Page 1

innovative infrared technology

Infrared thermometers

Infrared video thermometers

Infrared cameras

Portable thermometers

PRODUCT OVERVIEW

Non-contact temperature measurement

Page 2

The adequate measurement device

Spot measurement

or thermal image?

First of all, it is important to dene the measurement task and

to decide on one of these two measures:

A point measuring infrared ther-

mometer should be used if you know

where the critical point or the area to

be measured is positioned within your

application. The size of the measuring

object is important to dene which

lens is necessary.

It is therefore possible to monitor the

accurate temperature and optimize

processes – if necessary – before

quality problems arise.

Pyrometer congurator:

www.optris.com/pyrometer-selector

Which object surface?

The condition of the object surface

denes the measurement device

and wavelength to be used for

the application. The emissivity Ɛ

occupies a central position. The

choice of the right device is of great

importance especially for metals,

where the emissivity depends on

the temperature and wave length.

We are able to oer appropriate meas-

urement devices for most applications

throughout a wide product range.

The following explanation helps to

nd the right wavelength for your

application:

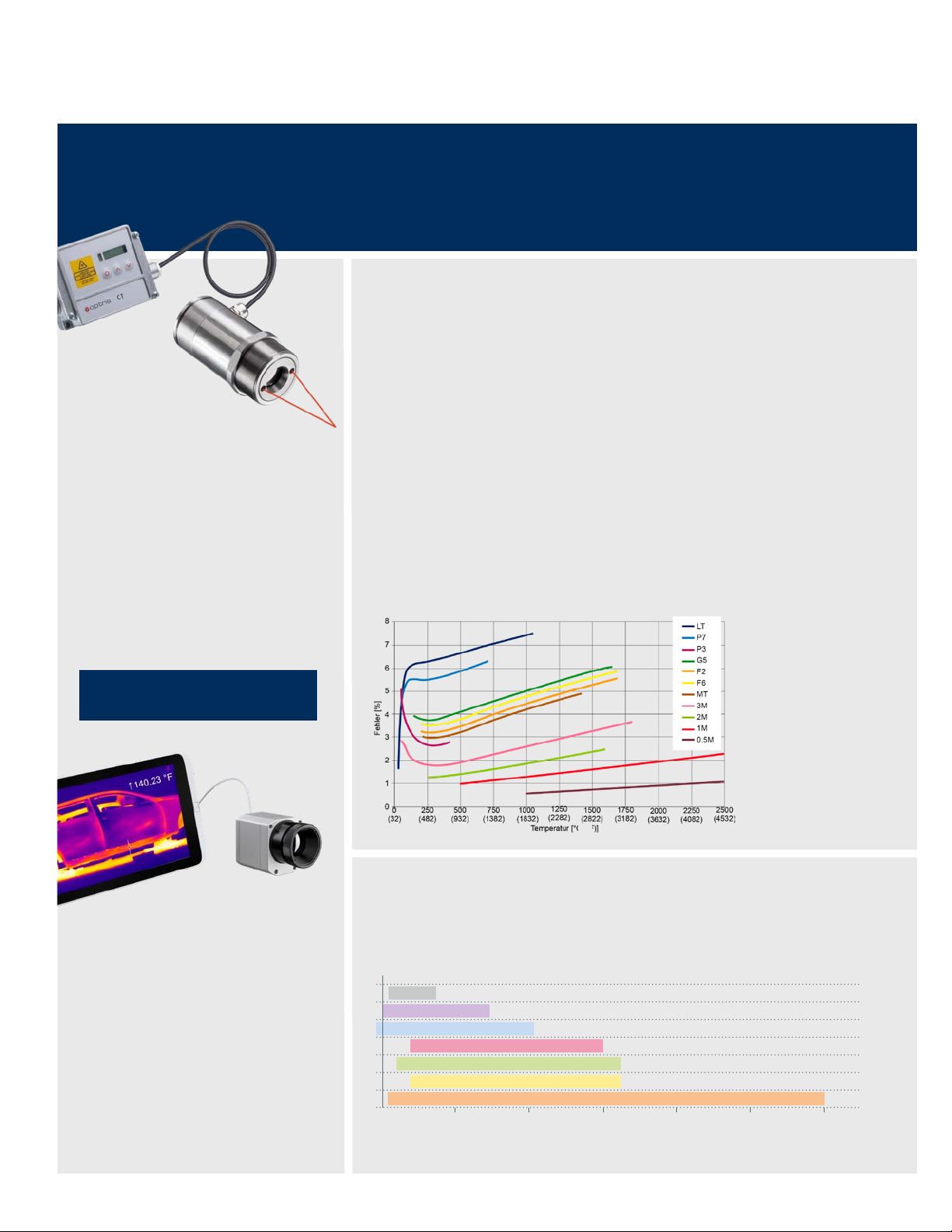

[°C]

■ 8 – 14 μm for non-metal surfaces

(Type of device: LT)

■ 0.5; 1.0; 1.6; 2.3 μm mainly for

liquid metals and metal surfaces

(Type of device: 05M; 1M; 2M; 3M)

■ 3.43 µm for thin plastic lms

like PE, PP and PS (Type of

device: P3)

■ 3.9; 4.24; 4.64; 7.9 μm for

special applications (Type of

device: MT; F2; F6)

■ 5.0 μm for glass surfaces

(Type of device: G5)

■ 7.9 μm for plastic foils and glass

surfaces (Type of device: P7/G7)

Short wavelengths reduce

measurement errors on

surfaces with low, unknown

or changing emissivity. This

occurs mostly with metals.

The diagram above shows

the measurement errors

across different wavelengths

if the emissivity is wrongly

adjusted by only 10 percent.

Infrared cameras should be used in

cases where more than one critical

area exists or the area cannot be

clearly dened. Critical areas can be

localized by the camera through the

demonstration of thermal images.

The areas can then be permanently

monitored by one or multiple xed

infrared thermometers.

2

Which temperature range?

The temperature is another factor to

decide on. The range should cover

all relevant temperatures of the appli-

µm

50 °C t o 400 °C

0 °C t o 710 °C

–50 °C t o 1030 °C

0 500 1000 1500 2000

Display of temperature over wavelength for the devices of the compact and the high performance series

(122 °F to 752 °F)

(32 °F to 1310 °F)

(–58 °F t o 1886 °F)

200 °C t o 1500 °C

100 °C t o 1650 °C

200 °C t o 1650 °C

50 °C t o 3000 °C

Temperature in °C (°F)

cation. The measurement range of

the devices is between –50 °C and

3000 °C (–58 °F and 5432 °F).

(392 °F to 2732 °F)

(212 °F t o 3002 °F)

(392 °F t o 3002 °F)

(122 °F t o 5432 °F)

2500 3000

P3

P7

LT

G7

G5

MT, F2, F6

05M, 1M, 2M, 3M

(5432) (4532) (3632) (2732) (1832) (932) (32)

Page 3

For further information on non-contact temperature measurement see our brochure on basics

of IR temperature measurement:

www.optris.com/downloads-compact-series

innovative infrared technology

Which process velocity?

To achieve accurate temperature measurement it is

important to know how fast measuring objects are

moving in front of the sensor or how fast they change

temperature.

Our fastest infrared thermometer captures changes

within 1 ms.

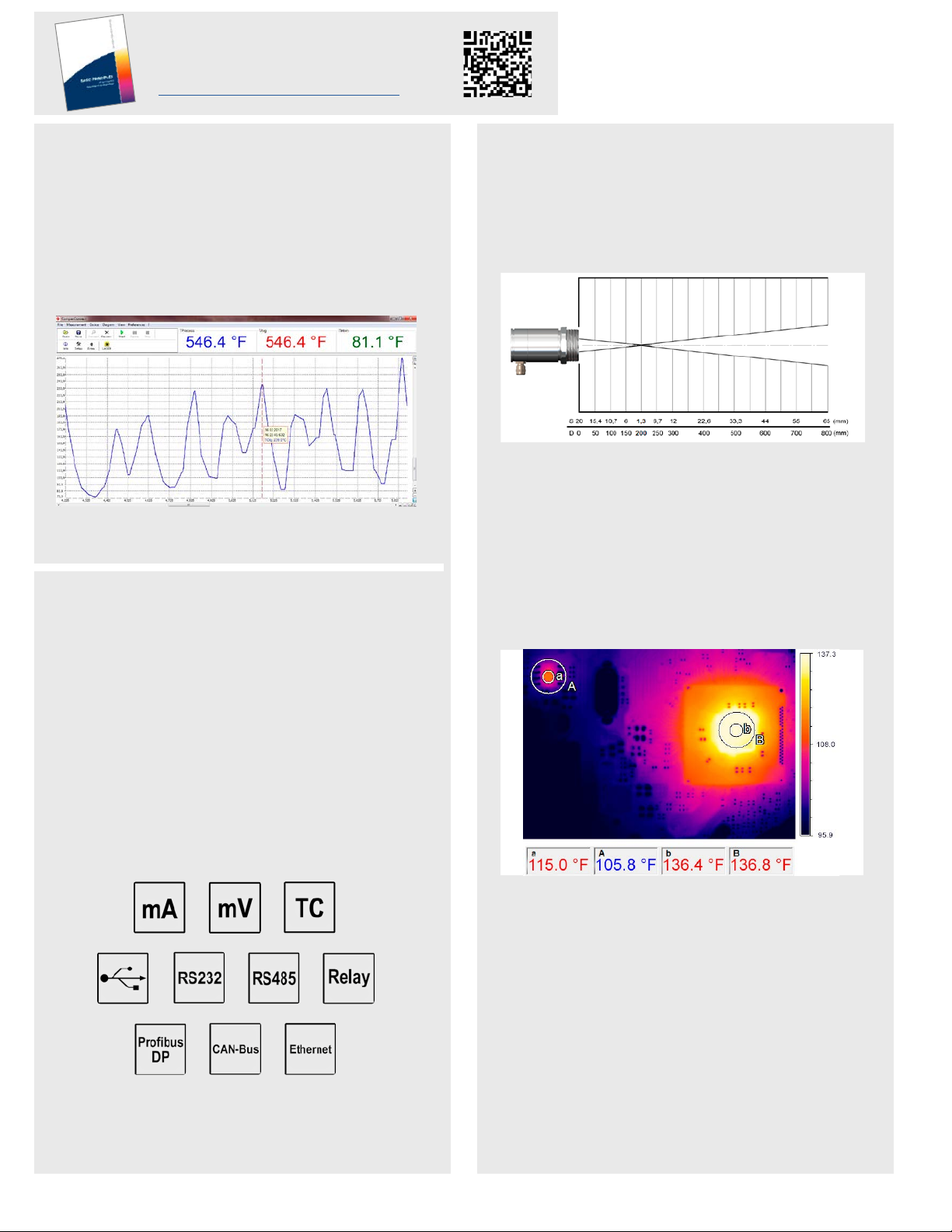

Display of fast temperature changes over a period of time.

Integration of sensors?

Our temperature sensors can be installed as part of the

process with mounting brackets or anges.

Object size and measurement distance

IR thermometers use the radiation signal emitted by the

entire measurement spot. The size of the measurement

spot (S) largely depends on the device, the optics

selected and the distance between the sensor and

measurement object plane (D):

Measurement spot diameter (S) depending on the measurement distance

(D) with an IR thermometer

For a precise temperature measurement, the measurement spot needs to be smaller than, or the same size as

the object to be measured.

