Page 1

71SO Overfill Prevention Valves and

71SO Testable Overfill Prevention Valves

Installation and Maintenance Instructions

IMPORTANT INFORMATION

FOLLOW ALL INSTRUCTIONS

Please read these warnings and use and assembly

instructions completely and carefully before starting. Failure to do so may cause product failure, or

result in environmental contamination due to liquid

leakage into the soil, creating hazardous spill conditions.

OPW Standard Product Warranty Tag: Notice: FlexWorks by OPW, Inc., VAPORSAVER™ and all other OPW

products must be used in compliance with all applicable federal, state, provincial and local laws, rules and

regulations. Product selection is the sole responsibility

of the customer and/or its agents and must be based

on physical specications and limitations, compatibility with the environment and material to be handled.

All illustrations and specications in this literature are

based on the latest production information available

at the time of publication. Prices, materials and specications are subject to change at any time, and models may be discontinued at any time, in either case,

without notice or obligation.

OPW warrants solely to its customer (the initial purchaser and any subsequent purchasers within the

warranty period) that the following products sold by

OPW will be free from defects in materials and workmanship under normal use and conditions for the periods indicated:

PRODUCT WARRANTY PERIOD

FlexWorks Primary Pipe 10 years from date of manufacture

All Products and replacement parts in-

stalled in the State of

California

Certied to California CP

-201 and/or CP-206

Standards*

All other Products and

replacement parts

*Products certied to California CP-201 and/or CP-206 Standards

have been factory tested and met all applicable performance stand-

ards and specications and will have an OPW registration card en-

closed/attached to the product.

1 year from date of installation (proof of

purchase from certied contractors/

technicians required)

OPW warrants ongoing compliance with

the standards and specications for the

duration of the warranty period required

by the State of California; this limited war-

ranty is under the condition the equip-

ment was installed and maintained by

trained and certied contractors/

technicians unless noted in Installation

Manual.

1 year from date of manufacture**

OPW’s exclusive obligation under this limited warranty is, at its option, to repair, replace or issue credit (in

an amount not to exceed the list price for the product)

for future orders for any product that may prove defective within the applicable warranty period. (Parts

repaired or replaced under warranty are subject to

prorated warranty coverage for remainder of the original warranty period). Complete and proper warranty

claim documentation and proof of purchase required.

All warranty claims must be made in writing and delivered during the applicable warranty period to OPW at

OPW 9393 Princeton-Glendale Road Hamilton, Ohio,

USA 45011, Attention: Customer Service Manager. No

products may be returned to OPW without its prior

written authority.

This limited warranty shall not apply to any FlexWorks

or VAPORSAVER™ product unless it is installed by an

OPW attested installer and all required site and warranty registration forms are completed and received by

OPW within 60 days of installation. This limited warranty also shall not apply to any FlexWorks, VAPORSAVER™

or other OPW product: unless all piping connections are

installed with a nationally-recognized or stateapproved leak detection device in each tank and dispenser sump (which are not for storage and from which

all discharge hydrocarbons must be removed, and the

systems completely cleaned, within 24 hours); unless

testable sumps utilize FlexWorks pipe and access ttings; unless a sump inspection log or an EPA recommended/required checklist is maintained and the results are furnished to OPW upon request; and unless

OPW is notied within 24 hours of any known or suspected product failure and is provided with unrestricted access to the product and the site. This limited warranty also shall not apply to any product which has

been altered in any way, which has been repaired by

anyone other than a service representative authorized

by OPW, or when failure or defect is due to: improper

installation or maintenance (including, without limitation, failure to follow FlexWorks Quick Reference Manual Installation Guide and all product warning labels);

abuse or misuse; violation of health or safety requirements; use of another manufacturer’s, or otherwise un-

1

Page 2

authorized, substances or components; soil or other

surface or subsurface conditions; or re, ood, storm,

lightning, earthquake, accident or any other conditions,

events or circumstances beyond OPW’s control .

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, AND ALL OTHER

WARRANTIES INCLUDING, WITHOUT LIMITATION, THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ARE HEREBY EXCLUDED.

OPW shall have no other liability whatsoever, whether

based on breach of contract, negligence, gross negligence, strict liability or any other claim, including, without limitation, for special, incidental, consequential or

exemplary damages or for the cost of labor, freight, excavation, clean-up, downtime, removal, reinstallation,

loss of prot, or any other cost or charges. No person or

entity is authorized to assume on behalf of OPW any

liability beyond this limited warranty. This limited warranty is not assignable.

** Date of manufacture on this product is located on

the at area of the valve body, under oat.

GENERAL INSTRUCTIONS

The OPW 71SO Overll Prevention Valve is designed for

tight ll, gravity drop applications to help prevent accidental or intentional overlling of underground storage

tanks. It is installed in the UST drop tube in place of a

standard drop tube.

The main 71SO valve closes when liquid reaches the

initial shut o point. A small bypass valve remains open

to allow the delivery hose to drain at 3-5 gallons per

minute. If the delivery truck valve is not closed after

initial shut-o, the bypass valve will close and will restrict all fuel delivery to ensure that the top of the tank

is not wetted per EPA requirements.

The 71SO models of the 71SO are designed to be installed with the following OPW products: Face Seal

Adaptor, OPW Spill Container or Multi-port, Jack Screw

Kit, Rotatable Product Adaptor, and Product Cap.

IMPORTANT

Read these assembly and installation instructions completely and carefully prior to starting. Check to make

sure all parts have been provided. Use only the parts

supplied; substitution of parts may cause product failure.

Failure to follow instructions may cause improper product operation or premature failure which may permit

storage tank overll. An overlled storage tank may

create hazardous conditions and/or environmental contamination.

CAUTION

Do not remove elastic band from around oat until

instructed to do so, as damage to valve may result.

WARNING

Failure to properly connect delivery hose and elbow, and/or disconnecting a liquid lled delivery

hose or elbow will result in a hazardous spill, which

may result in personal injury, property damage, re,

explosion, and water and soil pollution.

Make sure all connections, including the hose and

elbow connections, between storage tank and

transport are securely coupled.

Make sure the lip seal and/or all gaskets in the deliv-

ery elbow are properly in place to prevent spills.

Do not operate with damaged or missing parts,

which prevent tight connections.

Normal Operation: A Hose ”Kick” and reduced ow

signal that the tank is full. Close transport delivery

valve and drain hose into tank before disconnecting

any hose tting.

Overlled Tank: Failure of the hose to drain after closing the delivery valve signals an overlled tank. Do Not

Disconnect any delivery hose tting until the liquid level in the tank has been lowered to allow the hose to

drain into the tank.

WARNING

In the event you are splashed with fuel remove wet

clothing immediately. Skin contact with gasoline

can cause chemical burns and may result in inhalation of vapors that may be fatal. Never go inside

conned areas after being splashed and never go

near ignition sources.

IMPORTANT

Determine if the underground storage tank is equipped

with a ball oat vent valve, as illustrated in Figure 24. In

all systems, the shut-o point of the 71SO must be

reached before the ball oat reduces ow to ensure

proper overll valve operation.

TOOLS NEEDED FOR INSTALLATION AND ASSEMBLY:

1. 71SO-TOOL or 71SO-TOOLC or

71SO-TOOLCT (includes the following)

Sharp 3/16” drill bit with stop

Punch

NOTE: Testable 71SO models ending with a “T” require the 71SO-TOOLCT or modied 71SO-TOOL or

71SO-TOOLC

2

Page 3

2. Drill

3. Hammer

4. Tape measure

5. Hacksaw or cut-o saw, ne tooth; 24 teeth/inch

6. Fine half round le

7. Screwdriver - Phillips blade

8. Fine grit sandpaper / steel wool

9. Grease, black moly

10. Torque Wrench

11. Band clamp (3-3/4” diameter minimum)

12. TESTABLE MODELS ONLY: rivet tool for 1/8” mandrel, crimping tool / pliers, wire cutter / scissors,

pipe dope, 1/4” square drive extension or 3/8”

square drive extension with 3/8” to 1/4” socket

adapter.

WARNING

Using electrically operated equipment near gasoline

or gasoline vapors may result in re or explosion,

causing personal injury and property damage.

Check to assure the working area is free from such

hazards, and always use proper precautions.

IMPORTANT: The gures in this installation and

maintenance instruction may contain vapor recovery

equipment (including model numbers) that is not certied by the California Air Resources Board (CARB) for a

specic Phase I Vapor Recovery System. Please refer to

Exhibit 1 of the appropriate CARB Phase I Executive Order for a list of certied Phase I Vapor Recovery System

Equipment.

