Orbisphere 3600M, 3600, 311 Owner's Manual

3600O2.OM.E9903

3600 Analyzer for Oxygen

Operator’s Manual

Series 3600/3600M Indicating Instrument / Model 311xx Oxygen Sensor

© 1999 Orbisphere. Printed in Switzerland.

2 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

CE conformity

The 3600 / 3600M indicating instrument is manufactured conforming to the requirements of the

electromagnetic compatibility directive: 89 / 336 / CEE

and the low voltage directive: 73 / 23 / CEE

The instrument complies with all the requirements of the following electromagnetic

compatibility standards:

– 3600 instrument:

EN 50081-1 (Jan. 1992), EN 50081-2 (Nov. 1993), and EN 50082-1 (Jan. 1992)

As a result, the 3600 instrument can be used in residential and commercial sites, and for

light industry. It is designed for indoor use in a protected area.

– 3600M instrument:

EN 50081-1 (Jan. 1992), EN 50081-2 (Nov. 1993), and EN 50082-2 (Mar. 1995)

As a result, the 3600M instrument can be used in typical industrial locations.

The 3600 / 3600M instrument satisfies the conditions of the safety standard: EN 61010-1

(1993)

The 3600 / 3600M instrument is developed, manufactured, and inspected by Orbisphere, which

is certified in accordance with the quality standard: ISO 9001 / EN 29001

The tests for safety and for electromagnetic compatibility were performed by the CEM test

laboratory (EMC Fribourg SA, zone industrielle de Montenaz, CH-1728 Rossens) which is

acknowledged by the Swiss Federal Office of Metrology.

Supplementary safety recommendations

For safe operation of the instrument, it is imperative that these service instructions be read and

that the safety recommendations mentioned herein be scrupulously respected.

Opening the instrument exposes non-insulated electrical components with hazardous voltages.

Therefore the instrument should not be opened. If repairs or adjustments are necessary, the

instrument should be returned to an authorized Orbisphere service center.

If these danger warnings are not heeded, serious material or bodily injury could occur.

Dacron, Delrin, Tedlar, Tefzel, and Viton are registered trademarks of DuPont.

Hastelloy is a registered trademark of Haynes International.

Kynar is a registered trademark of The Pennwalt Corporation.

Monel is a registered trademark of IMCO Alloys International, Inc.

Saran is a registered trademark of Dow Chemical Co.

Swagelok is a registered trademark of Swagelok Co.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

3600 Analyzer for O2 Measurement—Operator’s Manual 3

3600O2.OM.E9903

Table of contents

1. Operating Instructions ................................................................................. 5

1.1 What you have received........................................................................................5

1.2 What to check before using the system................................................................6

1.3 Instrument Operation...........................................................................................8

1.3.1 Program Flow Charts...................................................................................................... 9

1.3.2 Oxygen Measurement ................................................................................................... 10

1.3.2.1 Warning Messages.....................................................................................................................11

1.3.3 Calibration Menus ......................................................................................................... 12

1.3.3.1 Instrument Barometric Pressure Calibration..........................................................................12

1.3.3.2 Oxygen Sensor Calibration in Air.............................................................................................12

1.3.3.3 Oxygen Sensor Direct Calibration...........................................................................................14

1.3.3.4 Model 28117 External Pressure Sensor Calibration...............................................................14

1.3.3.5 Model 32646.E Hydrogen Compensation for Oxygen Sensor..............................................16

1.4 Modify Options Menus ........................................................................................17

1.4.1 Display Units................................................................................................................. 18

1.4.2 Thermal Cutoff..............................................................................................................20

1.4.3 Alarm Outputs............................................................................................................... 20

1.4.3.1 Alarms Description...................................................................................................................21

1.4.4 Analog Outputs.............................................................................................................. 21

1.4.4.1 Analog Outputs Description.....................................................................................................22

1.4.5 Serial Output.................................................................................................................24

1.4.6 Salinity and Chlorinity Adjustments................................................................................ 24

1.4.7 H2 Compensation Option (Model 32646.E)................................................................... 25

1.4.8 Self Diagnostics ............................................................................................................. 25

1.4.9 Rolling Average.............................................................................................................. 26

1.4.10 Gas to Measure, CO2/H2S Insensitivity......................................................................... 26

1.4.11 Membrane Selection.................................................................................................... 27

1.5 Maintenance (Sensor Service)............................................................................28

1.5.1 When to Perform a Sensor Service................................................................................28

1.5.2 Remove Sensor from Sample......................................................................................... 28

1.5.3 Prepare Sensor for Cleaning..........................................................................................28

1.5.4 Electrochemical Cleaning...............................................................................................29

1.5.5 Chemical Cleaning......................................................................................................... 29

1.5.5.1 Ammonia Cleaning....................................................................................................................30

1.5.5.2 Nitric acid Cleaning...................................................................................................................30

1.5.6 Polish Sensor Face.........................................................................................................30

1.5.7 Replace Membrane........................................................................................................31

1.5.8 Put Sensor Back into Service..........................................................................................32

1.5.9 Shutting Down the System.............................................................................................32

1.5.10 Troubleshooting.......................................................................................................... 33

1.6 Spare Parts.........................................................................................................34

1.6.1 Oxygen Sensor and Protection Cap Diagram................................................................. 35

1.7 Data Acquisition Software..................................................................................37

1.7.1 Program Setup ..............................................................................................................37

1.7.1.1 Windows 3.1 Setup...................................................................................................................37

1.7.1.2 Windows 95 Setup....................................................................................................................37

1.7.2 Menu Overview.............................................................................................................38

1.7.3 Configuring the Program ............................................................................................... 38

1.7.4 Acquiring Data...............................................................................................................39

1.7.5 Printing, Copying, and Saving Data................................................................................. 40

1.8 Warranty Information.........................................................................................41

1.8.1 About this Manual..........................................................................................................41

4 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

2. Installation Guidelines.................................................................................42

2.1 Instrument Installation .......................................................................................42

2.1.1 Panel or 19-inch Rack Mount Instrument Installation...................................................... 42

2.1.1.1 Instrument Mounting................................................................................................................ 42

2.1.1.2 Power Input.............................................................................................................................. 44

2.1.1.3 Electrical Signal Connections.................................................................................................... 44

2.1.2 Wall Mount Instrument Installation.................................................................................46

2.1.2.1 Instrument Mounting................................................................................................................ 46

2.1.2.2 Power Input.............................................................................................................................. 47

2.1.2.3 Electrical Signal Connections.................................................................................................... 48

2.1.3 Portable Instrument Installation ..................................................................................... 48

2.1.3.1 Instrument Mounting................................................................................................................ 48

2.1.3.2 Power Input.............................................................................................................................. 48

2.1.3.3 Electrical Signal Connections.................................................................................................... 49

2.1.4 Instrument Connectors.................................................................................................. 50

2.1.4.1 Oxygen Sensor Wiring Identification.......................................................................................50

2.1.4.2 External Pressure Sensor Input Wiring Identification.............................................................50

2.1.4.3 RS-232 Wiring Identification....................................................................................................50

2.1.4.4 Recorder Output Wiring Identification................................................................................... 51

2.1.4.5 Alarm Output Wiring Identification......................................................................................... 51

2.1.5 User-supplied Cabling Requirements.............................................................................52

2.1.6 LEMO Connector Assembly Instructions.......................................................................52

2.1.7 Cable Gland Wiring Instructions ....................................................................................52

2.1.8 Instrument Servicing...................................................................................................... 53

2.1.8.1 Battery Replacement (portable instrument)..........................................................................54

2.1.8.2 Analog Current to Voltage Output Conversion.....................................................................54

2.1.8.3 Internal Fuse Replacement....................................................................................................... 54

2.2 Sensor Installation ..............................................................................................55

2.2.1 Model 29501 Sensor Socket Installation ........................................................................ 55

2.2.2 Model 32003 ProAcc Insertion/Extraction Valve Installation .......................................... 56

2.2.3 Model 32001.x Flow Chamber Installation.................................................................... 56

2.2.4 Model 32002.x Multiparameter Flow Chamber Installation........................................... 58

2.2.5 Model 28117 External Pressure Sensor Installation ....................................................... 59

3. Technical Information .................................................................................60

3.1 System Specifications..........................................................................................60

3.2 Principle of Operation.........................................................................................62

Appendix 1—Table of Oxygen Concentrations (ppm)...................................63

Index................................................................................................................69

