Page 1

Operator’s Manual

optris

®

PI LightWeight kit

Miniature lightweight PC with IR camera

for flight applications

Page 2

Optris GmbH

Ferdinand-Buisson-Str. 14

D – 13127 Berlin

Germany

Tel.: +49 30 500 197-0

Fax: +49 30 500 197-10

E-mail: info@optris.de

Internet: www.optris.de

Page 3

3

Table of contents

Table of contents

1

General notes ...................................................................................................................................... 7

1.1 Intended use ................................................................................................................................. 7

1.2 Warranty ....................................................................................................................................... 9

1.3 Scope of delivery .......................................................................................................................... 9

1.4 Maintenance ............................................................................................................................... 11

1.4.1 Cleaning .............................................................................................................................. 11

2 Technical Data .................................................................................................................................. 13

2.1 Data NetBox LW ......................................................................................................................... 13

2.1.1 General specifications ........................................................................................................ 13

2.1.2 Electrical specifications ....................................................................................................... 14

2.2 Data PI 400/ PI 450 LW .............................................................................................................. 15

Page 4

4

2.2.1 General specifications ........................................................................................................ 15

2.2.2 Electrical specifications ....................................................................................................... 19

2.2.3 Measurement specifications ............................................................................................... 20

2.2.4 Optical specifications .......................................................................................................... 21

3 Installation ......................................................................................................................................... 25

3.1 Mechanical Data PI 400/ PI 450 LW ........................................................................................... 26

3.2 Mechanical Data PI NetBox LW ................................................................................................. 27

4 Operation ........................................................................................................................................... 31

4.1 Operation modes of the NetBox LW ........................................................................................... 31

4.2 Stand-Alone operation ................................................................................................................ 32

4.3 Start a recording ......................................................................................................................... 35

4.4 SD card ....................................................................................................................................... 37

Page 5

5

Table of contents

4.5 Status-LEDs ................................................................................................................................ 38

4.6 Switch positions .......................................................................................................................... 39

4.7 Remote Access to the NetBox LW ............................................................................................. 40

4.7.1 Installation of Ultra VNC ..................................................................................................... 40

4.7.2 Display the NetBox ............................................................................................................. 43

4.8 Applications and start options ..................................................................................................... 44

4.9 Watchdog .................................................................................................................................... 50

4.10 Autostart...................................................................................................................................... 52

4.11 File transfer between NetBox LW and PC .................................................................................. 53

4.12 Communication ........................................................................................................................... 55

4.12.1 Ethernet direct communication ........................................................................................... 55

4.12.2 Ethernet network communication ....................................................................................... 65

Page 6

6

4.13 USB Driver .................................................................................................................................. 71

4.14 System time ................................................................................................................................ 71

4.15 Write protection filter ................................................................................................................... 73

5 System Recovery .............................................................................................................................. 77

6 Basics of Infrared Thermometry ..................................................................................................... 83

6.1 Emissivity .................................................................................................................................... 89

7 CE Conformity ................................................................................................................................... 91

Page 7

7

General notes

1 General notes

1.1 Intended use

The optris PI LightWeight Kit consists of a miniaturized lightweight PC (PI NetBox LW) and a weightoptimized optris PI400 LW or PI450 LW infrared camera. The system is ideally suited for radiometric

infrared recordings from the air like for maintenance work and quality inspections of solar and wind

power systems and for building thermography.

The PI NetBox LW (Miniature-PC) includes a Windows XP Professional operating system that allows

on-flight recording of infrared videos with up to 35 Hz.

The optris PI 400 LW or 450 LW calculates the surface temperature based on the emitted infrared

energy of objects [► 6 Basics of Infrared Thermometry]. The two-dimensional detector (FPA - focal

plane array) allows a measurement of an area which will be shown as thermal image using

standardized color palettes. The radiometric processing of the picture data enables the user to do a

comfortable detailed analysis with the software PI Connect retrospectively.

Page 8

8

Read the manual carefully before the initial start-up. The producer reserves the right to

change the herein described specifications in case of technical advance of the product.

The optris PI is a precise instrument and contains a sensitive infrared detector and a

high-quality lens. The alignment of the camera to intensive energy sources (high power

laser or reflections of such equipment, e.g.) can have effect on the accuracy of the

measurement or can cause an irreparable defect of the infrared detector.

• Avoid static electricity, arc welders, and induction heaters. Keep away from very

strong EMF (electromagnetic fields).

• Avoid abrupt changes of the ambient temperature.

• In case of problems or questions which may arise when you use the infrared

camera contact our service department.

Page 9

9

General notes

1.2 Warranty

Each single product passes through a quality process. Nevertheless, if failures occur contact the

customer service at once. The warranty period covers 24 months starting on the delivery date. After the

warranty is expired the manufacturer guarantees additional 6 months warranty for all repaired or

substituted product components. Warranty does not apply to damages, which result from misuse or

neglect. The warranty also expir es if you open the product. The manufacturer is not liable for

consequential damage or in case of a non-intended use of the product.

If a failure occurs during the warranty period the product will be replaced, calibrated or repaired without

further charges. The freight costs will be paid by the sender. The manufacturer reserves the right to

exchange components of the product instead of repairing it. If the failure results from misuse or neglect

the user has to pay for the repair. In that case you may ask for a cost estimate beforehand.

1.3 Scope of delivery

• PI NetBox LW (LightWeight) incl. micro SDHC card (8 GB)

• Power supply (100-240 VAC / 24 VDC)

• Power cable (with open ends for direct connection to a Lithium battery)

• Video cable (stereo jack-cinch)

• Video cable (stereo jack-open ends) with recording pin

• Ethernet cable, 1 m

• USB Recovery stick (2 GB)

Page 10

10

• optris PI400 LW or PI450 LW (LightWeight) with one lens and fixed mounted USB cable (30 cm)

and aluminum case

• Software PIConnect

• Operators manual

Figure 1: PI LightWeight kit inside the camera case

For a mobile use you can arrange all components of the system also inside the camera

case as shown in Figure 1. For that purpose single foam parts of the case can be

easily removed.

Page 11

11

General notes

1.4 Maintenance

1.4.1 Cleaning

The housing of the NetBox LW can be cleaned with a soft, humid tissue moistened with water or a water

based cleaner.

Blow off loose particles using clean compressed air. The lens surface can be cleaned with a soft, humid

tissue moistened with water or a water based glass cleaner.

Never use cleaning compounds which contain solvents (neither for the lens nor for the

housing).

Take care that no foreign substances penetrate into the venting slots of the NetBox

LW.

Page 12

12

Page 13

13

Technical Data

2 Technical Data

2.1 Data NetBox LW

2.1.1 General specifications

Operating temperature:

0…50 °C

Storage temperature:

-20...75 °C

Relative humidity:

10...95 %, non-condensing

Material (housing):

aluminum anodized/ plastic

Dimensions:

112 mm x 58 mm x 54 mm (L x B x H)

Weight:

160 g

Vibration:

IEC 60068-2-6 (sinus shaped), IEC 60068-2-64 (broad band noise)

Shock:

IEC 60068-2-27 (25 g and 50 g)

Operating system

Windows XP Professional

Page 14

14

2.1.2 Electrical specifications

Power supply:

8...48 VDC or Power over Ethernet (PoE/ 1000BASE-T)

Power consumption:

9.5 W (+ additional 2,5 W for PI camera)

Cooling:

passive (active via integrated fan for ambient temperatures > 50 °C)

Board:

COM Express mini embedded board

Processor:

Intel® AtomTM Z530/ 1,6 GHz

Hard disc:

4 GB SSD

RAM:

1 GB (DDR2, 533 MHz)

Ports:

3x USB 2.0; 1x Mini-USB 2.0 (Slave-Modus)

TV

out

Ethernet (Gigabit Ethernet)

Extensions

microSDHC card (up to 32 GB)

Additional functions

6x Status-LEDs (L1-L6)

Page 15

15

Technical Data

2.2 Data PI 400/ PI 450 LW

2.2.1 General specifications

Environmental rating:

IP40

Ambient temperature:

0...50 °C [PI 400 LW] / 0...70 °C [PI 450 LW]

Storage temperature:

-40...70 °C [PI 400 LW] / -40...85 °C [PI 450 LW]

Relative humidity:

10...95 %, non-condensing

Material (housing):

aluminum, anodized/ plastic

Dimensions:

46 x 56 x 84 - 88 mm (depending on lens)

Weight (incl. lens):

220 g

Cable length USB 2.0):

30 cm

Vibration1):

IEC 60068-2-6 (sinus shaped)

IEC 60068-2-64 (broad band noise)

Shock1):

IEC 60068-2-27 (25 g and 50 g)

