ORBITEC OSK 53 G, OSK 38 C, OSK 38 CW, OSK 21 C, OSK 53 GW Operating Instructions Manual

...

Operating instructions for OSK series S / G

As of 13.06.2016

Subject to change

ORBITEC GmbH

Willi-Brehm-Straße 8

D-63500 Seligenstadt

Phone: +49 (0)6182 / 78693-0

Fax: +49 (0)6182 / 78693-10

E-Mail: info@orbitec-group.com

Internet: www.orbitec-group.com

OSK S-series

OSK G-series

1

Operating instructions for OSK series S / G

Table of Contents

1. Preface ........................................................................................................................... 3

2. Safety instructions .......................................................................................................... 4

3. Product overview ............................................................................................................ 5

4. Features/benefits............................................................................................................ 7

5. Measurement chart and scope ....................................................................................... 8

6. Connection to the inverter / control ................................................................................10

7. Instructions ....................................................................................................................11

7.1. assembly of the collets ...........................................................................................11

7.2. Assembly welding head / drive unit ........................................................................13

7.3. Positioning of the electrode ....................................................................................15

7.4. Guidelines for electrode lengths in OSK .................................................................17

7.5. Preparation of pipes ...............................................................................................18

7.6. Tacking of the pipes ...............................................................................................18

7.7. Welding process .....................................................................................................20

8. Maintenance and product care ......................................................................................21

8.1. General instructions ...............................................................................................21

8.2. Cleaning .................................................................................................................22

8.3. Setting the end switch cam .....................................................................................25

8.4. Exchange of the drive shaft ....................................................................................27

8.5. Exchange of graphite nodule ..................................................................................29

8.6. Setting of tension lock ............................................................................................31

9. Type plate key ...............................................................................................................32

10. Accessories (available separately) .............................................................................33

11. Legal notices .............................................................................................................34

12. EC – Declaration of Conformity ..................................................................................35

13. Notes .........................................................................................................................36

2

Operating instructions for OSK series S / G

1. Preface

Thank you for choosing a closed welding head of the OSK series by Orbitec GmbH.

These operating instructions are intended assist in the handling of the OSK.

Please read the operating instructions carefully and completely and keep them for future

reference to avoid misuse.

Orbitec GmbH does not assume any liability for any unauthorised modifications, incorrect

use and repairs, and /or prohibited conversions, which are not expressly authorised by

Orbitec.

The OSK enables the orbital welding of pipes, pipe bends, t-sections etc.

By its closed construction and the interior protective atmosphere, the welding process is

protected from external influences.

The automated welding process facilitates repeatable results and guarantees consistent high

quality.

Furthermore, the welding heads can be changed, therefore welding heads of different sizes

can be used with one single drive unit.

Water cooling is possible for continuous operation and heavy duty applications such as, for

example, high wall thickness.

These operating instructions apply to the G-series, the subsequent S-series, as well as the

compact and water-cooled variants GW, SW, C, CS and CW.

Should you have any question regarding installation, commissioning or operation, please

contact our customer service on telephone number: +49 (0) 6182/78693-0.

3

Operating instructions for OSK series S / G

General Hazard Warnings!

The same rules as for TIG welding (Tungsten Inert-gas welding, or GTAW - Gas

Tungsten arc welding) apply.

The tool may only be used by trained personnel.

The tool may only be used for its intended purpose.

Orbitec GmbH does not assume any liability for unauthorised / incorrect

modifications, repairs, use and conversions, which are not expressly authorised by

Orbitec.

Please read and follow the operating instructions for this product and all related

system components.

Please observe the accident prevention regulations.

Please observe country-specific provisions.

Check all components for damage.

Do not continue to use a product if it is damaged.

Ensure a safe workplace.

Electrical danger!

An electrical shock can be fatal!

Install and earth welding equipment in accordance with local standards.

Do not touch any live components or electrodes with bare hands or wet protective

equipment.

Persons must isolate themselves from earth and the workpiece.

Do not touch any live parts during welding.

Risk of fire and burns!

Welding beads can lead to fire and burns.

Prior to switching on the machine, ensure that there are no solvents present in the

room air, for example in paint shops.

Do not store any flammable objects or cleaning agents at the workspace.

Dirt can often be flammable.

Wear suitable protective gloves.

Danger from radiation!

