Page 1

innovative infrared technology

Production

Quality Assurance

Research & Development

Test & Measurement

NON-CONTACT

TEMPERATURE MEASUREMENT

PLASTICS INDUSTRY

Page 2

Plastics industry

Wavelength in µm

2 4 6 8 10 12 14 16

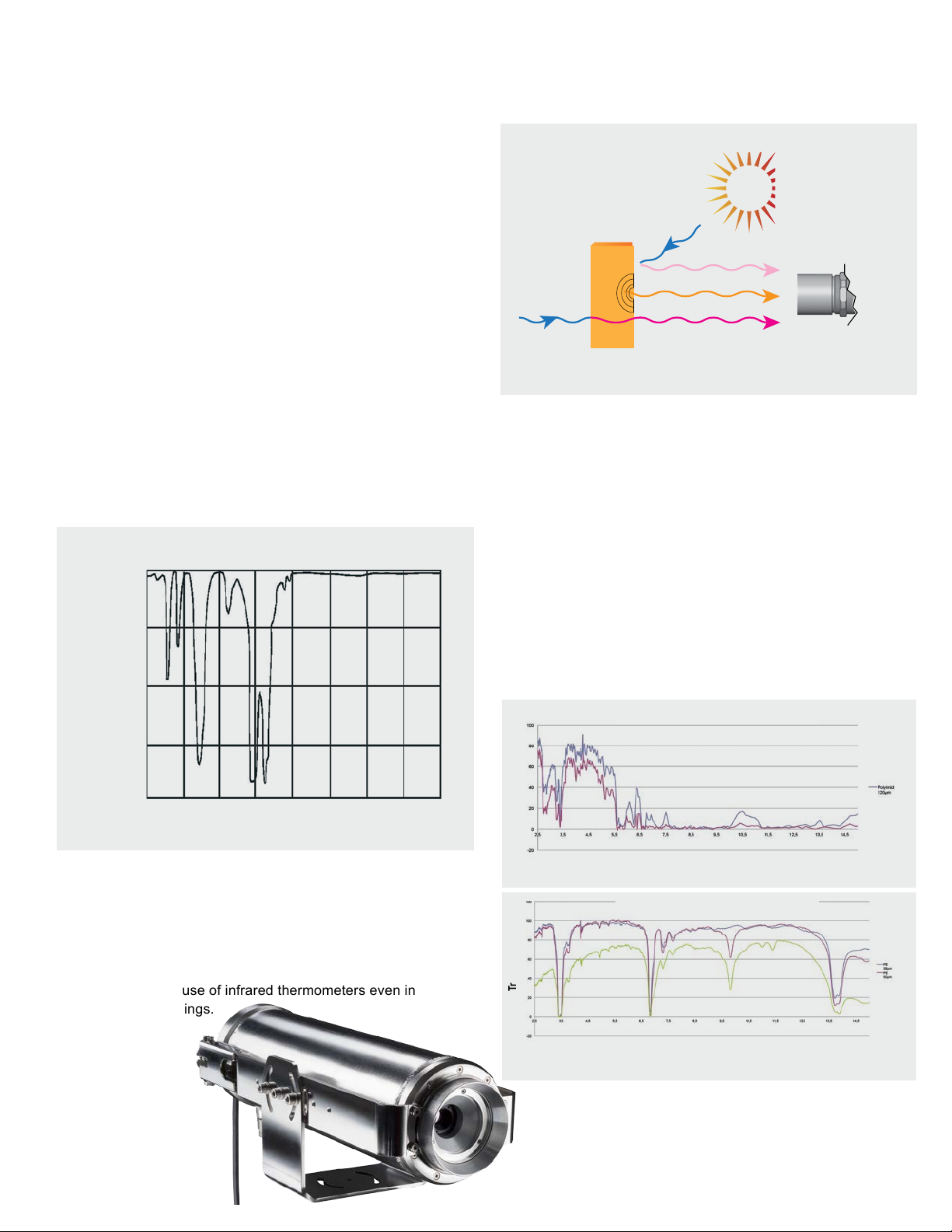

ENGINEERING / PHYSICS

Inuence from the surroundings

The illustration shows that the transmissivity of air strongly

depends on the wavelength. Strong attening alternates with

areas of high transmissivity – the so-called atmospheric windows.

