibration projection for the beginning and the end of the input range

setting the input type

Projection -99…999

Digital filters

Exponen. average from 2…100 measurements

Rounding setting the projection step for display

Mathematic functions

Tare* assigned to reset display in case of non-zero input signal

External control

Hold display/instrument blocking

Lock locking the control keys for access into Configuration menu

Tare tare activation

Resetting counter resetting/preset

Output

Analog programmable

0…5 mA, 0…20 mA, 4…20 mA (with error statement evaluation 3 mA)

0…2/5/10 V

0,2…2 200 Hz

4

* only for type DC, PM, DU

2. INSTRUMENT DESCRIPTION

OPERATION

The transmitter is set by two control keys on the front panel or via data line RS 232/485.

A standard equipment is the OM Link interface, through which it is possible to modify and store all settings. The

OM Link program is freely procurable, to be downloaded from the web site. For the connection an OM Link cable

is necessary.

All programmable parameters are stored in the EEPROM memory (they hold even after the instrument is switched

off).

EXTENSION

Excitation is suitable for feeding sensors and converters. It has a galvanic isolation of 12…24 VDC.

Comparators are assigned to control two limit values with relay output. The limits have adjustbale hysteresis as

well as selectable delay of the switch-on. Reaching the preset limits is signalled by LED and simultaneously by the

switch-on of the relevant relay.

Data outputs are for their rate and accuracy suitable for transmission of the measured data for further projection or

directly into the control systems. We offer an isolated RS 232 and RS 485 with the ASCII protocol.

Real time is an internal time control of data collection. It is suitable everywhere where it is neccessary to register

measured values in a given time segment. Up to 65 000 values may be stored in the instrument‘s memory. Data

transmission into PC via serial interface RS232/485

FIRMWARE www.orbit.merret.cz/update

With respect to the continuous development and innovation of our products it is now possible to download the most

recent program version for every instrument directly from the web pages.

After connecting the instrument to PC and running the program the upgrade is performed automatically .

Number of the current program version in your instrument can be found in „Configuration menu - service - identifi-

cation“

5

INSTRUCTIONS FOR USE OMX 100

3. CONNECTION

The lead for feeding the instrument should not be in the proximity of the incoming low-potential signals.

Contactors, motors with larger input power and other efficient elements should not be in the proximity of the instru-

ment.

The lead into the input of the instrument (the measured quantity) should be in sufficient distance from all power leads

and appliances. Provided this cannot be secured it is necessary to use shielded leads with connection to ground.

The instruments are tested in compliance with standards for use in industrial area, yet we recommend to abide by

the above mentioned principles.

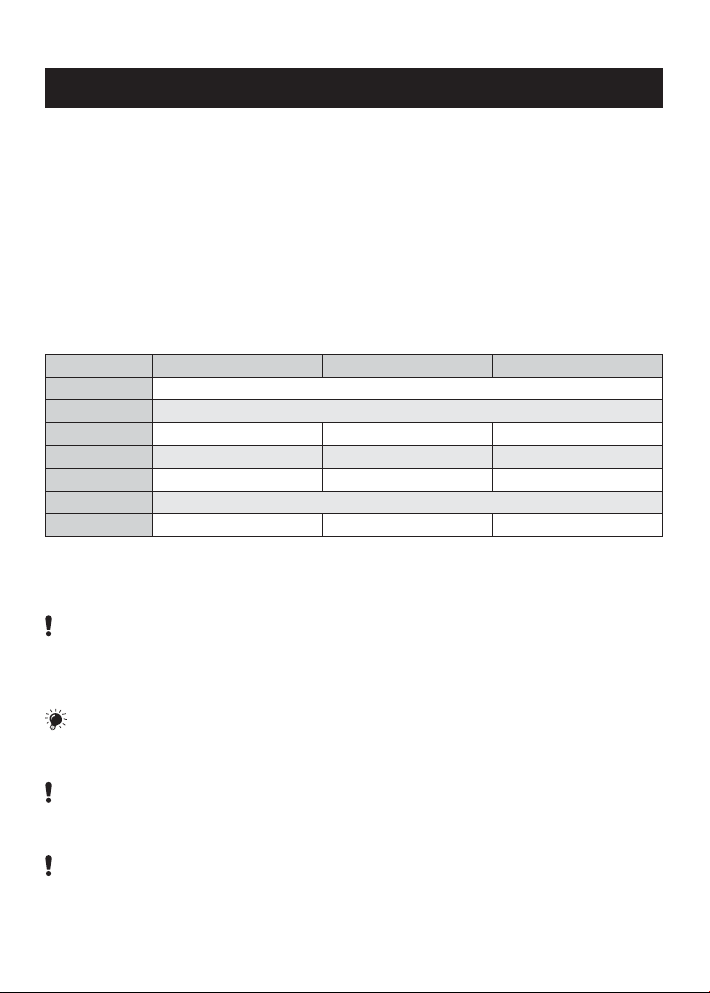

MEASURING RANGES

Type Input 1 Input 2 Input 3

OMX 100 PWR

OMX 100 PWR

OMX 100 DC

OMX 100 DC

OMX 100 PM

OMX 100 OHM

OMX 100 F

Input 1 > 0…60 mV * 0…150 mV * 0…300 mV * 0…1 A * 0…5 A

Input 2 > 0…10 V * 0…100 V * 0…150 V * 0…250 V * 0…450 V

±4/±40 mA ±0,4/±4 V ±40/±400 V

0…1/5 A 0…60/150 mV

0/4…20 mA 0…2 V 0…5/10 V

0…999 Ohm * 0...9,99 kOhm * 0...99,9 kOhm * 5…105 Ohm

< 30 V < 150 V < 300 V

Grounding on terminal „E“ has to be connected at

all times.

Feeding of an open collector (OC) for

frequency output max. 40 V, (internal

resistance 5k6)

Relay parameters listed in Technical data apply for resistance

load. Upon connection of induction load we recommend

fitting the leads to relay 1 A with a fuse for protection of

maximum load.

In RTD and OHM inputs it is necessar y in 2 or 3-wire connec-

tion to link the unconnected inputs to terminal board.

6

3. INSTRUMENT CONNECTION

232

485

POWER

LNE

-

+

AO - supply OC

+

+

L1

AO - frequency

-

OMX 100DC, PM, F

INPUT 2

INPUT 1

GND

-

INPUT 3

+

+

+

AO - voltage

+

Hold/Lock

AO - current

+

-

OMX 100DU

E

B

OMX 100PWR

INPUT I

INPUT U

GND

OMX 100RTD

ES-

ES+

S-

ES+

E-

S+

E-

S-

E+

OM Link

GND GND

RxD Rx/Tx+

TxD

L2

232

Rx/Tx-

485

+

Exc.