Ultraviolet and infrared light can cause burns to eyes and skin.

Protect eyes and body, wear suitable safety helmet with filter insert as well as

protective clothing.

Never look towards the electric arc without protection.

Personnel in close proximity must be protected by protective curtains or walls.

Danger from gases and smoke!

Smoke and gas can endanger your health.

Do not inhale the welding fumes.

Ensure sufficient ventilation.

If necessary, use an extraction system.

Observe the safety rules for welding work in small spaces and closed containers.

Danger of explosion!

Caution when using forming gases or gases containing hydrogen.

There is a danger of deflagration.

Only use gases that are suitable for your uses.

When using gases containing hydrogen, maximum 10% hydrogen.

Observe the provisions of the relevant safety data sheets.

Danger of crushing!

Do not reach into the body aperture when the rotor is running.

Do not reach into the moving machine parts.

2. Safety instructions

4

Operating instructions for OSK series S / G

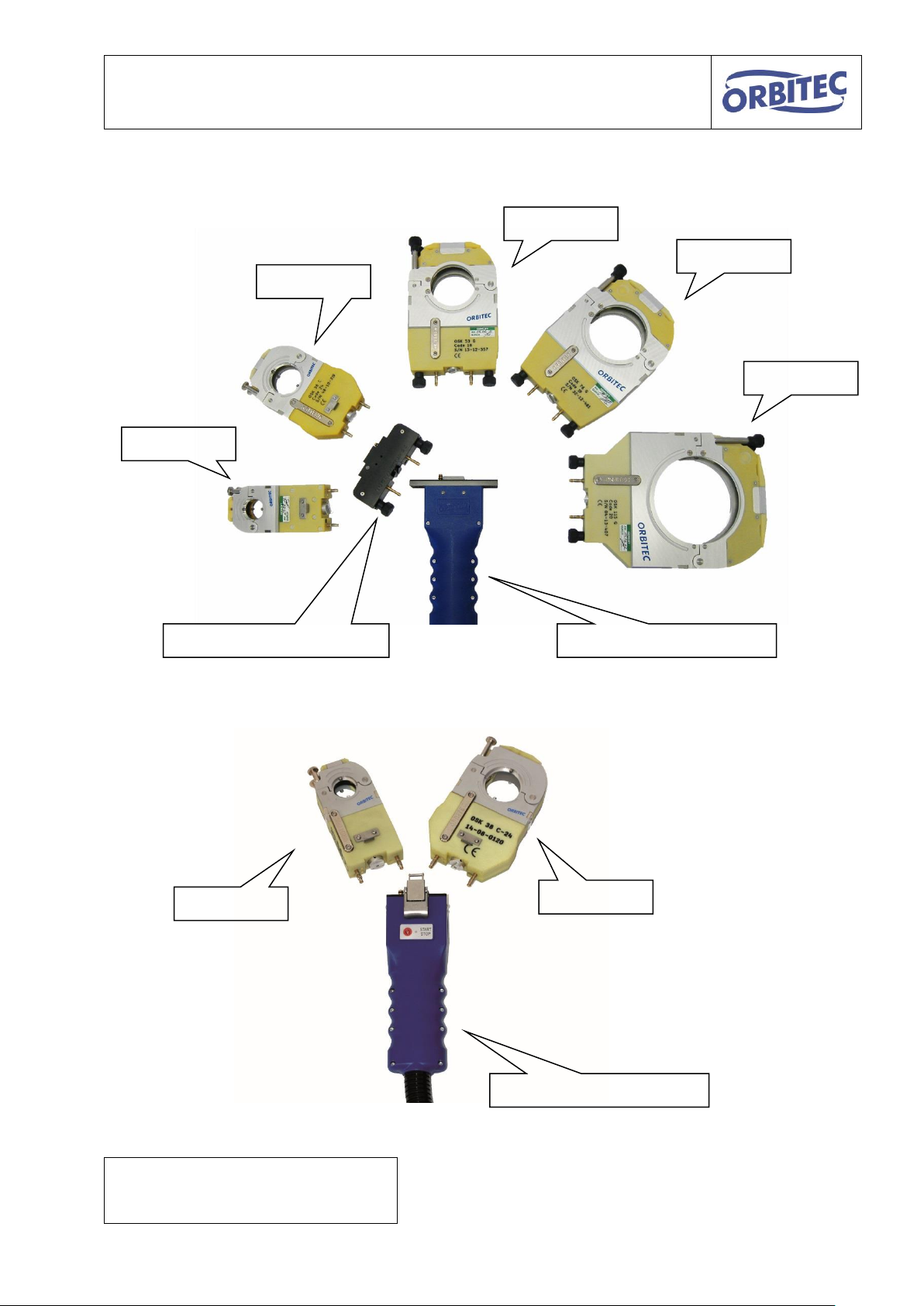

Adapter flange OSK C/G*

Drive unit OSK G

Drive unit OSK C

OSK 115 G

OSK 38 C

OSK 76 G

OSK 53 G

OSK 21 C

OSK 38 C

OSK 21 C

*The adapter flange enables the

connection of a C welding head to a G or S

drive unit

3. Product overview

5

Operating instructions for OSK series S / G

welding head

variant

function

OSK 21

C

gas-cooled

CW

water-cooled

OSK 38

C

gas-cooled

CW

water-cooled

OSK 53

G

gas-cooled

GW

water-cooled

OSK 76

G

gas-cooled

GW

water-cooled

OSK 115

G

gas-cooled

GW

water-cooled

S

gas-cooled

SW

water-cooled

drive unit

compatible with variant:

