Optoma EP1080, DX1080, OP1990, VE810, PV8530 Service Manual

...

SERVICE MANUAL

SI : TSE: Check: Approved:

Date Revise Version Description

2008.09.10 V1.0 Initial Issue

2008.09.22 V2.0 Modify Chapter 1 and add Chapter 7

2009.03.13 V3.0

Add EP1080 extended models: DX1080, OP1990,

VE810, DP7290, PV8530, P350, TX1080 and amend

the method of getting into FW mode in Chapter 5

EP1080/DX1080/OP1990/VE810/DP7290/

PV8530/P350/TX1080

Copyright March, 2009. All Rights Reserved P/N:36.8BH03G001

EP1080 Series

Condential

I

Preface

This manual is applied to EP1080 Series projection system. The manual gives you a brief

description of basic technical information to help in service and maintain the product.

Your customers will appreciate the quick response time when you immediately identify

problems that occur with our products. We expect your customers will appreciate the

service that you offer them.

This manual is for technicians and people who have an electronic background. Please

send the product back to the distributor for repairing and do not attempt to do anything that

is complex or is not mentioned in the troubleshooting.

Notice: The information found in this manual is subject to change without prior notice. Any

subsequent changes made to the data herein will be incorporated in future edition.

EP1080 Series Service Manual

Copyright March.2009

All Rights Reserved

Manual Version 3.0

EP1080 Series

Condential

II

Table of Content

Chapter 1 Introduction

Highlight 1-1

Compatible Mode 1-4

Chapter 2 Disassembly Process

Equipment Needed & Product Overview 2-1

Disassemble Lamp Cover Module 2-2

Disassemble Lamp Module 2-2

Disassemble Lens Shelter 2-3

Disassemble Top Cover Module 2-3

Disassemble Keypad Board Module 2-4

Disassemble Vent 2-5

Disassemble Rear Cover Module 2-7

Disassemble Formatter Board and Scaler Board Module 2-8

Disassemble Air Ductor 2-10

Disassemble System Fan Module 2-10