-

OMX 100T/C

INPUT

GND-CJC

+

7

INSTRUCTIONS FOR USE OMX 100

4. INSTRUMENT SETTING

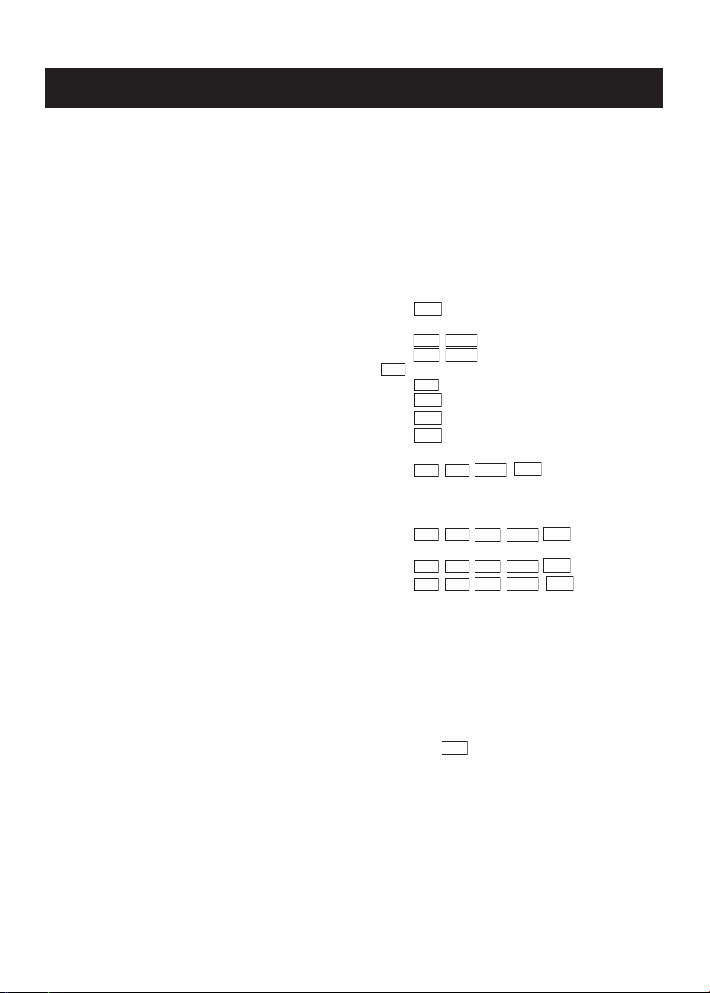

The instrument is set and controlled by 5 control keys located on the front panel. By means of these controls it is

possible to browse through the operating program and to select and set the required values.

Input value

+ 3 digit optional

projection of meas.unit

Relay status - red LED

ON number is alight

OFF number is not alight

OFF number is flashing

limits w/restriction

(hysteresis, delay)

Signalization - green LED

ON LED is alight

ON LED is flashing

error statement

OFF LED is not alight

SYMBOLS USED IN THE INSTRUCTIONS

DC AC PM DU OHM RTD T/C

INPUT

OUTPUT

12

Output value

+ 3 digit optional

projection of meas.unit

Control keys

Indicates the setting for given type of instrument

CONTROL KEYS FUNCTIONS

+

Measuring mode

UP* LEFT* UP + LEFT

tare/resetting tare projection access into menu

Moving around in the menu

move to next item return to previous level confirm selected item

Setting/selection - items

move up move down confirm selected item

Setting - numbers

change of current figure - up - move to higher decade confirm selected number

* control keys react after being released

8

4. INSTRUMENT SETTING

SETTING THE DECIMAL POINT AND THE (-) SIGN

DECIMAL POINT

Its selection in the setting mode is performed by control key with transition behind the highest decade, when the

data starts flashing. Positioning is performed by

For projection of value exceeding 999 the „k“ suffix may be set up (display value is multiplied by 1000, only for

frequency output).

MINUS SIGN

Setting the minus sign is performed by control key on the higher decade. When editing the item, figures change

in numeric row 0,1…9,-,0,1

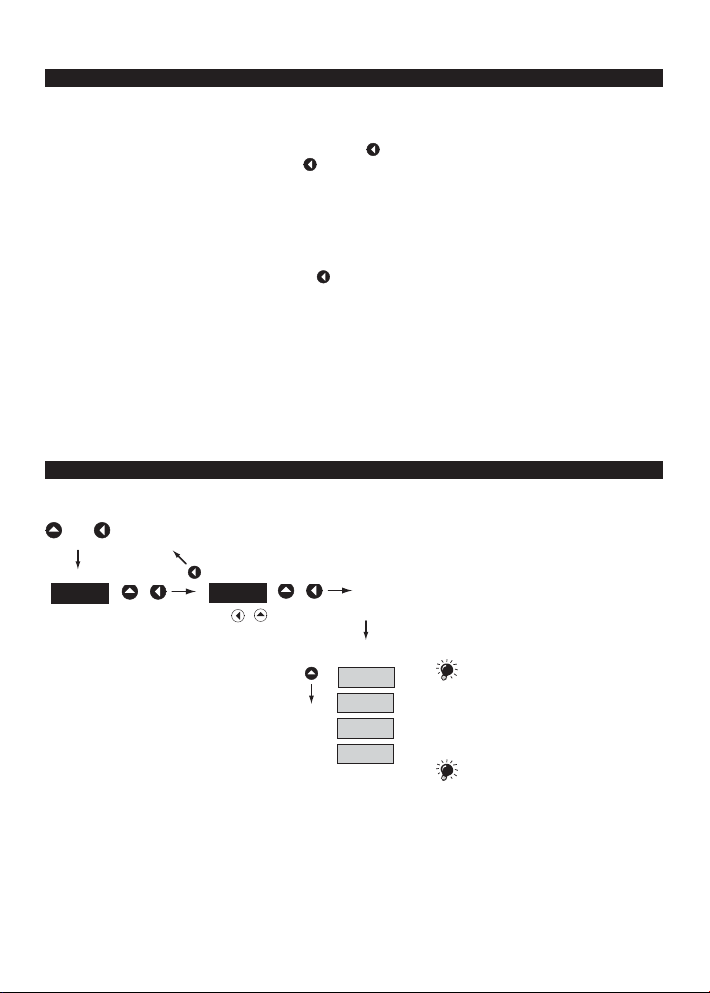

ACCESS INTO THE CONFIGURATION MODE

.

+

PAS

w/o saving

+

000

shift left

+

9,8,7…

OK

CHA .

INP .

The code from manufacture is always

preset to 000. In case of loss of access

password it is possible to use the universal access

code "177"

OUT.

SER.

If the code is preset to 000 the access

into the menu is free, i.e. without call for

its setting

9

INSTRUCTIONS FOR USE OMX 100

4.1 GUIDE THROUGH MINIMUM INSTRUMENT SETTING

Access into the „Configuration menu““

+

PAS

Selection of the measuring range/input type

+

INP.

CHA .

