Page 1

Goldpress 4+

OPERATING, MAINTENANCE AND SAFE USAGE

MANUAL OF THE GOLDPRESS 4+ MACHINE

Page 2

SAFETY INSTRUCTIONS:

• Before putting the machine into operation please

read the safety precautions, manufacturer recommendations and the operation manual. The operation

manual should be easily available at any time for the

operator.

• The machine should be installed on sturdy and

level floor .

• The machine should be protected against dust

and moisture.

• The machine must not be placed near the heating

units or ventilation units.

• The machine should not be used in vicinity

of inflammable liquids or gases.

• The machine may be power supplied only through

the original cord. A mains socket should be provided

with an efficient earthing. The supply voltage should

be consistent with the parameters specified on the

technical plate located on the machine housing.

If this principle is not obeyed, then electric shock

and fire may occur.

• The supplying cable should be protected against

any damage, must not be used to pull the machine

or to remove the plug from a socket .

• Making any changes to the electric installation of the

machine or in the supplying cable causes the hazard

of electric shock.

• The machine is turned off completely after removing

the plug from a socket.

• During a long standstill or before replacing the

machine, the plug should be removed from a mains

socket.

• Before removing the housing from the machine,

remove the plug from a socket necessarily.

• The power pack module is installed in the machine

base and provided with a mains fuse (access from

the bottom of the machine). If replacement of the

fuse is necessary, this should be effected by a suitably

qualified person.

• Do not touch the heater –

bbuurrnn hhaazzaarrdd..

• Before replacement of fonts fixed in the frame, wait

5÷10 min to make sure that the elements are cool

–

bbuurrnn hhaazzaarrdd

.

• The machine includes a sharp device (knife to cut

off the foil) – pay special attention when using the

device or operating nearby.

• The machine should be kept away from children reach.

• The machine must not be used for any other purposes than those indicated in the operating manual

• It is necessary to check if the machine operates

correctly. In case of any malfunctions, contacting

the servicing point is required

• The machine must not be located outside, should be

operated in room temperature higher than +8C/46,4 F.

• The machine should be operated according to general

safety rules.

• Any repairs can be made only by trained staff.