Disassemble Left Shielding Module 2-12

Disassemble Engine Module 2-13

Disassemble Color Wheel Module 2-14

Disassemble DMD Chip 2-15

Disassemble LVPS Module 2-15

Disassemble Ballast Module 2-16

Disassemble Blower Module 2-17

Disassemble Safety Switch 2-18

Disassemble IR Sensor Board and AIR Duct 2-18

EP1080 Series

Condential

III

Disassemble Left and Right Elevator Module 2-19

Rod Adjustment 2-21

Re-write Lamp Usage Hour 2-22

Chapter 3 Troubleshooting

LED Lighting Message 3-1

Main Procedure 3-2

Chapter 4 Function Test & Alignment Procedure

Test Equipment Needed 4-1

Service Mode 4-1

OSD Reset 4-1

Test Condition 4-2

Test Inspection Procedure 4-3

PC MODE 4-3

Calibration 4-7

Optical Performance Measure 4-10

Video Performance 4-12

Network Function Test 4-14

Others 4-16

Chapter 5 Firmware Upgrade

Equipment Needed 5-1

USB Driver Setup Procedure 5-2

Firmware Upgrade Procedure 5-3

EP1080 Series

Condential

IV

Chapter 6 EDID Upgrade

EDID Introduction 6-1

Equipment Needed 6-2

Setup Procedure(VGA-2 & DVI-D Port) 6-3

EDID Key-In Procedure(VGA-2 & DVI-D Interface) 6-3

Setup Procedure(VGA-1 & HDMI Port) 6-6

EDID Key-In Procedure(VGA-1 & HDMI Interface) 6-6

Chapter 7 Network FW Upgrade

Equipment Needed 7-1

Read Projector IP 7-2

Network Setting 7-3

PC Hardware Link 7-4

Appendix A

Exploded Image I

Appendix B

SerialNumberSystemDenition XIX

PCBACodeDenition XX

EP1080 Series Condential 1-1

Chapter 1

Introduction

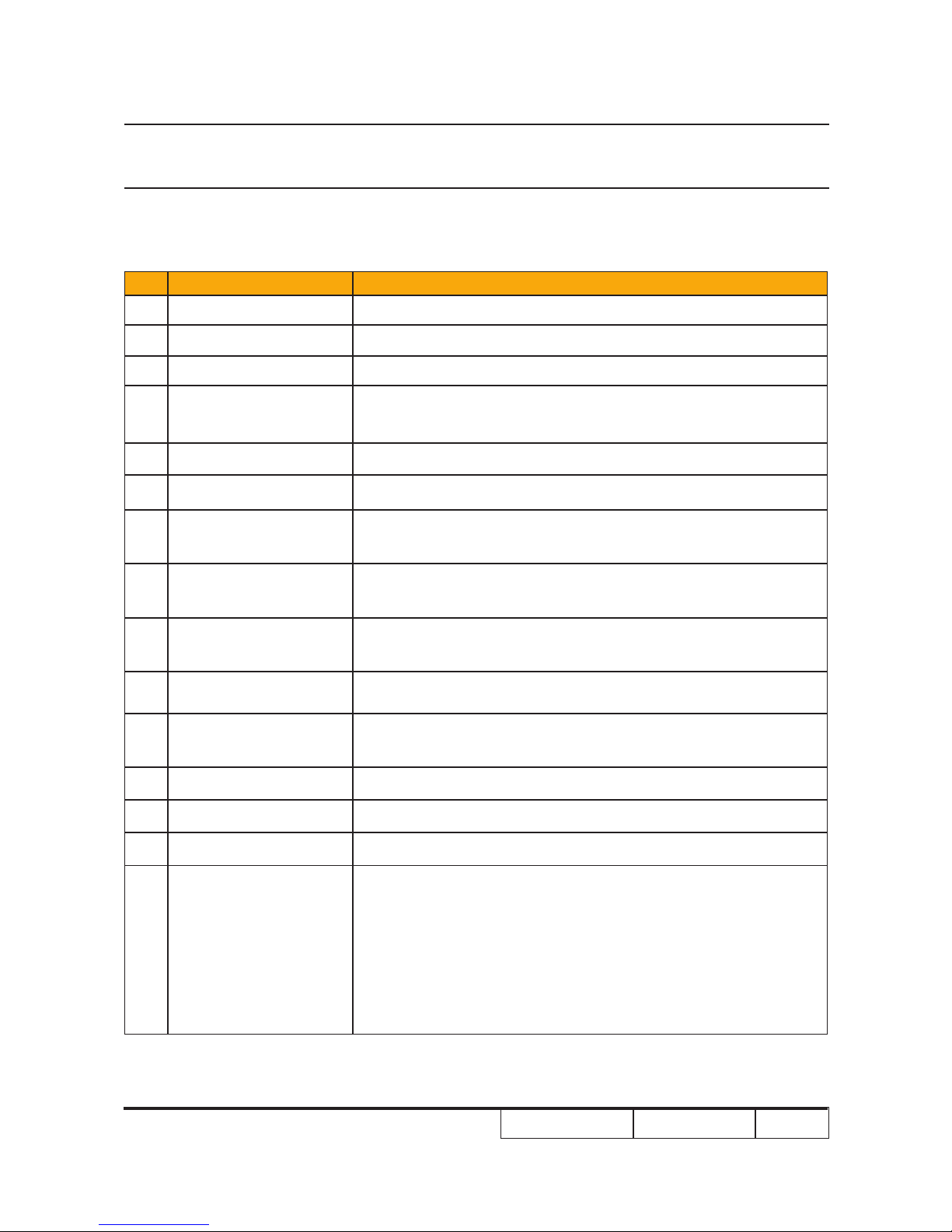

No Item Description

1 Dimension (L x W x H)

• 411 x 311 x 116 (mm)

2 Weight

• Unit(projector): approx. 10 lbs (< 11lb)

3 Tilt Angle

• 6 degree with elevator mechanism

4 Power Supply

• Universal AC 100--240V; 50 / 60 Hz with PFC input

• Provide for Philips 300W UHP E21.9 lamp

5 Keystone correction

• -5°~ +10° Vertical

6 Resolution

• 1920 x 1080P

7 Brightness

• 2,872 ANSI Lumens (Typical)

• 2,584 ANSI Lumens (Min.)

