Page 1

Operating instructions

For responsible bodies and persons using the machine

Orbital Welding Power Supply

ORBIMAT 180 SW

Machine No.:

Code 850 060 202 | EN | Translation of original o perating instr uctions

To ensure safe working read the operating

instructions before commissioning.

Retain the operating instructions

for future reference.

Page 2

All rights reserved, in particular the rights of duplication and distribution as well as translation. Duplication and reproduction in any form (print, photocopy, microfilm or electronic) require the written permission of Orbitalum Tools GmbH.

Page 3

ORBIMAT 180 SW | Operating instructions

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orbi talum.com, Ph one +49 (0) 77 31 792-0 3

1. About these instructions ......................................5

1.1 Warning messages .....................................5

1.2 Further symbols and displays .....................5

1.3 Abbreviations ............................................5

1.4 Further applicable documents ....................5

2. Information and safety instructions ......................6

2.1 Requirements for the responsible body .......6

2.2 Using the machine .....................................6

2.2.1 Proper use .......................................6

2.2.2 Machine constraints .........................7

2.3 Environmental protection/disposal .............7

2.3.1 Coolant ............................................7

2.3.2 Electric tools and accessories ...........7

2.4 Personnel qualification ..............................7

2.5 Fundamental information on operational

safety ........................................................8

2.6 Personal protective equipment ...................8

2.7 Remaining risks .........................................8

2.7.1 Injury through high weight ...............8

2.7.2 Burns and danger of fire through

high temperatures ...........................9

2.7.3 Tripping over the hose package ........9

2.7.4 Long-lasting physical damage

through wrong posture .....................9

2.7.5 Electric shock ..................................9

2.7.6 Danger through incorrect handling

of pressure tanks ........................... 10

2.7.7 Damage to eyes through radiation .. 10

2.7.8 Dangers through electromagnetic

fields ............................................. 10

2.7.9 Risk of suffocation through an

excessive argon share in the air ...... 11

2.7.10 Health problems ............................11

2.7.11 Danger of system tipping over ........11

2.7.12 Danger of explosion and fire ........... 11

2.7.13 General injuries through tools ........11

3. Description ........................................................12

3.1 ORBIMAT 180 SW .....................................12

3.2 Operating concept ....................................14

3.2.1 Operation via push switches

(softkeys) ......................................14

3.2.2 Operation via touch screen .............14

3.2.3 Operation via rotary knob...............14

3.2.4 Operation via an external

keyboard .......................................15

3.3 Warning signs ..........................................16

4. Scope of application...........................................17

4.1 Accessories .............................................17

4.1.1 ORBICAR W trolley..........................17

4.1.2 ORBICOOL Active ...........................17

4.1.3 ORBITWIN switching unit ................18

4.1.4 ORBmax oxygen meter ................... 18

4.1.5 Remote control with cable ..............18

4.1.6 OCL-30 coolant ............................... 18

4.1.7 ORBIPURGE forming set..................18

4.1.8 Paper rolls and ribbon cartridges ...18

5. Technical specifications .....................................19

6. Storage and transport ........................................20

6.1 Gross weight ............................................20

6.2 Preparing storage ....................................20

6.2.1 Removing the weld head from the

orbital welding power supply ..........20

6.2.2 Pumping out coolant ......................20

7. Commissioning ..................................................23

7.1 Scope of delivery .....................................23

7.2 Checking the scope of delivery .................23

7.3 Accessories (optionally available) .............23

7.4 Connecting the welding power supply .......24

7.4.1 Setting up machine ........................24

7.4.2 Connecting a gas bottle .................24

7.4.3 Connecting weld heads ..................25

7.4.4 Detaching coolant hoses ................25

7.4.5 Pumping out coolant ......................25

7.4.6 Closing off gas hose .......................25

7.5 Commissioning ........................................25

7.5.1 Topping up coolant .........................26

7.5.2 Connecting Remote control/dummy

plug ...............................................26

7.5.3 Switching on the power source .......27

7.5.4 Setting the language ......................28

7.5.5 Setting the measuring units ...........28

8. Operation ..........................................................29

8.1 Auto programming ...................................29

8.1.1 Setting parameters ........................29

8.1.2 Configuring weld head ...................29

8.1.3 Configuring material ......................30

8.1.4 Configuring protective gas .............30

8.1.5 Configuring pipe diameter ..............31

8.1.6 Configuring wall thickness .............31

8.1.7 Configuring wire feed .....................31

8.1.8 Calculating procedure ....................31

8.2 Testing the procedure ...............................32

8.2.1 Preparing weld head ......................32

8.2.2 Preparing electrode .......................32

8.2.3 Turning weld head ..........................32

8.2.4 Connecting forming gas .................34

8.2.5 Welding .........................................34

8.2.6 Interrupting the welding process ....36

8.3 Adjusting the procedure ...........................37

8.3.1 Reasons and steps for adjusting

procedure ......................................37

8.3.2 Making percental changes ..............37

TABLE OF CONTENTS

Page 4

ORBIMAT 180 SW | Operating instructions

4

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

8.3.3 Adjusting individual parameters .....38

8.3.4 Digital gas management.................38

8.3.5 Adjusting gas times .......................38

8.3.6 Adjusting ignition current, final

current and current slope-off ..........39

8.3.7 Adjusting the pool formation time ..39

8.3.8 Adjusting welding current and

transition times ("Slope") .............. 40

8.3.9 Adjusting pulse times ....................41

8.3.10 Adjusting weld speed and

transition time ("Slope") ................42

8.3.11 Changing the sector ...................... 44

8.4 Saving and calling up a procedure ........... 46

8.4.1 Saving a procedure ....................... 46

8.4.2 Calling up a procedure .................. 46

8.5 Locking machine with a login .................... 47

8.6 Tacking function ...................................... 48

8.7 Using the second gas pressure level

("Flow Force") ..........................................49

8.8 Connecting supplementary devices ..........51

8.8.1 ORB Residual Oxygen Meter ........... 51

8.8.2 Connecting and configuring the

BUP control unit ............................. 51

8.8.3 TIG manual welding torch ...............51

8.8.4 External remote control .................. 53

8.8.5 External printer (A4) .......................53

8.8.6 External monitor /HDMI ................. 53

8.9 Monitoring functions ................................ 53

8.9.1 General information ....................... 53

8.9.2 Adjusting limit values .....................54

8.10 Data documentation and data

management ............................................55

8.10.1 Managing data ............................... 55

8.10.2 Entering comments and application

data ("Process details") .................57

8.10.3 Working using USB ........................58

8.10.4 Viewing and printing data ..............59

8.10.5 Editing data on a PC with the

"OrbiProgCA" supplementary

software ....................................... 60

8.11 Updating and backup functions for the

software ................................................. 60

8.12 Updating software components ................ 61

8.13 Saving software components ...................61

8.14 Restoring software components ...............61

8.15 Working in other languages ...................... 61

8.15.1 Changing the language ..................61

8.15.2 Printing data in another language ...62

8.15.3 Creating a new operating

language .......................................62

8.16 Importing programs from other

Orbitalum power sources .........................62

8.16.1 Impor ting procedures ..................... 63

8.17 Special keyboard commands ....................63

8.18 Operation of the system with other mains

voltages ...................................................63

9. Service and troubleshooting .............................. 64

9.1 Performing service work .......................... 64

9.1.1 Pumping out coolant ..................... 64

9.1.2 Performing motor calibration ......... 64

9.1.3 Adjusting an external printer ......... 66

9.1.4 Switching on an internal printer ..... 66

9.1.5 Printing a test page ........................67

9.1.6 Service screen ...............................67

9.1.7 Info............................................... 68

9.2 Possible application/operating errors ...... 68

9.2.1 Uneven weld seam ("current

fluctuations") ............................... 68

9.2.2 Annealing colors inside/outside .... 68

9.2.3 Wide seam and no weld

penetration .................................... 69

9.2.4 Uneven seam/hole formation at

the end of welding .........................69

9.2.5 Ignition problems ...........................70

9.2.6 Machine does not start ..................70

9.3 List of error messages ..............................71

9.4 Status LED indicators ...............................75

9.5 Temporarily deactivating sensors and

monitoring functions ................................ 75

9.5.1 Sensors .........................................75

9.5.2 Monitoring limits ...........................75

9.5.3 External input for aborting .............75

9.6 Setting the date and time ......................... 76

10. Maintenance and troubleshooting ......................77

10.1 Instructions for care .................................77

10.2 Maintenance and care ..............................77

10.2.1 Storage..........................................78

10.3 Servicing/Customer service ......................78

11. EC Declaration of Conformity ....................79

Page 5

ORBIMAT 180 SW | Operating instructions About these instructions

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orbi talum.com, Ph one +49 (0) 77 31 792-0 5

1. ABOUT THESE INSTRUCTIONS

1.1 Warning messages

The warning messages used in these instructions warn you of injuries or damage to property.

Always read and observe these warning messages!

This is the warning symbol. It should warn you against dangers of injury. In order to avoid injuries or

death observe the measures marked with a safety sign.

WARNING LEVEL MEANING

DANGER!

Imminently hazardous situation that results in death or serious injuries if the safety measures are

not observed.

WARNING!

Potentially hazardous situation that may result in death or serious injuries if the safety measures

are not observed.

CAUTION!

Potentially hazardous situation that may result in slight injuries if the safety measures are not

observed.

NOTE! Potentially hazardous situation that may result in material damage if the safety measures are not

observed.

1.2 Further symbols and displays

SYMBOL MEANING

Important information for comprehension.

1.

2.

3.

...

Request for action in a sequence of actions: Action is required here.

Single request for action: Action is required here.

1.3 Abbreviations

ABBREVIATION MEANING

OM, SW ORBIMAT, Type "SmartWelder"

1.4 Further applicable documents

The following documents apply together with these operating instructions:

• Operating instructions of the orbital weld head

Page 6

Information and safety instructions ORBIMAT 180 SW | Operating instructions

6

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

2. INFORMATION AND SAFETY INSTRUCTIONS

2.1 Requirements for the responsible body

Workshop/outdoor/field use: The responsible body is responsible for safety in the danger zone around the machine, and

should allow only qualified personnel to enter the zone or operate the machine in the danger zone.

Employee safety: The operator has to observe the safety regulations described in this chapter as well as has to work

safety-consciously and with all prescribed safety equipment.

The employer undertakes to give the employees clear notice of the dangers arising that are specified in the EMF directives and to evaluate the workplace correspondingly.

Requirements for special EMF evaluations with regard to general activities, working materials and workplaces*:

TYPE OF WORKING MATERIALS OR

WORKPLACE

EVALUATION REQUIRED FOR:

Employees without

particular risk

Employees at particular

risk (with the exception

of those with active im-

plants)

Employees with active

implants

(1) (2) (3)

Arc welding, manual (including MIG (Metal

Inert Gas), MAG (Metal Active Gas), TIG (Tungsten Inert Gas)) under observance of triedand-tested procedures and without physical

contact to the line

No No Yes

* According to Directive 2013/35/EU

2.2 Using the machine

2.2.1 Proper use

The orbital welding power supply is intended solely for the following utilization:

• Utilization in combination with an orbital weld head of the company Orbitalum Tools GmbH or with

a compatible third-part device in combination with a weld head adapter of the company Orbitalum

Tools GmbH.

• TIG welding of materials that are specified in these operating instructions (see chap. 4, p. 17).

• Empty unpressurized tubes that are free of contaminations, explosive atmospheres or liquids.

Intended use also includes the following points:

• Permanent supervision of the machine during operation. The operator must always be able to stop the process.

• Observing all safety instructions and warning messages in these operating instructions.

• Observing of the further applicable documents.

• Complying with all inspection and maintenance work.

• Use of the machine solely in its original state.

• Usage solely of original accessories as well as original spare parts and operating materials.

• Usage solely of protective gases that are classified for TIG welding process in accordance with EN ISO 14175.

• Usage solely of coolant OCL-30 of the company Orbitalum Tools GmbH.

• Checking of all the safety-relevant items and functions before commissioning.

• Processing of those materials named in the operating instructions.

Page 7

ORBIMAT 180 SW | Operating instructions Information and safety instructions

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orbi talum.com, Ph one +49 (0) 77 31 792-0 7

• Purpose usage of all components involved in the welding processes as well as of all further factors that have an

influence on the welding process.

• Solely commercial usage.

2.2.2 Machine constraints

• The workplace can be in the tube preparation, in plant construction or in the plant itself.

• The machine is operated by one person.

• Erect the machine solely on a solid surface.

• A radial space requirement/freedom of movement of approx. 2 m around the machine is required for people.

• Work lighting: min. 300 Lux.

• Climate conditions: –10 °C to 40 °C; < 80% rel. humidity.

• Only work with the machine in dry surroundings (not in misty, rainy or stormy conditions). If appropriate use a welding tent.

• Cooling is only ensured with a full coolant tank.

2.3 Environmental protection/disposal

2.3.1 Coolant

Dispose of coolant in accordance with the local statutory regulations.

2.3.2 Electric tools and accessories

Used-up power tools and accessories contain a large amount of valuable raw materials and plastics which can be recycled.

(as per RL 20 02/96/EC)

• Used electronic devices marked with the adjacent symbol may not be disposed of with household waste in accordance with EU directives.

• By actively using the offered return and collection systems, you are doing your part to reuse and recycle used electronic devices.

• Used electronic devices contain parts that must be handled selectively according to the EU directive. Separate

collection and selective treatment are the basis for environmentally responsible disposal and protection of human

health.

• We will properly dispose of devices and machines from Orbitalum Tools GmbH purchased after August 13th, 2005

if they are sent to us postage-paid.

• In the case of used electronic devices which may represent a risk to human health or safety due to contamination

during use, we have the option of refusing return.

• The user is responsible for disposing of used electronic devices purchased before August 13th, 2005. Bitte wenden

Sie sich hierfür an einen Entsorgungsfachbetrieb in Ihrer Nähe.

• Important for Germany: Devices and machines of Orbitalum Tools GmbH may not be disposed of at communal

dumps, as they are only used in the commercial sector.