The transmissivity in the long-wave atmospheric window

(8 – 14 µm) is constantly high whereas there are measurable

extinctions by the atmosphere in the shortwave area, which may

lead to false results. Typical measuring windows are

1.1 – 1.7 µm, 2 – 2.5 µm and 3 – 5 µm.

Additional inuences can arise from heat sources in the

environment of the measuring object. To prevent wrong

measuring results due to increased ambient temperatures,

the infrared thermometer compensates the inuence of ambient

temperatures beforehand (as e.g. when measuring temperatures

of plastic foils in heating areas whereby the walls are hotter than

the measuring objects). A second temperature sensing head

helps to generate accurate measuring results by automatically

compensating the ambient temperatures and a correctly adjusted

emissivity.

Radiation

from

ambient

n

T

Object

amb

ρ

n

T

n

T

amb

obj

= α

ε

τ

Sensor

α = Absorption ρ = Reflectance τ = Transmission ε = Emissivity

Compensating ambient influences

Emissivity and temperature measurement

of plastics

Emissivity is a key factor in the accurate measurement

of temperatures. It depends on various inuences and must

be adjusted according to the application.

100

75

Transmissivity in %

50

25

0

Spectral transmissivity of air (1 m, 32 °C (90 °F), 75 % r. F.)

Dust, smoke and suspended matter in the atmosphere can pollute

the optics and result in false measuring data. Here air purge

collars (which are installed in front of the optics with

compressed air) help to prevent deposition of suspended

matter in front of the optics. Accessories for air and water

cooling support the use of infrared thermometers even in

hazardous surroundings.

Emissivity theoretically depends on the material, its surface

quality, wavelength, the measuring angle and, in some cases,

even the applied measuring conguration.

Plastics with a thickness of > 0.4 mm (0.02 in) and pigmented

lms can be measured very easily in the long-wave IR spectral

range (8-14 µm) with emissivities of ≥ 0.9.

IR Transmission of polyimide foil

Transmission [%]

Wavelength [µm]

Transmission of PE foil

Transmission [%]

2

Wavelength [µm]

The CoolingJacket Advanced enables an

operation within an ambient temperature

of up to 315 °C (599 °)