If the measurement spot is larger than the object, a temperature is calculated from the averaged heat radiation

signal from the object and its environment. In a colder

environment, it means that correspondingly, the temperature measurement value determined is too low.

Depending on the device, we oer dierent analog and

digital interfaces for data evaluation such as triggering,

alerting or saving of data.

Analog Interfaces:

0 – 20 mA, 4 – 20 mA, 0 – 5 V, 0 – 10 V,

Thermocouple (type J, type K)

Digital Interfaces:

USB, RS232, RS485, Relay, Probus DP, CAN Bus,

Ethernet

IR image of an electronics circuit board – adaptation of the measurement

spot to the object size

When transferred to the two-dimensional measurement

with IR cameras, the pixel size there needs to suit the

object size for the selected measurement distance. Here,

the object should ll at least 3 x 3 pixels.

In the example above, the correct temperature of a chip of

46 °C (114.8 °F) is determined with the suitable measure-

ment spot size (a). A measurement spot (A) which is three

times larger already leads to a measurement error of 5 °C

(41 °F) or 10 %. If you select a larger component on the

same circuit board (on the right in the picture), then in this

case, both measurement spots (b and B) provide the correct temperature measurement value of 58 °C (136.4 °F).

3

Page 4

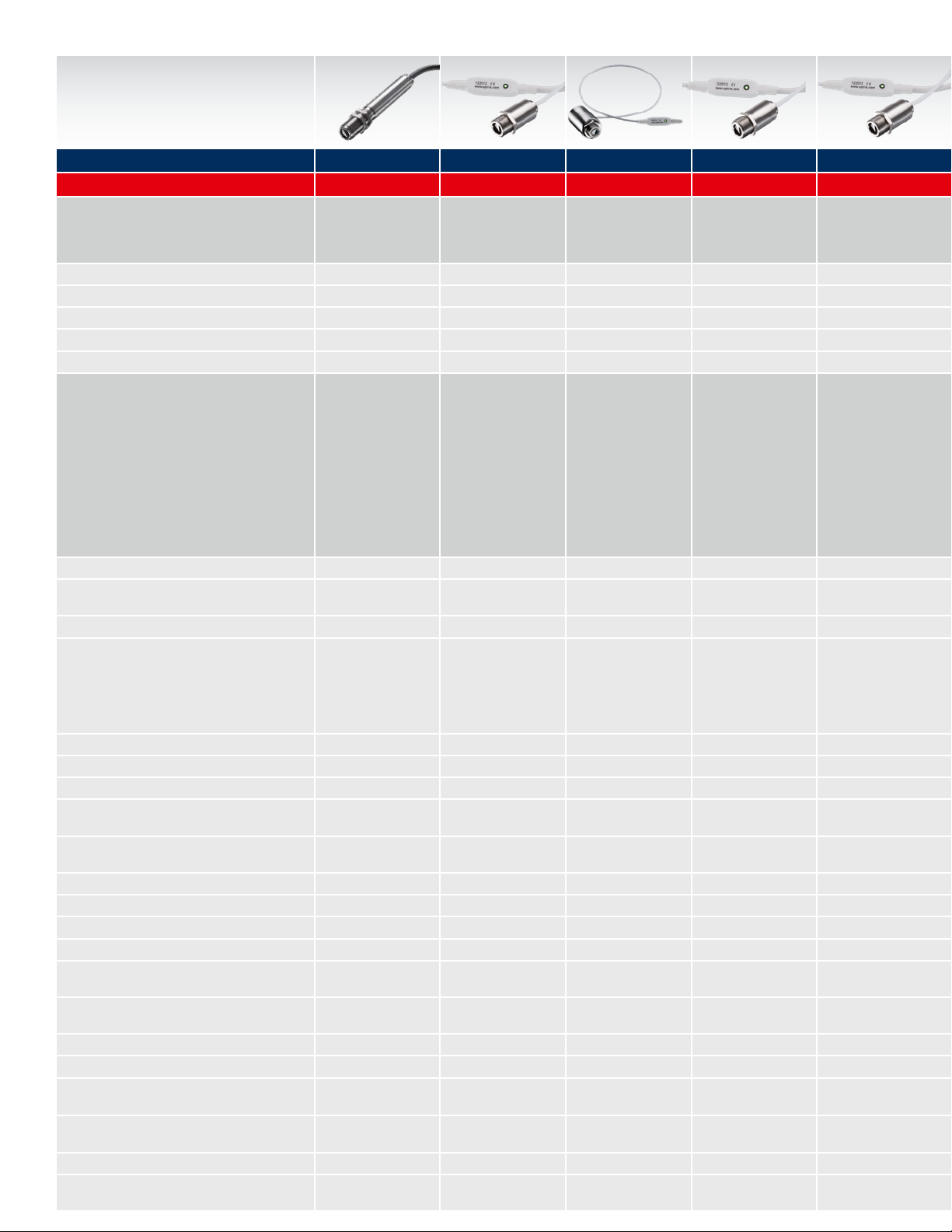

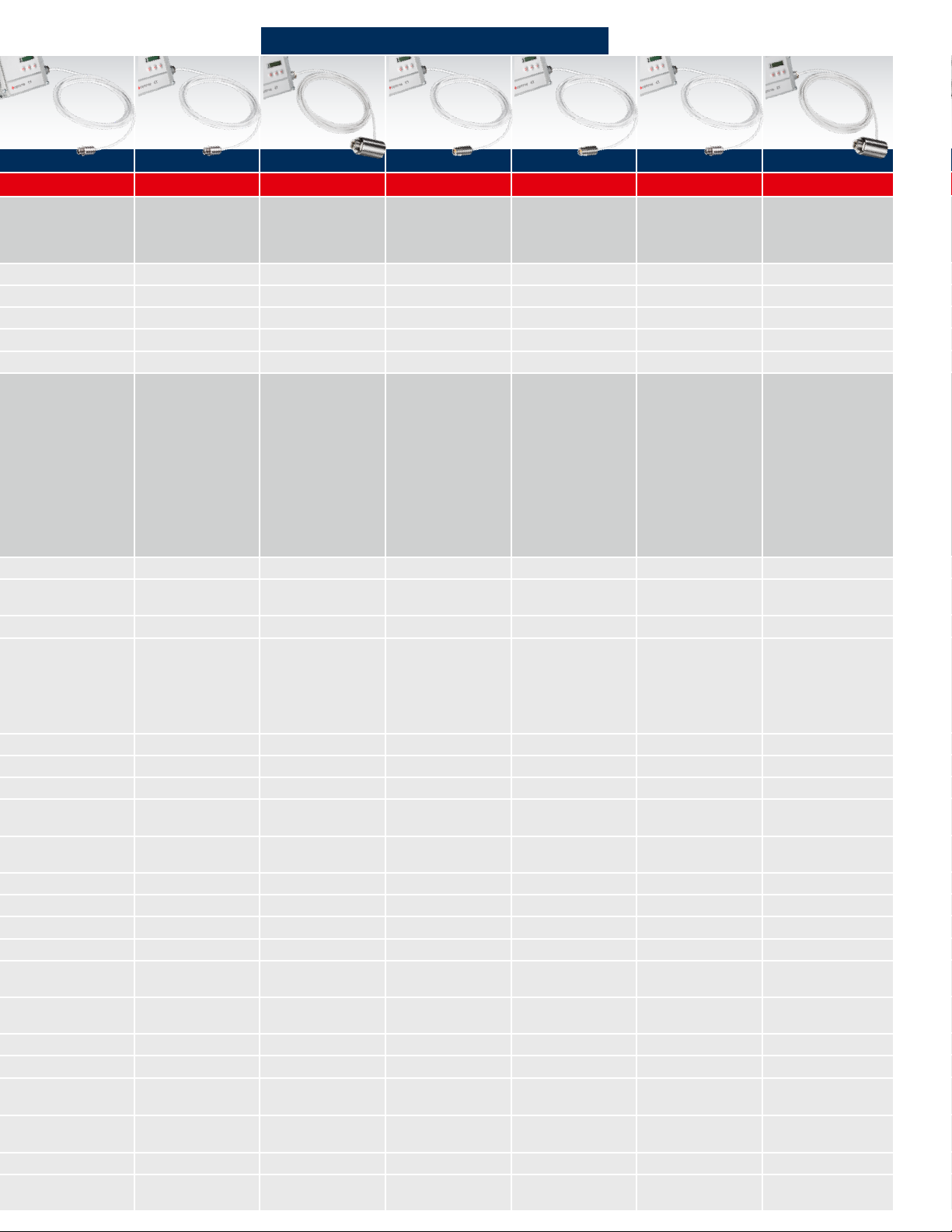

Compact series

Small, compact infrared thermo-

meters, ideal for use in cramped

and hot surroundings

Base Model CS CSmicro CSmicro CSmicro CSmicro CT CTfast CThot CT CT CT CT

Type LT LT02/ LT15(H)/ LT22H

Classication /

special features

Detector

Sensing head exchangeable

Head cable shortening

Thread (sensing head)

Spectral range

Temperature ranges

Single-piece sensor, smart

LED display (self diag

nostics, aiming support,

Single-piece sensor with

-

electronics in cable; smart

LED display

alarm, temp. code)

Thermopile

Thermopile

– – – – – ■ – ■ ■ ■ ■ –

■ ■

(behind electronics)

M12x1 M12x1 M18x1 M12x1 M12x1 M12x1 M12x1 M18x1 M12x1 M12x1 M12x1 M18x1

8 – 14 μm 8 – 14 μm 8 – 14 μm 1.6 μm 2.3 μm 8 – 14 μm 8 – 14 μm 8 – 14 μm 1M: 1.0 μm / 2M: 1.6 μm 2.3 μm 5.0 μm P3: 3.43 µm / P7: 7.9 μm

–40 ... 1030 °C

(–40 ... 1886 °F)

–50 ... 1030 °C

(–58 ... 1886 °F)

LT15 HS

Single-piece two-wire

sensor with electronics in

cable; high thermal sensiti

vity; smart LED display

2M 3M

Single-piece sensor for

temp. measurements on

-

metal; electronics in cable;

smart LED display

Single-piece sensor for

temp. measurements on

metal; electronics in cable;

smart LED display

Thermopile InGaAs Ext. InGaAs Thermopile Thermopile Thermopile 1M: Si / 2M: InGaAs Extended InGaAs Thermopile Thermopile (P7)

■

(behind electronics)

–20 ... 150 °C

(–4 ... 302 °F)

■

(behind electronics)

2ML: 250 ... 800 °C

(2ML: 482 ... 1472 °F)

2MH: 385 ... 1600 °C

(2MH: 725 ... 2912 °F)

■

(behind electronics)

3ML: 50 ... 350 °C

(3ML: 122 ... 662 °F)

3MH: 100 ... 600 °C

(3MH: 212 ... 1112 °F)

Temperature resolution

Optical resolution

Option: CF lens

Smallest spot (CF optics / add. CF lens)

Smallest spot (SF optics)

Sighting

Response time (90 %)

Accuracy

Analog O/P: 0-20 mA/4-20 mA/0-5 V/0-10 V/t/c (K/J)

Second analog output

USB / RS232 / RS485 / Probus / Ethernet

Peak / Valley / AVG / Advanced hold

T

Head min.

Amb

T

Head max.

Amb

T

Electronics max.