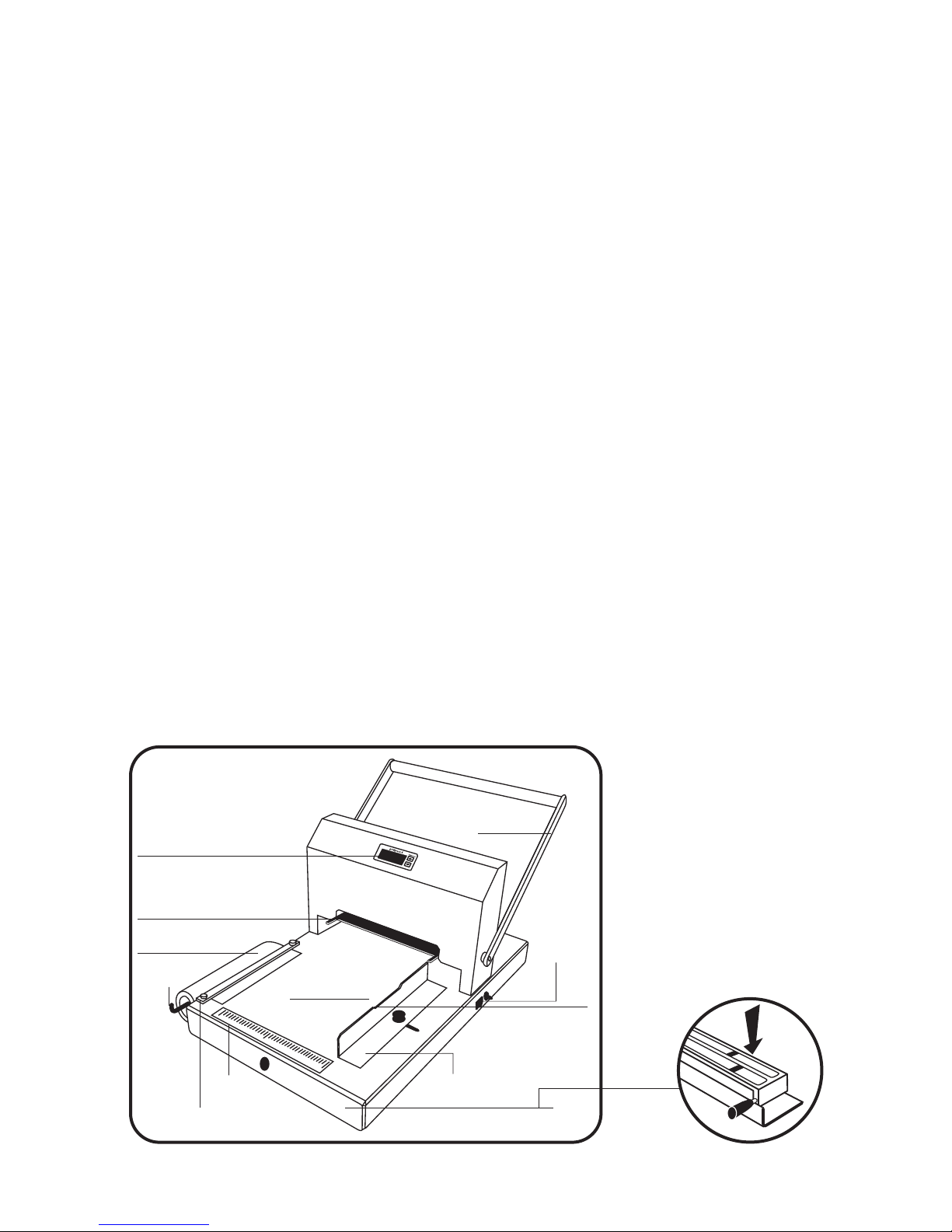

LCD display

heater + frame

foil

bail

scale

knife

to cut off the foil

ruler

arm

main

switch

guide

incision

in the guide wall

drawer

Design of the machine

holder to support

the frame

Page 3

General information

The GoldPress machine was designed to

make hot stampings on paper or card

board covers, as well as on covers coated

with glued paper sheets. It is also possible

to make hot stamps on plastic or plastic

coated materials, however the tests should

be carried out previously to check if the

material is suitable for the purpose.

The use of fonts makes it possible to compose any inscription (various kinds of fonts,

also in various languages and sizes, are

available) and to apply it on a cover or

another surface. It is also possible to prepare a special matrix (e.g. a logo) consistent with the GOLDCOVER standard. Also,

thanks to an O.Goldchannel Base device,

the imprintments on channels (backs of

OPUS covers) can be made.

The detailed information concerning extension of the possibilities of the machine can

be obtained from the supplier.

Operation of the machine does not need

special qualifications, however:

Before starting the work the operator

should read the manual carefully.

The GoldPress is built on the basis of an

eccentric press. It is fitted with a heater

(enabling to make hot stamps) and a microprocessor controller with a digital display to

maintain precisely a set temperature and

stamping time, which ensures constant

work conditions. A frame with a matrix or

fonts that form an inscription is mounted on

the heater. Side guide and a ruler make it

possible to position a cover in relation to

the central point of the frame. A movable

knife enables to cut off a required piece of

hot stamping foil.

A special container to store the fonts in

order is also available as an option.

Transport and storage:

• The GoldPress is an office device electrically supplied and adapted to operation

in office conditions. Both the machine

and its package should not be exposed

to moisture (e.g. rain).

• If moistened or flooded with water, the

machine should be delivered to a servicing point to carry out an inspection,

in order to avoid a risk of electric

shock.

• The machine should be stored in plus

Celsius temperatures (above 32F)

• Although the package protects the

machine, it should be handled with care.

Installation

• The machine does not need disassembling of transport protections.

• It is recommended to store the package

in case of repeated transportation

• The GoldPress is a machine adapted to

operating in office conditions.

• The machine does not work if the room

temperature is lower than +8 C/46,4 F

• The machine should be positioned on a

suitably tough, flat and stable surface.

• The rubber legs of the machine protect

the substrate against being scratched

and do not leave any traces.

• If the machine was exposed to minus

Celsius temperatures (below 32F), it may

be connected to mains after several

dozens of minutes due to condensation

of steam on cold metal elements.

• To ensure operator’s safety, the

machine may be supplied only

through the original cord. A mains

socket should be provided with efficient earthing. The supply voltage

must be consistent with the parameters specified on the technical plate

positioned on the machine housing.