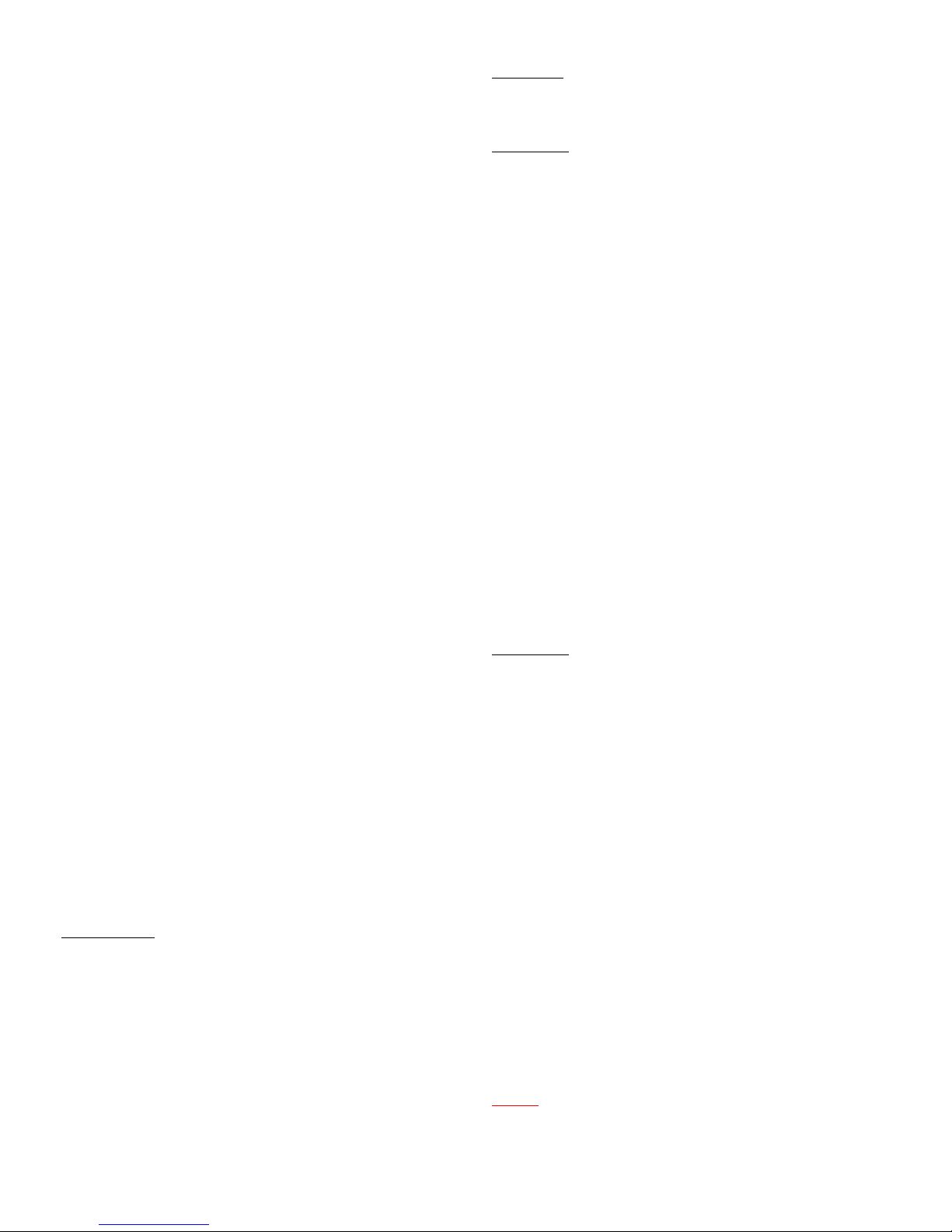

71SO Parts Diagram

Upper O-Ring Gasket

Screws, Qty 3

Inlet Tube

Polypak Seal

Upper Drop Tube

Valve Body

Float

Lower O-Ring

Lower Tube

Alternate Components - Testable Versions

Note: all components are the same except the

socket adaptor & cable assembly, rivet, testable

inlet tube, and ferrule.

Socket Adaptor & Cable

Assembly

Rivet

Ferrule

Testable Inlet

Tube

3

Page 4

IMPORTANT: The instructions below for the 71SO

Overll Prevention Valve are written for the initial

stage shuto at 95%, but can be adjusted to shuto

at any desired tank capacity. Please contact the Authority Having Jurisdiction (AHJ) and review local,

state, and national codes to determine the regulatory requirements governing shut-o capacity in your

region, as well as take into account other considerations such as extreme tank tilt. In all cases, the upper tube must protrude into the tank at least 6 1/2”

to ensure that the valve can shut o ow into the

tank completely before the top of the tank is wetted

as per EPA requirements.

HOW TO LOCATE THE POSITION OF THE 71SO AT

95% TANK CAPACITY

(Shut-o points can be adjusted to any capacity to

comply with AHJ Requirements)

The length of the upper tube and the placement of the

71SO valve body determine the shut-o point. Following the standard instructions for the OPW 71SO will provide for initial shuto at 95%. In all cases, the upper

tube length must be a minimum of 6-1/2" plus the

length of the riser pipe. All length measurements are in

inches.

INSTRUCTIONS

1) Find tank capacity (in gallons) from tank calibration

chart provided by tank manufacturer.

2) Calculate 95% of capacity

3) Locate the 95% volume number on the tank calibration chart.

4) Find the dipstick number (X) which corresponds to

the 95% tank volume. And, nd the dipstick number (Y) which corresponds to the 100% volume.

5) Subtract the dipstick number (X) from the tank diameter (Y) to nd the upper tube reference number

(Z).

(Y) - (X) = (Z)

6) Subtract 2" from (Z) to nd the upper tube depth

(C).

(Z) - 2" = C

7) Is C less than 6-1/2"?

NO Upper tube length is C plus the distance from

the top of the Face Seal Adaptor installed on

the riser pipe to the inside, top lip of the storage

tank (A).

Upper Tube Length = C + (A)

For testable models only, ending in “T”:

Upper Tube Length = C + (A) – 1-1/2”

YES Upper tube length is 6-1/2” plus the riser pipe

measurement (A).

Upper Tube Length = 6-1/2” + (A)

For testable models only, ending in “T”:

Upper Tube Length = 6-1/2” + (A) - 1-1/2”

NOTE: You must nd the actual tank capacity number that correlates to the 6-1/2” + (A) depth for the

station records. This number may also be used for

the purposes of calibrating an electronic tank level

system.

Figure 1

EXAMPLE

1) For an Owens-Corning Model G-3 Fiberglass® Tank

Calibration Chart:

Tank Capacity - 10,000 gal., nominal 9,403 gal.

NOTE: Use actual capacity only

2) 95% of actual tank capacity = 0.95 x 9403 gal. =

8933 gal.

3) The closest number which is less than 8933 gal. Is

8910 gal. Choosing the closest number less than

95% of actual capacity ensures that the initial

shuto will occur when the tank is no more than

95% full.

4) The calibration chart reading of 8910 gal. corresponds to a dipstick measurement of 82”.

4

Page 5

5) Dipstick number (X) = 82”

Tank diameter (Y) = 92”

(Y) - (X) = (Z) (92” - 82” = 10”)

(Z) = 10”

6) (Z) - 2” = C (10” - 2” = 8”)

C=8”

7) Is 8” less than 6-1/2”?

NO Measure the distance from the top of the FSA-

400 Face Seal Adaptor installed on the riser pipe

to the inside, top lip of the storage tank and obtain measurement (A).

Upper tube length = C + (A)

For testable models only, ending in “T”: Upper Tube

Length = C + (A) - 1-1/2”

ASSEMBLY INSTRUCTIONS

IMPORTANT: Each of the numbered steps in the instal-

lation instructions are designed as a CHECK LIST to ensure proper installation and trouble free operation of

the OPW 71SO Overll Prevention Valve.

Read and follow these steps carefully, checking them

o as you proceed.

Figure numbers correspond to step numbers for easy

reference.