OUT.

SER.

w/o saving

+

CL. T.

CL. C.

CFG

AUX.

KEY

000

shift left

MOD

M.P.S.

CH.S.

+

9,8,7…

DC - 1

U 0.4

U 4

U 40

400

I 4

I 40

RTD

2-W

3-W

4-W

T/C

OK

DC - 2

60 m

150

I 1

I 5

PM

U 2

U 5

U 10

I 0

I 4

B

R

S

T

E

J

K

N

F

FRE .

COU .

password

its setting

DC Input

- setting the input range is dependant on the

ordered measuring range

PM Input

- setting the input range

RTD Input

- setting the type of connection

- in 2 or 3-wire connection it is necessary to link

the unconnected inputs (see the connection)

T/C Input

- setting the type of thermocouple is dependant

on the ordered measuring range

- B type B Range 1

R type R Range 2

S type S

T type T

E type E Range 3

J type J

K type K

N type N

Input F

- setting the measuring mode

- FRE. Frequency measurement

COU. Impulse counter

Entering the introductory

PAS

access password

Standard manufacture

000

setting of the access

If the code is preset to 000 the access

into „CM“ is free, i.e. without call for

Setting the instrument

MOD

measuring range

10

Setting the display projection

+

C. A.

A. O.

SET

FIL.

FOR .

DES .

TYP

MIN

MAX

MIN

MAX

I 5

I 4

E 4

I 20

U 2

U1 0

FRE .

OFF

INP.

CHA .

OUT.

SER.

Setting the analog output type - U/I

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

DI S .

4. GUIDE THROUGH MINIMUM INSTRUMENT SETTING

Setting the display

MIN .

projection for minimum value

of the input signal

- range of the setting is -99…999

value of the input signal

- range of the setting is -99…999

DEF

Setting the display

MAX

projection for maximum

For type „F“ the items „SCA“ and „OFF“

will be displayed

Type - 0…5 mA

I 5

Type - 4…20 mA

I 4

Type - 4…20 mA with error

E 4

statement (3,0 mA)

Type - 0…20 mA

I 20

Type - 0…2 V

U 2

Type - 0…10 V

U1 0

Type - 0,2…2 200 Hz

FRE .

The output is off

OFF

Setting the analog output range - frequency

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

DI S . MIN

A. O.

TYP

F. MI

F. MA

MAX

Setting the beginning of the

F. MI

frequency range for item

„MIN“

- range of the setting is 0,2…2 200 Hz

„MAX“

- range of the setting is 0,2…2 200 Hz

range

- range of the setting is -99…999

- range of the setting is -99…999

Setting the end of the

F. MA

frequency range for item

Assigning the display value

MIN

to the beginning of the AO

Assigning the display value

MAX

to the end of the AO range

11

INSTRUCTIONS FOR USE OMX 100

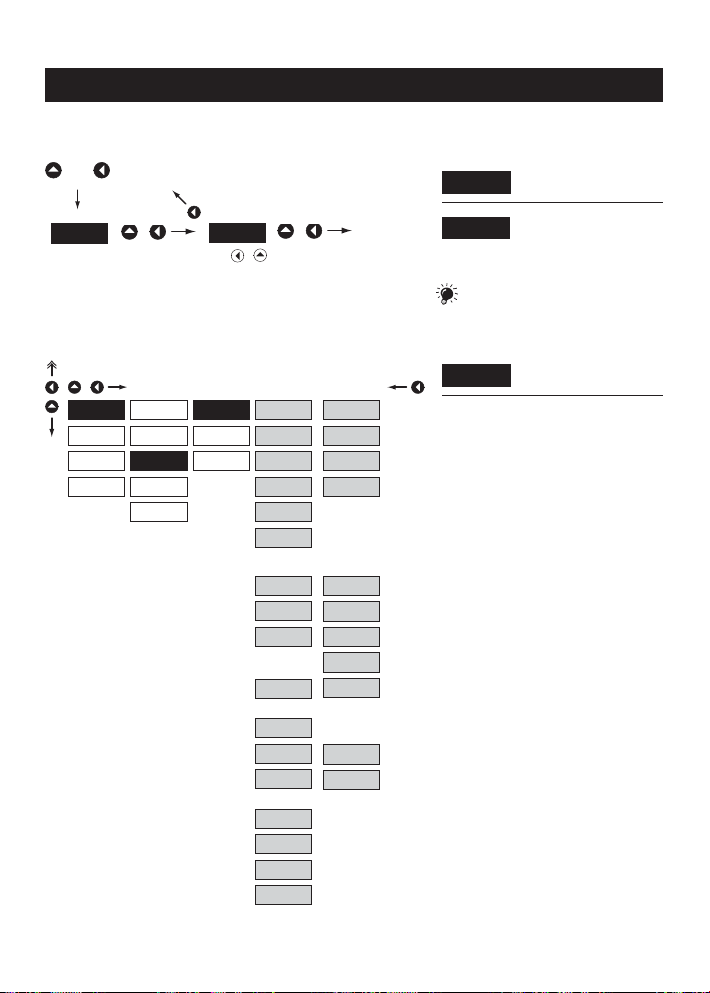

4.2 CONFIGURATION MENU

• designated for professional service and maintenance

• complete instrument setting

• access is protected by password or a shorting link on the input connector

23 .6

+

Upon delay longer than 30 s the programming mode is automatically discontinued and the instrument itself switches back to measuring mode

PAS

000

INP .

CHA .

CL. T. CFG .

Resetting internal values

SET FOR .

Setting

projection for

min/max input

signal

Entering the access password

CL. C

Counter

resetting

Auxiliary input

function

FIL.

Setting the

digital filters

Setting the

decimal point

OUT. LIM . DA T. A. O .

Setting

the limits,

hysteresis and

delay

Setting the

data output

Setting the

analog output

SER. RES. CA L N. PA.

Restoring

manufacture

setting/calibration

Instrument

calibration

Setting

new access

password

AUX.

Auxiliary input

function

DI S .

Mode of

display

projection

ID. .

Instrument

identification

KEY

Control key

function

Instrument setting

INP .

CHA

Instrument setting, calibration

OUT.

Setting the outputs

SER.

Service functions, authorization,

calibration

12

4.2.1 CONFIGURATION MODE - INPUT

+

CL. T.

INP.

CHA .

CL. C.

OUT.

SER.

4.2.1.1 INTERNAL VALUES RESETTING

+

INP.

CHA .

OUT.

SER.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

4. INSTRUMENT SETTING - CONFIGURATION MODE

The basic instrument functions are set in

this menu

Internal values resetting

CL. T.

Counter resetting

CL. C.

Type „F“

Selecting the measuring

CFG

range and measuring rate

Setting the external control

AUX.

input function

Setting the control-key

KEY

function

Tare resetting

CL. T.

4.2.1.2 COUNTER RESETTING

+

CL. T.

INP.

