Page 1

precision.

power.

simplicity.

Operating

instructions

Tube Squaring Machines

RPG ONE

RPG 1.5

RPG 2.5

Cordless

Electric

Code 790 036 766

Translation of original operating instructions

│ Machine No.:

________________________________

Page 2

All rights reserved, in particular the rights of duplication and distribution as well as translation.

Duplication and reproduction in any form (print, photocopy, microfilm or electronic) require the written

permission of Orbitalum Tools GmbH.

Page 3

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 Table of contents

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc I

Table of contents

Page

0 About these instructions 1

0.1

Warning messages 1

0.2

Other symbols and displays 2

0.3

Abbreviations 2

1

Safety instructions 3

1.1

Intended Use 3

1.2

Safety Regulations 3

1.3

Working with safety in mind 4

1.4

Environmental Protection/Disposal 6

1.5

Further safety regulations 6

2

Design of the product 7

2.1

RPG ONE Electric 7

2.2 RPG ONE Cordless 7

2.3

RPG 1.5 Electric 8

2.4

RPG 1.5 Cordless 8

2.5

RPG 2.5 Electric 9

2.6 RPG 2.5 Cordless 9

2.7

RPG 2.5 (Cordless) tool mounting plate 10

2.8

Accessories 11

2.8.1

Multifunctional tool (MFW) 11

2.8.2

Tool holder (WH) for beveling and squaring 11

2.8.3

Adapter clamping shell 12

2.8.4

Stainless steel clamping shells 12

3

Features and scope of application 13

3.1

Features 13

3.2

Scope of application 14

3.2.1

Application range 14

4

Technical data 14

4.1

Characteristics 14

5

Commissioning 15

5.1

Included with the machine* 15

5.2

Connection requirements 15

5.3

Assembly of the bench stand 15

5.4

Transportation 16

6

Operation 17

6.1

Determining tube dimension 18

6.2

Assembly of multifunctional tool (MFW) and tool holder

(WH) 18

6.2.1

Mount multifunctional tool 18

6.2.2

Assemble tool holder 19

6.3

Setting up and/or replacing clamping shell 20

6.3.1

Remove a clamping shell 20

6.3.2

Inserting a clamping shell 21

6.4

RPG 2.5: Setting up and/or replacing adapter clamping shell 22

Page 4

Table of contents Operating instructions RPG ONE, RPG 1.5, RPG 2.5

II (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.4.1 When is the adapter clamping shell necessary? 22

6.4.2

Removing clamping shell 22

6.4.3

Inserting adapter clamping shell 23

6.5

Clamping the tube 24

6.6

Selecting the speed range 25

6.6.1

Adjusting the speed: RPG Electric 25

6.6.2

Adjusting the speed: RPG Cordless 26

6.7

Processing the tube 27

6.7.1

Turn on the RPG Electric 28

6.7.2

Switching on RPG Cordless 28

6.7.3

Facing, feeds and Adjustments 29

6.7.4

Switching off RPG Electric 29

6.7.5

Switching off RPG Cordless 30

6.8

Processing in restricted environments 30

6.8.1

Change position of drive 30

6.8.2

Change position of body 31

7

Maintenance 32

8

What to do if? 33

8.1

Troubleshooting 33

8.2

Servicing/after-sales service 33

9

EU declaration of conformity 34

9.1 RPG ONE, RPG 1.5, RPG 2.5 34

9.2

RPG ONE Cordless, RPG 1.5 Cordless, RPG 2.5 Cordless 35

Page 5

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 0 About these instructions

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 1

0 About these instructions

For a quick understanding of these instructions and safe operation of the

machine, all the warning messages, notes and symbols used in these

instructions are presented here along with their meaning.