Amb

Functional inputs / number

External emissivity adjustment

External background temp. control / Trigger in-

put for reset of hold functions / Digital I/O pins

Simultaneous analog + digital O/P / Alarm O/P

as altern. to analog O/P / Additional alarm O/P

Voltage supply

Standard cable length options

4

0.1 K 0.1 K 0.025 K [>20 °C (>68 °F)] 0.1 K 0.1 K 0.1 K LT15F: 0.2 K / LT25F: 0.4 K 0.25 K 0.1 K 0.1 K L: 0.1 K / H: 0.2 K P3: 0.1 K / P7: 0.5 K

15:1 LT02: 2:1 / LT15 (H): 15:1 /

LT22 H: 22:1

■

0.8 mm @ 10 mm

(0.03 in @ 0.4 in)

■ ■ ■ ■ ■ ■ ■ ■ ■ – –

LT02: 2.5 mm @ 23 mm

(LT02: 0.1 in @ 0.9 in)

LT15 (H): 0.8 mm @ 10 mm

(LT15 (H): 0.03 in @ 0.4 in)

15:1 2ML: 40:1

2MH: 75:1

0.8 mm @ 10 mm

(0.03 in @ 0.4 in)

2MH: 1.5 mm@110 mm

(2MH: 0.06 in @ 4.3 in)

2ML: 2.7 mm@110 mm

(2ML: 0.11 in @ 4.3 in)

3ML: 22:1

3MH: 33:1

3ML: 1.5 mm @ 30 mm

(3ML: 0.06 in @ 1.2 in)

3MH: 1 mm @ 30 mm

(3MH: 0.04 in @ 1.2 in)

LT 22 H: 0.6 mm @ 10 mm

(LT 22 H: 0.02 in @ 0.4 in)

7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in) 7 mm (0.3 in)

LED aiming LED aiming LED aiming LED aiming LED aiming

25 ms 14 ms 150 ms 150 ms 10 ms 150 ms LT15F: 9 ms / LT25F: 6 ms 100 ms 1 ms 1 ms L: 120 ms / H: 80 ms P3: 100 ms / P7: 150 ms

±1.5 °C or ±1.5 %

(±3.0 °F or ±1.5 %)

– / – / ■ / ■ / ■

±1 °C or ±1 %

(±2 °F or ±1 %)

– / – / ■ / ■ / – or

– /

■ / – / – / –

±1 °C or ±1 %

(±2 °F or ±1 %)

– / – / ■ / ■ / – or

– /

■ / – / – / –

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

– / – / ■ / ■ / – or

– /

■ / – / – / –

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

– / – / ■ / ■ / – or

– /

■ / – / – / –

– – – – – ■ ■ ■ – – ■ ■

■ / – / – / – / – ■ / – / – / – / – ■ / – / – / – / – ■ / – / – / – / – ■ / – / – / – / – ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■

■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■

–20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F) –20 °C (–68 °F)

80 °C (176 °F) LT02 / LT15: 120 °C (248 °F)

75 °C (167 °F) 125 °C (257 °F)

LT15H/LT22H: 180°C (356°F)

80 °C (176 °F) 80 °C (176 °F) /

75 °C (167 °F) (mA version)

■

/ 1

■

(via Vcc adjust)

■ / ■ / – ■

■

/ 1

■

(mV version)

(mV version)

/ ■ / – ■

– / ■ / ■ ■ (mA version only) /

■ / ■

80 °C (176 °F) /

75 °C (167 °F) (mA version)

■

/ 1

■

(mV version)

(mV version)

/ ■ / – ■

■ (mA version only) /

■ / ■

80 °C (176 °F) /

75 °C (167 °F) (mA version)

■

/ 1

■

(mV version)

(mV version)

/ ■ / – ■

■ (mA version only) /

■ / ■

80 °C (176 °F) /

75 °C (167 °F) (mA version)

■

/ 1

■

(mV version)

(mV version)

/ ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / –

■ (mA version only) /

■ / ■

5 – 30 V DC 5 – 30 V DC 5 – 30 V DC 5 – 30 V DC 5 – 30 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC

1 / 3 / 8 / 15 m (3.3 / 9.8 /

26.2 / 49.2 ft)

0.5 + 0.5 m / up to 9 m

(1.6 ft / up to 29.5 ft)

0.5 + 0.5 m / up to 9 m

(1.6 ft / up to 29.5 ft)

0.5 + 0.5 m / up to 9 m

(1.6 ft / up to 29.5 ft)

0.5 + 0.5 m / up to 9 m

(1.6 ft / up to 29.5 ft)

Page 5

Spot size calculator: www.optris.com/spot-size-calculator

innovative infrared technology

LT02 / LT15 / LT22

Two-piece sensor with

separate electronic box

incl. display and program

ming keys

■

[–0.1 K/m]

LT02: –50 ... 600 °C

(LT02: –58 ... 1112 °F)

LT15: –50 ... 600 °C

(LT15: –58 ... 1112 °F)

LT22: –50 ... 975 °C

(LT22: –58 ... 1787 °F)

LT02: 2:1 / LT15: 15:1 /

LT22: 22:1

LT15F / LT25F LT02H / LT10H 1M / 2M 3M G5 P3 / P7

Two-piece sensor, fast

response time, separate

-

electronic box incl. display

and programming keys

■

[max. 3 m] (9.8 ft)

–50 ... 975 °C

(–58 ... 1787 °F)

LT15F: 15:1

LT25F: 25:1

Two-piece sensor for hot

surroundings with separate

electronic box incl. display

and programming keys

■

[–0.1 K/m]

–40 ... 975 °C

(–40 ... 1787 °F)

Two-piece sensor for high

temp. meas. of metal, se

parate electronic box incl.

display and progr. keys

■

[max. 3 m] (9.8 ft)

1ML: 485 ... 1050 °C

(1ML: 905 ... 1922 °F)

1MH: 650 ... 1800 °C

(1MH: 1202 ... 3272 °F)

1MH1: 800 ... 2200 °C

(1MH1: 1472 ... 3992 °F)

2ML: 250 ... 800 °C

(2ML: 482 ... 1472 °F)

2MH: 385 ... 1600 °C

(2MH: 725 ... 2912 °F)

2MH1: 490 ... 2000 °C

(2MH1: 914 ... 3632 °F)

LT02H: 2:1

LT10H: 10:1

L: 40:1

H: 75:1

Two-piece sensor for low

-

temp. meas. of metal, se

parate electronic box incl.

display and progr. keys

■ ■

L: 50 ... 400 °C

(L: 122 ... 752 °F)

H: 100 ... 600 °C

(H: 212 ... 1112 °F)

H1: 150 ... 1000 °C

(H1: 302 ... 1832 °F)

H2: 200 ... 1500 °C

(H2: 392 ... 2732 °F)

H3: 250 ... 1800 °C

(H3: 482 ... 3272 °F)

L: 22:1 / H: 33:1 /

H1–H3: 75:1

Two-piece sensor for temp.

-

meas. of glass, separate

electronic box incl. display

and programming keys

[–0.1 K/m]

L: 100 ... 1200 °C

(L: 212 ... 2192 °F)

H: 250 ... 1650 °C

(H: 482 ... 3002 °F)

L: 10:1

H: 20:1

Two-piece sensor for temp.

meas. on thin plastic film /

glass (P7), separate electr.

box incl. display + progr. keys

–

P3: 50 ... 400 °C

(P3: 122 ... 752 °F)

P7: 0 ... 710 °C

(P7: 32 ... 1310 °F)

P3: 15:1

P7: 10:1

LT02: 2.5 mm @ 23 mm

(LT02: 0.1 in @ 0.9 in)

LT15: 0.8 mm @ 10 mm

(LT15: 0.03 in @ 0.4 in)

0.5 mm @ 10 mm

(0.02 in @ 0.4 in)

LT02H: 2.5 mm @ 23 mm

(LT02H: 0.10 in @ 0.9 in)

1.5 mm @ 110 mm

(0.06 in @ 4.3 in)

LT10H: 1.2 mm @ 10 mm

(LT10H: 0.05 in @ 0.4 in)

3.4 mm @ 110 mm

(0.13 in @ 4.3 in)

–

P7: 1.2 mm @ 10 mm

(P7: 0.05 in @ 0.4 in)

LT22: 0.6 mm @ 10 mm

(LT22: 0.02 in @ 0.4 in)

– – – – – – –

±1 °C or ±1 %

(±2 °F or ±1 %)

±2 °C or ±1 %

(±4 °F or ±1 %)

±1.5 °C or ±1 %

(±3.0 °F or ±1 %)

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

±2 °C or ±1 %

(±4 °F or ±1 %)

P3: ±3 °C (±5 °F) or 1 %

P7: ±1.5 °C (±3 °F) or 1 %

■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■

P3: 0 °C (°F) / P7: –20 °C (–68 °F)

LT02: 130 °C (266 °F)

LT15 / LT22: 180 °C (356°F)

120 °C (248 °F) 250 °C (482 °F) 1M: 100 °C / 2M: 125 °C

(1M: 212 °F / 2M: 257 °F)

85 °C (185 °F) 85 °C (185 °F) 85 °C (185 °F) 85 °C (185 °F) 85 °C (185 °F) 85 °C (185 °F)

85 °C (185 °F) 85 °C (185 °F) P3: 75 °C / P7: 85 °C

(P3: 167 °F / P7: 185 °F)

P3: 75 °C (167 °F) /

P7: 85 °C (185 °F)

■

/ 3

■

/ 3

■

/ 3

■

/ 3

■

/ 3

■

/ 3

■

/ 3

■ ■ ■ ■ ■ ■ ■

■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■

1 / 3 / 8 / 15 m (3.3 / 9.8 /

26.2 / 49.2 ft)

1 / 3 / 8 / 15 m (3.3 / 9.8 /

26.2 / 49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 m (9.8 ft) 3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

5

Page 6

Accessories Compact series

Mechanical accessories

ACCTFB / ACCTFBMH / ACCTFB2

Mounting bracket, adjustable in one axis

(M12x1 sensing head, massive housing,

mounting of CT sensing head + LaserSightingtool)

ACCTTAS

Tilt assembly for heads with optical

resolution ≥10:1

Optical accessories

ACCTMB

Mounting bolt with thread M12x1

ACCTRAIL

Rail mount adapter for CT electronics

ACCTMG

Mounting fork, adjustable in 2 axes, with

thread M12x1

ACCTCOV

Closed cover for CT electronic box

ACCTKF40B270 / ACCTKF40GE

KF40 flange for CT1M, 2M, 3M with B270

window (up to 10-7 mbar) /

KF40 flange for CTLT with Ge window (up

to 10-7 mbar)

ACCTTAM25

Thread adapter M12x1 to M25x1.5 incl.

