Page 1

innovative infrared technology

INFRARED CAMERAS

The most portable infrared online cameras in the world

Page 2

The Compact- and the Precision Line oer

imaging infrared temperature measuring

devices for all applications

Advantages of the Xi Compact Line

• Motor focus

• Compact industrial imager for temperature measurements

from –20 to 900 °C (–4 to 1652 °F)

• Autonomous operation with automatic spot nder and

direct analog output – ideal for OEM use (Xi 80)

• Direct Ethernet and RS485 interface (Xi 80)

Automatic

hotspot search

Objects can be

thermally analyzed

and hot or cold

spots can be found

automatically.

Advantages of the PI Precision Line

• Interchangeable lenses

• Suited for fast processes (up to 1 kHz)

• High thermal sensitivity (up to 40 mK NETD)

• High optical resolution (up to 640 x 480 Pixel)

• Laser blocking lters

• Temperature measuring ranges from –20 to 2000 °C

(–4 to 3632 °F)

• Dierent spectral ranges

(500 nm / 1 µm / 7.9 µm / 7,5 – 13 µm)

Fast measurements

Temperature distributions on a

surface can be precisely recorded

at millisecond intervalls.

A drop of milk falling into a

cup of coffee.

Autonomous operation

with direct analog output

Up to 9 freely denable measuring

areas may be used as analog outputs

when using an external process interface.

Simple process integration

• Software Development Kit (SDK) for integration of the

camera into customer-specic software via Dynamic

link Library (DLL) or COM-Port.

• Interfaces to LabView and MATLAB are included as

well

optris® Microscope optics

The interchangeable and focusable microscope optics

enable electrical testing and thermal analysis of smallest

components at the same time - with an optical resoluti-

on of up to 28 µm. Fast processes can easily be

monitored with a frame rate of up to

125 Hz and, with the recording of

radiometric video sequences and

images, be saved for later analy-

sis.

2

Page 3

optris

®

Xi 80 / Xi 400

INFRARED CAMERAS FOR OEM USE

innovative infrared technology

Compact spot nder

IR camera

• Industrial imager for precise temperature measurements from –20 to 900 °C

(– 4 to 1652 °F)

• Rugged, compact imager with motor focus

• Autonomous operation with automatic spot search and direct analog output

• 80 Hz frame rate for the monitoring of fast thermal processes

• Extensive ready-to-use package for an attractive price – including

versatile image processing software and connection cables

Pyrometer or camera?

The Xi series is a fusion of a rugged, compact pyrometer

and a modern IR camera. Thanks to analog and digital

outputs as well as the option to process up to nine freely

denable measuring areas using an external process

interface, the Xi camera is perfectly suited for OEM applications.

Integrated spot nder function

The integrated spot nder function allows for precise temperature measurements of moving objects - without having

to readjust the sensor. The camera gures it out on its own,

without being connected to a PC.

Motor focus simplies handling

Both Xi models are equipped with a motorized foucus. The

free PIX Connect software enables a remote focusing from

the distance.

3

Page 4

optris

®

PI 160

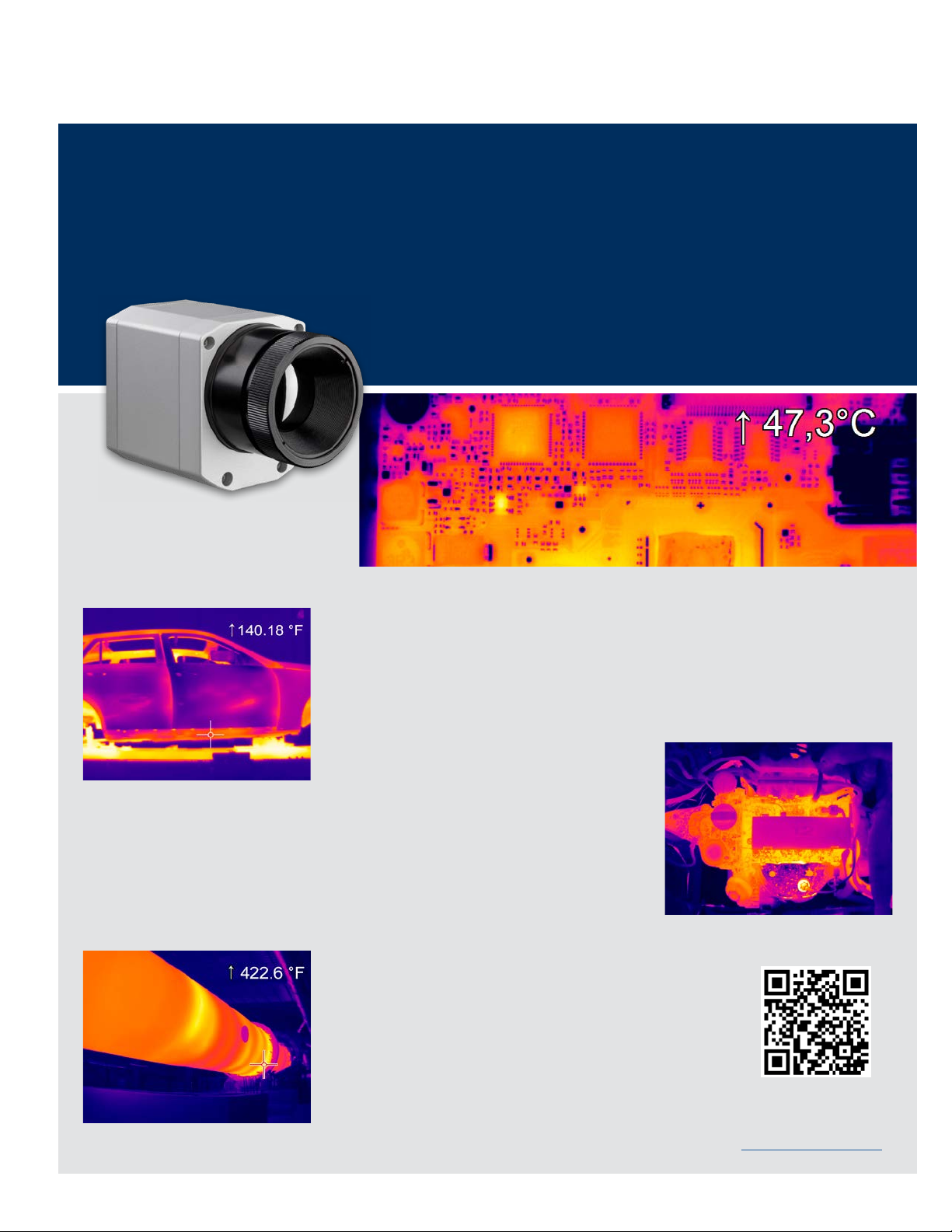

INFRARED CAMERA WITH 120 Hz FRAME RATE

Small camera for

fast processes

• Outstanding value for money

• Very good thermal sensitivity of 40 mK

• Thermal image up to 120 Hz

• Detector with 160 x 120 pixels

• Compact design (dimensions: 45 x 45 x 62 mm [1.8 x 1.8 x 2.4 in])

• Includes license-free analysis software and full SDK

Surface measurements in

industrial application

The optris® PI 160 infrared camera

is always used when temperature

monitoring of surfaces is required

and the single point measurement of

pyrometers is no longer sucient.

Hand as measurement object:

measurement eld size 240 mm x 180 mm

(9.45 in x 7.09 in)

pixel size 1.5 mm

160 x 120 pixels

10 x 10 pixels = 225 mm

(0.06 in)

2

Nowadays surface measurements

are essential in the automotive eld,

in plastic applications and in the solar

industry.

Suitable lenses for

every measurement

distance

Same measurement eld size at

dierent measurement dierences:

• Telephoto lens (6° x 5°):

2.13 m (7 ft) measurement

dierence

• Standard lens (23° x 17°):

0.6 m (2 ft) measurement

dierence

• Wide-angle lens (41° x 31°):

0.32 m (1 ft) measurement

dierence

• Wide-angle lens (72° x 52°):

0.17 m (0.6 ft) measurement

dierence

4

Application exaples, e.g. in the

automotive sector:

www.optris.com/automotive

Page 5

innovative infrared technology

optris

®

PI 200 / PI 230

INFRARED CAMERA WITH BI-SPECTRAL TECHNOLOGY

Two cameras in one

compact device

Surveillance mode:

Easy orientation at the measuring

point through separate display of the

visual picture.

• BI-SPECTRAL technology

• Time-synchronized visual image recording at up to 32 Hz (640 x 480 pixels)

• Real image camera is highly sensitive in low-light conditions

• Thermal images to 128 Hz (160 x 120 pixels)

• Compact design (dimensions: 45 x 45 x 62 mm [1.8 x 1.8 x 2.4 in])

• Includes license-free analysis software and full SDK

BI-SPECTRAL Technology

With the help of BI-SPECTRAL technology a visual image

(VIS) can be combined with a thermal image (IR) and plotted

synchronistically:

Crossfade mode:

Highlight critical temperatures by

means of crossfade (transparency

from 0 to 100 %) or by means of

superimposition of dened temperature elds (thresholds).

Monitoring of a carbon ribbon.

Measurement of the brake temperature in superimposed image

Cross fade of a VIS image above 35 °C (95 °F)

5

Page 6

optris

®

PI 400i

INFRARED CAMERA WITH HIGH

OPTICAL RESOLUTION

The smallest VGA

infrared camera in

the world

• 640 x 480 pixels

• Radiometric video recording at 32 Hz / 125 Hz in subframe-mode

(640 x 120 pixels)

• Compact size of 45 x 45 x 60 – 75 mm (1.8 x 1.8 x 2.4 - 3.0 in)

• Lightweight (195 [6.9 oz] g incl. lens)

• Includes license-free analysis software and full SDK

Razor sharp infrared

pictures and videos for

process optimization

With a casing size of only 46 x 45 x 60 - 70

mm (1.8 x 1.8 x 2.4 - 3.0 in) and a weight of

195 grams (6.9 oz) (incl. lens), the optris®

PI 400i is among the most compact infrared

cameras on the market.

The high-denition optris® PI 400i infrared camera is best used in applications where nest

thermal details matter.

It signicantly contributes to process optimization in both research and development and in

industry.

