OPW 71SO-TOOLC, 71SO-TOOL, 71SO-TOOLCT Maintenance Manual

71SO Overfill Prevention Valves and

71SO Testable Overfill Prevention Valves

Installation and Maintenance Instructions

IMPORTANT INFORMATION

FOLLOW ALL INSTRUCTIONS

Please read these warnings and use and assembly

instructions completely and carefully before starting. Failure to do so may cause product failure, or

result in environmental contamination due to liquid

leakage into the soil, creating hazardous spill conditions.

OPW Standard Product Warranty Tag: Notice: FlexWorks by OPW, Inc., VAPORSAVER™ and all other OPW

products must be used in compliance with all applicable federal, state, provincial and local laws, rules and

regulations. Product selection is the sole responsibility

of the customer and/or its agents and must be based

on physical specications and limitations, compatibility with the environment and material to be handled.

All illustrations and specications in this literature are

based on the latest production information available

at the time of publication. Prices, materials and specications are subject to change at any time, and models may be discontinued at any time, in either case,

without notice or obligation.

OPW warrants solely to its customer (the initial purchaser and any subsequent purchasers within the

warranty period) that the following products sold by

OPW will be free from defects in materials and workmanship under normal use and conditions for the periods indicated:

PRODUCT WARRANTY PERIOD

FlexWorks Primary Pipe 10 years from date of manufacture

All Products and replacement parts in-

stalled in the State of

California

Certied to California CP

-201 and/or CP-206

Standards*

All other Products and

replacement parts

*Products certied to California CP-201 and/or CP-206 Standards

have been factory tested and met all applicable performance stand-

ards and specications and will have an OPW registration card en-

closed/attached to the product.

1 year from date of installation (proof of

purchase from certied contractors/

technicians required)

OPW warrants ongoing compliance with

the standards and specications for the

duration of the warranty period required

by the State of California; this limited war-

ranty is under the condition the equip-

ment was installed and maintained by

trained and certied contractors/

technicians unless noted in Installation

Manual.

1 year from date of manufacture**

OPW’s exclusive obligation under this limited warranty is, at its option, to repair, replace or issue credit (in

an amount not to exceed the list price for the product)

for future orders for any product that may prove defective within the applicable warranty period. (Parts

repaired or replaced under warranty are subject to

prorated warranty coverage for remainder of the original warranty period). Complete and proper warranty

claim documentation and proof of purchase required.

All warranty claims must be made in writing and delivered during the applicable warranty period to OPW at

OPW 9393 Princeton-Glendale Road Hamilton, Ohio,

USA 45011, Attention: Customer Service Manager. No

products may be returned to OPW without its prior

written authority.

This limited warranty shall not apply to any FlexWorks

or VAPORSAVER™ product unless it is installed by an

OPW attested installer and all required site and warranty registration forms are completed and received by

OPW within 60 days of installation. This limited warranty also shall not apply to any FlexWorks, VAPORSAVER™

or other OPW product: unless all piping connections are

installed with a nationally-recognized or stateapproved leak detection device in each tank and dispenser sump (which are not for storage and from which

all discharge hydrocarbons must be removed, and the

systems completely cleaned, within 24 hours); unless

testable sumps utilize FlexWorks pipe and access ttings; unless a sump inspection log or an EPA recommended/required checklist is maintained and the results are furnished to OPW upon request; and unless

OPW is notied within 24 hours of any known or suspected product failure and is provided with unrestricted access to the product and the site. This limited warranty also shall not apply to any product which has

been altered in any way, which has been repaired by

anyone other than a service representative authorized

by OPW, or when failure or defect is due to: improper

installation or maintenance (including, without limitation, failure to follow FlexWorks Quick Reference Manual Installation Guide and all product warning labels);

abuse or misuse; violation of health or safety requirements; use of another manufacturer’s, or otherwise un-

1

authorized, substances or components; soil or other

surface or subsurface conditions; or re, ood, storm,

lightning, earthquake, accident or any other conditions,

events or circumstances beyond OPW’s control .

THIS LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, AND ALL OTHER

WARRANTIES INCLUDING, WITHOUT LIMITATION, THE

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, ARE HEREBY EXCLUDED.

OPW shall have no other liability whatsoever, whether

based on breach of contract, negligence, gross negligence, strict liability or any other claim, including, without limitation, for special, incidental, consequential or

exemplary damages or for the cost of labor, freight, excavation, clean-up, downtime, removal, reinstallation,

loss of prot, or any other cost or charges. No person or

entity is authorized to assume on behalf of OPW any

liability beyond this limited warranty. This limited warranty is not assignable.

** Date of manufacture on this product is located on

the at area of the valve body, under oat.

GENERAL INSTRUCTIONS

The OPW 71SO Overll Prevention Valve is designed for

tight ll, gravity drop applications to help prevent accidental or intentional overlling of underground storage

tanks. It is installed in the UST drop tube in place of a

standard drop tube.

The main 71SO valve closes when liquid reaches the

initial shut o point. A small bypass valve remains open

to allow the delivery hose to drain at 3-5 gallons per

minute. If the delivery truck valve is not closed after

initial shut-o, the bypass valve will close and will restrict all fuel delivery to ensure that the top of the tank

is not wetted per EPA requirements.