CHA .

OUT.

SER.

CL. C.

CFG

AUX.

KEY

Counter resetting

CL. C.

Holds valid for mode „Counter“

F

13

INSTRUCTIONS FOR USE OMX 100

4.2.1.3.1 SETTING THE MEASURING RANGE

+

CL. T.

INP.

CHA .

OUT.

SER.

CL. C.

CFG

AUX.

MOD

M.P.S.

CH.S.

KEY

DC - 1

U 0.4

U 4

U 40

400

I 4

I 40

RTD

2-W

3-W

4-W

T/C

Setting the instrument

MOD

measuring range

DC - 2

60 m

150

I 1

I 5

PM

U 2

U 5

U 10

I 0

I 4

B

R

S

T

F

FRE .

COU .

E

J

K

N

DC Input

- setting the input range is dependant on the

ordered measuring range

- U 0.4 ±0,4 V Range 1

U 4 ±4 V

U 40 ±40 V

400 ±400 V

60 m ±60 mV Range 2

150 ±150 mV

I 1 ±1 A

I 5 ±5 A

PM Input

- setting the input range

RTD Input

- setting the type of connection

- in 2 or 3-wire connection it is necessary to link

the unconnected inputs (see connection)

T/C Input

- setting the type of thermocouple is dependant

on the ordered measuring range

- B type B Range 1

R type R Range 2

S type S

T type T

E type E Range 3

J type J

K type K

N type N

Input F

- setting the measuring mode

- FRE. Frequency measurement

COU. Impulse counter

14

4. INSTRUMENT SETTING - CONFIGURATION MODE

4.2.1.3.2 SHIFTING THE BEGINNING OF THE RANGE

+

CL. T.

INP.

CHA .

OUT.

SER.

4.2.1.3.3 COMPENSATION OF 2-WIRE CONDUCT

+

CHA .

OUT.

SER.

4.2.1.3.4 SETTING THE MODE OF ASSESSMENT OF CJC

+

OUT.

SER.

INP.

INP.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

MOD

R. Ad.

LEA .

M.P.S.

A. ST.

MOD

r. Ad.

LEA .

M.P.S.

A. ST.

MOD

CJC

T.C. J.

M.P.S.

YES

IN . 1

IN . 2CHA .

Ex . 1

Ex . 2

RTD OHM

Shifting the beginning of

R. Ad.

the measuring range

- in cases when it is necessary to shift the

beginning of the range by a given value, e.g.

when using sensor in measuring probe

- entered directly in Ohm

RTD OHM

Compensation of 2-wire

LEA .

conduct

- for measurement accuracy it is always

necessary to perform compensation of the

conduct in case of 2-wire connection

- entered directly in Ohm

- prior to confirmation of the displayed

challenge „YES“ it is necessary to substitute

the sensor at the end of the conduct by a

short circuit

- preset from manufacture to „0“

T/C

Mode of assessment of

C.J .C.

cold junction

- description of the mode of assessment of cold

junction is in chapter 5, page 30

Measurement without

IN . 1

reference thermocouple

- CJC measurement on the instrument brackets

- cold junction measurement on the instrument

brackets with anti-series connection of ref.

thermocouple

- whole measuring system operates under

identical and constant temperature

- when using compensation box

Measurement with reference

IN . 2

thermocouple

Measurement without

Ex . 1

reference thermocouple

Measurement with reference

Ex . 2

thermocouple

15

INSTRUCTIONS FOR USE OMX 100

4.2.1.3.5 SETTING THE TEMPERATURE OF CJC

+

CL. T.

INP.

CHA .

OUT.

SER.

4.2.1.3.6 SETTING THE TIME BASE

+

CHA .

OUT.

SER.

Valid for the „Frequency“ mode

4.2.1.3.7 SETTING THE INPUT FILTER PARAMETERS

+

CHA .

OUT.

SER.

INP.

INP.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

MOD

CJC

T.C. J.

M.P.S.

MOD

M. T.CL. t.

FIL.

BAC

A. ST.

MOD

M.T.CL. t.

FIL.

BAC

A. ST.

0.5

OFF

200

100

0.1

10

40

DEF

1

5

DEF

5

T/C

Setting the temperature

T.. C. J.

of CJC

- range 0…60°C with compensation box

Method and process of the setting of

CJC is described in separate chapter

on page 31

F

Setting the measuring

M. T.

time - time base

- if you set the time of measurement e.g to 1s,

the measuring time is approximately from

1s to 2s (1 s + maximum one period of

measured signal). If no impulse comes within

2 s , it is understood that the signal has zero

frequency

- range of the setting of the time base is 0,5 s

to 10 s

- in the „RTC“ regime with projection of date

the set time determines the period of switching

between time/date, min. is 5 s, the date is

displayed for approximately 2,5

F

Setting the digital input

FIL.

filter

- through digital filter we may suppress

undesirable interfering impulses (e.g. relay

back-swings) on the input signal. The set

parameter indicates maximum possible

instrument frequency (Hz), which the

instrument may process without restriction

Valid for the „Counter“ mode

When entering the contact and if we

know the maximum input frequency we

recommend using the filter

16

4. INSTRUMENT SETTING - CONFIGURATION MODE

4.2.1.3.8 SETTING THE DISPLAY STATUS BACKUP

+

CL. T.

INP.

CHA .

OUT.

SER.

4.2.1.3.9 SETTING THE INSTRUMENT MEASURING RATE

+

OUT.

SER.

INP.

CFG

AUX.

KEY

CL. T.

CFG

AUX.

KEY

MOD

M.T.CL. t.

FIL.

BAC

A. ST.

MOD

M.P.S.

A. ST .

DI S .

ENB .

0.5

1. 2CHA .

2.5

5. 0

10. 0

20. 0

40. 0

80. 0

DEF

DEF

F

Setting the display status

BAC.

backup

- setting the restoration of display value after

power outage or instrument switchoff

After switch-on instrument

DI S .

resets itself to zero

After switch-on instrument

ENB .

reads the display status from

its memory

Valid for the „Counter“ mode

Setting the measuring

M.P.S.

rate

Rate - 0,5 measurements/s

0.5

Rate - 1,2 measurements/s

1. 2

Rate - 2,5 measurements/s

2.5

Rate - 5 measurements/s

5. 0

Rate - 10 measurements/s

10. 0

Rate - 20 measurements/s

20. 0

Rate - 40 measurements/s

40. 0

Rate - 80 measurements/s

80. 0

17

INSTRUCTIONS FOR USE OMX 100

4.2.1.3.10 SELECTION OF AUTOMATIC MENU PRESETTING

+

CL. T.

INP.

CFG

OUT.

SER.

When selecting „AUT.“ in type „F“ the decimal

point and description are preset in the range of

0,01 Hz…50,0 kHz. Limits and AO are set in kHz!

4.2.1.4 SELECTION OF EXTERNAL INPUT FUNCTION

+

INP. LOC .