Page 16

16

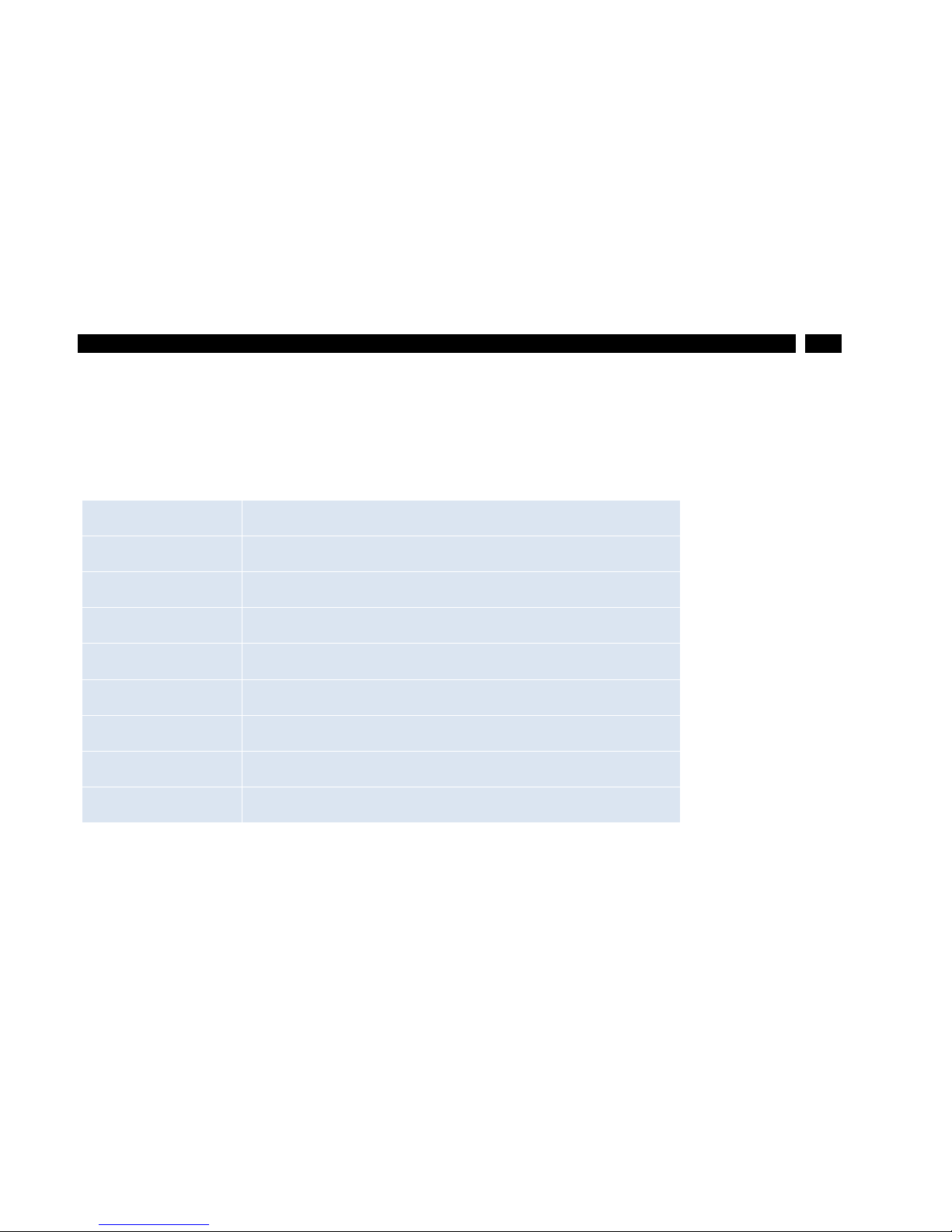

1) Used standards:

Figure 2: Used standards

Page 17

17

Technical Data

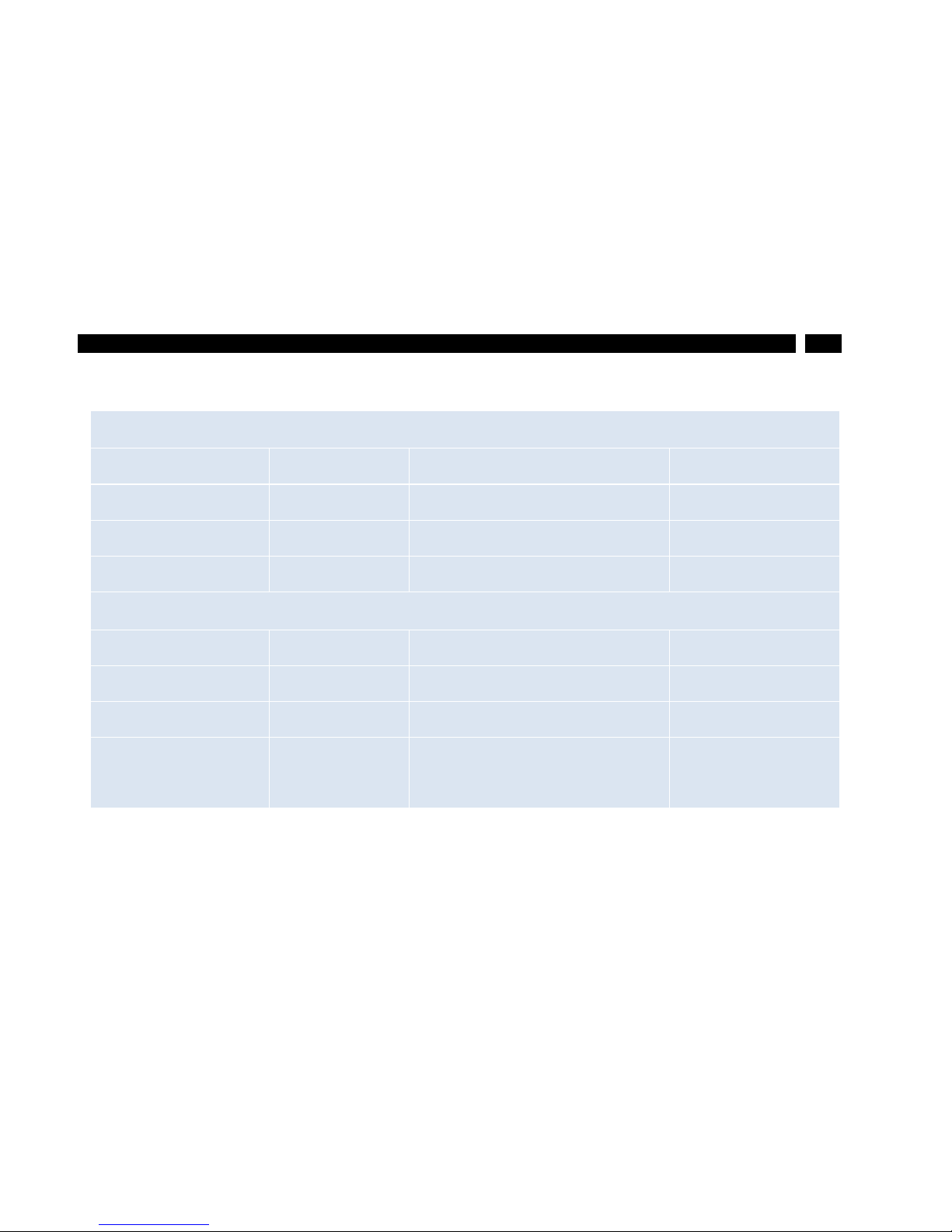

Stress program (camera in operation):

Shock, half sinus 25 g – testing Ea 25 g (acc. IEC 60068-2-27)

Acceleration

245 m/s2

(25 g)

Pulse duration

11 ms

Number of directions

6

(3 axes with 2 directions each)

Duration

600 Shocks

(100 Shocks each direction)

Shock, half sinus 50 g – testing Ea 50 g (acc. IEC 60068-2-27)

Acceleration

490 m/s2

(50 g)

Pulse duration

11 ms

Number of directions

6

(3 axes with two directions each)

Duration

18 Shocks

(3 Shocks each direction)

Page 18

18

Vibration, sinus shaped – testing Fc (acc. IEC60068-2-6)

Frequency range

10-500 Hz

Acceleration

29.42 m/s2

(3 g) Frequency change

1 Octave/ min

Number of axes

3

Duration

1:30 h

(3 x 0.30 h)

Vibration, broadband noise – testing F h (acc. IEC60068-2-64)

Frequency range

10-2000 Hz

Acceleration

39.3 m/s2

(4,01 g

RMS

))

Frequency spectrum

10-106 Hz

0,9610 (m/s2)2/Hz

(0,010 g2/Hz)

106-150 Hz

+6 dB/ Octave

150-500 Hz

1,9230 (m/s2)2/Hz

(0,020 g2/Hz)