3600 Analyzer for O2 Measurement—Operator’s Manual 5

3600O2.OM.E9903

1. Operating Instructions

1.1 What you have received

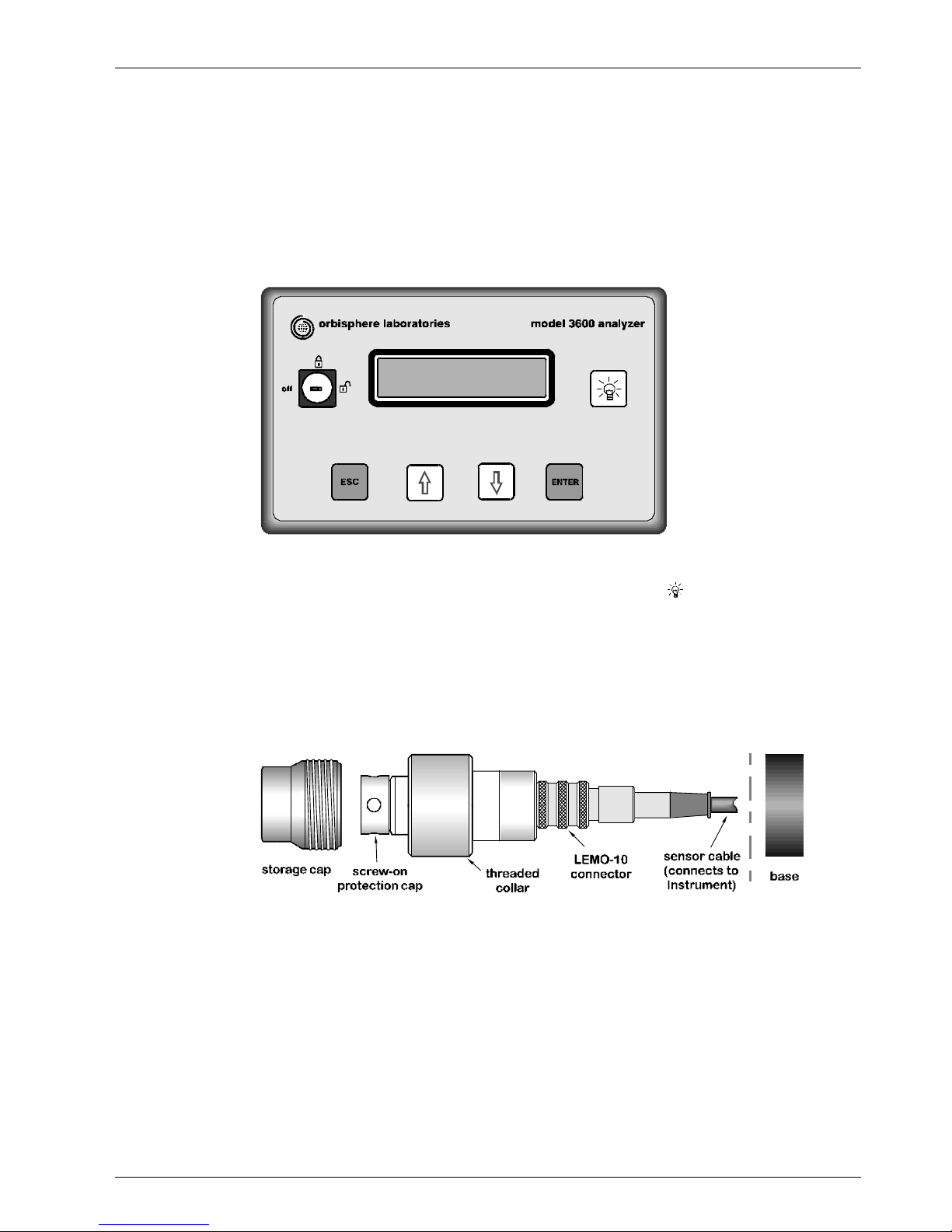

Your 3600 analyzer for oxygen measurements includes two basic components:

• A model 3600/1xx or 3600M/1xx Indicating Instrument, available as a

portable, process (panel or 19-inch rack mount), or wall mount unit; and

• A model 311xx.xx Oxygen Sensor.

These components are available in a variety of configurations, listed in section 3.

Indicating instrument, front panel

The front panel includes a key-lock to switch on the instrument; a two-line liquid

crystal display (LCD), displaying 16 characters across; a “ ” switch to illuminate

the LCD for three minutes when connected to an outside power source; plus four

control keys. Complete operating instructions for this instrument follow—note

that a “Program Flow Chart” in section 1.3.1 gives a handy overview of all onscreen instructions, in the order they appear.

The sensor has a threaded collar and storage cap on top. A plastic screw-on base at

its rear provides a stand for servicing, and protects the screw-on 10-pin LEMO

connection. The sensor cable has a mating LEMO-10 connector.

Oxygen sensor components, plus sensor cable and base—exploded view

A sensor recharge kit, in a blue plastic case, is also included with your shipment.

Inside this kit are the materials to maintain your sensor, such as membranes, a

special membrane mounting tool, polishing powder, and a polishing cloth. The

contents of this recharge kit are listed in section 1.6.

Check to see that any needed mounting hardware has been included. This varies

with each shipment, but in general a flow chamber, multi-parameter flow chamber

(where a model 28117 external pressure sensor also can be mounted), or sensor

socket is usually needed to bring the sensor in contact with the gaseous or liquid

sample. Note that the “Installation Guidelines” in section 2 of this manual include

all the instructions you will need to set up your system. Please refer to this section

now if you are still in the process of configuring your installation.

6 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

1.2 What to check before using the system

Before making initial measurements, first:

Check the voltage and line power—The indicating instrument is available in

115 VAC, 230 VAC, and 10–30 VDC versions. A sticker on the rear panel indicates

which voltage you have. Make sure that it is correct before connecting to a power

supply. Make sure that the ground of the AC supply is connected.

The DC connection must be made by the user, as described in section 2.1.

Note that the portable version can operate without connection to an external

power supply for a period up to 16 hours. If your instrument periodically displays

a “LOW BATTERY” message, it is necessary to recharge the batteries by plugging

the instrument into a power supply and leaving it plugged in overnight.

Check instrument mounting—The instrument is available in portable, process

(panel or 19" rack mount), or wall mount versions. If you are still configuring your

installation, refer to section 2.1 for relevant mounting information.

Check instrument connections—The instrument includes connections for line

power, the oxygen sensor, and an optional external pressure sensor. In addition,

the output pack (optional on portable instruments) includes alarm outputs, analog

current outputs, and an RS-232 serial output. Refer to section 2.1 for complete

wiring and connection information.

Check the oxygen sensor—Shipping conditions can adversely affect Orbisphere

oxygen sensors. You should perform a sensor service as described in section 1.5

before trying to make measurements.

However, if you intend to make trial measurements with the sensor as shipped,

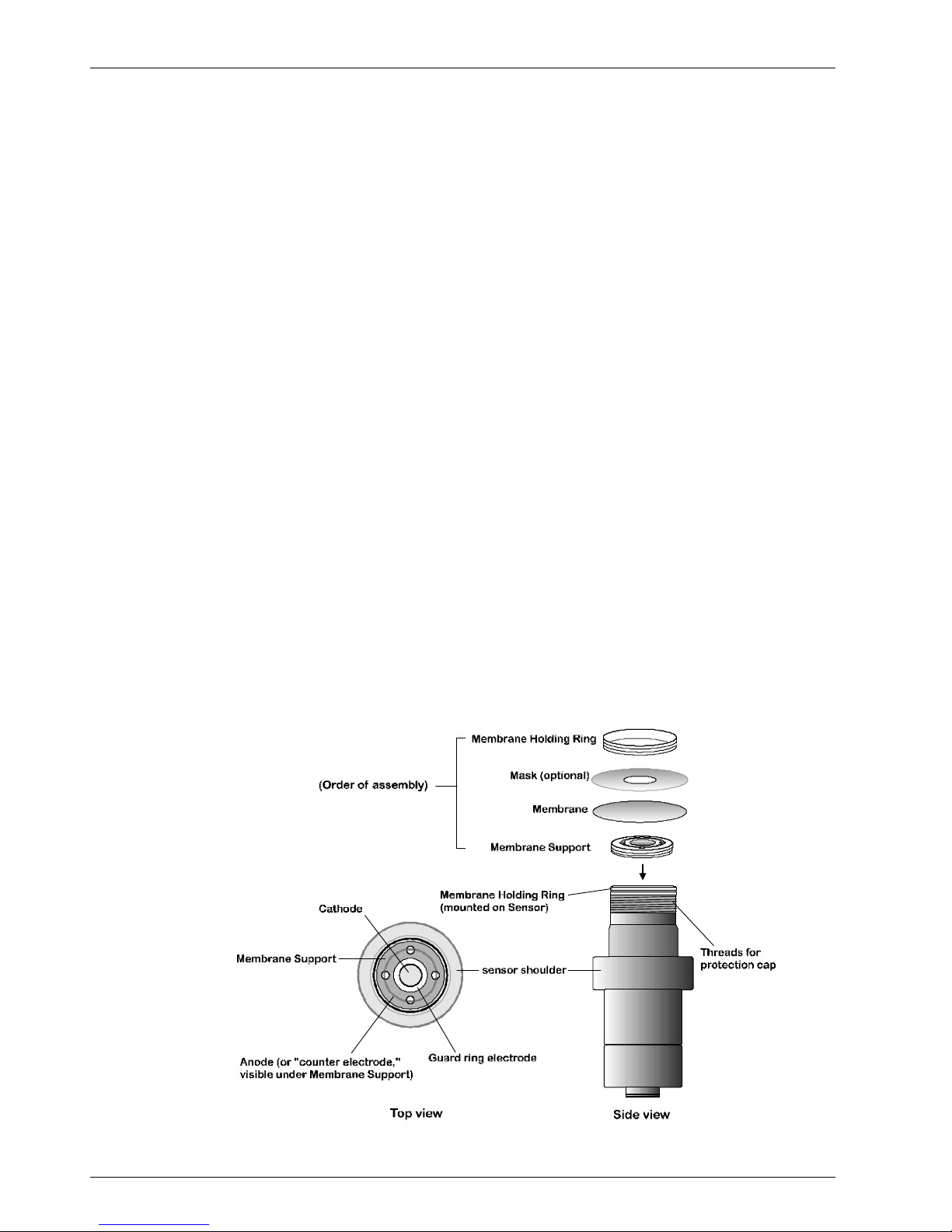

first examine the sensor head. To do this, remove the plastic base at the bottom of

the sensor, then unscrew the calibration cap by loosening its collar.

Your sensor head is fitted with a screw-on protection cap. For a view of the sensor

head, you must remove the cap, using the wrench supplied in your recharge kit.

Do this carefully, making sure not to disturb the membrane that covers the sensor

head, held in place by a membrane holding ring.

O2 sensor components, including exploded view of membrane assembly order

3600 Analyzer for O2 Measurement—Operator’s Manual 7

3600O2.OM.E9903

You should be able now to view the gold cathode, or “working electrode”, in the

center; a guard ring electrode surrounds the cathode, separated by a fine groove.

