Page 1

The 61ƒSTOP-1000 is an overfill prevention valve for

use with an aboveground storage tank (AST) where product is pumped from a transport vehicle into the AST.

The valve is designed to stop the flow of product when

the tank is filled to a pre-determined level.

WARNING: THE 61ƒSTOP IS DESIGNED FOR

TIGHT-FILL APPLICATIONS AND MUST ONLY

BE USED WITH APPROPRIATE CONNECTIONS.

FAILURE TO PROPERLY CONNECT THE

DELIVERY HOSE OR DISCONNECTING A

LIQUID-FILLED LINE WILL RESULT IN AN

EXTREMELY HAZARDOUS SPILL WHICH MAY

RESULT IN PERSONAL INJURY, PROPERTY

DAMAGE, FIRE, EXPLOSION OR WATER AND

SOIL CONTAMINATION.

INSTALLATION

The 61ƒSTOP-1000 is packaged with a 2" diameter,

4" long pipe nipple that is loosely threaded in the inlet

of the valve. A collar for attaching the assembly to a

4" riser is loosely assembled over the 4" long nipple.

A special adapter with a crossbar is loosely threaded on

the inlet end of the nipple. This nipple may be used on

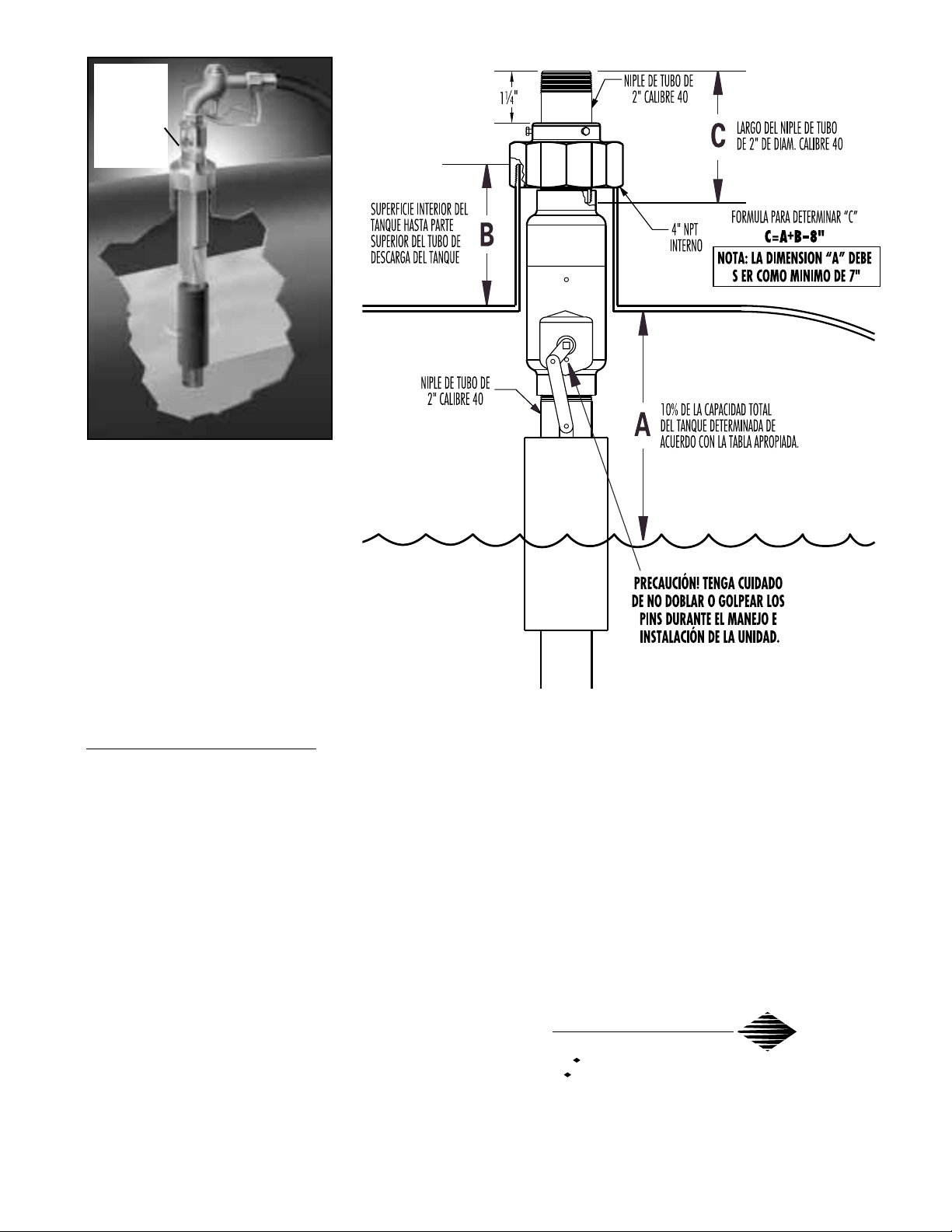

single wall tanks if dimension “B” (see illustration) is

between 3" and 6". If “B” dimension is 5"- 6", push

nipple down until the adaptor meets the collar.

However, the ullage will be affected by the length

of dimension “B”.

For “B” dimensions greater than 6", a different

2" diameter nipple length will need to be determined.

See illustration for determining dimension “C”.

Instructions for installations where the

4" long nipple is adequate, simply proceed

with the following steps:

1. Remove the special adapter from the inlet

of the nipple.

2. Remove the collar and nipple from the inlet

of the valve.

CAUTION! CARE MUST BE TAKEN TO PREVENT

DAMAGE TO THE FLOAT AND LINKAGE.

3. Apply a gasoline-resistant sealant to the outlet end

of the nipple and install it into the inlet of the valve.

4. Apply a gasoline-resistant sealant to the inlet end

of the nipple and thread the adapter in place.

5. Tighten the three (3) set screws in the collar.

6. Stand the valve upright, lift the float and release

it to make sure it works freely.

H-12676-M

February, 2000

Installation

Instructions

OPW 61ƒSTOP-1000 & -100M “THE STOPPER”

7. Apply a gasoline-resistant sealant to the threads of