2 mounting nuts

ACCTCF / ACCTPW

CF-lens or protective window (for LT) for

M12x1 sensing head

ACCTCFHT / ACCTPWHT for 1M, 2M, 3M

ACCTRAM

Right angle mirror for measurements 90° to the sensor

axis for sensing heads with optical resolution ≥10:1

6

ACCTCFE / ACCTPWE

CF-lens or protective window (for LT) with external thread

for air purge or massive housing

ACCTCFHTE / ACCTPWHTE for 1M, 2M, 3M

D08ACCTLST / ACCTOEMLST

Laser-Sightingtool (for CT )/ OEM Laser-Sightingtool,

635 nm, rotation symmetrical, for connection to CT electronics, power supply via CT electronic box or battery

+

ACCTPA + ACCTST20 20 (20 mm length) / ACCTST40 (40 mm length) / ACCTST88 (88 mm length)

Pipe adapter with M12x1 internal thread + Sighting tube with M12x1 external thread

Page 7

Air purges and protective housings

innovative infrared technology

ACCSAP

Air purge collar (for heads with optical

resolution ≥10:1)

ACCTAPLCF

Air purge collar, laminar, with integrated

CF-lens (for LT)

Combinations

ACCTAPMH

Air purge collar for Massive housing (D06)/

CSmicro HS/ CThot/ CT P3/ CT P7

ACCTAPLCFHT

Air purge collar, laminar, with integrated

CF-lens (for 1M/ 2M/ 3M)

Massive housing of:

• compact, brass (D06ACCTMHB)

• anodized aluminium (D06ACCTMHA)

• stainless steel (D06ACCTMHS)

ACCTAPL

Air purge collar, laminar

• stainless steel version with CF optics

(D06ACCTMHSCF)

• stainless steel version for HT CF optics

(D06ACCTMHSCFHT)

ACCTAP / ACCTAP2

Air purge for CT heads (not for heads with

32 mm length)

ACCTAPL

Air purge collar, laminar

ACCTFB

Mounting bracket for

M12x1 sensing head

+ +

ACCTMG

Mounting fork

+

ACCTMB

Mounting bolt

= =

Device adjustable in two

axes

= =

ACCTAB

Device adjustable in two

axes

ACCTFB2

Mounting bracket for sensing head + Sighting tool

+

D06ACCTAPMH

Massive housing, stainless

steel

D08ACCTLST /

ACCTOEMST

OEM Laser-Sightingtool

ACCTAPMH

Airpurge, stainless steel

Sensing head with LaserSighting tool

Massive housing with air

purge

7

Page 8

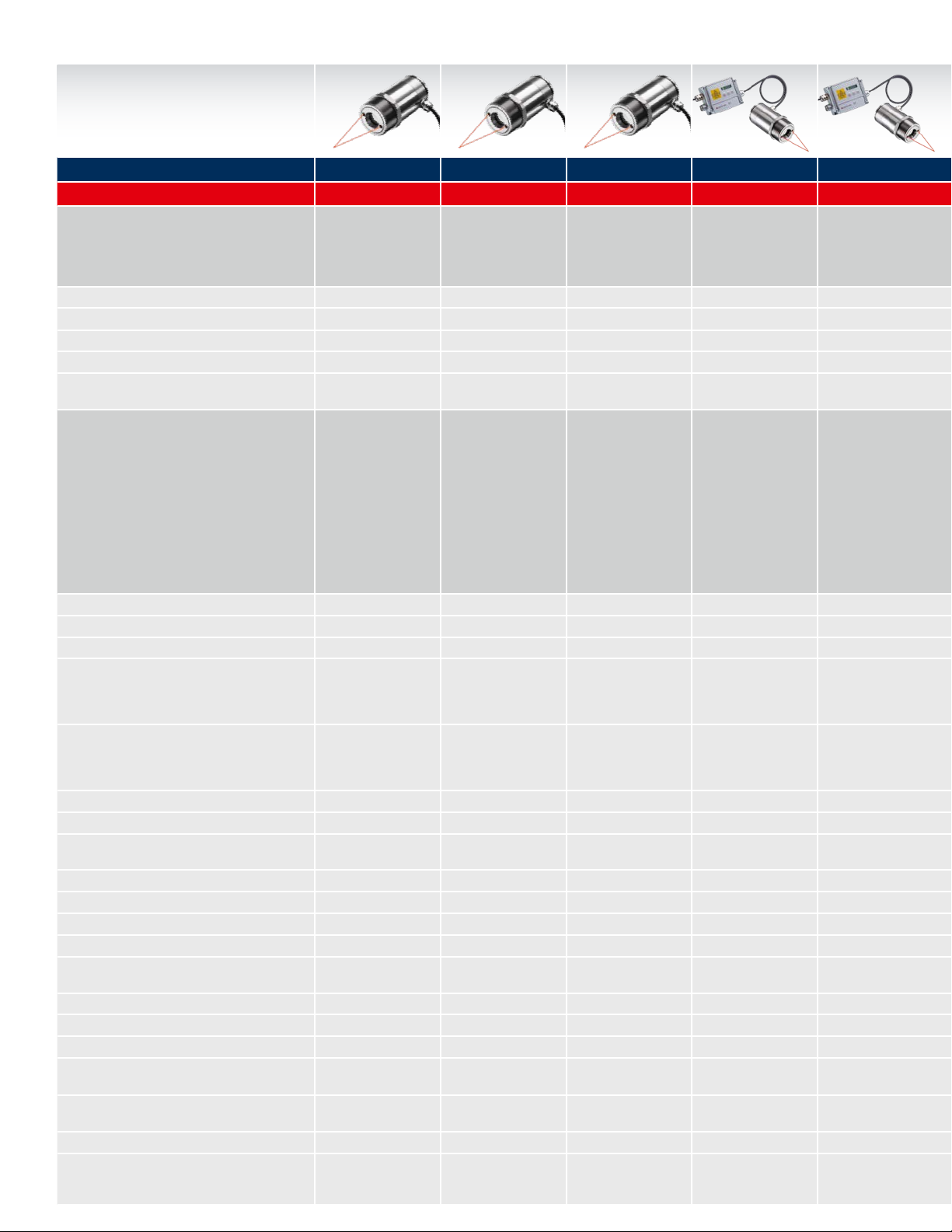

High performance series

Infrared thermometers with

highest optical resolution and

double laser

Base Model CSlaser CSlaser CSlaser CTlaser CTlaser CTlaser CTlaser CT XL CTlaser CTlaser CTlaser CTratio

Type LT / hs LT 2M G5HF LT / LTF 05M 1M / 2M 3M 3M MT / F2 / F6 G5 P7 1M

Classication /

special features

Detector

Sensing head exchangeable

Head cable shortening

Thread (sensing head)

Spectral range

Single-piece two-wire

sensor with electronics in

sensing head

Thermopile

Single-piece two-wire

sensor with electronics

in sensing head for

measurement of metal

InGaAs

Single-piece two-wire

infrared thermometer for

temperature measurement

of glass

Thermopile Thermopile

Two-piece sensor with

separate electronic

box with fast response

time, incl. progr. keys and

display

Two-piece sensor with

separate electronic box for

high temp. meas.of liquid

metal, incl. progr. keys and

display

Si 1M: Si / 2M: InGaAs

– – – ■ ■ ■ ■ – ■ ■ ■ –

■ ■ ■ ■

[max. 6 m] (19.7 ft)

■

[max. 6 m] (19.7 ft)

M48x1.5 M48x1.5 M48x1.5 M48x1.5 M48x1.5 M48x1.5 M48x1.5 M30x1 M48x1.5 M48x1.5 M48x1.5 M18x1

8 – 14 μm 1.6 μm 5.0 μm 8 – 14 μm 0.525 μm 1M: 1.0 μm / 2M: 1.6 μm 2.3 μm 2.3 μm MT: 3.9 μm / F2: 4.24 μm /

Temperature ranges

Temperature resolution

Optical resolution

Option: CF lens

Smallest spot (CF optics / add. CF lens)

Smallest spot (SF optics)

Sighting

Response time (90 %)

Accuracy

Analog O/P: 0-20 mA/4-20 mA/0-5 V/0-10 V/t/c (K/J)

Second analog output

USB / RS232 / RS485 / Probus / Ethernet

Peak / Valley / AVG / Advanced hold

T

Head min. / T

Amb

T

Electronics max.

Amb

Functional inputs / number

External emissivity adjustment

External background temp. control / Trigger in-

put for reset of hold functions / Digital I/O pins

Simultaneous analog + digital O/P / Alarm O/P

as altern. to analog O/P / Additional alarm O/P

Voltage supply

Standard cable length options

Head max.

Amb

8

LT: –30 °C ... 1000 °C

(– °F ... 1832 °F)

hs LT: –20 °C ... 150 °C

(–4 °F ... 302 °F)

L: 250 °C ... 800 °C

(482 °F ... 1472 °F)

H: 385 °C ... 1600 °C

(725 °F ... 2912 °F)

200 °C ... 1650 °C

(392 °F ... 3002 °F)

–50 °C ... 975 °C

(–58 °F ... 1787 °F)

1000 °C ... 2000 °C

(1832 °F ... 3632 °F)

LT: 0.1 K / hs LT: 0.025 K 0.1 K 0.1 K LT: 0.1 K / LTF: 0.5 K 0.2 K 0.1 K 0.1 K 0.1 K 0.1 K L: 0.1 K / H,HF: 0.2 K 0.5 K 0.1 K (> 900 °C) (>1652 °F)

50:1 300:1 45:1 LT: 75:1 / LTF: 50:1 150:1 L: 150:1 / H: 300:1

– – – – – – – – – – – –

1.4 mm @ 70 mm

(0.06 in @ 2.8 in)

0.5 mm @ 150 mm

(?.? in @ 5.9 in)

1.6 mm @ 70 mm

(0.06 in @ 2.8 in)

LT: 0.9 mm @ 70 mm

–

(0.04 in @ 2.8 in)

LTF: 1.4 mm @ 70 mm

(0.06 in @ 2.8 in)

24 mm @ 1200 mm

(0.9 in @ 47.24 in)

3.7 mm @ 1100 mm

(0.02 in @ 43.31 in)

27 mm @ 1200 mm

(1.1 in @ 47.24 in)

LT: 16 mm @ 1200 mm

(LT: 0.6 in @ 47.24 in)

7.3 mm @ 1100 mm

(0.29 in @ 43.31 in)

LTF: 24 mm @ 1200 mm

(LTF: 0.9 in @ 47.24 in)

Double laser Double laser Double laser Double laser Double laser Double laser Double laser

150 ms 10 ms 30 ms LT: 120 ms / LTF: 9 ms 1 ms 1 ms 1 ms 1 ms 10 ms

±1 °C or ±1 %

(±2 °F or ±1 %)

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

±1 °C or ±1 %

(±3 °F or ±1 %)

LT: ±1 °C or ±1 %

LTF: ±1.5 °C or ±1 %

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

– / ■ / – / – / – – / ■ / – / – / – – / ■ / – / – / – ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / –

– – – ■ – – – – ■ ■ ■ –

■ / – / – / – / – ■ / – / – / – / – ■ / – / – / – / – ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■ – / – / – / – / –

■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

– / – – / – – / – ■

–20 °C(68 °F)

/ 85 °C (185 °F))

85 °C

(185 °F)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

/ 3

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

– – – ■ ■ ■ ■ ■ ■ ■ ■ –

– / – / – – / – / – – / – / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – ■ / ■ / – – / ■ (via I/O pins)

■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ ■ / ■ / ■ (via I/O pins)

5 – 30 V DC 5 – 30 V DC 5 – 28 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC 8 – 36 V DC

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

Page 9

Spot size calculator: www.optris.com/spot-size-calculator

innovative infrared technology

Two-piece sensor with

separate electronic box

for high temp. meas. of

metal, incl. progr. keys and

display

■

[max. 6 m] (19.7 ft)

1ML: 485 °C ... 1050 °C

(1ML: 905 °F ... 1922 °F)

1MH: 650 °C ... 1800 °C

(1MH: 1202 °F ... 3272°F)

1MH1: 800 °C ... 2200 °C

(1MH1: 1472 °F ... 3982°F)

2ML: 250 °C ... 800 °C

(2ML: 482 °F ... 1472 °F)

