Page 1

innovative infrared technology

Production

Quality Assurance

Research & Development

Test & Measurement

NON-CONTACT

TEMPERATURE MEASUREMENT

GLASS INDUSTRY

Page 2

Glass industry

2 4 6 8 10 12 14 16

Wavelength in µm

Wavelengh [µm]

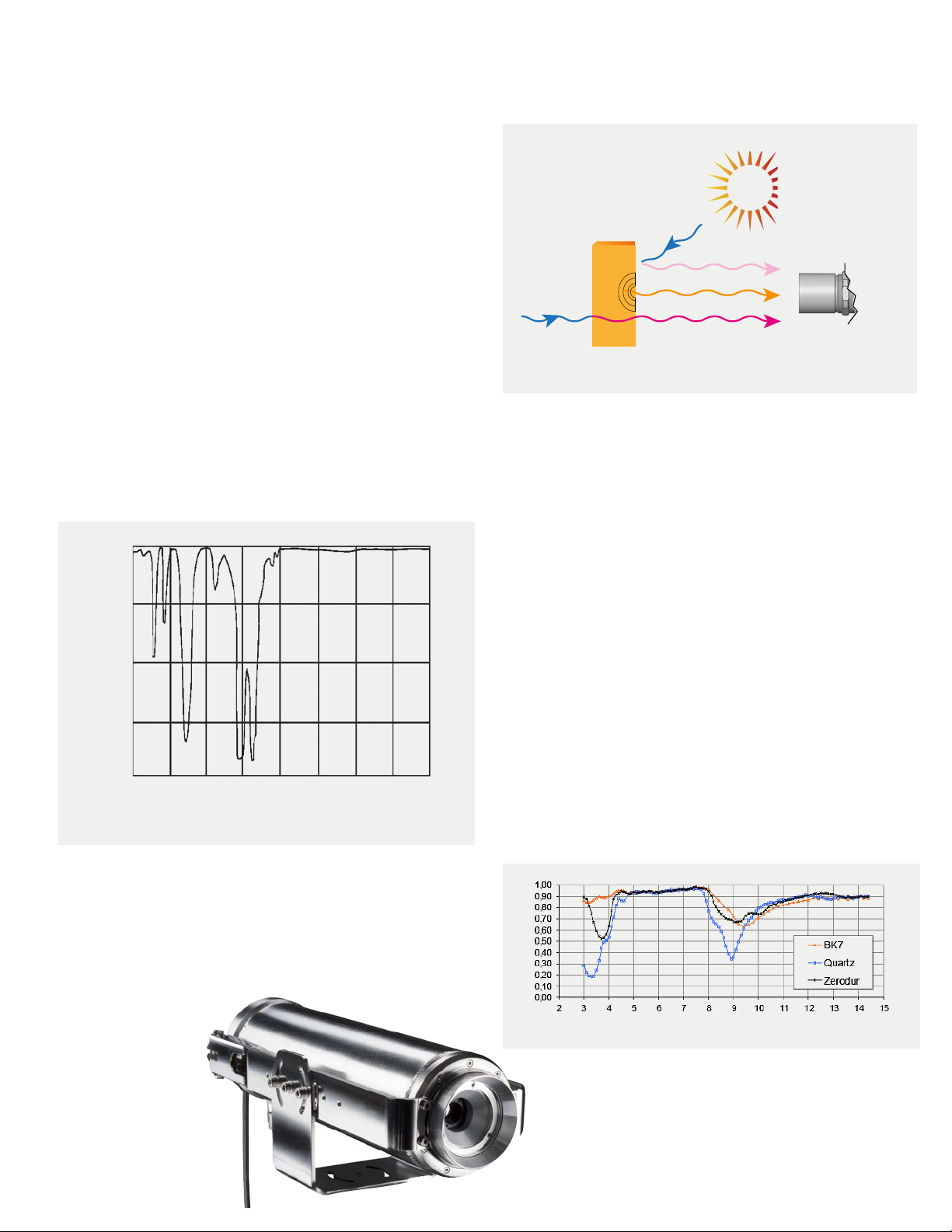

TECHNOLOGY AND PHYSICS

Inuence from the surroundings

The illustration shows that the transmissivity of air strongly

depends on the wavelength. Strong attening alternates with

areas of high transmissivity – the so-called atmospheric windows.