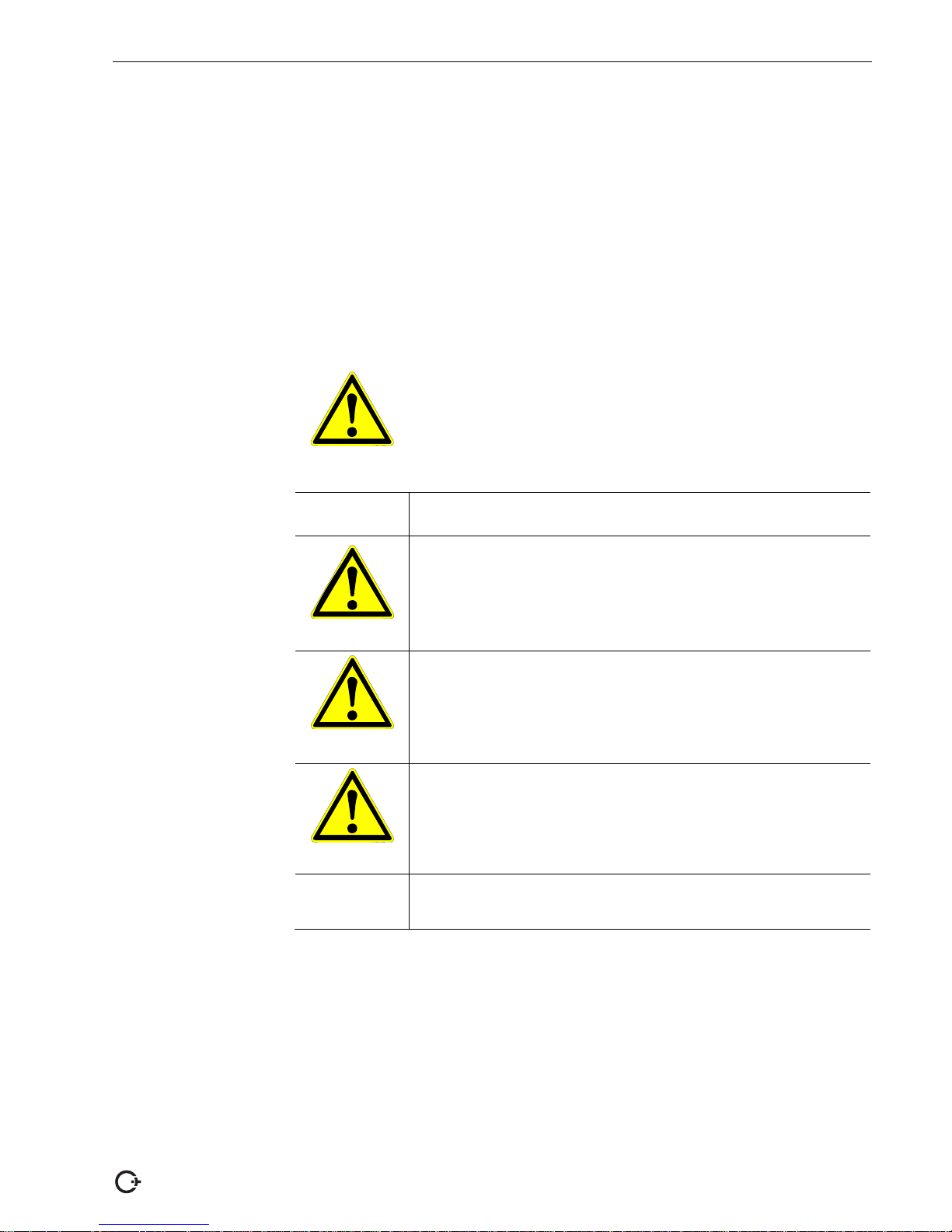

0.1 Warning messages

In these instructions, warning messages are used to warn you about the risks

of bodily injuries or property damage. Please read and observe these warning

messages at all times!

This is a warning symbol. It is designed to warn you against

risks of injury.

Please follow all instructions marked with this safety symbol in

order to avoid injuries or death.

Warning

Symbol

Meaning

DANGER

Direct danger!

Non-observance could result in death or critical injury.

: Restrictions (if applicable).

X Measures to minimize risks.

WARNING

Possible danger!

Non-observance could result in serious injury.

: Restrictions (if applicable).

X Measures to prevent risks.

ATTENTION

Dangerous situation!

Non-observance could result in minor injuries.

ATTENTION

Dangerous situation!

Non-observance could result in material damage.

Page 6

0 About these instructions Operating instructions RPG ONE, RPG 1.5, RPG 2.5

2 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

0.2 Other symbols and displays

Symbol Meaning

Important

Note

Notes: Contain particularly important information to be

understood.

Instruction: You should pay attention to this symbol.

1.

Request for action in a sequence of actions: You need to do

something here.

X

Single request for action: You need to do something here.

Z

Conditional request for action: You need to do something

here if the specified condition is met.

0.3 Abbreviations

Abbr. Meaning

RPG Tube Squaring Machine with electric drive

RPG Cordless Tube Squaring Machine with cordless drive

MFW Multifunctional tool

WH Tool holder

QTC® Quick Tool Change

Page 7

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 1 Safety instructions

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 3

Warning: While using electrical tools, the following safety measures need

to be observed in order to protect against electrical shock, risk of injury

or fire.

Read all these instructions before using this electrical tool, and preserve

the safety instructions carefully.

1 Safety instructions

The Tube Squaring Machine (later called RPG ONE, RPG 1.5 or RPG 2.5

(Cordless)) is built to state-of-the-art technology. Using this machine in a

manner other than that described in this manual can lead to personal injuries to

the user or of third parties. Furthermore, the machine or other objects may by

damaged.

Therefore:

• Always ensure that the machine is in good working order and comply with

these notes on safety.

• Keep complete documents close by the machine.

• Generally recognised procedures for the prevention of accidents should be

observed.

1.1 Intended Use

• Use RPG ONE, RPG 1.5 or RPG 2.5 exclusively as a bench machine for

processing thin-walled stainless-steel or steel tubes and welded micro

fittings.

• Use RPG ONE Cordless, RPG 1.5 Cordless or RPG 2.5 Cordless

exclusively as a mobile machine for processing thin-walled stainless-steel

or steel tubes and welded micro fittings at fixed tubeline systems.

• The user will be the only person liable for damages caused by

improper use.

1.2 Safety Regulations

• Only use the dimensions and materials specified in these instructions.

Other materials should be used only after consulting the Orbitalum Tools

after-sales service.

• Please read through the operating instructions and safety prescriptions

completely, before using the rechargeable battery and charger of the

RPG ONE Cordless, RPG 1.5 Cordless or RPG 2.5 Cordless.

• Only use original Orbitalum Tools spare parts and resources.

• Inspect the RPG ONE, RPG 1.5 or RPG 2.5 daily for visible signs of

damage or defects. Have any damages or defects repaired immediately.

Important

Page 8

1 Safety instructions Operating instructions RPG ONE, RPG 1.5, RPG 2.5

4 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

• Work on the electrical equipment must only be carried out by a qualified

electrician.

• Only operate the RPG ONE, RPG 1.5 or RPG 2.5 if the electrical restart

prevention is working correctly.

• Switch off the machine, allow it to run to a standstill and take out the plug

from the power supply unit or take out the rechargeable battery before any

change of tools, transport, maintenance and repair operations.

1.3 Working with safety in mind

“Make your contribution to safety in the workplace.”

• Report any unusual response from the machine to the person responsible

immediately.

• Be aware of safety aspects at all times during work.

• When working with the RPG, wear protective goggles and safety gloves.

• Tie up long hair (hair-net); do not wear loose-fitting clothes.

Note: Jewellery and ties could get caught in the rotating parts!

• Check that the work piece is correctly clamped.

• After the work process, have the machine switched off and let it run to a

standstill.

• Switch the machine off, allow it to run to a standstill or take out the

rechargeable battery before any change of tools, cleaning, maintenance,

setup and repair operations.

• During operations, keep hands away from the tools.

• Be aware of environmental influences: Do not use electric tools and

rechargeable batteries in a damp or wet environment. Ensure lighting is

adequate. Do not use in close proximity to flammable liquids or gases.

• Do not carry the electric tool by the cable and do not use the electric tool to

pull out the plug. Protect the cable from heat, oil and sharp edges (chips).

• Before and during the processing of tubes, ensure that the viewing window

is closed.

• In order to reduce vibrations, always work with sharp multifunctional tools

(MFW).

Page 9

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 1 Safety instructions

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 5

Danger of being injured by sharp cutting edges

: Do not touch the running tool while the machine is operating.

► Wear safety gloves.