2MH: 385 °C ... 1600 °C

(2MH: 725 °F ... 2912 °F)

2MH1: 490 °C ... 2000 °C

(2MH1: 914 °F ... 3632 °F)

Two-piece sensor with

separate electronic box

for low temp. meas. of

metal, incl. progr. keys and

display

Two-piece sensor with

separate electronic box

for laser applications, incl.

progr. keys and display

(no laser)

Two-piece sensor with separ.

electr. box incl. progr. keys

and display for meas.:

MT: through ames / F2: CO2

ame gas / F6: CO ame gas

Two-piece sensor with

separate electronic box for

meas. of glass, incl. progr.

keys and display

Two-piece sensor with

separate electronic box for

meas. of plastic foils, incl.

progr. keys and display

Ratio pyrometer with separate electr. box for high temp.

meas. of metal feat. glass

fiber cable and laser, incl.

progr. keys and display

Extended InGaAs Extended InGaAs Thermopile Thermopile Thermopile Si sandwich

■

[max. 6 m] (19.7 ft)

■ ■

[max. 6 m] (19.7 ft)

■

[max. 6 m] (19.7 ft)

■

[max. 6 m] (19.7 ft)

–

5.0 μm 7.9 μm 0.7 – 1.1 μm

F6: 4.64 μm

L: 50 °C ... 400 °C

(L: 122 °F ... 752°F)

H: 100 °C ... 600 °C

(H: 212 °F ... 1112 °F)

H1: 150 °C ... 1000 °C

(H1: 302 °F ... 1832 °F)

H2: 200 °C ... 1500 °C

(H2: 392 °F ... 2732 °F)

H: 100 °C ... 600 °C

(H: 212 °F ... 1112 °F)

H1: 150 °C ... 1000 °C

(H1: 302 °F ...1832 °F)

H2: 200 °C ... 1500 °C

(H2: 392 °F ... 2732 °F)

H3: 250 °C ... 1800 °C

(H3: 482 °F ... 3272 °F)

200 °C ... 1650 °C

(392 °F ... 3002 °F)

L: 100 °C ... 1200 °C

(L: 212 °F ... 2192 °F)

H: 250 °C ... 1650 °C

(H:482 °F ... 2912 °F)

HF: 200 °C ... 1650 °C

(HF: 392 °F ... 2912 °F)

0 °C ... 710 °C

(–32 °F ... 1310 °F)

700 °C ... 1800 °C

(1292 °F ... 3272 °F)

H3: 250 °C ... 1800 °C

(H3: 482 °F ... 3272 °F)

L: 60:1 / H: 100:1 / H1-H3: 300:1

H: 100:1 / H1-H3: 300:1 45:1 L/HF: 45:1 / H: 70:1 45:1 40:1

0.5 mm @ 150 mm

(0.02 in @ 5.9 in)

3.7 mm @ 1100 mm

(0.15 in @ 43.31 in)

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

0.5 mm @ 150 mm

(0.02 in @ 5.9 in)

11 mm @ 1100 mm

(0.4 in @ 43.31 in)

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

0.5 mm @ 150 mm

(0.02 in @ 5.9 in)

11 mm @ 1100 mm

(0.4 in @ 43.31 in)

–

±(0.3 % T

±(0.3 % T

meas

meas

+2 °C)

+4 °F)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

1.6 mm @ 70 mm

(0.06 in @ 2.8 in)

27 mm @ 1200 mm

(1.1 in @ 47.24 in)

1 mm @ 70 mm

(0.04 in @ 2.8 in)

17 mm @ 1200 mm

(0.7 in @ 47.24 in)

1.6 mm @ 70 mm

(0.06 in @ 2.8 in)

27 mm @ 1200 mm

(1.1 in @ 47.24 in)

7.7 mm @ 305 mm

(0.3 in @ 12.01 in)

31.3 mm @ 1143 mm

(1.2 in @ 45 in)

Double laser Double laser Double laser Laser

±1.5 °C or ±1 %

(±3 °F or ±1 %)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

L: 120 ms / H: 80 ms / HF: 10 ms

±1.5 °C or ±1 %

(±3 °F or ±1 %)

–20 °C(68 °F)

/ 85 °C (185 °F))

85 °C

(185 °F)

■

/ 3

150 ms 5 ms

±1.5 °C or ±1 %

(±3 °F or ±1 %)

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

(185 °F)

■

/ 3

±(0.5 % T

±(0.5 % T

–20 °C(68 °F)

/ 85 °C (185 °F)

85 °C

– / –

meas

meas

(185 °F)

+1 °C)

+2 °F)

/

■ (2)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

–

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 8 / 15 m (9.8 / 26.2/

49.2 ft)

3 / 6 / 10 / 15 / 22 m

(9.8/ 19.7 / 32.8/ 49.2 /

72.2 ft)

9

Page 10

Infrared video thermometers

Infrared video thermometers

with vario focus and patented

cross hair laser

Base Modell CSvideo CTvideo CTvideo

Type 2M (L / H) 1M / 2M (L / H) 3M (L / H)

Classication /

special features

Detector

Sensing head exchangeable

Head cable shortening

Thread (sensing head)

Spectral range

Temperature ranges

(scalable via software)

Temperature resolution

Optical resolution

Smallest spot (CF optics)

CF vario optics: focusable from

90 mm to 250 mm (0.02 in to 9.8 in)

Smallest spot (SF optics)

SF vario optics: focusable from

200 mm (7.9 ft) to innity

Sighting

Response time (90 %)

Accuracy

Outputs analog: 0 – 20 mA /

4 – 20 mA / 0 – 5 V / 0 – 10 V / t/c (K/J)

USB / RS232 / RS485 / Probus / Ethernet

Peak / Valley / AVG / Advanced hold

T

Head min. / T

Amb

T

Electronics max.

Amb

Functional inputs / number

External emissivity adjustment

External background temp. control

Trigger input for reset of hold functions

Simultaneous analog and digital output

Alarm O/P as an alternative to analog O/P

Additional alarm output

Voltage supply

Standard cable length

Cable length options

1)

Specifications available for object temperatures ≥ lower measurement range 50 °F

Head max.

Amb

Single-piece two wire sensor with electronics in

sensing head, video camera and cross hair laser

for measuring metal

Two-piece sensor with electronic box for high

temperature measurement of metals, video

camera and cross hair laser

Two-piece sensor with electronic box for low

temperature measurement of metals, video

camera and cross hair laser

InGaAs 1M: Si / 2M: InGaAs Extended InGaAs

–

■

[+CT 1M / 2M] [+CT 3M]

[max. 6 m] (19.7 ft) [max. 6 m] (19.7 ft)

M48x1.5 M48x1.5 M48x1.5

1.6 μm 1M: 1.0 μm / 2M: 1.6 μm 2.3 μm

250 °C ... 800 °C (2ML) (482 °F ... 1472 °F)

385 °C ... 1600 °C (2MH) (725 °F ... 2912 °F)

485 °C ... 1050 °C (1ML) (905 °F ... 1922 °F)

650 °C ... 1800 °C (1MH) (1202 °F ... 3272 °F)

800 °C ... 2200 °C (1MH1) (1472 °F ... 3992 °F)

250 °C ... 800 °C (2ML) (482 °F ... 1472 °F)

385 °C ... 1600 °C (2MH) (725 °F ... 2912 °F)

50 °C ... 400 °C (3ML) (122 °F ... 752 °F)

100 °C ... 600 °C (3MH) (212 °F ... 1112 °F)

150 °C ... 1000 °C (3MH1) (302 °F ... 1832 °F)

200 °C ... 1500 °C (3MH2) (392 °F ... 2732 °F)

250 °C ... 1800 °C (3MH3) (482 °F ... 3272 °F)

490 °C ... 2000 °C (2MH1) (914 °F ... 3632 °F)

0.1 K ML: 0.1 K / MH: 0.2 K 0.1 K

2MH: 300:1 / 2ML: 150:1 L: 150:1 / H: 300:1 L: 60:1 / H: 100:1 / H1 – H3: 300:1

2ML: 0.6 mm @ 90 mm (CF) (0.02 in @ 3.5 in)

2MH: 0.3 mm @ 90 mm (CF) (0.01 in @ 3.5 in)

2ML: 1.3 mm @ 200 mm (SF) (0.05 in @ 7.9 in)

2MH: 0.7 mm @ 200 mm (SF) (0.03 in @ 7.9 in)

1ML/2ML: 0.6 mm @ 90 mm (CF)

(0.02 in @ 3.5 in)

1MH-H1/ 2MH-H1: 0.3 mm @ 90 mm (CF)

(0.01 in @ 3.5 in)

1ML/2ML: 1.3 mm @ 200 mm (SF)

(0.05 in @ 7.9 in)

1MH-H1/ 2MH-H1: 0.7 mm @ 200 mm (SF)

(0.03 in @ 7.9 in)

3ML: 1.5 mm @ 90 mm (CF) (0.06 in @ 3.5 in)

3MH: 0.9 mm @ 90 mm (CF) (0.04 in @ 3.5 in)

3MH1 – H3: 0.3 mm @ 90 mm (CF)

(0.01 in @ 3.5 in)

3MH: 3.3 mm @ 200 mm (SF) (0.13 in @ 7.9 in)

3MH: 2.0 mm @ 200 mm (SF) (0.08 in @ 7.9 in)

3MH1 – H3: 0.7 mm @ 200 mm (SF)

(0.03 in @ 7.9 in)

video camera and cross hair laser video camera and cross hair laser video camera and cross hair laser

10 ms 1 ms 1 ms

±(0.3 % T

+2 °C) ±(0.3 % T

meas

+4 °F) ±(0.3 % T

meas

+2 °C) ±(0.3 % T

meas

+4 °F) ±(0.3 % T

meas

– / ■ / – / – / – ■ / ■ / ■ / ■ / ■ ■ / ■ / ■ / ■ / ■

■ / – / – / – / ■ ■ / – / – / – / ■ ■ / – / – / – / ■

■ / ■ / ■ / ■ ■ / ■ / ■ / ■ ■ / ■ / ■ / ■

–20 °C (–4 °F) / 70 °C (158 °F) –20 °C (–4 °F) / 85 °C (185 °F) –20 °C (–4 °F) / 85 °C (185 °F)

70 °C (158 °F) 85 °C (185 °F) 85 °C (185 °F)

– / – ■

/ 3

■

/ 3

– ■ ■

– ■ ■

– ■ ■

■ ■ ■

■ ■ ■

0 – 30 V / 500 mA (open-collector) 24 V / 50 mA (open-collector) 24 V / 50 mA (open-collector)

5 – 28 V DC 8 – 36 V DC 8 – 36 V DC

3 m (9.8 ft) 3 m (9.8 ft) 3 m (9.8 ft)

8 / 15 m (26.2 / 49.2 ft) 5 / 10 m (16.4 / 32.8 ft) 5 / 10 m (16.4 / 32.8 ft)

+2 °C) ±(0.3 % T

meas

meas

1)

1)

1)

+4 °F)

10

Page 11

Software included

Connection options for CSvideo 2M

innovative infrared technology

• Automatic snapshots (time or temperature dependent)

to control and document the process

• Graphic display and recording of the measurement

values

• Setup of sensor parameters and signal processing

functions

• Remote control of the sensor

Analog operation mode: 4 – 20 mA and

alarm interface. Setup & installation

via USB cable (hot Plug & Play)

