Page 1

Page 2

Ever since the founding of the company in 1968,

Orange has been a pioneering force in the guitar

amplification industry. Today, with a team of the

world’s finest engineers, Orange continues to

push back the boundaries of product design.

THANK YOU FOR CHOOSING ORANGE

Our commitment to craftsmanship and quality

control has allowed our products to stand the

test of time, giving their owners as much

pleasure now as the day they were bought. To

maintain this level of excellence, all Orange

products are put through many rigorous test

procedures before leaving the factory.

2

Page 3

WHAT’S IN THE BOX

1 x Valve Tester MKII

1 x Power Supply

1 x Mains lead

1 x Manual

1 x Pencil

3

Page 4

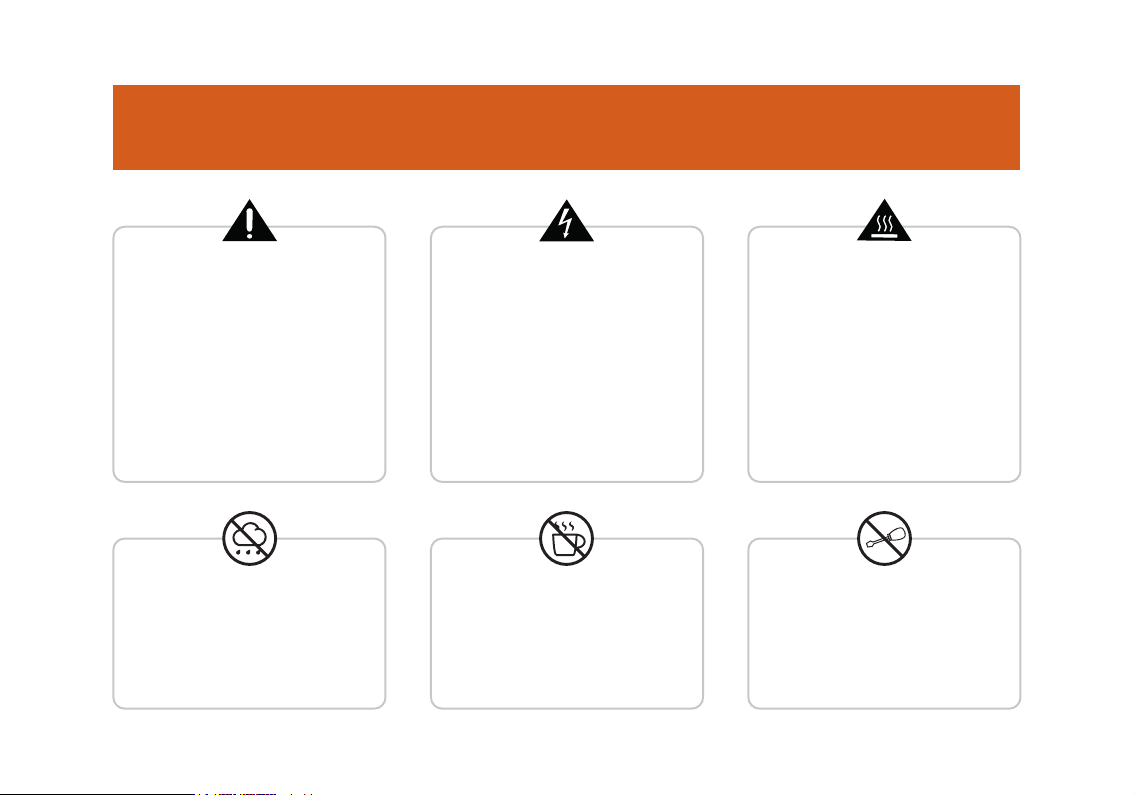

IMPORTANT SAFETY

The exclamation point within an

equilateral triangle and "WARNING" are

intended to alert the user to the

presence of important operating or

servicing instructions. Failure to heed

the instructions can result in severe

injury or death.

This equipment should be used under

the supervision of an adult at all times.

To reduce the risk of fire and electric

shock do not expose this apparatus to

rain or moisture. Do not use in damp

environments, e.g. bathrooms etc.

