OptoTest OP415 Instruction Manual

www.optotest.com

1.805.987.1700

Polarity Analyzer

Instruction Manual

OP415

1 of 29

Contacting OptoTest Corporation

1.805.987.1700 (7:30 a.m. to 5 p.m. PST)

www.optotest.com

engineering@optotest.com

OptoTest Corp.

4750 Calle Quetzal

Camarillo, CA 93012 USA

Notice of Proprietary Rights

The design concepts and engineering details embodied in this manual, which are

the property of OptoTest Corporation, are to be maintained in strict condence. No

element or detail of this manual is to be spuriously used or disclosed without the

express written permission of OptoTest Corporation. All rights are reserved. No part

of this publication may be reproduced, stored in a retrieval system, or transmitted

in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without prior written permission from OptoTest Corporation.

COPYRIGHT © 2018 by OptoTest Corp

ALL RIGHTS RESERVED

PRINTED IN THE UNITED STATES OF AMERICA

MnOP415-RevA

OP415

2 of 29

Table of Contents

Overview 3

Initial Preparation 4

Unpacking and Inspection 4

Damaged in Shipment 4

Standard Contents 4

Denition of Specications 5

Nomenclature 8

How to Navigate the User Interface 9

Front Panel Operation 10

Map Screen 10

Create Type Screen 14

Files Screen 16

Settings Screen 17

Example 1: Running a Test 20

Example 2: Create a New Type 22

Example 3: Create Power Level Reference 24

Example 4: Testing 12-Fiber Polarity 25

Warranty Information 27

OP415

3 of 29

Overview

The OP415 is designed to analyze the polarity and output quality of MTP®/MPO cable

assemblies of up to 24 bers. Individual power meters allow for testing 24 ber polarity

in 1.5 seconds and fewer channel counts in fractions of that time. The unit comes

pre-loaded with 12 and 24 ber types A, B, and C; along with the ability to create and

store new types. In addition, the unit is able to check the quality of a cable and store

test results, with internal storage for up to 256 cable types and test results.

The full color touchscreen display, compact design, and lightning fast test time make

the OP415 Polarity Analyzer the ideal test solution for environments where MTP/MPO

cables are manufactured or utilized.

The OP415 is able to analyze polarity for:

• Type A (12, 24)

• Type B (12,24)

• Type C (12,24)

• 8,12,16, 24 ber

• Custom Fiber Mappings

OP415

4 of 29

Initial Preparation

Unpacking and Inspection

The unit was carefully inspected; mechanically, electrically, and optically before shipment.

When received, the shipping carton should contain the items listed in Standard

Contents; account for and inspect each item. In the event of a damaged instrument,

write or call OptoTest Corp, California.

Note: Be aware that accessories such as detector adapters, remote head detectors,

and high performance reference cables will be located inside a small box labeled

“Accessories Inside”. If this box is not included with the original shipment, contact

OptoTest or their nearest distributor.

Please retain the shipping container in case re-shipment is required for any reason.

Damaged In Shipment

All instruments are shipped F.O.B. Camarillo when ordered from OptoTest.

If you receive a damaged instrument you should:

1. Report the damage to your shipper immediately.

2. Inform OptoTest Corporation.

3. Save all shipping cartons.

Failure to follow this procedure may aect your claim for compensation.

Standard Contents

1. Model OP415 Polarity Analyzer

2. 9V Power Supply and Power Cord

3. USB A-B cable

4. Certicate of Conformance

5. Instruction Manual

6. USB drive with applicable software and documentation (if ordered)

OP415

5 of 29

Definition of Specifications

Dynamic Range

The dynamic range, or measurement range, of the optical power meter spans from the

maximal power level the instrument can measure, without major saturation to the detector,

to the minimal power level where the thermal noise of the detector becomes greater

than the current produced by the incident light. For accurate power measurements, it

is NOT recommended to measure power levels at either end of the dynamic range (see

Linearity). The dynamic range is measured by comparing the absolute measured power

against a reference power. When the difference between the two exceeds 1dB either

end of the dynamic range has been reached.