► Tie up long hair (hair-net); do not wear loose-fitting clothes.

► Use the tube squaring machine only when the tube has been clamped.

► No chips or workpiece parts should be removed from the processing area

as long as the machine is running and the tool is not yet at rest.

Danger of eyes and hands being injured by hot and sharp-edged chips

flying around

: Do not touch the running tool while the machine is operating.

► Always wear protective goggles and safety gloves.

► Remove chips only with safety gloves. Remove long and bent chips with

pincers and/or side cutting pliers.

Danger of death by electric shock

If the mains cable is damaged, live parts may cause death if touched directly.

: Do not leave the power cord of the electric motor near the processing area

and/or the tool.

: Do not run the machine unattended.

Danger to life by unintentionally touching the ON/OFF switch

► The machine may only be operated using a fault current (FI) protect switch.

► Allow the machine to run to a standstill and remove the power plug from the

power supply unit or take out the rechargeable battery before any change

of tools, cleaning, maintenance, setup and repair operations.

WARNING

WARNING

DANGER

Page 10

1 Safety instructions Operating instructions RPG ONE, RPG 1.5, RPG 2.5

6 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

1.4 Environmental Protection/Disposal

• Dispose of chips and used gear lubricant oil according to the regulations.

Discarded electric tools and accessories contain a large share of

valuable raw and synthetic materials, which can be recycled. Therefore:

• Electrical (electronic) devices that are marked with the symbol to the left,

may not be disposed of with household waste in accordance with EU

regulations.

• By actively using the offered return and collection systems, you actively

contribute to the reuse, recycling and utilization of electrical (electronic)

devices.

• Electrical (electronic) used devices contain parts, which must be handled

selectively according to EU regulations. Separate collection and selective

treatment is the basis for environment-friendly disposal and the protection

of human health.

• Our appliances and products that were sold to you after August 13, 2005

will be disposed of according to legal standards after they have been

delivered free of cost to us by the customer.

• Taking back old appliances, which pose a risk to human health or safety

due to soiling during their use, may be refused.

• The disposal of old appliances that were placed on the market before

August 13, 2005 is the responsibility of the end user. Please contact a

disposal unit near you for this purpose.

• Important for Germany: our products may not be disposed of in municipal

disposal sites as they are used for industrial purposes only.

• Accumulators and batteries that are marked with the symbol to the left

may not be disposed of with household garbage according to EU directive

91/157/EEA.

• In batteries containing harmful substances, the chemical sign for the heavy

metal contained is indicated below the garbage can: Cd = Cadmium

• For Germany, it holds that: The end user is liable to return defective or

used batteries to the distributor or to a recycling center established for the

purpose.

1.5 Further safety regulations

Observe the regulations, standards and guidelines applicable in your country.

(as per RL 2002/96/EC)

Cd

Page 11

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 2 Design of the product

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 7

2 Design of the product

2.1 RPG ONE Electric

1 Tool recipient/housing 5 Fixing button

2 Viewing window 6 ON-OFF switch

3 Feed with scale divisions 7 Bench stand (removable)

4 Driving motor Metabo 1010 Plus 8 Release handle for fixing the

clamping shells

2.2 RPG ONE Cordless

1 Tool recipient/housing 5 Rechargeable battery

2 Viewing window 6 ON-OFF switch/speed regulator

3 Feed with scale divisions 7 Release handle for fixing the

4 Metabo driving motor clamping shells

1

2

3

4

5

6

7

8

1

7

2

3

6

5

4

Page 12

2 Design of the product Operating instructions RPG ONE, RPG 1.5, RPG 2.5

8 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

2.3 RPG 1.5 Electric

1 Large clamp handle 6 Fixing button

2 Tool recipient/housing 7 ON-OFF switch

3 Viewing window (slidable) 8 Bench stand (removable)

4 Feed with scale divisions 9 Small clamp handles

5 Driving motor Metabo 1010 Plus

2.4 RPG 1.5 Cordless

1 Large clamp handle 5 Rechargeable battery

2 Viewing window (slidable) 6 ON-OFF switch/speed regulator

3 Feed with scale divisions 7 Small clamp handle

4 Metabo driving motor 8 Tool recipient/housing

2

3

4

5

6

7

8

9

1

7

3

6

5

4

1

8

2

Page 13

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 2 Design of the product

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 9

2.5 RPG 2.5 Electric

1 Small clamp handles 8 Driving motor Metabo 1010 Plus

2 Housing 9 ON-OFF switch

3 Viewing window (slidable) 10 Fixing button

4 Feed with scale divisions 11 Clamping shell

5 Gear box unit 12 Tool recipient with tool holder

6 Speed regulator for pre-adjustment and multifunctional tool

(Step 1 + 2, refer to chap. 6.6.1, p. 25) (for description refer to chap. 2.7, p. 10)

7 Speed thumb wheel for fine-tuning 13 Bench stand (removable)

(Steps A – G, refer to chap. 6.6.1, p. 25)

14 Large clamp handle

2.6 RPG 2.5 Cordless

1 Small clamp handles 8 Rechargeable battery

2 Housing 9 ON-OFF switch/speed regulator

3 Viewing window (slidable) 10 Large clamp handle

4 Feed with scale divisions 11 Tool recipient with tool holder

5 Gear box unit and multifunctional tool

6 Speed switch

(for description refer to chap. 2.7, p. 10)

(Step 1 + 2, refer to chap. 6.6.2, p. 26)

12 Clamping shell

7 Metabo driving motor

1 2

3 4

5 6

8 9

10

1

11

13

14

7

12

1

3

5

1

12

2

4

6

7

8

9

10

11

Page 14

2 Design of the product Operating instructions RPG ONE, RPG 1.5, RPG 2.5

10 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

2.7 RPG 2.5 (Cordless) tool mounting plate

The tool mounting plate of the RPG 2.5 (Cordless) offers different tool holder

assembly possibilities, according to type of application:

• Facing (1) of 6.35 - 12.7 mm (¼" - ½")

• Facing (2) of 12.7 - 63.5 mm (½" - 2½")

• Beveling (3), dimension range as per bevel tool

X The tool holder (4) should be assembled in one of the 6 fastening threads

(5) as a function of the above listed processing type and tube outer

diameter.