2.4 Personnel qualification

CAUTION!

The orbital welding power supply may only be used by instructed personnel.

• Minimum age: 18 years old.

• No physical impairments.

• Operation of the machine by underage persons only under supervision by a person authorized to issue instructions.

• A basic knowledge of TIG welding process is advisable.

Page 8

Information and safety instructions ORBIMAT 180 SW | Operating instructions

8

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

2.5 Fundamental information on operational safety

CAUTION!

Observe valid safety and accident prevention regulations.

Improper usage can impair safety. This can result in life-threatening injuries.

X Never leave an welding power supply unattended when it is switched on.

X The operator has to ensure that no 2nd person is inside the danger zone.

X Do not modify or convert the orbital welding power supply.

X Use the orbital welding power supply only in proper operating order.

X Use only genuine tools, spare parts and accessories as well as specified operating materials.

X In case of changes in the operating behavior stop operation immediately and have the fault eliminated.

X Do not remove safety devices.

X In order to increase safety a customer-provided SPE-PRCD or a universal-current residual-current circuit-breaker 30

mA or an isolating transformer between the mains network and the welding power supply is required.

X Do not pull the machine at the hose package or the cable.

X Repair and maintenance work on the electrical equipment may only be carried out by a qualified electrician.

X Do not carry the machine by the hose package or the cable and do not use the machine to pull out the plug (except

in an emergency). Protect the cable against heat, oil and sharp edges (chips).

2.6 Personal protective equipment

The sole act of operating the welding power supply does not require personal protective equipment:

X When connecting and using a weld head observe the respective safety instructions and warning messages of the

weld head.

X Observe the remaining risks.

2.7 Remaining risks

2.7.1 Injury through high weight

The orbital welding power supply has a weight of 28 kg (61.73 lbs). A significant health hazard exists during lifting.

Danger of impact and crushing exists in the following situations:

CAUTION!

Falling of the orbital welding power supply during transportation or setting up.

CAUTION!

Falling of the orbital welding power supply caused by it being put down improperly.

X Use a suitable transport medium to transport the orbital welding power supply.

X Always use 2 persons to lift and remove the orbital welding power supply from the packaging.

X When lifting the machine do not exceed the permissible total weight of 25 kg for men and 15 kg for women.

X Place the orbital welding power supply on a stable base.

X Wear safety shoes.

Page 9

ORBIMAT 180 SW | Operating instructions Information and safety instructions

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orbi talum.com, Ph one +49 (0) 77 31 792-0 9

2.7.2 Burns and danger of fire through high temperatures

CAUTION!

The orbital weld head is hot after welding. Very high temperatures arise in particular after several

consecutive welding processes. There is a danger of burns or damage to the points of contact when

working on the orbital weld head (for example when changing clamps or mounting/removing the electrodes). Materials without thermal resistance (for example foam inlay of the transport packages) can

be damaged when coming into contact with the hot orbital weld head.

X Wear safety gloves.

X Wait until the surfaces have cooled down to below 50 °C before working on the orbital weld head or before packing

into the transport packaging.

WARNING!

Thermal problems can arise in the case of incorrect positioning of the forming system or the use of

impermissible materials in the welding area. In the worst case a fire will be started. Observe the

local general fire protection measures.

X Position the forming system correctly.

X Use only permissible materials in the welding area.

WARNING!

Danger of scalding through hot emitted liquids as well as hot plug connections during heavy operation.

X Heed the safety precautions of the technical supervisor/person in charge of safety.

2.7.3 Tripping over the hose package

CAUTION!

If a hose package is connected, there is the danger that persons may trip over it and be injured.

WARNING!

Tripping over could cause the plug to be pulled out so that in the worst case an arc may arise between

the plug and the orbital weld system. Burns and glaring light may be the result.

X Ensure that under no circumstances can people trip over the hose package.

X Do not place the hose package under tension.

X Ensure that the hose package is connected properly and that the strain relief is attached.

2.7.4 Long-lasting physical damage through wrong posture

X Use the machine so that an upright and comfortable body position can be achieved during operation.

2.7.5 Electric shock

WARNING!

The danger exists of unintentionally operating the ignition function when connecting or disconnecting a weld head from the welding power supply.

X Switch off the orbital welding power supply when connecting or disconnecting a weld head.

X Do not play with weld head.

X If the weld head is not ready for operation, switch it to the "Test" function.

WARNING!

Electrical hazards through contact.

Page 10

Information and safety instructions ORBIMAT 180 SW | Operating instructions

10

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

X Do not touch energized parts (workpieces), especially when igniting the arc.

X From the start of the welding process avoid contact with the tube and the housing of the orbital weld head.

X Wear dry safety shoes, dry metal-free (grommet-free) leather gloves and dry safety suits to minimize the electrical

hazard.

X Work on a dry surface.

DANGER!

Risk of death for people with heart problems or cardiac pacemakers.

X Do not allow persons with increased sensitivity to electrical hazards (e.g. weakness of the heart) to work with the

machine.

DANGER!

Danger of an electric shock in the case of improper reaching in into and opening of the machine.

X Allow only a professional electrician to access the electrical system.

DANGER!

The danger of an electric shock exists through non-compatible or damaged connectors.

X Do not use adapter plugs together with protectively grounded power tools.

X Ensure that the connecting plugs of the machine fit into the outlet.

X When connecting use a residual-current circuit breaker 30 mA.

2.7.6 Danger through incorrect handling of pressure tanks

WARNING!

Various injuries and damage to property.

X Heed safety regulations for pressure tanks.

X Heed safety data sheets for pressure tanks.

2.7.7 Damage to eyes through radiation

WARNING!

During the welding process infrared, glaring and ultraviolet rays arise that can seriously damage

the eyes.

X Keep the flip cover and swivel clamp closed during the welding process.

X During operation, wear eye protection to EN 170 and skin-covering safety clothing.

X At closed weld heads ensure proper working order of the eye protection.

2.7.8 Dangers through electromagnetic fields

DANGER!

Depending on the form of the workplace life-threatening electromagnetic fields can arise in the direct

vicinity.

X People with heart problems or cardiac pacemakers may not operate the welding system.

X The operator has to ensure safe design of the workplace in accordance with the EMF Directive 2013/35/EU.

X Use only electrical devices with protective insulation in the working area of the welding system.

X Observe electromagnetically-sensitive devices when igniting the system.

Page 11

ORBIMAT 180 SW | Operating instructions Information and safety instructions

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gm bH, D-78224 Sin gen, www.or bitalum.com , Phone +49 (0) 77 31 792-0 11

2.7.9 Risk of suffocation through an excessive argon share in the air

DANGER!

If the argon share in the air rises above 50%, lasting damage or risk of death can arise suffocation.

X Ensure sufficient ventilation in rooms.

X If necessary, monitor the oxygen level in the air.

2.7.10 Health problems

WARNING!

Poisonous vapors and substances during the welding process and handling of the electrodes!

X Use extraction devices in accordance with the professional association regulations (e.g. BGI: 7006-1).

X Extra caution is required with chrome, nickel and manganese.

X Do not use electrodes containing thorium.

2.7.11 Danger of system tipping over

WARNING!

Manifold injuries and damage to property through system (for example ORBICAR welding carriage,

gas bottle, welding power supply, cooling unit) tipping over from the application of force from outside!

X Set up the machine so that it stands securely against external influences.

X Keep moving masses at least 1 meter away from the machine.

2.7.12 Danger of explosion and fire

DANGER!

Danger of explosion and fire through flammable materials near the welding zone or solvent in the

room air.

X Do not weld near solvents (for example where painting is being carried out) or explosive substances.

X Do not use flammable substances as a base in the welding area.

X Ensure that no flammable materials or soiling is located near the machine.

2.7.13 General injuries through tools

CAUTION!

Injuries can occur during dismantling for the proper disposal of the orbital welding power supply

through uncertainties in handling tools.

X In case of uncertainties send the orbital welding power supply to Orbitalum Tools – proper disposal is carried out

here.

Page 12

Description ORBIMAT 180 SW | Operating instructions

12

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.0 9.18) OW_OR BIMAT_180SW_ BA_850 060202_00_ EN

3. DESCRIPTION

3.1 ORBIMAT 180 SW

1

4

2

5

6

7

8 9 10 11 12 13 14 15 16 17 18 19

20

3

26

27

31

32

2524

28

29

30

21 2322

33

34

Page 13

ORBIMAT 180 SW | Operating instructions Description

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbi talum.com, Pho ne +49 (0) 77 31 792-0 13

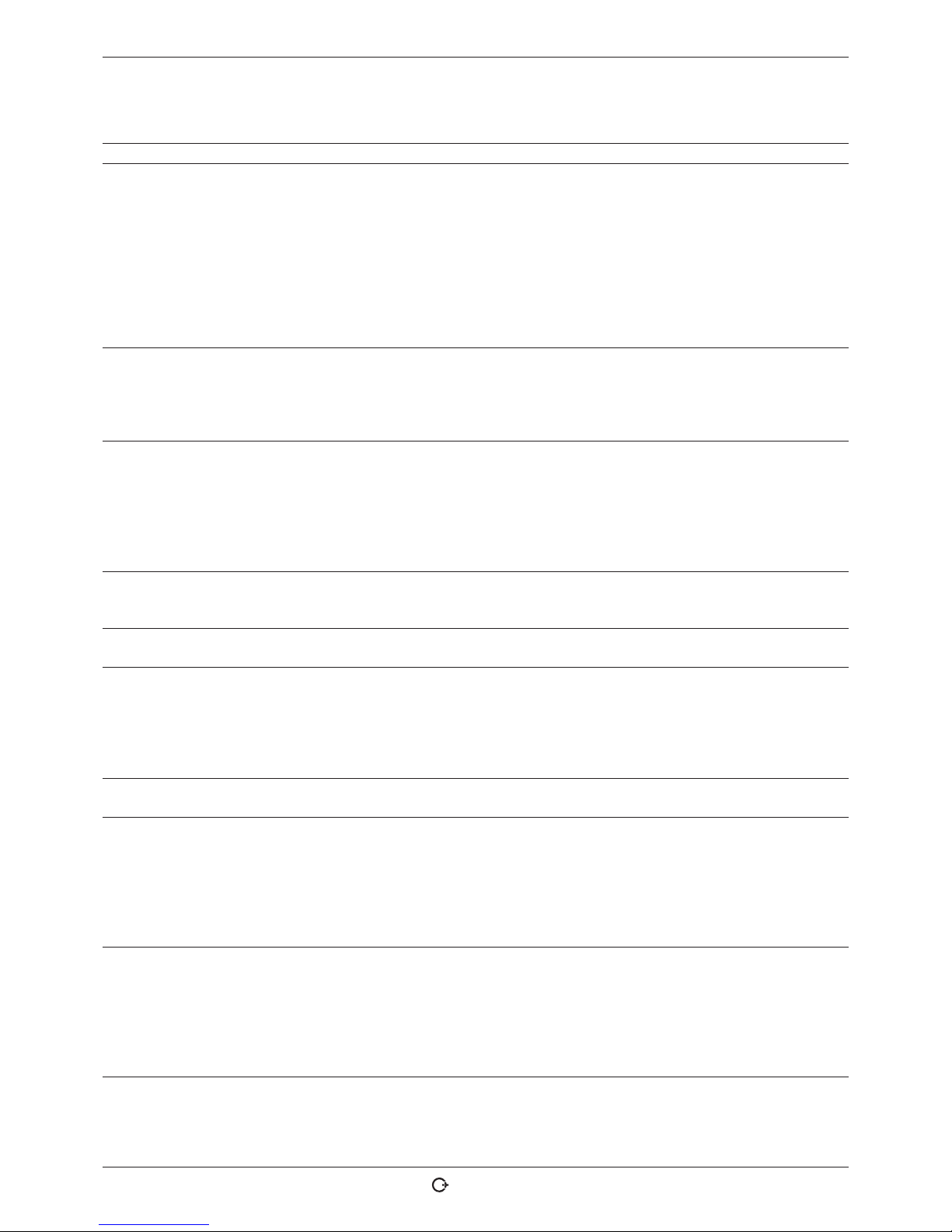

ITEM DESIGNATION FUNCTION

1 Color touch display Operating the welding power supply, see chap. 3.2, p. 14

2 Push switches (softkeys) Operating the welding power supply, see chap. 3.2, p. 14

3 Cover, hinged Protects the operating elements

4 Connection socket, "USB", front Connection possibility for USB devices (2x) (optional)

5 Integrated system printer For printing actual values and welding data reports

6 Rotary knob Operating the welding power supply, see chap. 3.2, p. 14

7 Carry handles Transporting the welding power supply

8 Main switch (green) Switch on the welding power supply; lights up green during operation

9 Off button (red) Switch off the welding power supply; lights up red during operation and

in "Stand-by" mode

10 Connection socket "BUP" Connection possibility for "BUP Control Box", forming gas pressure con-

troller (optional)

11 Connection socket "ORBmax" Connection possibility for "ORBmax", residual oxygen meter (optional)

12 Connection socket "Remote" Connection for remote external control (optional) or dummy plug

13 Connection socket "Weld head" Connection for weld head signal line

14 Connection socket "Gas" Connection for gas hose to the weld head

15 Coolant connection, blue Connection for coolant supply line

16 Eye, strain relief Strain relief weld head to the power source

17 Coolant connection, red Connection for coolant return line

18 Weld current socket Connection weld head

19 Weld current connection Connection weld head

20 Ventilation slot Venting the welding power supply

21 Connection socket "LAN", rear Connection possibility for LAN cable

22 Connection socket "USB", rear Connection possibility for USB devices (2x) – see Item 4

23 Connection socket "HDMI", rear Connection possibility for HDMI cable

24 Coolant level indication Indicates the fill level of the coolant in the tank

25 Tank opening with lid Holding of up to 2.2 liter coolant for cooling the connected weld tongs

and heads

26 Rating plate Indication of the machine data

27 Gas connection Weld gas input

28 Connection socket "External cooling" Connection of external cooling unit signal line

29 Connection socket "ORBITWIN" Connection for ORBITWIN Switching Unit

30 Power input socket Connection for power line

31 Connection socket Connection possibility superordinate control system

32 Connection socket Connection possibility CAN-compatible components

33 Surface for keyboard The optionally available keyboard can be placed before the softkeys.

34 LED display Display of operating states and coolant flow

Page 14

Description ORBIMAT 180 SW | Operating instructions

14

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17. 09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

3.2 Operating concept

The main control elements are the 6 push switches, whose current function assignment is displayed at the bottom margin of the display, the touch screen and the rotary knob. Direct access to standard functions (e.g. "Start" and "STOP")

is always possible. The entry of text is optionally possible using a keyboard that can be connected externally. If faults

occur (e.g. failure of the rotary knob or softkeys), the machine can be operated completely using the external keyboard.