Linearity

Photodetectors are, by nature, very linear over a wide range of optical input powers,

but the power meter electronics can affect the overall system linearity. The power meter

linearity is characterized and specified to know the measurement accuracy and linearity

over the full dynamic range. For accurate insertion loss measurements only power levels

that fall within the range with the best linearity (+/-0.05dB or better) should be measured.

Calibration Wavelength

The calibration wavelengths are the nominal wavelengths of the instrument’s calibration

points. The exact wavelength of each particular calibration is stated in the Certificate of

Calibration.

Calibration Traceability

The detector’s absolute calibration data is directly traceable to N.I.S.T. at the specified

calibration wavelength and the specified power level, typically -10dBm.

OP415

6 of 29

Absolute Accuracy

The absolute accuracy specification includes the total measurement uncertainties

involved in the calibration process including the transfer of the absolute power standard

from N.I.S.T. (Contact OptoTest for the detailed chain of uncertainties)

Optical Power Meter, Channel Performance

For multichannel instruments, the power meter circuit converts and digitizes the optical

power level with the given sampling interval. Changes in light levels such as modulation

will be averaged within that sampling interval.

Instrument, Warm-up Time

Optical power meters, in general, do not need any warm-up time unless the instrument

has to acclimate to a changing environment. In order to calibrate the instrument or to

perform stable measurements, the instrument should be acclimated for 15 minutes for

each 5ºC of temperature differential. For example, if the instrument was stored at 18ºC

and brought into an environment of 28ºC the instrument should be allowed to warm-up

for 30 minutes.