Page 19

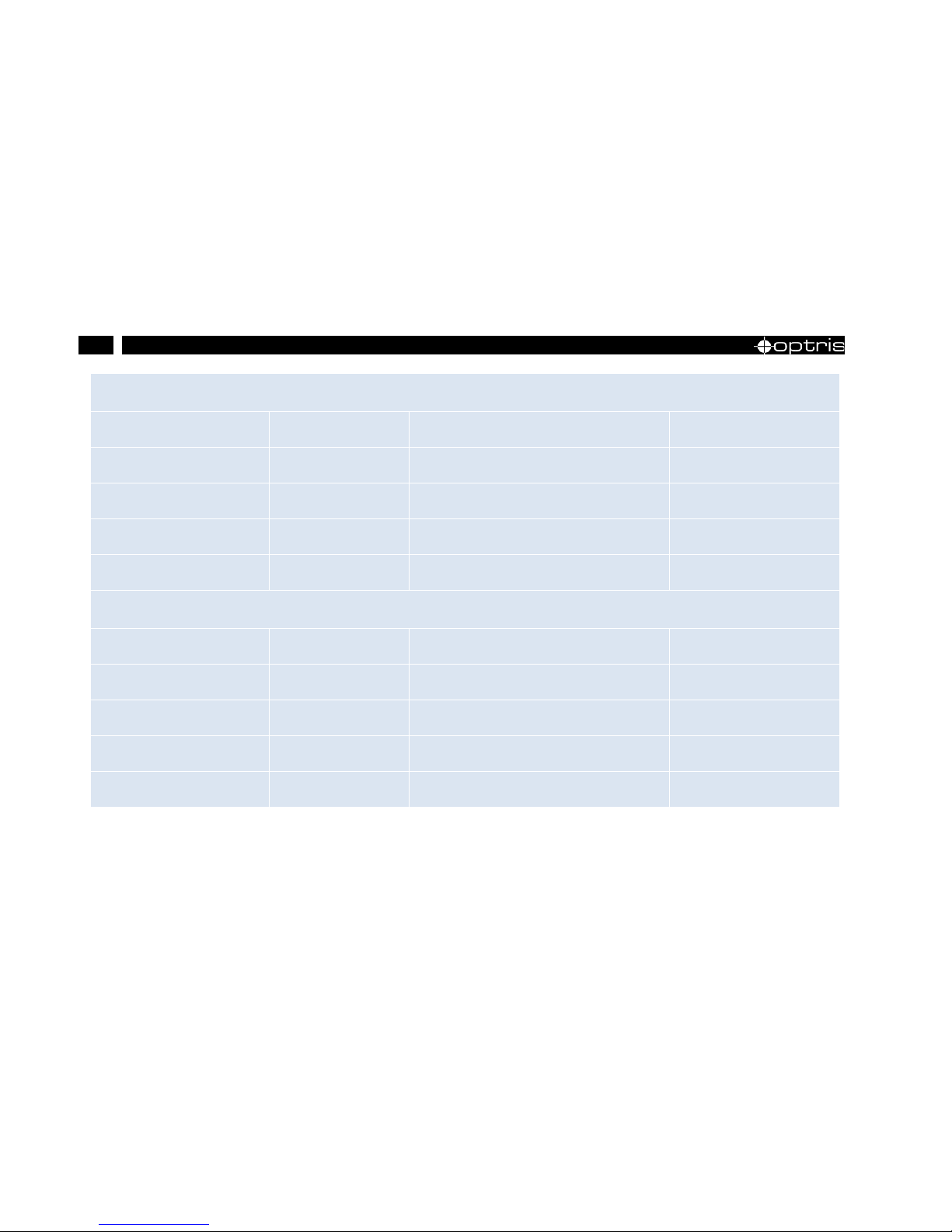

19

Technical Data

500-2000 Hz

-6 dB/ Octave

2000 Hz

0,1245 (m/s2)2/Hz

(0,00126 g2/Hz)

Number of axes

3

Duration

3 h

(3 x 1 h)

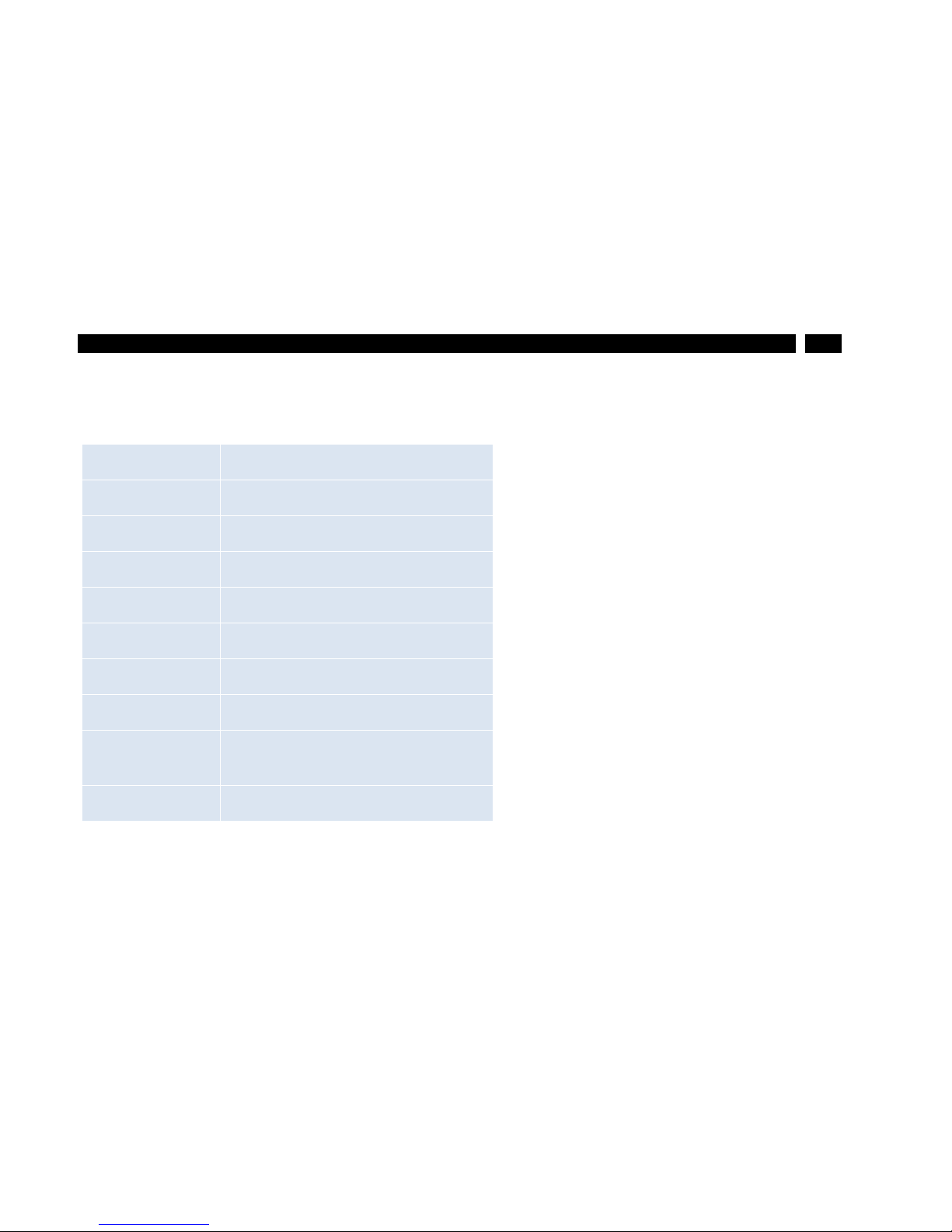

2.2.2 Electrical specifications

Power Supply:

5 VDC (powered via USB 2.0 interface)

Current draw:

Max 500 mA

Digital interface:

USB 2.0

Page 20

20

2.2.3 Measurement specifications

Temperature ranges:

-20...100 °C; 0...250 °C; 150...900 °C

Detector:

UFPA, 382 x 288 pixel

Spectral range:

7.5...13 µm

Lenses (FOV):

38° x 29°; 62° x 49°

System accuracy 1):

±2°C or ±2 %

Temperature resolution (NETD):

PI 400 LW 2): 0.08 K with 38° and 62°

P I450 LW 2): 0.04 K with 38° and 62°

Frame rate:

80 Hz

Emissivity:

0.100...1.000

Software:

PI Connect

1)

At ambient temperature 23±5 °C; whichever is greater;

2)