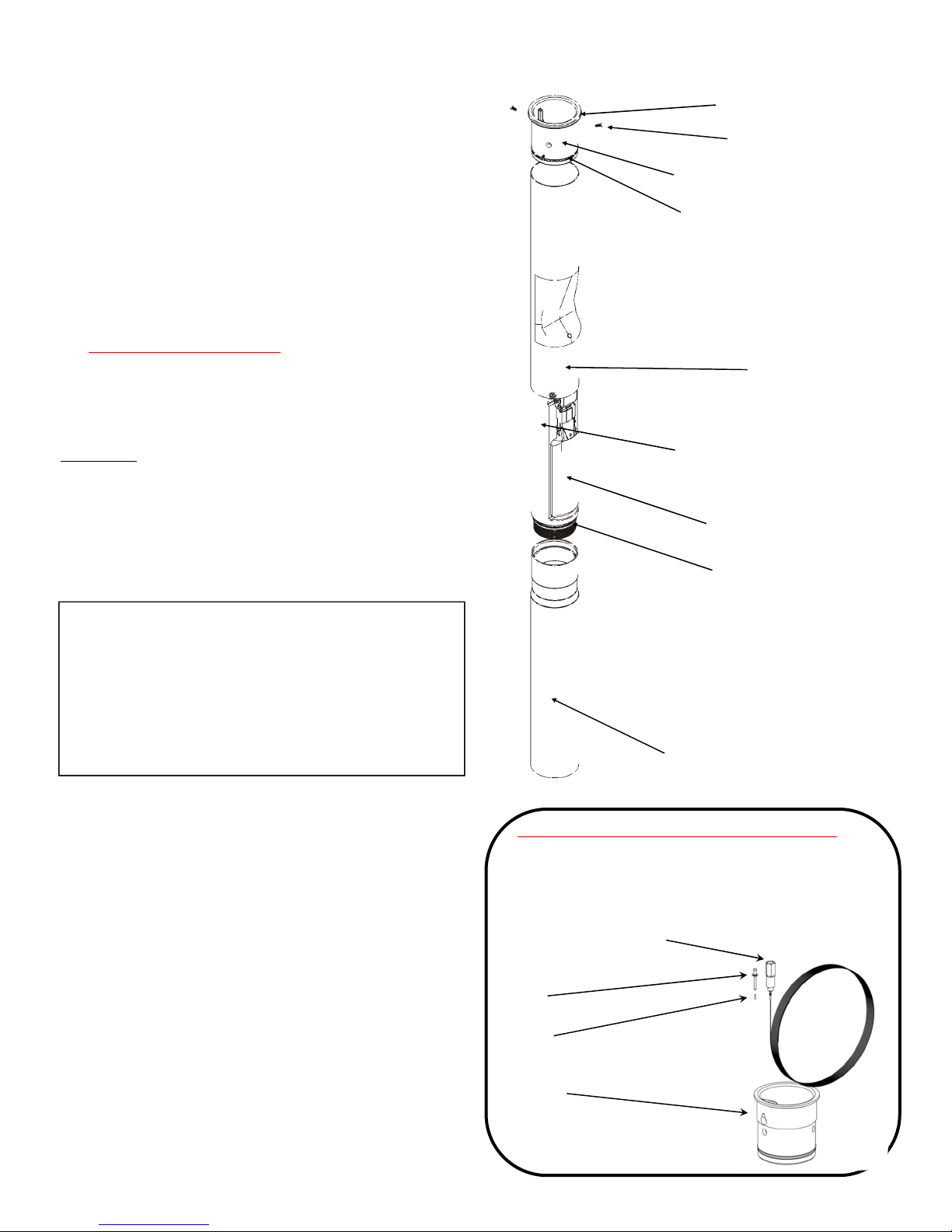

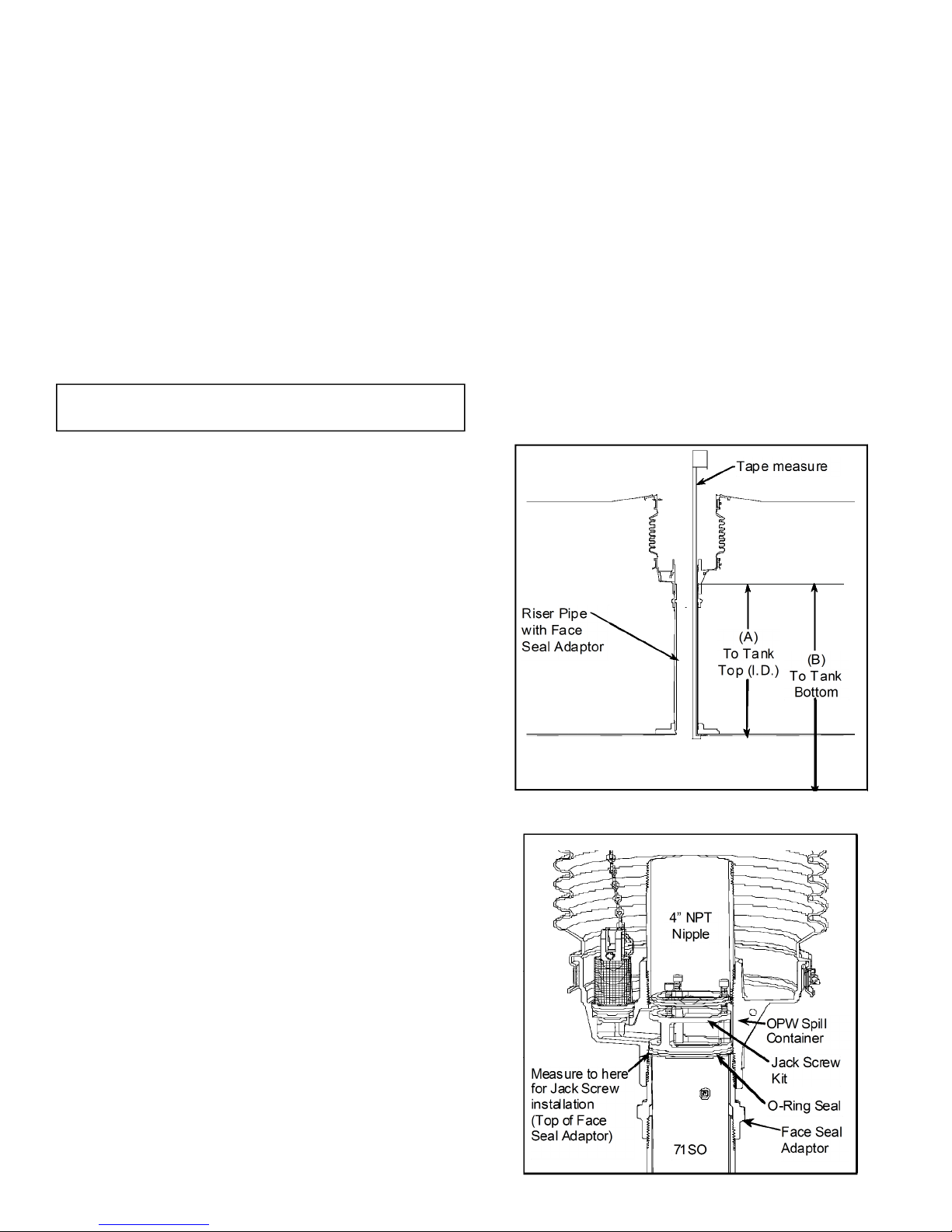

STEP 1: MEASURE

Install the OPW Face Seal Adaptor and the OPW Threadon Spill Container on the Fill Riser (Refer to the Installation Instructions Supplied with the Spill Container). Insert a tape measure through the riser pipe and hook it

under the inside of the tank in the lengthwise direction.

Measure the distance from the top of the Face Seal

Adaptor threads inside the base of the spill container

bucket just below the drain valve outlet window to the

inside, top lip of the storage tank (Dim. “A”) (See Figure

1 &1A).

The top ange on the 71SO will rest on the Face Seal

Adaptor just below the drain valve outlet, and be

locked in place between the Face Seal Adaptor and the

4" nipple that is installed in the spill container with the

Jack Screw Kit (See Figure 1A). (For riser pipe congurations other than that shown, consult installation

drawings or use other necessary means to measure Dimension “A”).

Using a tape measure, measure the distance from the

top of the Face Seal Adaptor in the spill container to the

bottom of the tank (Dim. “B”).

IMPORTANT: Inspect the riser pipe for any foreign material. Over spray from tank relining or any internal

burrs inside of pipe must be removed prior to installation. Failure to have an unobstructed riser pipe may

prevent proper installation and operation of the valve.

The 71SO is designed for installation into schedule 40

riser pipes. The 71SO cannot be installed into schedule

80 riser pipes.

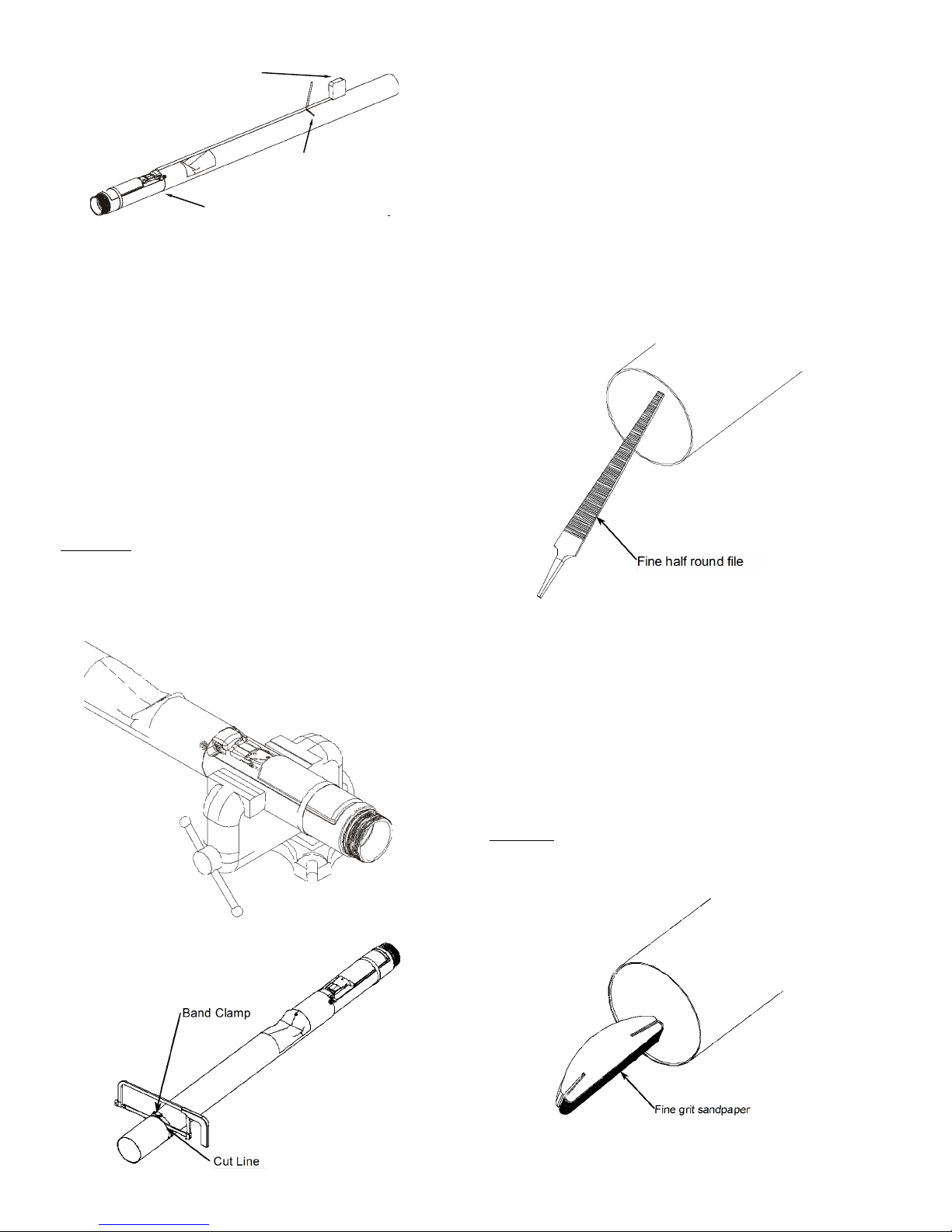

STEP 2: MARK THE TUBE

Use the result from Step 1 and HOW TO LOCATE THE

POSITION OF THE 71SO AT 95% TANK CAPACITY to

mark the upper tube. Measure the distance from the

seam where the upper tube and valve body meet. Use

a tape measure to mark the calculated upper tube

length onto the upper tube. See Figure 2.