The 71SO models of the 71SO are designed to be installed with the following OPW products: Face Seal

Adaptor, OPW Spill Container or Multi-port, Jack Screw

Kit, Rotatable Product Adaptor, and Product Cap.

IMPORTANT

Read these assembly and installation instructions completely and carefully prior to starting. Check to make

sure all parts have been provided. Use only the parts

supplied; substitution of parts may cause product failure.

Failure to follow instructions may cause improper product operation or premature failure which may permit

storage tank overll. An overlled storage tank may

create hazardous conditions and/or environmental contamination.

CAUTION

Do not remove elastic band from around oat until

instructed to do so, as damage to valve may result.

WARNING

Failure to properly connect delivery hose and elbow, and/or disconnecting a liquid lled delivery

hose or elbow will result in a hazardous spill, which

may result in personal injury, property damage, re,

explosion, and water and soil pollution.

Make sure all connections, including the hose and

elbow connections, between storage tank and

transport are securely coupled.

Make sure the lip seal and/or all gaskets in the deliv-

ery elbow are properly in place to prevent spills.

Do not operate with damaged or missing parts,

which prevent tight connections.

Normal Operation: A Hose ”Kick” and reduced ow

signal that the tank is full. Close transport delivery

valve and drain hose into tank before disconnecting

any hose tting.

Overlled Tank: Failure of the hose to drain after closing the delivery valve signals an overlled tank. Do Not

Disconnect any delivery hose tting until the liquid level in the tank has been lowered to allow the hose to

drain into the tank.

WARNING

In the event you are splashed with fuel remove wet

clothing immediately. Skin contact with gasoline

can cause chemical burns and may result in inhalation of vapors that may be fatal. Never go inside

conned areas after being splashed and never go

near ignition sources.

IMPORTANT

Determine if the underground storage tank is equipped

with a ball oat vent valve, as illustrated in Figure 24. In

all systems, the shut-o point of the 71SO must be

reached before the ball oat reduces ow to ensure

proper overll valve operation.

TOOLS NEEDED FOR INSTALLATION AND ASSEMBLY:

1. 71SO-TOOL or 71SO-TOOLC or

71SO-TOOLCT (includes the following)

Sharp 3/16” drill bit with stop

Punch

NOTE: Testable 71SO models ending with a “T” require the 71SO-TOOLCT or modied 71SO-TOOL or

71SO-TOOLC

2

2. Drill

3. Hammer

4. Tape measure

5. Hacksaw or cut-o saw, ne tooth; 24 teeth/inch

6. Fine half round le

7. Screwdriver - Phillips blade

8. Fine grit sandpaper / steel wool

9. Grease, black moly

10. Torque Wrench

11. Band clamp (3-3/4” diameter minimum)

12. TESTABLE MODELS ONLY: rivet tool for 1/8” mandrel, crimping tool / pliers, wire cutter / scissors,

pipe dope, 1/4” square drive extension or 3/8”

square drive extension with 3/8” to 1/4” socket

adapter.

WARNING

Using electrically operated equipment near gasoline

or gasoline vapors may result in re or explosion,

causing personal injury and property damage.

Check to assure the working area is free from such

hazards, and always use proper precautions.

IMPORTANT: The gures in this installation and

maintenance instruction may contain vapor recovery

equipment (including model numbers) that is not certied by the California Air Resources Board (CARB) for a

specic Phase I Vapor Recovery System. Please refer to

Exhibit 1 of the appropriate CARB Phase I Executive Order for a list of certied Phase I Vapor Recovery System

Equipment.