X The bigger the outer diameter of the tube, the further apart are the

fastening threads selected for the tool holder (see arrows).

X For exact positioning, install the tool holder (4) with a multifunctional tool in

the groove guide (6) and screw it in as a function of the desired processing

type along the groove guide and using the correct fastening thread (5).

X The groove guide (6) is provided with fine lines, so as to facilitate the

positioning of the tool holder (4).

Tool recipient without tool holder Tool recipient with tool holder

Notes

1

2

3

5

4

6

Page 15

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 2 Design of the product

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 11

2.8 Accessories

Please check the outer diameter of the tubes before ordering the clamping

shells. The different standards sometimes involve a special size (particularly

for tubes in accordance with DIN 2430).

2.8.1 Multifunctional tool (MFW)

Supplied as standard. Cutting insert with two cutting edges and highperformance coat of Futura

®

Balinit.

Can be used with all tool holders of the RPG series.

Article Pieces Code

Multifunctional tool MFW-P-2 1

790 038 314

Multifunctional tool MFW-P-2 10

790 038 315

2.8.2 Tool holder (WH) for beveling and squaring

Adjustable tool holder incl. Torx screw. Further tool holder for different bevel

angels on request.

Possible

application

Bevel

angle

Tube OD

RPG ONE (Cordless)

Tube OD

RPG 1.5 (Cordless)

Tube OD

RPG 2.5 (Cordless)

Application range

Squaring Beveling [°] [mm] [inch] [mm] [inch] [mm] [inch]

Standard tool holder WH12-I** x – – 3.0 - 25.4 0.118 - 1.000 3.0 - 63.5 0.118 - 2.500 3.0 - 63.5 0.118 - 2.500

Optional tool holder WH12-I x – – 12.7 - 25.4 0.500 - 1.000 12.7 - 63.5 0.500 - 2.500 12.7 - 63.5 0.500 - 2.500

Optional tool holder WH12-I for

micro fittings*

x – –

– –

3.0 - 21.2 0.118 - 0.835 6.35 - 21.2 0.250 - 0.835

Tool holder WH3-V-30 – x 30° max. 25.4 max. 1.000 max. 35.0 max. 1.378 max. 60.3 max. 2.374

Tool holder WH3-V-35 – x 35° max. 25.4 max. 1.000 max. 34.0 max. 1.339 max. 59.3 max. 2.335

Article Code

Standard tool holder WH12-I**

790 037 152

Optional tool holder WH12-I

790 037 154

Optional tool holder for micro fittings WH12-I*

790 037 156

Tool holder WH3-V-30

790 037 158

Tool holder WH3-V-35

790 037 159

* Only to be used with stainless steel clamping shells for micro fittings.

** Recommended application range with the standard tool holder: 3.0 - 12.7 mm (0.118 - 0.5 inch).

Page 16

2 Design of the product Operating instructions RPG ONE, RPG 1.5, RPG 2.5

12 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

2.8.3 Adapter clamping shell

Supplied as standard with the RPG 2.5 (Cordless). Using this adapter clamping

shell, the clamping shells for the RPG 1.5 can also be set up on RPG 2.5

machines, extending the processing range to min. 6.35 mm (0.250 inch).

Comes with:

• 1 Adapter clamping shell

• 1 long clamping screw

Article Code

Adapter clamping shell

790 030 094

2.8.4 Stainless steel clamping shells

Not supplied as standard.

For deformation-free clamping of tubes. Extremely durable. Ensures precise

mounting of tubes/micro fittings and quick change of clamping shells without

tools. For use on all materials with an OD from 6.0 mm up to 63.5 mm (0.236 -

2.500 inch).

You can find a range of clamping shell dimensions with code numbers in our

current product catalogue.

Page 17

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 3 Features and scope of application

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 13

3 Features and scope of application

3.1 Features

The RPG is designed for facing tube ends/welded micro fittings of metallic

materials and has the following properties:

• Preparation of tube ends for welding conforming to standards

• Tool holding system QTC® (Quick Tool Change):

Fastener for fixing the tool holder to the tool recipient

• Only one multifunctional tool necessary for:

– different tube wall thicknesses (up to 3 mm/0.118 inch)

– different tube materials (exclusively ferrous materials)

• Multifunctional tool:

– non standard tool holders are available on request to the case under

consideration

– tool with multiple cutting edges

– only if necessary, a screw for fastening and fixing the tools

– tool cover TiN

• Cordless drive:

– rotating / removable

– Motor with high performance and small size

– No memory effect

– Single cell monitoring in the cordless pack

– Electronic overload protection with integrated temperature monitor

– Robust cordless packs with capacity display

– Minimal self-discharge

– Environmentally friendly

– AIR COOLED technology for short charging times and a long service

life

• Electric drive:

– twistable/detachable

– speed-controlled electric motor with speed stabilization

– restart protection to prevent the machine from starting in an

uncontrolled

– way after it has been re-connected to the electric mains or after the

– voltage supply has been re-established after a power failure

• Quick change system for clamping shells

• Feed with scale divisions:

– total: 10 mm (0.394 inch)

– per rotation: 9 mm (0.354 inch)

– per graduation mark: 0.1 mm (0.004 inch)

• Simple movable viewing window and/or protection from chips makes clean

work possible

Page 18

4 Technical data Operating instructions RPG ONE, RPG 1.5, RPG 2.5

14 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

3.2 Scope of application

3.2.1 Application range

Machine type RPG ONE (Cordless) RPG 1.5 (Cordless) RPG 2.5 (Cordless)

Tube OD min.-max. [mm] 3.00 - 25.40 3.0 - 38.10 6.35* - 63.50

[inch] 0.118 - 1.000 0.118 - 1.500 0.250* - 2.500

Wall thickness max. [mm] 3.0 3.0 3.0

[inch] 0.118 0.118 0.118

* only with special adapter clamping shells (refer to chap. 2.8.3, p. 12).

• High-alloy steels (stainless steel material no. 1.40... to 1.45...)

• Unalloyed and low-alloy steels

• Aluminum

More upon request.