Figure 1

Figure 1A

5

Page 6

Figure 2

Tape measure

Seam

Mark Upper Tube

(Cut Line)

STEP 3: CUT THE UPPER DROP TUBE

Attach the supplied band clamp to the upper tube just

below the mark and ensure that it is assembled square

to the tube. The clamp can be used as a guide for making a square cut. If a vise is used, clamp on the valve

body casting only to avoid damage to the oat and

tubes (See Figure 3A). Carefully saw through the tube

squarely, at the mark made in Step 2. Use a hacksaw

with a new ne-tooth blade. Rotating the upper tube

as the sawing progresses will minimize run out and ensure a square 90-degree cut. Remove the band clamp

after tube is cut.

CAUTION - DO NOT use a pipe or tubing cutter to cut

the upper drop tube, this may damage the tube,

causing it to be out of round thereby prohibiting

assembly of the unit.

Figure 3A

IMPORTANT: Remove all chips and shavings generated

in steps 3 thru 5 out of the cut end of the tube. DO NOT

remove chips and shavings by dumping thru valve

body.

STEP 4: FILE THE UPPER DROP TUBE

File the upper tube square, and remove any burrs or

rough edges. Make sure the cut is at and square.

IMPORTANT: Carefully le a good chamfer on the inside edge of the drop tube to provide a lead-in for the

polypak seal and inlet tube installed in Step 8.

Figure 4

STEP 5: SAND THE UPPER DROP TUBE

Sand the inside of the drop tube with sandpaper and/or

steel wool to remove all burrs and sharp edges. After

sanding wipe down the inside of the tube with a clean

rag from the top to approximately 4 inches down to

remove any debris.

Caution: Failure to properly chamfer, sand, and

clean the drop tube may cut the seal and result in a

failure of a pressure decay leak test.

Figure 5

Figure 3B

6

Page 7

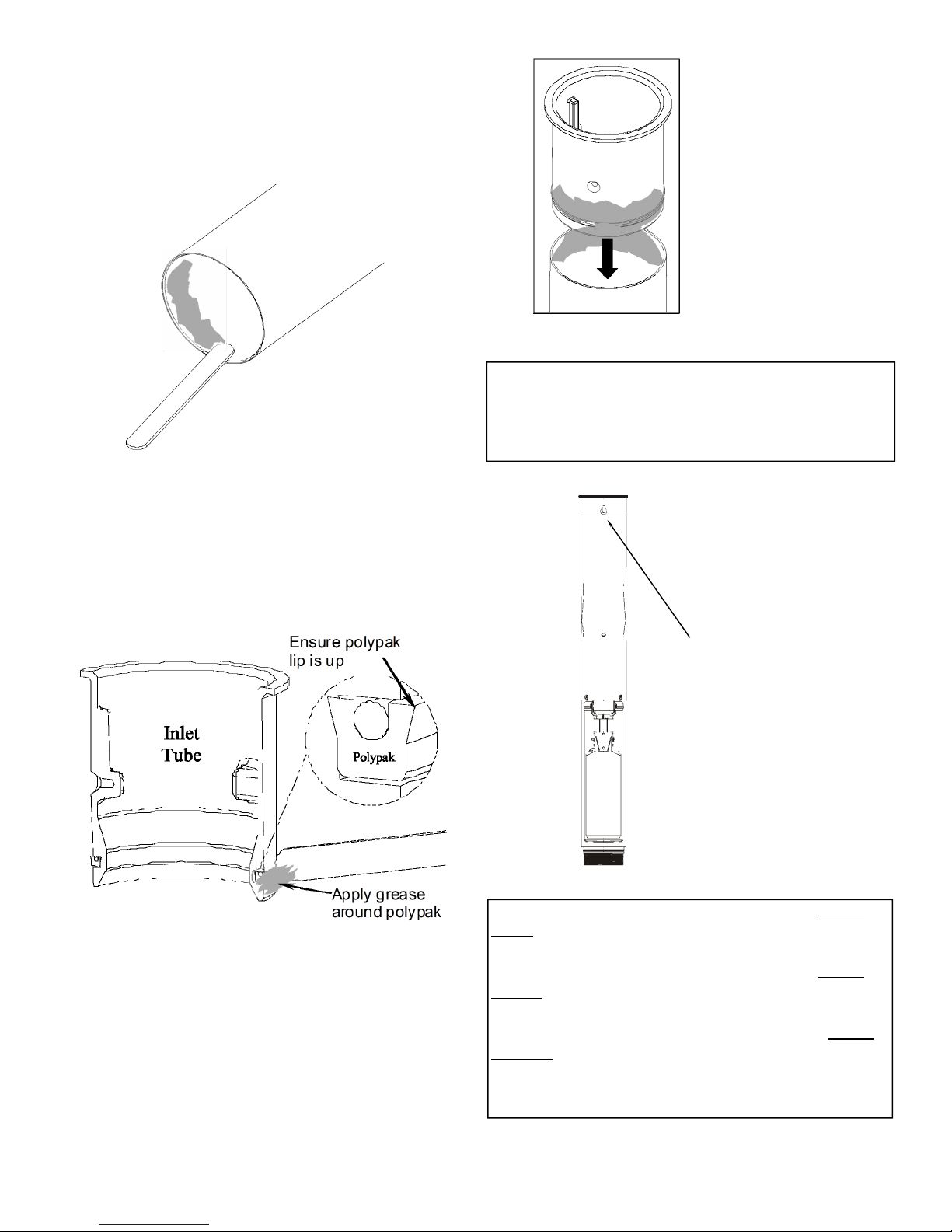

STEP 6: APPLY GREASE TO DROP TUBE

Apply black moly grease to the inside diameter of the

upper drop tube. Make sure coverage is completely

around the tube as shown in Figure 6.

Figure 6

STEP 7: APPLY GREASE TO POLYPAK SEAL

Ensure that the polypak seal is installed on the inlet

tube with the lip up as shown in Figure 7. Apply black

moly grease to the polypak as shown. Make sure coverage is completely around the polypak seal.

Figure 8

NOTE: Testable inlet tube must have cable port in

line with oat. Testable inlet tube bottoms out on

stop, it does not bottom out on inlet ange. See Fig-

ure 8A

Figure 7

STEP 8: INSTALL INLET TUBE

Insert the inlet tube into the upper tube until the upper

tube seats against the ange on the inlet tube. Ensure

polypak is inserted evenly and stays in inlet tube

groove.

Cable port must be in

line with oat

Figure 8A

Testable Models Only

SEE PAGE 8 FOR INSTRUCTIONS USING THE 71SOTOOL.

SEE PAGE 9 FOR INSTRUCTIONS USING THE 71SOTOOLC.

SEE PAGE 10 FOR INSTRUCTIONS USING THE 71SOTOOLCT.