Application examples, e.g. the early

detection of res in garbage bunkers:

www.optris.com/re-prevention

6

Page 7

innovative infrared technology

optris

®

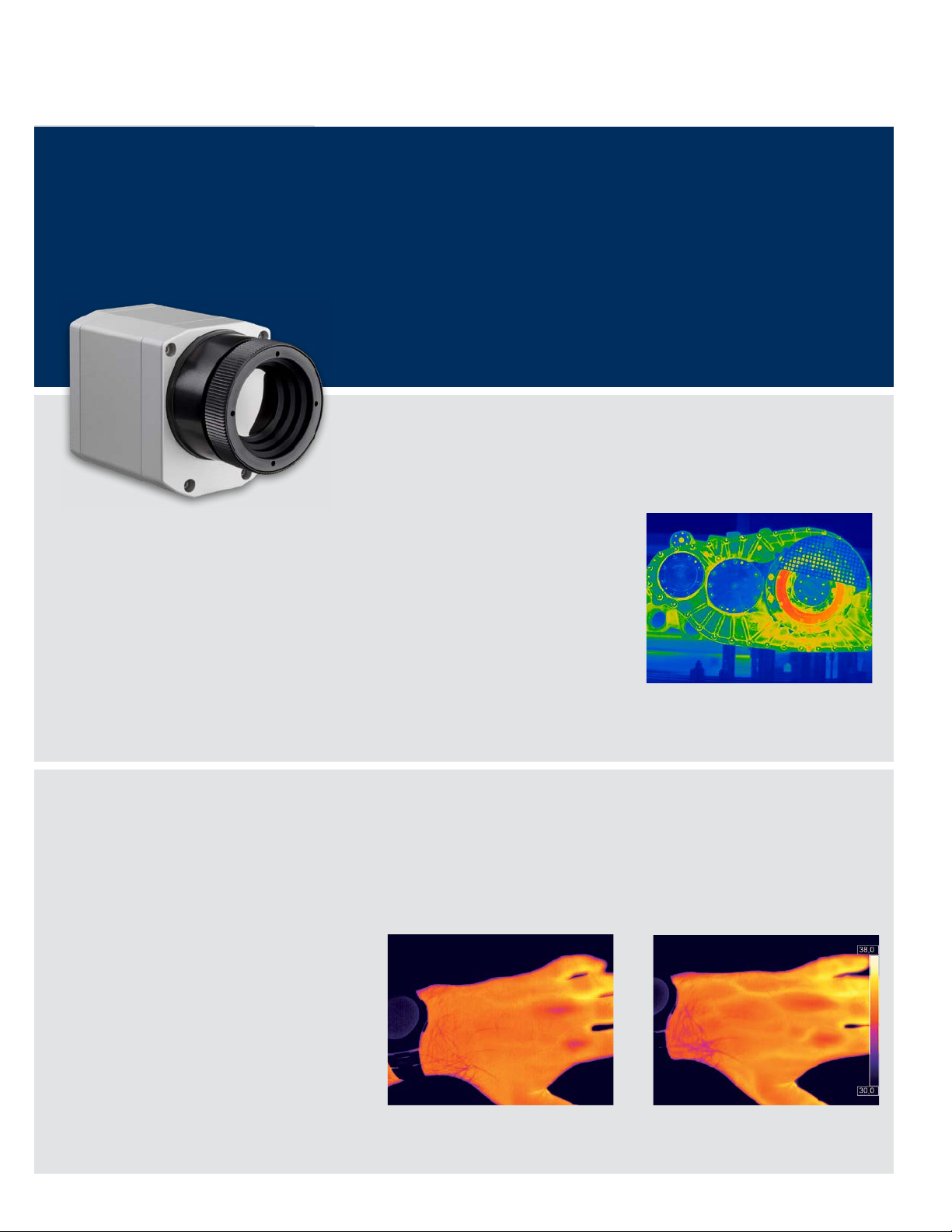

PI 450i

INFRARED CAMERA WITH VERY HIGH THERMAL SENSITIVITY

Detection of

minimal temperature

dierences

• The smallest camera in its class 45 x 45 x 60 –75 mm

(1.8 x 1.8 x 2.3 - 2.95 in)

• Exceptional thermal sensitivity at 40 mK

• Thermal image recording up to 80 Hz

• Interchangeable lenses & industrial accessories

• Lightweight (195g (6.88 oz) incl. lens)

• Detector with 382 x 288 pixels

• Usable at ambient temperatures of up to 70 °C (158 °F) without the need for

additional cooling

Highest temperature

resolution of 40 mK

With an optical resolution of 40 mK, the

®

optris

PI 450i is used for measuring

the most subtle temperature dierences, e.g. in the quality control of

products or in preventive medicine.

Application example in the

medical sector

Due to the very high resolution of the optris® PI 450i, even veins

can be made visible unter the skin.

80 mK

40 mK (PI 450)

7

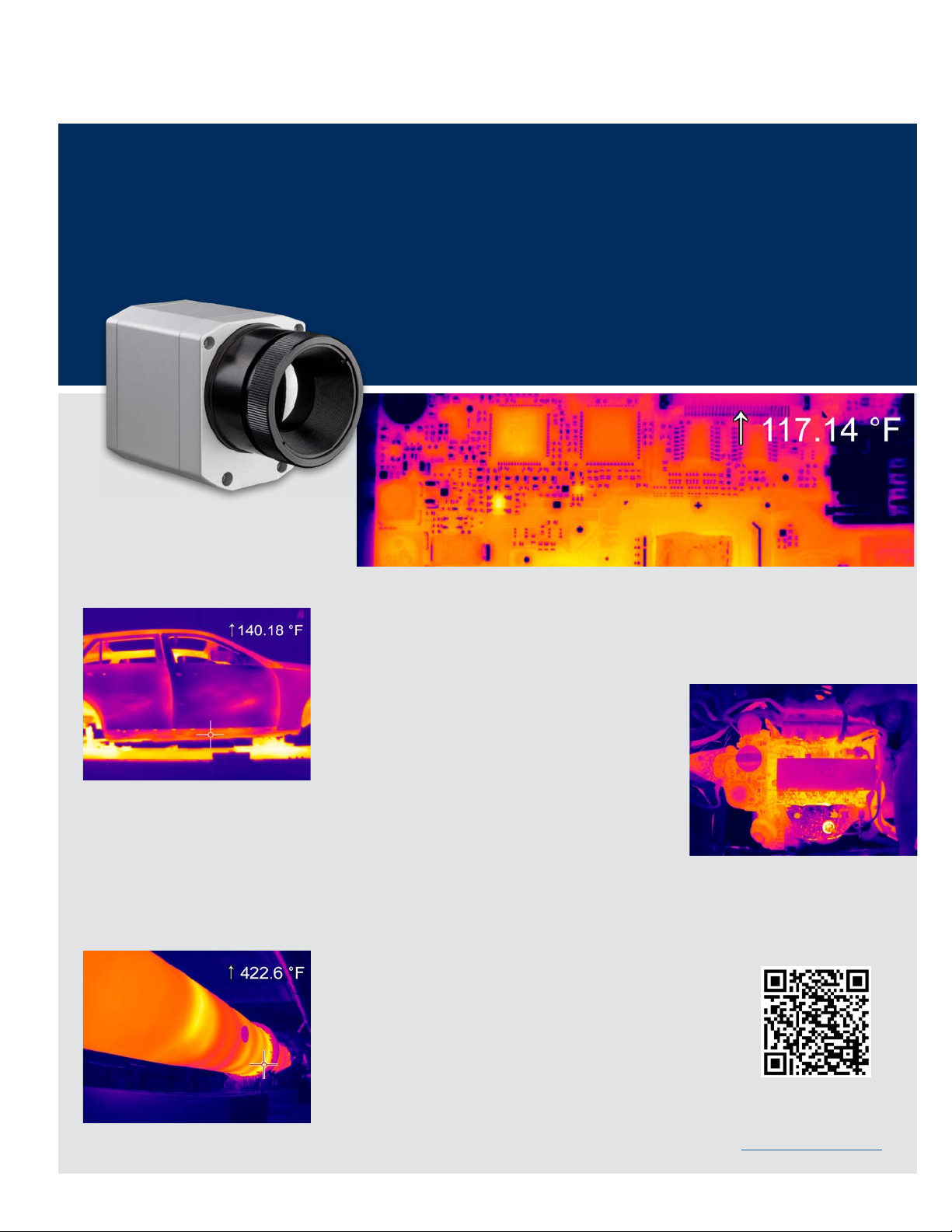

Page 8

optris

®

PI 640

THERMOGRAPHY IN VGA RESOLUTION

The smallest VGA

infrared camera in

the world

• 640 x 480 pixels

• Radiometric video recording at 32 Hz / 125 Hz in subframe-mode

(640 x 120 pixels)

• Compact size of 46 x 56 x 90 mm (1.8 x 2.2 x 3.5 in)

• Lightweight (320 g (11.3 oz) incl. lens)

• Includes license-free analysis software and full SDK

Razor sharp infrared

pictures and videos for

process optimization

With a casing size of only 46 x 56 x 90 mm

(1.8 x 2.2 x 3.5 in) and a weight of 320 g

(11.3 oz) (incl. lens), the optris® PI 640 is

among the most compact infrared cameras

on the market.

The high-denition optris® PI 640 infrared

camera is best used in applications where

nest thermal details matter.

It signicantly contributes to process opti-

mization in both research and development

and in industry.

Application examples, e.g. the early

detection of res in garbage bunkers:

www.optris.com/re-prevention

8

Page 9

optris

®

PI 450 G7 / PI 640 G7

SURFACE TEMPERATURE MEASUREMENTS

ON GLASS WITH LOW REFLECTIONS

innovative infrared technology

High-resolution

thermography for

the glass industry

Infrared camera with line-scan function

Heating zone

600 °C (1112 °F) 50 °C (122 °F)

Construction of a glass tempering plant.

Cooling zone

• Usable at ambient temperatures of up to 70 °C (158 °F) without the need for

additional cooling

• With an integrated lter for the spectral range of 7.9 μm

• Compact size of 46 x 56 x 90 mm (1.8 x 2.2 x 3.5 in)

• Frame rate up to 125 Hz

• Line scan function through license-free analysis software optris® PIX Connect

• Max. scan angle of 111 ° with 800 pixels per line

Exact temperature

measurements on glass

surfaces via line-scan

camera function

The temperature of glass is best

measured in the range of spectral

absorption bands. For this purpose

the optris

integrated 7.9 μm lter which enables

an anechoic IR surface temperature

measurement. Its compact size makes

the optris

ticularly suitable for use in conned

spaces and for installation in industrial

facilities. The infrared camera is fully

operational at ambient temperatures of

up to 70 °C (158 °F) without the need

for cooling. With an imaging frequency

of up to 125 Hz, glass products can

be continuously tested, even in fast

processing.

®

PI 450 / PI 640 G7 has an

®

PI 450 / PI 640 G7 par-

Glass panes between heating and cooling zone.

Application examples for the glass

industry:

www.optris.com/temperature-monitoring-

glass-industry

The line-scan camera function

(linescan mode) of the PIX Connect

software enables the exact temperature measurement of panes of glass

during transport on conveyor belts.

This is a particularly important quality

factor in tempering processes, e.g. in

ESG and VSG.

Glass tube manufacturing.

Hot-spot measurement in the production of glass

bottles.