Value is vali d at 40 Hz and 25°C room temperature

Page 21

21

Technical Data

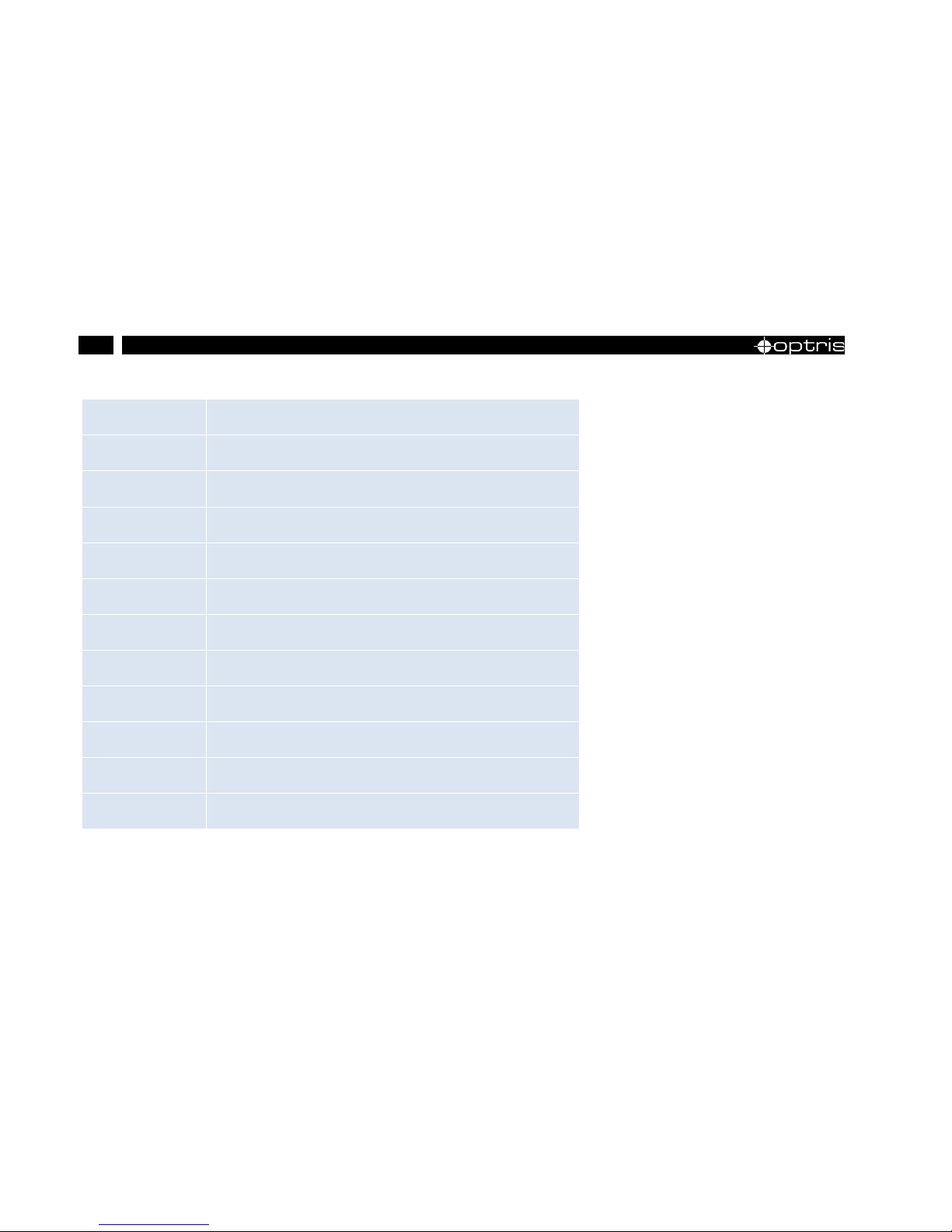

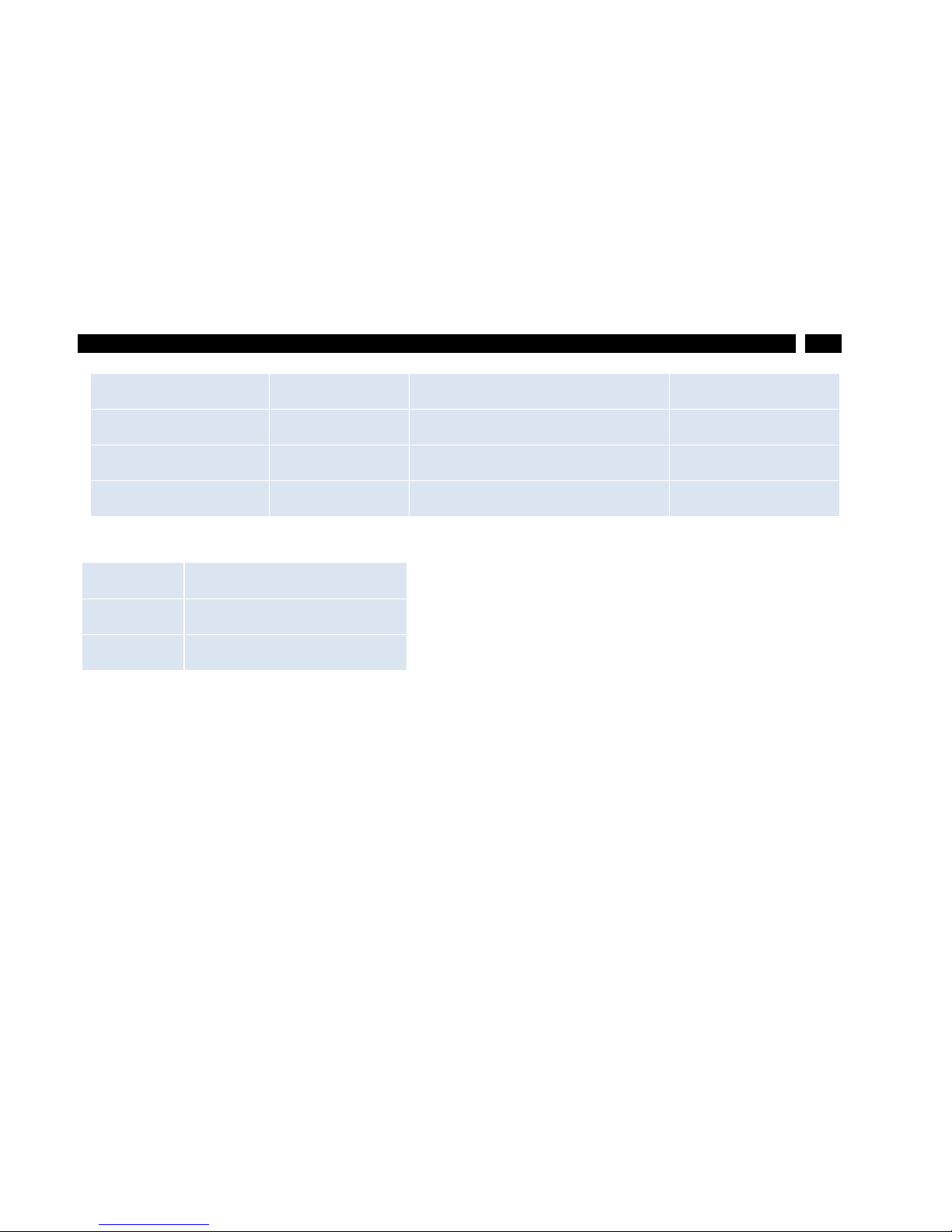

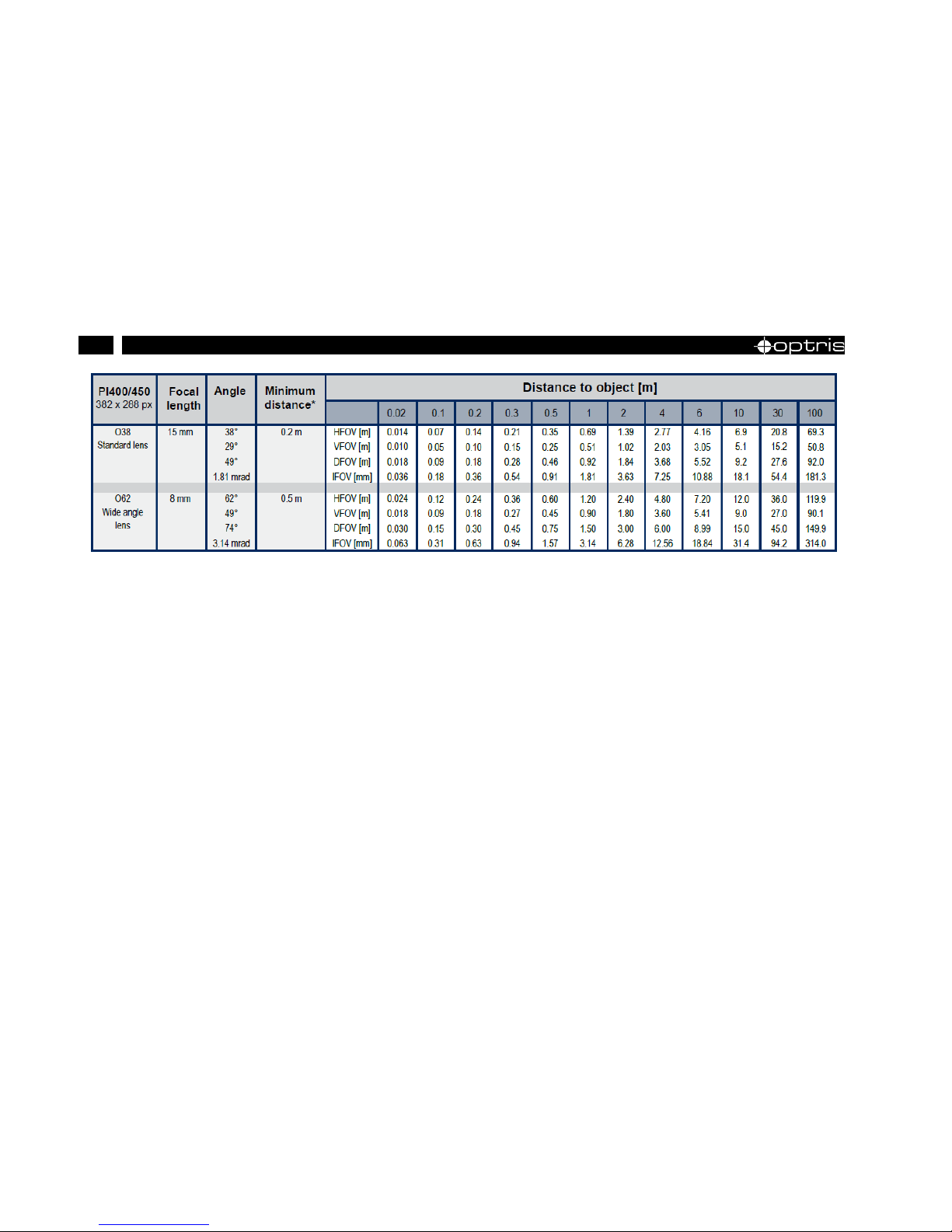

2.2.4 Optical specifications

Figure 3: Focusing of the lens

1

Lens

Different parameters are important if using infrared cameras. They display the connection between the

distance of the measured object and the size of the pixel (see

Table 1).

• Make sure that the focus of the infrared camera is adjusted correctly. For focusing

turn the lens (Figure 3).

• For the PI 400 LW and PI 450 LW two different lenses are available: 38° x 29° and

62° x 49° FOV.

Page 22

22

Table 1: Table with examples showing what spot sizes and pixel sizes will be reached in which distance. For

individual configuration there are different lenses available. Wide angle lenses have a radial distortion due to their

large opening angle; the software PIConnect an algorithm which corrects this distortion.

* Note: The accuracy of measurement can be outside of the specifications for distances below the defined minimum distance.