Note: testable 71SO models ending with a “T” require the

71SO-TOOLCT or modied 71SO-TOOL or 71SO- TOOLC

7

Page 8

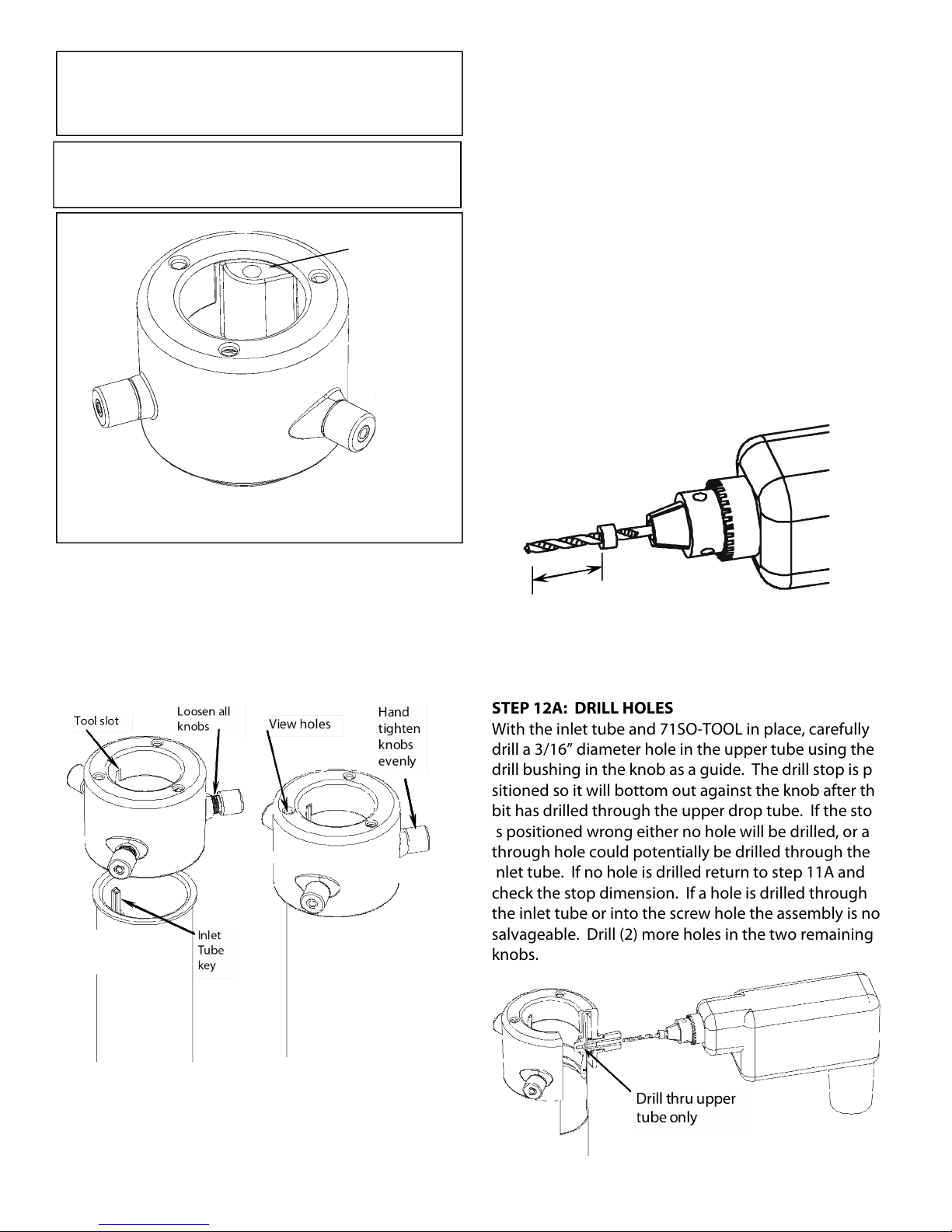

71SO-TOOL PROCEDURE BELOW,

FOR 71SO-TOOLC, SEE PAGE 9

FOR 71SO-TOOLCT, SEE PAGE 10

Note: 71SO-TOOL can only be used with testable

overll valves if modied as shown below. A 2”

wide slot must be added to accommodate cast lug.

Add 2” wide

slot to use with

testable valves

71SO-TOOL Modications for Testable Inlet

STEP 9A: INSERT 71SO-TOOL OVER INLET TUBE

To install the 71SO-TOOL (sold separately) over the inlet

tube, rst loosen all three knobs, so the tool can pass

freely over the inlet tube ange. Align the slot on the

tool with the key on the inlet tube and insert the tool

down. See Figure 9A.

STEP 10A: TIGHTEN THE 71SO-TOOL

Use the three view holes to ensure that the tool seats

out at against the top of the inlet tube. To prevent

vertical movement of the tool during drilling, hand

tighten all three knobs evenly to the upper drop tube.

See Figure 10A.

STEP 11A: PREPARE DRILL AND BIT

Conrm that the stop on the 3/16” drill bit supplied

with the 71SO-TOOL is in the correct position before

drilling. The stop is factory installed at a distance between 2” to 2-1/16” from the tip with the 71SO-TOOL. If

the stop is not at the correct position it must be xed

before drilling.

CAUTION: If the drill stop is not in the proper location failure of a pressure decay leak test may result.

Tip to stop dimension must be

2” to 2-1/16”.

Figure 11A

STEP 12A: DRILL HOLES

With the inlet tube and 71SO-TOOL in place, carefully

drill a 3/16” diameter hole in the upper tube using the

drill bushing in the knob as a guide. The drill stop is positioned so it will bottom out against the knob after the

bit has drilled through the upper drop tube. If the stop

is positioned wrong either no hole will be drilled, or a

through hole could potentially be drilled through the

inlet tube. If no hole is drilled return to step 11A and

check the stop dimension. If a hole is drilled through

the inlet tube or into the screw hole the assembly is not

salvageable. Drill (2) more holes in the two remaining

knobs.

Figure 9A

Figure 10A

Figure 12A

8

Page 9

71SO-TOOLC PROCEDURE BELOW,

FOR 71SO-TOOL, SEE PAGE 8

FOR 71SO-TOOLCT, SEE PAGE 10

Note: 71SO-TOOLC can only be used with testable

overll valves if modied as shown below.

Add a 10-24 UNC thread or similar

to all three legs of the 71SOTOOLC in the area shown. Use set

screws to secure tool to upper

tube.

71SO-TOOLC Modications for Testable Inlet

STEP 9B: INSERT 71SO-TOOLC OVER INLET TUBE

To install the 71SO-TOOLC (sold separately) over the

inlet tube, rst loosen the thumb screw, so the tool can

pass freely over the inlet tube ange. Align the slot on

the tool with the key on the inlet tube and insert the

tool down. See Figure 9B.

STEP 10B: TIGHTEN THE 71SO-TOOLC

Ensure that the tool seats at against the top of the inlet

tube. To prevent vertical movement of the tool during

drilling, hand tighten the thumb screw against the upper drop tube. See Figure 10B.

STEP 11B: PREPARE DRILL AND BIT

Conrm that the stop on the 3/16” drill bit supplied

with the 71SO-TOOLC is in the correct position before

drilling. The stop is factory installed at a distance between 1-3/16” to 1-1/4” from the tip with the 71SOTOOLC. If the stop is not at the correct position it must

be xed before drilling.

CAUTION: If the drill stop is not in the proper location failure of a pressure decay leak test may result.

Figure 11B

STEP 12B: DRILL HOLES

With the inlet tube and 71SO-TOOLC in place, carefully

drill a 3/16” diameter hole in the upper tube using the

hole in the 71SO-TOOLC as a guide. The drill stop is positioned so it will bottom out against the tool after the

bit has drilled through the upper drop tube. If the stop

is positioned wrong either no hole will be drilled, or a

through hole could potentially be drilled through the

inlet tube. If no hole is drilled return to step 11B and

check the stop dimension. If a hole is drilled through

the inlet tube or into the screw hole the assembly is not

salvageable. Drill (2) more holes in the two remaining

guide holes.

Figure 12B

9

Page 10

71SO-TOOLCT PROCEDURE BELOW,

FOR 71SO-TOOL, SEE PAGE 8

FOR 71SO-TOOLC, SEE PAGE 9

STEP 9C: INSERT 71SO-TOOLCT OVER INLET TUBE

To install the 71SO-TOOLCT (sold separately) over the

inlet tube, rst loosen the thumb screws, so the tool can

pass freely over the inlet tube ange. Align the slot on

the tool with the key on the inlet tube and insert the

tool down. See Figure 9C .

Loosen

thumb

screws

Tool Slot

Hand tighten

thumb screws

Inlet

Tube

Key

Figure 11C

STEP 12C: DRILL HOLES

With the inlet tube and 71SO-TOOLCT in place, carefully

drill a 3/16” diameter hole in the upper tube using the

hole in the 71SO-TOOLCT as a guide. The drill stop is

positioned so it will bottom out against the tool after

the bit has drilled through the upper drop tube. If the

stop is positioned wrong either no hole will be drilled,

or a through hole could potentially be drilled through

the inlet tube. If no hole is drilled return to step 11C

and check the stop dimension. If a hole is drilled

through the inlet tube or into the screw hole the assembly is not salvageable. Drill (2) more holes in the two

remaining guide holes.

Figure 9C

Figure 10C

STEP 10C: TIGHTEN THE 71SO-TOOLCT

Ensure that the tool seats at against the top of the inlet

tube. To prevent vertical movement of the tool during

drilling, hand tighten the thumb screws against the upper drop tube. See Figure 10C.

STEP 11C: PREPARE DRILL AND BIT

Conrm that the stop on the 3/16” drill bit supplied

with the 71SO-TOOLCT is in the correct position before

drilling. The stop is factory installed at a distance between 1-3/16” to 1-1/4” from the tip with the 71SOTOOLCT. If the stop is not at the correct position it must

be xed before drilling.

CAUTION: If the drill stop is not in the proper location failure of a pressure decay leak test may result.

Figure 12C

10

Page 11

STEP 13: DIMPLE FIRST HOLE

Remove tool. Remove any chips or burrs from the drilling operation. Place the assembly on a solid surface.

Using the punch supplied with the 71SO-TOOL, 71SOTOOLC, and 71SO-TOOLCT, align the tip of the punch

with the drilled hole and dimple the upper drop tube by

striking the punch with a hammer until the drop tube is

formed into countersunk hole in the inlet tube. After

punching, remove any chips that may have fallen into

the inlet tube screw hole.

Figure 13

STEP 14: ASSEMBLE FIRST SCREW

Ensure that the drop tube was formed into the countersunk screw hole as shown in Figure 14 if not return to

Step 13. Apply black moly grease to screw and tighten

rst screw into inlet tube with a screwdriver. Use only

the taptite screws that are supplied with the unit. Seating torque is 20 in-lbs min. to 35 in-lbs max. Screw head

should be ush with the drop tube. Do not over tighten.

Figure 14

STEP 15: DIMPLE REMAINING HOLES

Remove any chips or burrs from the drilling operation.

Dimple the next (2) holes as done in Step 13. Make sure

the assembly is on a solid surface when punching. After

punching, remove any chips that may have fallen into

the inlet tube screw hole.

Figure 15

STEP 16: ASSEMBLE OTHER SCREWS

Apply black moly grease to screws and tighten the other (2) screws into inlet tube with a screwdriver as done

in Step 14. Use only the taptite screws that are supplied

with the unit. Seating torque is 20 in-lbs min. to 35 inlbs max. Do not over tighten.

STEP 17: APPLY GREASE TO LOWER O-RING AND

BODY THREADS

Apply black moly grease to the lower tube o-ring and

body threads as shown. Make sure coverage is completely around the o-ring. Install o-ring in groove just

above threads.