9

Page 10

optris

®

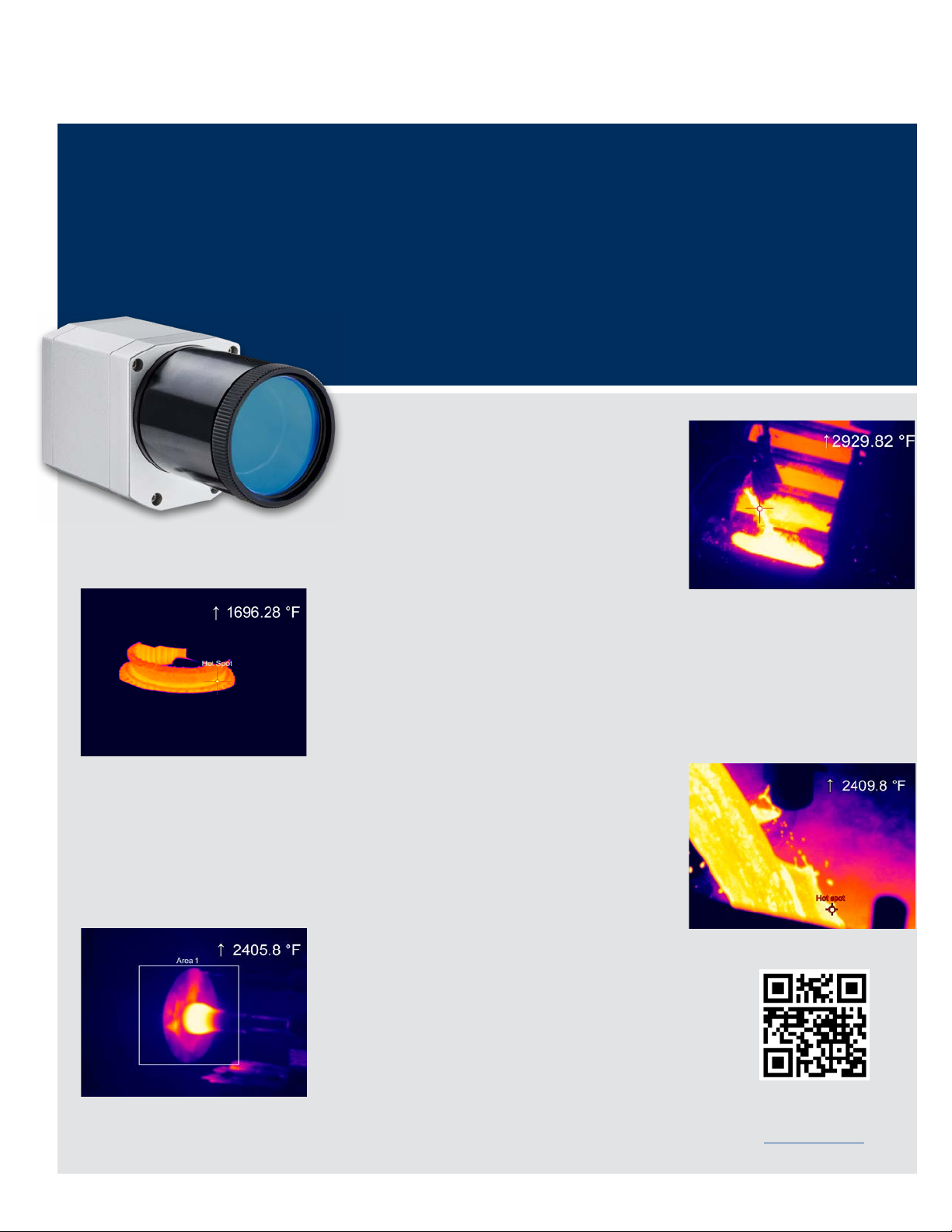

PI 05M / PI 1M

INFRARED CAMERAS FOR THE

SHORTWAVE DOMAIN

Ultra compact

infrared cameras for

the metal industry

• Highly dynamic CMOS detector with an optical resolution of up to 764 x 480 pixels

• Very large temperature measurement ranges (without sub-ranges)

of 450 °C to 1800 °C (842 °F to 3272°F) (PI 1M) and

of 900 °C to 2000 °C (1652 °F to 3632 °F) (PI 05M)

• Frame rates and linescanning function up to 1 kHz for fast processes

• Real-time output of 8 x 8 pixels with 1 ms response time

• Includes license-free analysis software and full SDK

• New: PI 05M – Ideally suited for all laser processing applications with

solid-state lasers in NIR through excellent blocking of radiation above 540 nm

Intelligent temperature measurement – innovative and fast

The new optris® PI 05M and PI 1M

IR cameras are specially suited for

measuring the temperature of metals, as

these exhibit a distinctly higher emissivity

at the short measurement wavelength of

500 nm and 1μm than at measurements

in the previously conventional wavelength

range of 8 – 14 μm.

Measurement of a pouring stream.

Induction heating

Electrical upsetting.

Especially the new spectral range of

500 nm enables for more precise measurements at changing emissivities and is

less sensitive to atmospheric inuences.

Thus, the PI 05M is ideally suited for

temperature measurements of molten

metals. A direct 1 ms analog output allows

both camera models a readout of a freely

selectable 8 x 8 pixel region in real-time.

The use of these new image sensors

allows a large dynamic range for temperature measurement so that the previously

necessary use of relatively many and

narrowly dened sub-ranges is no longer

required. Intelligent measuring with a

pyrometer is now possible thanks to the

two-dimensional

the

optris® PI 05M and PI 1M.

Thanks to the large measurement

temperature range of 450 ... 2000 °C

(842 ... 3632°F), the optris

PI 1M IR camera satises practically all

demands in the elds of metal production

and processing.

temperature recording of

®

PI 05M and

Measurement of a pouring stream.

Application exaples for the metal industry:

www.optris.com/metal

10

Page 11

optris

®

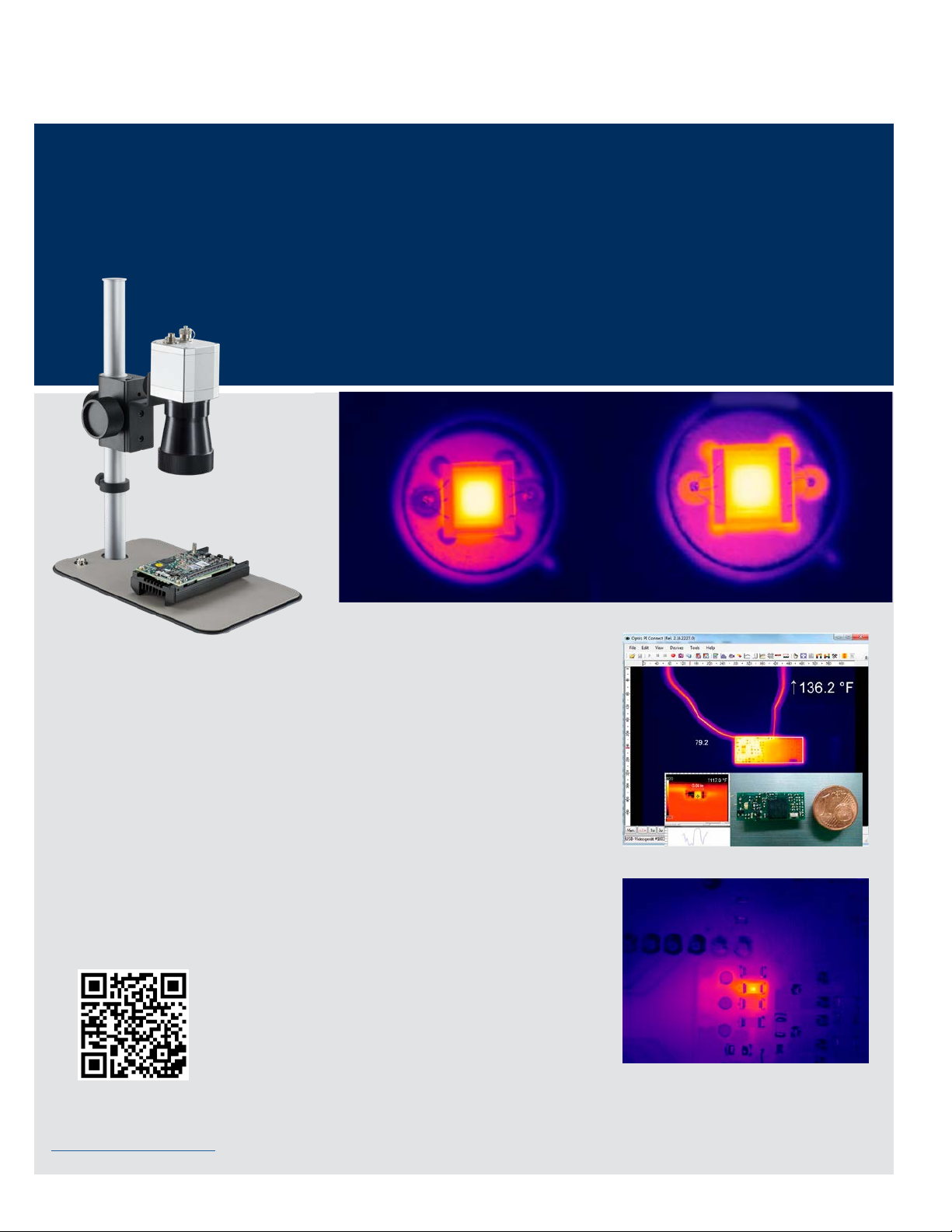

Microscope optics

INTERCHANGEABLE LENSES FOR MACRO IMAGES

• Hochdynamischer CMOS-Detektor with einer optischen Auösung

Microscope optics

for the inspection of

electronic boards

• Exchangeable, focusable optics for most exible use of the camera

bis to 764 x 480 Pixel

• Analysis of small chip level components down to 28 μm

• Sehr großer Temperaturmessbereiche (ohne Unterbereiche)

• Hands-free operation for simultaneous testing and IR imaging

von 450 °C bis 1800 °C (PI 1M), bzw. von 900 °C bis 2000 °C (PI 05M)

• Frame rates up to 125 Hz allow inspection of fast processes (like pulsed laser

• Bildfrequenz/ Linescanning bis to 1 kHz for schnelle Prozesse

diodes)

• Echtzeit-Ausgabe von 8x8 Pixel bei einer Einstellzeit von 1 ms

• Radiometric video or ti recording with +/-2 °C (3.6 °F) measurement

• Lizenzfreie Analysesoftware and komplettes SDK inklusive

accuracy

• Neu: PI 05M - Ideal geeignet for alle Laserbearbeitungsprozesse with

• License-free analysis software and complete SDK included

Festkörperlasern im nahen IR durch hervorragende Blockung von Strahlung

oberhalb 540 nm

innovative infrared technology

Application exaples for the analysis of

electronic boards:

www.optris.com/electronics-industry

High resolution

microscope optics for

test & measurement

The interchangeable lenses for the

optris® PI 450 and optris® PI 640 now

also oer additional microscope lens

systems. Apart from detailed macro

recordings of individual components,

these also allow recordings of the entire circuit board.

High resolution macro shots of individual components are possible with a spatial resolution of 28 µm, the distance

between the measurement object and

camera is variable and can be adjusted

between 80 and 100 mm (3.15 and

3.94 in).

The high-quality thermal and geometric

detail resolution of the infrared cameras ensures precise functional testing

of electronic products, as even the

smallest temperature dierences to be

accurately detected.