Connection options for CTvideo 1M / 2M / 3M

standard version

24 – 48 V DC or

Power over Ethernet

Digital operation mode: process control

(video and temperature) via software

PoE

high temperature version

24 – 48 V DC or

Power over Ethernet

PoE

11

Page 12

Accessories High performance series

Mechanical accessories

ACCTLFB

Mounting bracket, adjustable in one axis

ACHAMA

Mounting adapter: Mounting and pipe

flange

Air purges and cooling units

ACCTLAB

Mounting bracket, adjustable in two axes

ACCTCOV

Closed cover for CT electronic box

ACCJAB

Mounting bracket for CoolingJacket, adjustable in two axes

ACCTRAIL

Rail mount adapter for CT electronics

ACCTXLAB

Mounting bracket CT XL, adjustable in

two axes

ACCTLTA20UN

Thread adapter M48x1,5 to 20 UN-2A

thread incl. mounting nut

ACCTAPMH

Air purge collar CTratio

ACCTLCJ

CoolingJacket (stainless steel) for CSlaser/ CTlaser/ CSvideo/ CTvideo

ACCTLAP

Air purge collar CxL/ CxV

12

ACCTXLAP

Air purge collar CT XL

ACCTLW

Water cooled housing CxL/ CxV, stainless steel, for

T

up to 175 °C

amb

Page 13

Optical accessories

innovative infrared technology

ACHAST300 + ACHAPA

Sighting tube M48x1,5, 300 mm length +

pipe adapter with M48x1,5 internal thread

Combinations

+

CT electronic box ACCTRAIL

Rail mount adapter

+

ACCJAFUxx + ACCJAPWPI2xxLW /

ACCJAFUxx + ACCJAPWCTLSW

Focussing unit with protective window for CoolingJacket

=

Electronic box on rail mount

adapter

ACHAMA

Mounting adapter

=

ACCJAFUxx + ACCJAPGMS 2 or 3

Focussing unit with protective grid for CoolingJacket

Advanced

+

ACHAST300 / ACHAPA

Sighting tube / pipe adapter

+

=

ACCTLRM

Furnace wall mount for

CSlaser/ CTlaser

=

CT electronic box ACCTCOV

Closed cover for

CT electronic box

ACCTLCJA

CoolingJacket Advanced

Closed CT electronic box

ACCTLAP

Air purge

+ =

ACCJAAPLS

Air purge laminar for CoolingJacket Advanced

ACCTLW

Water cooled housing

CoolingJacket Advanced with air purge laminar

Cooling sensing head

+ purging of optics

13

Page 14

Portable thermometers

High-quality infrared

thermometers with

integrated USB

interface

Base Model P20 P20 MS MSPlus MSPro

Type LT 1M / 2M / 05M LT LT LT

Detector

Spectral range

Temperature ranges

Temperature resolution

Optical resolution

Smallest spot (SF optics)

Sighting

Response time (90 %)

Accuracy

(at T

23 ±5 °F)

Amb

PC interface / Software

Probe connection (t/c)

T

Min. / Max.

Amb

Display MAX / MIN / HOLD

HIGH / LOW alarm

Data logger / capacity

Emissivity

Thermopile Si / InGaAs Thermopile Thermopile Thermopile

8 – 14 μm 1M: 1.0 μm / 2M: 1.6 μm /

0 °C ... 1300 °C

(32°F ... 2372 °F)

1 K 1 K 0.2 K 0.1 K 0.1 K

120:1 1M / 2M: 300:1 / 05M: 150:1 20:1 20:1 40:1

100 mm @ 12 m

(3.94 in @ 39.4 ft)

Double laser Double laser Laser Laser Laser

300 ms 100 ms 300 ms 300 ms 300 ms

±2 °C or ±1 %

(±4 °F or ±1 %)

USB /

■

– – – – ■

0 °C / 50 °C

(32 °F / 122 °F)

■ ■ ■ ■ ■

■ ■ – ■ ■

■

/ 2000

0.100 ... 1.100 0.100 ... 1.100 0.95 fixed 0.100 ... 1.100 0.100 ... 1.100

05M: 525 nm

1M: 650 °C ... 1800 °C

(1M: 1202 °F ... 3272 °F)

2M: 385 °C ... 1600 °C

(2M: 725 °F ... 2912 °F)

05M: 1000 °C ... 2000 °C

(05M: 1832 °F ... 3632 °F)

1M / 2M: 12 mm @ 3.6 m

(1M / 2M: 0.47 in @ 11.8 ft)

05M: 24 mm @ 3.6 m

(05M: 0.94 in @ 11.8 ft)

±(0.3 % T

±(1 % T

USB /

0 °C / 50 °C

(32 °F / 122 °F)

■

/ 2000

+2 °C)

meas

+4 °F)

meas

■

8 – 14 μm 8 – 14 μm 8 – 14 μm

–32 °C ... 420 °C

(–26 °F ... 788°F)

13 mm @ 140 mm

(0.51 in @ 5.51 in)

±1 °C or ±1 %

(±2 °F or ±1 %)

USB /

0 °C / 50 °C

(32 °F / 122 °F)

– – ■

■

–32 °C ... 530 °C

(–26 °F ... 986 °F)

13 mm @ 140 mm

(0.51 in @ 5.51 in)

±1 °C or ±1 %

(±2 °F or ±1 %)

USB /

0 °C / 50 °C

(32 °F / 122 °F)

■

–32 °C ... 760 °C

(–26 °F ... 1400 °F)

13 mm @ 260 mm

(0.51 in @ 10.2 in)

±1 °C or ±1 %

(±2 °F or ±1 %)

USB /

0 °C / 50 °C

(32 °F / 122 °F)

/ 20

■

Best optics for portable thermometers

The optics of the portable P20 thermometers are designed for

mean as well as long distances. The optris

laser and aiming scope for accurate sighting so that even

more distant objects can be measured precisely.

High optical resolution of 120:1 to 300:1

14

®

P20 has a target

Smallest measuring spot:

100 mm @ 12 m (3.94 in @ 39.4 ft)

Smallest measuring spot:

12 mm @ 3.6 m (0.47 in @ 11.8 ft)

Page 15

optris® Xi Infrared cameras

innovative infrared technology

– The Compact Line

Compact spot nder IR camera

for applications in rough industrial environments

Optics calculator: www.optris.com/optics-calculator

New

Basic model Xi 80 Xi 400

Type IR IR

Detector FPA, uncooled (34 µm pitch) FPA, uncooled (17 µm pitch)

Optical resolution 80 x 80 pixels 382 x 288 pixels

Spectral range 7.5 – 13 μm 7.5 – 13 μm

Temperature ranges –20 ... 100 °C (–4 to 212°F)

Frame rate 50 Hz 80 Hz / 27 Hz

Optics (FOV) 30° (f = 5.1 mm [0.20 in])

0 ... 250 °C (32 to 482 °F)

(20) 150 ... 900 °C

12° (f = 12.7 mm [0.50 in])

55° (f = 3.1 mm [0.12 in])

80° (f = 2.3 mm [0.09])

1)

(302 ... 1652 °F1))

–20 ... 100 °C (–4 to 212°F)

0 ... 250 °C (32 to 482 °F)

(20) 150 ... 900 °C1) (302 ... 1652 °F1))

29° x 22° (f = 12.7 mm [0.50 in])

18° x 14° (f = 20 mm [0.79 in])

53° x 38° (f = 7.7 mm [0.30 in])

80° x 54° (f = 5.7 mm [0.22 in])

New

Macro optics – 18° x 14° (f = 20 mm [0.79 in]), smallest measuring spot: 90 µm)

Focus Manual motor focus Manual motor focus

Optische Auösung (D:S) 190:1 (12° optics) 390:1 (18° optics)

Thermal sensitivity (NETD) 100 mK 80 mK

Accuracy ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater

PC interfaces

Direct in-/outputs /

Standard process interface (PIF)

Industral process interface (PIF) 3x 0/4 – 20 mA or 0–10 V outputs,

Cable length (USB) USB: 1 m (standard), 3 m (9.8 ft), 5 m (16.4 ft), 10 m (32.8 ft) and

Ambient temperature

Size / class Ø 36 x 90 mm (1.41 x 3.54 in) (M30x1 thread) / IP 67 (NEMA 4) Ø 36 x 100 mm (1.41 x 3.94 in) (M30x1 thread) / IP 67 (NEMA 4)

Weight 185 g (6.53 oz) 200 g (7.05 oz)

Shock/ Vibration

Power supply USB / PoE / 5-30 VDC via USB

Scope of supply (standard) • Xi camera

3)

USB 2.0 / Ethernet (100 Mbit/s) / PoE / RS 485

1x 0/4–20 mA output

1x input (analog or digital)

Optically isolated

3x input (analog or digital),

3x relays (0 – 30 V) / 400 mA),

1x fail-safe relay; stackable up to 3 PIFs; optically isolated

20 m (65.6 ft)

Ethernet / RS485: 100 m

0 ... 50 °C (41 ... 122 °F) 0 ... 50 °C (41 ... 122 °F)

IEC 60068-2 IEC 60068-2

• USB cable (1 m)

• Cable for in-/outputs (1 m) with terminal block

• Mounting bracket with tripod thread, mounting nut

• Software package optris

• Quick start guide

®

PIX Connect

2)

USB 2. 0 / optional USB to GigE (PoE) interface

1x 0–10 V input

1x digital input (max. 24 V)

1x 0–10 V output

2 x 0–10 V inputs, 1x digital input (max. 24 V)

3 x 0–10 V outputs,

3 x relays (0–30 V / 400 mA),

1x fail-safe relay

USB: 1 m (standard), 3 m (9.8 ft), 5 m (16.4 ft), 10 m (32.8 ft) and

20 m (65.6 ft)

• Xi camera

• USB cable (1 m)

• Cable for in-/outputs (1 m) with terminal block

• Mounting bracket with tripod thread, mounting nut

• Software package optris® PIX Connect

• Quick start guide

1)

Accuracy effective starting at 150 °C (302 °D)

3)

For further details see operator‘s manual

2)

Direct in- and outputs are not available while using the RS485 interface

15

Page 16

optris® PI infrared cameras

- The Precision Line

Compact infrared cameras for

fast online applications, including linescanner

Basic model PI 160 PI 200 / PI 230 PI 400i / PI 450i PI 640

Type IR BI-SPECTRAL IR IR IR IR

Detector FPA, uncooled (25 μm pitch) FPA, uncooled (25 μm pitch) FPA, uncooled (17 μm x 17 μm) FPA, uncooled (17 µm pitch) FPA, (25 µm pitch) FPA, (17 µm pitch)

Optical resolution 160 x 120 pixels 160 x 120 pixels 382 x 288 pixels 640 x 480 pixels VGA 382 x 288 pixels @ 80 Hz

Spectral range 8 – 14 μm 8 – 14 μm 8 – 14 μm 8 – 14 μm 8 – 14 μm 8 – 14 μm

Temperature ranges –20 ... 100 °C (–4 ... 212°F)

(20) 150 ... 900 °C (302 ... 1652 °F)

200 ... 1500 °C (392 ... 2732 °F) (option)

Frame rate 120 Hz 128 Hz

1)

–20 ... 100 °C (–4 ... 212°F)

(20) 150 ... 900 °C (302 ... 1652 °F)

2)

200 ... 1500 °C (392 ... 2732 °F) (option)

4)

1)

–20 ... 100 °C (–4 ... 212°F)

(20) 150 ... 900 °C (302 ... 1652 °F)

2)