4 Technical data

4.1 Characteristics

Machine type RPG ONE RPG ONE

Cordless

RPG 1.5 RPG 1.5

Cordless

RPG 2.5 RPG 2.5

Cordless

[mm]

390x200x70 261x255x80 400x350x160 275x255x90 500x300x170 260x300x320

Dimensions (lxhxd)

[inch]

15.35x7.87x2.76 10.28x10.04x3.15 15.75x13.78x6.30 10.83x10.04x3.54 19.69x11.81x6.69 10.24x11.81x12.60

[kg]

4.14 2.88 4.7 3.44 6.6 5.23

Weight (without

accessories)

[lbs]

9.13 6.35 10.36 7.58 14.6 11.8

Versions

230 V. 50/60 Hz EU

110 V. 50/60 Hz EU

120 V. 50/60 Hz US

230 V. 50/60 Hz EU

115 V. 60 Hz US

230 V. 50/60 Hz EU

110 V. 50/60 Hz EU

120 V. 50/60 Hz US

230 V. 50/60 Hz EU

115 V. 60 Hz US

230 V. 50/60 Hz EU

110 V. 50/60 Hz EU

120 V. 50/60 Hz US

230 V. 50/60 Hz EU

115 V. 60 Hz US

Power [W]

1010 – 1010 – 1010 –

Voltage rechargeable

battery

[V]

– 18 – 18 – 18

Speed of the tool [rpm]

145 - 380 0 - 400 145 - 380 0 - 400 1. speed: 9 - 52

2. speed: 27 - 153

1. speed: 0 - 24

2. speed: 0 - 83

Sound pressure level

(EN 23741)

[dB (A)]

approx. 78 approx. 78 approx. 78 approx. 78 approx. 78.2 approx. 78.2

Vibration level (EN 50144) [m/s²]

< 2.5 < 2.5 < 2.5 < 2.5 < 2.5 < 2.5

Tube materials

Page 19

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 5 Commissioning

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 15

5 Commissioning

X Check all parts of the delivery for completeness and damage in

transportation.

X Report any missing parts or transportation damage to your supplier

immediately.

5.1 Included with the machine*

• 1 Tube Squaring Machine RPG ONE, RPG 1.5 or RPG 2.5 (Cordless)

• 1 Durable storage and shipping case

• 2 Rechargeable batteries, 1 battery charger (for cordless versions only)

• 1 Overload protection (square nut 790 037 118)

• 1 Adapter clamping shell (Code 790 030 094, for RPG 2.5 versions only)

• 1 Tool holder WH (Code 790 037 152) with

1 Multifunctional tool MFW (Code 790 038 314)

• 1 Tool set

• 1 Set of operating instructions and spare parts list

* Subject to change

5.2 Connection requirements

The mains supply must meet the following requirements:

• 1-phase alternating current, protection class II:

230 V, 50/60 Hz

110 V, 50/60 Hz

120 V, 50/60 Hz

230 V, 50/60 Hz EU, Cordless: 18 V

115 V, 60 Hz US, Cordless: 18 V

• Mains fuse at least 10 A

5.3 Assembly of the bench stand

The bench stand for RPG ONE, RPG 1.5 and RPG 2.5 Electric needs to be

assembled for commissioning the machine.

X Fasten the bench stand on the machine with a spanner (SW4x150).

Checking the parts

of delivery

Bench stand

Page 20

5 Commissioning Operating instructions RPG ONE, RPG 1.5, RPG 2.5

16 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

5.4 Transportation

Risk of injury due to unintentional activation of the machine

During transportation, the ON/OFF switch (speed regulator) may

unintentionally be activated, please check the machine is switched off before

operating.

X Allow the machine to run to a standstill and remove the power plug from the

power supply unit or take out the replaceable battery before transportation

and/or change of operating environment.

The RPG is a portable machine. Special resources are not required for

transportation (carry the machines as shown in the diagrams to ensure safe

transportation).

RPG ONE Electric and RPG 1.5 Electric RPG ONE Cordless and RPG 1.5 Cordless

RPG 2.5 Electric RPG 2.5 Cordless

DANGER

Page 21

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 17

6 Operation

Risk of injury due to unintentional activation of the machine

X Allow the machine to run to a standstill and remove the power plug from

the power supply unit or take out the replaceable battery before repair,

maintenance, job set-ups, change of tools as well as after the end of an

operation.

Risk of injury due to rotating tool

: Do not touch the tool holder or tool mounting plate whilst processing; keep

loose clothes away from the processing area.

X Run the machine only with a clamped tube and a closed viewing window

(1) (Note: the RPG ONE is not

equipped with a slidable viewing window).

Viewing window open Viewing window closed

DANGER

1

1

Page 22

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

18 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.1 Determining tube dimension

1. Determine the tube dimension to be processed.

2. Select tool holder, multifunctional tool and clamping shells (accessories,

refer to chap. 2.8, p. 11).

Please check the outer diameter of the tubes before ordering the clamping

shells. The different standards sometimes involve a special size (particularly

for tubes in accordance with DIN 2430).

6.2 Assembly of multifunctional tool (MFW) and

tool holder (WH)

Danger of being injured by sharp cutting edges!

: Do not touch the cutting edges while mounting the multifunctional tool.

X Wear protective gloves.

6.2.1 Mount multifunctional tool

X Screw on the multifunctional tool (1) with Torx screwdriver onto the tool

holder (2).

Note

WARNING

2

1

Page 23

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 19

6.2.2 Assemble tool holder

1. Install tool holder (1) with multifunctional tool in the groove guide frontal

from the front and place the processing type and outer diameter of tube

accordingly. RPG 2.5 (Cordless)

: according to the type of application

(beveling/squaring) install the tool holder in one of the 6 fastening threads

as per description in chap. 2.7, p. 10).

2. Tighten screw (2) of the tool holder with the spanner.

RPG ONE and RPG 1.5 (Cordless) RPG 2.5 (Cordless)

The tool holder with the multifunctional tool is now assembled.

1

2

1

2

Page 24

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

20 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.3 Setting up and/or replacing clamping shell

1. Select correct clamping shell according to tube dimension (refer to

chap. 2.8.4, p. 12).

2. Unscrew the clamp handles:

Turn out the release handle (1) (the end of the release handle must be

flush with the inside of the housing).

Unscrew the clamp handle (large handle) (2) (the end of the clamp handle

must be flush with the inside of the housing).