Figure 17

11

Page 12

STEP 18: LOWER TUBE ASSEMBLY

If a vise is used, clamp on the valve body casting only to

avoid damage to the oat and tubes. Thread the lower

tube onto the valve body until the lower tube bottoms

out on valve body. Tube can be tightened by hand or

with a strap wrench. If a strap wrench is used try to position it on the threaded insert portion of the lower tube

to prevent damaging the tube.

Figure 18

NOTE: Before installing the valve in the tank, a pressure test can be performed on the valve to check for

vapor tightness. Seal o both ends of the tube with

inatable plumber’s plugs. Apply a maximum 10"

W.C. (1/3 PSI) air pressure. If pressure does not hold

and a leak can be located with soap solution, do not

install the valve. Send the valve back to OPW for

warranty evaluation.

CAUTION: Do not over-pressurize. Excess pressure

can damage the valve.

STEP 19: CUT LOWER TUBE

Measuring from the underside of the inlet tube ange,

mark the overall length of the drop tube a distance of

(B) minus 6". Determine dimension (B) from the measurements taken in Step 1, Figure 1 (Top of the Face Seal

Adapter below the drain valve outlet in the spill container to the bottom of the tank). Saw o the excess

tube at a 45-degree angle or per local codes or requirements and le o any sharp burrs (Refer to Figure 24).

Optional: Install the OPW Tank Bottom Protector on

the lower tube (Refer to Installation instructions supplied with the Tank Bottom Protector).

IMPORTANT: Remove all chips and shavings out of the

cut end of the tube. DO NOT remove chips and shavings by dumping thru valve body.

FOR STANDARD VAPOR TIGHT MODELS, PROCEED

TO STEP 20 ON PAGE 14.

FOR TESTABLE MODELS, PROCEED TO PAGE 13.

12

Page 13

TESTABLE PROCEDURE ONLY, FOR STANDARD MODELS, PROCEED TO NEXT PAGE.

STEP 1T: INSTALL SOCKET ADAPTOR ASSY

Put cable thru threads in inlet tube and out thru cable

port on side of inlet tube. Thread the socket adaptor

assembly nger tight into the inlet tube. Note: the cable port on the inlet tube must be in line with the oat

as shown previously in Figure 8A.

Socket

adaptor

assembly

Cable

port

Figure 1T

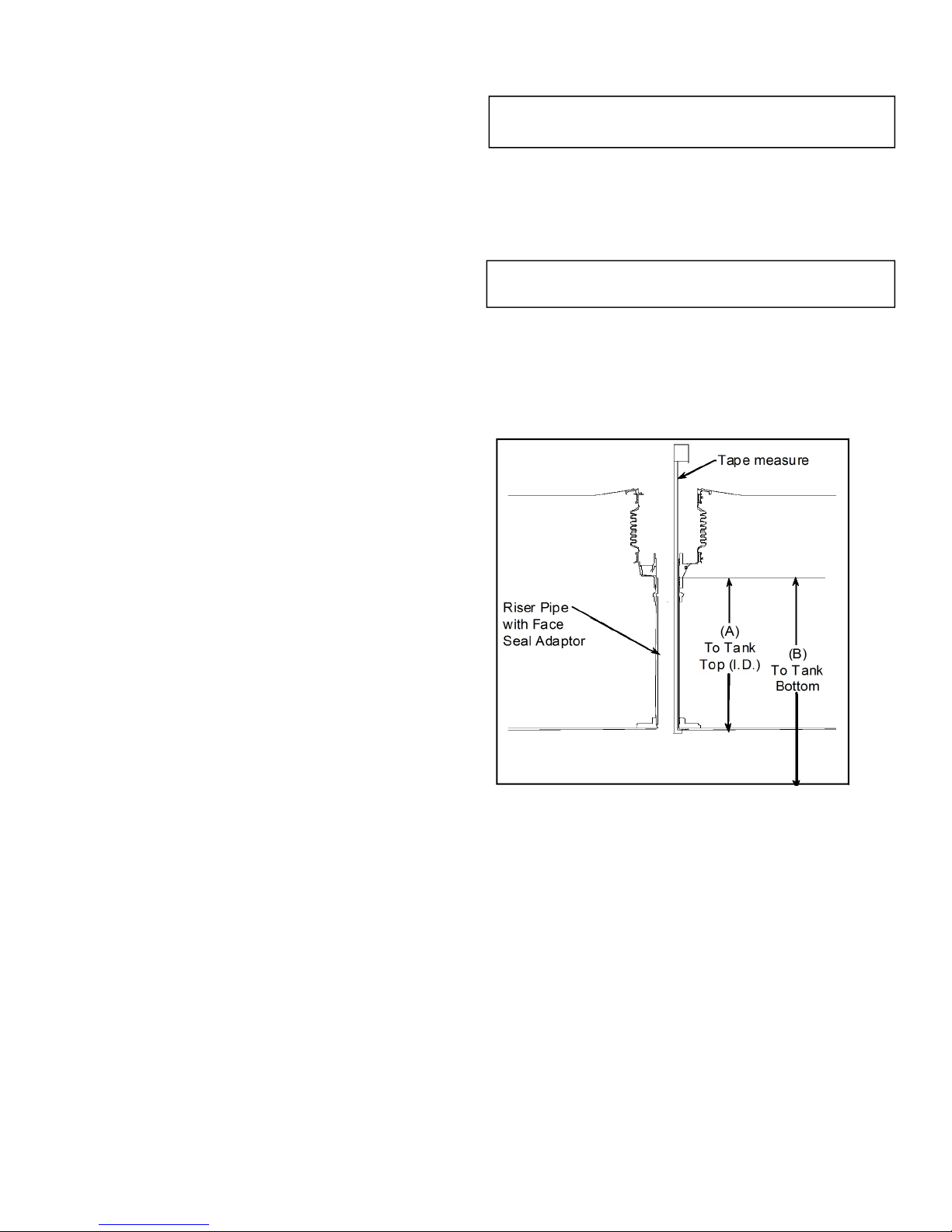

STEP 2T: PASS CABLE THRU FERRULE

Pass cable thru ferrule. Loop cable and then pass cable

back thru ferrule. Keep ferrule loose until cable length

is determined in the next step. Note: if cable end frays

it may be necessary to trim the cable again to pass thru

ferrule.

1/8” mandrel

rivet

Ferrule

Trim

cable

after

step 3T

Loop

Figure 2T

STEP 3T: DETERMINE CABLE LENGTH

Run cable along upper tube and over the top plate on

the oat bracket as shown. With the oat in the down

position (as shown in Figure 3T) align loop in cable with

rivet and top hole in oat bracket. Use the rivet as a

template to size the loop in the cable and pull cable

tight and crimp ferrule with crimping tool / pliers onto

cable at this location. Trim excess cable with wire cutter / scissors. For reference, from the seam where the

upper tube and valve body meet to the end of the cable

after trimming will require approximately 3.5” of cable.

Cable over oat bracket

Seam

Figure 3T

STEP 4T: ATTACH CABLE TO FLOAT BRACKET

Ensure cable is over the oat bracket. Using the supplied rivet align loop in cable with top hole in oat

bracket and pass rivet thru cable loop and oat bracket

hole. Using rivet tool for 1/8” dia mandrel attach rivet

and cable to the oat bracket. See last page for list of

replacement cable parts.

Attach rivet to top hole

Figure 4T

STEP 5T: ENSURE PROPER CABLE OPERATION

Unthread the socket adaptor assembly from the inlet

tube and ensure oat and poppet move freely when

socket adaptor assembly is pulled on. It should only

require 3” to 4” of movement in order to actuate the

oat and poppet. Thread socket adaptor assembly nger tight into inlet tube after testing.

13

Page 14

STEP 20: PREPARE FILL RISER FOR VALVE INSERTION

IMPORTANT: Inspect the riser pipe for any foreign ma-

terial. Over spray from tank relining or any internal

burrs inside of pipe must be removed prior to installation. Failure to have an unobstructed riser pipe may

prevent proper installation or operation of the valve.

Thoroughly clean top of riser pipe.

STEP 21: REMOVE ELASTIC BAND

Remove the elastic band securing the oat to the valve

body. The oat will move into an outward position.

STEP 22: INSERT DROP TUBE

Make sure the upper O-Ring gasket is under the ange

of the inlet tube. Hold the oat down against the valve

body and slowly insert the drop tube overll valve into

the riser pipe. Do not force valve into the riser pipe. If

any obstruction or foreign matter interferes with

smooth insertion of the valve, the riser pipe must be

cleared.

WARNING

Failure to follow the assembly

and installation instructions or

use of excessive force to insert

the OPW 71SO will VOID THE

WARRANTY.

Diculty in removing the existing

ll tube (if there is one) means

there may be an obstruction in the

riser pipe. Look for burrs, deformations, excess tank lining material or other projections that may

interfere with easy insertion of the

OPW 71SO. The 71SO is designed

for insertion into schedule 40 pipe. If

Figure 22

schedule 80 pipe has been used for the

riser, the 71SO cannot be installed. If seamed pipe has

been used, the internal weld bead may interfere with

the OPW 71SO and prevent installation. If the OPW

71SO won’t slip in easily DON’T FORCE IT! Damage to

the valve may result if excess force is used. Examine the

riser pipe carefully; determine the nature of the obstruction; take appropriate steps to remove it.

STEP 23: CHECK INSTALLATION

Insert the drop tube all the way into the tank until the

ange and gasket seat onto the top of the Face Seal

Adaptor. The oat will swing out into the operating

position as it passes into the tank.