The lightning flash with arrowhead

symbol, within an equilateral triangle,

is intended to alert the user to the

presence of un-insulated ‘dangerous

voltage’ within the product’s

enclosure that may be of sufficient

magnitude to constitute a risk of

electric shock to persons.

Do not place objects containing

liquids on, or near the product.

Do not operate this apparatus or

connect/disconnect a power plug

whilst hands are wet.

The “Caution, hot surface” symbol

indicates the marked item may be hot.

Ensure the apparatus is installed with

plenty of space around the unit

(> 6”/12.5cm) as this apparatus may

generate heat under normal use. This

equipment is not intended to be used on

soft support (like beddings, blankets etc.).

This equipment should always be placed

on a flat, stable surface.

Do not attempt to gain access to

the interior of the product. No user

serviceable parts inside. Refer all

servicing to qualified servicing

personnel.

4

Page 5

The Orange Valve Tester MKII (VT MKII) supply input is

19V DC 65W. The DC input socket is centre positive

polarity and the barrel plug is a ‘standard 2.5mm type.’

To avoid the risk of product damage it is highly recommended to only use the power supply supplied with the

product, or an exact equivalent.

This device complies with the Canadian Interference Regulations CAN ICES-3(B)/NMB-3(B).

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

Warning valves can get hot during testing, ensure they

are cool to handle before removing from the valve tester.

Valves are fragile, so always be gentle when handling

them and attaching or detaching them from the VT MKII.

!

2) This device must accept any interference received, that may cause undesired operation.

1) This device may not cause harmful interference.

Note: This equipment has been tested and found to comply with the limits for Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and if not installed and used in accordance with the instructions, may cause harmful interference to radio communications.

5

Page 6

WHY CHOOSE THE ORANGE VT MKII?

Commercial valve testers have been available, almost since valves were invented, incorporating many excellent

techniques and designs over the years. However, the vast majority have a number of common features, which we

considered to be a barrier to the modern valve user namely:

• They require a certain level of user interaction in that parameters have to be set for individual valves being tested.

• They require a certain depth of knowledge about valve theory, which some users may not have.

• The results obtained on meters or digital readouts require a certain level of user interpretation.

• They are often quite large and bulky.

In a lot of cases, they are also not very portable and

since most are mains operated, require selection of

mains voltage if required to be used in other than their

native country. When developing the VT MKII we

decided to ‘break the mould’ to produce a fully

automatic valve tester, which performs a wide range of

tests quickly and accurately.

Requiring little or no knowledge of valve theory, it can

be operated by experienced users and those who just

want to know that the valves in their amplifier are in

good condition. It requires no user interaction other

than inserting the valve to be tested into the correct

socket, selecting the type from a list using two

up/down buttons using an LED bar display, then finally

pressing an ‘OK’ button to start the test.

6

Page 7

The test then proceeds without any further user input

and elapsed time is shown on the LED display during the

test, then one of three LED’s is lit to indicate a ‘GOOD’,

‘WORN’ or ‘FAIL’ condition.

In addition, the LED display indicates a ‘matching

number’ which is based on a summation of the many

results obtained during the test and has been specifically

designed to reflect the operation of the valve, according

to its normal function in an audio amplifier.

For example, power valves are graded with their

emission and control grid performance as primary

factors, whereas pre-amp valves are graded with

different parameters to reflect their role in signal

amplification and phase splitting applications. If the

valve is faulty or worn, then this will be indicated at the

end of the test.

The simplicity of operation belies what is going on

‘inside the box’, where a sophisticated microprocessor

controlled testing system (incorporating TubeSyncⓇ

Technology) is in operation, allowing full control over all

inter-electrode switching and measurement operations.

In addition all voltages required by the tester are

internally derived, stabilised and controlled by the

microcontroller, allowing rapid static and transient

tests without generating unnecessary heat. The test

algorithms used have been developed using data from

tests on hundreds of new, used and faulty valves.

We are passionate about valve technology and our aim

throughout has been to make the Orange VT MKII a

sophisticated, modern, truly portable valve tester

which is primarily useful but also stylish, appealing to

all valve users whether amateur, professional or in the

music retail trade.