The anode, or “counter electrode”, is underneath the membrane support. You will

get a better look at all these components during your first sensor service. Before

making a measurement, check the sensor head to see that:

• The membrane holding ring is firmly in place,

• The membrane surface is smooth and wrinkle-free,

• The electrolyte beneath the membrane is free of bubbles,

• The electrodes appear clear, clean, and bright.

Check sensor placement—The oxygen sensor can be placed:

• In a flow chamber (for on-line sampling, that is, samples drawn off line by

6-mm or ¼-inch tubing);

• In a sensor socket or ProAcc insertion/extraction valve for measurements

made directly in a sampling pipe; or

• Directly into “loose” liquid or gas-phase samples.

Check to see that the sensor installation recommendations in the Installation

Guidelines, section 2.2, are followed before proceeding with measurements.

8 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

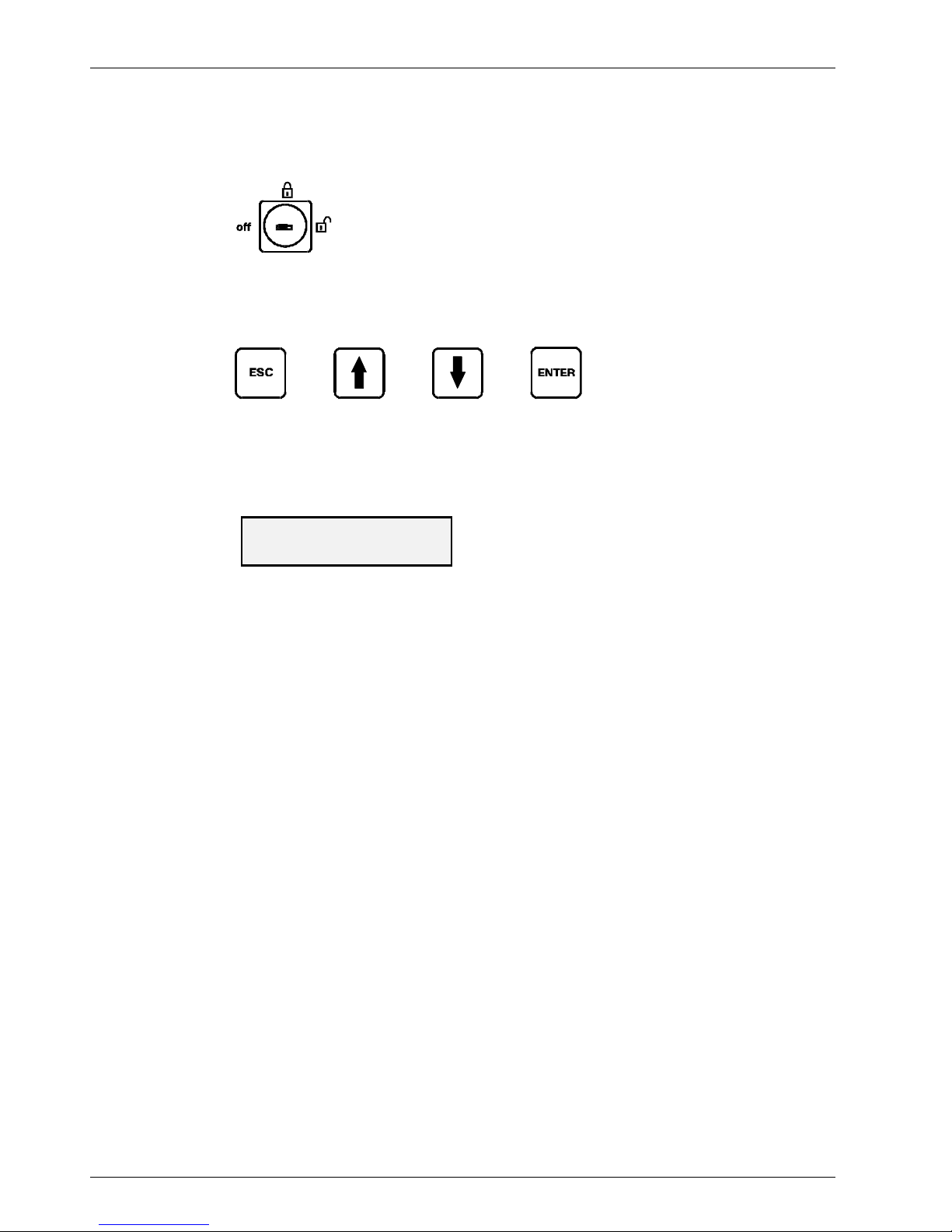

1.3 Instrument Operation

Once you have reviewed the previous sections of this manual, connect the sensor

to the instrument and turn the keyswitch to the horizontal “on” position. The

system automatically starts in “measurement” mode.

Front Panel Keyswitch

The instrument function keys are active only if the keyswitch is in the horizontal

“on” position. Choose the vertical “locked” position when measuring, to avoid

accidental or unauthorized parameter modification.

Instrument Function Keys

The red “ESC” key lets you jump back a step in the program. Following the flow

chart in section 1.3.1, you will see, for example, if your instrument were displaying

the “Measurement” menu, pressing “ESC” would return you to “Measure

Options Calibrate” (also known as the “main menu”).

MEASURE OPTIONS

CALIBRATE

Use the yellow “ñ” and “ò” arrow keys to scroll through available options at

various stages of operation. Pressing “ñ” moves the “blink” from right to left and

“ò” moves it in the opposite direction. During measurement, use these keys to fix

on a specific displayed measurement range, as described in section 1.3.2.

The red “ENTER” key (“DO” on older instruments) lets you select an item. Note

that when inputting numbers (for example, an alarm limit) the menu displays four

digits, with one digit highlighted by the symbol “^”. This digit is incremented by

pressing “ñ” key and decremented by pressing “ò”. Pressing “ENTER” shifts the

highlight one digit to the right, until last digit, in which case the new whole value is

memorized. (Note that if power is disconnected, the system remembers any values

entered via the “ENTER” key when power is resumed.)

The “ENTER” key also activates a single RS-232 transmission when the

instrument is measuring (and the RS-232 output is in “Manual” mode, as

described in section 1.4.5).

For most installations, calibrating the instrument’s internal atmospheric pressure

sensor and calibrating the O2 sensor in air are necessary first steps. The instrument

is factory calibrated for typical applications. However, it is recommended that you

recalibrate the O2 sensor before making any measurements, using the procedures

described in section 1.3.3.

You may wish to familiarize yourself with the “Modify Options” menus described

in section 1.4. Your instrument is pre-set with certain default values, which enable

you to get started on actual measurements with a newly delivered system, but later

you may need to make other choices of parameters.