Screw out clamping shell retainers (small handles) (3) till free play is

achieved (the end of the handles must be flush with the inside of the

housing).

RPG ONE (Cordless) RPG 1.5 (Cordless) RPG 2.5 (Cordless)

6.3.1 Remove a clamping shell

X If a clamping shell that has already been assembled needs to be replaced,

it can now be removed by simply pressing on it.

RPG ONE (Cordless):

RPG 1.5 (Cordless),

RPG 2.5 (Cordless):

2

3

3

2

3

1

Page 25

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 21

6.3.2 Inserting a clamping shell

1. Press a little on the clamping shell and install it in the body.

The Orbitalum logo should cover the clamping shell with the point marked in

red on the body (see arrows below).

The clamp shell has been installed correctly, if it is locked in place. If the

clamping shell is not locked, this fact can be rectified by a gentle turn of the

clamping shell.

2. Setting up clamping shells:

Screw in the clamping shell with the release handle (1).

Screw in the clamping shell with the clamping shell retainers (small

handles) (2).

RPG ONE (Cordless) RPG 1.5 (Cordless) RPG 2.5 (Cord less)

The clamping shell has now been set up correctly.

RPG 1.5 (Cordless),

RPG 2.5 (Cordless):

Note

RPG ONE (Cordless):

RPG 1.5 (Cordless),

RPG 2.5 (Cordless):

1

2

2

2

Page 26

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

22 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.4 RPG 2.5: Setting up and/or replacing adapter

clamping shell

6.4.1 When is the adapter clamping shell necessary?

Whenever tubes with an outer diameter of 6.35 - 38.1 mm (0.250" - 1.5") need

to be processed. For further details refer to chap. 2.8.3, p. 12.

1. Select correct clamping shell according to the tube dimension (refer to

chap. 2.8.4, p. 12).

2. Unscrew the clamp handle (large handle) (1) (flush with the body on the

inside, see arrows).

3. Unscrew out the clamping shell retainers (small handles) (2) till free play is

achieved (flush with the body on the inside, see arrows).

RPG 2.5 (Cordless)

6.4.2 Removing clamping shell

X If a clamping shell has already been assembled, it can now be removed by

simply pressing on it.

Adapter clamping shell

1

2

2

Page 27

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 23

6.4.3 Inserting adapter clamping shell

1. Install the adapter clamping shell into the body. The cavity of the clamping

shell should thereby be flush with the cavity of the RPG 2.5-body (see

arrow).

2. Screw in the adapter clamping shell with the clamping shell retainers (small

handles) (2).

3. Press on the clamping shell slightly and install it into the adapter clamping

shell.

The Orbitalum logo should cover the clamping shell with the point marked in

red on the body (see arrows below).

4. Screw in the clamping shell with the clamp handle (large handle) (3).

The clamping shell has been correctly installed, if it is locked in place. If the

clamp shell is not locked, this can be rectified by a gentle turn of the clamp

shell.

The clamping shell has now been installed correctly.

Important

Note

2

2

3

Page 28

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

24 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

Tool breakage

Using the adapter clamping shell could lead to collisions with the tool.

X Take care that there is enough space between the tool and the adapter

clamping shell.

6.5 Clamping the tube

Risk to life due to tilting machine and/or tilting tube

Non-observance could result in death or critical injury.

X Support long tubes with suitable fixtures.

Tool breakage

A multifunctional tool can be damaged by incorrectly setting up the tube.

X Before clamping the tube, take care that there is enough space between

the MFW and the tube.

X Clamp the tube squarely, ensuring that the tube and machine axes are

aligned. If care is not taken, the tube end may not be processed at right

angles.

1. Set up the tube in the clamping shell of RPG or with the use of a

RPG Cordless, guide the machine to the tube and pick it up with the

clamping shell.

2. To clamp the tube tightly, rotate the clamp handle (large handle) (1)

clockwise until stop.

Clamp tube with RPG Electric:

tube to machine

Clamp tube with RPG Cordless:

machine to tube

The tube can be processed now.

ATTENTION

DANGER

ATTENTION

Note

1

1

Page 29

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 25

X To remove the tube from the machine, rotate the clamp handle (large

handle) (1) anti-clockwise up to the stop.

6.6 Selecting the speed range

There are 2 speed levels in the RPG drives.

It is recommended that you work exclusively with speed level 1.

RPG ONE and RPG 1.5: disabled speed level 2 upon delivery.

Type of machine Speed range level 1 [min–1] Speed range level 2 [min–1]

RPG ONE 145 - 380 (disabled)

RPG ONE Cordless 0 - 400 (disabled)

RPG 1.5 145 - 380 (disabled)

RPG 1.5 Cordless 0 - 400 (disabled)

RPG 2.5 9 - 52 27 - 153

RPG 2.5 Cordless 0 - 24 0 - 83

6.6.1 Adjusting the speed: RPG Electric

The chip removal characteristic may be influenced by the speed.

The speed level can be pre-installed using the speed regulator (1) in the

RPG Electric. The outer diameter of the tube can be adjusted precisely using

the thumb wheel (2):

Speed regulator (1) level codes

Tortoise Level 1 9 - 52 min

–1

Hare Level 2 27 - 153 min

–1

Fine-tuning of the thumb wheel speed regulator (2)

RPG ONE RPG 1.5 RPG 2.5

Level

Tube OD

[mm]

Tube OD

[inch]

Level

Tube OD

[mm]

Tube OD

[inch]

Level

Tube OD

[mm]

Tube OD

[inch]

C

3.18 0.125

C

3.18 0.125

G

6.35 0.250

B

6.35 0.250

B

6.35 0.250

D

38.10 1.500

A

12.70 0.500

A

12.70 0.500

C

50.80 2.000

A

25.40 1.000

A

38.10 1.500

B

63.50 2.500

X Increase speed using thumb wheel (2).

X Decrease speed using thumb wheel (2).

Note

Increasing speed

Decreasing speed

Tortoise

level 1

1

2

Hare

level 2

Page 30

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

26 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.6.2 Adjusting the speed: RPG Cordless

The speed-level is pre-installed in the RPG Cordless versions via the speed

switch (1) (speed ranges, refer to chap. 6.6, p. 25) and fine-tuned via the

speed regulator (2).