Recording of a circuit board with the optris®

PI 640

11

Page 12

optris® Xi Infrared cameras

– The Compact Line

Compact spot nder

IR camera or applications in

rough industrial environments

Optics calculator: www.optris.com/optics-calculator

New

Basic model Xi 80 Xi 400

Type IR IR

Detector

Optical resolution

Spectral range

Temperature ranges

Frame rate

Optics (FOV)

Macro optics

Focus

Optical resolution (D:S)

Thermal sensitivity (NETD)

Accuracy

PC interfaces

Direct in-/inputs

Standard Process Interface (PIF)

Industrial Prozess-Interface (PIF)

Cable length (USB)

Ambient temperature

Size / class

Weight

Shock/ Vibration

3)

Power supply

Scope of supply (standard)

FPA, uncooled (34 µm pitch) FPA, uncooled (17 µm pitch)

80 x 80 pixels 382 x 288 pixels

8 – 14 μm 8 – 14 μm

–20 ... 100 °C (–4 to 212°F)

0 ... 250 °C (32 ... 482 °F)

(20) 150 ... 900 °C (302 ... 1652 °F)

50 Hz 80 Hz / 27 Hz

30° (f = 5.1 mm [0.20 in])

12° (f = 12.7 mm [0.50 in])

55° (f = 3.1 mm [0.12 in])

80° (f = 2.3 mm [0.09])

– 18° x 14° (f = 20 mm [0.79 in]), smallest measuring spot: 90 µm)

Manual motor focus Manual motor focus

190:1 (12° lens) 390:1 (18° lens)

100 mK 80 mK

±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater

USB 2.0 / Ethernet (100 Mbit/s) / PoE / RS485

1x 0/4 – 20 mA output

1x input (analog or digital); optically isolated

–

3x 0/4 – 20 mA or 0–10 V outputs,

3x inputs (analog or digital),

3x relays (0 – 30 V) / 400 mA),

1x fail-safe relay; stackable up to 3 PIFs; optically isolated

USB: 1 m (standard), 3 m, 5 m, 10 m and 20 m

(3.3 ft (standard), 9.8 ft, 16.4 ft, 32.8 ft and 65.6 ft)

Ethernet / RS485: 100 m

0 ... 50 °C (32 ... 122 °F) 0 ... 50 °C (32 ... 122 °F)

Ø 36 x 90 mm (1.4 x 3.5 in) (M30x1 thread) / IP 67 (NEMA 4) Ø 36 x 100 mm (1.4 x 3.9 in) (M30x1 thread) / IP 67 (NEMA 4)

185 g (6.5 oz) 200 g (7.1 oz)

IEC 60068-2 IEC 60068-2

USB / PoE / 5-30 VDC via USB

• Xi camera

• USB cable (1 m [3.3 ft])

• Cable for in-/inputs (1 m [3.3 ft]) with terminal block

• Mounting bracket with tripod thread, mounting nut

• Software package optris

• Quick start guide

®

PIX Connect

1)

2)

–20 ... 100 °C (–4 to 212°F)

0 ... 250 °C (32 ... 482 °F)

(20) 150 ... 900 °C (302 ... 1652 °F)

29° x 22° (f = 12.7 mm [0.50 in])

18° x 14° (f = 20 mm [0.79 in])

53° x 38° (f = 7.7 mm [0.30 in])

80° x 54° (f = 5.7 mm [0.22 in])

USB 2. 0 / optional USB to GigE (PoE) interface

–

1x 0–10 V input

1x digital input (max. 24 V)

1x 0–10 V output

2 x 0–10 V inputs, 1x digital input (max. 24 V)

3 x 0–10 V outputs,

3 x relays (0–30 V / 400 mA),

1x fail-safe relay

USB: 1 m (standard), 3 m, 5 m, 10 m and 20 m

(3.3 ft (standard), 9.8 ft, 16.4 ft, 32.8 ft and 65.6 ft)

• Xi camera

• USB cable (1 m [3.3 ft])

• Cable for in-/inputs (1 m [3.3 ft]) with terminal block

• Mounting bracket with tripod thread, mounting nut

• Software package optris

• Quick start guide

®

PIX Connect

New

1)

1)

Accuracy effective starting at 150 °C (302 °F)

2)

Direct in- and outputs are not available while using the RS485 interface

3)

For further details see operator's manual

12

Page 13

innovative infrared technology

optris® PI Infrared cameras

– The Precision Line

Optics calculator: www.optris.com/optics-calculator

Compact infrared cameras for

fast online applications – including line scanner

Basic model PI 160 PI 200 / PI 230 PI 400i

Type IR BI-SPECTRAL IR

Detector

Optical resolution

Spectral range

Temperature ranges

Frame rate

FPA, uncooled (25 µm pitch) FPA, uncooled (25 µm pitch)

160 x 120 pixels 160 x 120 pixels 382 x 288 pixels

8 – 14 μm 8 – 14 μm 8 – 14 μm

–20 ... 100 °C (–4 ... 212°F),

0 ... 250 °C (32 ... 482 °F),

(20) 150 ... 900 °C (302 ... 1652 °F)

200 ... 1500 °C (392 ... 2732 °F) (Option)

120 Hz 128 Hz

1)

,

–20 ... 100 °C (–4 ... 212°F),

0 ... 250 °C (32 ... 482 °F),

(20) 150 ... 900 °C (302 ... 1652 °F)

3)

200 ... 1500 °C (392 ... 2732 °F) (Option)

4)

1)

,

FPA, uncooled (

–20 ... 100 °C (–4 ... 212°F),

0 ... 250 °C (32 ... 482 °F),

(20) 150 ... 900 °C (302 ... 1652 °F)

3)

200 ... 1500 °C (392 ... 2732 °F) (Option)

80 Hz / switchable to 27 Hz

17 μm x 17 μm)

1)

,

3)

Optics (FOV)

Thermal sensitivity (NETD)

Option visual camera

(BI-SPECTRAL only)

Accuracy

PC interfaces

Process-

Standard PIF

Interface

(PIF)

Industrial PIF

(optional)

Ambient temperature (T

Amb

Storage temperature

Relative humidity

Size / Class

Weight

Shock/ Vibration

Tripod mount

Power supply

Scope of supply (standard)

23° x 17° / f = 10 mm (0.9 in) or

6° x 5° / f = 35.5 mm (1.4 in) or

41° x 31° / f = 5.7 mm (0.2 in) or

72° x 52° / f = 3.3 mm (0.13 in)

40 mK with 23° x 17° FOV / F = 0.8

0.3 K with 6° x 5° FOV / F = 1.6

0.1 K with 41° x 31° FOV and

72° x 52° FOV / F = 1

– Optical resolution: 640 x 480 pixels

±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater

USB 2. 0 / optional USB to GigE (PoE) interface USB 2. 0 / optional USB to GigE (PoE) interface USB 2. 0 / optional USB to GigE (PoE) interface

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe-relays

)

0 ... 50 °C (32 ... 122 °F) 0 ... 50 °C (32 ... 122 °F) 0 °C ... 50 °C (32 °F ... 122 °F)

– 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F)

20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing

45 (1.77) x 45 (1.77) x 60 – 76 mm

(2.36 - 2.99 in) (depending on lens and focus

position) / IP 67 (NEMA 4)

195 g (6.9 oz), incl. lens 215 g (7.6 oz), incl. lens 195 g (6,88 oz), incl. lens

IEC 60068-2 IEC 60068-2 IEC 60068-2

1/4-20 UNC 1/4-20 UNC 1/4-20 UNC

via USB via USB via USB

• USB camera with 1 lens

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Aluminum case

®

PIX Connect

2)

23° x 17°

6° x 5° / f = 35.5 mm (1.4 in) or

41° x 31°

72° x 52° / f = 3.3 mm (0.13 in)

40 mK with 23° x 17° FOV / F = 0.8

0.3 K with 6° x 5° FOV / F = 1.6

0.1 K with 41° x 31° FOV and

72° x 52° FOV / F = 1

Frame rate: 32 Hz

Optics (FOV): PI 200: 54° x 40°,

PI 230: 30° x 23°

1x 0 – 10 V input, 1x digitaler input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe-relays

45 (1.77) x 45 (1.77) x 60 – 76 mm

(2.36 - 2.99 in) (depending on lens and focus

position) / IP 67 (NEMA 4)

• USB camera with 1 lens and

• USB cable (1 m [3.3 ft])

• Table tripod

• Focus tool

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Aluminum case

/ f = 10 mm (0.9 in) or

2)

/ f = 5.7 mm (0.2 in) or

4)

BI-SPECTRAL technology

®

PIX Connect

18° x 14° / f = 20 mm (f = 1.6 in) or

29° x 22° / f = 12.7 mm (f = 0.7 in) or

53° x 38° / f = 7.7 mm (f = 0.4 in) or

80° x 54° / f = 5.7 mm (f = 0.3 in)

75 mK with 29°, 53°, 80° FOV

0.1 K with 18° FOV / F = 1.1

–

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relays

45 x 45 x 60 – 75 mm (1.8 x 1.8 x 2.3 - 2.95 in)

(depending on lens and focus position)/ IP 67

(NEMA 4)

• USB camera with 1 lens

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Aluminum case (PI 400i)

• Robust hard shell case (PI 450i)

®

PIX Connect

1)

Accuracy effective starting at 150 °C (302 °F)

2)

For ideal combination of IR and VIS image, a 41° HFOV lens is recommended

(PI 200). For the PI 230, a 23° lens is recommended.

3)

The additional measuring range is not available for 72°

(PI 160 / 2xx), 80° (PI 4xx) and 90° (PI 640) lenses.

13

Page 14

optris® PI Infrared cameras

– The Precision Line

Compact infrared cameras

for fast online applications –

including line scanner

New

Basic model PI 640 Microscope optics

PI 450 G7

PI 450 / PI 640

Type IR IR IR IR IR IR

Detector

Optical resolution

Spectral range

Temperature ranges

Frame rate

Optics (FOV)

Thermal sensitivity (NETD)

Accuracy

PC interface

Process

Standard PIF

Interface

FPA, uncooled (17 µm pitch) FPA, uncooled

640 x 480 pixels VGA PI 450: 382 x 288 pixels @ 80 Hz

8 – 14 μm 8 – 14 μm 7.9 μm 7.9 μm 0.85 – 1.1 μm 500 – 540 nm

–20 ... 100 °C (–4 ... 212°F),

0 ... 250 °C (32 ... 482 °F),

150 ... 900 °C (302 ... 1652 °F)

200 ... 1500 °C (392 ... 2732 °F) (Option)

32 Hz /

125 Hz in subframe mode (640x120 pixels)

29° x 22° / f = 18,7 mm (0.7 in) or

13° x 10° / f = 41 mm (1.6 in) or

53° x 40° / f= 10.5 mm (0.4 in) or

80° x 56° / f = 7.7 mm (0.3 in)

75 mK PI 450: 90 mK

±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±1 % of reading (object temp. <1400 °C) (<2552 °F)

USB 2.0 / optional USB to GigE (PoE) interface USB 2.0 / optional USB to GigE (PoE) interface

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

1)

,

(PI 450: 25 µm pitch

PI 640: 17 µm pitch)

(switchable to 27 Hz)

PI 640: 640 x 480 pixels @ 32 Hz

640 x 120 pixels @ 125Hz

–20 ... 100 °C (–4 ... 212°F),

0 ... 250 °C (32 ... 482 °F),

150 ... 900 °C (302 ... 1652 °F)

4)

PI 450: 10° x 8° (F=1.1) / f= 44 mm (1.7 in)

PI 640: 12° x 9° (F=1.1) / f= 44 mm (1.7 in)

Smallest measuring spot:

PI 450: 42 µm / PI 640: 28 µm

PI 640: 120 mK

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

1)

(PIF)

Industrial PIF

Ambient temperature (T

(optional)

)

Amb

Storage temperature

Relative humidity

Size / Class

Weight

Shock/ Vibration

Tripod

Power supply

Scope of supply (standard)

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

0 ... 50 °C (32 ... 122 °F) PI 450: 0 ... 70 °C (32 ... 158 °F)

– 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 85 °C (–40 .. 185 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F)

20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing

46 (1.81) x 56 (2.00) x 76 – 100 mm

(2.99 - 3.94 in) (depending on lens and focus

position)/ IP 67 (NEMA 4)

320 g (11.3 oz), incl. lens 370 g, (13.1 oz), incl. lens 320 g, incl. lens 320 g (11.3 oz), incl. lens 320 g (11.3 oz), incl. lens 320 g (11.3 oz), incl. lens

IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2

1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC

via USB via USB via USB via USB via USB via USB

• USB camera with 1 lens

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Robust hard shell case

®

PIX Connect

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

PI 640: 0 ... 50 °C (32 ... 122 °F)

46 (1.81) x 56 (2.00) x 119 – 126 mm

(4.69 - 4.96 in) (depending on focus position)/

IP 67 (NEMA 4)

• USB camera

• Standard lens (PI 450: O29; PI 640: O33)

• Mikroscope lens (MO44)

• Mikroscope stand

• Standard USB cable (1 m [3.3 ft])

• Standard PIF

• Manual

• Software package optris

• Robust hard shell case

®

PIX Connect

FPA, uncooled (25 µm pitch)

382 x 288 pixels

200 ... 1500 °C (392 ... 2732 °F) 200 ... 1500 °C (392 ... 2732 °F) 450

80 Hz / switchable to 27 Hz 32 Hz / 125 Hz in subframe mode (640x120

229° x 22° / f = 18,7 mm (0.7 in) or

13° x 10° / f = 41 mm (1.6 in) or

53° x 40° / f= 10.5 mm (0.4 in) or

80° x 56° / f = 7.7 mm (0.3 in)

130 mK 130 mK < 1 K (700 °C) (1292 °F)

USB 2.0 / optional USB to GigE (PoE) interface USB 2. 0 / optional USB to GigE (PoE) interface

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

– 40 ... 70 °C (–40 ... 158 °F) / 0 ... 50 °C (32 ... 122 °F) 5 ... 50 °C (41 ... 122 °F) 5 ... 50 °C (41 ... 122 °F)

46 (1.81) x 56 (2.00) x 76 – 100 mm

(2.99 - 3.94 in) (depending on lens and focus

position)/ IP 67 (NEMA 4)

• USB camera with 1 lens

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cabel with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Robust hard shell case

®

PIX Connect

14

Page 15

innovative infrared technology

Optics calculator: www.optris.com/optics-calculator

PI 640 G7

PI 1M PI 05M

FPA, uncooled (17 µm pitch) CMOS (15 µm pitch) CMOS (15 µm pitch)

640 x 480 pixels 764 x 480 pixels @ 32 Hz

382 x 288

pixels

@ 80 Hz (switchable to 27 Hz)

72 x 56 pixels @ 1 kHz

764 x 8 pixels @ 1 kHz (fast line-scan mode)

5)

... 1800 °C (8425) ... 3272 °F) (27 Hz mode)

5)

... 1800 °C (9325) ... 3272 °F) (80 Hz and

500

32 Hz mode)

5)

... 1800 °C (11125) ... 3272 °F) (1 kHz mode)

600

Up to 1 kHz / 1 ms real time analog output

Pixel)

33° x 25° (f = 18.7 mm) (0.7 in)

15° x 11° (f = 41.5 mm) (1.6 in)

60° x 45° (f = 10.5 mm) (0.4 in)

90° x 64° (f = 7.7 mm) (0.3 in)

(0 - 10 V) von 8 x 8 pixels (freely selectable)

FOV @ 764 x 480 px:

39° x 25° (f = 16 mm) (0.6 in)

26° x 16° (f = 25 mm) (1.0 in)

13° x 8° (f = 50 mm) (2.0 in)

9° x 5° (f = 75 mm) (3.0 in)

FOV @ 382 x 288 px:

20° x 15° (f = 16 mm) (0.6 in)

13° x 10° (f = 25 mm) (1.0 in)

7° x 5° (f = 50 mm) (2.0 in)

4° x 3° (f = 75 mm) (3.0 in))

764 x 480 pixels @ 32 Hz

382 x 288 pixels @ 80 Hz (switchable to 27 Hz)

72 x 56 pixels @ 1 kHz

764 x 8 pixels @ 1 kHz (fast line-scan mode)

900 ... 2000 °C (1652 ... 3632 °F) (27 Hz mode)

950 ... 2000 °C (1742 ... 3632 °F) (32 / 80 Hz mode)

1100 ... 2000 °C (2012 ... 3632 °F) (1 kHz mode)

Up to 1 kHz / 1 ms real time analog output

(0 - 10 V) von 8 x 8 pixels (freely selectable)

FOV @ 764 x 480 px:

26° x 16° (f = 25 mm) (1.0 in)

< 2 K (1400 °C) (2552 °F) for 27 Hz, 32 Hz, 80 Hz

< 2 K (1000 °C) (1832 °F)

< 2.5 K (1400 °C) (2552 °F) for 1 kHz

±1,5 % of reading

USB 2. 0 / optional USB to GigE (PoE) interface USB 2. 0 / optional USB to GigE (PoE) interface

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

FOV @ 382 x 288 px:

13° x 10° (f = 25 mm) (1.0 in)

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

46 (1.81) x 56 (2.00) x 76 – 100 mm

(2.99 - 3.94 in) (depending on lens and focus

position)/ IP 67 (NEMA 4)

• USB camera with 1 lens

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

®

PIX Connect

• Robust hard shell case

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

46 (1.81) x 56 (2.00) x 88 – 129 mm (3.46 - 5.08 in) with

protection tube (depending on lens and focus position) / IP

67 (NEMA 4)

• USB camera with 1 lens

• Lens protection tube incl. protective window

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

• Manual

• Software package optris

• Aluminum case

• Optional: CoolingJacket, HT cable

5)

+75 °C (167 °F) higher starting temperature when using optics

with focal length f=50 mm and f=75 mm

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA),

1x fail-safe relays

46 (1.81) x 56 (2.00) x 88 – 129 mm (3.46 - 5.08 in) with

6)

protection tube (depending on lens and focus position) / IP

67 (NEMA 4)

6))

• USB camera with 1 lens

• Lens protection tube incl. protective window

• USB cable (1 m [3.3 ft])

• Table tripod

• PIF cable with terminal block (1 m [3.3 ft])

®

PIX Connect

• Manual

• Software package optris

®

PIX Connect

• Aluminum case

• Optional: CoolingJacket, HT cable

6)

Only applies when using the lens protection tube

15

Page 16

optris

®

PI NetBox

MINI PC FOR OPTRIS® PI SERIES

Stand-alone

solution for

optris

®

PI series

• Miniature PC as an add-on to the

PI series for stand-alone system or

for cable extension via GigE

• Integrated hardware and software

watchdog

• Installation of additional user

software possible

• Status LEDs

• Processor: Intel

®

E3845 Quad Core /

1.91 GHz, 16 GB SSD, 2 GB RAM

• Connections: 2x USB 2.0,

1x USB 3.0, 1x Mini USB 2.0, Micro

HDMI, Ethernet (Gigabit Ethernet),

Micro SDHC / SDXC card

• Operating system: Windows 7

Professional

• Wide supply voltage range (8 – 48 V

DC) or Power over Ethernet (PoE)

• Can be integrated with

CoolingJacket Advanced

General specications

Ambient temperature 0 ... 50 °C (32 ... 122 °F)

Storage temperature –20 ... 75 °C (–4 ... 167 °F)

Relative humidity 10 – 95 %, non-condensing

Material (casing) Anodized aluminum

Dimensions 113 x 57 x 47 mm (4.4 x 2.2 x 1.9 in)

Weight 385 g (13.6 oz)

Vibration IEC 60068-2-6 (sine-shaped) / IEC 60068-2-64 (broadband noise)

Shock IEC 60068-2-27 (25 G and 50 G)

Operating system Windows 7 Professional

Electrical specications

Voltage supply 8 – 48 V DC or Power over Ethernet (PoE / 1000BASE-T)

Power consumption 7.5 W (+ additional 2.5 W for PI camera)

Cooling Active via two integrated fans

Module COM Express

Processor Intel

Hard drive 16 GB SSD

RAM 2 GB (DDR2, 533 MHz)

Connections 2x USB 2.0, 1x USB 3.0, 1x Mini USB 2.0, Micro HDMI, Ethernet (Gigabit Ethernet)

Memory card slots micro SDHC / SDXC card

Additional features 4x Status LEDs

®

mini embedded board

®

E3845 Quad Core, 1.91 GHz

Stand-alone solution with GigE remote access

Analog OUT / IN

Digital IN

PI Process

Interface

8 – 48 V DC

HDMI

PIX Connect

Network

GigE

Control monitor

USB Keyboard / Mouse

PC

16

Remote access / setup

Page 17

optris

®

USB Server Gigabit 2.0

SIMPLE CABLE EXTENSION

innovative infrared technology

Simple cable

extension for the

optris

optris

®

PI series and

®

Xi 400

• Fully compatible with USB 2.0, Data

transfer rate 1.5 / 12 / 480 mbps, USB

transfer mode: isochronous

• Network connection via

Gigabit Ethernet

• For all models in the optris

as well es the optri

• Full TCP/IP support incl. routing

and DNS

Technical data

USB connections 2 x USB A Port

USB speed 480 Mbit/s

Network 10/100/1000 BaseT (max. 1000 Mbit/s)

Power supply Power over Ethernet (PoE) class 3 (6.49 – 12.95 W) or

Power consumption External power supply (24 V DC) without USB devices: typ. 120 mA

Ambient temperature Storage: – 40 ... 85 °C (–40 ... 185 °F)

s®

®

PI series

Xi 400

via screw terminal DC 24 V ... 48 V (+/–10 %)

External power supply (24 V DC) with 2 USB devices each 2.5 W : typ. 420 mA

In operation, individually assembled: 0 ... 50 °C (32 ... 122 °F)

• Two independent USB connections

• Power via PoE or external voltage

supply at 24 – 48 V DC

• Galvanic isolation 500 V

(network connection)

• Remote conguration via web-based

management

• Certied technology from

Wiesemann & Theis

RMS

Permissible relative

humidity

Casing Compact plastic casing for DIN rail mount, 105 x 75 x 22 mm (4.13 x 2.95 x 0.87 in)

Weight 200 g (7.1 oz)

Contents • 1 x USB Server Gigabit

Protocols

USB protocols USB 1.0 / 1.1 / 2.0 Control / Bulk / Interrupt / Isochronous

Protocols for direct network connection

Connection options

0 – 95 % (non-condensing)

• 24 V DC wall plug transformer

• Quick guide*

* Included on PIX Connect CD or Compact Connect CD:

– USB-Redirector

– WuTility Management Tool

– Operating instructions (DE / EN)

TCP/IP: Socket

Auxiliary protocols: ARP, DHCP, HTTP, PING Inventory keeping,

group management

Network / Internet

24 – 48 V DC or

Power over Ethernet

PoE

PC

PIX Connect /

CompactConnect

17

Page 18

optris

®

CoolingJacket

UNIVERSAL PROTECTIVE HOUSING FOR

COOLING UP TO 315 °C (599 °F)

Universal protection

for the optris

®

PI

series in harsh

industrial

environments

• Operation at ambient temperatures

of up to 315 °C (599 °F)

• Air/Water cooling with integrated

air purging and optional protective

windows

• Modular design for easy tting of

dierent devices and lenses

Technical

data

Protective rating

Ambient

temperature

Relative

humidity

Material (casing)

Dimensions 237 mm x 117 mm x 138 mm

CoolingJacket CoolingJacket

IP 52 IP 65 IP 65

up to 180 °C (356 °F) up to 315 °C (599 °F)

10 – 95 %,

non-condensing

V2A V2A V2A

(9.33 in x 4.61 in x 5.43 in)

• Trouble-free, on the spot sensor

removal via quick-release chassis

• Integration of additional components

like PI NetBox, USB Server Gigabit

and Industrial Process Interface (PIF)

in the extended version

Advanced Standard

1)

10 – 95 %,

non-condensing

271 mm x 166 mm x 182 mm

(10.7 in x 6.54 in x 7.17 in)

CoolingJacket

Advanced Extended

up to 315 °C (599 °F)

10 – 95 %,

non-condensing

426 mm x 166 mm x 182 mm

(16.8 in x 6.54 in x 7.17 in)

1)

Dimensions in mm

Weight 4.5 kg (9.9 lbs) 5.7 kg (12.6 lbs) 7.8 kg (17.2 lbs)

Air purge collar G1/4″ internal thread

Cooling water

ttings

Cooling water

pressure

Contents • CoolingJacket, consisting

1)

Cable for up to 250 °C (482 °F) ambient temperature as well as cable cooling for up to 315 °C (599 °F) available.

2)

Focusing unit and front part are exchangeable and have to be ordered seperately.

CoolingJacket Advanced – Standard versionCoolingJacket Advanced – Extended version

G3/8″ external thread

G1/4″ internal thread

G3/8″ external thread

max. 15 bar (217 psi) max. 15 bar (217 psi) max. 15 bar (217 psi)

of housing and chassis

G1/4″ internal thread

G3/8″ external thread

G1/4″ internal thread

G3/8″ external thread

• CoolingJacket Advanced,

consisting of housing with

mounting brackets, chassis

and focusing unit respectively front part

• Installation instructions

2)

CoolingJacket

G1/4″ internal thread

G3/8″ external thread

G1/4″ internal thread

G3/8″ external thread

• CoolingJacket Advanced,

consisting of housing with

mounting brackets, chassis

and focusing unit respectively front part

• Mounting accessories for

– PI Netbox or

USB Server Gigabit

– Industrial PIF

• Installation instructions

2)

18

142 (5.6)

166 (6.5)

approx. 426 (16.8)

142 (5.6)

166 (6.5)

approx. 271 (10.7)

114 (4.5)

138 (5.4)

Ø 88.90

R5

229 (9.0)

Page 19

optris

®

laminar air purge

AIR PURGE FOR RUGGED ENVIRONMENTS

innovative infrared technology

Laminar air purge for

rugged environments

• Protection for rugged environments

• Air and water cooling, exible laminar

air stream for protection from dirt and

dust

• Easy maintenance due to folding

mechanism

Technical data

Protective rating IP 65

Ambient temperature Up to 315 °C (599 °F) (with water cooling)

Material Aluminum

Dimensions (B x H x T) 200 x 189 x 43 mm (7.87 x 7.44 x 1.69 in)

Weight 1.9 kg (4.2 lb)

Air purge connection NW 7.2

Cooling water

connection

G3/8″ external thread

• Focussable from the outside once

installed

• Protection window for mechanical

protection integrated

• Also available as line scanner version

Cooling water pressure Max. 8 bar

Volume ow

Air pressure 1.1 - 8 bar

Protective window Necessary

Version/Options Also available as line scan option

1)

A protective window (67 x 3 mm) has to be ordered separately.

Dimensions in mm

Laminar air purge: standard model Laminar air purge: line scan model Laminar air purge: connections

120 l/min

1)

19

Page 20

optris

®

Industrial Process Interface

WITH FAIL-SAFE MONITORING

Camera and

process control

for use in an

industrial

environment

• Industrial Process Interface for

PI series and Xi 400 with 3 analog-/

alarm outputs, 2 analog inputs,

1 digital input, 3 alarm relays

• Industrial Process Interface for Xi 80

with 3 analog-/alarm outputs, 3 inputs

(analog or digital), 3 alarm relays

• 500 V AC

isolation voltage

RMS

• Separate fail-safe relay output

• The PI / Xi hardware with all cable connections and the PIX Connect software

are permanently monitored during

operation

• Combination of up to 3 PIFs when

using the Xi 80

between camera and process

General specications

Protective rating IP65 (NEMA-4)

Ambient temperature –30 ... 85 °C (–22 ... 185 °F)

Storage temperature –30 ... 85 °C (–22 ... 185 °F)

Humidity 10 – 95 %

Vibrational stability IEC 60068-2-6 (non condensing)/ IEC 60068-2-64 (broadband noise)

Shock stability IEC 60068-2-27 (25 G and 50 G)

Weight 610 g (21.5 oz) (with 5 m (16.4 ft) cable)

Cable lengths 5 m (16.4 ft) HT cable (standard), optional 10 m (32.8 ft) and 20 m (65.6 ft)

Electrical specications

Xi 80 PI series and Xi 400

Voltage supply 5 – 24 V DC 5 – 24 V DC

LED indicators 2 green LEDs for voltage and fail-safe /

Isolation 500 V AC

Outputs 3 analog- / alarm outputs / 3 alarm relays

Inputs 3 inputs (analog or digital) 2 analog inputs / 1 digital input

Ranges 0/4–20 mA or 0–10 V (for A01–3),

3 red LEDs for status of alarm relays

between camera and

RMS

process

0–10 V or 24 V (for inputs 1–3),

0–30 V/400 mA (for alarm relays DO

1–3)

2 green LEDs for voltage and fail safe /

3 red LEDs for alarm relay status

500 V AC

process

1

3 analog / alarm outputs / 3 alarm relays

0 – 10 V (for AO 1 – 3)

0 – 30 V / 400 mA (for alarm relays

DO1 – 3), 0 – 10 V (for AI 1 – 2),

24 V (for DI)

between PI camera and

RMS

2)

Programmable functions

Analog inputs • Emissivity setting

• Ambient temperature compensation

• Reference temperature

• Uncommitted value

Digital input • Flag control

• Triggered snapshots, triggered recordings, triggered line scan camera,

triggered event grabber, max./min. search reset

• Flag control

• Triggered snapshots, triggered recordings, triggered line scan camera,

triggered event grabber, max./min.

search reset

1)

20

Analog outputs • Main measurement range

1)

Active when AO1, 2 or 3 is / are programmed as alarm output 2) Dependent on supply voltage

• Measurement range

• Internal temperature

• Flag status

• Alarm

• Frame sync.

• Fail-Safe

• External communication

Page 21

optris

®

Outdoor protective housing

UNIVERSAL PROTECTIVE HOUSING FOR THE

INFRARED CAMERAS OF THE OPTRIS® PI SERIES

innovative infrared technology

Universal outdoor

protection for

infrared cameras of

the optris

®

PI series

• Environmental rating IP 66

• Additional air purge collar allows for a continuous operation in dusty

and humid conditions

• Heating element and built-in fan enable for a 24/7 operation from –40 (–40 °F) to

50 °C (122 °F)

• Installation of USB Server Gigabit possible for integration

into control systems over large outdoor distances

Specications

Environmental rating IP 66

Ambient temperature –40 ... 50 °C (–40 ... 122 °F)

Heating PTC heater (automatically starting at T< 15 °C (T< 59 °F)) /

fan for homogeneous temperature distribution

Power supply 24 V DC

Power 70 W

Protective window Germanium (Ge), zinc sulfide (ZnS), Borofloat or foil

Air purge collar Integrated

Integrable additional

components

Max. FOV 90° (HFOV)

Accessories Optional wall mount bracket

Example of fail-safe monitoring of the PI camera with connected PLC

PIF terminal box for convenient

5 – 24 V DC

[1]

[3]

[4]

[5]

Fail-Safe-Status:

Normal: Relais closed LED on

Alarm: Relais open LED o

connection of process cables

FS

open [1–5]

PC

PIX Connect

[6]

USB Server Gigabit

Industrial Process interface (PIF)

[2]

PLC

Vcc

R

Digital IN

Fail-safe monitoring states

[1] Loss of PIF power supply

[2] Cable break in fail-safe cable

[3] Interruption of PI-PIF

connector cable

[4] PI camera malfunction

[5] Loss of PI power supply/

Interruption of USB cable

[6] Malfunction of PIX Connect

software

Low = OK

High = FS

21

Page 22

optris

®

SOFTWARE

PIX Connect

Comprehensive

IR camera software

Real-time temperature information in main window,

as digital display or as

graphic

• No additional costs or licensing restrictions

• Modern software with intuitive user interface

• Remote control of camera

• Display of numerous images in dierent windows

• Compatible with Windows 7, 8 and 10 as well as Linux (ubuntu)

• Two Software Development Kits for Windows and Linux included

• Various language options, incl. translation function

• Temperature display in °C or in °F

Pre-dened layouts make it quick and easy to start with your

applications. And because we know that every measurement

task has its own individual requirements, we have ensured

that it is quite easy to adapt the preset layout to suit your

individual requirements.

The user interface of the PIX Connect software can

also be adapted to suit your personal

workow: Software windows can be

easily arranged using drag & drop; in

the toolbar you can save shortcuts for

functions relevant to your appli-

cation – or even remove links

which you do not need.

Our layouts – as individual

as your applications

The PIX Connect software makes a wide range of preset

color palettes available. This allows optimal depiction of

thermal contrasts. The pre-dened color palettes can be

individually adapted to be able to cater for the specic requi-

rements of your respective application.

Associated temperature groups (isotherms) can be identi-

ed by color markers and highlighted. It is also possible to

dene temperature values in advance; pixels above, below,

or between these values are highlighted in color.

Regardless of whether you

are working on a desktop PC or

a tablet, the user interface can be adap-

ted.

The right color palette for

every application

22

Page 23

Measuring areas

innovative infrared technology

It is not just a matter of

size, but also depends on

the content: designing a

suitable measurement area

The size and shape of measurement area can be freely designed and moved. For an easy introduction, a large selec-

tion of pre-dened measurement area shapes is available.

You can set up as many measurement areas as you like in

the camera's eld of view. To do this, it is possible to make a

distinction between main and ancillary elds.

Various modes can be set in a measurement area, such as

minimum value, maximum value, or average value, or you

can rule out the detection of hot or cold spots.

The separate setting of the emissivity for measurement

areas allows various material surfaces to be monitored with

a single camera.