3600 Analyzer for O2 Measurement—Operator’s Manual 9

3600O2.OM.E9903

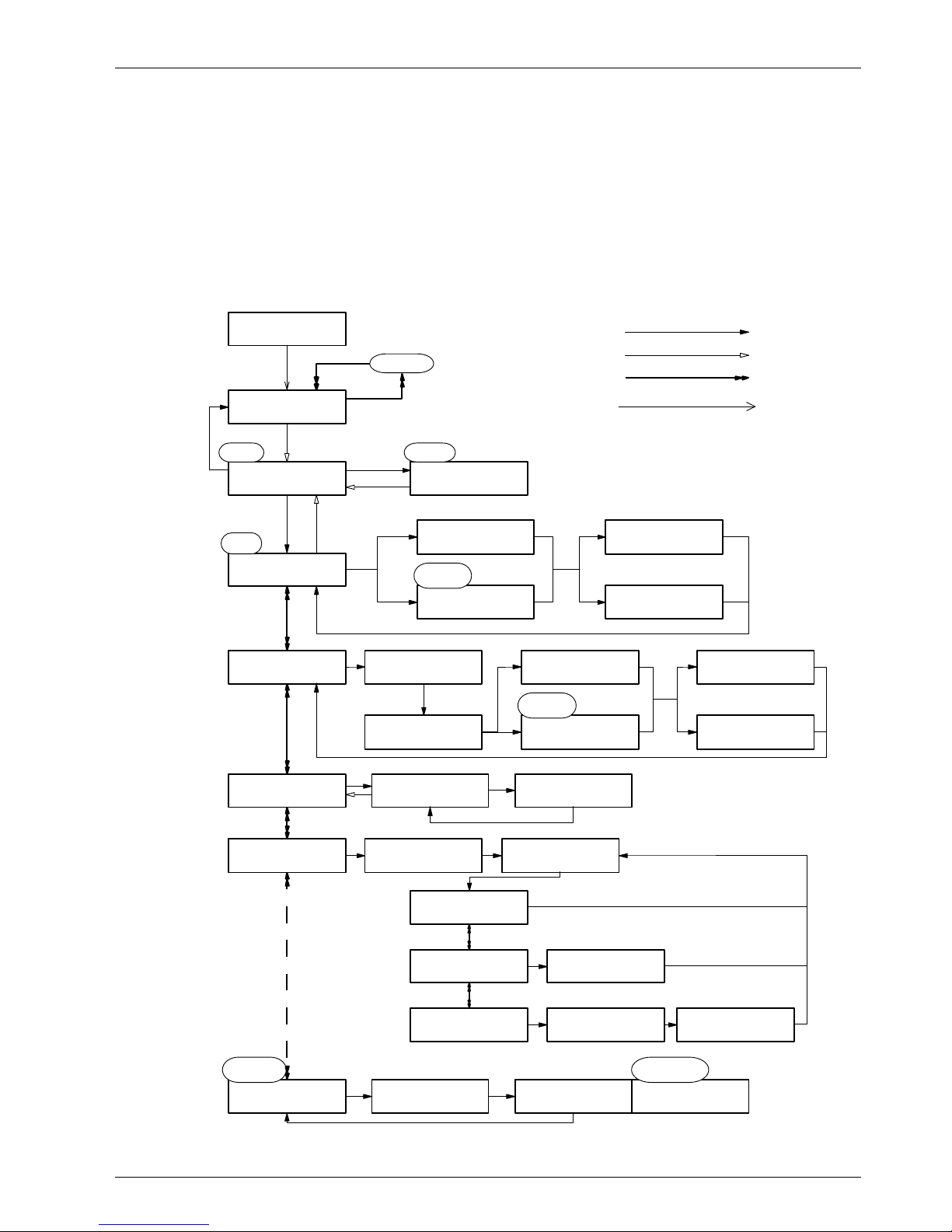

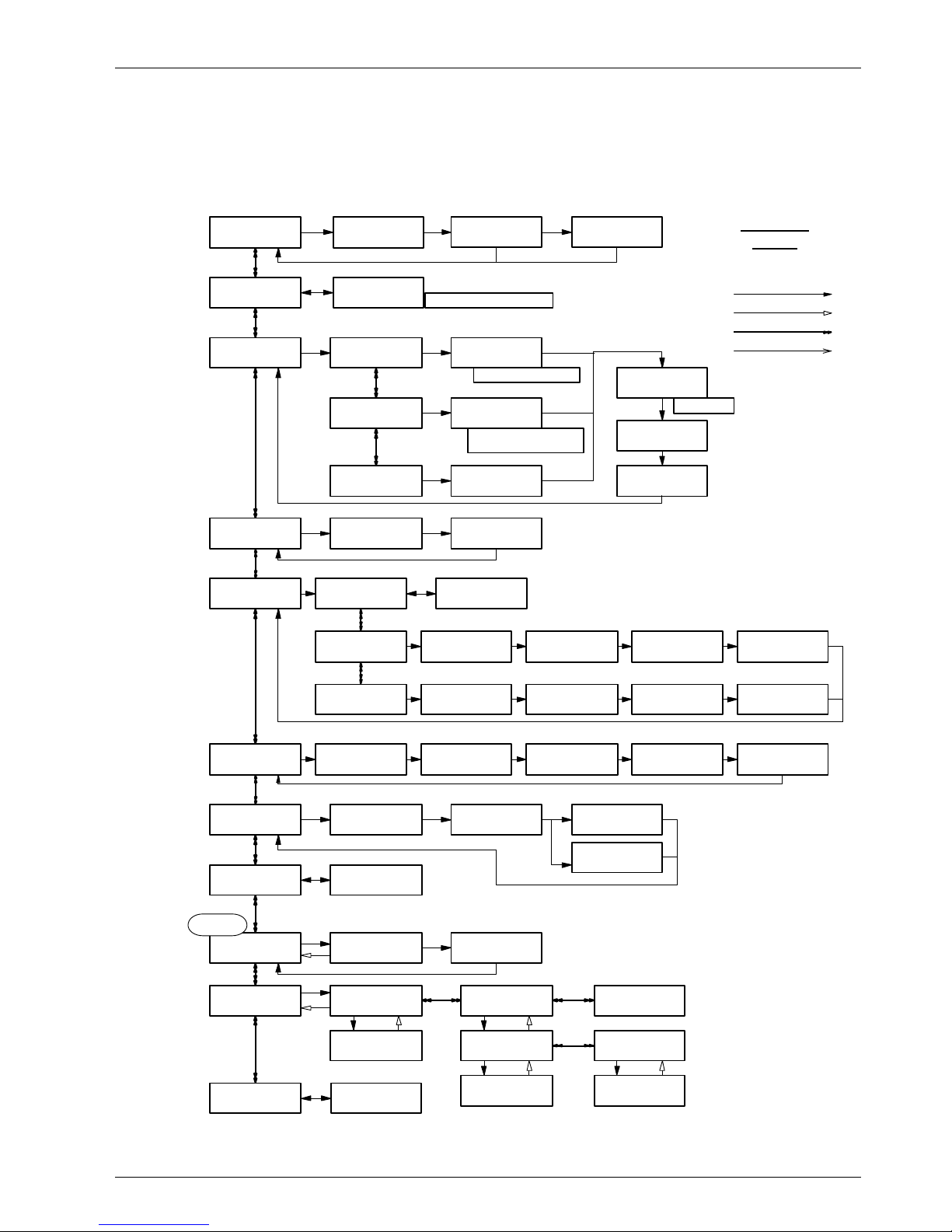

1.3.1 Program Flow Charts

The following flow chart depicts the menus you encounter when the instrument is

first turned on, and an overview of the menu choices. The Measure menu is

described further in section 1.3.2. The Calibration menus depicted below are

described further in section 1.3.3. The Modify Options menus are described in

more detail in section 1.4.

The flow lines are keyed to specific instrument actions. Note that when more than

one item is available within the same menu, the chart uses ellipses (“. . .”) to show

that there are more choices to follow (but you will not see the ellipses on screen).

You may highlight any one of these choices by pressing “ñ” or “ò”.

MEASURE OPTIONS

CALIBRATE

CALIBRATION

IN AIR

(See section 1.6 for

Modify Options menus)

O2 = 7.024 pmv 3

T = 22.3 °C

METHOD

TWO POINTS

V.32603-05.X

18/2/98

Main Menu

CALIBRATION

DIRECT

Calibration

Menu

Change range

CALIBRATION

BAROM. PRESSURE

MODIFY OPTIONS

DISPLAY UNITS

CALIBRATION

EXTERN. PRESSURE

NOW XXX% OF

LAST CALIBRATION

CALIBRATION

OUT OF BOUNDS

CALIBRATION

COMPLETE

NOW XXX% OF

EXPECTED CURRENT

CALIBRATION 0000

CONDITION ^

CC = 8.123 pmv 3

UP/DOWN MODIFIES

NOW XXX% OF

LAST CALIBRATION

CALIBRATION

OUT OF BOUNDS

CALIBRATION

COMPLETE

NOW XXX% OF

EXPECTED CURRENT

PRESSURE

XXXX mbar

BAROMETRIC 0000

PRESSURE ^

after

first calibration

CURRENT

XX.XX nA

EXTERN. PRESSURE

XXXX mbar

LOW POINT 0000

bar ^

CALIBRATION

PURE HYDROGEN

NOW XXX % OF

LAST CALIBRATION

H2 PRESSURE 0000

(CAL) mbar ^

available as

option 32646.E

METHOD

DEFAULT

after

first calibration

METHOD

ONE POINT

Options Menu

ONE POINT 0000

mbar ^

PRESSURE SENSOR

50 psia

HIGH POINT 0000

bar ^

after first calibration

AUTOMATIC (no keystroke required)

ESC

UP/DOWN

ENTER

10 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

1.3.2 Oxygen Measurement

Typical 3600 instruments are delivered with the appropriate measurement and

membrane selections pre-set for your application. However, you can change these

settings if desired. Instructions for the various “options” included are found in

section 1.4, the Modify Options Menu.

The simplest way to check if your system is pre-set for the right measurement

units is to place the system in oxygen measurement mode. Switch on the

instrument (if necessary) to bring up the “Measurement” mode (or select it from

the “Measure Options Calibrate” menu by using the yellow “ñ” or “ò” key if

necessary). You should see a screen like this.

O2 = 00.00 xxx 3

T = 00.0° x ∞

(Note that your system will display actual numerical values in place of the zeros,

and units of measurements for the “x’s” shown here.) If the unit of measurement

on the top line is as expected—for example, in parts per million expressed as

“ppm”—and the appropriate temperature measurement value is expressed (°C,

°K, or °F), then you should be ready to begin to make measurements by placing

your sensor in the sample. (The infinity symbol “∞” only appears as shown when

the system is “busy”, that is, occupied with an internal operation for a few

seconds. Keyboard input will not be accepted during these interruptions.)

Range indication

The range indication appears at the rightmost position of the display’s top line. If

the last position in this line is blank, then you are operating in autoranging mode.

Otherwise, a single digit from 1 to 5 appears, to show which fixed range the

instrument is in. Pressing the “ñ” key will scan this digit upward (“ò” goes

downward) through the permitted “number of ranges” (see section 1.4.1), until it

goes blank, to show that the autoranging mode has been reached. You will also see

the “resolution” of the displayed concentration changing. For example, if you are

configured for three ranges, then you can scan upward through the sequence

...blank-1-2-3-blank... etc. You may see the following message on one or more

fixed ranges (shown here as “Range 3”) during this sequence:

OVERRANGE

RANGE 3

This means that the measured oxygen concentration exceeds the upper limits of

these ranges. Normal corrective action is to press the “ñ” key to reach a less

sensitive range, of which the upper limit exceeds the measured oxygen

concentration. Note that you may see an “Overrange Range 0” message as well.

This is an indication that you are measuring outside the normal limits while in

autoranging mode.

Before making measurements, you should familiarize yourself with the “Modify

Options” menus described in section 1.4. While your instrument is pre-set with

certain default values to anticipate your measurement conditions (for example,

number of ranges, dissolved vs. partial pressure), you may change these for your

application.

What to expect during oxygen measurement

Any sensor previously exposed to the air (or to air-saturated liquid) will, once

placed in a typical sample, generate a signal that decays rapidly at first, then more

slowly as it approaches the actual oxygen level.

3600 Analyzer for O2 Measurement—Operator’s Manual 11

3600O2.OM.E9903

It is normal for the rightmost digits to vary slightly; this is a reaction to slight

variations in oxygen content. However, if drastic changes in temperature occur at

the sensor while in use, correct readings will lag as the sensor adjusts to the new

temperature. The instrument’s response time depends on the membrane used,

anywhere from 7.2 seconds, to 90 seconds, for 90% of total change at 25°C.

(These and other data are found in section 3, “Technical Information”.)