The transmissivity in the longwave atmospheric window (8 – 14

µm) is constantly high whereas there are measurable alleviations

by the atmosphere in the shortwave area, which may lead to false

results. Typical measuring windows are 1.1 – 1.7 µm,

2 – 2.5 µm and 3 – 5 µm.

Additional inuences can arise from heat sources in the

environment of the measuring object. To prevent wrong measuring results due to increased ambient temperatures, the infrared

thermometer compensates the inuence of ambient temperatures

beforehand (as e.g. when measuring temperatures of glass

surfaces in heating areas whereby the walls are hotter than the

glass surfaces). A second tem-perature sensing head helps to

generate accurate measuring results by automatically

compensating the ambient temperatures and a correctly adjusted

emissivity.

100

Radiation

from

ambient

n

T

Object

amb

ρ

n

T

n

T

amb

obj

= α

ε

τ

Sensor

α = Absorption ρ = Reflectance τ = Transmission ε = Emissivity

Compensating ambient influences

Emissivity and temperature measurement

For the accurate measurement of temperatures,

emissivity is a key factor. It is dependent on various

inuences and must be adjusted according to the

application.

75

Transmissivity in %

50

25

0

Spectral transmissivity of air (1 m, 32 °C (90 °F), 75 % r. F.)

Dust, smoke and suspended matter in the atmosphere can pollute

the optics and result in false measuring data. Here air purge

collars (which are installed in front of the optics with compressed

air) help to prevent deposition of suspended matter in front of the

optics. Accessories for air and water cooling support the use of

infrared thermometers even in hazardous surroundings.

Emissivity theoretically depends on the material, its surface quality, wavelength, the measuring angle and, in some cases, even

the applied measuring conguration.

Glass usually exhibits an emissivity of 0.85 in the longwave range

(8 – 14 μm). In processes with higher temperatures glass surfaces

are measured with 5.0 μm or 7.9 μm because in those spectral

ranges the emissivity is ≥0.95.

The main advantage of 7.9 µm is the lower angle dependency of

the glass surface reection in this wavelength range. This means

that the surface temperature can be measured independently of

the reection even at an inclined viewing angle.

Emissivity

2

Spectral emissivity of glass

The CoolingJacket Advanced enables an

operation within an ambient temperature

of up to 315 °C (599 °F)