function

Drive unit OSK C

C

gas-cooled

drive unit OSK CW

CW

water-cooled

drive unit OSK G

G / S

gas-cooled

drive unit OSK GW

GW / SW

water-cooled

drive unit OSK S

G / S

gas-cooled

drive unit OSK SW

GW / SW

water-cooled

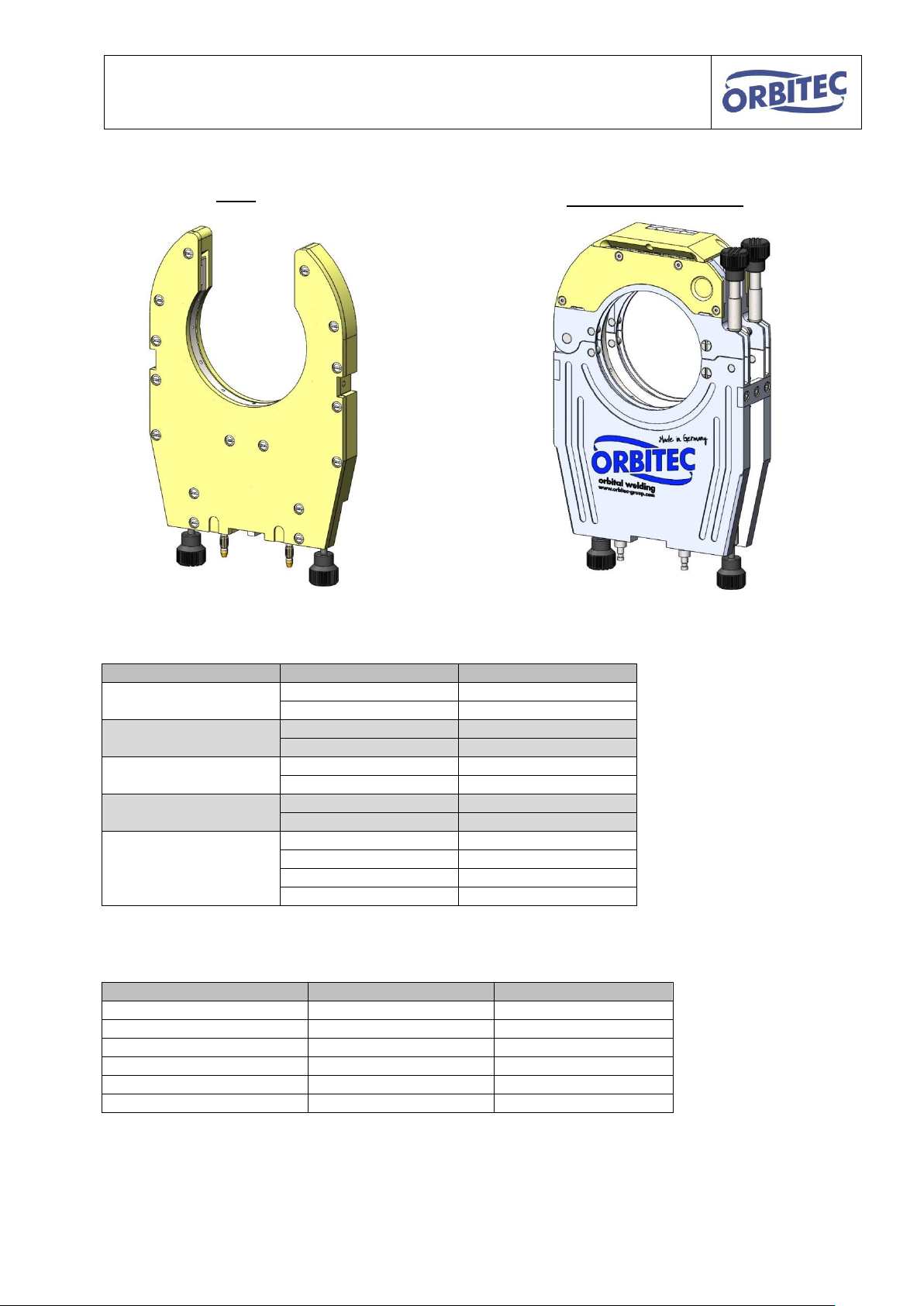

Body

Clamping shell housing

The following OSK welding tools are available:

The following drive units are available:

6

Operating instructions for OSK series S / G

4. Features/benefits

The closed OSK welding heads have the following features:

The closed construction and the inert gas atmosphere inside protect the welding

process against external influences and guarantee a qualitative high-grade welding

seam.

The automated welding process facilitates repeatable results and guarantees

consistent high quality.

The welding head can be separated from the drive unit.

Therefore five different welding heads can be used with one drive unit.

Electrodes with Ø 1.6 mm and Ø 2.4 mm can be used.

Each welding head is available in a water-cooled variant or can be upgraded to a

water-cooled variant (from S-series onwards also OSK 38 and OSK 21).

Collets exchangeable by quick-change system.

Simple assembly and dismantling.