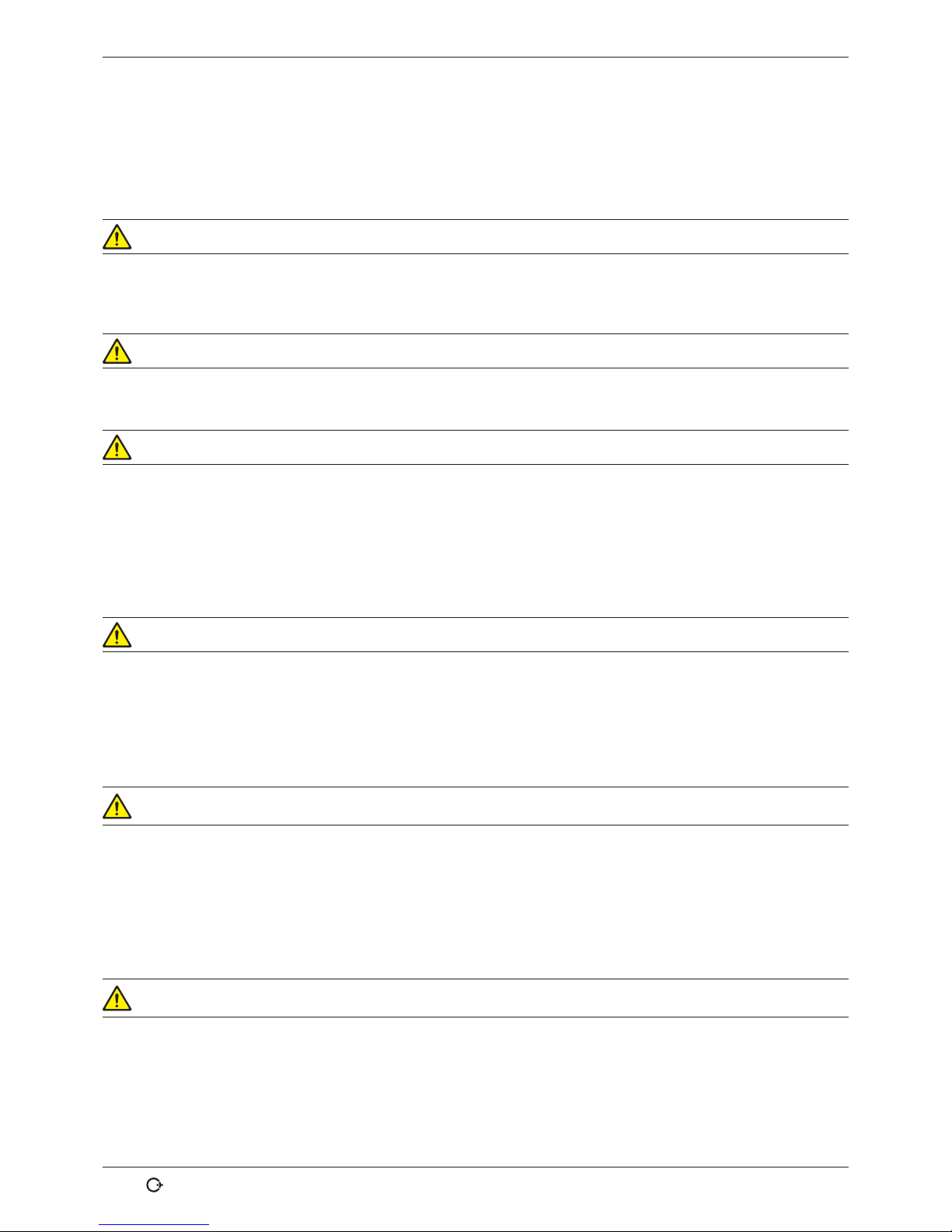

3.2.1 Operation via push switches (softkeys)

The five push switches (Items 1 - 6) are assigned with

standard functions as softkeys.

Examples:

The push switch (Item 6) is usually assigned the "Menu"

function, meaning pressing it brings you directly to the

main menu, regardless of which sub-menu currently appears in the display. The push switch

(Item 3) is assigned the "Save" function. This allows a procedure change to be saved rapidly.

1

2

3

4

5

6

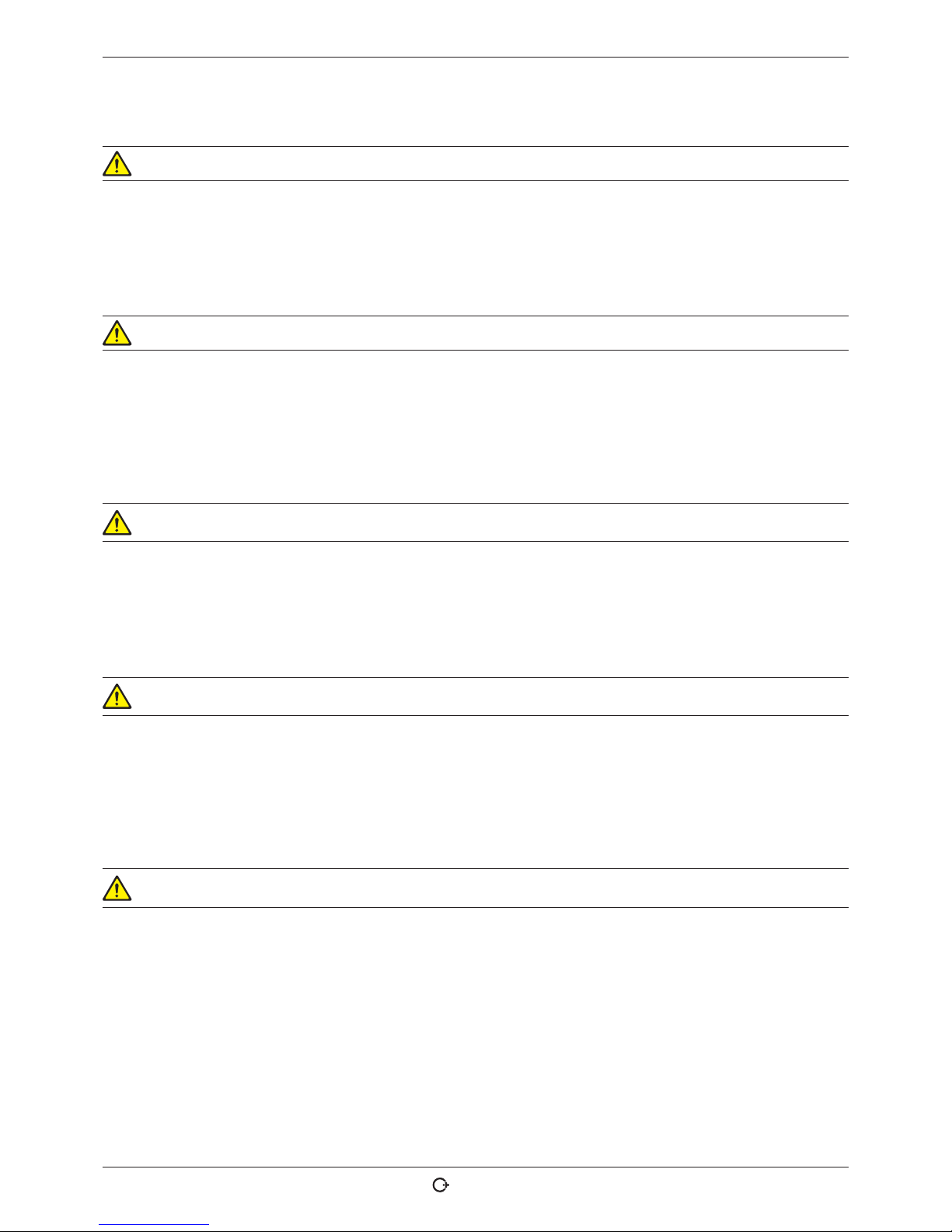

3.2.2 Operation via touch screen

Rapid and efficient operation via touch screen. Directly

touch the values to be changed. A virtual keyboard is

displayed. Operation while wearing protective gloves only

possible to a limited extent and not recommended.

7

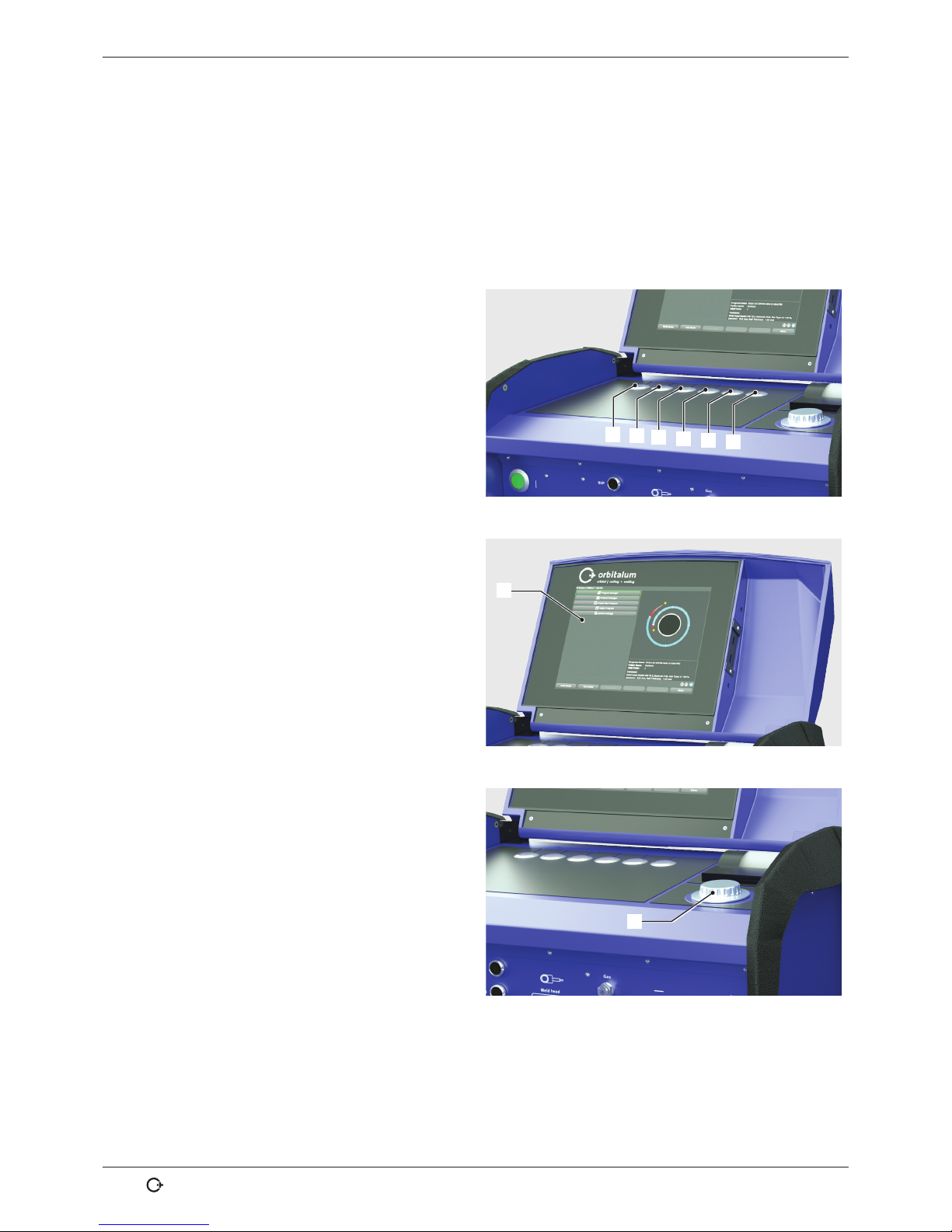

3.2.3 Operation via rotary knob

The rotary knob (Item 8) has either a fine or rough detent

when being turned, depending on whether you are

navigating between menu items/fields (rough detent) or

setting parameter values (for example weld current) (fine

detent).

Navigating to a menu item/field in the display:

X Turn the rotary knob.

The menu item/field appears in blue.

8

Page 15

ORBIMAT 180 SW | Operating instructions Description

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orb italum.com, P hone +49 (0) 77 31 792-0 15

Select the menu item/field:

X Briefly press the rotary knob. The menu item is selected.

Exiting the menu and navigating to the next-higher menu level:

X Press the rotary knob long (> 2 seconds). The menu of the next-higher level appears in the display.

Setting a parameter/Entering a value:

X Highlight a field. The field appears in red.

X Change the value within the specified limit values: Turn the rotary knob.

X Saving the value and exiting the field: Briefly press the rotary knob.

3.2.4 Operation via an external keyboard

Navigating to a menu item/field in the display:

X Press the UP and DOWN arrow buttons.

Selecting the menu item/field:

X Press the ENTER key.

Setting a parameter/Entering a value:

X Highlight a field. The field appears in red.

X Entering a value: Change with the arrow buttons or enter directly with the number keys.

X Saving the value and exiting the field: Press the ENTER key.

Entering comments on procedures:

X Select a comment field.

X Enter the text using the keyboard.

Using push switches (softkeys) on the keyboard:

Function keys F1 through F6 on the external keyboard correspond to push switches 1 through 6.