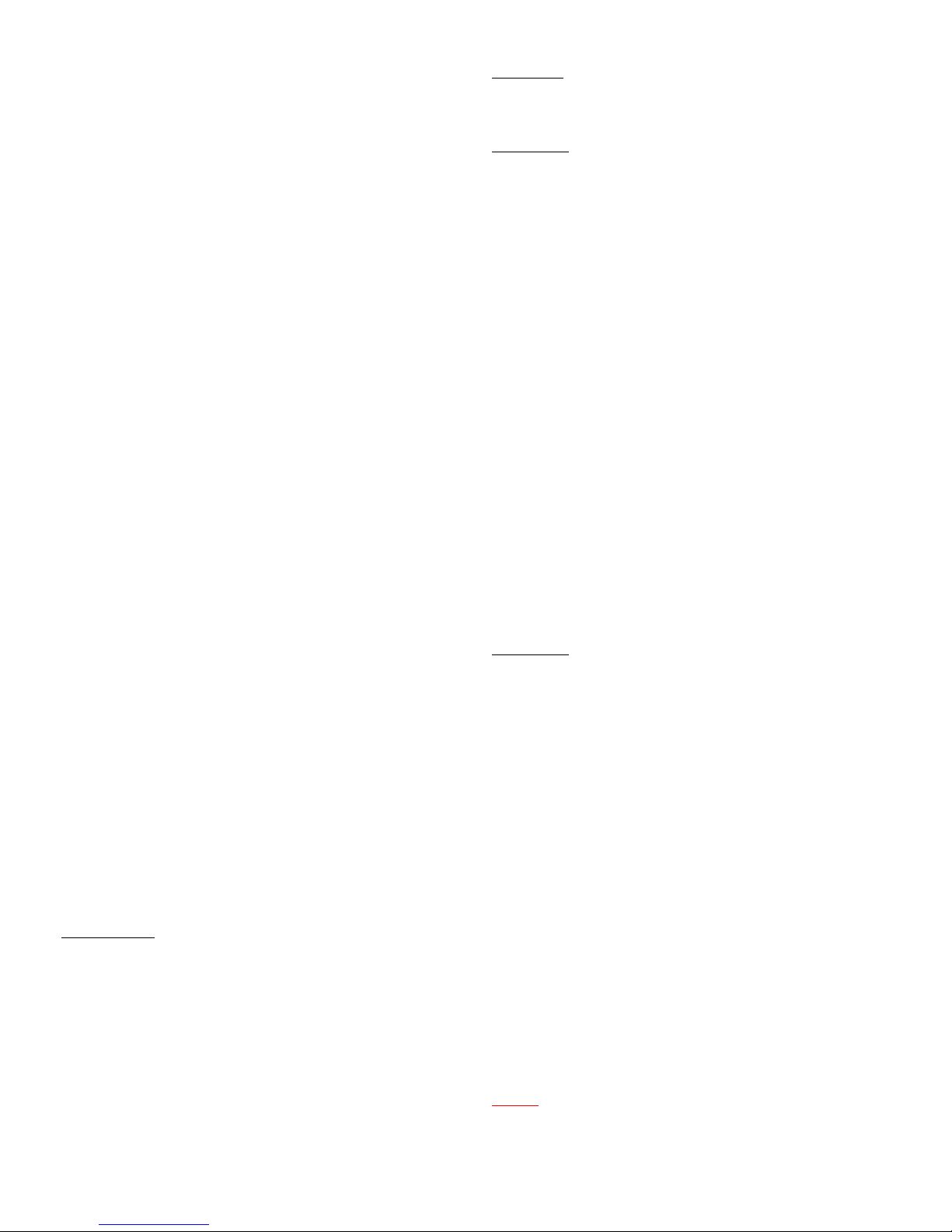

71SO Parts Diagram

Upper O-Ring Gasket

Screws, Qty 3

Inlet Tube

Polypak Seal

Upper Drop Tube

Valve Body

Float

Lower O-Ring

Lower Tube

Alternate Components - Testable Versions

Note: all components are the same except the

socket adaptor & cable assembly, rivet, testable

inlet tube, and ferrule.

Socket Adaptor & Cable

Assembly

Rivet

Ferrule

Testable Inlet

Tube

3

IMPORTANT: The instructions below for the 71SO

Overll Prevention Valve are written for the initial

stage shuto at 95%, but can be adjusted to shuto

at any desired tank capacity. Please contact the Authority Having Jurisdiction (AHJ) and review local,

state, and national codes to determine the regulatory requirements governing shut-o capacity in your

region, as well as take into account other considerations such as extreme tank tilt. In all cases, the upper tube must protrude into the tank at least 6 1/2”

to ensure that the valve can shut o ow into the

tank completely before the top of the tank is wetted

as per EPA requirements.

HOW TO LOCATE THE POSITION OF THE 71SO AT

95% TANK CAPACITY

(Shut-o points can be adjusted to any capacity to

comply with AHJ Requirements)

The length of the upper tube and the placement of the

71SO valve body determine the shut-o point. Following the standard instructions for the OPW 71SO will provide for initial shuto at 95%. In all cases, the upper

tube length must be a minimum of 6-1/2" plus the

length of the riser pipe. All length measurements are in

inches.

INSTRUCTIONS

1) Find tank capacity (in gallons) from tank calibration

chart provided by tank manufacturer.

2) Calculate 95% of capacity

3) Locate the 95% volume number on the tank calibration chart.

4) Find the dipstick number (X) which corresponds to

the 95% tank volume. And, nd the dipstick number (Y) which corresponds to the 100% volume.

5) Subtract the dipstick number (X) from the tank diameter (Y) to nd the upper tube reference number

(Z).

(Y) - (X) = (Z)

6) Subtract 2" from (Z) to nd the upper tube depth

(C).

(Z) - 2" = C

7) Is C less than 6-1/2"?

NO Upper tube length is C plus the distance from

the top of the Face Seal Adaptor installed on

the riser pipe to the inside, top lip of the storage

tank (A).

Upper Tube Length = C + (A)

For testable models only, ending in “T”:

Upper Tube Length = C + (A) – 1-1/2”

YES Upper tube length is 6-1/2” plus the riser pipe

measurement (A).

Upper Tube Length = 6-1/2” + (A)

For testable models only, ending in “T”:

Upper Tube Length = 6-1/2” + (A) - 1-1/2”

NOTE: You must nd the actual tank capacity number that correlates to the 6-1/2” + (A) depth for the

station records. This number may also be used for

the purposes of calibrating an electronic tank level

system.