200 ... 1500 °C (392 ... 2732 °F) (option)

80 Hz / switchable to 27 Hz 32 Hz / 125 Hz in subframe mode

1)

2)

Optics (FOV) 23° x 17° / f = 10 mm (0.9 in) or

Thermal sensitivity (NETD) 40 mK with 23° x 17° FOV / F = 0.8

Option visual camera (BI-SPECTRAL camera only)

Accuracy ±2 °C (±3.6 °F) or ±2 %, whichever is

PC interfaces

Process

interface

(PIF)

Ambient temperature (T

Storage temperature – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) PI 400i: – 40 ... 70 °C (–40 ... 158 °F)

Relative Humidity 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing

Size / class 45 (1.77) x 45 (1.77) x 60 – 76 mm

Weight 195 g (6.9 oz), incl. lens 215 g (7.6 oz), incl. lens 195 g (6.88 oz), incl. lens 320 g (11.3 oz), incl. lens 370 g, (13.1 oz), incl. lens 370 g, (13.1 oz), incl. lens

Shock/ Vibration IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2

Tripod mount 1/4-20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC

Power supply via USB via USB via USB via USB via USB via USB

Scope of supply (standard) • USB camera with 1 lens

Standard PIF 1x 0 – 10 V input, 1x digital input

Industrial PIF

(optional)

) 0 ... 50 °C (32 ... 122 °F) 0 ... 50 °C (32 ... 122 °F) PI 400i: 0 ... 50 °C (32 ... 122 °F) /

Amb

6° x 5° / f = 35.5 mm (1.4 in) or

41° x 31° / f = 5.7 mm (0.2 in) or

72° x 52° / f = 3.3 mm (0.13 in)

0.3 K with 6° x 5° FOV / F = 1.6

0.1 K with 41° x 31° FOV and

72° x 52° FOV / F = 1

– Optical resolution: 640 x 480 pixels

greater

USB 2. 0 / optional USB to GigE (PoE) Interface USB 2.0 / optional USB to GigE (PoE) Interface USB 2.0 / optional USB to GigE (PoE) Interface US B 2.0 / optional USB to GigE (PoE) Interface USB 2 .0 / optional USB to GigE (PoE) Interface

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

(2.36 - 2.99 in) (depending on lens and focus

position) / IP 67 (NEMA 4)

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Aluminum case

23° x 17° / f = 10 mm (0.9 in) or

6° x 5° / f = 35.5 mm (1.4 in) or

41° x 31° / f = 5.7 mm (0.2 in) or

72° x 52° / f = 3.3 mm (0.13 in)

40 mK with 23° x 17° FOV / F = 0.8

0.3 K with 6° x 5° FOV / F = 1.6

0.1 K with 41° x 31° FOV and

72° x 52° FOV / F = 1

Frame rate: 32 Hz

Optics (FOV): PI 200: 54° x 40°,

PI 230: 30° x 23°

±2 °C (±3.6 °F) or ±2 %, whichever is

greater

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

45 (1.77) x 45 (1.77) x 60 – 76 mm

(2.36 - 2.99 in) (depending on lens and focus

position) / IP 67 (NEMA 4)

• USB camera with 1 lens and

BI-SPECTRAL technology

• USB cable (1 m)

• Table tripod

• Focussing tool

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Aluminum case

4)

18° x 14° / f = 20 mm (f = 1.6 in) or

29° x 22° / f = 12.7 mm (f = 0.7 in) or

53° x 38° / f = 7.7 mm (f = 0.4 in) or

80° x 54° / f = 5.7 mm (f = 0.3 in)

PI 400i: 80 mK with 29°, 53°, 80° FOV

PI 450i: 40 mK with 29°, 53°, 80° FOV optics

mentioned above: F = 0.9

PI 400i: 0.1 K with 18° FOV / F = 1.1

PI 450i: 0.06 K with 18° FOV / F = 1.1

– – – –

±2 °C (±3.6 °F) or ±2 %, whichever is

greater

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

PI 450i: 0 ... 70 °C (32 ... 158 °F)

PI 450i: – 40 ... 85 °C (–40 ... 185 °F)

45 x 45 x 60 – 75 mm (1.8 x 1.8 x 2.3 - 2.95

in) (depending on lens and focus position)/ IP

67 (NEMA 4)

• USB camera with 1 lens

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Aluminum case (PI 400i)

• Robust hard shell case (PI 450i)

16

Page 17

Optics calculator: www.optris.com/optics-calculator

innovative infrared technology

NewNew

–20 ... 100 °C (–4 ... 212°F)

(20) 150 ... 900 °C (302 ... 1652 °F)

1)

200 ... 1500 °C (392 ... 2732 °F) (option)

Microscope optics PI 450

(switchable to 27 Hz)

–20 ... 100 °C (–4 ... 212°F)

0 ... 250 °C (32 ... 483 °F)

2)

(20) 150 ... 900 °C (302 ... 1652 °F)

1)

Microscope optics PI 640

640 x 480

640 x 120

–20 ... 100 °C (–4 ... 212°F)

0 ... 250 °C (32 ... 483 °F)

(20) 150 ... 900 °C (302 ... 1652 °F)

pixels

pixels

@ 32 Hz

@ 125Hz

1)

Up to 1 kHz / 1 ms real time analog output

(640x120 pixels)

29° x 22° / f = 18,7 mm (0.7 in) or

13° x 10° / f = 41 mm (1.6 in) or

10° x 8° (F=1.1) / f= 44 mm (1.73 in)

Smallest measuring spot: 42 µm

(0 - 10 V) of 8 x 8 pixels (freely selectable)

12° x 9° (F=1.1) / f= 44 mm (1.73 in)

Smallest measuring spot: 28 µm

53° x 40° / f= 10.5 mm (0.4 in) or

80° x 56° / f = 7.7 mm (0.3 in)

75 mK 90 mK 120 mK

±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater

USB 2. 0 / optional USB to GigE (PoE) Interface

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

1x 0 – 10 V input, 1x digital input

(max. 24 V), 1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input

(max. 24 V), 3 x 0 – 10 V outputs,

3 x relays (0 – 30 V / 400 mA), 1x fail-safe relay

0 ... 50 °C (32 ... 122 °F) 0 ... 70 °C (32 ... 158 °F) 5 ... 50 °C (41 ... 122 °F)

– 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F)

46 (1.81) x 56 (2.00) x 76 – 100 mm

(2.99 - 3.94 in) (depending on lens and focus

position)/ IP 67 (NEMA 4)

• USB camera with 1 lens

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Robust hard shell case

46 (1.81) x 56 (2.00) x 119 – 126 mm

(4.69 - 4.96 in) (depending on focus position)/ IP 67 (NEMA 4)

• USB camera

• Standard lens (PI 450: O29; PI 640: O33)

• Microscope lens (MO44)

• Microscope stand

• Standard USB cable (1 m)

• Standard-PIF

• Manual

• Robust hard shell case

• Software package optris® PIX Connect

46 (1.81) x 56 (2.00) x 119 – 126 mm

(4.69 - 4.96 in) (depending on focus position)/

IP 67 (NEMA 4)

• USB camera

• Standard lens (PI 450: O29; PI 640: O33)

• Microscope lens (MO44)

• Microscope stand

• Standard USB cable (1 m)

• Standard-PIF

• Manual

• Robust hard shell case

• Software package optris® PIX Connect

1)

Accuracy effective starting at 150 °C (302 °F)

2)

The addidional measuring range is not

available for the 72° (PI 160 / 2xx),

80° (PI 4xx) and 90° (PI 640) optics

3)

For the best combination of IR- and

VIS image, we recommend the 41° HFOV

optics for the PI 200 and the 23° HFOV

optics for the PI 230

4)

The following options may be chosen:

Option 1 (IR with 96 Hz at 160 x 120 px;

VIS with 32 Hz at 640 x 480 px)

Option 2 (IR with 128 Hz at 160 x 120 px;

VIS with 32 Hz at 596 x 447 px)

17

Page 18

optris® PI infrared cameras

- The Precision Line

Compact infrared cameras for

fast online applications, including linescanner

Basic model PI 450 G7

PI 640 G7

Type IR IR IR IR

Detector FPA, uncooled (25 μm pitch) FPA, uncooled (17 μm pitch) CMOS (15 μm pitch) CMOS (15 μm pitch)

Optical resolution 382 x 288 pixels 640 x 480 pixels 764 x 480 pixels @ 32 Hz

Spectral range 7.9 μm 7.9 μm 0.85 – 1.1 μm 500 nm – 540 nm

Temperature range 200 ... 1500 °C (392 ... 2732 °F) 200 ... 1500 °C (392 ... 2732 °F) 450

Frame rate 80 Hz / switchable to 27 Hz 32 Hz / 125 Hz in subframe mode (640x120 pixels) Up to 1 kHz / 1 ms real time analog output (0 - 10 V) of 8 x 8 pixels

Optics (FOV) 29° x 22° (f = 18.7 mm [0.74 in])

Thermal sensitivity (NETD) 130 mK 130 mK < 1 K (700 °C [1292 °F])

Accuracy ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±2 °C (±3.6 °F) or ±2 %, whichever is greater ±1 % of reading (object temp. <1400 °C [2552 °F])

PC interfaces

Process

interface

(PIF)

Ambient temperature (T

Storage temperature – 40 ... 85 °C (–40 ... 185 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F) – 40 ... 70 °C (–40 ... 158 °F)

Relative Humidity 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing 20 – 80 %, non-condensing

Size / class 46 (1.81) x 56 (2.00) x 76 – 100 mm (2.99 - 3.94 in) (depending on

Weight 320 g (11.3 oz), incl. lens 320 g (11.3 oz), incl. lens 320 g (11.3 oz), incl. lens 320 g (11.3 oz), incl. lens

Shock/ Vibration IEC 60068-2 IEC 60068-2 IEC 60068-2 IEC 60068-2

Tripod mount 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC 1/4 - 20 UNC

Power supply via USB via USB via USB via USB

Scope of supply (standard) • USB camera with 1 lens

Standard PIF 1x 0 – 10 V input,

Industrial PIF

(optional)

) 0 ... 70 °C (32 ... 158 °F) 0 ... 50 °C (32 ... 122 °F) 5 ... 50 °C (41 ... 122 °F) 5 ... 50 °C (41 ... 122 °F)

Umg

13° x 10° (f = 41 mm [1.61 in])

53° x 40° (f = 10.5 mm [0.41 in])

80° x 56° (f = 7.7 mm [0.30 in])

USB 2. 0 / optional USB to GigE (PoE) interface USB 2.0 / optional USB to GigE (PoE) interface USB 2.0 / optional USB to GigE (PoE) interface US B 2.0 / optional USB to GigE (PoE) interface

1x digital input (max. 24 V),

1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input (max. 24 V),

3 x 0 – 10 V outputs,

3 x relays (0 – 30 V/ 400 mA), 1x fail-safe relay

lens and focus position)/ IP 67 (NEMA 4)

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Robust hard shell case

33° x 25° (f = 18.7 mm [0.74 in])

15° x 11° (f = 42 mm [1.65 in])

60° x 45° (f = 10.5 mm [0.41 in])

90° x 64° (f = 7.7 mm [0.30 in])

1x 0 – 10 V input,

1x digital input (max. 24 V),

1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input (max. 24 V),

3 x 0 – 10 V outputs,

3 x relays (0 – 30 V/ 400 mA), 1x fail-safe relay

46 (1.81) x 56 (2.00) x 76 – 100 mm (2.99 - 3.94 in) (depending on

lens and focus position)/ IP 67 (NEMA 4)