Page 23

23

Technical Data

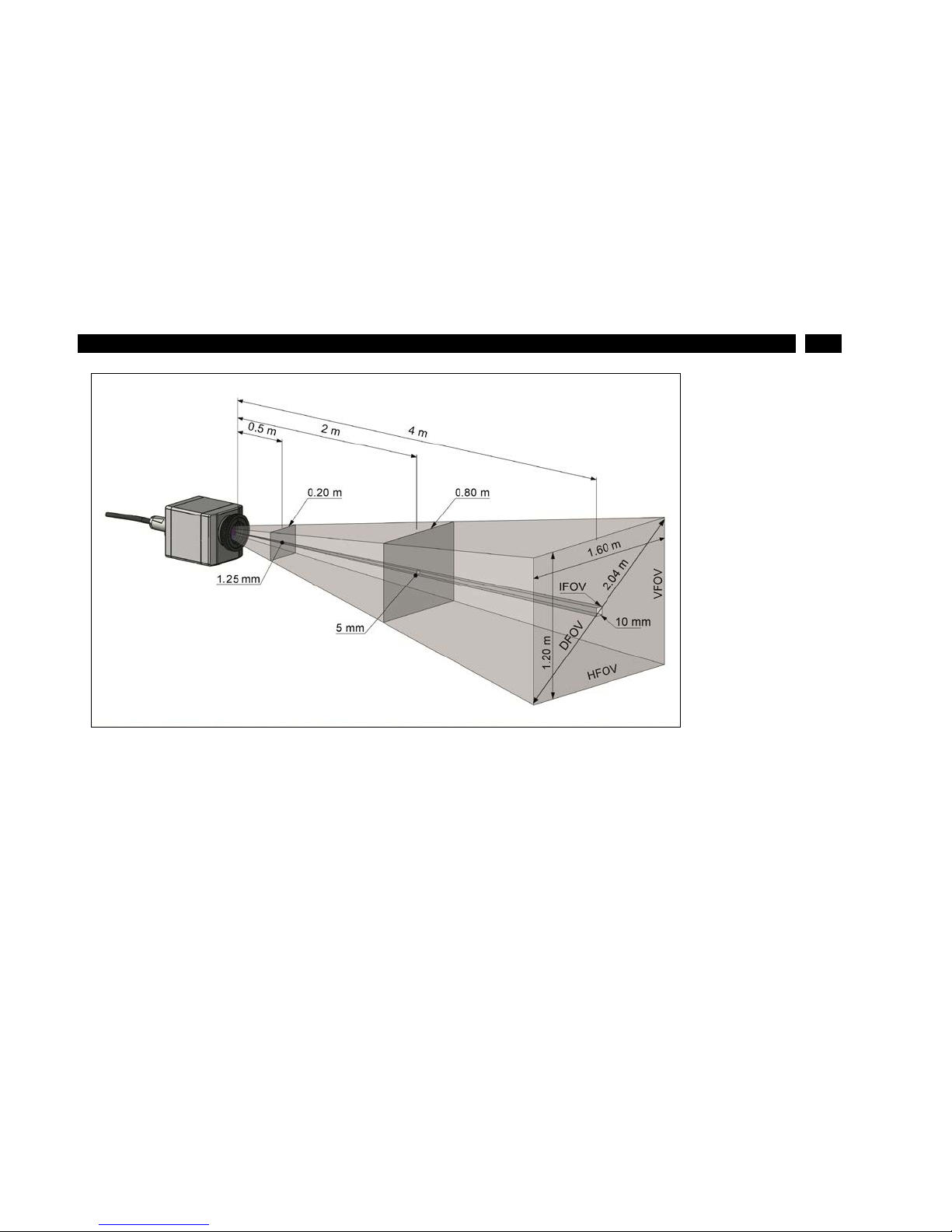

Figure 4: Measurement field of the infrared camera optris PI representing the 23° x 17° lens

Page 24

24

■

HFOV: Horizontal enlargement of the total measuring at object level

■

VFOV: Vertical enlargement of the total measuring at object level

■

IFOV: Size at the single pixel at object level

■

DFOV: Diagonal dimension of the total measuring field at object level

■

MFOV: Recommended, smallest measured object size of 3 x 3 pixel

Page 25

25

Installation

3 Installation

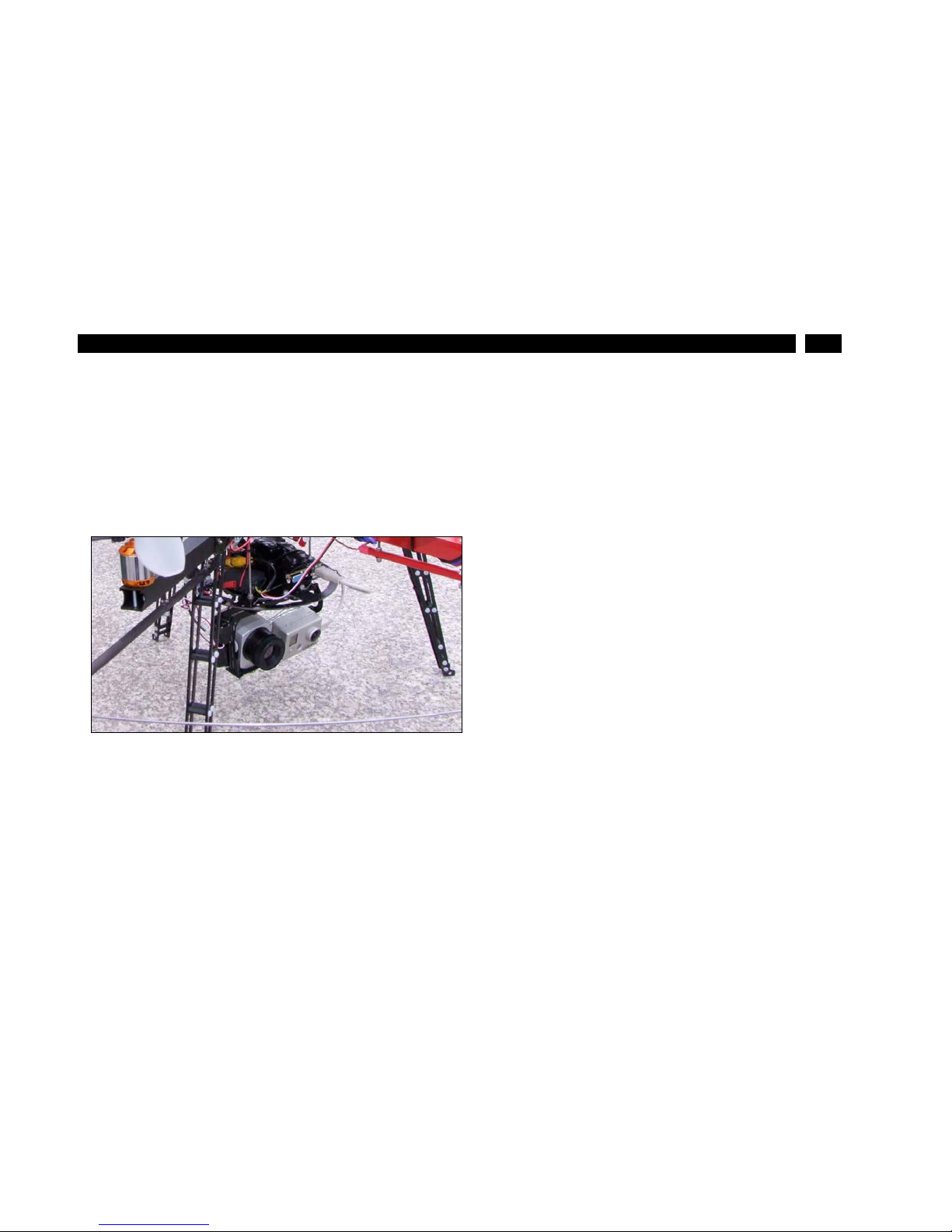

The PI 400 LW/ 450 LW are equipped with two metric M4 thread holes on the bottom side (6 mm depth)

and can be installed either directly via these threads or with help of the tripod mount (also on bottom

side). The separate PI camera sensing head can be mounted on the stabilization platform of a drone

together with a visual camera (in the picture: GoPro camera). The NetBox PC can be mounted

separately.

Figure 5: PI LightWeight on a drone together with GoPro HD camera

Page 26

26

3.1 Mechanical Data PI 400/ PI 450 LW

Figure 6: Dimensions PI 400/ PI 450 LW

Page 27

27

Installation

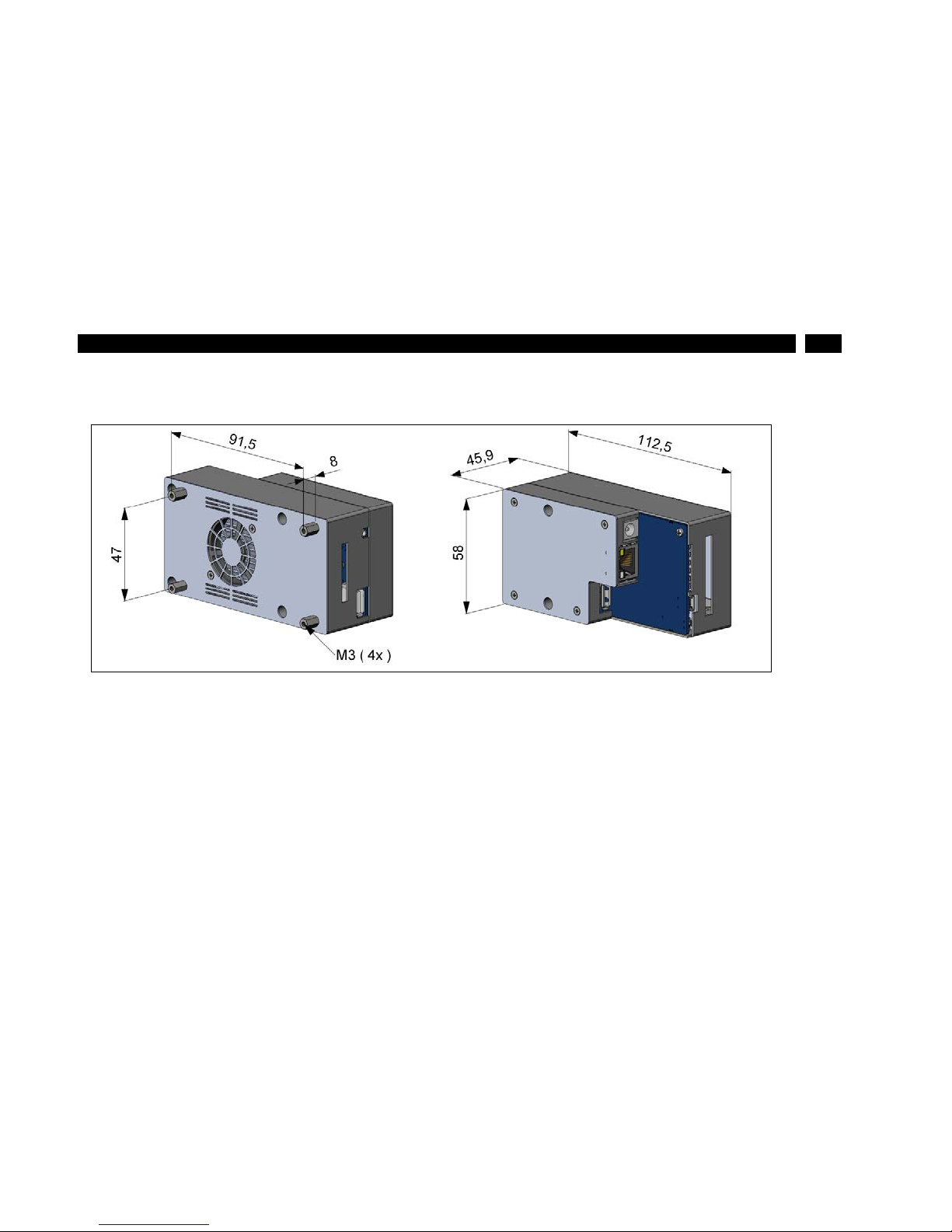

3.2 Mechanical Data PI NetBox LW

Figure 7: Dimensions PI NetBox LW

Page 28

28

Figure 8: Controls and connections PI NetBox LW

Page 29

29

Installation

1

Cooling fan

6

USB 2.0 socket

2

Video

out

socket

7

Ethernet socket

3

USB 2.0 socket

8

Mode switch (S1/ S2)