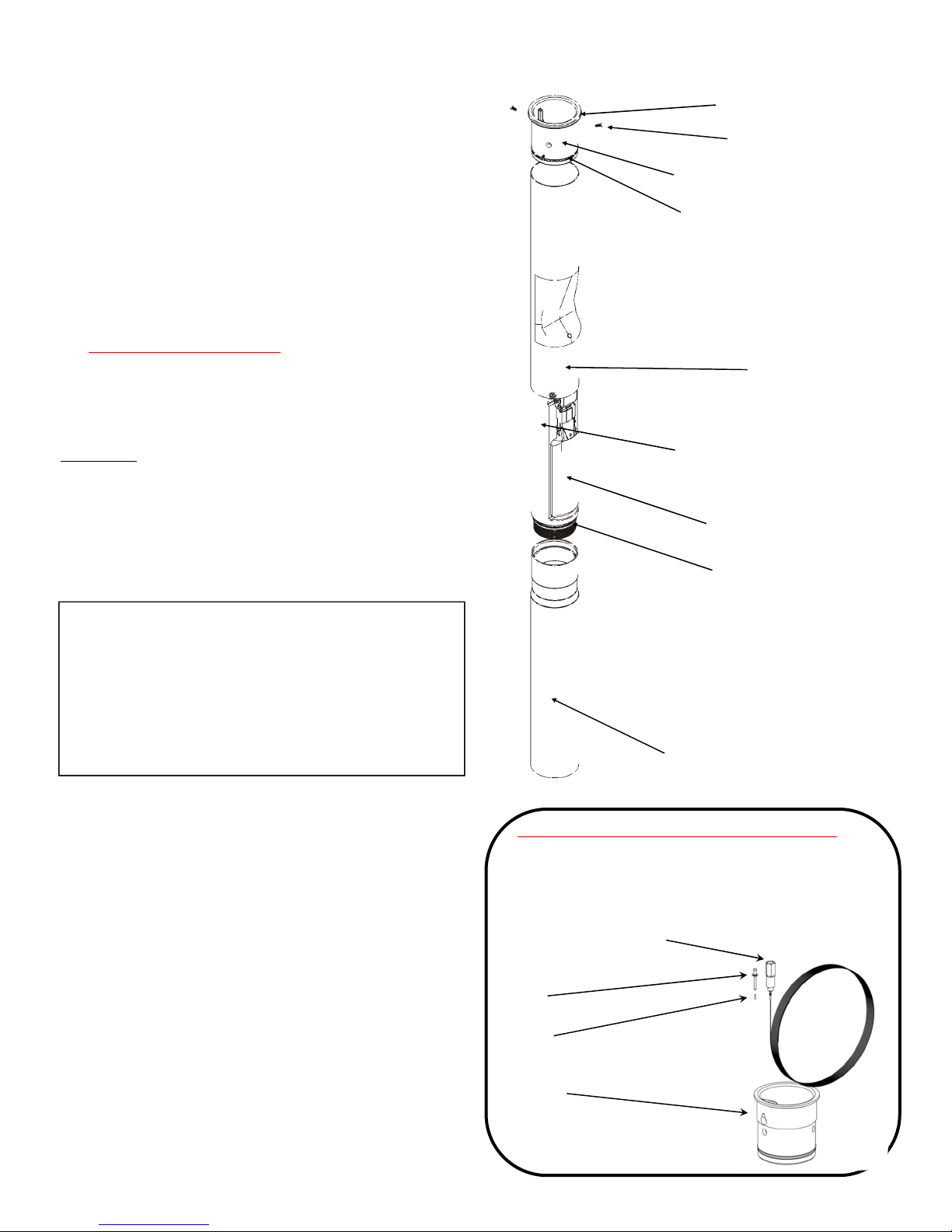

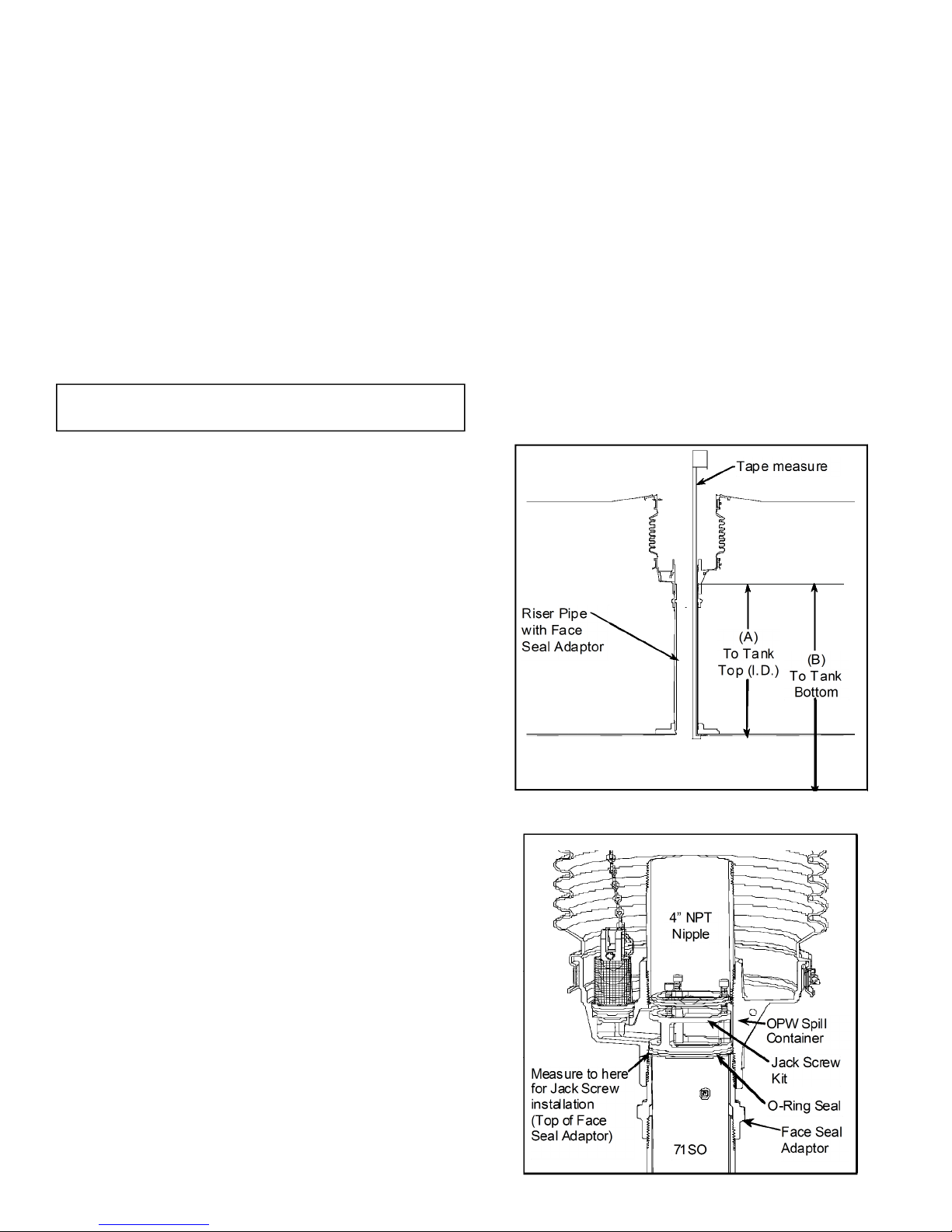

Figure 1

EXAMPLE

1) For an Owens-Corning Model G-3 Fiberglass® Tank

Calibration Chart:

Tank Capacity - 10,000 gal., nominal 9,403 gal.

NOTE: Use actual capacity only

2) 95% of actual tank capacity = 0.95 x 9403 gal. =

8933 gal.

3) The closest number which is less than 8933 gal. Is

8910 gal. Choosing the closest number less than

95% of actual capacity ensures that the initial

shuto will occur when the tank is no more than

95% full.

4) The calibration chart reading of 8910 gal. corresponds to a dipstick measurement of 82”.

4

5) Dipstick number (X) = 82”

Tank diameter (Y) = 92”

(Y) - (X) = (Z) (92” - 82” = 10”)

(Z) = 10”

6) (Z) - 2” = C (10” - 2” = 8”)

C=8”

7) Is 8” less than 6-1/2”?

NO Measure the distance from the top of the FSA-

400 Face Seal Adaptor installed on the riser pipe

to the inside, top lip of the storage tank and obtain measurement (A).

Upper tube length = C + (A)

For testable models only, ending in “T”: Upper Tube

Length = C + (A) - 1-1/2”

ASSEMBLY INSTRUCTIONS

IMPORTANT: Each of the numbered steps in the instal-

lation instructions are designed as a CHECK LIST to ensure proper installation and trouble free operation of

the OPW 71SO Overll Prevention Valve.

Read and follow these steps carefully, checking them

o as you proceed.

Figure numbers correspond to step numbers for easy

reference.

STEP 1: MEASURE