CHA .

OUT.

SER.

AUX.

KEY

CL. T.

CFG

AUX.

KEY

MOD

M. P.S.

A. ST.

AU. 1

ENA .

DI S .CH A.

HLD.

TAR .

CL. C.

DEF

DEF

DC PM

Menu presetting

CH.S.

Enable

ENA .

- depending on the set input the following items

will be preset automatically:

- CHANNELS: MIN/MAX, FOR, DES

- OUT: A.O. > MIN/MAX

- aut. preset items will disappear from the menu

and reappear again after setting „MAN“

- example for input 4-20mA (PM):

MIN/MAX > 4-20; FOR > 00.0; DES > mA;

A.O. MIN/MAX > 4-20

- as a standard, according to individual items

on the menu

„COU“

Disable

DI S .

Selection of external input

AU 1

function

LOCK, locking the control

LOC .

keys on the instrument

HOLD, stop measuring of

HLD.

the entire instrument

TARE - Tare* activation

TAR .

Counter resetting

CL. C.

only for type „F“, mode

OHM

F

4.2.1.5 SET TING ANOTHER FUNCTION OF THE CONTROL KEY „ENTER“

+

CL. T.

INP. ENB .

CHA .

OUT.

SER.

18

CFG

AUX.

KEY

ALL

DEF

DI S .

Setting another function

ALL

of the control key

Without function

DI S .

Activation of keys for Tare*

ENB .

projection, in type „F“ in

mode „COU“ > resetting to zero

* only for type DC, PM, DU, F

4. INSTRUMENT SETTING - CONFIGURATION MODE

19

INSTRUCTIONS FOR USE OMX 100

4.2.2 CONFIGURATION MODE - CHANNELS

+

INP . SET

CHA.

OUT.

SER.

Items „MIN“ and „MAX“ resp. „SCA“ and „OFF“ are

displayed only when the menu is set to „Manual“

INP > CFG > CH.S > MAN

4.2.2.1 DISPLAY PROJECTION

+

INP .

CHA.

OUT.

SER.

+

INP .

CHA.

OUT.

SER.

FIL.

FOR .

DES .

SET

FIL.

FOR .

DES .

SET

FIL.

FOR .

DES .

MIN

MAX

SCA

OFF

Only for type „F“

In this menu instrument parameters are set

Setting the display

SET

projection for minimum/

maximum value of the input signal

Input type Setting options

DC

AC

PM

DU

OHM

RTD

T/C

F

of the input signal

- range of the setting is -99…999

input signal

- range of the setting is -99…999

- calibration constant is for the conversion of

input value to required display value

- by setting the minus value the direction of

counting changes, i.e. we count down

- range: -0,00001...999999,

- shifting the beginning of measurement by

a set value which will always be read upon

resetting the instrument to zero

- range: -99999...999999,

Setting the digital filters

FIL.

Setting the decimal point

FOR .

Setting the measuring units

DES .

DC PM

DU

Setting the display

MIN .

projection for minimum value

Setting display projection

MAX

for maximum value of the

Setting the calibration

SCA

constant

Setting the additive constant

OFF

„PRESET“

OHM

DEF

DEF

= 0

F

= 1

20

4.2.2.2 SET TING THE DIGITAL FILTERS

+

INP . MOD

CHA.

OUT.

SER.

4.2.2.3 SET TING THE DECIMAL POINT

+

INP . 000 .

CHA.

OUT.

SER.

SET

FIL.

FOR .

DES .

SET

FIL.

FOR.

CON .

00. 0

0. 00

FL. P.DES .

OFF

EXP .

RND.

4. INSTRUMENT SETTING - CONFIGURATION MODE

Setting the digital filters

FIL.

Setting the filtration constant

CON .

- this menu is always displayed after selection

of a particular type of filter

- the value is calculated from a number of

measurements selected in „CON“

- range 2…100

- it is set by an optional number which

determines the projection step

(e.g. step 2,5 - 0, 2.5, 5, 7.5, etc.)

- the instrument allows classic projection of a

number with placement of the decimal point

as well as projection with floating point,

allowing to display the number in its most

precise form „FL.P.“

Filters are off

OFF

Selection of exponential

EXP

filter

Rounding the measured

RND.

value

DC PM

DU

Setting the decimal point

FOR .

Setting the DP

000.

Setting the DP

00. 0

Setting the DP

0. 00

Setting the DP

FL. P.

OHM

F

21

INSTRUCTIONS FOR USE OMX 100

4.2.2.4 SET TING THE MEASURING UNITS DESCRIPTION

+

INP .

CHA.

OUT.

SER.

Set description

Table of symbols is on page 30

SET

FIL.

FOR .

DES.

Description position

INPUT

OUTPUT

ASCII symbol code

move to next code

number setting

DC PM

DU

Setting the projection of

DES

measuring units on the

display

- the instrument allows to add three symbols

to classic numeric formats. The setting is

performed by means of shifted ASCII code.

Upon the setting the upper number indicates

the symbol position, the lower line displays

entered symbol on the first position and on

the last two positions the code of the relevant

symbol from 0 to 95.

Description is cancelled by entering symbols

00

- instruments with input for temperature

measurement display °C as a standard

first line (upper) thousands and next line units

to hundreds

In „COU“ mode in type „F“ the projection

in format 000000 is divided in two parts,

OHM

F

22

4. INSTRUMENT SETTING - CONFIGURATION MODE

23

INSTRUCTIONS FOR USE OMX 100

4.2.3 CONFIGURATION MODE - OUTPUTS

+

INP .

CHA .

OUT.

SER.

4.2.3.1.1 LIMITS - TYPE OF RELAY SWITCHING

+

INP .

CHA .

OUT.

SER.

The process of setting the limit 2 is identical

with the setting for Limit 1

LIM

DAT .

A. O .

DI S

LIM

DAT .

A. O .

DI S .

L 1

L 2

TYP

LIM .

HYS.

TIM .

CLO .

OPE.

In this menu it is possible to set parameters

of the instrument output signals

Setting the type and the

LIM

switching of limits

Setting the type and the

DAT .

parameters of data output

Setting the type and the

A. O .

parameters of analog output

Display projection mode

DI S .

Setting the type of relay

Typ

evaluation

DEF

Relay switches on when

CLO .

condition is met

Rely switches off when

OPE.

condition is met

4.2.3.1.2 LIMITS - SETTING THE BOUNDS

+

OUT.

LIM

DAT .

A. O .

L 1

L 2

INP .

CHA .

SER.

The process of setting the limit 2 is identical

with the setting for Limit 1

24

TYP

LIM .

HYS.

TIM .DI S .

Setting the bounds for relay

LIM .

switch-on

- within full display rangee

- within full display rangee

- in range 0…99,9 s

Setting hysteresis only in

HYS.