Disobeying the above rule may result

in electric shock or fire.

Preparation for work:

1. Mount the back guide (the one without

the scale) at the back of the machine by

putting the screw of the guide into the

slot.

2. Insert the plug into a mains socket.

Note!

Make sure the temperature of the

room where the machine is placed

exceeds +8 C/46,4 F. If it does not, the

machine will not work.

Page 4

3. Mount a roll of foil on the bail located on

the left side of the machine.

4. Switch the power supply on (the main

switch is located on the right side of the

machine)

On the display the following will appear:

- control inscription “OPUS”

- set heater temperature (e.g. 100 C or

212F – if the temperature is set in

Fahrenheit degrees)

- set stamping time (e.g. 001,5 – means:

1,5 second)

- current heater temperature

If the current heater temperature differs

from the set one for more than +/- 3

degrees, the figures (which indicate the

current heater temp.) blink slowly and

change (aiming to the value of set temperature). Blinking stops when the current heater temperature reaches the set

temperature (including +/- 3 degrees

deviation).

Note!

The temperature can be measured

both in Celsius and Fahrenheit scales.

To change the scale from Celsius into

Fahrenheit, press (with the machine

switched off) the “:” button (downward arrow) and switch on the

machine at the same time. Keep

pressing the button for c.a. 4 seconds

until you see the inscription “St F” on

the display (means that the scale has

been changed).

When changing the scale from

Fahrenheit into Celsius, do the similar

pressing the ”<” button (upward

arrow), until the inscription “St C”

appears on the display.

5. Wait until the current heater temperature

reaches the set temperature and the figures on the display stop blinking.

6. The machine is ready to work.

Setting the temperature and

stamping time

The best results for hot stamping when

using Opus supplies (hot stamping foil and

covers) are obtained with the following settings:

• set heater temperature : 100 C/212 F

• set stamping time : 1,5-2 seconds

However, if the stamping results are not

satisfactory , a change in the settings may

be necessary.

To set the heater temperature, move the

arm maximally up. To change the temperature, press the ”

<” (upward arrow) or “:”

(downward arrow) button until you get the

required temperature. When setting the temperature, the figures on the display blink quickly.

After you get the temperature required, it is

saved in the memory of the Goldpress and

the machine returns to show the current

heater temperature (as already mentioned,

if the current temperature varies for more

than +/- 3 C from set temperature, the figures on the display blink slowly).

Set stamping time appears on the display

when the arm of the machine is maximally

put down. The counting down starts; after

the set time passes an inscription END

appears on the display. That means that

the arm should be lifted.

Stamping time can be set between 0,5 and

10 seconds. To set the suitable time, put

the arm maximally down. Then, pressing

the ”

<” (upward arrow) or “:” (downward

arrow) button set the required time. For a

moment the figures on the display blink

quickly and then an inscription END

appears. That means that new settings

have been saved in the memory.

Counter

The machine is equipped with a counter,

which reckons how many imprintments

have been made. The value of counter

appears for 2 seconds after lifting the arm.

If the arm was put down and then only the

settings of stamping time were changed ,

the counter does not recognize it as an

imprintment.

The value of counter is deleted every time

when switching off the machine.

Preparing the fonts

and matrixes

With the Goldpress machine you can hot

stamp inscriptions (with fonts) or logo, symbols, signs etc (with matrixes). Inscriptions

Page 5

can be made both on covers and, using the

O.Goldchannel Base, on channels (backs

of OPUS covers).

Note!

When hot stamping on channels, use

only 5,5mm or 6 mm fonts.

A. PREPARING THE FONTS

1.Take the frame out of the heating slot and

put it on a holder. This way you can comfortably put the fonts in and out of the

frame.

Note!

If the frame or the fonts were previously

used or located in the heating slot during the heating period, wait 5÷10 min

until they get cold. For that reason we

recommend having several sets of

fonts, frames and holders.

2. Compose a required text by putting suitable fonts into the frame.

Note!

The types should be put in and taken out

by means of a special pliers. The ends of

the pliers should be inserted into the

holes in the fonts (see the picture) or

embrace the fonts (in case of 4mm size).

The holes enable to distinguish between

the top and the bottom of a font. The bottom hole of a font is larger or located closer to the edge (4 mm high fonts,

because of their small measurements,

have only one hole – at the bottom)

If you prepare fonts to be hot stamped

on the channels, use only 5,5 mm

or 6 mm ones. Using smaller fonts may

result with their damage.