Page 16

Description ORBIMAT 180 SW | Operating instructions

16

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_OR BIMAT_180SW_ BA_850 060202_00 _EN

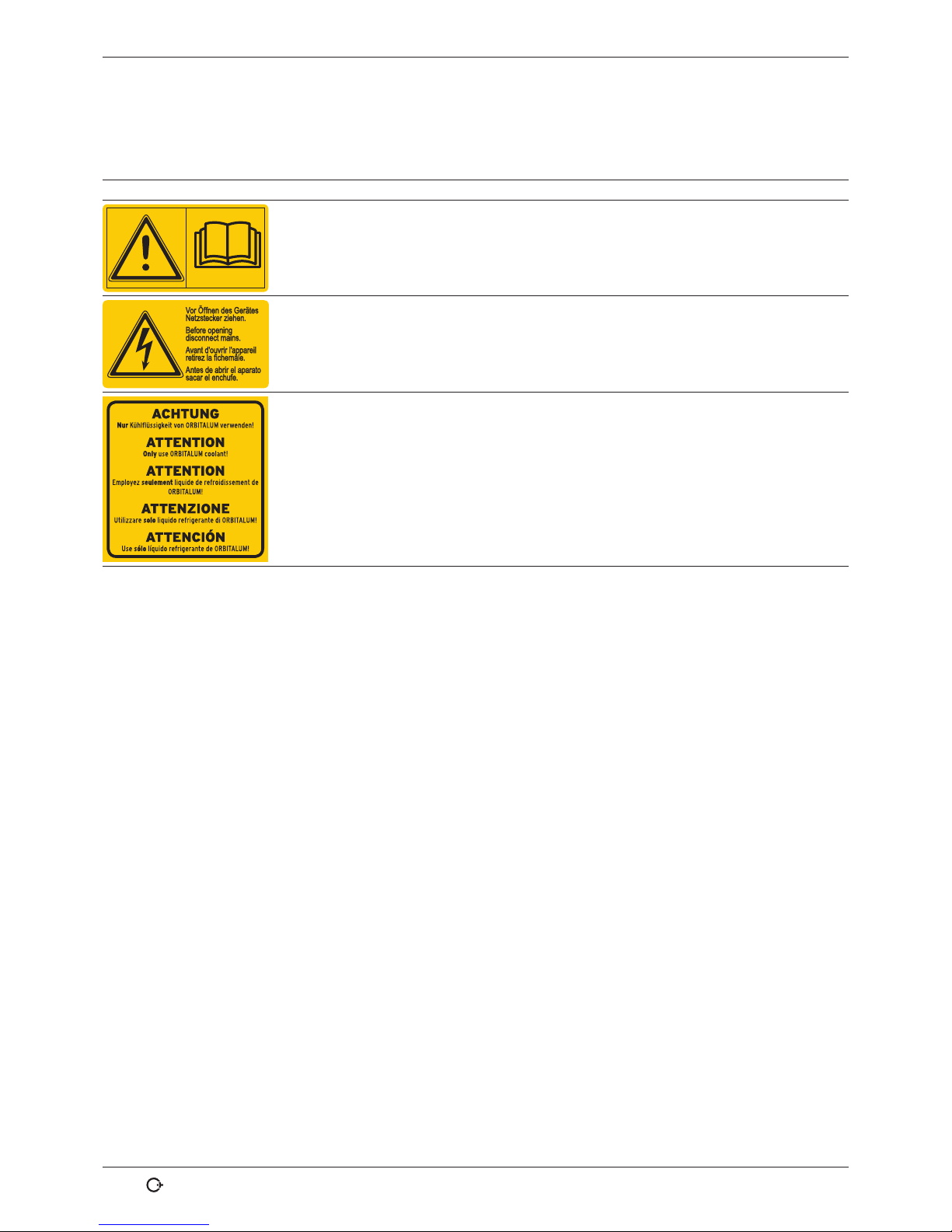

3.3 Warning signs

The warning signs and safety signs located on the machine must be observed.

Image Position on machine Meaning Code

Hood inside Read the safety instructions! 871 001 057

Rear panel Before opening the unit disconnect the

mains plug.

850 060 025

Side, left Caution: Only use Orbitalum coolant! 884 001 001

Page 17

ORBIMAT 180 SW | Operating instructions Scope of application

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 17

4. SCOPE OF APPLICATION

The ORBIMAT 180 SW is characterized by the following scope of application and functions:

• For welding using the Tungsten Inert Gas (TIG) process

• Can be used for all materials that are fundamentally suitable for the TIG welding process.

• Simple and convenient operation thanks to multifunctional rotary knob or touch screen

• DC current welding source

• WIDE RANGE input voltages for safe operation of power sets or voltage networks with extreme fluctuations in voltage

• "Flow Force" function to reduce the gas pre-flow and post-flow time

• "Permanent gas" function

• Digital regulation of the weld gas quantity

• Monitoring of coolant and weld gas

• Control option for cold wire feed

• Possibility of connecting an external remote control

• Constant or pulsed wire feed motion and rotation

• Optimal visibility and operating conditions thanks to clearly laid-out 12.4" swivel monitor

• Graphically-supported operating interface and multilingual menu navigation via color display

• Metric and imperial measuring units

• Process-oriented, stable and real-time operating system without power-down sequence

• Automatic weld head recognition and resulting parameter modification

• Motor current monitoring of the drive motors

• Capacity to store over 5.000 welding procedures, providing systematic and clear procedure management thanks to

the creation of folder structures

• Welding data logging and printout of actual values

• Integrated system printer

• Possibility of connecting a monitor or printer (through HMDI/USB/LAN)

• Optional PC software (OrbiProg CA) for welding procedure management and logging

• Integrated, folding carrying grips

• Option to program up to 99 sectors

• Power and motor slope adjustment between the individual sectors

• Integrated liquid cooling system for cooling the connected weld heads

• Can only be used in combination with separately available liquid cooling system

4.1 Accessories

Optionally available:

WARNING!

Danger presented by using accessories that have not been approved.

Various injuries and damage to property.

X Use only original tools, spare parts, materials, and accessories from Orbitalum Tools.

4.1.1 ORBICAR W trolley

Thanks to its integrated liquid cooling function the ORBICAR W trolley

is the perfect supplement to the ORBIMAT 180 SW power source.

Beside the liquid cooling, the trolley is equipped with a practical holder for gas

bottles.

4.1.2 ORBICOOL Active

Very efficient compressor cooling device.

Particularly suitable for welding units in series production.

Page 18

Scope of application ORBIMAT 180 SW | Operating instructions

18

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.0 9.18) OW_OR BIMAT_180SW_ BA_850 060202_00_ EN

4.1.3 ORBITWIN switching unit

To increase productivity, the ORBITWIN switching unit is available which allows the

alternately operation with 2 weld heads on the ORBIMAT.

4.1.4 ORBmax oxygen meter

For optical oxygen measurement using fluorescence extinction.

The ORBmax does not require any heating-up time. It recognizes the oxygen percentage reliably, rapidly and precisely during the entire welding process.

4.1.5 Remote control with cable

For transferring all the commands important for welding to the power source.

It is not required when working with enclosed orbital weld heads.

4.1.6 OCL-30 coolant

1 canister already included in the scope of delivery of the ORBIMAT 180 SW power

source.

Anti-freeze pre-mix for ORBIMAT power sources and cooling units to avoid freezing of

the cooling water. Protects up to –30 °C (-22°F) outside temperature. Increased service life of components of the cooling system through very high corrosion protection

and high pH-value. Excellent ignition characteristics due to low conductivity. Clear

cooling liquid.

4.1.7 ORBIPURGE forming set

For rapid and efficient internal forming during pipe and molded part weld connections

while at the same time reducing gas consumptions.

4.1.8 Paper rolls and ribbon cartridges

For internal system printer.

Suitable for all ORBIMAT orbital welding power supplies.

Page 19

ORBIMAT 180 SW | Operating instructions Technical specifications

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbit alum.com, Pho ne +49 (0) 77 31 792-0 19

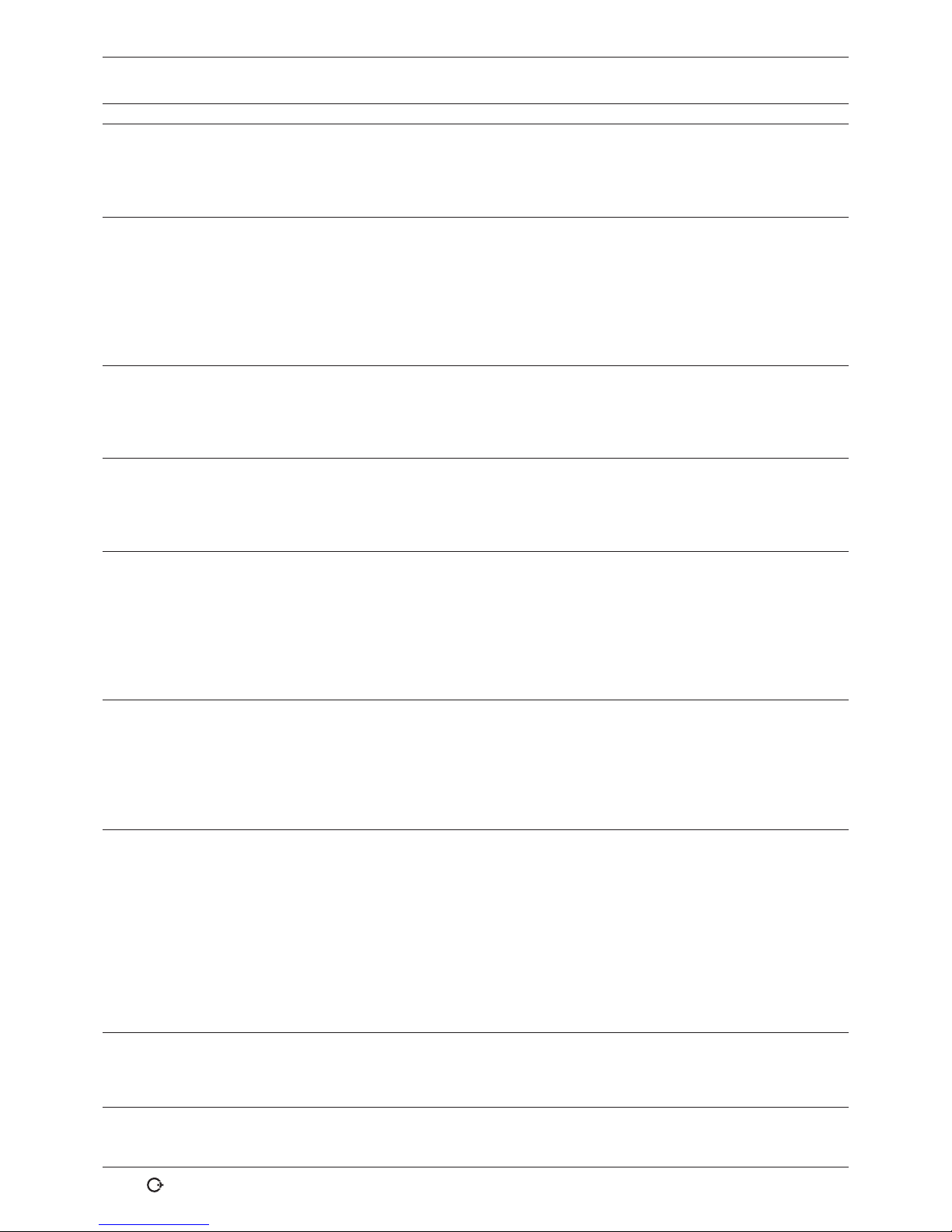

5. TECHNICAL SPECIFICATIONS

PARAMETER UNIT ORBIMAT 180 SW REMARKS

Code 850 000 001

Weld system type Welding rectifier (inverter)

Input (mains)

Mains system 1 phase + PE

Mains input voltage [V (AV)] 110 - 230

Permissible voltage tolerance [%] +/–10

Mains frequency [Hz] 50/60 –

Continuous input current [A (AC)] 15.3

Continuous input [kVA] 3.6

Current consumption, max. [A (AC)] 19.5

Connection value, max. [kVA] 13.5

Power factor [cos ϕ] 1.0 (with 180 A)

Output (welding circuit)

Setting range weld current [A (DC)] 3 - 180 In 0.1 A increments

Weld current reproducibility [%] +/– 0.5

Rated current at 100% duty cycle [A (DC)] 160

Rated current at 60% duty cycle [A (DC)] 180

Weld voltage, min. [V (DC)] 10

Weld voltage, max. [V (DC)] 20

Open-circuit voltage, max. [V (DC)] 85

Ignition power, max. [Joule] 0.9

Ignition voltage, max. [kV] 10

Output (control)

Rotation motor voltage, max. [V (DC)] 24 PWM signal

Wire feeding motor voltage, max. [V (DC)] 24 PWM signal

Rotation motor current, max. [A (DC)] 1.5

Wire feeding motor current, max. [A (DC)] 1.5

Rotation tacho voltage [V (DC)] 0 - 10 Rotation speed, actual value

Other

Degree of protection IP 23 S

Cooling type AF

Insulation class F

Dimensions (wxdxh) [mm]

[inch]

600 x 400 x 310

23.6 x 15.7 x 12.2

300 CA without cooling unit

Weight [kg]

[lbs]

24.6

54.23

Gas input pressure [bar] 3 - 10 Via pressure reducer

Recommended gas input pressure [bar] 4 Via pressure reducer

Coolant volume [l] 2.2

Coolant pressure, max.

[bar] 4

Sound level, max. [dB (A)] 70

Page 20

Storage and transpor t ORBIMAT 180 SW | Operating instructions

20

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_ ORBIMAT_180S W_BA_ 850060202_ 00_EN

6. STORAGE AND TRANSPORT

6.1 Gross weight

ARTICLE WEIGHT*

ORBIMAT 180 SW [kg] 28.0

[lbs] 61.73

* incl. transpor t packaging

WARNING!

Damage of electronic components with personal harm and damage to property.

If coolant is still located in the machine during transportation, coolant can enter from the tank into

the machine interior if tilted strongly.

X Pump out coolant before transporting.

WARNING!

Danger of injury through high weight of the orbital welding power supply!