Install the OPW Face Seal Adaptor and the OPW Threadon Spill Container on the Fill Riser (Refer to the Installation Instructions Supplied with the Spill Container). Insert a tape measure through the riser pipe and hook it

under the inside of the tank in the lengthwise direction.

Measure the distance from the top of the Face Seal

Adaptor threads inside the base of the spill container

bucket just below the drain valve outlet window to the

inside, top lip of the storage tank (Dim. “A”) (See Figure

1 &1A).

The top ange on the 71SO will rest on the Face Seal

Adaptor just below the drain valve outlet, and be

locked in place between the Face Seal Adaptor and the

4" nipple that is installed in the spill container with the

Jack Screw Kit (See Figure 1A). (For riser pipe congurations other than that shown, consult installation

drawings or use other necessary means to measure Dimension “A”).

Using a tape measure, measure the distance from the

top of the Face Seal Adaptor in the spill container to the

bottom of the tank (Dim. “B”).

IMPORTANT: Inspect the riser pipe for any foreign material. Over spray from tank relining or any internal

burrs inside of pipe must be removed prior to installation. Failure to have an unobstructed riser pipe may

prevent proper installation and operation of the valve.

The 71SO is designed for installation into schedule 40

riser pipes. The 71SO cannot be installed into schedule

80 riser pipes.