7

Operating instructions for OSK series S / G

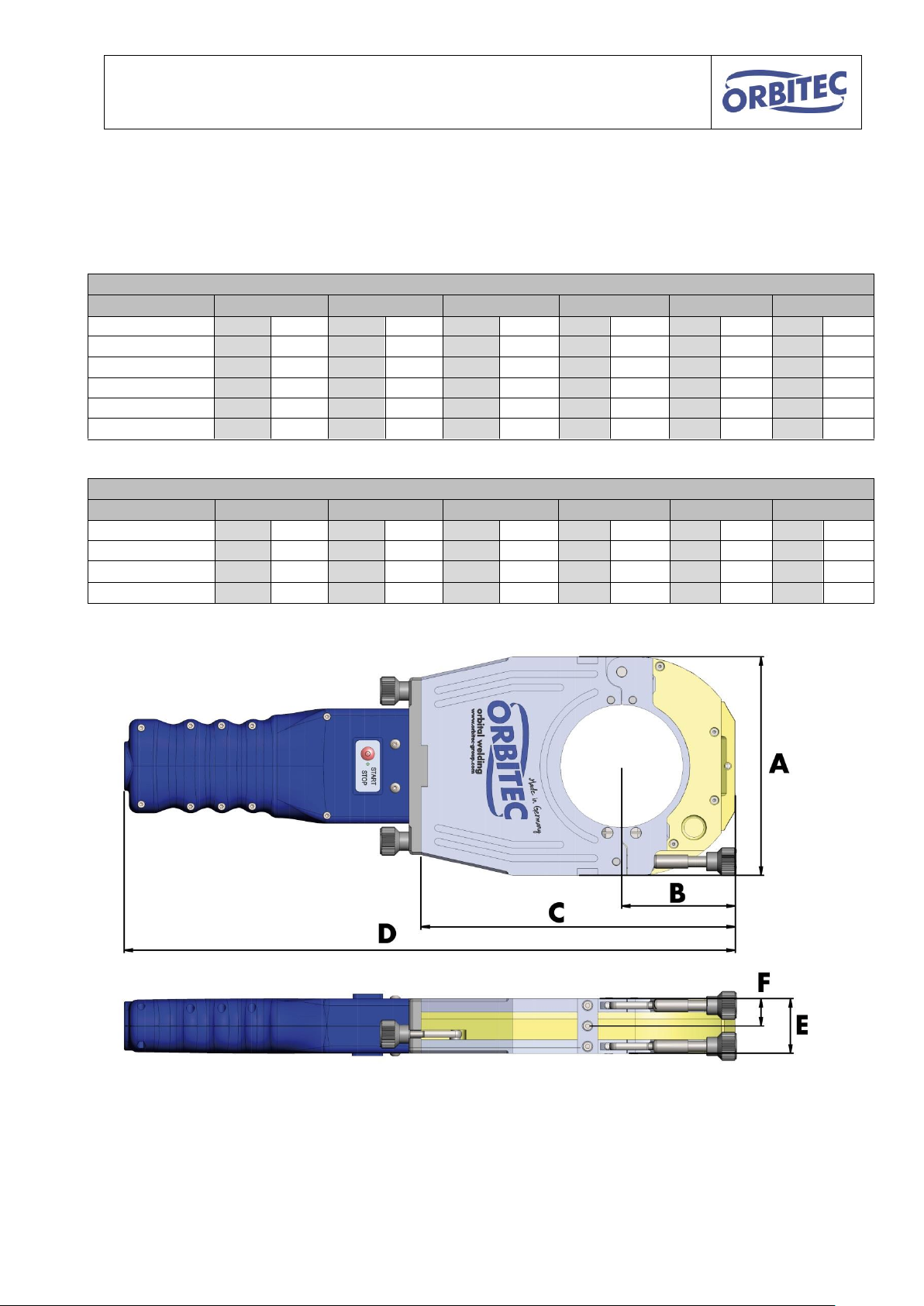

G-series

welding head

A B C D E

F

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

OSK 21 C

70

2.756

40

1.575

150

5.906

370

14.567

33

1.299

16

.630

OSK 38 C

102

4.016

53

2.087

175

6.890

390

15.354

33

1.299

16

.630

OSK 53 G / GW

140

5.512

73

2.874

210

8.268

430

16.929

44

1.732

22

.866

OSK 76 G / GW

160

6.299

83

3.268

230

9.055

445

17.520

44

1.732

22

.866

OSK 115 G / GW

200

7.874

103

4.055

270

10.630

485

19.094

44

1.732

22

.866

S-series

welding head

A B C D E

F

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

OSK 21 CW

70

2.756

39.5

1.555

146

5.748

365.5

14.390

35

1.378

17.5

.689

OSK 38 CW

102

4.016

54

2.156

177

6.969

396

15.591

35

1.378

17.5

.689

OSK 115 S / SW

200

7.874

103

4.055

270

10.630

487.5

19.192

40

1.575

20

.787

5. Measurement chart and scope

The dimensions of the OSK series are as follows:

8

Operating instructions for OSK series S / G

welding head

scope (outside diameter)

scope (outside diameter)

OSK 21

3.17 mm – 21.3 mm

0.125 inch – 0.839 inch

OSK 38

3.17 mm – 38.1 mm

0.125 inch – 1.500 Inch

OSK 53

6 mm – 53 mm

0.250 inch – 2.087 Inch

OSK 76

6 mm – 76.2 mm

0.250 inch – 3.000 Inch

OSK 115

8 mm – 114.3 mm

0.368 inch – 4.500 inch

Clamping jaws are

available in all

common pipe

diameters.

(special sizes on

request)

The scopes of the OSK series is as follows:

9

Operating instructions for OSK series S / G

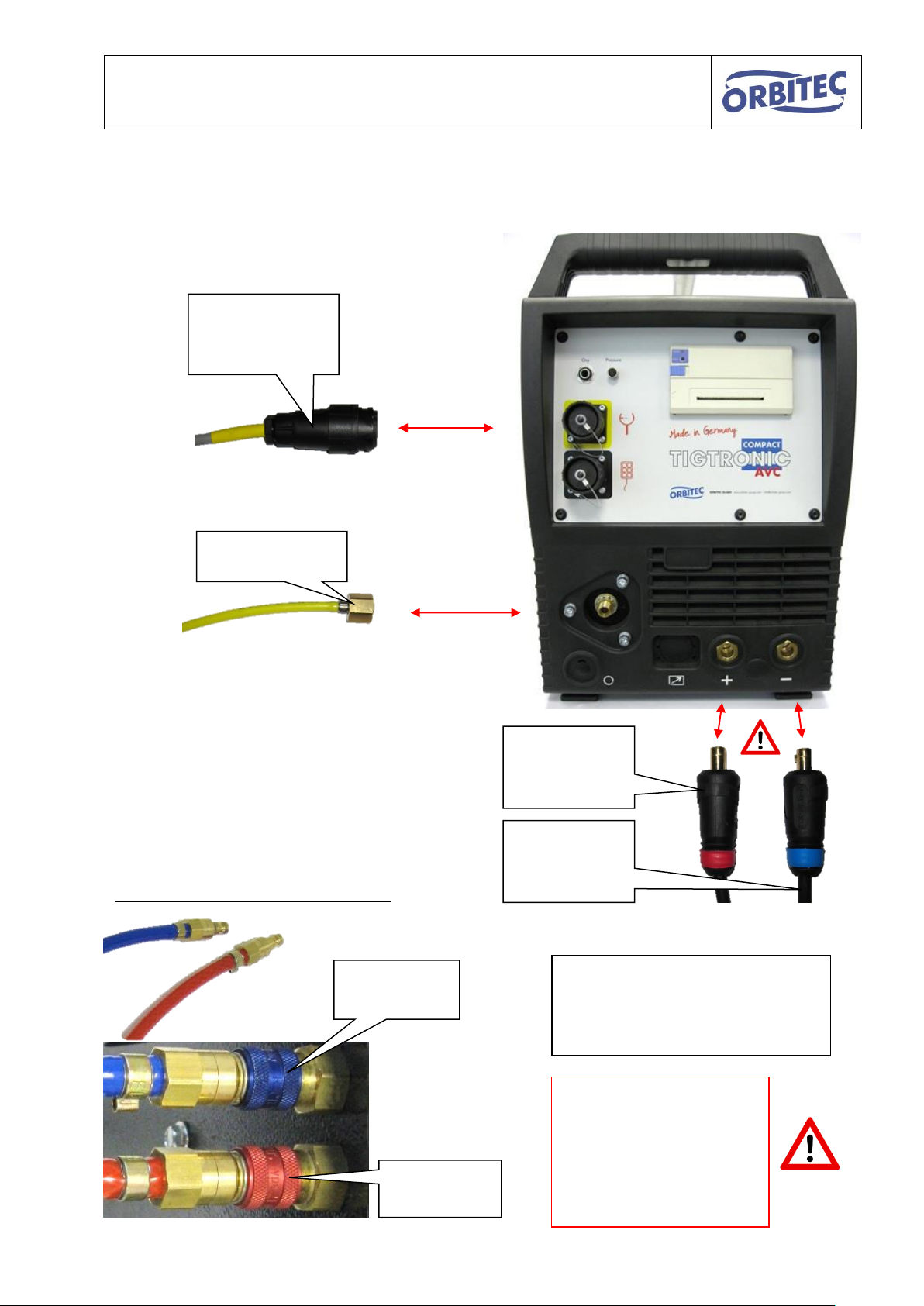

Gas connection

Connection

control

marked yellow

positive pole

(Mass)

marked red

minus pole

(electrode)

marked blue

Additionally in case of water-cooling:

Water flow

blue

Water return

flow red

Please follow the

relevant instructions

regarding the

commissioning, operation

and the safety

precautions

In case of water-cooling, you will

also require the water cooling unit

Cool 50

Item no. 1.2.0118

6. Connection to the inverter / control

10

Operating instructions for OSK series S / G

Rear lock (fixed)

Front lock (flexible)

Collets

Recesses for lock

Lock closed

(for the locking of the

collets)

Lock open

(for the insertion and

removal of the collets)

Recess

inside

Recess

outside

Large recesses to the rear

(fixed lock)

Small recesses to the front

(flexible lock)

7. Instructions

7.1. assembly of the collets

As a rule, one set of collets consisting of four identical individual parts is required. These are

inserted into the clamping shell housing and each are held into place and locked by 2

cylinders.

11

Operating instructions for OSK series S / G

3. Close lock.

1. Insert collet at the rear

2. Insert collet at the front

1.

2.

3.

Open the lock and insert the collets as depicted.

Assemble the remaining three collets in the same way.

12

Loading...

Loading...