Page 3

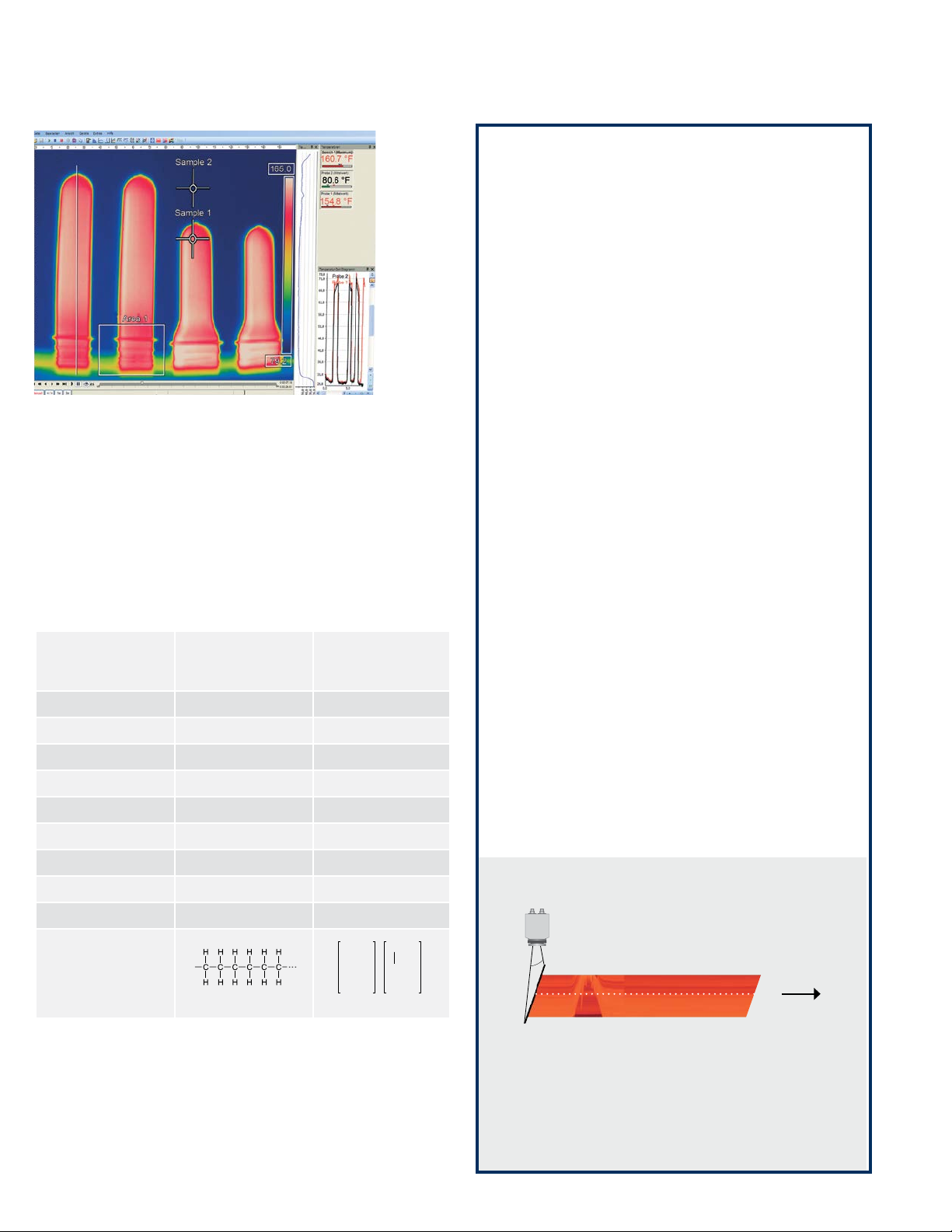

innovative infrared technology

Line scan with compact infrared camera

for thick plastic lms

Plastics processors produce a wide range of products

of various dimensions, thicknesses, textures, colors

and embossed patterns. Here the manufacturing is

subject to numerous thermal processes which have

to be continually and rigorously checked at various

critical points.

In order to ensure quality, a high level of temperature

homogeneity is required and this is checked at

various stages, including during thermoforming and

in the calender zone, by means of a line scan.

In-depth inspection of preforms during bottle production.

Very thin plastic lms are, however, transparent in this spectral

range, meaning that a temperature measurement is only possible

with the aid of material-specic absorption bands in the IR

spectrum via correspondingly narrow-band sensitive IR sensors.

Polyethylene, polypropylene, nylon und polystyrene, for example,

are IR opaque at 3.43 μm; for polyester, polyurethane, Teon,

FEP and polyamide, in contrast, it is 7.9 μm.

C-H band

3.43 μm

P3 > 50 °C (122 °F)

C-F Ester band

7.95 μm

P7 > 0 °C (32 °F)

Polyethylene (PE) Yes No

Polypropylene (PP) Yes No

Cellophane Ye s No

Polystyrene (PS) Yes No

Fluoroplastic (FEP) No Yes

Polyimide No Yes

When using an infrared camera as a line scanner,

an arbitrary line is selected from the detector array.

In addition to the compact construction and the lower

price, there are two signicant benets: the line to

be scanned can be positioned anywhere using the

software and the user receives a complete IR image

quasi as additional information – these are important

advantages, especially during system setup.

The cameras can accurately measure surface temperatures of moving measurement objects using minimal

apertures. This function is of particular signicance

in the plastics industry, since homogeneity of foil

temperature has a direct impact on the quality of the

nal product. During the production process,

temperatures are measured accordingly at many

points and it is possible to intervene in the process,

when necessary, if there are deviations in setpoint

temperatures.