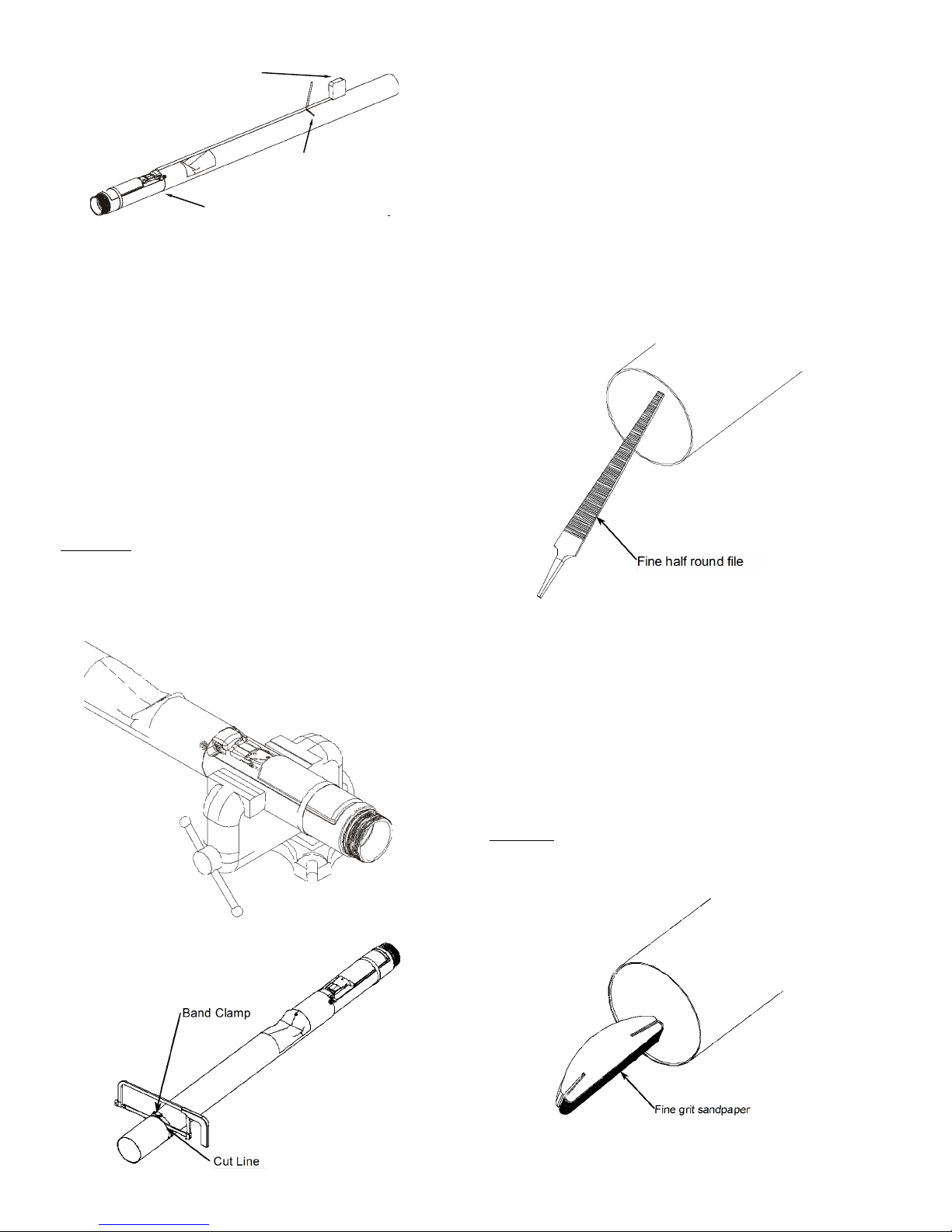

STEP 2: MARK THE TUBE

Use the result from Step 1 and HOW TO LOCATE THE

POSITION OF THE 71SO AT 95% TANK CAPACITY to

mark the upper tube. Measure the distance from the

seam where the upper tube and valve body meet. Use

a tape measure to mark the calculated upper tube

length onto the upper tube. See Figure 2.

Figure 1

Figure 1A

5

Figure 2

Tape measure

Seam

Mark Upper Tube

(Cut Line)

STEP 3: CUT THE UPPER DROP TUBE

Attach the supplied band clamp to the upper tube just

below the mark and ensure that it is assembled square

to the tube. The clamp can be used as a guide for making a square cut. If a vise is used, clamp on the valve

body casting only to avoid damage to the oat and

tubes (See Figure 3A). Carefully saw through the tube

squarely, at the mark made in Step 2. Use a hacksaw

with a new ne-tooth blade. Rotating the upper tube

as the sawing progresses will minimize run out and ensure a square 90-degree cut. Remove the band clamp

after tube is cut.

CAUTION - DO NOT use a pipe or tubing cutter to cut

the upper drop tube, this may damage the tube,

causing it to be out of round thereby prohibiting

assembly of the unit.

Figure 3A

IMPORTANT: Remove all chips and shavings generated

in steps 3 thru 5 out of the cut end of the tube. DO NOT

remove chips and shavings by dumping thru valve

body.

STEP 4: FILE THE UPPER DROP TUBE

File the upper tube square, and remove any burrs or

rough edges. Make sure the cut is at and square.

IMPORTANT: Carefully le a good chamfer on the inside edge of the drop tube to provide a lead-in for the

polypak seal and inlet tube installed in Step 8.

Figure 4

STEP 5: SAND THE UPPER DROP TUBE

Sand the inside of the drop tube with sandpaper and/or

steel wool to remove all burrs and sharp edges. After

sanding wipe down the inside of the tube with a clean

rag from the top to approximately 4 inches down to

remove any debris.

Caution: Failure to properly chamfer, sand, and

clean the drop tube may cut the seal and result in a

failure of a pressure decay leak test.