the 4" fitting in the top of the tank. Slide the valve

assembly through the fitting.

8. Thread the collar onto the fitting. The valve is now

ready for operation.

Instructions for installations where a longer, 2"

diameter nipple (dimension “C”) must be used, i.e., a

nipple length greater than 4". See Illustration for

determining length of nipple.

If dimension “B” is greater than 6", proceed

with the following steps:

1. Determine dimension “C” (length of 2" diameter

nipple) by adding dimension “A” and “B” and

subtracting 8": A+B - 8"= C.

Note: “A” dimension

must be a minimum of 7".

2. Cut and thread the new nipple which corresponds

to dimension “C”.

3. Remove adapter from the inlet of the existing

nipple and slide the collar off the nipple.

4. Remove the existing nipple from the valve.

5. Apply a gasoline-resistant sealant to one end of the

new nipple and thread it into the inlet of the valve.

6. Apply a liberal amount of grease to the o-ring in the

collar and slide the collar onto the nipple with the

4" threaded end toward the valve for a distance of

1

1

⁄4". Tighten the 3 set screws.

7. Apply a gasoline-resistant sealant to the inlet end of

the nipple and thread the adapter in place.

8. Stand the assembly upright, lift the float and

release it to make sure it works freely.

9. Apply a gasoline-resistant sealant to the threads of

the 4" fitting in the top of the tank and slide the

valve assembly through the fitting.

10. Thread the collar onto the fitting. The valve is

now ready for operation.

Note: OPW recommends using a drop tube, such

as the OPW 61FT Series with all 61ƒSTOPs.

OPERA

TING PROCEDURES

CAUTION: READ THESE INSTRUCTIONS

CAREFULLY AND COMPLETELY BEFORE

OPERATING THIS DEVICE.

The 61ƒSTOP-1000 “The Stopper” is provided

a special adaptor which requires the appropriate

attachment for connection to achieve a tight fit.

CAUTION! OPERATIONS PROCEDURES CONTINUED

ON NEXT PAGE.

OPW

®

Page 2

PROCEDIMIENTOS PARA OPERACION

CUIDADO: LEA ESTAS INSTRUCCIONES POR COMPLETO

Y CON ATENCION ANTES DE OPERAR EL DISPOSITIVO.

El 61ƒStop-1000 “The Stopper” viene provista de una

adaptador especial que requiere ser instalado correctamente

para lograr un encaje apretado.