For 6 mm fonts use only 1L6 frame (with

1 line). For 5,5 mm fonts fix the inscription into the middle line of 3L5,5 frame.

Also, make sure the fonts are placed in

the frame frontally (not upside-down);

this also concerns stamping on channels.

3. Lock the text in the frame by means of

the stops.

4. Insert the frame into the heating slot and

wait about 3 min until the fonts are hot.

Note!

To make storing and keeping fonts in

order easier, we recommend using a

movable container (see the picture).

Storing the fonts in the container helps

to find a required letter quickly and prevents from losing the fonts.

B. PREPARING THE MATRIX

You can order a special, customized matrix

(O.Matrix) from OPUS, made according to

your own design. O.Matrix is suitable to use

with Goldpress machine.

You can also use your own matrix , if its

measurements do not exceed 35 mm x 179

mm (1,37 in. x 7,04 in.). However, in this

case you need to use also a special tape

(O.Mounting Tape) and a plate (O.Matrix

base) to mount it in Goldpress.

O.Matrix

(customized matrixes ordered in Opus)

1. Put the O.Matrix into a special frame

Page 6

(O.Matrix frame or O.Matrix/1L4 frame -

depending on the matrix size).

2. Insert the frame into the heating slot and

wait until the matrix is hot.

Customer`s matrix

1. Stick the tape to the back of your matrix

(by taking off the protection layer) and

cut it along the matrix edge.

2. Stick the matrix to O.Matrix Base

Note!

Before sticking the matrix, make sure

that the inscription/logo on the matrix is

parallel to the bottom edge of the plate

(O.Matrix Base)

3. Put the plate (O.Matrix Base) with the

matrix into the frame (O.Matrix frame)

4. Insert the frame into the heating slot and

wait until the matrix is hot.

Note!

The heating time of a matrix depends on

its size and can vary from few to tens of

minutes. Therefore it is necessary to

conduct a test to check if the matrix is

hot enough.

Preparing the document

for hot stamping

1. Center a cover with the ruler located

along the drawer edge.

2. Determine the height of the inscription

using the scale on the side guide and,

subsequently, set the rear and side

guides.

3. In order to cut foil off, pull a suitable

piece of foil under the knife (preferably,

the foil area should be larger than that of

the heater) and pull it vigorously

upwards. You can also remove the knife

and cut the foil in any other place.

4. Arrange the plates depending on the

type of covers to be hot stamped.

Preparing the plates

A. ADJUSTMENT

1.Lower the basic plate (3) by turning all its

knobs maximally counter-clockwise and

place it into the heating slot of the

Gopdpress 4+ machine.

Note!

The plate should be put directly into the

heating slot by lifting it up a little (do not slide

it into the slot).

2. On the basic plate (3) put the plate #1

and then plate #2.

Page 7

Note!

Plate #2 has pins, which should be placed

into the holes of plate#1 and basic plate (3)

3. On the top put the adjusting plate (4); its

bent wall should be placed down and

should face you.

4. Put the arm of the machine down.

5. Keeping the arm down, turn the knobs of

the basic plate (3) maximally clockwise

6. Lift the arm of the machine

Note!

Repeat steps 5, 6, 7 for several times.

7 Take the adjusting plate (4) off.

Note!

The process of adjusting should assure

the highest quality of hot stamping.

However, it may happen to be necessary

to increase the pressure on the cover

(e.g. pale dots within the embossed

area) or decrease the pressure (e.g.

blurred letters). In such case:

-turn the knobs of the basic plate (3)

clockwise – to increase the pressure

-turn the knobs of the basic plate (3)

counter-clockwise – to decrease

the pressure

Also, if the inscription is not uniformly

hot stamped (e.g. left side is hot

stamped correctly, while right side is

blurred) , turn the adequate knobs

clockwise or counter-clockwise (to

increase/decrease the pressure on the

adequate side of the basic plate (3)).

Note!

Adjustment does not have to be conducted every time when changing the

fonts or type of cover. It should be

repeated only after the hot stamping

result is not satisfactory.

B. ARRANGING THE PLATES DEPENDING ON THE TYPE OF COVER

Metalbind cover (set of two separated covers and a channel)

1. Put the basic plate (3) into the heating

slot, and then the plate #1 and plate#2

2. Put the cover to be hot stamped on the

plates.