7

Page 8

BEFORE USING YOUR VALVE TESTER

With the VT MKII, Orange has designed a compact, safe and simple alternative to the large, dubious and

complicated valve testers of the past. However, despite its small size the VT MKII is a highly accurate and sensitive

piece of test equipment, and should be treated as such.

When in use the VT MKII is taking thousands of micro measurements and performing a vast array of tests in order

to grade your valves. These tests measure very small voltage and current changes under high impedance

conditions, which means a number of external factors can affect the end results.

TO OBTAIN THE MOST CONSISTENT READINGS, WE ADVISE OBSERVING THE FOLLOWING:

With temperature being a factor we suggest that the

VT MKII is used, wherever practically possible, in a

location where temperature and humidity will remain

constant. If inconsistent test results are being

observed during the first couple of tests allow for

further time for the effects of humidity, condensation

and temperature to neutralise and re-test.

The grading/matching system is based on a decision

made after performing over 20 tests. For this reason

and the sensitive nature of valves (particularly 12AX7/

ECC83s) some slight variance may be seen during

testing. If this is observed allow the valve to cool, move

the VT MKII into an area of constant conditions and

re-test.

8

Page 9

Any condensation which may occur on the valve bases

or internally can influence initial results. Due to the

thermal insulation properties of the packaging and the

high thermal mass of the metal case, the VT MKII may

remain at a very low temperature for a considerable

time if left in the packaging. If it is brought into a warm

room and immediately used, condensation will

naturally occur and produce false test readings. We

recommend the VT MKII is allowed to stand for around

30 minutes out of its packaging before initial use for

these effects to subside.

! !

%

Do not test hot or warm valves. The VT MKII uses high

voltages to ensure accurate readings from the valves

which are tested with the correct voltages as stated in

their manuals. Under testing, the valve will become

warm and this heat will alter impedances inside the

valve. If the same valve is then repeatedly tested

before being allowed to return to room temperature, or

if a warm valve is tested having just been used (e.g. in

an amplifier), false readings will be given. We advise

leaving valves to reach or return to room temperature

before testing.

9

Page 10

CONTROLS AND FUNCTIONS

A B C

Valve socket for octal power valves.

A

Valve socket for EL84 valves.

B

Valve socket for pre-amp valves.

C

Selected valve type text (both UK and US).

D

Valve matching value (range between 1 & 15).

D

E

F

G

E

Valve status result: GOOD, WORN, FAIL.

F

Control buttons. Centre button selects valve

G

type and starts the test. The two outer buttons

move valve selection from right to left.

10

Page 11

VALVE SOCKETS & VALVE SELECTION

VALVE SOCKETS PHYSICALLY DAMAGED VALVES

No damage will occur to the VT MKII by testing faulty or

EL34/6CA7; 6L6;

6V6/6V6GTA; KT66;

KT77; KT88; KT120

6550; 5881;

EXPANSION MODULE

EL84/6BQ5

ECC81/12AT7;

ECC82/12AU7;

ECC83/12AX7; 12BH7

damaged valves.

Under no circumstances should any attempt be made

to insert into the test socket or to test a valve which is

physically damaged, as this could present a hazard to

the user or others.

If a glass valve envelope is accidentally damaged during

a test, the ‘OK’ button should be used to terminate the

test and the power connector removed.

The valve should then be allowed to cool after which it

should be removed using protective gloves and then

safely disposed of. DO NOT touch any exposed metal

parts of the valve during the operation and ensure that

no fragments of glass remain around the tester before

using it again.

!

11

Page 12

USING YOUR VALVE TESTER

STEP 1 STEP 2

Decide which valve you would like to test and identify

what valve test socket is required for the test.

Octal power valves (EL34s, KT66 etc.) use valve socket 1.

EL84 valves use valve socket 2.

Preamp (ECC83, 12BH7) valves use valve socket 3.

STEP 3 STEP 4

Ensure the supplied power lead is connected to the

tester and is switched on. Press the ‘OK’ button to start,

then by moving the left and right selector buttons

select the valve type which you are about to test.

When the correct valve type has been selected press

‘OK’ again and the test will commence.

Carefully insert the valve into the correct valve socket and

ensure it is seated correctly.