The orbital welding power supply has a weight of 28.0 kg (61.73 lbs).

X Always lift the orbital weld head with two persons or use a suitable means of transport.

X When lifting the machine do not exceed the permissible total weight of 25 kg for men and 15 kg

for women.

6.2 Preparing storage

Carry out the following steps before storage:

6.2.1 Removing the weld head from the orbital welding power supply

For procedure see operating instructions of weld head.

6.2.2 Pumping out coolant

1. Connect the drain hose to the coolant connection,

blue.

2. Hold the end of the drain hose into a collecting vessel

(min. 3 liter).

1

Page 21

ORBIMAT 180 SW | Operating instructions Storage and transport

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbit alum.com, Pho ne +49 (0) 77 31 792-0 21

Carry out the following steps in the menu of the welding power supply:

To protect the pump against possible dry running, the

software stops pumping out after approx. 30 seconds.

3. In the main menu, call up the "System settings" menu

item by turning the rotary knob.

4. Briefly press the rotary knob.

The "System settings" sub-menu appears.

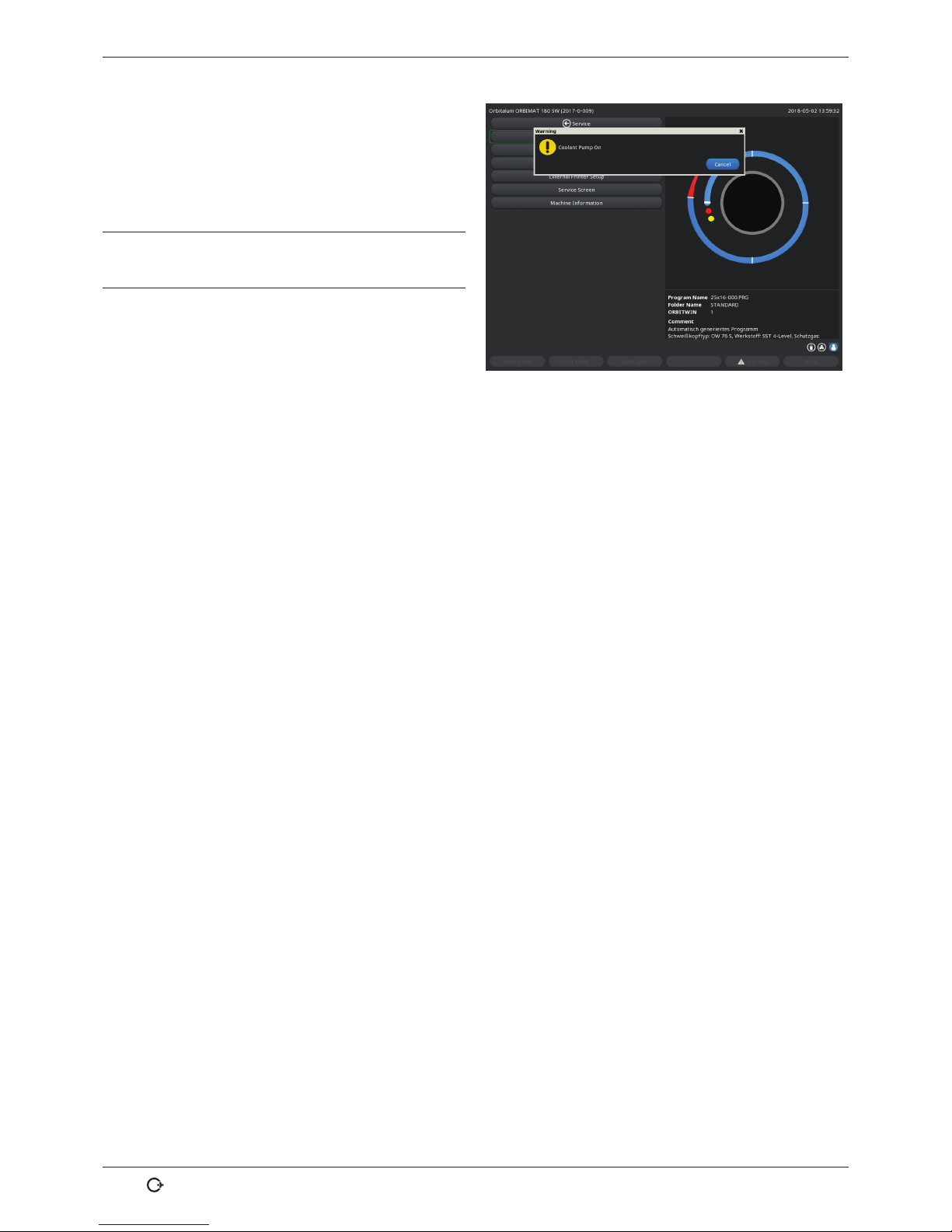

Fig. 1: Main menu (long form)

5. Navigate to the "Service" menu item.

6. Briefly press the rotary knob.

The desired selection appears.

Fig. 2: Sub-menu – System settings

7. Select the "Coolant pump on" menu item.

8. Briefly press the rotary knob.

The "Pumping coolant out" message appears.

The "Cancel" button is highlighted in blue.

Fig. 3: Sub-menu – Service

Page 22

Storage and transpor t ORBIMAT 180 SW | Operating instructions

22

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW _ORBIMAT_180 SW_BA_ 850060202_ 00_EN

9. Confirm "Cancel" by briefly pressing the rotary knob.

The coolant pump is switched off.

10. Check the fill level indication and abort the process

when the tank is empty.

NOTE! When the pump runs dry, this is accompa-

nied by an audible increase in speed.

X Abort the process immediately.

Fig. 4: Coolant – Pumping out

If the coolant does not exit the hose within a maximum of 10 seconds:

11. Stop drainage, as prolonged dry running can damage the pump.

12. Check the coolant level.

13. Check whether the pump is started and a pumping sound can be heard.

Page 23

ORBIMAT 180 SW | Operating instructions Commissioning

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen, w ww.orbit alum.com, Phon e +49 (0) 77 31 792-0 23

7. COMMISSIONING

7.1 Scope of delivery

SCOPE OF DELIVERY CODE QUANTITY UNIT

ORBIMAT 180 SW Welding Power Supply 850 000 001 1 Pc.

Hose connection set ORBIMAT 875 030 018 1 Pc.

Dummy plug for remote control socket 875 050 006 1 Pc.

3.5 liter coolant OCL-3018 850 030 010 1 Bottle

Operating instructions with calibration certificate 850 060 201 1 Set

QuickStart guide 850 060 020 1 Pc.

Subject to modifications.

7.2 Checking the scope of delivery

X Check delivery for completeness and damage caused by transport.

X Report any missing parts or damage caused by transport to your supplier immediately.

7.3 Accessories (optionally available)

• ORBICAR W carriage with integrated liquid cooling

• ORBICOOL Active compressor cooling unit

• ORBITWIN Switching Unit

• Remote control with cable

• ORBmax residual oxygen meter

• Double pressure reducer

• TIG manual welding torch for ORBIMAT

Page 24

Commissioning ORBIMAT 180 SW | Operating instructions

24

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW _ORBIMAT_180 SW_BA _850060202_ 00_EN

7.4 Connecting the welding power supply

CAUTION!

Damage to the orbital welding power supply through the mains supply voltage being exceeded.

X Check whether the mains supply voltage corresponds to the specifications in chap. 5.

X Observe requirements for the power supply: RCCB 30 mA.

DANGER!

Faulty ignition in case of unmounted or incorrectly positioned weld head!

Electric shock, bodily injury and damage to property also at other devices.

X If the weld head is not ready for operation, switch the machine to the "Test" function.

DANGER!

Improper access to and opening of the ORBIMAT system.

Electric shock.

X Disconnect the system from the mains.

X Remove all the external devices connected to the system (weld heads, etc.).

X If the machine was in operation beforehand, allow it to cool down sufficiently.

X Allow only a professional electrician to access the electrical system.

[ Never connect an opened system to the mains network.

DANGER!

Liquid in the housing due to improper use and transport.

Electric shock.

[ Do not place liquids (beverages) on the system.

X Do not block ventilation slots.

X Check housing interior for moisture after transporting the machine and leave it open to air it out

if necessary.

WARNING!

Ultraviolet radiation from the arc while welding.

Damage to eyes and burning of skin.

X During operation, wear eye protection to EN 170 and skin-covering safety clothing.

X At closed weld heads ensure proper working order of the eye protection.

WARNING!

Hot leaking liquids and hot plug connections during heavy operation.

Danger of scalding.

X Heed the safety precautions of the technical supervisor/person in charge of safety.

CAUTION!

Hot surfaces of the weld head and weld points, including for a period of time after welding.

Danger of burns.

X Wear safety gloves.

7.4.1 Setting up machine

X First set up the system for connection in such a way that it is as accessible as possible from the front and rear.

X Ensure that the machine is disconnected from the mains network on all sides.

X Secure the machine against being switched on unintentionally.

X Place the machine on a stable, fixed and plane base.

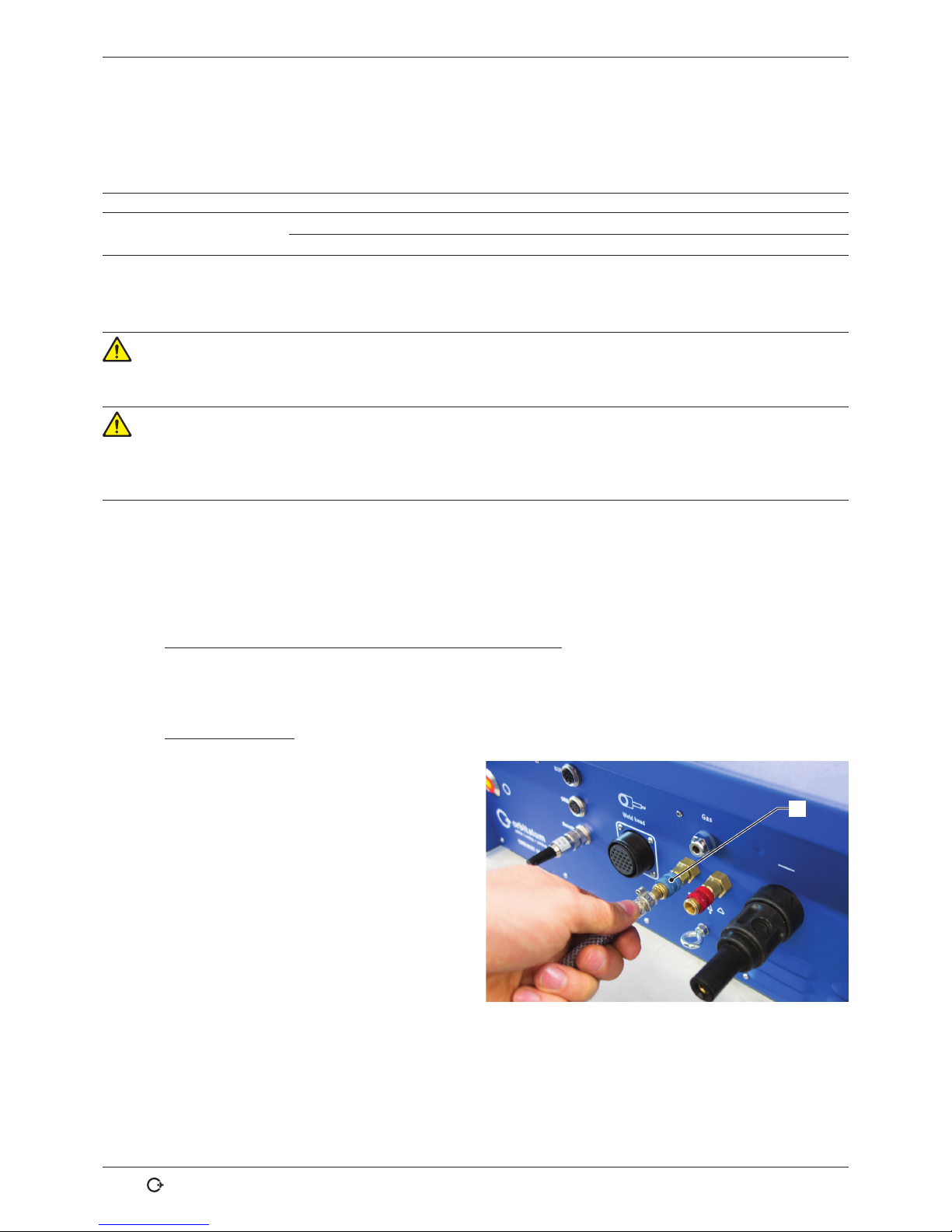

7.4. 2 Connecting a gas bottle

DANGER!

Exceeding the maximum permissible operating pressure of the forming gas can result in lethal

injuries.

X A pressure reducer must be used.

1. Check the stability of the gas bottle. Secure the gas bottle against falling over.

2. Ensure that the union nut on the pressure reducer fits the thread on the valve of the gas bottle.

3. Mount the pressure reducer on the gas bottle.

4. Connect the gas distributor (there is no gas distributor if a double pressure reducer is used).

5. Screw both included gas hoses onto the gas distributor or the double pressure reducer respectively..

6. Insert the gas hose (which is intended for connection to the power source and is identified by the plug-in nipple

made of brass on the end) into the provided connection socket on the rear back of the power source.

7. Connect the weld head.

Page 25

ORBIMAT 180 SW | Operating instructions Commissioning

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbi talum.com, Pho ne +49 (0) 77 31 792-0 25

7.4. 3 Connecting weld heads

For procedure see operating instructions of weld head.

7.4.4 Detaching coolant hoses

X Lightly push back the front ring on the machine-side connection and pull off the coolant hose.

7.4.5 Pumping out coolant

The connections of the machine close automatically when the coolant hose is removed.

X When connecting the coolant hoses, pay attention to the flow and return lines.

1. Connect the drain hose to the coolant connection, blue.

2. Close off the coolant hoses with the included plugs to prevent the coolant from running out of the weld head.

7.4.6 Closing off gas hose

X Actuate the side pawl on the hose-side plug connection and pull gas hose out of connection.