Figure 5

Figure 3B

6

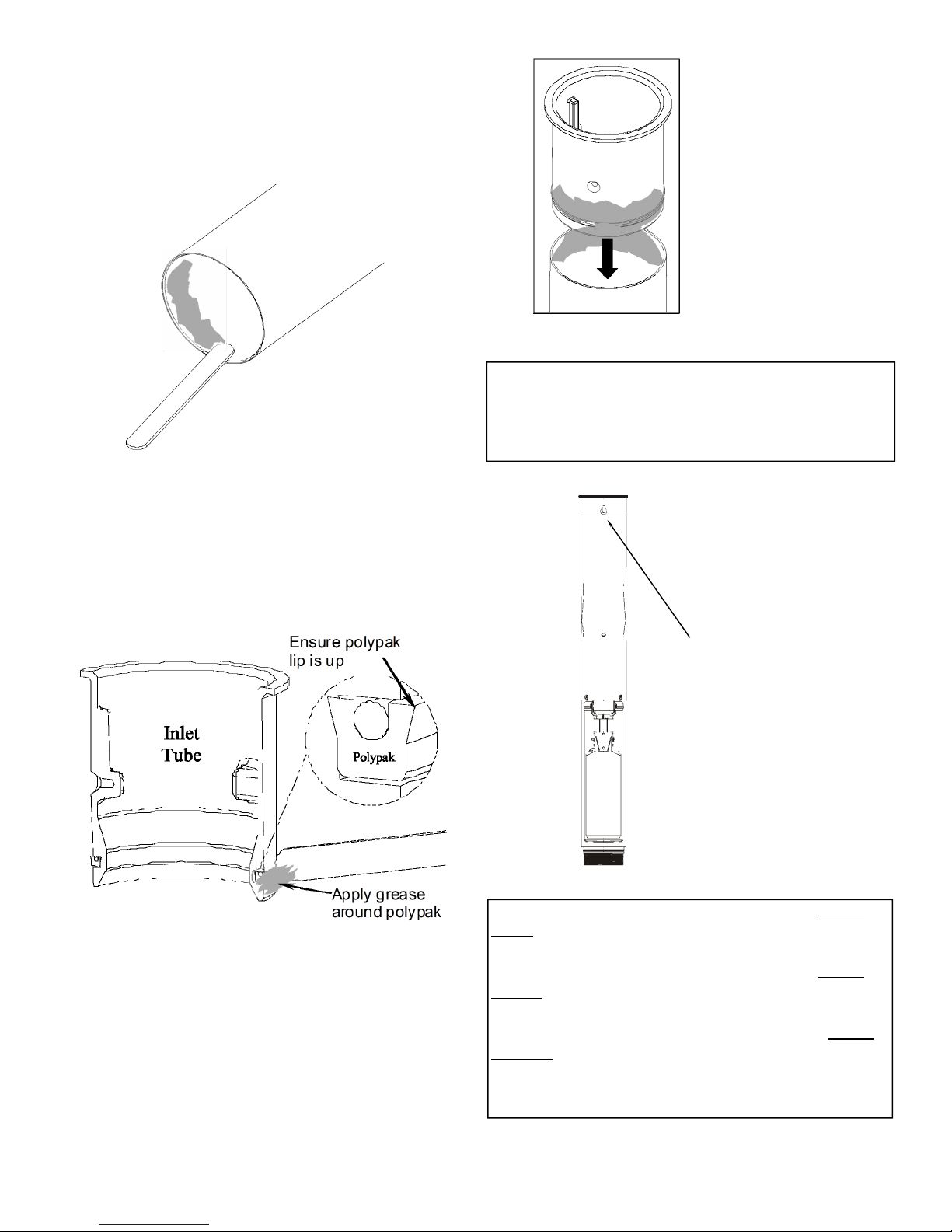

STEP 6: APPLY GREASE TO DROP TUBE

Apply black moly grease to the inside diameter of the

upper drop tube. Make sure coverage is completely

around the tube as shown in Figure 6.

Figure 6

STEP 7: APPLY GREASE TO POLYPAK SEAL

Ensure that the polypak seal is installed on the inlet

tube with the lip up as shown in Figure 7. Apply black

moly grease to the polypak as shown. Make sure coverage is completely around the polypak seal.

Figure 8

NOTE: Testable inlet tube must have cable port in

line with oat. Testable inlet tube bottoms out on

stop, it does not bottom out on inlet ange. See Fig-

ure 8A

Figure 7

STEP 8: INSTALL INLET TUBE

Insert the inlet tube into the upper tube until the upper

tube seats against the ange on the inlet tube. Ensure

polypak is inserted evenly and stays in inlet tube

groove.

Cable port must be in

line with oat

Figure 8A

Testable Models Only

SEE PAGE 8 FOR INSTRUCTIONS USING THE 71SOTOOL.

SEE PAGE 9 FOR INSTRUCTIONS USING THE 71SOTOOLC.

SEE PAGE 10 FOR INSTRUCTIONS USING THE 71SOTOOLCT.