C-bind cover (typical cover with a built-in

channel)

1. Put the basic plate (3) into the heating slot

and a plate #2 on it.

2. Put the C-bind cover with its channel up.

3. Inside the cover , in the place where you

are going to hot stamp, insert the CB

layer (4)

4. Put the cover (with the CB layer in) on

the plates

Preparing the channel for hot

stamping.

With the machine ONLY the O•CHANNELS

manufactured by OPUS can be hot

stamped.

To hot stamp on channels you need to use

O.GoldChannel Base

1. Fix the changeable part onto the channel

base (pins of the base should fix into the

holes in the changeable part). Make sure

that the size of the changeable part (indicated in front) must be same as the size

of the channel you want to hot stamp on.

2. Put the channel on the changeable part;

make sure the bent side wall of the channel is placed in front of you (see the picture). If necessary, centre the channel

using the scale sticked on the base

Page 8

3. Put the basic plate (3) into the heating slot.

4. Insert the base and the channel under

the heating slot.

Hot stamping

1. Put a cut off piece of foil in the place

where you want to make hot stamps.

2. Insert the cover under the heating slot.

Make sure that the foil strip is positioned

exactly under the frame.

3. Press the arm of the machine maximally

down until the counter starts to count

down the time

4. After the set time passes (inscription

END appears) lift the arm.

Note!

If the current heater temperature is too low – an

inscription LO appears. It is necessary then

wait the heater to get hot.

If the current heater temperature is too high –

an inscription HI appears. You need to wait until

the heater cools down.

5.Take the cover (channel) out and remove

the foil strip.

To change an inscription or a matrix,

remove the frame from the heating slot

(note: the frame is hot), put it away on the

holder, wait 5÷10 minutes until the frame

is cold and, subsequently, start composing

a new text or mounting a new matrix.

Note!

After hot stamping is done, we recommend to wipe

the hot stamped inscription with a soft cloth (in

order to get rid of the remainings of hot

stamping foil).

Maintenance:

The machine needs neither lubrication nor

perio-dical surveys. The points to be lubricated have been preserved in the factory.

The machine housing is coated with powder varnish. The machine can be cleaned

with detergents commonly available in the

market. Do not use any solvents!

Technical data:

Rated voltage:.................................. 230V 50 Hz

Max power consumption: .......................... 500W

Rated power consumption: ........................ 80W

Dimensions DxSxW (in.): .............. 546x362x278

Operating temperature: .......................... ~100°C

Temperature adjustment range: ........ 50-150°C

Temperature stabilization: ........ microprocessor

Maximum cover width (with the side stop): ...... 265mm

Maximum cover width (without the side stop): 305mm

Technical data: (North America)

Rated voltage: .................... 110-120V 50-60 Hz

Max power consumption: .......................... 250W

Rated power consumption: ........................ 50W

Dimensions DxSxW (in.): .......... 21,5x14,2x10,9

Operating temperature: ............................ ~212F

Temperature adjustment range: ........ 122÷302F

Temperature stabilization: ........ microprocessor

Maximum cover width (with the side stop): ........ 10,4 in

Maximum cover width (without the side stop): ...... 12 in

Page 9

DEFECT

The machine does

not switch on

The display does not indicate

a temperature

The device does not achieve a

desired temperature or exceeds

it significantly.

Pale dots appear within hot

stamped inscription

Stamped letters are blurred,

traces of paint are visible

beyond letter edges

POSSIBLE CAUSE

Temperature of the room

is lower than +8 C/46,4 F

The plug is not connected to mains

Lack of voltage in a socket

The device is damaged

Check what temperature

has been set

The device is damaged

Too low temperature

Too short time of stamping

Too low pressure

Too high temperature

Too long time of stamping

Too high pressure

REMEDY

Place the machine in a room

temperature higher than

+8C/46,4 F

Insert the plug to mains socket

Connect the machine to another socket

Contact the supplier

Set a suitable temperature

Contact the supplier

Increase temperature

Increase stamping time

Increase the pressure

(turn clockwise the knobs of the

basic plate (3)

Reduce temperature

Reduce stamping time

Lower the pressure

(turn counter-clockwise

the knobs of the basic plate (3)

25.04.05

Loading...

Loading...