Dierences and averaging between dierent measurement

areas are easy to calculate with the PIX Connect software.

Saved measurement areas can be displayed as an image,

a digital display or a diagram and can then be saved for

further analysis.

Graphic display of the temperature values

Temperature values can be shown along a straight line as

temperature proles as well as as 3D diagrams.

A temperature/time diagram can be used to analyze the

temperature development over time. Individual time sections

can be lifted out of the diagram and be analyzed in detail by

zooming in and out.

Diagrams dened in this way can be exported from the software and be saved in Excel for further analysis.

23

Page 24

optris

®

PIX Connect

FEATURES

Recording and display

Recording video sequences for

later analysis and documentation

The snapshot option works like a screenshot; an individual

image is recorded from the live picture. This snapshot is

a radiometric image (*.ti), where all the temperature and

measurement area information at the time of the recording

is saved for every pixel.

The software can be used to save the recording from the

thermal imaging camera as video sequences which can

then be saved for analysis later on. The video sequence is

recorded for every pixel including all temperature information. An integrated screen capture function makes it simple to

retrospectively generate videos in wmv format.

BI-SPECTRAL video analysis where both an IR as well as

a VIS image are recorded makes it easy to highlight critical

temperature ranges.

Videos recorded can be processed retrospectively. For example, individual sections can be cut out of a recording and

can be saved as an independent sequence.

Saved video recordings are available for analysis. The sequences can be played back in slow motion or time lapse for

this purpose. It is also possible to play back as a continuous

loop.

Snapshots – all temperature

information in one picture

The snapshots can be saved as text format for detailed

analysis, i.e. as text image data (.csv format) and can then

be made available for analysis in Excel. It is also possible to

continue processing the image data with standard programs

such as Photoshop or Windows Media Player.

The recorded images can be rotated and reversed, and you

can also magnify individual sections of them. 3D display is

also possible.

24

Page 25

Merging

The fields of vision of three cameras (top) are converted into one single image

via the merging function (right)

The merging function

combines several

camera angles together

in a single picture

innovative infrared technology

The PIX Connect software gives you the option of grouping

together several cameras within a software instance, i.e.

the eld of view of several infrared cameras are merged together to make a single picture. For processes with several

control points in particular, it is helpful to concentrate the various angles on one screen. Merging several cameras also

makes it possible to get an all-round view of a 3D object.

You can merge several cameras either using a direct USB

connection or via Ethernet. While in the rst case, every

camera needs to have its own USB port; for the second option, one Ethernet connection is enough. The cameras here

are each connected to the Ethernet switch on the PC via a

USB Server Gigabit 2.0.

Alarms

Various alarms can be activated for measurement areas as

well as for previously dened temperature values or ranges

using the PIX Connect software. Apart from minimum and

maximum values, it is also possible to set so-called advance alarms. These will emit a warning when the measured

temperature approaches the dened minimum or maximum

value, therefore giving you more options and time to react.

If the measured temperature reaches one of these previous-

ly dened values, then the software will trigger an alarm. In

addition to that, the critical event can be easily documented

as a snapshot or video recording and be used for analysis

later on.

Dening several alarm

values allows quick

intervention

25

Page 26

optris

®

PIX Connect

LINE SCAN CAMERA SOFTWARE MODE

For the

measurement

of moving

objects

The advantages

Heating zone

Product

The optris

equipped with a line scan camera

function. The line scanner is primarily

used for processes involving moving

measurement objects, like rotary kiln

measurements or large quantities on

conveyor belts (batch process).

Simple monitoring of processes

with limited visual access

IR camera

Cooling zone

®

PIX Connect software is

Indirect visualization

of heat distribution in

ovens via camera

installation at oven exit

Example of usage:

rotary kiln in the chemical industry

Only 3 steps

to initialize

the function

Step 1

Activation of the line scan

camera function (continuous,

self-triggered, external

trigger) and denition of the

position of the lines in the

thermal image. For this the

camera itself serves as an

orientation aid.

640 pixels

111°

Reference pyrometer

800 pixels

Lines have FOV of up to 111° for

detailed process analysis, e.g on

wide conveyor belts

any number of lines

800 pixels

Up to 32 Hz data recording*

of unlimited lines which in turn

produce a thermal image of any

given resolution

Increase in the number

of pixels, e.g. from

640 pixels to 800 pixels

by using diagonal screen

measurement

Step 2

Conguration of line scan

function, e.g. number of lines

displayed or set trigger for

automatic saving of images.

Step 3

Denition of individual layouts,

e.g. display of saved images

in the snapshot process.

Layout example for display of line scan

camera function

* Up to 125 Hz data recording when using 90° lense in subframe mode (640 x 120)

26

Page 27

Optical data

OPTICS

innovative infrared technology

Precise measuring at various

distances

A choice of lenses allows you to precisely measure objects

at various distances, from close and standard distances right

up to large distances. The IR cameras of the optris® PI series

allow for changing between several lenses.

With infrared cameras there are

various parameters which display

the relationship between the distance from the measuring object and the size of the pixel on the object plane. In choosing

the correct lens, the following should be taken into

account:

Measuring field of optris® PI

infrared camera using a 23° x 17° lens

1.26 mm

(0.05 in)

0.2 m

(0.66 ft)

HFOV

Horizontal expansion of the total measuring

eld on the object plane.

VFOV

Vertical expansion of the total measuring eld

on the object plane

IFOV

Size of individual pixels on the object plane

DFOV

Diagonal expansion of the total measuring eld

on the object plane

MFOV

Recommended, smallest measuring object size

of 3 x 3 pixels or 2 x 2 pixels when using the

PI microscope optics or the Xi 80, respectively

IFOV

10 mm

(0.4 in)

5 mm

(0.2 in)

0.81 m

(2.66 ft)

0.5 m (1.64 ft)

4 m (13.1 ft)

Optics calculator

Measurement eld sizes

for any given distance can

be calculated online at

www.optris.com/optics-calculator

2 m (6.6 ft)

VFOV 1.20 m (3.94 ft)

DFOV 2.04 m (6.70 ft)

HFOV 1.61 m (5.29 ft)

27

Page 28

Optical data

OPTICS

Xi 80

80 x 80 px

F05

Standard lens

F13

Telephoto lens

Focal length

[mm]

Minimum

5 0,2 m

13 0,3 m

(0.7 ft)

(1.0 ft)

measurement

distance*

30°

30°

43°

6.67 mrad

12°

12°

17°

2.66 mrad

Angle

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

0.05

(0.002)

0.028

(0.001)

0.028

(0.001)

0.039

(0.12)

0.33

(1.08)

(0.001)

0.056

(0.002)

0.056

(0.002)

0.079

(0.003)

(0.03)

0.022

(0.001)

0.022

(0.001)

0.031

(0.001)

(0.01)

Distance to measurement object [m]

0.1

0.2

0.3

0.5

(0.01)

(0.01)

(0.02)1 (0.04)2 (0.08)4 (0.16)6 (0.24)

(0.004)

(0.004)

(0.006)

0.279

(0.01)

0.279

(0.01)

0.39

(0.02)

3.33

(0.13)

0.11

0.11

0.15

1.3

(0.05)

(0.008)

(0.008)

0.67

0.3

(0.004)

(0.004)

(0.006)

(0.002)

(0.002)

(0.002)

0. 111

0. 111

0.158

1.33

(0.05)

0.043

0.043

0.061

0.5

(0.02)

(0.007)

(0.007)

(0.009)

(0.003)

(0.003)

(0.004)

0.167

0.167

0.24

2.0

(0.08)

0.065

0.065

0.092

0.8

(0.03)

0.557

(0.02)

0.557

(0.02)

0.79

(0.03)

6.67

(0.26)

0.21

0.21

0.30

(0.01)

2.7

(0.11)

10

30

100

(0.39)

(1.18)

(3.94)

55.8

(2.20)

55.8

(2.20)

78.9

(3.11)

666.67

(26.3)

21.3

(0.84)

21.3

(0.84)

30.1

(1.19)

265.6

(10.1)

1.115

2.230

3.346

(0.04)

(0.09)

(0.13)

1.115

2.230

(0.09)

3.15

(0.12)

26.67

(1.05)

0.85

(0.03)

0.85

(0.03)

1.20

(0.05)

10.6

(0.42)

3.346

(0.13)

(0.19)

40.00

(1.57)

1.28

(0.05)

1.28

(0.05)

1.81

(0.05)

15.9

(0.63)

(0.04)

1.58

(0.06)

13.33

(0.53)

0.43

(0.02)

0.43

(0.02)

0.60

(0.06)

5.3

(0.21)

4.7

5.6

(0.22)

5.6

(0.22)

7.9

(0.31)

66.67

(2.63)

2.1

(0.08)

2.1

(0.08)

3.0

(0.12)

26.6

(1.05)

16.7

(0.66)

16.7

(0.66)

23.7

(0.93)

200.00

(7.89)

6.4

(0.25)

6.4

(0.25)

9.0

(0.35)

79.7

(3.14)

F03

Wide angle lens

F02

Wide angle lens

3 0,2 m

(0.7 ft)

2 0,2 m

(0.7 ft)

55°

55°

79°

11.15 mrad

80°

80°

113°

15.45 mrad

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

0.057

(0.002)

0.057

(0.002)

0.080

(0.003)

0.6

(0.02)

0.090

(0.004)

0.090

(0.004)

0.127

(0.005)

0.08

(0.03)

(0.006)

(0.007)

(0.007)

0.110

(0.04)

0.110

(0.04)

0.156

1.2

(0.05)

0.174

0.174

0.246

(0.01)

1.6

(0.06)

(0.009)

(0.009)

(0.012)

(0.014)

(0.014)

0.218

0.218

0.308

2.3

(0.09)

0.343

0.343

0.483

(0.02)

3.2

(0.13)

(0.013)

(0.013)

(0.018)

0.325

0.325

0.459

3.4

(0.13)

0.509

(0.02)

0.509

(0.02)

0.72

(0.03)

4.7

(0.19)

(0.021)

(0.021)

0.539

0.539

0.762

(0.03)

5.6

(0.22)

0.884

(0.04)

0.88

(0.04)

1.19

(0.05)

7.8

(0.31)

106.7

(6.60)

106.7

(6.60)

150.9

(5.94)

1114.8

(43.9)

167.5

(6.59)

167.5

(6.59)

236.9

(9.32)

1545.5

(60.8)

1.07

2.14

4.27

6.41

10.7

32.0

(0.04)

(0.08)

(0.17)

(0.25)

(0.42)

(1.26)

1.07

2.14

4.27

6.41

10.7

15.1

111. 5

16.8

16.8

23.7

32.0

(1.26)

45.3

(1.78)

334.5

(13.2)

50.3

(1.98)

50.3

(1.98)

71.1

(2.80)

463.7

(18.3)

(0.04)

(0.08)

(0.17)

(0.25)

(0.42)

1.52

3.02

6.04

44.6

9.49

61.9

9.06

(0.36)

66.9

(2.63)

10.058

(0.40)

10.058

(0.40)

14.2

(0.56)

92.8

(3.65)

(0.60)

(4.39)

(0.66)

(0.66)

(0.93)

154.6

(6.09)

(0.06)

(0.12)

(0.24)

11.2

2.38

15.5

(0.132)

(0.132)

22.4

(0.88)

3.357

3.357

4.75

(0.19)

31.0

(1.22)

(1.76)

6.708

(0.26)

6.708

(0.26)

(0.37)

(2.44)

(0.44)

1.682

(0.07)

1.682

(0.07)

(0.09)

(0.61)

Table with examples showing which measurement field sizes and pixel sizes will be reached at which distance. For optimal configuration of the camera there are various

lenses available. Wide angle lenses have radial distortion due to the angle of their aperture. The PIX Connect software has an algorithm which corrects this distortion.