Page 3

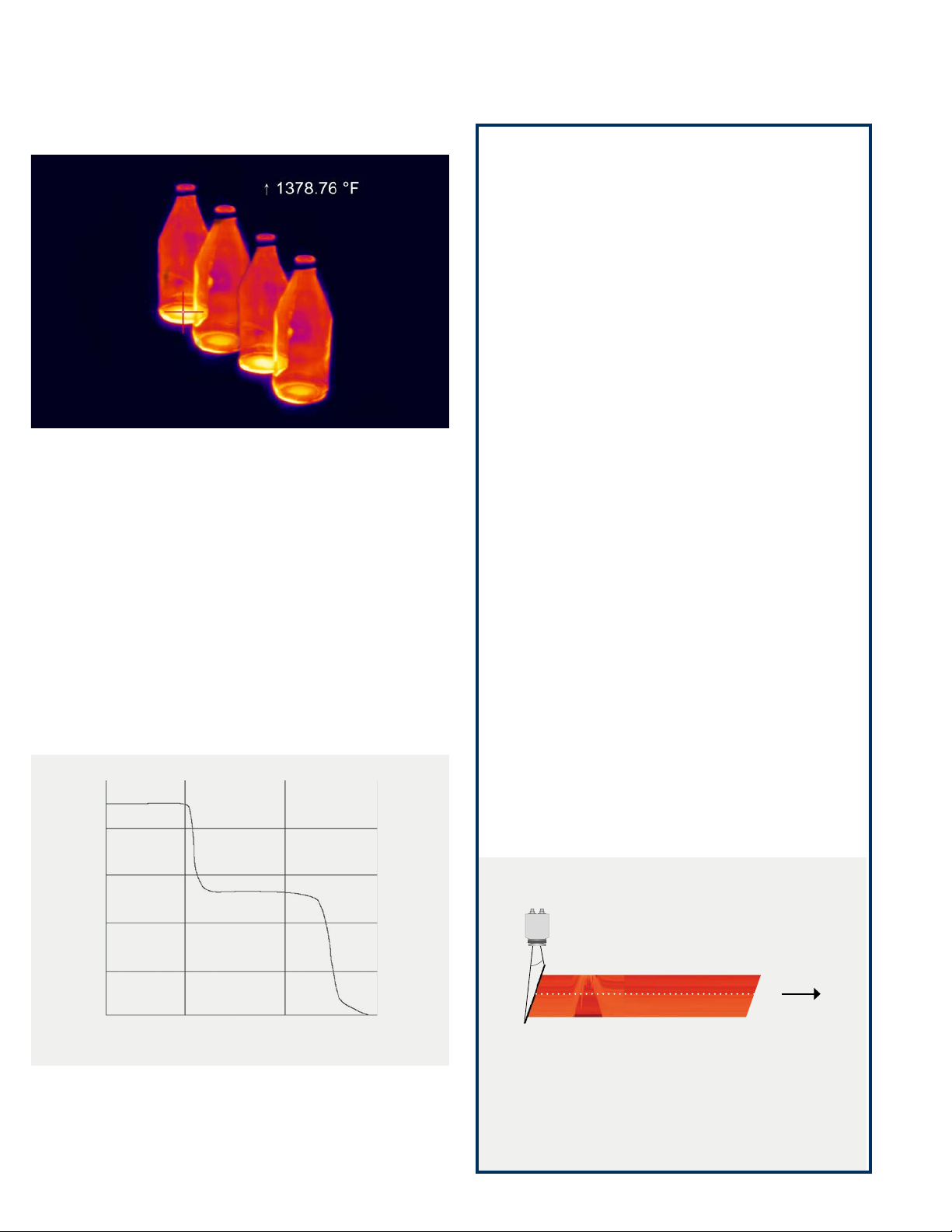

Temperature measurement of glass

Hot spot detection at glass bottle production

If you measure temperatures of glass with IR thermometers or

the special IR camera optris PI G7 it implies that you take care of

reection and transmissivity. A careful selection of the wavelength

facilitates measurements of the glass surface as well as of the

deeper layers of the glass. Wavelengths of 1.0 µm, 2.2 µm or

3.9 µm are appropriate for measuring deeper layers whereas

5 µm are recommended for surface measurements. If temperatures are low, you should use wavelengths between 8 and 14 µm in

combination with an emissivity of 0.85 in order to compensate

reection. For this purpose a thermometer with short response

time should be used as glass is a bad heat conductor and can

change its surface temperature quickly.

100

innovative infrared technology

Line scan with compact infrared camera

Optris infrared cameras are equipped with licensefree PI Connect software. The software enables the

cameras to operate as line scan cameras.

Line scanners are traditionally used in the glass

industry for various measurement procedures. In

these devices, a point detector is coupled with a

rotating mirror to consequently generate a linear

optical scan of the object. These devices are bulky

and expensive.

When using an infrared camera as a line scanner,

an arbitrary line is selected from the detector array.

In addition to the more compact construction and the

lower price, there are two signicant benets: the line

to be scanned can be positioned anywhere using the

software and the user receives a complete IR image

quasi as additional information – these are important

advantages, especially during system setup.

The cameras can accurately measure surface temperatures of moving measurement objects using minimal

apertures. This function is of particular signicance in

the glass industry, since the glass temperature has

a direct impact on the quality. During the production

process, temperatures are measured accordingly

at many points and it is possible to intervene in the

process, when necessary, if there are deviations in

setpoint temperatures.

For example, the Optris PI 450 G7, a special IR

camera for glass applications, can scan the complete

glass width using in the oat process (Up to 4 m [13 ft])

with an 80° lens using the diagonals as scan line at a

height of 2.1 m (6.9 ft).