Measurement outputs

The 3600 instrument provides several analog output signals. The analog outputs

represent the measured oxygen concentration, sample temperature, pressure, and

a range indication. These signals are available as 0–5 Volts, 0–20 mA, or 4–20 mA.

You can rescale the oxygen concentration output for your application

requirements. See section 1.4.4 for further description of these analog outputs.

In addition, alarm relay contacts are available in certain 3600 instrument models.

The alarm relays are set in response to various system or measurement conditions.

You can set your own measurement limits—if the measured oxygen concentration

is outside of these limits, the instrument activates the appropriate alarm relay. See

section 1.4.3 for further description of these alarm outputs.

After-use and storage

If you expect not to use your sensor for more than a few months, you should

clean the sensor, as described in section 1.5, and store it “dry”, without electrolyte,

with the storage cap in place for protection.

1.3.2.1 Warning Messages

The following table shows warning messages that appear on the screen in place of

the oxygen concentration, and their explanation.

Message Explanation

CHECK THE SENSOR The sensor is disconnected.

WARNING

THERMAL CUTOFF

The sample temperature exceeds the set upper limit.

See section 1.4.2.

ATTENTION

HIGH LIMIT

The oxygen concentration lies above the high alarm limit. See

section 1.4.3.

ATTENTION

LOW LIMIT

The oxygen concentration lies below the low alarm limit. See

section 1.4.3.

OVERRANGE *

RANGE 1 through 5 (max.)

The oxygen concentration exceeds the upper limit of the

specified measurement range. See section 1.4.1.

OVERRANGE

RANGE 0

The oxygen concentration exceeds the measurement limit while

in “Autoranging” mode. See section 1.4.1.

* If the “OVERRANGE” message appears, it should be sufficient to press the “ñ” key to reach a

less sensitive range. It may also be necessary to enable access to such ranges by pressing “ESC”,

and then raising the “number of ranges” as described in section 1.4.1.

12 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

1.3.3 Calibration Menus

As delivered, 3600 systems are pre-calibrated. However, it is recommended that

you recalibrate the oxygen sensor before making any measurements.

The calibration menu permits the calibration of the oxygen sensor, as well as the

instrument’s internal barometric pressure sensor and an optional external pressure

sensor. The calibration menus are shown in the program flow chart in section

1.3.1.

Note that when you select the calibration menu, the instrument discontinues all

measurement operations.

1.3.3.1 Instrument Barometric Pressure Calibration

The instrument’s atmospheric pressure sensor can be calibrated against your own

barometer.

To calibrate, press “ESC” if necessary to bring up the “Measure Options

Calibrate” screen and highlight “Calibrate”, then press “ENTER”. You will see the

menu below:

CALIBRATION

BAROM. PRESSURE

This menu also includes the options of “In Air”, “Direct”, or “Extern. Pressure”.

Press the “ñ” or “ò” key until “Barom. Pressure” is highlighted, and then press

“ENTER” to see the instrument’s atmospheric pressure measurement:

PRESSURE

980 mbar

If this value (the 980 mbar* value shown is an example only) is acceptable, press

“ESC” to return to the main “Calibration” menu screen. Otherwise, you can

change the value by pressing “ENTER” to bring up this screen:

BAROMETRIC 0000

PRESSURE ^

Use the “ñ” or “ò” key to increment or decrement the each of the four digits, and

press “ENTER” after each digit to move the cursor one place to the right. The

fourth time “ENTER” is pressed, , the instrument stores the value and then returns

to the previous screen. Again, if this is acceptable, press “ESC”. Otherwise, you

may repeat the process by pressing “ENTER” again and re-entering the numbers.

1.3.3.2 Oxygen Sensor Calibration in Air

Once you are satisfied with the barometric pressure indication, the sensor may be

placed in water-saturated air, to provide a known oxygen reference against which

to calibrate. This is done by unscrewing the sensor storage cap, placing the cap

under tap water, then shaking off the water, leaving a few drops inside the cap.

Before replacing the storage cap, note that the screw-on protection cap should be

in place on the sensor head. (If you use a Dacron mesh inside the protection cap,

make sure it is dry before attempting to calibrate.) Then loosely place the storage

cap back on the sensor, holding it in place by a few turns of its collar. The storage

cap and sensor should now be at about the same temperature.

Now turn to the instrument. With the screen displaying

*

Pressure conversion factors are:

1 bar = 1000 mbar = 750.1 Torr or mm Hg = 29.53 inches Hg = 987 atm = 14.5 psi = 100 kPa.

3600 Analyzer for O2 Measurement—Operator’s Manual 13

3600O2.OM.E9903

MEASURE OPTIONS

CALIBRATE

use the “ñ” or “ò” key to highlight “Calibrate”, and then press “ENTER”.

CALIBRATION

IN AIR

To calibrate in air, use the “ñ” or “ò” key to highlight “In Air”, and then press

“ENTER”. This activates the calibration routine.

NOW 95.00% OF

LAST CALIBRATION

The instrument displays the sensitivity of the sensor (that is, the current per unit

partial pressure of oxygen) as a percentage of the sensitivity determined when

calibration was last performed. If, for example, “95% of last calibration” is

displayed, as shown here, then sensitivity has drifted downwards by 5 % since

calibration was last performed. The displayed percentage must be between 30%

and 170% in order to be able to proceed. If this is the case, press “ENTER” to

execute the calibration and display this message briefly . . .

CALIBRATION

COMPLETE

. . . followed by the “Calibration In Air” screen. If you press “ENTER” when the

displayed percentage is outside the permitted range, you will see

CALIBRATION

OUT OF BOUNDS

and you will need to re-examine the sensor for conditions discussed in section 1.2.

In most instances, the sensor will need to be serviced, a procedure described in

section 1.5.

In the program flow chart, section 1.3.1, you will see the note “After first

calibration”. The system considers a “first calibration” to be performed whenever

any particular membrane model is selected by pressing “ENTER” in the “Select

Membrane” menu, or when you have changed any of the options in the “Gas to

Measure” menu. Instead of getting a message on-screen with a percentage of the

“last calibration”, you will see a screen like the following as the system

compensates for the change in parameters;

NOW 95.00% OF

EXPECTED CURRENT

Pressing “ENTER” here will give you either a “Calibration Complete” or

“Calibration out of Bounds” message, as described above.

For reference, a four-page “Table of Oxygen Calibrations” is included in Appendix

1. These tables are useful for verifying your results when have finished sensor

calibration and are back in the “Measurement” mode.

It is possible to receive a “CALIBRATION OUT OF BOUNDS” message even

though you have thoroughly serviced the sensor in accordance with the

procedures in section 1.5. While it is possible that the sensor is in need of repair by

an authorized Orbisphere service representative, it is also possible that the

14 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

instrument simply needs to be reset to its default “Expected Current” after

repeated re-calibrations.

To reset the instrument, enter the “Modify Options/Membrane”, highlight the

membrane model number you are using, and press “ENTER” to “re-select” the

membrane (see also section 1.4.11).

This informs the instrument that it should perform its calibration against expected

current, rather than against the “Last Calibration”. If the sensor is performing

properly, the instrument will accept a new calibration, and you should now receive

a “Calibration Complete” message.

1.3.3.3 Oxygen Sensor Direct Calibration

A “Direct” calibration routine is used when calibrating the oxygen sensor against a

sample of a known oxygen content (that is, a span gas).

(Note that a instrument normally making dissolved oxygen measurements but

calibrated against a gaseous sample using the procedures below will first have to

be configured as a “partial pressure” analyzer, using the “Modify Options” menus

described in section 1.4.1.)

To calibrate, first select the “Calibrate” from the main menu. Press “ñ” or “ò”

until “Direct” is blinking, then press “ENTER”, to bring up this screen:

CALIBRATION 0000

CONDITION ^

Assuming you know the oxygen content to be a certain value, say 8.123 parts per

million of oxygen, you can adjust the value for these four digits with the“ñ” or

“ò” key, and press “ENTER” to activate. This calibration condition screen

(abbreviated “CC”) appears:

CC = 8.123 ppm 3

UP/DOWN MODIFIES

As with instrument menus for alarms and outputs, the unit of measurement and

range are displayed on the top line along with the known value. Pressing

“ENTER” will record this calibration value; the next screen will relate this

calibration to the previous one, as seen before in the “Calibration in Air” menu. As

before, if the value is not within 50 to 150% of the previous calibration, a

“CALIBRATION OUT OF BOUNDS” message prompts you to take corrective

action.

1.3.3.4 Model 28117 External Pressure Sensor Calibration

The 3600 instrument can be fitted with an external pressure sensor, model 28117,

capable of measuring up to 3.5 bar (50 psia). This pressure sensor is mated to the

model 32002 multi parameter flow chamber, as described in the Installation

Guidelines, and interfaces with the instrument via a 4-pin LEMO connector.

If you wish to calibrate your 28117 pressure sensor against a known pressure,

choose “Extern. Pressure” from “Calibration” menu, and press “ENTER” for the

pressure sensor screen.

PRESSURE SENSOR

50 psia

Press “ENTER”, and the instrument now displays what it believes to be the

current external pressure. You can use this as a monitoring screen later:

3600 Analyzer for O2 Measurement—Operator’s Manual 15

3600O2.OM.E9903

EXTERN. PRESSURE

0100 mbar

If this agrees with your current atmospheric reading, then press “ESC” to return to

the menu of interest. However, if you wish to re-calibrate, press “ENTER” to

select the method of calibration.

METHOD

ONE POINT

To calibrate, you have three menu choices:

• “One Point” which permits you to input one pressure value;

• “Two Point” which requires that you calibrate against high and low pressure

values (generally recommended only for high-pressure applications); and

• “Default” which lets the system make its own adjustments.

Use the “ñ” or “ò” buttons to highlight the desired method, and press “ENTER”.

Selecting “Default” causes the instrument to determine the calibration, then return

to the current atmospheric reading display, as shown above.