7.5 Commissioning

DANGER!

Faulty ignition in case of unmounted or incorrectly positioned weld head.

Electric shock, bodily injury and damage to property also at other devices.

X If the weld head is not ready for operation, switch the machine to the "Test" function.

DANGER!

Improper access to and opening of the ORBIMAT system.

Electric shock.

X Disconnect the system from the mains.

X Remove all the external devices connected to the system (weld heads, etc.).

X If the machine was in operation beforehand, allow it to cool down sufficiently.

X Allow only a professional electrician to access the electrical system.

[ Never connect an opened system to the mains network.

DANGER!

Liquid in the housing due to improper use and transport.

Electric shock.

[ Do not place liquids (beverages) on the system.

X Do not block ventilation slots.

X Check housing interior for moisture after transporting the machine and leave it open to air it out

if necessary.

WARNING!

Ultraviolet radiation from the arc while welding.

Damage to eyes and burning of skin.

X During operation, wear eye protection to EN 170 and skin-covering safety clothing.

X At closed weld heads ensure proper working order of the eye protection.

WARNING!

Hot leaking liquids and hot plug connections during heavy operation.

Danger of scalding.

X Heed the safety precautions of the technical supervisor/person in charge of safety.

CAUTION!

Hot surfaces of the weld head and weld points, including for a period of time after welding.

Danger of burns.

X Wear safety gloves.

Before welding is carried out the cooling circuit is filled with coolant.

Page 26

Commissioning ORBIMAT 180 SW | Operating instructions

26

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.0 9.18) O W_ORBIMAT_18 0SW_BA _850060202 _00_EN

X Ensure that the machine is not connected to the mains network during filling.

X Secure the machine against being switched on unintentionally.

Please adhere to the following steps, otherwise the pump could be damaged by running dry:

7.5.1 Topping up coolant

1. Open the tank lid and fill ORBITALUM coolant OCL-30

(Code 850 030 010) carefully into the tank (2) until the

coolant level has reached the "MAX" marking on the

sight glass at the left-hand side panel of the power

source (3).

2

3

Use of other cooling units such as compressor cooling device, type ORBICOOL Active):

1. Fill in coolant in accordance with the operating instructions of the unit.

2. Connect the coolant hoses at the front connectors of the power source to ensure the coolant flow and temperature

monitoring by the power source.

7.5.2 Connecting Remote control/dummy plug

1. Connect the supplied dummy plug (4) or the optionally available remote control (5) (code 875 050 001) via the

adapter cable (6) (included in the scope of delivery of the remote control) to the remote control socket (7).

2. If a remote control is connected, the STOP button (8) must be unlocked as well.

3. The power source cannot be switched on without the dummy plug or unlocked remote control.

4

5

6

7

8

Page 27

ORBIMAT 180 SW | Operating instructions Commissioning

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbit alum.com, Pho ne +49 (0) 77 31 792-0 27

7.5.3 Switching on the power source

CAUTION!

X Observe requirements for the

power supply: RCCB 30 mA.

1. Connect the machine to the mains network.

2. The Off button (red) (9) lights up as soon as the machine is connected to the mains network.

3. Switch on the ORBIMAT at the green main switch (10).

The operating system is loaded and the main menu

appears in the display (11).

9

10

11

Problems while switching on

Does the machine not start the first time it is switched on?

X Check whether the pilot light in the main switch is lit up.

Is the pilot light not lit up?

There is a problem with the power supply (no voltage, plug not inserted).

X Check whether the power plug is properly inserted.

X Have the power supply checked.

Is the STOP indicator on the front panel lit up?

With external remote control connected: EMERGENCY-STOP switch is pressed.

1. Unlock EMERGENCY-STOP switch by turning it counterclockwise.

2. Switch off machine.

3. Wait at least 5 seconds and then switch machine on again.

Is an external remote control not connected?

The dummy plug is missing from the remote control connection, EMERGENCY-STOP is activated.

X Insert dummy plug to close the EMERGENCY-STOP circuit if necessary.

Page 28

Commissioning ORBIMAT 180 SW | Operating instructions

28

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_ ORBIMAT_180S W_BA_ 850060202_0 0_EN

7.5.4 Setting the language

The factory setting for the system language is "German".

Changing the language:

1. In the main menu call up the menu item "System

settings" by turning the rotary knob and confirm by

pressing.

2. Subsequently call up the menu item "Language".

3. Select the desired language and confirm with the

rotary knob.

Fig. 5: Setting the language

7.5.5 Setting the measuring units

The operating system can be set to "Metric" or "Imperial" measuring units.

The factory setting is "Metric".

Changing the measuring unit:

1. In the main menu call up the menu item "System

settings" by turning the rotary knob and confirm by

pressing.

2. Subsequently call up the menu item "System adjustments".

3. Use the rotary knob to select the desired measuring

unit under "Imperial sizes" by selecting "Yes/No" and

confirm.

Fig. 6: Setting the measuring unit

The ORBIMAT is now ready to operate.

Page 29

ORBIMAT 180 SW | Operating instructions Operation

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen, w ww.orbit alum.com, Phon e +49 (0) 77 31 792-0 29

8. OPERATION

8.1 Auto programming

8.1.1 Setting parameters

1. Connect the weld head.

2. Switch on the machine.

The main menu appears in the display.

3. Select and highlight the "Auto programming" menu item.

The following display appears:

Field "....":

Return to main menu.

Fields "Weld head model" to "Wall thickness":

Parameter entry.

Field "Wire feed":

Welding with/without filler wire.

"Calculate program":

Calculation of the procedure with the entered parameters.

Fig. 7: Sub menu – Auto programming

8.1.2 Configuring weld head

1. Select the "Weld head" field and briefly press the rotary knob.

The following display appears:

A list of the weld heads which can be used with this system appears.

This system automatically detects the type of connected

head and offers it for selection first. In the example, this

is an OW 76S.

Fig. 8: Selecting a weld head

Page 30

Operation ORBIMAT 180 SW | Operating instructions

30

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_ ORBIMAT_180S W_BA_ 850060202_0 0_EN

2. Select the desired weld head by turning the rotary knob.

– or –

Select the weld head highlighted by the system.

3. Confirm by briefly pressing the rotary knob.

8.1.3 Configuring material

X Select the "Material" field and briefly press the rotary knob.

The following display appears:

Materials in the list:

• Carbon steel

• Stainless steel

• Titanium

Fig. 9: Selecting the material

1. Select the material.

2. Confirm by briefly pressing the rotary knob.

8.1.4 Configuring protective gas

1. Select the "Gas type" field and briefly press the rotary knob.

2. Select the protective gas.

3. Confirm by briefly pressing the rotary knob.

Page 31

ORBIMAT 180 SW | Operating instructions Operation

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbi talum.com, Pho ne +49 (0) 77 31 792-0 31

8.1.5 Configuring pipe diameter

1. Select the "Diameter" field.

The following display appears:

2. Select the value by pressing the rotary knob.

3. Enter values via the external keyboard or the rotary

knob.

The value range is automatically limited to the possible

diameter range of the connected or previously selected

weld head here.

Fig. 10: Pipe diameter setting

8.1.6 Configuring wall thickness

1. Select the "Wall thickness" field and briefly press the rotary knob.

The value range is limited to 4 mm (0.157").

We recommend a "tulip-shaped" or "U-shaped" preparation for wall thicknesses approx. 4 mm

(0.157") and larger, which might require carrying out your own weld tests. Auto programming can

be helpful here, because you can enter the thickness of the bluntly-joined root face (usually 1.5 - 2.5

mm/0.059" - 0.098") as the wall thickness first, and then manually improve the auto programmed

procedure calculated in this way.

2. Select the value by pressing the rotary knob.

3. Enter values via the external keyboard or the rotary knob.

8.1.7 Configuring wire feed

Selection is only possible if the connected weld head is capable of cold wire feeding.

If cold wire feeding is not possible, the option fields have a gray background, "No" is configured and this cannot be

changed by the operator (see also Fig. 10).

1. Select the "Wire feed" field and briefly press the rotary knob.

2. Select the "Yes" option (with wire feed) and "No" option (without wire feed).

8.1.8 Calculating procedure

X Select and briefly press the "Calculate procedure" menu item.

The procedure is calculated. The main menu appears in the display.

Page 32

Operation ORBIMAT 180 SW | Operating instructions

32

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.0 9.18) O W_ORBIMAT_18 0SW_BA _850060202 _00_EN

8.2 Testing the procedure

8.2.1 Preparing weld head

These operating instructions can only provide basic information on the most commonly used weld heads (due to the

variety of tools which can be connected).

In the following, the important actions for so-called "open" weld tongs and cassette heads are listed.

X Refer to detailed information on preparing the operating instructions of the weld head.

D Gas bottle and weld head connected, see chap. 7.4, p. 24.

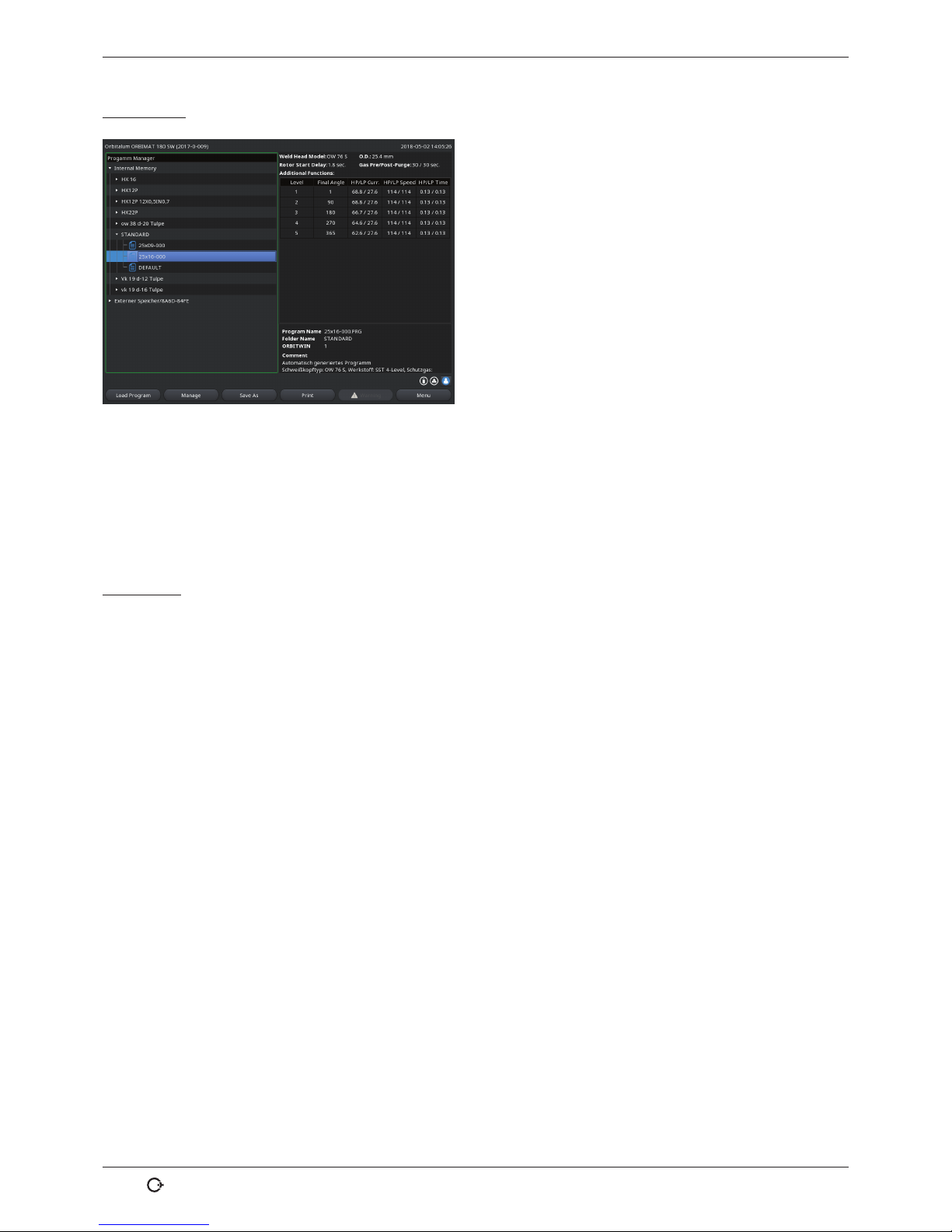

D Commissioning carried out, see chap. 7.5, p. 25.

D Machine switched on.

8.2.2 Preparing electrode

For almost all Orbitalum weld heads, electrodes with a diameter of 1.6 mm (0.063") and 2.4 mm (0.094") can be used.

X For "Micro head" type OW 12: Use only electrodes with a 1.0 mm (0.039") diameter.

X Up to a current of approx. 100 amperes (high-pulse): Use electrodes with a 1.6 mm (0.063") diameter (recommen-

dation).

X Calculate the electrode diameter based on the max. weld current of the application.

If lower currents are used, the use of 2.4 mm (0.094") electrodes can lead to a worsening of the

ignition characteristics and "wandering" of the arc at the electrode.

X Ensure good grinding of the electrode. Use an appropriate electrode grinding device. such as the ESG Plus tungsten

grinder (recommendation).

WARNING!

Sharply ground and pointy electrodes!

Danger of injury.