The optris PI 640, in combination with the 90° lens,

allows for high-resolution line scanning with up to

800 pixels and a maximum scan angle of 111° with

the use of the diagonal dimension.

Acrylic Yes Yes

Polycarbonate Yes Yes

Polyester Yes (>10 μm) Yes

F2F

–C–C–C–C–

Polyethylene

Further information in our infrared basics brochure:

www.optris.com/optris-downloads

CF

3

2

F

n m

FEP

Lines have FOV of

up to 111° for detailed

process analysis.

F

2

111 °

any number of lines

800 Pixel

Up to 125 Hz data recording

of unlimited lines which in turn

produce a thermal image of

any given resolution

3

Page 4

Applications of

temperature measurement technology

PRODUCTION OF PLASTICS

The measurement of process, instrument and workpiece

temperatures is a crucial factor in production and quality

control in the plastics industry. In many areas only

non-contact temperature monitoring is possible, and this is

where infrared cameras and infrared thermometers are used.

Optris offers compact cameras in the long-wave range as well

as point sensors.

Flat lm and sheet extrusion

In at lm and sheet extrusion the molten mass is pressed through

a wide slit die and then processed further using a

calender. In this process the lm is gradually cooled. The

infrared sensors measure the temperature of the lm at various

points, thereby monitoring the process. Infrared cameras also

allow cracks and surface defects to be detected.

Injection molding

Infrared

thermometer

Infrared

camera with

line scan

mode

Extruder

Infrared

camera

Infrared

thermometer

Rotational molding

The rotational molding process is a specialist technique used

in the manufacturing of plastic parts and is primarily used for

larger objects. Here a negative mold is lled with a powdered or

liquid raw material such as PE or PP and then sealed. The mold

is then heated in an oven to a maximum of 320 °C (608 °F) and

rotated biaxially. This causes the material to stick to the mold,

layer by layer. The mold is subsequently cooled in a chamber and

the plastic part removed. Upon opening the mold, the product is

thermally tested to allow the production process to be readjusted

if necessary.

Infrared

camera

Injection molding is the most common production process in the

manufacture of moldings from thermoplastic polymers. It is used

in particular in the intermittent mass production of complex moldings where the size of the workpieces ranges from the smallest

of cogs right up to large containers. The weight of a workpiece

starts at 1 mg (0.001 g) and goes up to 100 kg (220.5 lb).

The pellets, often mixed with additives, are added to the cylinder

via the funnel. The pellets are plasticized by the mechanical

friction caused by the movement of the screw inside the cylinder

as well as the external application of heat from the heating bands.

The resulting liquid mass is pushed to the tip of the screw and

is then forced into the die in front of it through the injection unit

nozzle.

The molding compound cools in the die which then opens when

the hardening process is complete. To ensure the high quality of

the molding it requires optimum temperature management,

especially during the cooling phase in the die. The moldings,

meanwhile, are automatically checked for homogenous

temperature distribution immediately after

ejection with infrared cameras.

Further information can be found in our application note “Injection molding” at

www.optris.com/plastics

4

Page 5

innovative infrared technology

Extrusion blow molding of lms

Film

tube

Infrared

thermometer

Infrared camera

Infrared

thermometer

Extruder

Similar to injection molding, the molten mass is pushed out of the

extruder – however, in this case not into a die, rather through a

die with a ring nozzle. The resulting lm tube is then pulled

vertically and blown up in the process. During this process air is

used to cool the tube both inside and out.

From the moment the molten mass emerges from the nozzle, the

temperature of the lm tube needs to be measured at various

points in order to ensure the characteristics and quality of the

product.

Thermoforming

Sheets or unrolled lm made from thermoplastic polymers are fed

into the molding machine and then, in the rst step, warmed up

on both sides until the semi-nished product is completely melted.

When a pre-dened temperature has been reached, the lm is

then sucked into a tempered mold using a vacuum. Only when

the product has cooled down again and is dimensionally stable is

it transported further to be nished.