Only one valve must be inserted into the tester at a time.

Valves must be tested at room temperature.

Testing a hot valve may result in a failure as the tester is

calibrated to heat the valve up as part of the test sequence.

It takes approximately two minutes for the tester to test

a valve, during this time a number of orange LEDs will

illuminate and flash.

As the test progresses the number of LEDs illuminated

will gradually decrease until the test is completed. If the

valve fails at any point, the test is automatically

terminated and the red ‘FAIL’ LED is illuminated.

12

Page 13

STEP 5 TEST STATUS

Once the test completes and the green, yellow or red

indicator lights, then the test is finished; however, as

valves may get hot during the test, we recommend that

you make sure that the glass envelope is cool before

attempting to remove it.

In any case, we recommend the use of protective gloves

when handling valves.

Note: Some specific faults found by the VT MKII may be either transitory or not immediately obvious when used in normal

operation. However, they could manifest themselves when the valve comes under stress or heavy load during a performance.

GREEN - If the green LED is illuminated this indicates

that the valve is GOOD.

YELLOW - If the yellow LED is illuminated this indicates

that the valve is worn and should be replaced

as soon as possible.

RED - If a red LED is illuminated this indicates that the

valve has failed.

In the case of a RED FAIL light the tester will also display

a number ranging from 1-8, this reflects the valve failure

mode. (See the fault log at the back of the handbook).

For example : if the FAIL LED and LED 7 are illuminated

simultaneously after a test, the valve is a fail and the

reason for the failure is due to control grid leakage.

13

Page 14

NEW FEATURES ON THE VT MKII

A more rugged mechanical design

with improved test sockets

Improved algorithm with higher

current capability

Valve failure mode identification

Capability to function with external

expansion modules enabling the testing of

other valve types such as rectifiers and EF86s

New enhanced grid leakage

detection test

New microphony function for ECC81, ECC82

and ECC83 and 12BH7 pre-amp valves

New thermal runaway test

Capability to test directly heated valves

such as a 300B via the expansion module

14

Page 15

VALVE MATCHING NUMBER

A ‘matching number’ indicated by the LED(s) at the end

of the test, is based on a combination of measured

parameters to give an indication of how the valve will

perform, according to its typical function in an amplifier.

After the valve has been tested, the tester will assign a

matching number ranging from 1 to 15. Basically: the higher

the value, the higher the gain of the valve. If a number of

valves are tested, the gain or ‘matching valve’ can then be

used to group together pairs or quads of valves.

VALVE MATCHING VALUE FOR DOUBLE TRIODE

(PRE-AMP VALVES)

Double triode (pre-amp valves) have two valves inside one

envelope i.e. an A & B side. After the MK II has tested a

double triode (providing that the valve passes) two

matching value LEDs will illuminate.

For section A the LED will flash and for section B the LED

will be constant. If only one constant LED is illuminated,

this means that both sides of the valve are the same.

In general, the closer the LEDs are together the better,

if two matching valves are apart by more than 6 values

the VT MKII will fail the valve. See the examples below.

Both sections of the valve are fairly well matched.

Both sections of the valve are the same (one constant LED).

15

Page 16

MICROPHONY MODE

To begin the microphony test insert the valve into

the PRE-AMP socket. (ECC81, ECC82, ECC83, 12BH7

valves only).

Toggle along to number 15 and hold the right

button down for 3 seconds. When the yellow light

comes on the valve is heating up.

When the valve is heated, the yellow light will go out and

the green will come on. The valve is now ready, tap the

valve gently with a pencil to test microphony. Note: If

there is any noise present in the valve some LEDs will

illuminate prior to tapping.

The higher the LEDs go in the moving LED bar, the

greater the microphonic disturbance. Note: this test is

indicative only, however with experience the user can

easily detect a valve that exhibits a microphony issue.

16

Page 17

EXPANSION MODULES

Insert the expansion module, then select number 15

using the right arrow button. The yellow and green light

will illuminate for a second and then go out. This

indicates the tester has downloaded the test parameters

for the particular valve.

The number 15 LED should then remain solid, LEDs 1-14

will flash. to start the test press the OK button.