8 Contrast

• 1,500 :1 full on/full off (Typical)

• 1,200 :1 full on/full off (Min.)

9 Uniformity

• 70% Japan standard (Typical)

• 60% Japan Standard (Min.)

10 Throw ratio

• 1.85 – 2.22:1 distance/width

11 Projection lens

• F/ 2.6~2.89, f = 39.12~46.91 mm. 1.2X Zoomed Focal Lens.

• Offset : 136 +/- 5%

12 Color wheel

• 5 Segment, RYGWB (R80Y40G82W78B80)

13 System controller

• Dual DDP3021, DAD1000, PMD1000 for 1080p DMD

14 Lamp

• Philips 300Watt E21.9 UHP

15 Altitude

• Operating

0~2,500 ft 5°C~35°C

2,500~5,000 ft 5°C~30°C

5,000~10,000 ft 5°C~25°C

• Storage

40,000 ft

1-1 Highlight

EP1080 Series

Condential

2

No Item Description

16 Maximum Humidity

• Operating:

5 ~ 35°C, 80%RH (Max.), non-condensing

• Storage:

-20 ~ 60°C, 80%RH (Max.), non-condensing

17 Video compatibility

• NTSC: NTSC M/J, NTSC 4.43

• PAL: PAL B/D/I/G/H, PAL M, PAL N

• SECAM: SECAM B/D/G/K/L

• SDTV: 480i, 480p, 576i, 576p,

• HDTV: 720p(50Hz),720p(60Hz),1080i(50Hz),1080i(60Hz),

1080p (60Hz)

18 Input signal

• Analog RGB signal(PC)

Analog RGB 0.7Vp-p, 75 ohm

Analog RGB 1Vp-p, 75 ohm, Sync. signal

Separate TTL H,V Sync.

Composite TTL Sync.

• Video signal

Composite video 1Vp-p, 75 ohm

S-video Luminance 0.714Vp-p, 75 ohm

Chrominance 0.286Vp-p, 75 ohm

19 Temperature

• Operating: 5 ~ 35°C

• Storage: -20 ~ 60°C

20 DMD Chip

• TI DMD, Single chip 0.95” Dark Chip 1 LVDS 1080p Super

value DMD

21 Number of active dots

• 1920(H) x 1080(V)

22 Audio

• in (3.5mm) x 3 for VGA1, VGA2, DVI-D

• out (3.5mm) x 1

• in RCA(L/R) x 1 for S-video, Composite

23 Cooling System

• Advanced air ow

• One fan/ two blowers(in projector) with low system acoustic

noise level

• Temperature control circuits with adaptive voltage control fan

speed

• Max touch temperature follows UL60950 regulation

1-

Condential

1-3

No Item Description

24 Power consumption

• Full power(at normal mode):typical 400W+/-10% at 110V AC

• ECO power(at ECO mode):typical 340W +/-10% at 110V AC

• Standby mode: < 14W at 110V AC

25 Terminal

• One HDMI input connectors (Support Audio input)

• One DVI-D input

• Two VGA input

• One VGA output

• One S-Video

• One Composite Video

• One 12V relay

• Audio-in (3.5mm) x 3 for VGA1, VGA2, DVI-D

• Audio-out (3.5mm) x 1

• Audio-in RCA(L/R) x 1 for S-video, Composite

• One D-sub 9-pin RS-232 port

• USB x 1 (Type B)