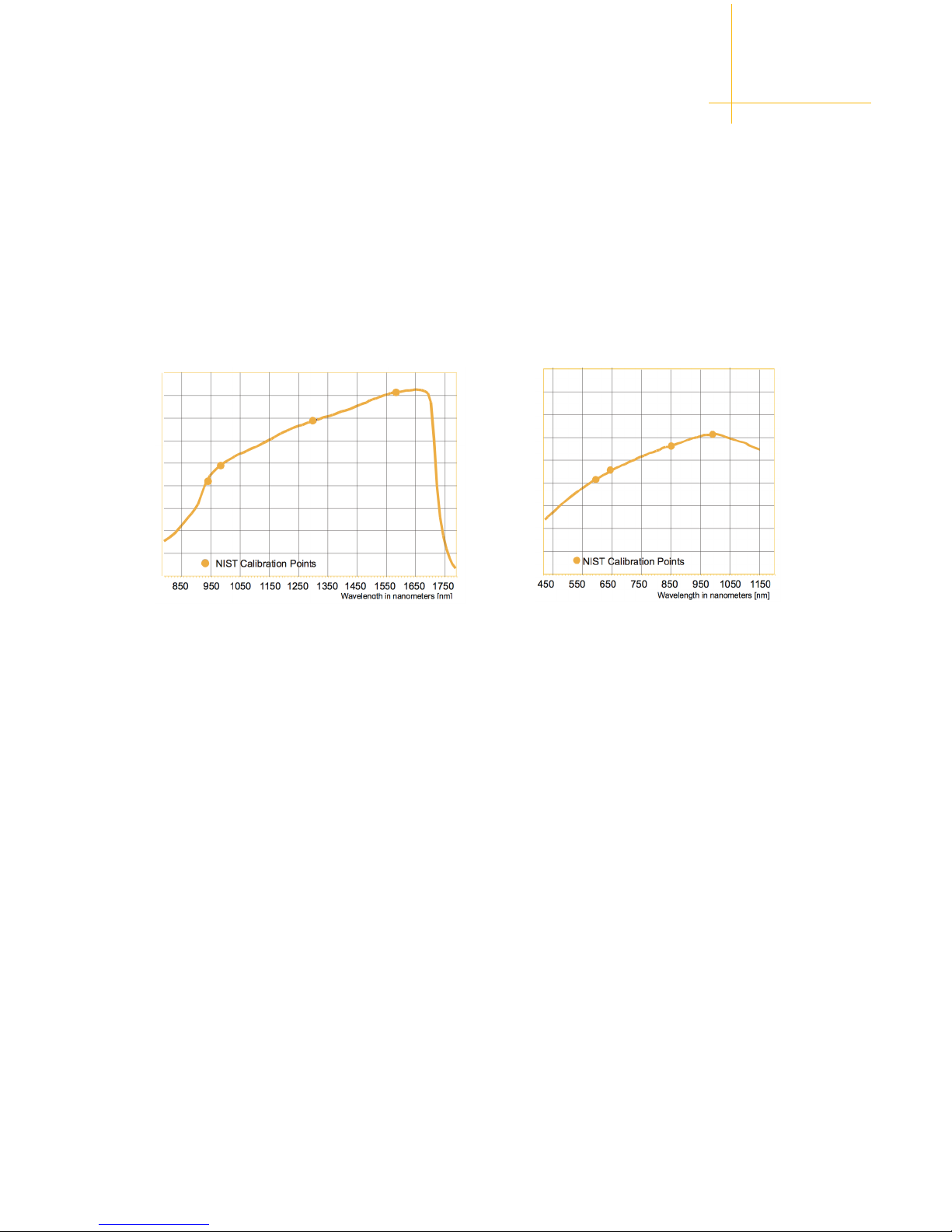

Responsivity of InGaAs Detectors Responsivity of Silicon Detectors

Note that other detector types are available such as IN5 (5mm InGaAs) IN10 (10mm InGaAs) as

well as WSR (wide spectral range) and might exhibit a different spectral responsivity.

Definition of Specifications

Spectral Responsivity

Depending on the detector type, InGaAs (Indium Gallium Arsenide) or Silicon the

spectral responsivity, the efficiency of the detector to convert optical power into

electrical current, changes with wavelength.

OP415

7 of 29

Definition of Specifications

Recommended Recalibration Period

This is the recommended time period for re-calibration in order to maintain accuracy

specifications. The recommendation is made based upon statistics on detector aging.

However, it is up to the metrology policies and procedures within each company to

define the calibration cycles on optical power meters.

Optical Power Meter, Fiber Compatibility

The amount of areal coverage of the detector, or the portion of the light emitted from

the fiber being measured, depends on the mechanical features of the optical interface,

the active area of the detector and the numerical aperture (NA) of the fiber. A fiber

with a large NA, for example 100/140 multimode fiber, may not under fill a small area

detector hence the absolute power reading will be less than actual.

Reference Cable

The reference cable is the cable with which the DUTs will be measured against. Typically

reference cables are required to be of a defined quality with a specified connector/

endface polish.

Instrument, Environmental

Operating Temperature: This is the temperature range in which the instrument will

conform to the specifications after the specified warm-up time.

Storage Temperature: This is the temperature range at which the instrument can

be stored with the power off without any damage or any loss of specification to the

instrument. It is required that the instrument be brought back to within the operating

temperature range before it is turned on.

Humidity: The relative non-condensing humidity levels allowed in the operating

temperature range.

OP415

8 of 29

Nomenclature

Touchscreen Display

Power Button

(Keyed)