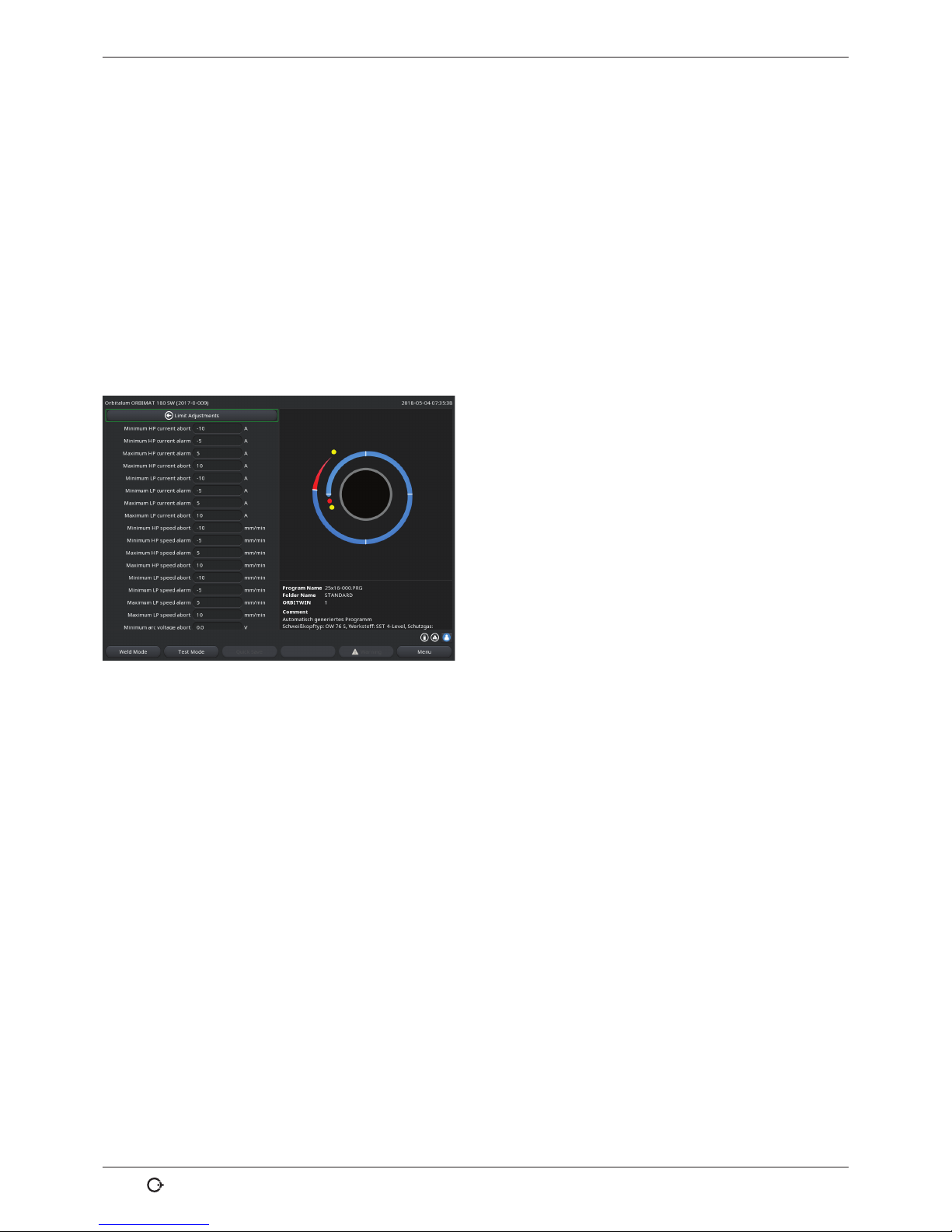

X Store ground electrodes so that there is no danger of injury.

8.2.3 Turning weld head

You can turn the weld heads with a motor for insertion of the electrode.

CAUTION!

Clamping of fingers possible during manual moving.

X During clamping in move the rotor electrically in the opposite direction.

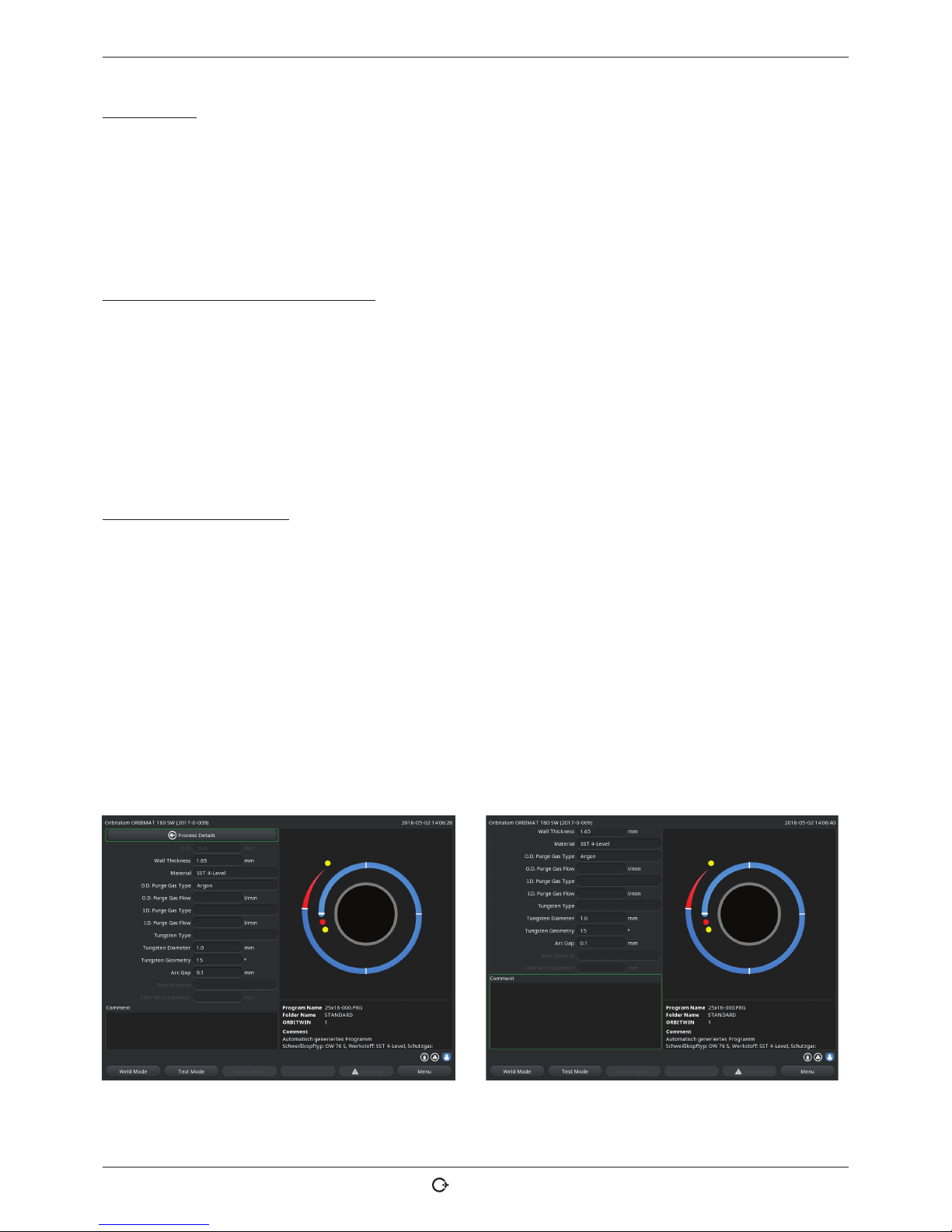

CAUTION!

Unintended starting of the welding procedure!

Danger of injury. Damage to materials and machine.

In the "ready to start" condition (see Fig. 11) the "Start" button could be pressed by an unauthorized person and start the welding procedure.

X Switch off the welding power supply for electrode replacement.

X After inserting the electrode ensure that the "Start" button in the display does not have a red

background.

X Only use the function for motor movement from the "red" start area if the weld head is being

moved immediately before starting the process, e.g. to change the starting position.

Page 33

ORBIMAT 180 SW | Operating instructions Operation

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbit alum.com, Pho ne +49 (0) 77 31 792-0 33

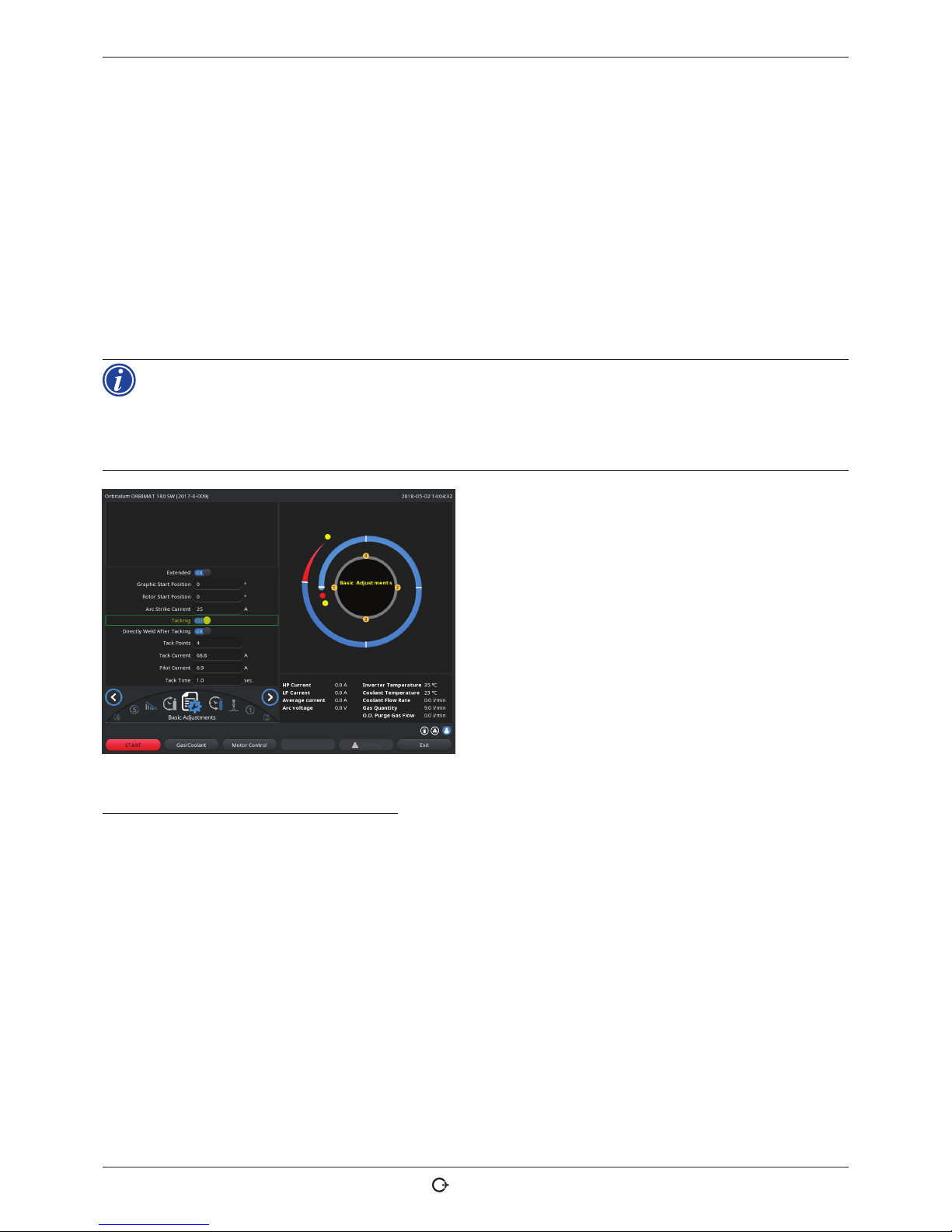

"Test mode" is indicated by the "Start" button having a yellow background.

The start command in test mode starts running a procedure without igniting an arc and therefore

without weld current; the gas valve and coolant pump are switched off. You can use this "dry run"

to check the change in level at the intended points on the pipe and the run of the motor.

Fig. 11: Machine ready to start – Welding (left) Fig. 12: Machine ready to start – Test run (right) – Start

X To change between the welding mode and the test mode the yellow "GAS" button at the weld head remote control

or at the handle of the weld head can be activated by pressing it and keeping it pressed for 3 seconds.

With the remote control of the weld head:

X Press the gray "Motor" button until the desired position is reached. Only one rotation direction is possible here.

With an additional remote control (optional, available as accessory):

X Press the "MOTOR+" or "MOTOR –" button.

The rotor turns in the selected direction as long as a button is being pressed.

With the push switches of the machine:

X Call up main menu, if necessary.

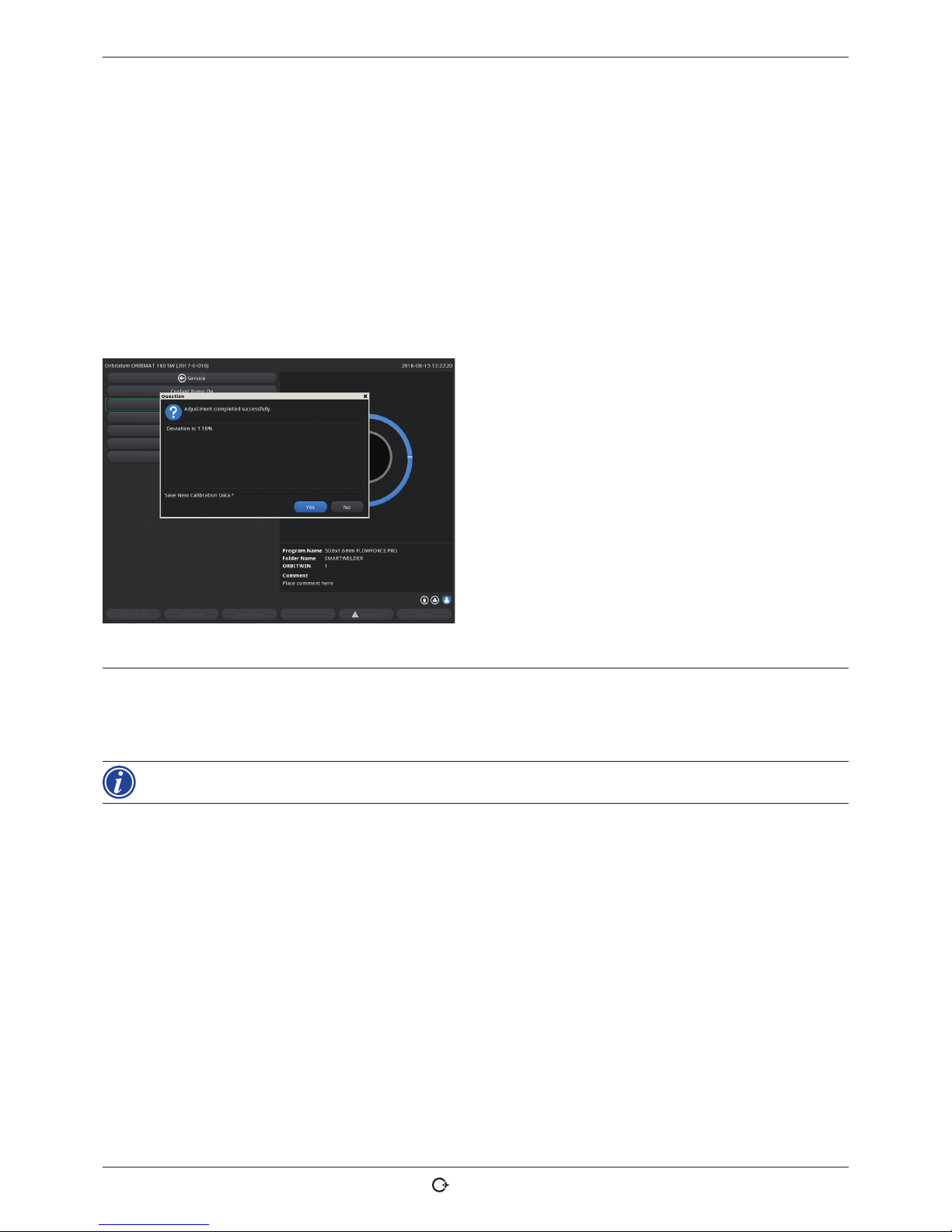

X Press softkey 2 "Test ".