• The harder the speed regulator (2) is depressed, the higher is the speed.

• Chip removal can be influenced by the speed.

• The processing of tubes can slow down and/or influence the speed, and it

can be controlled with the speed regulator (2).

X Regulate the speed with the speed regulator and/or the ON/OFF switch (2).

X Press the speed regulator (2) further down.

X Release the speed regulator (2).

Notes

Increasing speed

Decreasing speed

2

1

Page 31

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 27

6.7 Processing the tube

Risk of injury by unintentional activation of the machine

X Allow the machine to run to a standstill and remove the power plug from the

power supply unit or take out the replaceable battery before repair,

maintenance, job set-ups, change of tools as well as after the end of an

operation.

Risk of injury by rotating tool recipient

: Do not touch the tool mounting plate while the machine is in operation;

keep loose clothes away from the processing area.

X Only operate the machine with a clamped tube and closed viewing window.

Risk of injury due to hot and sharp-edged chips

X Always wear protective goggles.

X Remove chips only with safety gloves. Remove long and bent chips with

pincers and/or side cutting pliers.

Tool breakage

Excessive feed can damage the cutting tool during the processing.

X Refer to "Troubleshooting", chap. 8.1, p. 33.

X Only drive the rotating tool with limited feed to the tube!

A tube that is not sawn off at right-angles can damage the tool (MFW) if the

distance between the cutting edge and the tube end is too small.

X Before starting the RPG, ensure that there is enough distance between the

cutting edge (MFW) and the tube end.

RPG Cordless:

Excessive feed during the operation

, and the ON/OFF switch still remains

depressed, the operation may be damaged (by overheating).

X Release the ON/OFF switch immediately and separate the machine from

the tube.

If the speed is reduced too quickly whilst operating, the tool may "dig in",

causing damage to the face and the tool, and may cause the machine to stop.

X Always reduce the feed gradually.

WARNING

ATTENTION

Page 32

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

28 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.7.1 Turn on the RPG Electric

1. Check if the viewing window is closed, and close it, if necessary.

2. Set the desired speed via the speed regulator (1).

3. Activate the ON-OFF switch (2).

The machine starts.

If the tool vibrates after starting, the cutting speed is too high.

X Reduce the speed (refer to chap. 6.6.1, p. 25).

6.7.2 Switching on RPG Cordless

1. Check whether the viewing window is closed, and close it, if necessary.

2. Connect battery (1) to RPG Cordless.

3. Activate the ON/OFF switch and/or speed regulator (2).

The machine starts.

Note

1

2

2

1

Page 33

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 29

If the tool vibrates after starting, the cutting speed is too high.

X Reduce speed (refer to chap. 6.6.2, p. 26).

6.7.3 Facing, feeds and Adjustments

• Each division means an insertion of 0.1 mm (0.004 inch).

• Do not exceed clamp thickness of 0.05 mm (0.002 inch) with chip removal.

Excessive feed levels will reduce the speed or even stop the machine (refer

to "Troubleshooting", chap. 8.1, p. 33).

1. Introduce the tool with feed (1) to the tube, until the tool is in contact.

Feed RPG Electric

Feed RPG Cordless

2. When the tool is cutting at the complete face of the tube:

Z continue the tool with the same pressure further, until the desired

processing result is achieved.

Z To achieve the optimum squareness and finish, the tool should be

allowed to rotate for 2-3 revolutions without any feed being applied.

6.7.4 Switching off RPG Electric

1. Release ON-OFF switch (2).

The machine stops.

2. Remove plug from power supply.

3. Remove tube from machine (refer to chap. 6.5, p. 24).

Note

Feed with scale

division (1)

2

1

1

Page 34

6 Operation Operating instructions RPG ONE, RPG 1.5, RPG 2.5

30 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

6.7.5 Switching off RPG Cordless

1. Release ON/OFF switch and/or speed regulator (3).

The machine stops.

2. Remove rechargeable batteries.

3. Remove machine from tube (refer to chap. 6.5, p. 24).

6.8 Processing in restricted environments

To make operation easier, the position of the machine with respect to the tube

can be changed as follows:

6.8.1 Change position of drive

1. Release screw (1) on the reverse of the body.

Screw position of RPG ONE Cordless,

RPG 1.5 Cordless, RPG 2.5 Cordless

Screw position of RPG ONE Electric,

RPG 1.5 Electric, RPG 2.5 Electric

2. Rotate drive to desired position.

3. Install screw (1).

3

1

1

Page 35

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 6 Operation

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 31

6.8.2 Change position of body

Body position changeable only at the RPG 2.5 (Cordless).

1. Fully unscrew headless screw (2) on the reverse of the body.

2. Rotate body to desired position (only possible in 4 x 90° steps).

Pay attention to countersinks in the body.

3. Assemble headless screw (2).

2

Page 36

7 Maintenance Operating instructions RPG ONE, RPG 1.5, RPG 2.5

32 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

7 Maintenance

Risk of injury due to unintended activation of the ON-OFF switch.

X The machine may only be operated using a fault current (FI) protect switch.

X Allow the machine to run to a standstill and take out the plug from the

power supply unit or take out the rechargeable battery before any change

of tools, cleaning, maintenance, setup and repair operations.

Interval Activity

Every time the machine

is cleaned

X Clean clamping shell and body/tool recipient.

Every time the tool

is changed

X Clean tool holder and multifunctional tool.

DANGER

Page 37

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 8 What to do if?

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 33

8 What to do if?

8.1 Troubleshooting

The following table gives you the possible causes while troubleshooting.

Problem Possible cause Remedy

Feed is too big or battery is almost

empty.

X Disassemble tool holder and

take out tube from the machine.

X Remove chip using side cutting

pliers and file off section.

X Introduce carefully during new

processing.

Tool (MFW) is causing a “step”

during facing.

MFW or WH loose.

X Screw in MFW or WH tightly.

Battery completely discharged.

X Charge battery (refer to attached

operating instructions of the

charger).

X Use spare battery.

Rechargeable battery power system

of the RPG Cordless does not work.

Battery not connected to RPG

Cordless.

X Connect battery to RPG

Cordless.