(+) values

Setting the offset of the limit

TIM .

switch-on

4.2.3.2.1 DATA OUTPUT - RATE

+

INP .

CHA .

OUT.

SER.

4.2.3.2.2 DATA OUTPUT - ADDRESS

+

INP .

CHA .

OUT.

SER.

4.2.3.3.1 ANALOG OUTPUT - TYPE

LIM

DAT.

A. O .

DI S .

LIM

DAT.

A. O .

DI S .

BD

ADR.

BD

ADR.

1. 2

2.4

4. 8

9. 6

19. 2

38.4

DEF

4. INSTRUMENT SETTING - CONFIGURATION MODE

Setting the data output

DB

rate

Rate - 1 200 Baud

1. 2

Rate - 2 400 Baud

2.4

Rate - 4 800 Baud

4. 8

Rate - 9 600 Baud

9. 6

Rate - 19 200 Baud

19. 2

Rate - 38 400 Baud

38.4

Setting the instrument

ADR.

address

- setting within the range of 0…31

- manufacture setting 00

DEF

Setting the analog output

TYP

type

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

A. O.

DI S .

TYP

MIN

MAX

I 5

I 4

E 4

I 20

U 2

U1 0

FRE .

OFF

DEF

Type - 0…5 mA

I 5

Type - 4…20 mA

I 4

Type - 4…20 mA with error

E 0

statement (3,0 mA)

Type - 0…20 mA

I 20

Type - 0…2 V

U 2

Type - 0…10 V

U1 0

Type - 0,2…2 200 Hz

FRE .

The output is off

OFF

25

INSTRUCTIONS FOR USE OMX 100

4.2.3.3.2 ANALOG OUTPUT - RANGE

+

INP .

CHA .

OUT.

SER.

4.2.3.4 DISPLAY PROJECTION

+

INP .

CHA .

OUT.

SER.

LIM

DAT .

DI S . MIN

LIM

DAT .

DI S .

A. O.

A. O.

TYP

F. MI

F. MA

MAX

REF.

MAX

1 s

OFF

Setting the analog output

A. O .

range

- analog output is isolated and its value

corresponds with the displayed data. It is fully

programmable, i.e. it allows to assign the AO

limit points to any two arbitrary points of the

entire measuring range

Setting the beginning of the

F. MI

frequency range for item

„MIN“

- range of the setting is 0,2…2 200 Hz

„MAX“

- range of the setting is 0,2…2 200 Hz

range

- range of the setting is -99…999

- range of the setting is -99…999

- it burdens the processor performance, i.e.

in fully equipped transmitter the arithmetic

operation may be slowed down

- after pressing the control key the display is

active after 60 s at max. projection rate

Setting the end of the

F. MA

frequency range for item

Assigning the display value

MIN

to the beginning of the AO

Assigning the display value

MAX

to the end of the AO range

Display projection mode

DI S .

Display refresh

REF

Display value is changing at

MAX

maximum rate

Display value is being

1 s

restored 1x per second

Display is off

OFF

26

4. INSTRUMENT SETTING - CONFIGURATION MODE

27

INSTRUCTIONS FOR USE OMX 100

4.2.4 CONFIGURATION MODE - SERVICE

+

INP .

CHA .

OUT.

SER.

4.2.4.1 RESTORATION OF MANUFACTURE SETTING

+

INP . SETRES.

CHA .

OUT.

SER.

RES.

CAL .

N. PA .

ID.

CAL .

N. PA .

ID.

The instrument‘s service functions are set

in this menu

Restoration of the

RES.

manufacture setting and

instrument calibration

setting

- in case of incorrect setting or calibration it is

- reading the manufacture calibration and

Input range calibration for

CAL .

„DU“ version

Setting new access

N. PA.

password

Instrument identification

ID.

Restoration of the

RES.

instrument manufacture

possible to return to manufacture setting. Prior

execution of the changes you will be asked to

confirm your selection „YES“

original setting of items in the menu (DEF)

28

4. INSTRUMENT SETTING - CONFIGURATION MODE

4.2.4.2 INPUT RANGE CALIBRATION

+

INP . RES.

CHA .

OUT.

SER.

Before pressing „ENTER“ the potentiometer

runner has to be at rest

4.2.4.3 SET TING NEW ACCESS PASSWORD

+

INP . RES.

CHA .

OUT.

SER.

4.2.4.4 INSTRUMENT IDENTIFICATION

CAL.

N. PA .

CAL .

N. PA.

MIN

MAX

ID.

ID.

DU

Input range calibration

CAL.

- when MIN is displayed move the

potentiometer runner into required minimum

position and confirm by „Enter“, calibration is

confirmed by the „OK“ notice

- when MAX is displayed move the

potentiometer runner into required maximum

position and confirm by „Enter“, calibration is

confirmed by the „OK“ notice

Setting new access

N. PA.

password for

„Configuration menu“

- this option allows to change the numeric code

its setting

which blocks the access into the instrument

„Configuration mode“. The range of the

numeric code is 0…999

If the code is preset to 000 the access

into the menu is free, i.e. without call for

+

INP . RES.

CHA .

OUT.

SER.

CAL .

N. PA.

ID.

Projection of the

ID.

instrument version

- the display shows the type identification of the

instrument with the number of revision

- instrument name - program version - SW date

e.g.: OMX, 100, PM2, 003, 000,

29

INSTRUCTIONS FOR USE OMX 100

5. TABLE OF SYMBOLS

The instrument allows to add two descriptive symbols to classic numeric formats (at the expense of the number of

displayed places). The setting is performed by means of shifted ASCII code. Upon modification the first two places

display the entered symbols and the last two places the code of the relevant symbol from 0 to 95. Numeric value of

given symbol equals the sum of the numbers on both axes of the table.

Description is cancelled by entering characters with code 00

01234567 01234567

00 !"#$%&'

88()*+,- ./

16 16 01234567

24 24 89 : ; <=> ?

32 32 @A B C D E F G

40 40 HI JKLMNO

48 48 PQ R S T UVW

56 56 XYZ[\]^_

64 64 `abcde fg

72 72 hi jklmno

80 80 pq r s t uvw

88 88 xyz { |}~

30

6. METHOD OF MEASURING OF CJC

6. METHOD OF MEASURING OF CJC

Istrument with input for temperature measurement with thermocouple allows for setting of two types of measurement

of the cold junction.

Measuring thermocouple

+

V

-

+

OM xxx T/C

Reference thermocouple

WITH REFERENCE THERMOCOUPLE

a reference thermocouple may be located in the same place as the measuring instrument or in place with stable

temperature/compensation box

when measuring with reference thermocouple set

when using a thermostat (a compensation box or environment with constant temperature) set in the instrument menu

T.C.J.. its temperature (applies for setting CJC to Ex. 2)

if the reference thermocouple is located in the same environment as the measuring instrument then set in the instru-

ment menu

by a sensor located in the instrument terminal board.