PROCEDIMIENTOS PARA ABASTECIMIENTO:

1. Asegúrese que la pistola esté provista del acoplador

correcto para lograr conexión adecuada.

2. Monte el acoplador al adaptador.

3. Active la bomba.

4. Abra la pistola despacio.

5. Monitoree el indicador de nivel de líquido durante

abastecimiento.

6. Observe la manguera ya que cualquier movimiento

rápido indica que ha ocurrido un cierre.

PROCEDIMIENTOS PARA DESCONEXION:

1. Después de ocurrir corte, cierre la pistola.

2. Desactive la bomba en el vehículo de transporte.

3. Vuelva a abrir la pistola y espere aproximadamente dos

minutos. Esto permite que se reduzca la presión en la

manguera.

¡CUIDADO! SI SE TRATA DE DESCONECTAR EL

ACOPLADOR CUANDO HAY PRESION EN LA MANGUERA

SE DERRAMARA PRODUCTO.

4. Cierre la pistola y desacople la conexión despacio.

5. Remueva la pistola cuidadosamente y reemplace

la tapa.

OPW ofrece conector con bloqueo de

leva en nuestra pistola manual estándar

190, para ser usada con “The Stopper”.

Esta nueva conexión con bloqueo

de leva provee alto caudal confiable y

abastecimientos de gran volumen

sin derrames.

Otras características de la pistola

incluyen: cuerpo liviano de aluminio,

obturadores dobles para fácil apertura

contra la presión de entrada, enganche

para mantener abierta la pistola de

cuatro posiciones y área grande en la

palanca para mejor control.

Pistola

equipada

con

acoplador

con bloqueo

de leva

© Copyright 2000, OPW Fueling Components Printed In USA

OPW

®

A DOVER RESOURCES COMPANY

FUELING COMPONENTS

P.O. Box 405003 Cincinnati, Ohio 45240-5003

(513)870-3219 (800)422-2525 (Sólo órdenes)

(513)870-3100 (Otras Ilamadas)

Intn'l Ph: (513) 870-3315

Intn'l Fax: (513) 870-3157

Page 3

FILLING PROCEDURES:

1. Make sure the nozzle is equipped with the appropriate coupler to achieve an adequate connection.

2. Attach the coupler to the adaptor.

3. Turn on the pump.

4. Slowly open the nozzle.

5. Monitor the liquid level gauge during fill.

6. Watch for any quick movement of the hose

which indicates that shut-off has occurred.

DISCONNECTION PROCEDURES:

1. After shut-off has occurred, close the nozzle.

2. Turn off the pump at the transport vehicle.

3. Re-open the nozzle and wait approximately

2 minutes. This allows the pressure in the hose

to be reduced.

OPW offers a cam-lock connector for

our standard 190 manual nozzle, for use

with “The Stopper”.

This new cam-lock connection provides

for reliable, high flow and mess-free bulk

fuel deliveries.

Additional nozzle features include:

Lightweight aluminum body, dual poppets

for easy opening against inlet pressure,

four position hold-open latch and large

lever area for maximum grip.

Nozzle

equipped

with

cam-lock

coupler

CAUTION! ATTEMPTING TO DISCONNECT THE

COUPLER WITH PRESSURE IN THE HOSE WILL

RESULT IN THE RELEASE OF PRODUCT.

4. Close the nozzle and slowly uncouple the

connection.

5. Remove the nozzle carefully and replace the cap.

© Copyright 2000, OPW Fueling Components Printed In USA

Page 4

H-12676-M

INSTRUCCIONES

PARA

INSTALACION

OPW 61ƒSTOP-1000 & -100M “THE STOPPER”

La 61ƒSTOP-1000 es una válvula de prevención de sobrellenado para ser usada con tanques exteriores de almacenamiento (AST) donde el producto es bombeado del vehículo de transporte directamente al AST. Ha sido diseñada para

cerrar el flujo de producto cuando el líquido en el tanque

llega a un nivel predeterminado.

ADVERTENCIA: La 61ƒSTOP HA SIDO DISEÑADA

PARA APLICACIONES DE LLENADO HERMETICO Y

DEBE SER USADA CON LAS CONEXIONES APROPIADAS.