Further information can be found in our application note “Plastics industry“ at

www.optris.com/plastics

Thermoforming

Heating zone

(Injection) stretch blow molding

For the manufacturing of PET bottles, the stretch blow

molding or injection blow molding processes are used, whereby

the preforms are heated until viscous. The heated forms are then

fully formed in a blow mold using a stretching process. Before

being transported further the bottle is

(Injection) stretch blow molding

Heating zone

Infrared

camera

Temperature control

Molding zone

cooled inside a die. Depending on the texture of the

preform and the desired end product, the preform needs

to be brought up to a process temperature of 100 °C.

Optris PI cameras are used to monitor this process.

5

Page 6

Plastics industry

INFRARED CAMERAS AND INFRARED THERMOMETERS

The optris CT P3 infrared thermometer, with its

extremely narrow-band spectral range of 3.43 µm,

is particularly suited to the temperature

measurement of very thin plastic

materials such as PE, PP and PS.

optris

The temperature range extends from 50 to 400 °C (122 °F to 752 °F)

with a machine response time of 100 ms. The sensing head can

withstand temperatures of up to 75 °C (167 °F) without additional coo-

ling. The lm thermometer‘s separate electronics box is equipped with

easy-to-access programming buttons and a backlit LCD display.

The innovative optris CT P7 infrared thermometer,

with its specic spectral range of 7.9 µm, is particularly suited to the temperature measurement

of thin plastic materials such as PET,

PU, PTFE and PA.

optris

It has a temperature range of 0 to 710 °C ( 32 to 1,319 °F), while the

sensing head is resistant to temperatures of up to 85 °C (185 °F)

without additional cooling. The machine sensing time is 150ms.

The pyrometer‘s separate electronics box features easy-to-access

programming buttons and a backlit LCD display.

®

CT P3

®

CT P7

New

The optris CTlaser P7 infrared thermometer is

suited to the temperature measurement of thin

plastic materials like, for example, PET, PU,

PTFE and PA. It measures the smallest

objects with the greatest of accuracy.

optris

The IR thermometer boasts a wide temperature range of 0 to 710 °C (1,319 °F) and can be

used at temperatures of up to 85 °C (185 °F) without additional cooling. It can capture objects as

small as 1.6 mm (0.06 in) from a distance of 70 mm (2.76 in). A double laser precisely marks the

measuring spot. The pyrometer‘s separate electronics box has easy-to-access programming buttons

and a backlit LCD display. Additionally, a variety of selectable outputs ensures the reliable transfer of

measured data and easy SPS integration.

6

®

CTlaser P7

Page 7

The infrared cameras in the optris PI series are xed thermography systems

that offer outstanding value for money. In the plastics industry the LT cameras

(8-14 µm) are used for molding or lm thicknesses of over 0.4 mm (0.02 in). The

thermal imaging cameras are connected to a computer via USB 2.0 or integrated

into a PLC and are ready to use immediately after connecting.

Compact infrared cameras

innovative infrared technology

At 120 Hz the optris PI 160 (160 x 120 px) is ideally

suited to fast processes.

For applications which require bi-spectral recording, the

optris PI 200 / 230 (160 x 120 px) is a good solution.

The optris PI 400 / 450 (382 x 288 px) impresses

with its high thermal sensitivity from 40 mK.

For high-resolution line scanning at high speeds

(125 Hz) or for close, detailed inspection, the

optris PI 640 (640 x 480 px) VGA camera is an

outstanding choice.

optris

®

PI Connect

Software (Merging function)

In conned spaces in a machine, when there is

not enough room to measure at the recommended

distance, it may be necessary to use two or more

infrared cameras to scan, for example, the entire

product width. With the PI Connect software the data

streams of the individual cameras can be simply

combined to form an overall IR image, meaning the

user can see the whole process or the temperature

distribution across the entire lm width in a single

software window.

7

Page 8

Subject to change · Temperature measurement plastics industry-BR-US2017-11-A

Optris Infrared Sensing, LLC

200 International Drive

Suite 170

Portsmouth, NH 03801 USA

Phone: (603) 766-6062

E-mail: sales@optris-ir.com

www.optris.com

innovative infrared technology

Loading...

Loading...