CJC to IN. 2. Based on this selection the measurement of the surrounding temperature is performed

+

J

-

J

2

1

-

CJC in the instrument menu to IN. 2 or EX. 2

WITHOUT REFERENCE THERMOCOUPLE

inaccuracy originating from the creation of dissimilar thermocouples on the transition point terminal-conductor of

the thermocouple is not compensated for in the instrument

when measuring without reference thermocouple set

when measuring temperature without reference thermocouple the error in the measured data may be even 10°C

(applies for setting

CJC to Ex. 1)

CJC in the instrument menu to IN. 1 or Ex. 1

31

INSTRUCTIONS FOR USE OMX 100

7. DATA PROTOCOL

The instruments communicate via serial line RS232 or RS485. For communication they use the ASCII protocol.

Communication runs in the following format:

ASCII: 8 bit, no parity, one stop bit

The transfer rate is adjustable in the instrument menu and depends on the control processor used. The instrument

address is set in the instrument menu in the range of 0 ÷ 31. The manufacture setting always presets the ASCII protocol,

rate of 9600 Baud, address 00. The type of line used - RS232 / RS485 - is determined by an exchangeable card

automatically identified by the instrument.

COMMANDS FOR INSTRUMENT OPERATION

The commands are described in specification you can find at www.orbit.merret.cz/rs.

A command consists of a number and a letter, where the letter size is of significance.

DETAILED DESCRIPTION OF COMMUNICATION VIA SERIAL LINE

Activity Type Protocol Data transferred

Data solicitation (PC)

Data transfer

(Instrument)

Command tranfer

(Instrument) - identification

Command confirmation (Instrument)

232 ASCII # A A <CR>

485 ASCII # A A <CR>

232 ASCII > R SP D D D D D (D) (D) <CR>

485 ASCII > R SP D D D D D (D) (D) <CR>

232 ASCII # A A 1 Y <CR>

485 ASCII # A A 1 Y <CR>

ASCII

232

485

ok ! A A <CR>

bad ? A A <CR>

ASCII

ok ! A A <CR>

bad ? A A <CR>

Legend

#

AA

<CR>

<SP>

NP

D

R

!

?

>

32

35 23

0...31

13 0D

32 20

30H...3F

33 21

63 3F

62 3E

Beginning of the command

H

Two signs of the inst. address (sent in ASCII - decades and units, ex."01")

Carriage return

H

Space

H

Number and command - command code

Data - usually signs "0"..."9","-","." ; (D) - dp. and (-) may prolong data

Relay status; zero bit corresponds with 1st relay, 1st bit with 2nd relay, etc.

H

Positive command confirmation (ok)

H

Negative command confirmation (bad)

H

Beginning of the transmitted data

H

8. ERROR STATEMENTS

ERROR CAUSE ELIMINATION

E. D.U.

E. D.O..

E. T.U.

E. T.O.

E. I.U.

E.I.O.

E.HW.

E.EE.

E.DT.

E.CL.

display underflow

number is too small (large negative) to be

displayed

display overflow

number is too large to be displayed

table underflow

number outside tablerange

table overflow

number outside tablerange

range underflow (A/D converter)

input signal is smaller than the one allowed

by instruments range

range overflow (A/D converter)

input signal is larger than the one allowed

by instruments range

some part of the instruments does not

function properly

EEPROM error

damaged data in EEPROM

DATA error

data in EEPROM outside the range

EEPROM error

memory is blank („DEF“ values presetting

has initialized)

change display projection

change display projection

change display projection or table range

change display projection or table range

change input signal value

change input signal value

when reported repeatedly send the instrument for repair

when reported repeatedly send the instrument for repair

information about performed automatic

data correction in EEPROM

„Def“ values will be used in emergency

but calibration data will be impaired

> send for repair

8. ERROR STATEMENTS

33

INSTRUCTIONS FOR USE OMX 100

34

35

INSTRUCTIONS FOR USE OMX 100

9. TECHNICAL DATA

INPUT

selectable in configuration menu DC

DC 1 ±4 mA < 200 mV Input 1

±40 mA < 200 mV Input 1

±400 mV 100 kOhm Input 2

±4 V 100 kOhm Input 2

±40 V 10 MOhm Input 3

±400 V 10 MOhm Input 3

DC 2 ±1 A < 150 mV Input 1

±5 A < 150 mV Input 1

±60 mV 100 kOhm Input 2

±150 mV 100 kOhm Input 2

range is fixed, as per order PWR

Range U: 0...10 V 100 kOhm Input 2

0...100 V 10 MOhm Input 2

0...150 V 10 MOhm Input 2

0...250 V 10 MOhm Input 2

0...450 V 10 MOhm Input 2

Range I: 0...60 mV 100 kOhm Input 1

0...150 mV 100 kOhm Input 1

0...300 mV 100 kOhm Input 1

0...1 A < 150 mV Input 1

0...5 A < 150 mV Input 1

selectable in configuration menu PM

0/4...20 mA < 400 mV Input 1

0...2 V 1 MOhm Input 2

0...5 V 1 MOhm Input 3

0...10 V 1 MOhm Input 3

range is fixed, as per order OHM

0...999 Ohm

0...9,99 kOhm

0...99,9 kOhm

Connection: 2, 3 or 4 wire

RTD

Pt xxxx -50°…450°C

Ni xxxx -50°...250°C

Type Pt: 100/500/1 000 Ohm, platinum couple

s α=0,00385Ohm/Ohm/°C

Type Ni: Ni 1 000/10 000, 5000 ppm/6180 ppm

Connection: 2, 3 or 4 wire

5...105 Ohm

selectable in configuration menu T/C

Type: J (Fe-CuNi) -200°...900°C

K (NiCr-Ni) -200°...1 300°C

T (Cu-CuNi) -200°...400°C

E (NiCr-CuNi) -200°...690°C

B (PtRh30-PtRh6) 300°...1 820°C

S (PtRh10-Pt) -50°...1 760°C

R (Pt13Rh-Pt) -50°...1 740°C

N (Omegalloy) -200°...1 300°C

DU

Lin.pot.supply. 2,5 VDC/6 mA

min. potentiometer resistance is 500 Ohm

F

Range: 0,02…50 kHz

Input: upon contact, TTL, PNP/NPN

Measuring mode: counter/frequency

Function: data backup, time backup, Preset

Filtration constant: 0/5/10/100/200 Hz

Time base: 0,1/0,5/1/5/10 s

Calibrat. coefficient: 0,01…9999 Hz

Preset: 0…9999

PROJECTION

Display: LCD with blue illumination,

2x 3 symbols + 2x description (3 symbols)

Projection: -99…999

DP: adjustable - in programming mode

INSTRUMENT ACURACY

TC: 100 ppm/°C

Accuracy: ±0,2 % of range + 1 digit

±0,3 % of range + 1 digit T/C, PWR

±0,05 % of range + 1 digit F

Resolution: 0,1°/1°C RTD

Rate: 0,5 - 1,2 - 2,5 - 5 - 10 - 20 - 40 - 80 measurements/s

Overload capacity: 10x (t < 100 ms), 2x (long-term)

Digital filter adjustable in configuration menu

Compensation of conduct: max. 20 Ohm RTD

Comp.of CJC: adjustable T/C

Functions: Tare - display resetting

Hold - stop measuring (upon contact)

Lock - control keys locking

OM Link: Company communication interface for operation,

Watch-dog: reset after 25 ms

Calibration: at 25°C and 40 % r.h.