* Please note: Please use the optics calculator on our website in order to calculate measurement fields with shorter measurement distances: http://www.optris.com/optics-calculator

The measurement accuracy of the camera may lie outside of the specifications for distances below the defined minimum measurement distance.

1)

PI 05M is only available with OF25 optics

28

Page 29

innovative infrared technology

Xi 400

382 x 288 px

F12

Standard lens

F20

Telephoto lens

Focal length

[mm]

Minimum

13 0,2 m

20 0.3 m

(0.7 ft)

(1.0 ft)

measurement

distance*

Angle

29°

22°

37°

1.34 mrad

18°

14°

23°

0.85 mrad

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

0.05

(0.002)

0.1

(0.001)

0.051

(0.002)

0.038

(0.001)

0.064

(0.03)

0.1

(0.00)

Distance to measurement object [m]

0.2

0.3

0.5

(0.001)

0.104

(0.004)

0.078

(0.003)

0.130

(0.005)

0.263

(0.01)

0.068

(0.03)

0.051

(0.002)

0.086

(0.003)

0.170

(0.05)

(0.006)

(0.005)

(0.008)

(0.004)

(0.003)

(0.005)

(0.01)

(0.02)1 (0.04)2 (0.08)4 (0.16)6 (0.24)

(0.021)

0.53

0.39

(0.02)

0.66

(0.03)

1.3

(0.05)

0.33

(1.08)

0.25

(0.01)

0.41

(0.02)

0.9

(0.04)

0.16

0.12

0.20

0.4

(0.02)

0.101

0.076

0.13

0.26

(0.01)

(0.008)

0.26

(0.01)

0.20

0.33

(1.08)

0.7

(0.03)

0.17

(0.07)

0.13

(0.05)

0.21

(0.08)

0.4

(0.02)

1.06

(0.04)

0.79

(0.03)

1.32

(0.05)

2.7

(0.11)

0.66

(0.03)

0.49

(0.02)

0.82

(0.03)

1.7

(0.07)

10

30

100

(0.39)

(1.18)

(3.94)

2.11

3.17

(0.08)

(0.13)

1.58

2.64

5.4

1.31

0.99

1.64

3.4

2.36

(0.09)

3.96

(0.16)

(0.32)

1.97

(0.08)

1.48

(0.06)

2.46

(0.10)

(0.20)

(0.06)

(0.10)

(0.21)

(0.05)

(0.04)

(0.07)

(0.13)

8.1

5.1

5.3

15.9

(0.21)

(0.63)

3.9

6.6

13.4

3.3

2.5

4.1

8.5

11.8

(0.47)

19.8

(0.80)

40.3

(1.59)

9.8

(0.39)

7.4

(0.29)

12.3

(0.48)

25.5

1.00)

(0.15)

(0.26)

(0.53)

(0.31)

(0.10)

(0.16)

(0.33)

52.9

(2.08)

39.4

(1.55)

66.0

(2.60)

134.4

(5.29)

32.7

(1.29)

24.6

(0.97)

40.9

(1.61)

85.0

(3.35)

F08

Wide angle lens

F06

Super wide angle

lens

8 0,2 m

(0.7 ft)

6 0,2 m

(0.7 ft)

53°

38°

66°

2.20 mrad

80°

54°

94°

3.01 mrad

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

HFOV [m]

VFOV [m]

DFOV [m]

IFOV [mm]

0.069

(0.004)

0.047

(0.002)

0.084

(0.003)

0.2

(0.01)

(0.004)

(0.003)

(0.005)

(0.006)

(0.004)

(0.007)

0.107

0.076

0.132

0.3

(0.01)

0.149

0.098

0.178

0.3

(0.01)

(0.006)

0.21

(0.08)

0.15

0.25

(0.01)

0.5

(0.02)

0.30

(0.01)

0.20

(0.01)

0.36

(0.01)

0.6

(0.02)

100.0

(3.94)

69.5

(2.73)

121.8

(4.80)

220.0

(8.74)

157.7

(6.21)

101.7

(4.00)

187.6

(7.39)

300.9

(11.85)

0.31

0.51

1.01

2.00

4.00

6.00

10.0

29.9

(0.01)

(0.02)

(0.04)

(0.08)

(0.16)

(0.24)

(0.39)

(1.18)

0.22

0.35

0.70

1.39

2.78

4.87

8.8

6.29

4.06

7.49

12.0

4.17

(0.16)

7.30

(0.29)

13.2

(0.52)

9.43

(0.37)

6.10

(0.24)

11.23

(0.44)

18.1

(0.71)

(0.08)

(0.01)

(0.03)

(0.06)

(0.12)

0.38

0.62

1.23

2.2

1.57

1.01

1.87

3.0

2.44

(0.10)

4.4

(0.17)

3.14

(0.12)

2.03

(0.08)

3.74

(0.147)

6.0

(0.24)

(0.19)

(0.35)

(0.25)

(0.16)

(0.29)

(0.47)

(0.02)

(0.02)

(0.05)

0.7

0.9

1.1

(0.04)

0.78

(0.03)

0.51

(0.02)

0.93

(0.04)

1.5

(0.06)

(0.09)

(0.06)

(0.04)

(0.07)

(0.12)

(0.03)

0.46

(0.02)

0.30

(0.01)

0.55

(0.02)

(0.04)

6.9

12.2

22.0

15.7

10.2

18.7

30.1

20.8

(0.82)

36.5

(1.43)

66.0

(2.60)

47.3

(1.86)

30.5

(1.20)

56.3

(2.22)

90.3

(3.56)

(0.27)

(0.48)

(0.87)

(0.62)

(0.40)

(0.74)

(1.19)

29

Page 30

Optical data

OPTICS

PI 160 / 200

160 x 120 px

O23

Standard lens

Focal length

10 0,2 m

[mm]

Minimum measurement

(0.7 ft)

distance*

23°

17°

29°

2.48 mrad

Angle

HFOV [m (ft)]

VFOV [m (ft)]

DFOV [m (ft)]

IFOV

[mm (in)]

(0.07)

(0.04)

(0.03)

(0.05)

(0.00)

0.02

0.012

0.009

0.015

0.1

0.1

(0.33)

0.043

(0.14)

0.032

(0.11)

0.054

(0.18)

0.3

(0.01)

Distance to measurement object [m (ft)]

0.2

0.3

0.5

(0.66)

(0.98)

(1.64)1 (3.28)2 (6.56)4 (13.2)6 (19.7)

0.08

0.12

0.21

0.41

0.81

(0.26)

0.06

(0.2)

0.10

(0.33)

0.5

(0.02)

(0.39)

0.09

(0.29)

0.16

(0.53)

0.8

(0.03)

(0.69)

0.15

(0.49)

0.26

(0.85)

1.3

(0.05)

(1.34)

0.30

(0.98)

0.51

(1.67)

2.5

(0.10)

(2.67)

0.60

(1.97)

1.01

3.31)

5.0

(0.20)

1.62

(3.90)

1.21

(3.97)

2.02

(6.63)

9.9

(0.39)

2.44

(8.00)

1.81

(5.94)

3.03

(9.94)

14.9

(0.59)

10

(32.8)

4.1

(13.45)

3.0

(9.84)

5.1

(16.7)

24.8

(0.98)

30

(98.4)

12.2

(40.03)

9.0

(29.5)

15.2

(49.9)

74.4

(74.4)

100

(328.1)

40.6

(133.2)

30.1

(98.6)

50.5

(165.7)

248.0

(9.76)

O6

Telephoto lens

O48

Wide angle lens

O72

Wide angle lens

35.5 0.5 m

(1.6 ft)6°

5.7 0,2 m

(0.7 ft)

3.3 0,2 m

(0.7 ft)

5°

8°

0.70 mrad

41°

31°

51°

4.39 mrad

72°

52°

89°

7,51 mrad

HFOV [m (ft)]

VFOV [m (ft)]

DFOV [m (ft)]

IFOV

[mm (in)]

HFOV [m (ft)]

VFOV [m (ft)]

DFOV [m (ft)]

IFOV [

mm (in)]

HFOV [m (ft)]

VFOV [m (ft)]

DFOV [m (ft)]

IFOV [

mm (in)]

0.022

(0.07)

0.016

(0.05)

0.027

(0.09)

0.1

(0.00)

0.039

(0.12)

0.027

(0.09)

0.048

(0.16)

0.2

(0.01)

0.082

(0.27)

0.059

(0.19)

0.101

(0.33)

0.4

(0.01)

0.152

(0.5)

0.106

(0.35)

0.186

(0.61)

0.8

(0.31)

0.16

(0.52)

0.11

(0.36)

0.19

(0.62)

0.9

(0.03)

0.29

(0.95)

0.20

(0.65)

0.36

(1.18)

1.5

(0.06)

0.23

(0.75)

0.17

(0.55)

0.29

(0.95)

1.3

(0.05)

0.43

(1.41)

0.30

(0.98)

0.53

(1.73)

2.3

(0.09)

0.06

(0.19)

0.04

(0.13)

0.07

(0.23)

0.4

(0.01)

0.38

(1.24)

0.28

(0.91)

0.47

(1.54)

2.2

(0.08)

0.72

(2.36)

0.50

(1.64)

0.87

(2.85)

3.8

(0.15).

0.11

(0.36)

0.09

(0.29)

0.14

(0.46)

0.7

(0.02)

0.76

(2.49)

0.55

(1.8)

0.94

(3.08)

4.4

(0.17)

1.42

(4.66)

0.99

(3.24)

1.74

(5.71)

7.5

(0.3)

(11.35)

0.23

(0.75)

0.17

(0.56)

0.28

(0.92)

1.4

(0.05)

1.51

(4.95)

1.10

(3.6)

1.86

(6.1)

8.8

(0.34)

2.84

(9.31)

1.98

(6.49)

3.46

15.0

(0.6)

(22,67)

0.45

(1.48)

0.34

(1.11)

0.57

(1.87)

2.8

(0.11)

3.00

(9.84)

2.19

(7.18)

3.72

(12.2)

17.5

(0.68)

5.66

(18.6)

3.95

(13.0)

6.91

30.0

(1.2)

(14.76)

(33.95)

0.68

(2.23)

0.51

(1.67)

0.85

(2.79)

4.2

(0.16)

4.50

3.28

(10.8)

5.57

(18.3)

26.3

(1.03)

8.49

(27.9)

5.92

(19.4)

10.35

45.0

(1.8)

1.1

(3.6)

0.8

(2.62)

1.4

(4.6)

7.0

(0.27)

7.5

(24.6)

5.5

(18.0)

9.3

(30.5)

43.9