80

Transmissivity in %

60

40

20

0

2 3 4 5

Further information in our infrared basics brochure:

www.optris.com/optris-downloads

Wavelengh [µm]

Lines have FOV of

up to 111° for detailed

process analysis.

111 °

any number of lines

800 Pixel

Up to 125 Hz data recording

of unlimited lines which in turn

produce a thermal image of

any given resolution

3

Page 4

Applications of

Temperature measurement technology

PRODUCTION OF GLASS

Production optimization in the

oat glass process

After the tin bath, the at glass band has a temperature of about

600 °C (1,112 °F); the rst infrared camera in line-scan mode is

applied for temperature monitoring at the transition to the cooling

zone. The glass is transported through various cooling ranges in

the cooling zone. Between the cooling ranges, infrared cameras

are also installed in the cooling ranges for temperature

monitoring, in order to guarantee optimal quality.

Software adjustments for line-scan process

Measurement areas at float glass production

Infrared cameras with line scan mode

FloatMelting process Tin bath

> 1,500 °C (2,732 °F) 600 °C (1,112 °F)

Continuous control during the production of container glass

Container glass, meaning for example bottles in all sizes

and forms, must be multiply monitored for its processrelevant temperature during the production process.

When the molten glass exits through the feeder, the glass

strand is cut. The thereby resulting molten glass drops

must have a temperature of about 1000 °C (1,832 °F) to

ensure quality. Temperature measurement was previously

only possible with point-measuring infrared thermometers

due to the high velocity. The innovative Optris PI 1M now

also enables this measurement via surface measurement

with an image rate of up to 1000 Hz.

During the forming process, which takes place at

temperatures of over 500 °C (932 °F), infrared sensors are

also used for monitoring. Since the process only takes a

few seconds, the reaction of the sensors is of critical

importance here. The thermal measurement of the

glass can be inuenced by direct measurement of the glass

surface or indirect measurement of the surface of the for-

ming tool for both the forming of the parison shape as well

as during nishing of the mould.

To complete the nishing process, another

temperature control to reduce tension takes

place in the containers. The glass is heated again

and subsequently gradually cooled in a cooling

tunnel over a period of up to 30 minutes. When

the containers exit the heating zone, the cooling

process is supported and controlled by

temperature measurement.

Cooling process

4

Page 5

Single-pane safety glass production with

correct temperature measurement technology

For the production of single-pane safety glass (SPSG), the cut

and processed at glass is heated in a furnace under continuous

movement at over 600 °C (1,112 °F). During the transport of the

heated glass in the pretension zone, an infrared camera monitors the temperature distribution on the glass surface in linescan mode. During the pretension process, where the glass is

shock-cooled, inhomogeneities can be compensated. The quality

of the SPSG mainly depends on a homogeneous thermal treatment, which is ensured by the application of temperature

measurement technology.

innovative infrared technology

Infrared camera with line scan mode

Heating process Cooling process

600 °C (1,112 °F) 50 °C (122 °F)

Measurement areas at SPSG production

Ensuring the quality of laminated

safety glass

50 °C (122 °F)

Infrared

thermometer

Infrared camera

with line scan mode

Laminated safety glass (LSG) consists of at least two at panes

of glass, which are laminated in a clean room with a sheet of

PVB lm between them. The temperature of the lm can be

monitored with infrared thermometers. In the pre-lamination

furnace, the glass panes are heated in order to melt the lm and

simultaneously press the “sandwich” together, to prevent air

pockets. During the transition to the autoclaves, the temperature

distribution is monitored with an infrared camera, in order to

adjust the heating elements in the pre-lamination furnace for

subsequent panes, when necessary.

Heating with IR

radiation and rolling

Infrared thermometer /

Infrared camera

Measurement areas at LSG production

Laminating room Final control

5

Page 6

Glass industry

INFRARED CAMERAS AND INFRARED THERMOMETERS

The IR thermometer’s stainless steel measuring

head is extremely small and can be employed

in ambient temperatures of up to 85 °C (185 °F)

without additional cooling. A multi-installation of

the pyrometers, e. g. in series as line scanner, is

therefore cost-efcient and can be performed

optris

Due to its special spectral range of 5.0 µm, the

pyrometer optris

measurement of glass temperatures, e.g. during

container glass production and vehicle glass

production.