1°C T/C

0°...98°C or automatic (99)

setting and update of instrument SW

36

* values apply for resistance load

9. TECHNICAL DATA

OUTPUTS

Analog: isolated,

programmable w/ resolution of max. 12 bit

Non-linearity: 0,2 % of the range

TC: 100 ppm/°C

Rate: response to change of value< 100 ms

Voltage: 0…2 V/5 V/10 V, on request ±5 V/±10 V

Current: 0…5/20 mA/4…20 mA, on request ±20 mA

- compensation of conduct up to 450 Ohm

Corrugation: 5 mV of residual corrugation at output voltage 10 V

Frequency: 0,2…2 200 Hz

isolated, programmable, open collector with the

option of external supply (max. 40 V) vie intervnal

resistance (5k6)

COMPARATOR

Type: digital, adjustable in menu

Limits: -99…999

Hysteresis: 0…999

Delay: 0…99,9 s

Outputs: 2x relays with switch-on contact

(230 VAC/30 VDC, 3 A)*

contact switching on < 50 ms

Relays: 1/8 HP 277 VAC, 1/10 HP 125 V, Pilot Duty D300

DATA OUTPUTS

Protocols: ASCII

Data format: 8 bit + no parity + 1 stop bit (ASCII)

Rate: 1 200…38 400 Baud

RS 232: isolated, two-way communication

RS 485: isolated, two-way communication,

addressing (max. 31 instrument)

EXCITATION

Adjustable: 12…24 VDC/20 mA, isolated

- cannot be combined with data output

POWER SUPPLY

Options: 24/110/230 VAC, 50/60 Hz, ±10 %, 5 VA

10…30 VDC/max. 150 mA, isolated

Protection: melting fuse inside the instrument

VAC (T 80 mA), VDC (T 630 mA)

MECHANIC PROPERTIES

Material: PP 66 (UL 94 -V0), blue

Dimensions: 113 x 98 x 35 mm

Installation: to DIN rail, width 35 mm

OPERATING CONDITIONS

Connection: connector terminal board, conductor cross section up

to 2,5 mm

2

Stabilisation period: within 15 minutes after switch-on

Working temp.: 0°…60°C

Storage temp.: -10°…85°C

Protection: IP20

Overvoltage categ.: EN 61010-1, A2

Insulation resist.:** for pollution degree II, cat. measuring III.

AC power supply > 600 V (BI), 300 V (DI)

DC power supply > 500 V (BI), 250 V (DI)

EMC: EN 61000-3-2+A12; EN 61000-4-2, 3, 4, 5, 8, 11;

EN 550222, A1, A2

** BI - Basic insulation, DI - Dual insulation

37

INSTRUCTIONS FOR USE OMX 100

10. INST.DIMENSIONS AND INSTALLATION

Side viewFront view

INPUT

OUTPUT

97 mm

12

35 mm

Installation to DIN rail of 35 mm width

38

113 mm

11. CERTIFICATE OF GUARANTEE

ge

perform

instrument.

o

a

- m

- in

- in

- u

- o

t

not apply for defects caused by:

. . .

ARANTEE

.. . . . . . . . . . . . .

S

YE

R

11. CERTIFICATE OF GUARANTEE

Product OMX 100 DC PWR PM DU RTD T/C OHM F

Type . . . . . . . . . . . . . . . . . . . .

Manufacturing No . . . . . . . . . . . . . . . . . . . .

. . .

Date of sale . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

A guarantee period of 24 months from the date of sale to the user applies to this instrument.

Defects occuring during this period due to manufacture error or due to material faults shall be eliminated free of

charge.

For instrument quality, function and construction the guarantee shall apply provided that the instrument was connected

and used in compliance with the instruction for use.

The guarantee shall not apply for defects caused by:

- mechanic damage

- in transport

- intervention of unqualified person incl. the user

- unavoidable event

- other unprofessional interventions

The manufacturer performs guarantee and post-guarantee repairs unless provided for otherwise.

ri

h

echanic dama

transport

navoidable event

li

n

Stamp, signature

39

INSTRUCTIONS FOR USE OMX 100

DECLARATION OF CONFORMITY

Assessment of conformity pursuant to Section 12, par. 4 b, d of Act No. 22/1997 Coll.

Company: ORBIT MERRET, spol. s r.o.

Klánova 81/141, 142 00 Prague 4, Czech Republic, IČO: 00551309

Manufacturer: ORBIT MERRET, spol. s r.o.

Vodňanská 675/30, 198 00 Prague 9, Czech Republic

The manufacturer declares at its full responsibility that the product presented hereunder meets all technical requirements, is safe for use when used under the terms and conditions determined by Orbit Merret, spol.s r.o., and that

our company has taken all steps to ensure conformity of all products of the type referred-to below, which are being

brought out to the market, with technical documentation and requirements of the appurtenant Ordinance.

Product: Digital transmitter to DIN rail

Type: OMX 100

Version: DC, PM, PWR, RTD, T/C, DU, OHM, F

Conformity is assessed pursuant to the following standards:

Electr. safety: EN 61010-1

EMC: EN 50131-1, chapt. 14 and chapt. 15

EN 50130-4, chapt. 7 EN 61000-4-11

EN 50130-4, chapt. 8 EN 61000-4-11

EN 50130-4, chapt. 9 EN 61000-4-2

EN 50130-4, chapt. 10 EN 61000-4-3

EN 50130-4, chapt. 11 EN 61000-4-6

EN 50130-4, chapt. 12 EN 61000-4-4

EN 50130-4, chapt. 13 EN 61000-4-5

EN 50130-5, chapt. 20

prEN 50131-2-1, article 9.3.1

EN 61000-4-8

EN 61000-4-9

EN 61000-3-2 ed. 2:2001

EN 61000-3-3: 1997, Cor. 1:1998, Z1:2002

EN 55022, chapt. 5 and chapt. 6.

As evidence serve the protocols of authorised and accredited organisations:

VTÚE Praha, examination laboratory No. 1158, accredited by ČIA

VTÚPV Vyškov, examination laboratory No. 1103, accredited by ČIA

Prague, 18. 12. 2003 Miroslav Hackl v.r.

General manager

40

TECHDOK - OMX 100 - 2004 - v.2.2 - en

Loading...

Loading...