The main menu in test mode appears in the display, and the "Start" button is yellow.

X Press softkey 4 "Motor".

The assignment of the softkeys for controlling the motor changes.

X Press "Motor forward" or "Motor backward" button.

The motor runs in the selected direction as long as the button is being pressed.

X Press softkey "Home".

The weld head turns to the open position.

X Press softkey "Motor OK" to exit the operating scheme.

X Press softkey 5 "Menu" to change directly to the main menu.

Page 34

Operation ORBIMAT 180 SW | Operating instructions

34

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_ORBIM AT_180SW_B A_85006 0202_00_E N

8.2.4 Connecting forming gas

With orbital welding, sufficient gas coverage must also be ensured inside the pipe ("root protection") with an inert gas

(usually argon). This also applies for the so-called "black" (ferritic) materials.

CAUTION!

X A pressure reducer must be used.

X Plug up lines of the gas bottle with suitable stoppers.

X Open the regulator on the gas bottle and set a low flow rate for the forming gas.

X Ensure sufficient gas pre purge time before starting the machine.

To determine the right time, the residual oxygen meter (ORB) can be used.

CAUTION!

Impermissible gas pressure inside the pipe. Penetration of melted metal into the weld head!

Damage to weld head.

X Ensure that gas pressure does not build up inside the pipe.

X When using closed weld heads, ensure that the same gas type is used both outside and inside

the pipe, i.e. the same gas both for the machine (weld head) and that which is fed into the pipe.

Different gas types can lead to an undefined mixture of both gases in the welding pocket and thus

to uneven weld penetration.

X Do not use "classic" forming gases with up to 30% hydrogen content.

A small amount of hydrogen which ends up in the welding pocket from inside the pipe via the pipe

joint can lead to considerably greater penetration, as the hydrogen releases additional energy during

combustion. Values gained from experience: An admixture of only 2% hydrogen has roughly the

same effect on penetration as a 10% increase in weld current.

8.2.5 Welding

Starting the welding process

X Before starting, read the section "Interrupting the welding process" (see chap. 8.2.6, p. 36) so that you can take

action immediately in case irregularities arise during a test run.

D Power source programmed

D Weld heads prepared for welding: properly connected and positioned

D Gas bottle secured and opened

D Machine switched on

D The main menu appears in the display.

X Press softkey 1 "Weld".

The machine is ready to start. The "Start " button in the display is red.

X Press softkey 1 "Start".

– or –

X Press the START button on an external remote control, if connected.

– or –

X Press the red START/STOP button on the weld head.

The coolant pump starts up, and the solenoid valve is opened. After the programmed gas pre-flow time passes, the arc is

ignited and the welding process begins.

Page 35

ORBIMAT 180 SW | Operating instructions Operation

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools Gmb H, D-78224 Singe n, www.orb italum.com, P hone +49 (0) 77 31 792-0 35

The machine carries out the welding process completely.

X Observe the welding process continuously and be prepared to take action at any time.

X With open weld tongs: Ensure proper guidance of the hose assembly while the rotor is circling.

Possible problems with the welding process:

• Incorrectly set weld current.

• LP weld tong not tensioned tightly enough.

• Forming gas quantity too high, holes being formed.

X In these cases, interrupt the welding process (see chap. 8.2.6, p. 36).

Welding process – Sequence

The machine carries out the welding process completely. During the welding process, the machine monitors the welding

process and the following parameters:

• Coolant flow rate: The welding process is stopped if the limit value of 0.8 l/min is undershot.

• Gas flow: The welding process is interrupted if approximately 3 l/min is undershot.

• The weld current, weld voltage and weld speed process parameters: Limit values specified in the procedure are

taken into account.

The following details appear in the display during the running welding process:

Process completion: Bar graph with specification of process completion (in %) for the respective current sector.

Correction factor: Percent value by which the current in

the current process was changed in comparison to the

saved procedure.

Parameters pipe diameter to wire LP speed: Display of

the process parameters of the procedure. The values can

be changed during the welding process. The changes

are saved by pressing the rotary knob (keyboard: ENTER)

to the current welding process. The changes are not yet

saved in the procedure. Fields with a gray background

cannot be edited.

Fig. 13: Display during running welding process

Graphic: Display of the weld sequence. After starting up, a pointer pointing to the inner yellow dot appears during gas

pre purge. After the gas pre purge, pool formation occurs (the time after ignition during which no rotational movements

are occurring for buildup of the weld pool). In the individual sectors, the respective current sector is highlighted in

white, and the accompanying red indicator indicates the current electrode position. The current sector number and current position (in angular degrees) appear in the bottom section of the graphic.

Info field: The following information appears in the info field (below the graphic): Name of the folder in which the procedure is saved, name of the running procedure, current measurement values for coolant flow (in l/min), coolant temperature and inverter temperature (in °C); gas flow, mean current, arc voltage.

Warning messages and error messages appear in the "Warning" field.

The info field only appears during a running welding process.

Other: The following information appears on the two bottom lines: Help texts for operation with the rotary knob. On

the right, information on the activated printer and the USB stick. When the printer is activated (for example log printing

after welding) or the storage medium is activated (procedure being loaded), the symbols are highlighted in blue.

Page 36

Operation ORBIMAT 180 SW | Operating instructions

36

orbitalum tools GmbH, D-78224 Sing en, www.or bitalum.com, P hone +49 (0) 77 31 792-0 (17.09.18) OW_ ORBIMAT_180S W_BA_ 850060202_0 0_EN

Softkeys: The current assignment of the softkeys appears at the bottom edge of the display. During the welding process, only softkeys 1 and 2 ("STOP" and "Final slope") are active.

Ending the welding process

If the process can no longer be controlled, shut down the system by using the main switch or pull

out the power plug!

The following steps are carried out automatically at the end of the welding process:

• Current is automatically sloped off to the programmed final current.

• The arc is extinguished.

• Gas flow and liquid cooling are deactivated after the programmed time expires.

• Machine switches to ready-to-start condition.

8.2.6 Interrupting the welding process

Switching off the entire system

X Switch off machine at the main switch.

– or –

X Press the EMERGENCY-STOP button on connected remote control.

The entire machine is disconnected from the mains network immediately and completely (both poles). No other functions

are carried out here: The gas flow is interrupted immediately. The current weld becomes unusable.

Stopping a running process

X Press softkey 1 ("STOP").

– or –

X Press the STOP button on the connected remote control.

– or –

X Press the red START/STOP button on the weld head.

The weld current is switched off immediately. The machine remains in operation, the gas post purge time runs and the

liquid cooling of the weld head is carried out until the end of the gas post purge time.

A slight crater can arise in the seam on the workpiece, and this can be compensated for by over-welding it.

Premature slope-off of a running process

X Press softkey 2 ("Final slope").

– or –

X Press the "Final" button on the weld head.

– or –

X Press the slope-off symbol on the connected remote control.

The machine slopes off the weld current as per the procedure. The weld head continues running during the slope-off

phase. After slope-off, the weld current is switched off, the gas post purge and pump continue running until the end of

the programmed time.

Page 37

ORBIMAT 180 SW | Operating instructions Operation

(17.09.18) OW_ORBIMAT_180SW_BA_850060202_00_EN orbitalum tools GmbH , D-78224 Singen , www.orbit alum.com, Pho ne +49 (0) 77 31 792-0 37

8.3 Adjusting the procedure

8.3.1 Reasons and steps for adjusting procedure

The auto programming of the machine cannot take all influencing factors into account during welding. Procedures can

be adjusted after the test run for this reason.

Possible reasons are:

• Batch-dependent fluctuations in the material composition.

• Different dissipations (pipe on solid parts) etc. For example due to components with different sizes.

X Improve the procedure step by step. When adjusting, change only one parameter at a time so that you can better

judge the influence on welding.

X Save the adjusted procedure.

X After the adjustment, carry out a test run of the parameters.

X Observe the effects of the adjustment and carry out further adjustments if necessary.

8.3.2 Making percental changes

Reason: Welding result even, but weld seam penetrated too lightly or too strongly.

The percentage change affects all levels (sectors) on high- and low-pulse current.

After the test run, the "Scale weld" field is highlighted in the display.

1. Highlight a field.

2. Adjust and save the value with the rotary knob or keyboard:

Positive value: Increase the weld current.

Negative value: Reduce the weld current.

The settable value range can be limited in the procedure (for example only max. +5% and min. –5%).

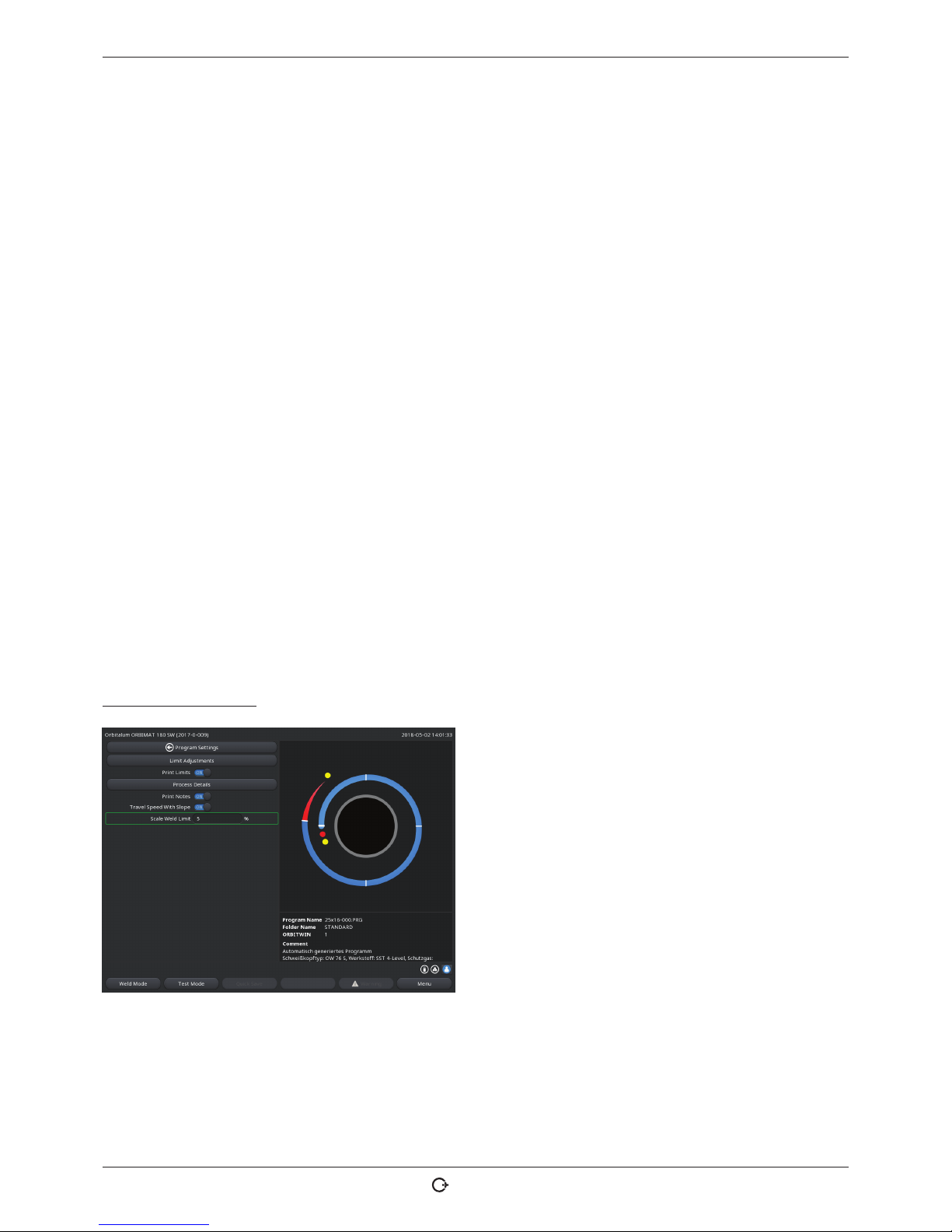

Changing the scale weld

1. In the main menu, select "System settings" > "Program settings".

The current limit within which the operator can change

the scale weld in "completed" mode (production mode) is

specified in the "Scale weld limit" field.

Example: Specification "5%" – Change in range from –5%

to +5% (absolute range: 10%).

2. Adjust and save the value with rotary knob or keyboard.

Fig. 14: Scale weld limit

Page 38