• RJ-45 x 1

• One 3-pin AC power inlet port

EP1080 Series

EP1080 Series

Condential

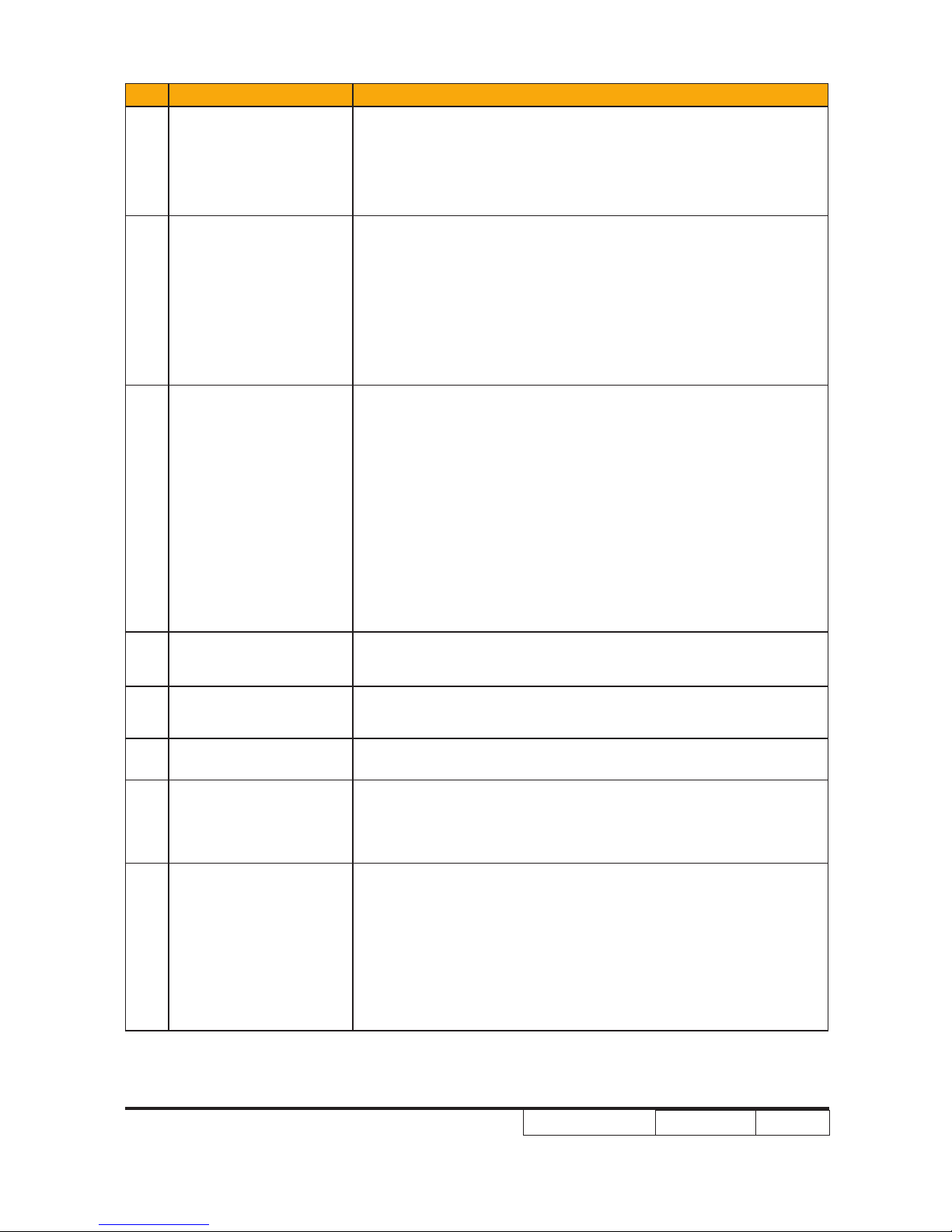

1-2 Compatible Mode

Analog

Compatibility Resolution V-Sync [Hz]

VGA

640x350 70

640x350 85

640x400 85

640x480 60

640x480 72

640x480 75

640x480 85

720x400 70

720x400 85

SVGA

800x600 56

800x600 60

800x600 72

800x600 75

800x600 85

XGA

1024x768 60

1024x768 70

1024x768 75

1024x768 85

WXGA*

1280x720 60

1280x768 60

1280x768 85

SXGA

1280x1024 60

1280x1024 75

SXGA+ 1400x1050 60

UXGA 1600x1200 60

1-4

EP1080 Series

Condential

1-5

Compatibility Resolution V-Sync [Hz]