4

Power supply socket

9

Mini USB socket (slave mode)

5

Status-LEDs (L1-L6)

10

microSDHC card slot

Page 30

30

Page 31

31

Operation

4 Operation

4.1 Operation modes of the NetBox LW

The NetBox LW can be used in three different operation modes:

• Stand-alone operation w ith an IR camera (Standard mode)

• Ethernet direct connection to a PC (point-to-point connection)

• Ethernet communication via a network or via the internet

For powering the NetBox you can use instead of a lithium-polymer battery also the supplied power

adapter. Alternatively the NetBox can also be powered via the Ethernet cable (PoE – Power over

Ethernet). In this case a PoE injector is needed.

• Use the recommended PoE injector (O rder No .: ACP IPO E) only.

• Damages which are caused by usage of another PoE injector are excluded from

warranty

Page 32

32

4.2 Stand-Alone operation

As a stand-alone PC the NetBox LW expands the IR cameras PI400 LW and PI450 LW to a system for

radiometric infrared video recording.

• For a self-contained power supply we recommend a lithium-polymer battery with a

voltage between 8 and 14 VDC.

• To switch between the analog video output signal of the PI 400 LW / LW 450 and a

visual camera we recommend the use of an electronic universal switch from Co.

Conrad

(Order No.: 227389-62).

• To start an IR video recording during the flight we recommend the SMD power

switch from Conrad (Order No.: 191779-62). Triggering via the GPIO of the Netbox

LW.

Page 33

33

Operation

Figure 9: Recommended video system integration of the PI LightWeight

Page 34

34

After powering the NetBox LW the system will boot and is ready after 2-3 minutes. A video monitor which

is connected to the system via the video adapter cable will show then the IR live picture of the camera in

full screen mode.

Figure 10: Video

out

socket of the NetBox LW

• Before switching on the NetBox LW and monitor must be connected via cable to

ensure a correct initialization of the video output.

• A change of the preset PAL mode to NTSC e.g. can be done in the BIOS.

[Keyboard and monitor necessary]

Page 35

35

Operation

4.3 Start a recording

1. To start the recording remotely use t he supp lie d video c able (Order No.: ACPILKVCB2), see

Figure 11 left:

bk (thick)

GND

bk (thin)

Recording trigger

rt

Video signal

The recording starts if the trigger is connected with GND and stops if you interrupt this connection.

Figure 11: Video cable (Order No.: ACPILKVCB2) left and video cable (Order No.: ACPILKVCB2C) right

The second video cable (Order No.: ACPILKVCB2C) can be used for a direct connection of the system

to a monitor – the recording can be started by the micro switch.

Page 36

36

Alternatively you can start the recording by using the red sliding switch at the backside of the IR camera.

1. To start a recording move the switch into the right position .

2. To stop a recording remove the switch back into the left position.

Figure 12: Start and stop a recording

Page 37

37

Operation

4.4 SD card

1. To remove the card take a ball pen or similar and push onto the card from outside carefully.

2. Take care when you insert a card. Place it correctly into the according guide slot.

Figure 13: Changing of the SDHC card

• The NetBox LW will be delivered with an 8 GB SDHC card which is already

installed on the unit. If required you can exchange this card. The NetBox is

supporting SD cards up to 32 GB capacity.

• After insertion of a SD card a NTFS formatting is needed.

Page 38

38

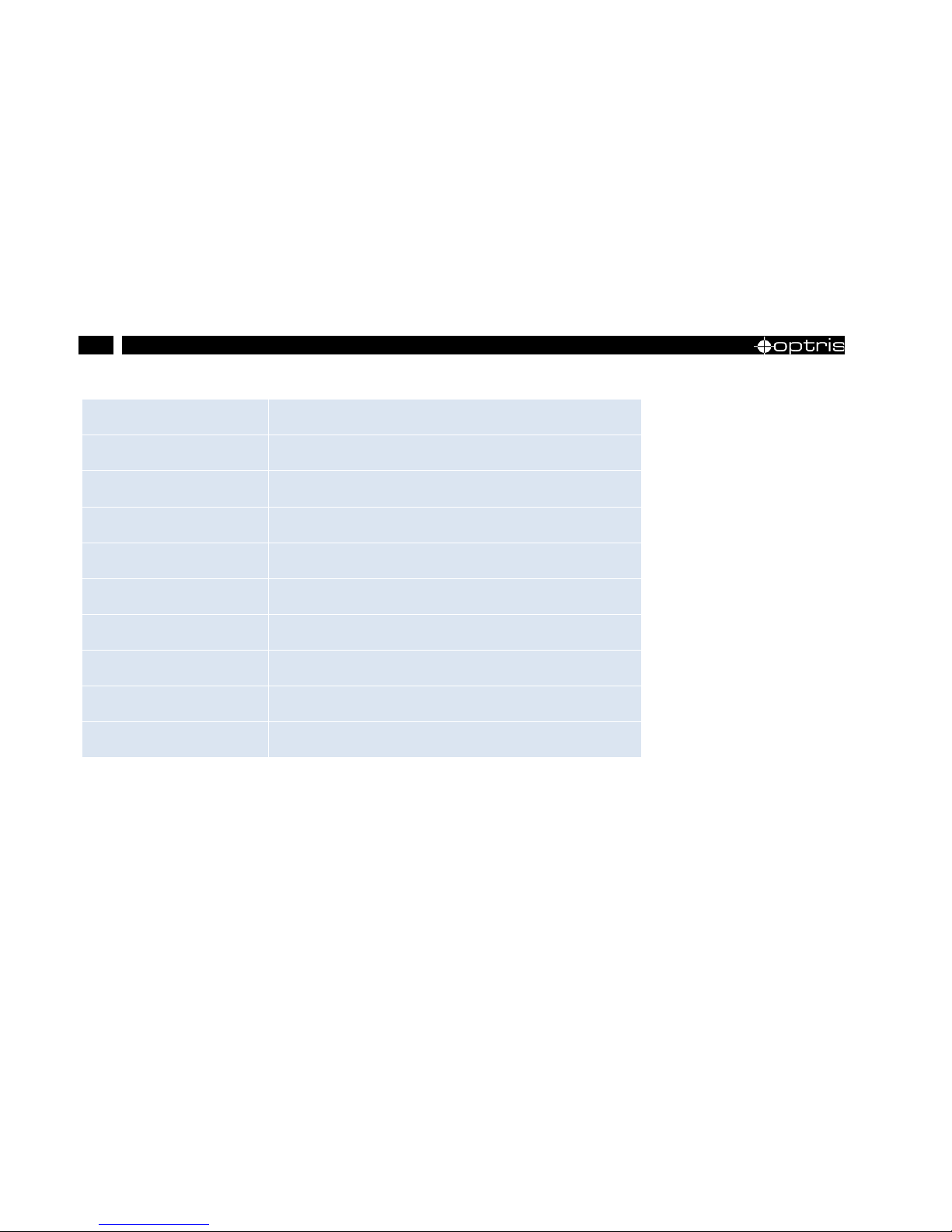

4.5 Status-LEDs

The NetBox LW is equipped with 6 status LEDs (L1-L6):

LED

Function

LED is lightning, if

L1

Power

NetBox is powered via PoE or a power supply (via power connector)

L2

Power out

NetBox is powered via PoE and (in this case) supplies 12 V at the power connector

L3

Net data

video frames are transmitted through the network connection continuously (flashing)

L4

USB Data

the imager is connected to an USB port, the calibration files are loaded and the raw data files are

delivered by the imager continuously (flashing)

L5

Application OK

the main application (Connect or Imager NNet Server) is running properly

L6

Mini USB-port

a PC is connected to a Mini USB port

Table 2: NetBox status information

Page 39

39

Operation

4.6 Switch positions

The mode switch is set default to S1. At position S2 the IR camera which is connected to the USB-A

socket will be linked directly with the Min i-USB socket. With this you get a direct access to the IR camera

from a PC which is connected to the Mini USB socket without changing cables on the NetBox LW.

Figure 14: Mode switch (S1/ S2)

Page 40

40

4.7 Remote Access to the NetBox LW

For settings on the NetBox LW you can connect a keyboard and a mouse to the available USB sockets

as well as a monitor to the VGA socket (or a TV monitor via the TV

out

adapter cable). ► 4.1 Stand-alone

Operation

Another very simple way is remote control software, for example remote desktop (RDP) which is available

on each Windows system or Ultra VNC which you will find on your software CD. After installation you can

have access to the NetBox either from a PC directly connected over an Ethernet cable or from a PC

which is located anywhere and connected to the same network. Also remote connection via the internet is

possible.

1)

1)

For remote access from outside to a NetBox LW connected to a company network ask your system administrat or for possi bl y

necessary settings.

4.7.1 Installation of Ultra VNC

1. Start install.bat which is located on your PIConnect-CD in the folder \PI NetBox.

2. After installation you will find the following short cuts on your desktop.

Page 41

41

Operation

Figure 15: Short cuts

3. Use the short cut SyncViewer for access to a NetBox which is directly connected to your PC over

an Ethernet cable. This short cut is synchronizing the time automatically on the NetBox and is

starting then the UltraVNC viewer which is showing the screen of the NetBox.