Note: testable 71SO models ending with a “T” require the

71SO-TOOLCT or modied 71SO-TOOL or 71SO- TOOLC

7

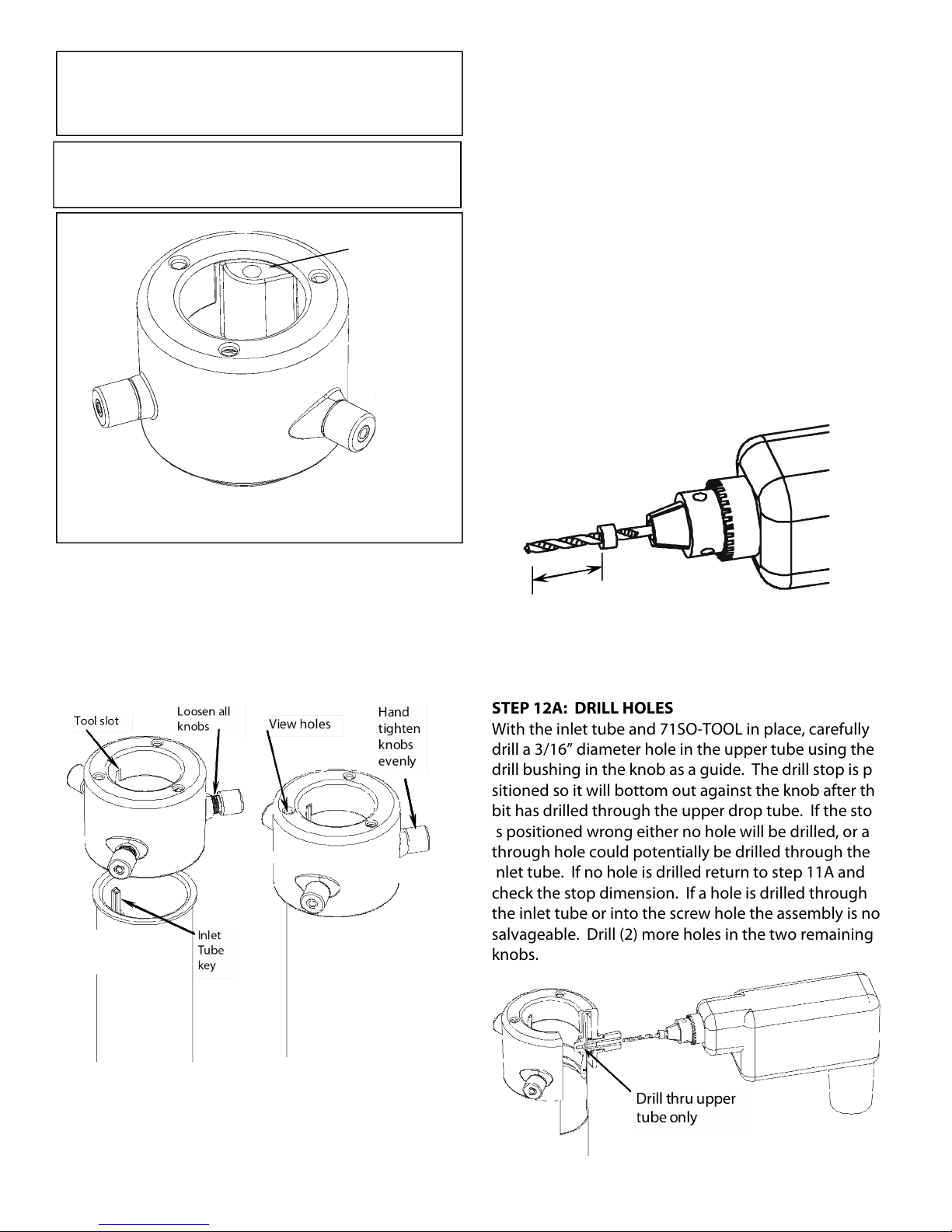

71SO-TOOL PROCEDURE BELOW,

FOR 71SO-TOOLC, SEE PAGE 9

FOR 71SO-TOOLCT, SEE PAGE 10

Note: 71SO-TOOL can only be used with testable

overll valves if modied as shown below. A 2”

wide slot must be added to accommodate cast lug.

Add 2” wide

slot to use with

testable valves

71SO-TOOL Modications for Testable Inlet

STEP 9A: INSERT 71SO-TOOL OVER INLET TUBE

To install the 71SO-TOOL (sold separately) over the inlet

tube, rst loosen all three knobs, so the tool can pass

freely over the inlet tube ange. Align the slot on the

tool with the key on the inlet tube and insert the tool

down. See Figure 9A.

STEP 10A: TIGHTEN THE 71SO-TOOL

Use the three view holes to ensure that the tool seats

out at against the top of the inlet tube. To prevent

vertical movement of the tool during drilling, hand

tighten all three knobs evenly to the upper drop tube.

See Figure 10A.

STEP 11A: PREPARE DRILL AND BIT

Conrm that the stop on the 3/16” drill bit supplied

with the 71SO-TOOL is in the correct position before

drilling. The stop is factory installed at a distance between 2” to 2-1/16” from the tip with the 71SO-TOOL. If

the stop is not at the correct position it must be xed

before drilling.

CAUTION: If the drill stop is not in the proper location failure of a pressure decay leak test may result.

Tip to stop dimension must be

2” to 2-1/16”.

Figure 11A

STEP 12A: DRILL HOLES

With the inlet tube and 71SO-TOOL in place, carefully

drill a 3/16” diameter hole in the upper tube using the

drill bushing in the knob as a guide. The drill stop is positioned so it will bottom out against the knob after the

bit has drilled through the upper drop tube. If the stop

is positioned wrong either no hole will be drilled, or a

through hole could potentially be drilled through the

inlet tube. If no hole is drilled return to step 11A and

check the stop dimension. If a hole is drilled through

the inlet tube or into the screw hole the assembly is not

salvageable. Drill (2) more holes in the two remaining

knobs.

Figure 9A

Figure 10A

Figure 12A

8

Loading...

Loading...