• USB camera with 1 lens

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Robust hard shell case

18

Page 19

Optics calculator: www.optris.com/optics-calculator

PI 1M PI 05M

innovative infrared technology

382 x 288

pixels

@ 80 Hz (switchable to 27 Hz)

72 x 56 pixels @ 1 kHz

764 x 8 pixels @ 1 kHz (fast linescan mode)

5)

... 1800 °C (8425) ... 3272 °F) (27 Hz mode)

5)

500

... 1800 °C (9325) ... 3272 °F) (80 Hz and 32 Hz mode)

6005) ... 1800 °C (11125) ... 3272 °F) (1 kHz mode)

(freely selectable)

FOV @ 764 x 480 px:

39° x 25° (f = 16 mm [0.63 in])

26° x 16° (f = 25 mm [0.98 in])

13° x 8° (f = 50 mm [1.97 in])

9° x 5° (f = 75 mm [2.95 in])

FOV @ 382 x 288 px:

20° x 15° (f = 16 mm [0.63 in])

13° x 10° (f = 25 mm [0.98 in])

7° x 5° (f = 50 mm [1.97 in])

4° x 3° (f = 75 mm [2.95 in])

< 2 K (1000 °C [1382 °F])

1x 0 – 10 V input,

1x digital input (max. 24 V),

1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input (max. 24 V),

3 x 0 – 10 V outputs,

3 x relays (0 – 30 V/ 400 mA), 1x fail-safe relay

764 x 480 pixels @ 32 Hz

382 x 288 pixels @ 80 Hz (switchable to 27 Hz)

72 x 56 pixels @ 1 kHz

764 x 8 pixels @ 1 kHz (fast linescan mode)

900 ... 2000 °C (1652 ... 3632 °F) (27 Hz mode)

950 ... 2000 °C (1742 ... 3632 °F) (32 / 80 Hz mode)

1100 ... 2000 °C (2012 ... 3632 °F) (1 kHz mode)

Up to 1 kHz / 1 ms real time analog output (0 - 10 V) of 8 x 8 pixels

(freely selectable)

FOV @ 764 x 480 px:

26° x 16° (f = 25 mm) [0.98 in]

FOV @ 382 x 288 px:

13° x 10° (f = 25 mm [0.98 in])

< 2 K (1400 °C [2552 °F]) for 27 Hz, 32 Hz, 80 Hz

< 2,5 K (1400 °C [2552 °F]) for 1 kHz

±1.5 % of reading

1x 0 – 10 V input,

1x digital input (max. 24 V),

1x 0 – 10 V output

2 x 0 – 10 V inputs, 1x digital input (max. 24 V),

3 x 0 – 10 V outputs,

3 x relays (0 – 30 V/ 400 mA), 1x fail-safe relay

46 (1.81) x 56 (2.00) x 88 – 129 mm (3.46 - 5.08 in) with protection

tube (depending on lens and focus position) / IP 67 (NEMA 4)

6)

• USB camera with 1 lens

• Lens tube incl. protective window

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Manual

• Software package optris® PIX Connect

• Aluminum case

• Optional: CoolingJacket, HT cable

5)

+75 °C (167 °F) higher start temperature for optics with

focal length f= 50 mm, f= 75 mm

6)

Only applies when lens protection tube is used

46 (1.81) x 56 (2.00) x 88 – 129 mm (3.46 - 5.08 in) with protection

tube (depending on lens and focus position) / IP 67 (NEMA 4)

6)6)

• USB camera with 1 lens

• Lens tube incl. protective window

• USB cable (1 m)

• Table tripod

• PIF cable with terminal block (1 m)

• Software package optris® PIX Connect

• Manual

• Aluminum case

• Optional: CoolingJacket, HT cable

For further information on our infrared

cameras see our infrared

camera brochure:

www.optris.com/downloads-infrared-

cameras

19

Page 20

Infrared cameras EXPANSION OPTIONS

Outdoor protective housing for infrared cameras PI NetBox

Features:

• Environmental rating IP 66

• Additional air purge collar allows for a continuous operation in dusty

and humid conditions

• Heating element and built-in fan enable for a 24/7 operation from

–40 °C to 50 °C (–40 °F to 122 °F)

• Installation of USB Server Gigabit and industrial process interface

possible for integration into control systems over large outdoor

distances

Features:

• Miniature PC as an add-on to the PI series for stand-alone system

or for cable extension via GigE

• Integrated hardware and software watchdog

• Installation of additional user software possible

• Status LEDs

• Processor: Intel

2 GB RAM

• Connections: 2x USB 2.0, 1x USB 3.0, 1x Mini USB 2.0, Micro HDMI,

Ethernet (Gigabit Ethernet), Micro SDHC / SDXC card

• Operating system: Windows 7 Professional

• Wide supply voltage range (8 – 48 V DC) or Power over

Ethernet (PoE)

• Can be integrated into CoolingJacket Advanced

®

E3845 Quad Core / 1.91 GHz, 16 GB SSD,

USB Server Gigabit 2.0 – for infrared cameras of optris®

PI series and optris® Xi 400

Features:

• Fully USB 2.0 compatible, Data rates: 1.5 / 12 / 480 mbps,

USB transfer mode: Isochronous

• Network connection via Gigabit Ethernet

• For optris

• Full TCP/IP support incl. routing and DNS

• Two independent USB ports

• Supply from PoE or external power supply with 24 – 48 V DC

• Galvanic isolation 500 V

• Remotely congurable via Web Based Management

• Proven technology from Wiesemann & Theis

®

PI series and optris® CTvideo/ CSvideo series

(network connection)

RMS

Industrial process interface (PIF) for optris® PI series +

®

optris

Features:

• Industrial process interface for PI series and Xi 400 with

3 analog / alarm outputs, 2 analog inputs, 1 digital input,

3 alarm relays

• Industrial process interface for Xi 80 with 3 analog-/alarm outputs,

3 inputs (analog or digital), 3 alarm relays

• 500 V AC

• Separate fail-safe relay output

• PI / Xi hardware including all cable connections and PIX Connect

software are permanently observed during operation

• Option Xi 80: stackable up to 3 PIFs

Xi 400 / for optris® Xi 80

isolation voltage between camera and process

RMS

20

Page 21

Connection options for the Industrial Process Interface (PIF)

5–24 V DC

FS

open [1–5]

Connection options for PI NetBox

Analog OUT / IN

Digital IN

PI Process

Interface

8 – 48 V DC

Terminal box for convenient connection of process

cables

PC

PIX Connect

Control monitor

HDMI

innovative infrared technology

PLC

Vcc

R

Digital IN

Low = OK

High = FS

Connection options for USB Server Gigabit

USB Server Gigabit

PIX Connect

GigE

24 – 48 V DC or

Power over Ethernet

PoE

Network

Network / Internet

USB Keyboard / Mouse

Remote access / setup

PC

PC

PIX Connect

CoolingJacket Advanced

Features:

• Operation at ambient temperatures up to 315 °C (599 °F)

• Air/ water cooling with integrated air purging and

optional protective windows

• Modular concept for easy installation of dierent devices and optics

• Trouble-free sensor disassembling on site with quick release chassis

• Integration of additional components like PI NetBox, USB Server

Gigabit and Industrial Process Interface (PIF) in extended version

Laminar air purge

Features:

• Protection for rugged environments

• Air and water cooling, exible laminar air stream for protection from dirt

and dust

• Easy maintenance due to folding mechanism

• Focussable from the outside once installed

• Protection window for mechanical protection integrated

• Also available as line scanner version

21

Page 22

optris

SOFTWARE

®

PIX Connect

Comprehensive

IR camera software

1

• No additional costs

• No licensing restrictions

• Modern software with intuitive user interface

• Remote control of camera via software

• Display of numerous images in dierent windows

• Compatible with Windows 7, 8 and 10

• Extensive license-free analysis and

two Software Development Kits

for Windows and Linux (ubuntu)

included

3

High degree of individualization

for customer-specic imaging

• Various layout options for

individual customization

(window arrangement, toolbar)

• Temperature display in °C or °F

• Various language options including

translate function

• Choice of individual measurement parameters

tailored to the respective application

• Editing of the thermal image (ip, rotate)

• Individual start options (full screen, hidden etc.)

Video recording and

snapshot function

5

(IR or BI-SPECTRAL)

• Recording of video sequences and individual

images for later analysis or documentation

22

• BI-SPECTRAL video analysis (IR and VIS) to

highlight critical temperatures

• Adjustable frame rate to reduce data volume

• Display of snapshot process for direct analysis

Page 23

2

innovative infrared technology

Detailed online and

oine data analysis

• Real time temperature information in main

window, as digital display or graphic display

• Detailed analysis with the help of measurement

elds, automatic hotspot and coldspot search

• Logical linking of temperature information

(measurement eld discrepancy, image

subtraction)

• Slow-motion replay of radiometric datasets and

analysis even without connected camera

• Editing of sequences, e.g. cut and save individual images

• Various color palettes to highlight thermal contrasts

6

Automatic process

control and quality control

4

Temperature data analysis

and documentation

• Triggered data gathering

• Radiometric video sequences (*.ravi)

• Individual setting of alarm thresholds

depending on the process

• BI-SPECTRAL monitoring mode (IR and VIS)

for easy orientation at the measuring point

• Denition of visual or acoustic alarms and analog data output

• Analog and digital signal input (parameter)

• External communication of software via Comports, DLL

• Adjustment of thermal image via reference values

• Measurement elds can be freely designed or created

• Radiometric snapshots (*.ti)

• Text les including comprehensive temperature

information for analysis in Excel (*.csv, *.dat)

• Files with color information for standard programs like

Photoshop or Windows Media Player (*.avi, *.ti)

• Data transfer in real time to other software programs via DLL

or COM-Port interfaces

23

Page 24

Application elds

Laminating of vehicle interior

Vehicle interiors are partly

equipped with dierent surface

decors during a laminating process. The decor temperature is

controlled and optimized during

this time.

Product: optris

®

Production of glass syringes

During the production of glass

syringes, the needle is glued to

the glass tube. Punctual measuring pyrometers are used to monitor and control the process and

ensure the quality of the syringes.

Product: optris

®

Induction heating processes

Induction heating has acquired

high importance within the area

of heat treatment of metal. The

aimed-for texture structure of

the metal depends on the ideal

temperature time process.

CSmicro LT

CTfast LT

Function tests of assembled circuit boards

More and more manufacturers

of electronic components and

circuit boards are turning to the

use of non-contact temperature

measurement due to the increasing

productivity of their components.

Product: optris

®

PI 450

Hot deforming of metals

Narrow temperature limits need

to be met during hot deforming

processes of metal. Handheld

devices can be used for sporadic

monitoring in forging and bending

processes.

Product: optris

®

P20 2M

Preventive electrical maintenance

Almost every current asset which

is supported by energy turns hot

before a breakdown. Temperature

monitoring can best be provided

in line with preventive electronic

maintenance.

Product: optris

®

CTlaser 1M

innovative infrared technology

Product: optris

Optris Infrared Sensing, LLC

200 International Drive

Suite 170

Portsmouth, NH 03801 USA

Phone: (603) 766-6062

E-mail: sales@optris-ir.com

www.optris.com

®

MS LT

Specications are subject to change without notice · Product Overview-BR-US2018-09-A

Loading...

Loading...