Figure 23

Make sure that the oat is aligned along the length of

the tank. The length of the tank can easily be determined by locating other manholes or pump boxes that

are installed around other tank ttings. Look into the

drop tube and align the deector with the length of the

tank.

For testable models only: Unthread the socket adap-

tor assembly from the inlet tube (a 3/8” square drive

extension will attach to the socket adaptor, secure all

tools to ensure they don’t fall into the tank or valve) and

ensure oat and poppet move freely when socket adaptor assembly is pulled on. When looking down into the

upper tube ensure poppet is visible when socket adaptor is pulled and resets properly when socket adaptor is

released. See page 17 for full testing details. If poppet

does not actuate freely take appropriate steps to correct

before proceeding.

CAUTION: No obstruction in the tank can be within

14" from the center of the riser pipe or the valve

may not operate properly (See Figure 24).

STEP 24: ALIGN VALVE

Install the OPW Jack Screw Kit and a 4" NPT nipple to

lock the valve in place. Refer to the Installation Instructions supplied with the Jack Screw Kit. For testable

models ensure that the socket adaptor is aligned so

it does not interfere with the jack screw kit. (see Fig-

ure 24A). Install the Rotatable Product Adaptor (Refer

to Installation Instructions supplied with the Product

Adaptor.) Make sure that the valve does not rotate

while tightening the adaptor by observing the position

of the deector. The valve must remain aligned

along the length of the tank as in Step 23. Repeat

this step as necessary to assure proper valve alignment.

14

Page 15

Figure 24

Figure 24A

Orient socket

adaptor between jack

screw bolts

FOR TESTABLE MODELS ONLY: Check installation

again as done in Step 23 to ensure poppet actuates and

resets properly. See page 17 for full testing details. Apply pipe dope to the socket adaptor threads. Pipe dope

should be a non-hardening gasoline resistant pipe

thread seal compound. Install socket adaptor and

torque to 3.5 ft-lbs (42 in-lbs) minimum to 5.0 ft-lbs (60

in-lbs) maximum. After installing socket adaptor where

required, pressure test testable overll valve per CARB

TP201.1D to ensure valve is vapor tight.

15

Page 16

STEP 25: INSTALL WARNING PLATE

Bend the three warning plate ears down then slide the

tie wrap over the warning plate ears and position warning plate against riser pipe approximately 1" below the

adaptor. Tighten the tie wrap securely. The valve is

now fully installed and in operating position.

NOTE: the warning plate includes important warnings, operating parameters, and listing information

and must be installed.

Figure 25

STEP 26: VALVE REMOVAL

The valve can be removed for tank leak testing, inspection, etc., by removing the Rotatable Product Adaptor,

the 4" nipple, and the Jack Screw Kit. Reinstall per the

above instructions.

For testable models only: It is not necessary to re-

move the valve to check poppet movement / function.

See Page 17 for full testing details.

STEP 27: ELECTRONIC LIQUID LEVEL MONITORING

If an electronic level monitor is installed, it must be calibrated to match the top of the 71SO valve body, which

must correlate with 95% of the actual tank capacity.

Figure 26 - Product Identication

16

Page 17

TEST INSTRUCTIONS

POPPET & FLOAT MOVEMENT

FOR TESTABLE MODELS ONLY

TOOLS NEEDED FOR TESTING:

1. 1/4” square drive extension or 3/8” square drive extension with 3/8” to 1/4” socket adapter.

2. Torque wrench / 1/4” or 3/8” square drive ratchet

wrench.

3. Pipe dope.

4. Flashlight (optional).

TEST STEP 1:

Remove spill container cover and ll cap from ll adapter and look down into the tube and make sure no debris

or foreign objects are present. If debris or foreign objects are present take appropriate steps before proceeding. Look down into the tube and ensure poppet is

completely protected by the deection shield. See Test

Figure 1. If poppet is exposed and tank is not full the

overll valve should be replaced. A ashlight may help

when inspecting the tube.

TEST STEP 2:

Unthread the socket adaptor assembly from the inlet

tube using a 1/4” square drive extension and wrench.

The extension will attach to the socket adaptor. Secure

all tools to ensure they don’t fall into the tank or valve.

With the extension still attached pull on the socket

adaptor and cable assembly and ensure oat and poppet move / function properly. It should only require 3”

to 4” of movement and less than 5 lbs of force in order

to actuate the oat and poppet. When looking down

into the upper tube ensure poppet is visible and moves

into the ow path (see Test Figure 1 & 2) when socket

adaptor is pulled and resets properly when socket adaptor is released. If poppet does not actuate freely take

appropriate steps to correct.

TEST STEP 3:

Apply pipe dope to the socket adaptor threads. Pipe

dope should be a non-hardening gasoline resistant pipe

thread seal compound. Make sure poppet and oat

have reset properly and are not visible then install socket adaptor and torque to 3.5 ft-lbs (42 in-lbs) minimum

to 5.0 ft-lbs (60 in-lbs) maximum. After installing socket

adaptor, to ensure vapor tightness, OPW recommends

conducting pressure testing per CARB TP201.1D. Some

areas may require pressure testing of overll valve per

CARB TP201.1D to ensure valve is vapor tight. If the

drop tube fails pressure testing it may be necessary to

check the seal at the poppet adaptor threads. Reinstall

ll cap and spill container cover after testing.

Open Poppet Closed Poppet

Test Figure 1

Open

Poppet

Test Figure 2

Socket

adaptor

Pull on extension and

socket adaptor

Closed

Poppet

Float moves

up

17

Page 18

PREVENTIVE MAINTENANCE

Annually, inspect the apper in the 71SO to see that it is

open by looking down the drop tube opening (see inspection procedure below). Test the 71SO drop tube

seals with CARB procedure TP-201.1D. If the drop tube

seal passes testing, no further maintenance is required.

If the drop tube fails testing, replace the drop tube seal

with OPW P/N: H11931M for 4” Tubes. Re-test the 71SO

drop tube with CARB procedure TP-201.1D. The lower

tube o-ring seal OPW P/N: H14840M can also be replaced. If this does not correct the leak the 71SO needs

to be replaced.

FOR TESTABLE MODELS ONLY: The socket adaptor

can be removed and poppet and oat movement and

function inspected without removing the valve. See

Page 17 for full testing details. If replacement parts are

needed for testable models the following items are

available: OPW P/N 206741 Testable Inlet Tube S/A,

206740 Socket Adaptor and Cable Assembly, and 61SOK

-0001 Float Kit.

CAUTION: Do not insert any foreign object into drop

tube if apper is in the closed position. For example, a tank level measuring stick. This will damage

the valve and void the Warranty. ALWAYS check

apper location before “sticking” the tank. If apper is in the closed position, the tank is either overlled and you need to wait until the liquid level goes

down or the 71SO is damaged and needs to be replaced.

Inspection Procedure to Ensure Proper Operation

Note: For testable models valve does not need to be

removed from tank. See page 17 for testable instructions.

INSP 1. Remove the overll valve from the tank as described in step 26.

INSP 2. Visually inspect the valve for damage. Make

sure no debris or foreign objects are in or on the valve.

Good Valve

Bad Valve

Figure 27

Note: Figure 27 shows poppet location with oat arm

not activated.

INSP 4. Inspect the oat by lifting upward. The oat

should move freely without any binding. See Figure

28.

INSP 3. With the oat in the normal (down) position,

visually inspect the valve to ensure the poppet is not

exposed outside the deection shield. See Figure 27.

Figure 28

INSP 5. View down the tube to ensure the poppet is

moving into the ow path when lifting the oat. See

Figure 29.

18

Page 19

Figure 29

INSP 6. If there is no apparent damage or restrictions

reinstall the valve per the above instructions and test

per local requirements.

71SO Performance Specications

This Overll Prevention Valve has been manufactured

and tested to, and met, the following California specications. Performance Requirement: Leak rate to be less

than or equal to 0.17 CFH@2.0” W.C.

Torque Specication

Taptite Screws, #10-24 thread cutting, 20 in-lbs minimum to 35 in-lbs maximum. Testable Models Only:

Socket Adaptor, 1/4” NPT, 3.5 ft-lbs (42 in-lbs) minimum

to 5.0 ft-lbs (60 in-lbs) maximum.

IMPORTANT: Leave these installation instructions

and maintenance procedures with the station operator.

19

Page 20

Appendix A

71SO Overll Valve Upper Tube Calculation Worksheet

Important: This is meant to be supplemental worksheet and not a substitute to following the installation

manual instructions. All length measurements are in inches. Please contact the Authority Having Jurisdiction (AHJ) and review local, state, and national codes to determine the regulatory requirements governing

shut-o capacity in your region, as well as take into account other considerations such as extreme tank tilt.

Desired tank capacity for shut-o: SO%= _______

Dipstick Number on Tank Chart that corresponds to 100% volume (Y) =

Dipstick Number on Tank Chart that corresponds to SO% (X) =

Upper Tube Reference Number Z=Y-X

2

Upper Tube Depth Inside Tank C = Z-2”

Distance from top sealing surface for 71SO Lip

top of Storage Tank

2

For Non-Testable 71SO models only

1

to inside the

A=___________

(Y)

(X)

(Z)

(C)

In all cases for non-testable 71SO models, the top of the valve body must protrude at least 6 ½” into the tank to

provide a minimal clearance for proper operation.3 Additionally the total Upper Tube Length must be at least 16”

of length to include the protective bend in the tube.