Tool tends to vibrate. Speed too high.

X Reduce speed

(see chap. 6.6, p. 25).

Strong tendency to vibrate.

Axial or radial play in the

components.

MFW loose.

X Check machine for freedom from

play.

X Check MFW on fixed seat.

The processed tube is jagged or has

a burr which is too big.

MFW blunt.

X Replace MFW.

8.2 Servicing/after-sales service

For ordering spare parts, refer to the separate spare parts list.

For troubleshooting, please contact your competent branch office directly.

Please indicate the following details:

• Machine type:

– RPG ONE (Cordless)

– RPG ONE (Electric)

– RPG 1.5 (Cordless)

– RPG 1.5 (Electric)

– RPG 2.5 (Cordless)

– RPG 2.5 (Electric)

• Machine no.: (refer to name plate)

Page 38

9 EU declaration of conformity Operating instructions RPG ONE, RPG 1.5, RPG 2.5

34 (02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc

orbitalum tools gmbh

9 EU declaration of conformity

9.1 RPG ONE, RPG 1.5, RPG 2.5

EG-Konformitätserklärung

Declaration of conformity

Dichiarazione di conformità

Déclaration de conformité

Declaración de conformidad

Orbitalum Tools GmbH

Josef-Schüttler-Straße 17

78224 Singen, Deutschland

Tel.: +49 (0) 77 31 792-0

Fax: +49 (0) 77 31 792-524

According to machine guideline 2006/42/EG (MaschR), Appendix II A

Die Bauart der Maschine:

The following product:

Il seguente prodotto:

Le produit suivant:

El producto siguiente:

RPG ONE Tube Squaring Machine

RPG 1.5 Tube Squaring Machine

RPG 2.5 Tube Squaring Machine

Seriennummer:

Series number:

Numero di serie:

Nombre de série:

Número de serie:

Baujahr / Year / Anno / Année /

Año:

ist entwickelt, konstruiert und gefertigt in Übereinstimmung mit folgenden EG-Richtlinien:

was designed, constructed and manufactured in accordance with the following EC guidelines:

è stata progettato costruito e commercializzato in osservanza delle seguenti Direttive:

a été dessiné, produit et commercialisé selon les Directives suivantes:

ha sido proyectado construido y comercializado bajo observación de las siguientes Directivas:

Maschinen-Richtlinie (2006/42/EG)

EMV-Richtlinie (2004/108/EG)

Niederspannungsrichtlinie (2006/95/EG)

Folgende harmonisierte Normen sind angewandt:

The following harmonized norms have been applied:

Le seguenti norme armonizzate ove applicabili:

Les normes suivantes harmonisées où applicables:

Las siguientes normas armonizadas han sido aplicadas:

DIN EN ISO 12100-1 (2003)

DIN EN ISO 12100-2 (2003)

DIN EN 61029-1 (2003)

DIN EN 1037 (1995)

DIN EN 50144-1 (1998)

DIN EN 55014-1 (2003)

DIN EN 55014-2 (2002)

DIN EN 61000-3-2 (2001)

DIN EN 61000-3-3 (2002)

Singen, 22.01.2010

Markus Tamm

Managing Director

Hasan Caglar

Product Manager

Page 39

Operating instructions RPG ONE, RPG 1.5, RPG 2.5 9 EU declaration of conformity

orbitalum tools gmbh

(02.10) MT_RPG ONE, RPG 1.5, RPG 2.5_BA_04_790036766_00.doc 35

9.2 RPG ONE Cordless, RPG 1.5 Cordless,

RPG 2.5 Cordless

EG-Konformitätserklärung

Declaration of conformity

Dichiarazione di conformità

Déclaration de conformité

Declaración de conformidad

Orbitalum Tools GmbH

Josef-Schüttler-Straße 17

78224 Singen, Deutschland

Tel.: +49 (0) 77 31 792-0

Fax: +49 (0) 77 31 792-524

According to machine guideline 2006/42/EG (MaschR), Appendix II A

Die Bauart der Maschine:

The following product:

Il seguente prodotto:

Le produit suivant:

El producto siguiente:

RPG ONE Cordless Tube Squaring Machine with cordless drive

RPG 1.5 Cordless Tube Squaring Machine with cordless drive

RPG 2.5 Cordless Tube Squaring Machine with cordless drive

Seriennummer:

Series number:

Numero di serie:

Nombre de série:

Número de serie:

Baujahr / Year / Anno / Année /

Año:

ist entwickelt, konstruiert und gefertigt in Übereinstimmung mit folgenden EG-Richtlinien:

was designed, constructed and manufactured in accordance with the following EC guidelines:

è stata progettato costruito e commercializzato in osservanza delle seguenti Direttive:

a été dessiné, produit et commercialisé selon les Directives suivantes:

ha sido proyectado construido y comercializado bajo observación de las siguientes Directivas:

Maschinen-Richtlinie (2006/42/EG)

EMV-Richtlinie (2004/108/EG)

Niederspannungsrichtlinie (2006/95/EG)

Folgende harmonisierte Normen sind angewandt:

The following harmonized norms have been applied:

Le seguenti norme armonizzate ove applicabili:

Les normes suivantes harmonisées où applicables:

Las siguientes normas armonizadas han sido aplicadas:

DIN EN ISO 12100-1 (2003)

DIN EN ISO 12100-2 (2003)

DIN EN 61029-1 (2003)

DIN EN 1037 (1995)

DIN EN 50144-1 (1998)

DIN EN 55014-1 (2003)

DIN EN 55014-2 (2002)

DIN EN 61000-3-2 (2001)

DIN EN 61000-3-3 (2002)

Singen, 22.01.2010

Markus Tamm

Managing Director

Hasan Caglar

Product Manager

Page 40

Orbitalum Tools GmbH

Sales Contact:

Tel. +49 (0) 77 31 / 792-0

Fax +49 (0) 77 31 / 792-524

tools@orbitalum.com

www.orbitalum.com

An ITW Company

Plant:

Division Orbitalum

Josef-Schüttler-Straße 17

78224 Singen

Germany

790 036 766_00/01 (02.10)

© Orbitalum Tools GmbH

D-78224 Singen 2010

Printed in Germany

Loading...

Loading...