Activating “One Point” brings up this screen:

ONE POINT 0000

mbar ^

Note that you must enter the absolute (gauge plus atmospheric) pressure. Adjust

each digit with the “ñ” or “ò” key, and press “ENTER” to activate and return to

the “Extern. Pressure” display, as shown above.

The “Two Point” calibration method differs from “One Point” only by requiring

that a “high” and “low” pressure be applied and entered. While this is more time

consuming and is not usually required for precise measurement, it does offer an

additional parameter for the instrument to use for pressure compensations.

LOW POINT 0000

bar ^

The “Two Point” calibration method also requires that you enter the absolute

(gauge plus atmospheric) pressure for each point. Adjust each digit with the “ñ”

or “ò” key, and press “ENTER” to go to the high pressure screen:

HIGH POINT 0000

bar ^

Adjust each digit with the “ñ” or “ò” key, and press “ENTER” to save and return

to the “Extern. Pressure” display, as shown above.

During “Two Point” calibration, error messages are displayed if the sensor voltage

does not fall within a relatively narrow boundary of the expected voltage at both

points. (The possible error messages displayed are: “Pressure points too close”,

“Voltage points too close”, Bad slope”, or “Bad intercept”.) These messages mean

that either the sensor is not functional and should be replaced or repaired, or that

an error has been made in the calibration procedure. If these messages are

displayed, try repeating the two point calibration.

16 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

1.3.3.5 Model 32646.E Hydrogen Compensation for Oxygen Sensor

This software option permits you to operate the O2 sensor in samples containing

high levels of H2. This calibration routine requires that a source of reasonably pure

(for example, 99.8% or better) H2 be available, along with an accurate pressure

gauge. To operate, choose “Pure Hydrogen” from the “Calibration” routine and

then press “ENTER” to bring up this screen:

H2 PRESSURE 1000

(CAL) mbar ^

Using the “ñ” or “ò” key to adjust each digit and “ENTER” to activate, enter the

absolute (gauge plus atmospheric) pressure of the H2 sample (value must not be

zero). The first time this calibration is performed, you will see a menu as follows:

CURRENT

12.34 nA

This is the system’s way of establishing a baseline for the expected sensor current

(in nanoamperes; above is an example only) in the presence of pure H2.

Subsequent calibrations will yield a menu like this:

NOW 95.4% OF

LAST CALIBRATION

Note that in order to use this option, the “H2 Compensation” routine under

“Modify Options” must be enabled. See section 1.4.7.

3600 Analyzer for O2 Measurement—Operator’s Manual 17

3600O2.OM.E9903

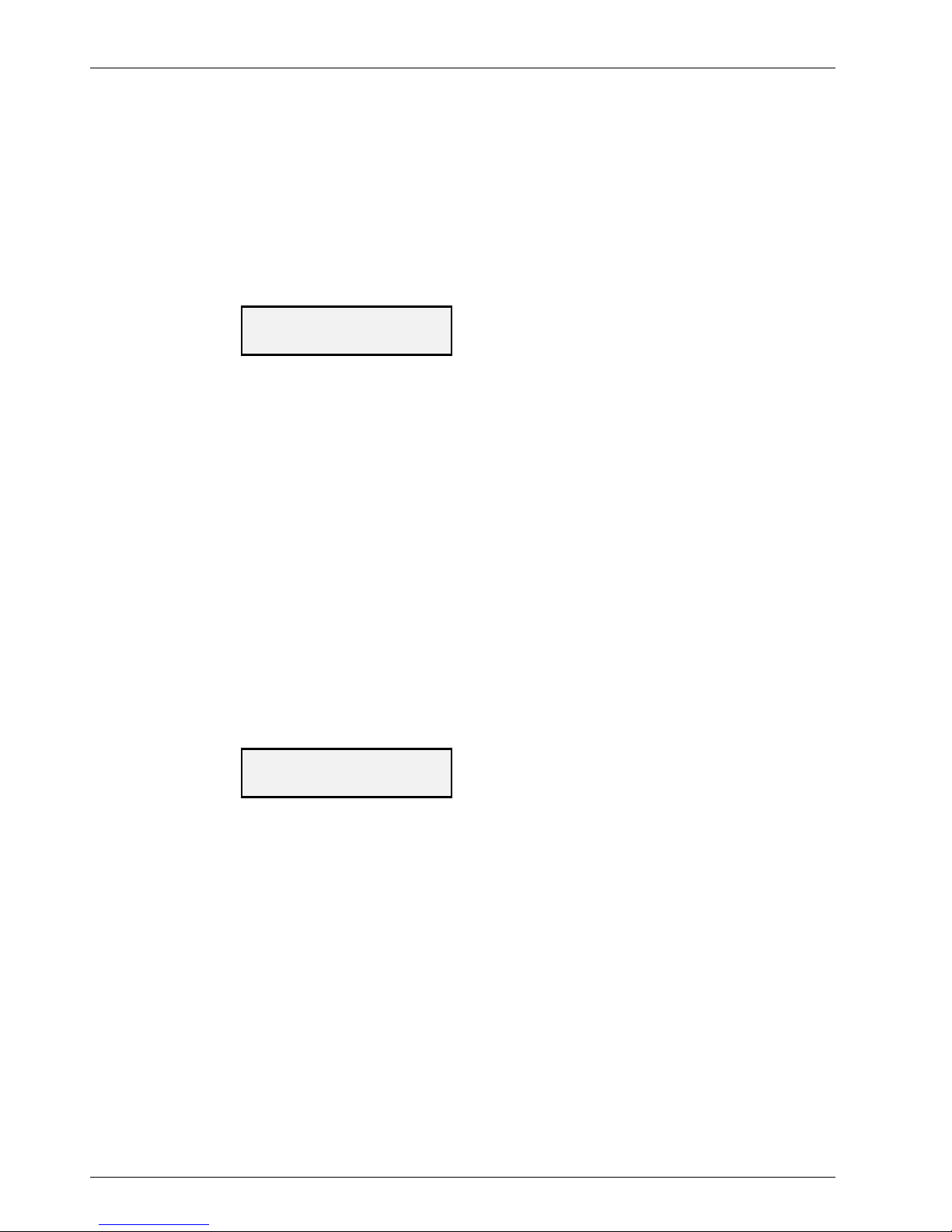

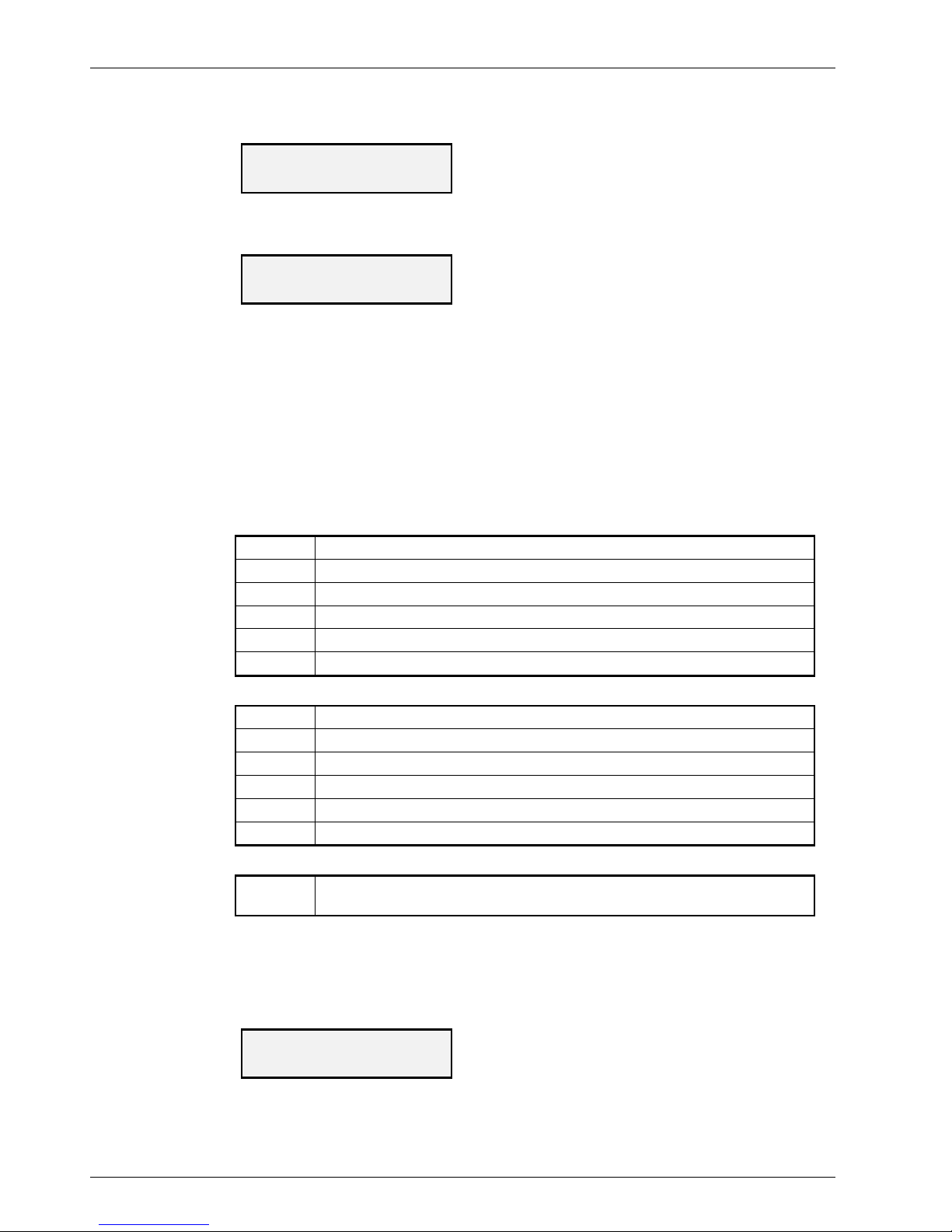

1.4 Modify Options Menus

The Options menus include a full set of programmable outputs, plus the ability to

specify different membranes, units of measurement, sample media, and sampling

conditions. The flow chart below gives you a complete screen-by-screen depiction

of the available menus.