VGA

640x480 60

640x480 72

640x480 75

640x480 85

SVGA

800x600 60

800x600 75

800x600 85

XGA

1024x768 60

1024x768 70

1024x768 75

1024x768 85

WXGA

1280x768 60

1280x768 70

HD

1280x720 60

1280x1024 60

1280x1024 75

SXGA+ 1400x1050 60

UXGA 1600x1200 60

Digital

EP1080 Series Condential

2-1

Chapter 2

Disassembly Process

2-1 Equipment Needed & Product Overview

1. Screw Bit (+) :105

2. Screw Bit (+) :107

3. Screw Bit (-) :107

4. Hex Sleeves 5 mm

5. Tweezers

6. Projector

* Before you start: This process is protective level II. Operators should wear electrostatic chains.

* Note: - If you need to replace the scaler board, you have to record the lamp usage hour.

- As the process of EP1080 extended models disassembling is the same as EP1080, we

take EP1080 for example here.

EP1080 Series Condential 2-2

2-3 Disassemble Lamp

Module

1. Unscrew 2 screws (as red circle) on the

Lamp Module.

2. Take off Lamp Module.

2-2 Disassemble Lamp

Cover Module

1. Unscrew 2 screws (as red circle) on the

Lamp Cover.

2. Disassemble Lamp Cover Module.

EP1080 Series Condential 2-3

2-4 Disassemble Lens

Shelter

1. Turn the projector backside.

2. Press two sides of the Lens Shelter as

red arrow point and take it up.

2-5 Disassemble Top Cover

Module

1. Unscrew 4 screws from the Bottom

Cover (as red circle).

2. Unscrew 2 screws from the Rear Cover

(as yellow circle).

3. Push forward to remove the Top Cover

Module.

4. Unplug 1 FPC Cable from the Scaler

Board Module (as blue circle).