The IP Address Finder starts a tool which will list all NetBoxes located in your network or directly

connected to your PC. Time synchronization is operable as well. At the same time scanning of the whole

network or a certain IP address range is provided. With the filter function a selective search for NetBoxes

is possible.

By pressing one of the sync buttons you can synchronize a previously selected NetBox or all listed ones

simultaneously with the system time of your local PC while IP Address Finder is running.

The NetBox is set to Central European Time (CET or CEST) by factory default. Depending on

the time zone setting of your local PC time differences during synchronization are possible. In

this case the time zone setting on the NetBox needs to be changed. ►

4.14 System time

Page 42

42

Figure 16: NetBox lister

With the UltraVNC Viewer a simultaneous access to one NetBox from different PCs inside a

network is possible.

Page 43

43

Operation

For access to a NetBox inside your network start the program UltraVNC View er which is located in the

program folder NetBox – UltraVNC. After starting the viewer the following screen appears:

Figure 17: UltraVNC Viewer setup

4.7.2 Display the NetBox

1. Enter the IP-address of the NetBox and press Connect. The information is provided by the

IP Address Finder.

2. Enter the password Remote and confirm with Log On.

Page 44

44

Figure 18: VNC Identification

4.8 Applications and start options

On the desktop of the NetBox LW the following short cuts are available:

Figure 19: Application Start Config short cut and Application Start Manager short cut

Application Start Config:

Starts the configuration dialog (Config Server)

Application Start Manager:

Starts the program selected in the configuration dialog

Page 45

45

Operation

In the configuration dialog you can select programs which start automatically after booting the NetBox:

Figure 20: Config Server window

After booting the system the PIConnect software starts in full screen mode with a

special flight layout (factory-provided).

• Option: User defined in Application Start Config

Page 46

46

The Imager Net Server application is needed for the operation modes:

• Ethernet direct connection to a PC (point-to-point connection)

• Ethernet communication via a network or internet

1. Apply User defined to start PI Connect or Imager Net Server with modified command line

parameters [Args].

Example:

No

No automatic start of the program

Imager Net Server

Automatic start of the server application

PI Connect

Automatic start of the PI Connect software

User defined

User defined start of one of the upper two programs

The start options selected in the configuration dialog are saved automatically in the

NetBox and are available after a restart.

Page 47

47

Operation

Figure 21: Configuration to start PIConnect in full screen mode

Figure 22: Screen of the NetBox LW – Imager Net Server left and of the NetBox – PI Connect right

Page 48

48

If the IR camera is connected to the NetBox two applications are shown:

Monitor Imager Net Server and Imager Net Server or PI Connect.

Appl. Watchdog:

Counter for the application monitoring function

Device:

Frequency of the device

Processing:

Frequency of the processing

Net connection:

Frequency of the network

Monitor:

Display mode (VGA or TV-Out)

Application:

Monitored software application

Table 3: Monitor Imager Net Server application window

Figure 23: Menu selection

Page 49

49

Operation

Menu

File

Exit of the program

Devices

Shows the connected imager

Flag

Manual operation of the camera flag

USB video device

Serial number of the connected imager device

T (C, F, B):

Device temperatures (°C):

C: FPA-Chip

F: Flag temperature

B: Housing temperature

PIFin (A, D):

Status of the PIF input:

A: Analog IN (AI)

D: Digital IN (DI)

HW Cnt.:

Hardware-Counter (frame counter)

ADU (192, 144):

ADU value of the center pixel (e.g.192, 144 at PI4xx)

Freq (D, P, N):

Frequency (Hz):

D: Device

P: Processing

Page 50

50

N: Network

Time:

Time per single frame

Queue:

Number of frames in network queue

FOV, TR:

Field of view (horizontal) of the imager lens, Temperature range

Table 4: Imager Net Server – Application window

4.9 Watchdog

If the main application (Imager Net Server respectively PIConnect) for any reason does not work

properly (in case of a software crash) or is closed, the monitor application restarts the program

automatically.

In addition the Watchdog application observes the Windows operating system continuously – find the

symbol [WD] in the right part of the task bar:

Figure 24: Watchdog symbol in the task bar

Page 51

51

Operation

If the Watchdog application identifies a system error the NetBox restarts automatically. The Watchdog

window opens by clicking the right mouse button on the symbol in the task bar. It shows the following

information.

Figure 25: Window Watchdog

• Status information

• Internal set parameters

• Elapsed time since start

Consider that all restarts will be counted even those which were not initialized by the

Watchdog application.

Page 52

52

• Last elapsed time

• Number of restarts (can be reset with the right mouse button on WD symbol – Reset counter)

4.10 Autostart

In the Windows Autostart folder of the NetBox LW the following short cuts are set by factory default:

Figure 26: Startup window

Page 53

53

Operation

ewfMonitor

Write protection filter

MouseHider

Hides the mouse pointer after 10 s of inactivity

Watchdog

Starts the Watchdog application

Application Start Manager

Starts the program selected in the Application

Start Config

4.11 File transfer between NetBox LW and PC

1. To exchange files between the NetBox and a PC which is connected directly or located in the

network move the cursor to the title bar of the UltraVNC Viewer window and press the right

button of the mouse. Start File Transfer.

2. Alternatively use the following short cut in the task bar of the viewer:

Figure 27: File Transfer short cut

Page 54

54

The window shows the local PC (LOCAL MACHINE) on the left side and the NetBox (REMOTE

MACHINE) on the right side. Files can be copied between both computers via the network link by

selecting them and by confirming with the Send button respectively Receive button.

Figure 28: File transfer window

Page 55

55

Operation

4.12 Communication

4.12.1 Ethernet direct communication

1. Connect the IR camera and the NetBox with the supplied USB connection cable.

2. Connect the PC and the NetBox with an Ethernet cable.

3. Add the power supply to the NetBox and connect it to the electric circuit. The NetBox boots up the

system and is ready to use after approx. 2-3 minutes. With orderly function LED 1 (L1) and LED 5

(L5) are illuminating.

The applied Ethernet cable must be complied at least with category 5 (Cat-5 according

ISO/IEC 11801).

Page 56

56

Figure 29: Ethernet direct connection (point-to-point connection)/ NetBox LW p owered via power supply

4. Using a PoE injector the power supply for the NetBox is not needed. In this case the PoE injector

must be connected as shown in

Figure 30. With orderly function L1, L2 and L5 are illuminating.

Page 57

57

Operation

Figure 30: Ethernet direct connection (point-to-point connection)/ NetBox LW via PoE injector

Connection to the NetBox LW

The communication with the NetBox is occ urr ing via the TCP/ IP protocol (Transmission Control Protocol/

Internet Protocol). The NetBox gets its IP address (Internet protocol address) either from a DHCP server

or operates with a fixed IP address.

The NetBox is already set to a fixed IP address (192.168.0.100) by factory default.

Page 58

58

With a direct connection to a PC both the NetBox as well as the PC must use a fixed IP address. A DHCP

server is not available.

Once the following settings must be done on your PC (the procedure is depending on the operating

system and can differ from the following description – Windows 7 is specified here).

1. Go to System controls and open Network- and Sharing Center. If there is a

connection to the network (e.g. com pan y network) the following information appears:

Figure 31: Basic network information

Page 59

59

Operation

2. Enter Local Area Connection – status screen (Figure 32 [1]) is shown and subsequently

Properties.

3. Mark Internet protocol Version 4 (TCP/IPv4) in the Properties window (

Figure 32

[2]) and go to Properties again.

4. Open register Alternate Configuration in window (

Figure 32 [3]) and enable the checkbox

User configured.

5. Enter a user defined IP address for your PC. Consider that the network part of the address is

identic to the network part of the IP address of the NetBox, thus 192.168.0. For the host part

use an address which is different from the one of the NetBox (100); e.g. 1.

If there is no network connection click Network- and Sharing Center,

then Change Adapter Settings. After it Local Area Connection, right

mouse button: Properties [-> cont in ue with it em 3].

Page 60

60

Figure 32: Windows – Local Area Connection Status [1], Local Area Connection Properties [2] und Internet protocol

version 4 (TCP/IPv4) properties [3]

Page 61

61

Operation

Figure 33: Alternate Configuration

After connecting your PC with the NetBox via an Ethernet cable a point-to-point connection is established.

This may take several minutes. Your network is shown as non-identified network in the Network and

Sharing Center.

1. Start the PIConnect software on your local PC and open with the menu Tools/ Extended/

remote devices...

Page 62

62

2. Set the Enable checkbox and enter the address range of your local network in Detect

devices (range 0 to 255).

3. Enable the Filter checkbox and enter NetBox. Press the Ping button to detect devices within

the range and with NetBox in their name.

4. Select the desired frame rate in Remote framerate which should be transmitted via network.

5. In the Hosts area your NetBox is listed. Assign it and confirm with OK.

Figure 34: Remote device window

Page 63

63

Operation

In the menu Devices the imager which is connected to the NetBox is shown as remote device. Select

the following functions:

Figure 35: Remote device

Connect

Connect with the remote device manually

Restart

Restart of the Imager Net Server Application on the NetBox

Reboot

Reboot of the NetBox

Remove

Remove of the device entry in this menu

Page 64

64

6. If the applied imager is connected to the NetBox for the first time a warning message appears.

Confirm with Yes.

Figure 36: Warning

Figure 37: Sending calibration data files

Page 65

65

Operation

The calibration files are transferred from your PC to the NetBox automatically and stored there.

Alternatively a manual copy of the calibration files is possible via USB stick to the NetBox folder

D:\Imager\Cali.

The live image of the IR camera is displayed on your PC.