Is C less than 6 ½” Yes / No

If NO, Upper Tube Length (D)= C + A

If YES, Upper Tube Length (D)= 6 ½ “+ A

Upper Tube Length = ___________

For Testable 71SO models only

In all cases for Testable 71SO models, the top of the valve body must protrude at least 6 ½” into the tank to provide

a minimal clearance for proper operation.3 Additionally the total Upper Tube Length must be at least 14 ½” of

length to include the protective bend in the tube.

Is C less than 5” Yes / No

If NO, Upper Tube Length (D)= C + A – 1 ½ “

If YES, Upper Tube Length (D) = 6 ½” + A – 1 ½ “

Upper Tube Length = ___________

1

Sealing surface may be the top of the Face Seal Adaptor, the built in sealing ledge inside some spill containers, or on non-

vapor tight applications the top of the pipe nipple

2

Some Underground Storage tanks utilize a manway system at the top. Make sure to use the top of the storage tank for

measurement and not to top of the manway. Consult your underground tank manufacturer for height of the manway

3

This measurement is taken from the seam where the upper tube is attached to the valve body to the inside of the tank top.

20

Page 21

Appendix B

71SO Overll Valve in Tank Shut o Level Worksheet

Important: This is meant to be supplemental worksheet and not a substitute to following the installation

manual instructions. All length measurements are in inches. Please contact the Authority Having Jurisdiction (AHJ) and review local, state, and national codes to determine the regulatory requirements governing

shut-o capacity in your region, as well as take into account other considerations such as extreme tank tilt.

Take the following measurements with the valve installed in the tank:

Distance from the 71SO inlet tube ange to the cast

lug in the 71SO body (see gures), upper tube length.

Note: the Upper Tube Length must be at least 16” to in-

clude the protective bend in the tube.

(D) = ______________________

Distance from the 71SO inlet tube ange to the top and

bottom of lower tube, valve length.

(W) = _____________

(U) = _____________

Distance from the 71SO inlet tube ange to the bottom

of the tank. Note: If a tank bottom protector is present it

may be necessary to add this thickness to dimension

(OPW 6111 & 61TP models add 0.6”)

(B) = _____________

From the tank calibration chart provided by tank manufacturer nd the dipstick number (Y) which corresponds

to the 100% volume.

(Y) = _____________

1. To determine shut-o percentage:

Subtract upper tube length (D) from distance to tank

bottom (B)

(X) = (B) – (D) - 2” =________________________

Using the tank calibration chart provided by the tank

manufacturer determine the tank capacity at the calculated (X) dimension and the 100% volume (Y) tank

capacity.

(X) tank capacity in gallons = _______________

(Y) tank capacity in gallons = _______________

SO% = (X) capacity / (Y) capacity x100 = __________

(B)

To Tank

(U) Valve

Length,

top of cut

Note: The overll valve must be installed per AHJ requirements and all applicable local, state, and national codes. If

the overll valve is set above the allowable shut-o percentage the overll valve must be removed and replaced. For

reference 40 CFR part 280 Subpart B Section 280.20 overll

valves should be set to a maximum of 95%.

(D)

Upper

Tube

(W) Valve

Length,

bottom of

cut

(Y)

Tank

Chart

100%

Volume

Dipstick

21

Page 22

2. To determine lower tube distance from tank

bottom to bottom of cut:

Subtract valve length (W) from distance to tank

bottom (B)

(V) = (B) – (W) = _____________

Note: Lower tube clearance must meet tank manufac-

turer requirements and all AHJ, local, state, and national

codes. Typical clearance is about 4”. If lower tube clearance is not met valve must be removed and adjusted to

meet these requirements.

3. To determine lower tube distance from tank

bottom to top of cut:

Subtract valve length (U) from distance to tank

bottom (B)

(T) = (B) – (U) = _____________

Note: Lower tube distance from tank bottom to top of

cut must meet all AHJ, local, state, and national codes.

For reference per 40 CFR 63 subpart CCCCCC / NESHAP

the lower tube can be no more than 6” from the bottom

of the tank. If lower tube distance is not met valve must

be removed and adjusted to meet these requirements.

4. To determine oat alignment:

Looking into upper tube (see gure) the oat should be

aligned along the length of the tank. If oat is not

aligned properly adjustments need to be made.

Cast lug

in 71SO

body

View into drop tube from above

Float direction

22

Page 23

Appendix C

HOW TO LOCATE THE POSITION OF THE 71SO FOR COMPLETE SHUT-OFF AT A GIVEN TANK CAPACITY

Note: This Appendix only applies when AHJ require-

ments call for complete shut-o at a given tank capacity.

See page 4 for standard measurements.

The length of the upper tube and the placement of the

71SO valve body determine the shut-o point. The sample calculation below will provide for complete shut-o

at 95%. In all cases, the upper tube length must be a

minimum of 6-1/2" plus the length of the riser pipe. All

length measurements are in inches.

INSTRUCTIONS

1. Find the tank capacity (in gallons) from the tank calibration chart provided by the tank manufacturer.

2. Calculate 95% of capacity.

3. Locate the 95% volume number on the tank calibration chart.

4. Find the dipstick number (X) which corresponds to

the 95% tank volume. And, nd the dipstick number

(Y) which corresponds to the 100% volume.

5. Subtract the dipstick number (X) from the tank diameter (Y) to nd the upper tube reference number (Z).

(Y) - (X) = (Z)

6. Add 1.5" to (Z) to nd the upper tube depth E.

(Z) + 1.5” = E

7. Is E less than 6-1/2"?

NO Upper tube length is E plus the distance from the

top of the Face Seal Adaptor installed on the riser

pipe to the inside, top lip of the storage tank (A).

Upper Tube Length = E + (A)

For testable models only, ending in “T”:

Upper Tube Length = E + (A) – 1-1/2”

YES Upper tube length is 6-1/2" plus the riser pipe

measurement (A).

Upper Tube Length = 6-1/2" + (A)

For testable models only, ending in “T”:

Upper Tube Length = 6-1/2" + (A) – 1-1/2”

NOTE: You must nd the actual tank capacity number that correlates to the 6-1/2” + (A) depth for the

station records. This number may also be used or

the purposes of calibrating an electronic tank level

system.

EXAMPLE

1. For an Owens-Corning Model G-3 Fiberglass® Tank

Calibration Chart:

Tank Capacity - 10,000 gal., nominal 9,403 gal.

NOTE: Use actual capacity only

2. 95% of actual tank capacity = 0.95 x 9403 gal. =

8933 gal.

3. The closest number which is less than 8933 gal. Is

8910 gal. Choosing the closest number less than

95% of actual capacity ensures that complete

shuto will occur when the tank is no more than

95% full.

4. The calibration chart reading of 8910 gal. corresponds to a dipstick measurement of 82".

5. Dipstick number (X) = 82"

Tank diameter (Y) = 92"

(Y) - (X) = (Z) (92 "- 82" = 10")

(Z) = 10"

6. (Z) + 1.5" = E (10" + 1.5" = 11.5")

E = 11.5"

7. Is 11.5" less than 6-1/2"?

NO Measure the distance from the top of the FSA-400

Face Seal Adaptor installed on the riser pipe to

the inside, top lip of the storage tank and obtain

measurement (A).

Upper tube length = E + (A)

For testable models only, ending in “T”:

Upper Tube Length = E + (A) – 1-1/2”

23

Page 24

Appendix C (continued)

Important: This is meant to be supplemental worksheet and not a substitute to following the installation

manual instructions. All length measurements are in inches. Please contact the Authority Having Jurisdiction (AHJ) and review local, state, and national codes to determine the regulatory requirements governing

shut-o capacity in your region, as well as take into account other considerations such as extreme tank tilt.

Take the following measurements with the valve installed in the tank:

Distance from the 71SO inlet tube ange to the cast

lug in the 71SO body (see gures), upper tube length.

Note: the Upper Tube Length must be at least 16” to in-

clude the protective bend in the tube.

(D) = ______________________

Distance from the 71SO inlet tube ange to the top and

bottom of lower tube, valve length.

(W) = _____________

(U) = _____________

Distance from the 71SO inlet tube ange to the bottom

of the tank. Note: If a tank bottom protector is present it

may be necessary to add this thickness to dimension

(OPW 6111 & 61TP models add 0.6”)

(B) = _____________

From the tank calibration chart provided by tank manufacturer nd the dipstick number (Y) which corresponds

to the 100% volume.

(Y) = _____________

1. To determine complete shut-o percentage:

Subtract upper tube length (D) from distance to tank

bottom (B)

(X) = (B) – (D) + 1.5” =________________________

Using the tank calibration chart provided by the tank

manufacturer determine the tank capacity at the calculated (X) dimension and the 100% volume (Y) tank

capacity.

(X) tank capacity in gallons = _______________

(Y) tank capacity in gallons = _______________

Complete SO% = (X) capacity / (Y) capacity x100 =

__________

71SO Overll Valve in Tank Complete Shut O Level Worksheet

(D)

Upper

Tube

(B)

To Tank

(U) Valve

Length,

top of

Note: The overll valve must be installed per AHJ requirements and all applicable local, state, and national

codes. If the overll valve is set above the allowable

shut-o percentage the overll valve must be removed

and replaced.

(W) Valve

Length,

bottom

of cut

(Y)

Tank

Chart

100%

Volume

Dipstick

Note: This Appendix only applies to valves installed per Appendix C. See Appendix B for the standard valve

installation tank shut o level worksheet.

24

Page 25

3250 US 70 Business West

Smithfield, NC 27577

Customer Service:1-(800) 422-2525

Technical Service and Questions:

1-(877) OPW-TECH

www.opwglobal.com

Part Number: H15524PA

Issue Date: 06/05/2018 REV O

Supercedes: 02/05/2018 REV N

25

Loading...

Loading...