The infrared thermometer optris

®

CT G5

®

CT G5 is perfectly suited for the

®

CTlaser G5

allows for temperature measurement of smallest

objects of 1 mm (0.04 in) from a distance of

70 mm (2.76 in). Due to its very short response

time of 10 ms it is often used for fast processes.

even in limited spaces. The temperature range is

from 100 °C to 1,650 °C (212 °F to 3,002 °F).

optris

With a spectral range of 5.0 µm, the two-part infrared

thermometer optris

precise measurement of glass surfaces. The devices

are employed for temperature measurement in e.g. manufacturing processes of vehicle glass and and at glass.

®

CTlaser G5

®

CTlaser G5 is especially designed in

The infrared thermometer optris® CSlaser G5HF

has been specically designed for temperature

measurement of glass. Its standardized two-wire

interface provides a reliable measuring data

transmission and allows for an easy integration

of the temperature sensors into a PLC.

optris

The optris® CSlaser G5 is perfectly suited for temperature control of production processes of at glass and

vehicle glass. Also, the measurement during cooling

and heating processes of single-pane safety glass

and laminated sheets safety glass is important.

®

CSlaser G5HF

Also in the manufacturing of

laboratory glass equipment or the

production of glass bottles, the pyrometer

delivers excellent results and is thus employed

for quality assurance and process coordination.

The IR thermometer is additionally equipped with

an innovative double laser visor for a precise

marking of the measuring spot. A variety of optics

ensures high adaptability with diverse applications.

6

Page 7

®

The infrared cameras optris

G7 are industry specic models within the PI series.

They are especially developed for the glass in-

dustry, working with a spectral range of 7.9 μm.

PI 450 G7 and PI 640

innovative infrared technology

The temperature range of 200 °C to 1,500 °C

(392 °F to 2,732 °F) allows the implementation in

diverse applications in production, dressing and

further processing of glass.

optris

These infrared cameras should be used when temperature values within a eld are to be detected. In due

to the low price an infrared camera could be the better

solution in comparison to rows of infrared thermometers.

The infrared thermometer optris

an extremely short response time of 6 ms. The

unchoppered sensor allows a continuous temperature surveillance of fast processes in a spec-

trum of –50 °C up to 975 °C (–58 °F up to 1,787 °F).

The thermal imager optris® PI 160 allows for exact

For fast processes

optris

optris

Both products are preferably used in the packaging

industry and in bottling plants. In mass production,

it is essential that high-output processes are monitored

®

PI 450 G7 / PI 640 G7

®

CTfast LT has

®

PI 160 and

®

CTfast LT

Line

scan

camera

measurements from an object size of 1.5 mm

(0.06 in) on and is, due to its measurement speed

of 120 Hz, perfectly suited for employment in

research and development, test stations, and

process automation as well as for portable

measurement tasks.

continuously and without friction.

Deciding which of the two products should

be used, depends on the measuring area. From

a measurement of more than 7 measuring points,

it is less expensive to use an infrared camera.

The pyrometer optris® CThot LT has been

developed for the most extreme conditions in

high-temperature areas and is acclaimed for

its especially high temperature resistance.

Employment of the infrared thermometer in

ambient temperatures of up to 250 °C (482 °F)

optris

The optris® CThot LT is used in production

processes and rening processes of glass.

Due to its extremely high temperature

resistance, it is also suitable for ovens

and closed chambers.

®

CThot LT

without additional cooling poses absolutely no

problems. Due to the mentioned features, the

IR pyrometer is especially suited for applications in

glass industries. On request, the IR thermometers

are available as models for applications in

explosion-threatened areas.

7

Page 8

Subject to change · Temperature measurement glass industry-BR-US2017-11-B

Optris Infrared Sensing, LLC

200 International Drive

Suite 170

Portsmouth, NH 03801 USA

Phone: (603) 766-6062

E-mail: sales@optris-ir.com

www.optris.com

innovative infrared technology

Loading...

Loading...