Laser Emission

Safety Label

Removable

Front Panel

Removable

Feet

Source

Port

Receive

Port

OP415

9 of 29

Map Screen

Create Screen

File Screen

Settings Screen

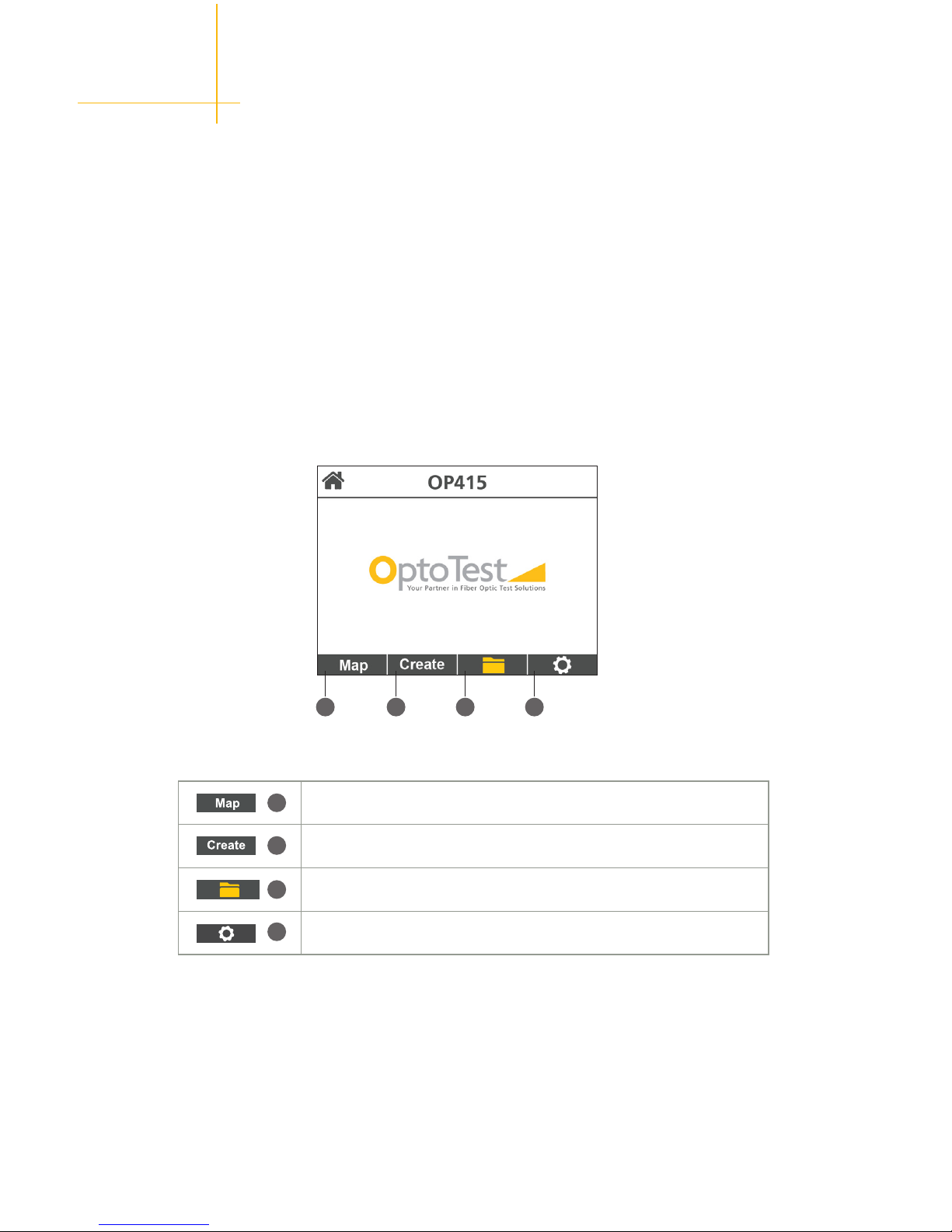

How to Navigate the User Interface

The OP415 is equipped with a full color touchscreen display, eliminating the need for

physical buttons and allowing for increased functionality through the front panel.

Home Screen

At startup, the unit loads the Home screen. From here the user can select the Map

screen, Create screen, File screen or the Settings screen.

Note: There is an option in the Settings to go directly to the Map screen at power up.

1

2

3

4

1 2 3 4

Loading...

Loading...