SI NO SE CONECTA DEBIDAMENTE LA MANGUERA DE

DESCARGA O SI NO SE DESCONECTA DEBIDAMENTE

UNA LINEA LLENA DE LIQUIDO, SE PUEDE OCASIONAR

UN DERRAME EXTREMADAMENTE PELIGROSO, RESULTANDO EN SERIAS LESIONES PERSONALES Y DAÑOS

MATERIALES, FUEGO, EXPLOSION O CONTAMINACION

DEL SUELO Y EL AGUA.

INSTALACION

La 61ƒSTOP-1000 ha sido empaquetada con un niple de

tubería de 2” de diámetro por 4” de largo, enroscado sin

apretar en la entrada de la válvula. Por encima del niple de

4”, se ha ensamblado sin apretar un collar para conectar la

unidad al tubo de entrada de 4” del tanque. Un adaptador

especial con barra cruzada ha sido enroscado sin apretar en

el extremo de entrada del niple. Este niple puede ser usado

en tanques de pared simple si la dimensión “B” (vea ilustración) es entre 3” y 6”. Si la dimensión “B” es de 5” a 6”,

empuje el niple hacia abajo hasta que el adaptador se

encuentre con el collar. Sin embargo, la merma se verá afectada por el largo de la dimensión “B”.

Para dimensiones “B” mayores de 6”, se necesita

determinar un largo diferente para el niple de 2”. Vea

la ilustración para determinar la dimensión “C”.

Instrucciones para instalaciones en las que el

niple de 4” de largo es adecuado. Proceda con los

pasos siguientes:

1. Remueva el adaptador especial de la entrada

del niple.

2. Remueva el collar y el niple de la entrada

de la válvula.

¡CUIDADO! SE DEBE TENER MUCHO CUIDADO PARA NO

DAÑAR EL FLOTADOR Y LAS UNIONES.

3. Aplique un sellador resistente a la gasolina al

extremo de salida del niple e instálelo en la entrada

de la válvula.

4. Aplique un sellador resistente a la gasolina al extremo

de entrada del niple y enrosque el adaptador.

5. Apriete los tres (3) tornillos en el collar.

6. Posicione la válvula hacia arriba, levante el flotador y

déjelo ir para asegurarse que está trabajando correctamente.

7. Aplique un sellador resistente a la gasolina a los

enrosques de la pieza de unión encima del tanque.

Deslice la válvula a través de la pieza de unión.

8. Enrosque el collar a la pieza de unión. La válvula está

pronta para operación.

Instrucciones para instalaciones en las que se debe usar

un niple de 2” de diámetro más largo (dimensión “C”),

por ejemplo, un niple de más de 4” de largo. Vea la ilustración para determinar el largo del niple.

Si la dimensión “B” es mayor de 6”, proceda

con los pasos siguientes:

1. Determine la dimensión “C” (el largo del niple de

2” de diámetro) sumando la dimensión “A” y “B” y

restando 8”. A+B - 8”=C. Note que la dimensión

“A” debe ser por lo mínimo 7”.

2. Corte y enrosque el nuevo niple que corresponde

a la dimensión “C”.

3. Remueva el adaptador de la entrada del niple

existente y deslice el collar fuera del niple.

4. Remueva el niple existente de la válvula.

5. Aplique un sellador resistente a la gasolina al un

extremo del nuevo niple e enrósquelo en la entrada

de la válvula.

6. Aplique una gran cantidad de grasa al anillo O en el

collar y deslice el collar en el niple con el extremo

enroscado de 4” hacia la válvula a una distancia de

1-1/4”. Apriete los 3 tornillos.

7. Aplique un sellador resistente a la gasolina al extremo

de entrada del niple y enrosque el adaptador en

su lugar.

8. Posicione la válvula hacia arriba, levante el flotador

y déjelo ir para asegurarse que está trabajando

correctamente.

9. Aplique un sellador resistente a la gasolina a los

enrosques de la pieza de unión encima del tanque.

Deslice la válvula a través de la pieza de unión.

10. Enrosque el collar a la pieza de unión. La válvula está

pronta para operación.

Nota: OPW recomienda utilizar un tubo de

ilenado como el de la Serie OPW 61FT

en todos los 61ƒSTOPS

¡CUIDADO! VEA LAS INSTRUCCIONES DE OPERACION.

OPW

®

Loading...

Loading...