Expansion modules are available to purchase separately.

For further information please see orangeamps.com

17

Page 18

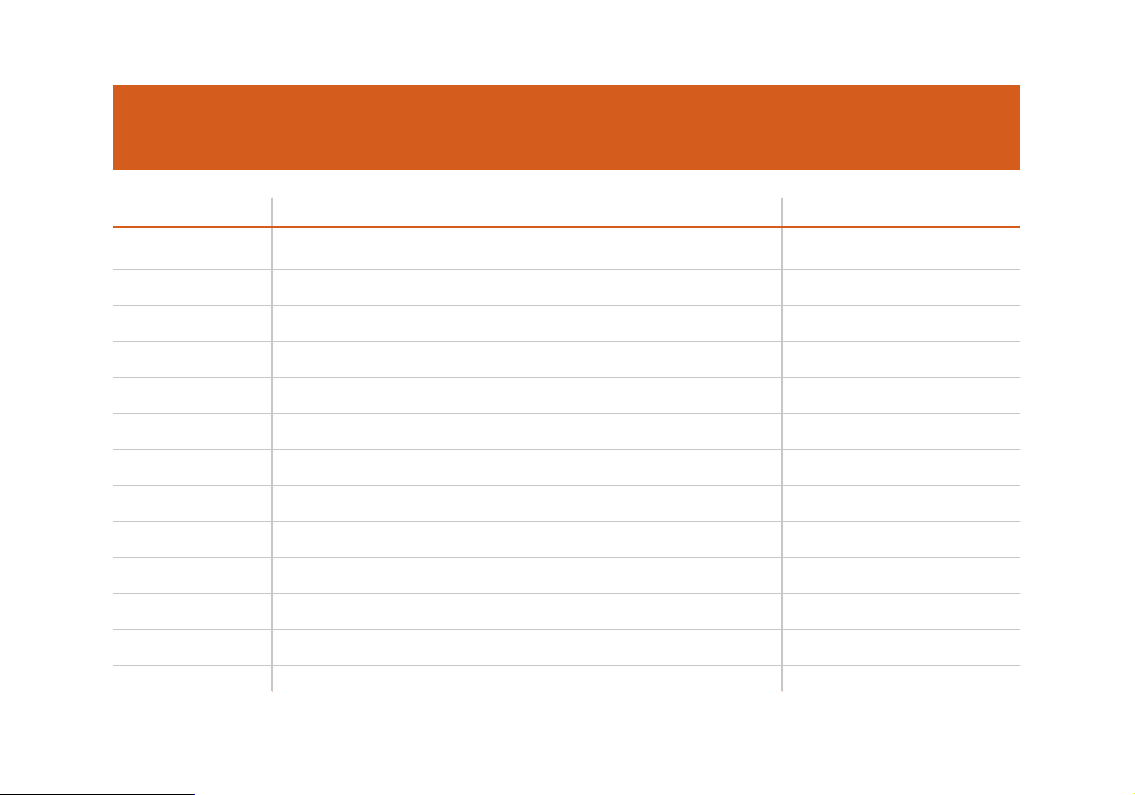

FAULT LOG

FAULT NUMBER

1 - Immediate fail

1 - Fail during test

2

3 - Pentode test

3 - Triode test

4 - Pentode test

4 - Triode test

5 - Pentode test

5 - Triode test

6 - Pentode test

6 - Triode test

7

8

REASON FOR FAULT

Heater open circuit or value missing

Heater current below minimum valve for valve type

Heater current too high

Anode current exceeds max valve for valve type

Anode 1 current exceeds max valve for valve type

Anode current does not achieve min value for valve type

Anode 1 current does not achieve min value for valve type

Screen grid current exceeds max value for valve type

Anode 2 current exceeds max valve for valve type

Screen current does not achieve min value for valve type

Anode 2 current does not achieve min value for valve type

Control grid leakage

Thermal runaway during test

ALTERNATIVE REASON

Total or partial short circuit

Internal leakage or short

Internal leakage or short

Very low emission

Very low emission

Internal leakage or short

Internal leakage or short

Very low emission

Very low emission

18

Page 19

Page 20

orangeamps.com

Loading...

Loading...