WHICH MODE?

MODE 0

LOWEST RANGE

XXXX XXX.X XX.XX

NUMBER OF RANGES

2 3 4 5

TEMPERATURE

°C °F °K

THERMAL CUTOFF

DISABLED ENABLED

GAS MEASUREMENT

PARTIAL PRESSURE

DISSOLVED

ppm ppb:ppm mg/l

MODIFY OPTIONS

DISPLAY UNITS

MODIFY OPTIONS

THERMAL CUTOFF

GAS MEASUREMENT

DISSOLVED

MODIFY OPTIONS

ALARMS

PARTIAL PRESSURE

mbar bar kPa

...X.XXX

...%sat(O2) %sat(air)

mgB mgU

...ppm:% psia Atm

MODIFY OPTIONS

ANALOG OUTPUT

MODIFY OPTIONS

H2 COMPENSATION

MODIFY OPTIONS

SALINITY

MODIFY OPTIONS

SERIAL OUTPUT

WHICH MODE?

MODE 1

OPTIONS

MENU

FRACTION

pmv:%V

THERMAL 0000

CUTOFF ^

CONFIGURE ALARMS

GENERAL

GENERAL ALARM

DISABLED ENABLED

HIGH/HIGH 0000

LIMIT ^

HIGH 0000

LIMIT ^

HH = 43.21 ppm 3

UP/DOWN MODIFIES

H = 1.234 ppm 1

UP/DOWN MODIFIES

AL = 58.76 ppb 1

UP/DOWN MODIFIES

CUSTOM ANALG OUT

DISABLED ENABLED

ANALOG OUT 0000

LOW LEVEL ^

AH = 8.765 ppm 1

UP/DOWN MODIFIES

RS-232

MANUAL AUTO

GAS MEASUREMENT

FRACTION

MODIFY OPTIONS

ROLLING AVERAGE

MODIFY OPTIONS

MEMBRANE

SELECT MEMBRANE

2956 2958 29552

...2952 2995 2935 29521

MODIFY OPTIONS

SELF DIAGNOSTIC

GAS TO MEASURE?

O2

MODIFY OPTIONS

GAS

CO2 INSENSITIVE

NO YES

DIAGNOSTIC TOOLS

SENSOR

DIAGNOSTIC TOOLS

KEYBOARD

available as

option 32646.E

H2 COMPENSATION

DISABLED ENABLED

H2 PRESSURE 0000

(MEAS) mbar ^

DIAGNOSTIC TOOLS

MEMORY

CURRENT

XX.XX nA

PUSH/CONTINUOUS

UP DOWN

PUSH/LATCHED

UP DOWN ENTER

ROLLING AVERAGE

DISABLED 3 5 7 9

H2S INSENSITIVE

NO YES

SAL. CORRECTION

DISABLED ENABLED

SELECT UNITS g/l

CHLORIN. SALIN.

CHLORINITY 0000

MAX 30g/l ^

SALINITY 0000

MAX 54g/l ^

Key to flow lines:

ANALOG OUT 0000

HIGH LEVEL ^

CONFIGURE ALARMS

HIGH/HIGH

HIGH 0000

LIMIT ^

LOW 0000

LIMIT ^

H = 4.321 ppm 3

UP/DOWN MODIFIES

L = 123.4 ppb 1

UP/DOWN MODIFIES

(configuration

download)

CONFIGURE ALARMS

HIGH/LOW

AUTOMATIC

UP/DOWN

ESC

ENTER

YES

NO

18 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

To activate the “Modify Options” menu when your system is in Measurement

mode, press the red “ESC” key to reveal this menu:

MEASURE OPTIONS

CALIBRATE

Using the yellow “ñ” or “ò” arrow keys, highlight “Options” and press

“ENTER” to display the Modify Options menu.

MODIFY OPTIONS

DISPLAY UNITS

The first “Modify Options” screen will depend on which option was last used. For

this manual, we will start with the “Display Units” option.

1.4.1 Display Units

The “Display Units” option allows you to specify whether your oxygen

measurement is for dissolved gas, fraction, or partial pressure; which units of

measurement are to be displayed; the display resolution (decimal placement); the

number of ranges desired; and the temperature units to be displayed.

Below are the standard choices of display units (certain specialized applications

may have additional units available as well):

Dissolved (in water)

ppb:ppm gas concentration in parts per billion or parts per million, by weight *

ppb gas concentration in parts per billion, by weight

ppm gas concentration in parts per million, by weight

mg/l gas concentration in milligrams per liter

%sat(O2) gas concentration in percentage, relative to water saturated in Oxygen

%sat(Air) gas concentration in percentage, relative to water saturated in Air

Partial Pressure

bar gas pressure in bars

mbar gas pressure in millibars

kPa gas pressure in kiloPascals

psia gas pressure in pounds per square inch, absolute pressure

Atm gas pressure in atmospheres

ppm:% gas pressure, relative to calibration pressure, in parts per million or percentage *

Fraction

pmv:%V percentage of gas volume, relative to external pressure sensor (partial pressure /

external pressure), expressed as parts per million or percentage, by volume *

* Composite measurement units—both units are available in autoranging mode; when the

measurement drops below 1.000 of the higher (second listed) units, the measurement is displayed

in the lower (first listed) units.

Under the “Modify Options” menu, highlight “Display Units” using the “ñ” or

“ò” arrow keys, and then press “ENTER” to display this screen:

DISPLAY UNITS

DISSOLVED

You have the choice of “Dissolved”, “Partial Pressure”, or “Fraction” oxygen

measurement. Use the “ñ” or “ò” arrow keys to move the highlight from one

choice to another, and press “ENTER” to select that option.

3600 Analyzer for O2 Measurement—Operator’s Manual 19

3600O2.OM.E9903

For “Dissolved” measurement, the choices are presented as follows:

DISSOLVED

ppb:ppm ppb ppm

The complete list of available units is: ppm, mg/l, % saturation with O2, % sat Air,

and ppb:ppm (plus mg/liter in solvent units “mgU” and “mgB”.) In the ppb:ppm

mode, concentrations below 1 ppm are displayed in ppb (1 ppm = 1000 ppb).

If you are making “Partial Pressure” measurements, this screen appears:

PARTIAL PRESSURE

ppm:% psia Atm

The complete list of available units is mbar, bar, kPa, ppm:%, psia, and Atm. In the

ppm:% mode, concentrations below 1% are displayed in ppm (1% = 10000 ppm).

Please be warned that there is no pressure compensation of partial pressure

measurements. Thus, the ppm:% units are valid only if the total pressure remains

constant at the calibration pressure.

Activating the “Fraction” oxygen measurement brings up this screen:

FRACTION

pmv:%V

Fraction measurement is corrected for external pressure. Thus, you must have the

model 28117 external pressure sensor connected (see the Installation Guidelines,

sections 2.1.4.2 and 2.2.5) and calibrated (see section 1.3.3.4) properly. This unit of

measurement “behaves” identically to other composite units, in that

measurements below 1%V are displayed in parts per million (1%V = 10000 pmv).

Dissolved, Partial Pressure and Fraction menus all proceed to this screen, to

determine display resolution:

LOWEST RANGE

XX.XX XXX.X

You can adjust the placement of the decimal point on the lowest measurement

range to one of the options (X.XXX, XX.XX, XXX.X, or XXXX) by pressing the

arrow keys to highlight your choice; then press “ENTER” to activate. Note that

the units on the “lowest range” will be the most sensitive available. Hence, if

ppb:ppm had been selected, then your selection of lowest range refers to ppb.

Next is the menu for specifying the number of measurement ranges.

NUMBER OF RANGES

2 3 4 5

For example, if you only want measurement values from “XX.XX” to “XXX.X”

with the “XX.XX” value as the “lowest”, you would select “2” from this menu.

You should select 5 ranges for a “composite” unit like ppm:%. In that case, you

could request the 5 ranges: X.XXX, XX.XX, and XXX.X ppm, X.XXX and

XX.XX %.

You can specify temperature units, in the last screen of this routine:

TEMPERATURE

°C °F °K

20 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

1.4.2 Thermal Cutoff

If the sample temperature could exceed the compensated temperature range of the

sensor, you can set an upper temperature limit to automatically cut off the

electrical signal to the sensor to extend the life of the sensor. (As an example, for

steam cycle operation, you may want to set the cutoff for 40.0° C.)

Under the “Modify Options” menu, highlight “Thermal Cutoff” using the “ñ” or

“ò” arrow keys, and then press “ENTER” to display this screen:

THERMAL CUTOFF

DISABLED ENABLED

Highlight “Enabled” to display:

THERMAL 000.0

CUTOFF ^

Note that the menu highlights an individual digit. This means you must press “ñ”

or “ò” to increment or decrement this digit; then press “ENTER” to move to the

next digit. After pressing “ENTER” a fourth time to enter all the digits, the

instrument returns to the “Modify Options” menu. Once this is set, if the sample

temperature exceeds your limit, the outputs drop to their lowest value and a

“WARNING THERMAL CUTOFF” message appears on the display.

1.4.3 Alarm Outputs

The Alarms menus configure the instrument’s internal relays for alarm outputs.

The alarms configuration (High/Low, High/High, or General) determines the

manner in which these relays respond to various conditions. For High/Low and

High/High configurations, separate measurement limits can be set—if the

measured oxygen concentration is outside of these limits the instrument activates

the appropriate alarm relay (see section 1.4.3.1 for description of the alarm relay

responses).