4.12.2 Ethernet network communication

1. Connect the IR camera and the NetBox with the supplied USB connection cable.

2. Connect the Ethernet connection of the NetBox with a network or internet (via a router e.g.).

3. Add the power supply to the NetBox and connect it to the electric circuit. The NetBox boots up the

system and is ready to use after approx. 2-3 minutes. With orderly function LED 1 (L1) and LED 5

(L5) are illuminating.

Consider that the NetBox must be converted to DHCP using a network connection.

Page 66

66

Figure 38: Ethernet network connection/ NetBox LW powered via power supply

4.

Using a PoE injector the power supply for the NetBox is not needed. In this case the PoE injector

must be connected as shown in

Figure 39. With orderly function L1, L2 and L5 are illuminating.

Page 67

67

Operation

Figure 39: Ethernet network connection/ NetBox LW powered via PoE injector

If the NetBox is used in a network it gets its IP address from a DHCP server. In order to find the

PIConnect on your local PC the address range of the local network must be known. For this start the

program IP Address Finder (► 4.7 Remote access to the NetBox).

1. Start the PIConnect software on your local PC and open with the menu Tools/ Extended/

remote devices...

2. Set the Enable checkbox and enter the address range of your local network in Detect

devices (range 0 to 255).

Page 68

68

3. Enable the Filter checkbox and enter NetBox. Press the Ping button to detect devices within

the range and with NetBox in their name.

4. Select the desired frame rate in Remote framerate which should be transmitted via network.

5. In the Hosts area your NetBox is listed. Assign it and confirm with OK.

Figure 40: Remote device window

In the menu Devices the imager which is connected to the NetBox is shown as remote device. Select

the following functions:

Page 69

69

Operation

Figure 41: Remote device

Connect

Connect with the remote device manually

Restart

Restart of the Imager Net Server Application on the NetBox

Reboot

Reboot of the NetBox

Remove

Remove of the device entry in this menu

6. If the applied imager is connected to the NetBox for the first time a warning message appears.

Confirm with Yes.

Page 70

70

Figure 42: Warning

Figure 43: Sending calibration data files

The calibration files are transferred from your PC to the NetBox automatically and stored there.

Alternatively a manual copy of the calibration files is possible via USB stick to the NetBox folder

D:\Imager\Cali. The live image of the IR camera is displayed on your PC.

Page 71

71

Operation

4.13 USB Driver

The USB-IR camera as well as the USB sticks, the USB keyboards or the USB mouses do not need a

special device driver. To ensure a convenient use of the NetBox LW and its recommended standard

components, system messages to new installed USB devices are suppressed therefore.

If other USB devices are connected, which require a specific driver installation it might be necessary to

start the installation in the device manager manually.

4.14 System time

• The set time zone can be changed in the tab Time Zone. To save the new setting

permanently the ► 4.15 Write Protection Filter must be deactivated temporarily.

• The SyncViewer and the IP Address Finder tool enable manual time

synchronization with a PC which is conn ec ted direc t l y or via network .

► 4.7 Remote access to the NetBox

Page 72

72

Figure 44: Date and time properties

The NetBox LW does not contain a CMOS battery which is typically used to keep the system time if the

computer is switched off. That is why during operation the time is saved continuously. In case of a restart

the system time is proceeding automatically beginning at the last saved value. With it achieving a

chronology of imager recordings which create an automatic file name generation. If the NetBox is

connected with the internet the current time is synchronized after a certain period automaticall y via

internet time server.

Page 73

73

Operation

4.15 Write protection filter

The NetBox LW is equipped with a write protection filter (factory-provided). It reliably protects the

operation system and the complete C drive. Furthermore the write protection filter switches off the device

without a shutdown of the operating system.

The write protection filter (ewfMonitor) is illustrated as a red or green dot in the task bar or as a short cut.

The colors have the following meaning:

Red dot: saved mode

Green dot: writing mode

Use the NetBox with an enabled write protection filter only! [Red dot: Saved mode

enabled; green dot: writing mode enabled].

Page 74

74

Figure 45: Short cut - Write protection filter (ewfMonitor) in Autostart folder

To save changed settings or to install additional software the write protection must be deactivated

temporarily.

1. Move the cursor to the red dot in the task bar and click the right mouse button.

Select between four different actions:

Save and reboot

Changes will be saved + restart

Save and

shutdown

Changes will be saved + shutdown

Page 75

75

Operation

Standard write

mode

Switch to writing mode (green dot)

Reboot

Restart without saving changes

The SSD drive of the NetBox LW has two partitions by factory default. The write protection refers to

partition C only. In partition D application data can be saved. The calibration data of the imager is stored

there too.

Page 76

76

Page 77

77

System recovery

5 System Recovery

1. Connect the NetBox WL with a VGA monitor and an USB keyboard, put in the USB recovery stick

to a free port and switch on the NetBox. If the start display (Fig. 41) is indicated confirm with the

ESC button for at least 2 seconds.

Figure 46: Start display of the NetBox LW

• In case a recovery of the Windows operating system of the NetBox LW is

necessary you should use the supplied USB recovery stick. Follow the steps

described hereafter. Do not disconnect power from the NetBox during the

recovery procedure.

• After the system recovery the NetBox is in the delivery status. All data stored before

on the SSD will get lost.

• The write protection filter must be enabled (red dot is displayed) after recovery.

Page 78

78

2. Select USB Device and press Enter. Then the connected USB stick is shown. Confirm with Enter

as well.

Figure 47: Selecting the USB-Stick

Page 79

79

System recovery

Figure 48: Several displays during recovery

After complete system recovery the NetBox shuts down automatically and switches off (all LEDs are off ) .

3. Disconnect the power supply shortly (pulling off the power supply unit). Afterwards reconnect the

power and boot the system up.

Page 80

80

4. Click the Next button and select Random SID. Confirm with Next.

Figure 49: SID selection

With the rename option you can give the NetBox a different name.

5. Rename the NetBox (optional). It must not be more than 15 characters. Then confirm with Next

for two times.

Page 81

81

System recovery

Figure 50: Rename option

Page 82

82

After this the system shuts down. The NetBox is ready for use again.

Figure 51: System update

Page 83

83

Basics of Infrared Thermometry

6 Basics of Infrared Thermometry

Depending on the temperature each object emits a certain amount of infrared radiation. A change in the

temperature of the object is accompanied by a change in the intensity of the radiation.

Searching for new optical material William Herschel by chance found the infrared radiation in 1800.

Figure 52: William Herschel (1738-1822)

Page 84

84

He blackened the peak of a sensitive mercury thermometer. This thermometer, a glass prism that led sun

rays onto a table made his measuring arrangement. With this, he tested the heating of different colors of

the spectrum. Slowly moving the peak of the blackened thermometer through the colors of the spectrum,

he noticed the increasing temperature from violet to red. The temperature rose even more in the area

behind the red end of the spectrum. Finally he found the maximum temperature far behind the red area.

Nowadays this area is called “infrared wavelength area”.

Figure 53: The electromagnetic spectrum and the area used f or tempera t ure mea sur eme nt

For the measurement of “thermal radiation” infrared thermometry uses a wave-length ranging between

1 µ and 20 µm. The intensity of the emitted radiation depends on the material. This material contingent

constant is described with the help of the emissivity which is a known value for most materials

(see enclosed table emissivity).

Page 85

85

Basics of Infrared Thermometry

Infrared thermometers are optoelectronic sensors. They calculate the surface temperature on the basis of

the emitted infrared radiation from an object. The most important feature of infrared thermometers is that

they enable the user to measure objects contactless. Consequently, these products help to measure the

temperature of inaccessible or moving objects without dif f ic ulties.

Figure 54: Main principle of noncontact thermometry

Infrared thermometers basically consist of the following components:

• Lens

• Spectral filter

• Detector

• Electronics(amplifier/ linearization/ signal processing)

Page 86

86

The specifications of the lens decisively determine the optical path of the infrared thermometer, which is

characterized by the ratio Distance to Spot size. The spectral filter selects the wavelength range, which is

relevant for the temperature measurement. The detector in cooperation with the processing electronics

transforms the emitted infrared radiation into electrical signals.

The advantages of noncontact thermometry are clear - it supports:

• temperature measurements of moving or overheated

objects and of objects in hazardous surroundings

• very fast response and exposure times

• measurement without inter-reaction, no influence on the

• measuring object

• non-destructive measurement

• long lasting measurement, no mechanical wear

Page 87

87

Basics of Infrared Thermometry

Figure 55: Noncontact thermometry

Page 88

88

Application field:

Monitoring of electronic

cabinets

R&D of electroni cs

R&D of electroni c parts

Process control extruding

plastic parts

Process control

manufacturing s olar

modules

Process control at

calendering

R&D of mechanical parts

Monitoring of cables

Page 89

89

Basics of Infrared Thermometry

6.1 Emissivity

Definition: The intensity of infrared radiation, which is emitted by each body, depends on the temperature

as well as on the radiation features of the surface material of the measuring object. The emissivity (ε –

Epsilon) is used as a material constant factor to describe the ability of the body to emit infrared energy. It

can range between 0 and 100 %. A “blackbody” is the ideal radiation source with an emissivity of 1.0

whereas a mirror shows an emissivity of 0.1. If the emissivity chosen is too high, the infrared thermometer

may display a temperature value which is much lower than the real temperature – assuming the

measuring object is warmer than its surroundings. A low emissivity (reflective surfaces) carries the risk of

inaccurate measuring results by interfering infrared radiation emitted by background objects (flames,

heating systems, chamottes). To minimize measuring errors in such cases, the handling should be

performed very carefully and the unit should be protected against reflecting radiation sources.

Figure 56: Capability of an object to emit radiation

I

Passed radiation

ε

Reflection

ρ

Transmission

τ

Emissivity=Absorption

ε + ρ+ τ = 1

Page 90

90

Figure 57: Spectral emissivity of several materials: 1 Enamel, 2 Plaster, 3 Concrete, 4 Chamotte

Page 91

91

CE Conformity

7 CE Conformity

Page 92

optris PI LightWeight kit-MA-E2014-11-B

Loading...

Loading...