To select the alarms configuration, under the “Modify Options” menu, highlight

“Alarms” using the “ñ” or “ò” arrow keys, and then press “ENTER”:

CONFIGURE ALARMS

HIGH/LOW

This menu also includes the choices “High/High” and “General”. Use the arrow

keys to highlight your choice, and then press “ENTER” to set that configuration.

Note that whenever you select a configuration from this menu, the other two

configurations are cleared from the instrument, and are no longer active.

For the “General” selection, the next menu allows you to enable or disable the

general alarms:

HIGH/LOW ALARM

DISABLED ENABLED

Highlight “Enabled” and press “ENTER” to enable the general alarms, then the

instrument returns to the “Modify Options” menu. (Measurement limit alarms are

not available in this configuration.)

For the “High/Low” selection, you see a menu like the following to set the

measurement limits for this configuration:

HIGH 0000

LIMIT ^

3600 Analyzer for O2 Measurement—Operator’s Manual 21

3600O2.OM.E9903

Use the “ñ” or “ò” arrow keys to increase or decrease the highlighted digits, and

then press “ENTER” to move to the next digit. First, set up all of the significant

digits of the desired limit without regard for the position of the decimal point or

units. Once the fourth digit is set, press “ENTER” to see the following screen:

H = 43.21 ppm 3

UP/DOWN MODIFIES

In this menu, “H” represents the High Limit value. The rightmost digit on the top

line indicates which range is affected: 1 refers to the lowest range, 2 to the second

range, and so on. Use the “ñ” or “ò” keys to modify this setting, and then press

“ENTER” to save your selection.

The instrument then proceeds to the second set of limit menus (Low Limit in our

example; in the last screen, “L” represents the Low Limit). After you enter the

second limit, the instrument returns to the “Modify Options” menu.

For the “High/High” configuration selection, menu operation is as above, except

that the menus use the abbreviations “H” (for High Limit) and “HH” (for HighHigh Limit) in place of the “L” and “H”.

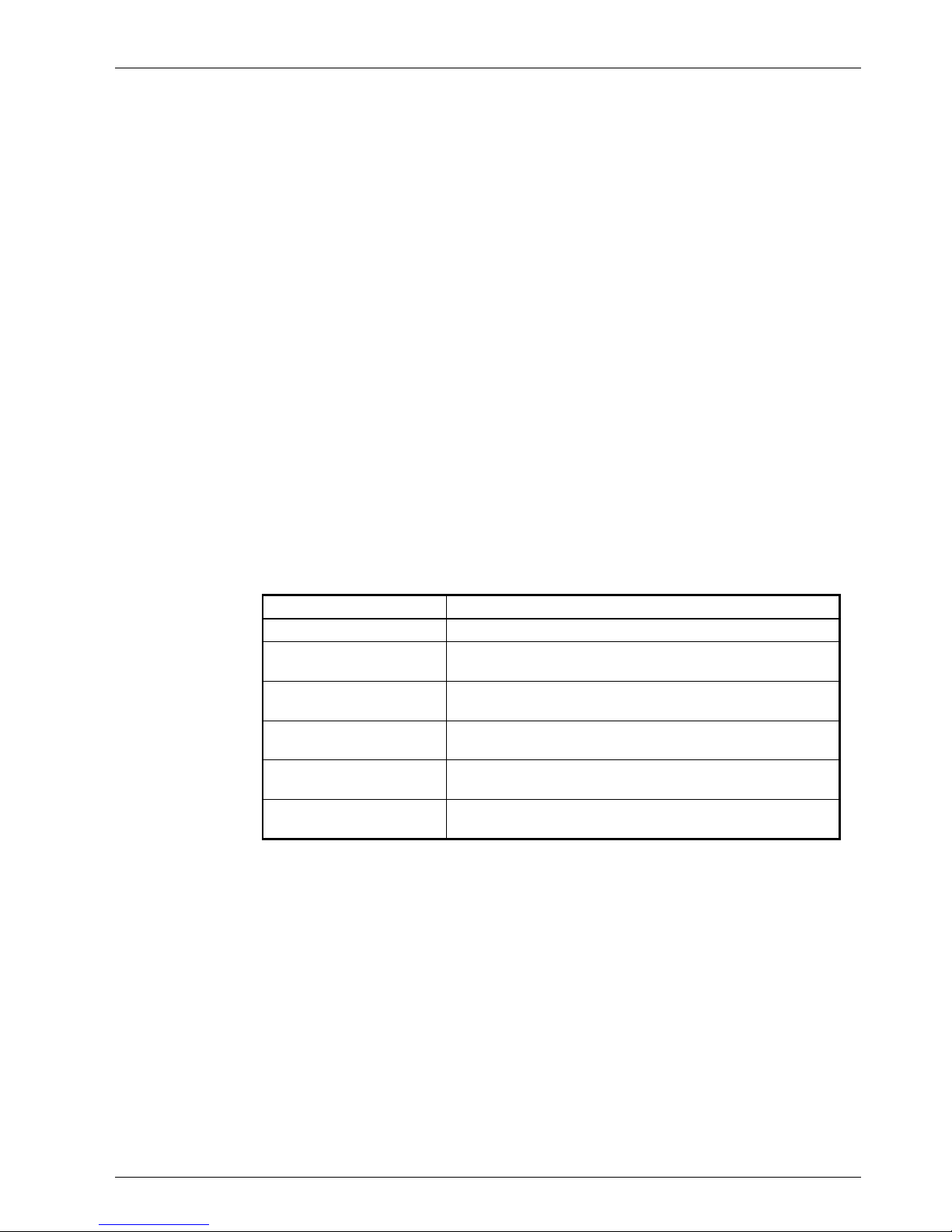

1.4.3.1 Alarms Description

Two alarm relays are provided (“C” and “C1”) in certain instrument models. The

alarms configuration (High/Low, High/High, or General), set using the above

“Alarm Outputs” menus, determines the manner in which the alarm relays

respond to various system or measurement conditions. These alarm conditions

and alarm relay responses are shown in the following table. Note that certain alarm

conditions set both alarm relays.

Configure Condition “C” relay “C1” relay

High/Low No alarm: low limit < O2 concentration < high limit

Low alarm: O2 concentration < low limit

High alarm: high limit < O2 concentration

High/High No alarm: O2 concentration < high limit

High alarm: high limit < O2 conc. < high-high limit

High/High alarm: high-high limit < O2 conc.

General Normal Measurement operation

Overrange, Thermal cutoff, Negative gas signal, Sensor

disconnected, Instrument switched off, or not in

Measurement

Note: This table shows the alarm relay response for the normally open (NO) contacts of each relay

= relay closed, = relay open; the normally closed (NC) contacts are the

reverse state of those shown above.

After a Low, High, or High-High alarm condition is signaled, the instrument clears

the Low alarm when the measured O2 concentration rises to 1% above the low

limit, or clears the High or High-High alarm when the gas concentration drops to

1% below the high or high-high limit respectively.

See section 2.1.4.5 for alarm relay contacts wiring identification.

1.4.4 Analog Outputs

The instrument provides several analog output signals representing sample

measurements (see section 1.4.4.1 for description of these analog outputs). The

Analog Outputs menus scale the O2 concentration output signal between any two

custom concentration limits, for use with external equipment such as recorders.

22 3600 Analyzer for O2 Measurement—Operator’s Manual

3600O2.OM.E9903

Under the “Modify Options” menu, highlight “Analog Output” using the arrow

keys, and then press “ENTER” to display this screen:

CUSTOM ANALG OUT

DISABLED ENABLED

Highlight “Enabled” and press “ENTER” to set your custom analog output levels.

ANALOG OUT 0000

LOW LEVEL ^

Use the “ñ” or “ò” arrow keys to increase or decrease the highlighted digits, and

then press “ENTER” to move to the next digit. First, set up all of the significant

digits without regard for the position of the decimal point or units. Once the fourth

digit is set, press “ENTER” to see the following screen:

AL = 43.21 ppm 3

UP/DOWN MODIFIES

In this menu, “AL” represents the Analog Low Level. The rightmost digit on the

top line indicates which range is affected: 1 refers to the lowest range, 2 to the

second range, and so on. Use “ñ” or “ò” to modify this setting, and then press

“ENTER” to save your selection.

The instrument then proceeds to the Analog High Level menus, similar to the two

above (in the last screen, “AH” is used as the abbreviation). After you enter the

high level, the instrument returns to the “Modify Options” menu.

1.4.4.1 Analog Outputs Description

Four analog outputs are available when the instrument is connected to an external

AC or DC power supply (but not available for battery power). The analog outputs

provide separate signals that represent the measured O2 concentration,

temperature, pressure, and a range indication. These outputs are available as 0–5

Volts, 0–20 mA, or 4–20 mA. See section 2.1.4.4 for analog (recorder) output

wiring connections, and section 2.1.8.2 for current/voltage output conversion.

The analog outputs are generated using a 12-bit digital converter; thus, the

minimum increment of any output can be determined by dividing the output range

by 4096. For example: You could set the gas concentration range to 0–500 ppm for

4–20mA, and your recorder would still pick up changes of 0.2 ppm. The accuracy

of each increment is 1%.

O2 concentration (gas) output

You can scale the analog output signal representing sample O2 concentration

between any two gas concentration levels, “AL” and “AH” (see menus above).

The default values of these levels are 0 and 9999, respectively. When “Custom

Analog Output” is enabled (with the “Analog Output” menus above), the AL and

AH levels can be set as desired.

The relation between the analog output current “I” (in mA) or voltage “V”, and

the gas concentration “C” is as follows, as scaled by these limits:

0–20 mA C = AL + (AH - AL) * I/20

4–20 mA C = AL + (AH - AL) * (I - 4)/16

0–5 Volts C = AL + (AH - AL) * V/5

Loading...

Loading...