EP1080 Series Condential 2-4

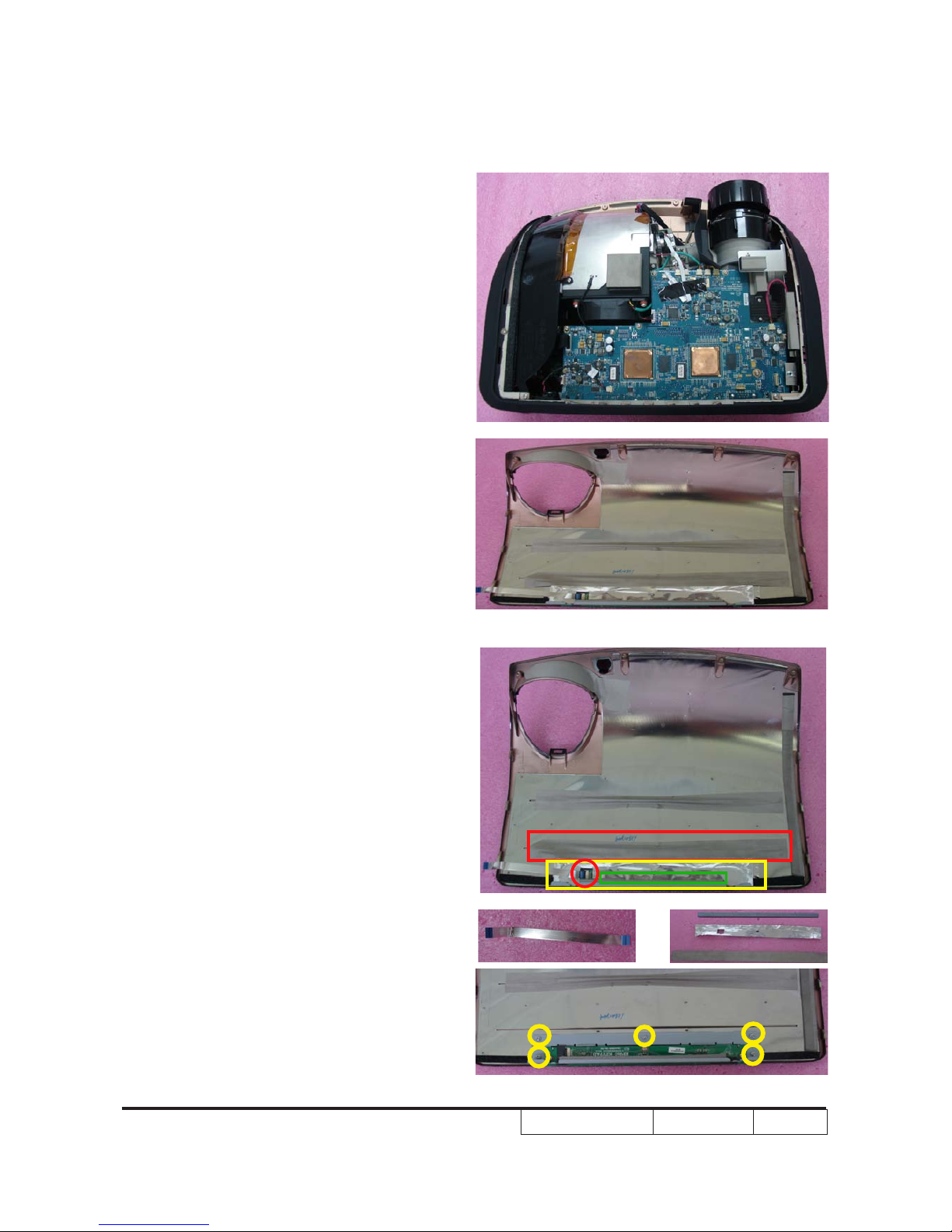

5. Disassemble the Top Cover Module.

2-6 Disassemble Keypad

Board Module

1. Unplug 1 FPC cable (as red circle).

2. Take off EMI Gasket (as green square),

EMI Type (as red square) and Keypad

Type (as yellow square).

3. Unscrew 5 screws (as yellow circle).

4. Disassemble the Keypad Board Module.

EP1080 Series Condential 2-5

5. Unscrew 5 screws (as blue circle).

6. Separate Keypad Board,Keypad Button,

LED Transparent Bar and Keypad Brac-

ket.

2-7 Disassemble Vent

1. Unscrew 1 screw on the Left Vent (as red

circle).

2. Turn the projector to backside and

unscrew 3 screws (as blue circle).

3. Uplug 1 connector (as yellow square) and

remove the Left Vent.

EP1080 Series Condential 2-6

4. Unplug 4 clips (as red sqaure) and

remove the Speaker.

5. Unscrew 2 screws on the Right Vent

(as green circle).

6. Turn the projector backside and unscrew

3 screws (as orange circle).

7. Remove the Right Vent.

EP1080 Series Condential 2-7

2-8 Disassemble Rear Cover

Module

1. Unscrew 10 hex screws (as red circle)

and 3 usual screws (as yellow circle).

2. Turn the projector backside and unscrew

3 screws (as green circle).

3. Unplug the connector (as orange sqaure)

and remove the Rear Cover.

4. Unplug 4 clips (as red sqaure).

EP1080 Series Condential 2-8

2-9 Disassemble Formatter

Board and Scaler Board

Module

1. Take off mylar (as red square).

2. Unplug 10 connectors (as yellow square).

3. Unscrew 7 screws (as green circle).

4. Remove the Formatter Board and Scaler

Board Module.

Note:The formatter board is connected on

the DMD board (as yellow square).

5. Remove the Speaker.

EP1080 Series Condential 2-9

5. Unplug 3 connectors (as blue square) to

seperate two boards.

6. Take off Lan Board from the Formatter

Board.

7. Take off 3 Hex screws (as green circle)

from the Scaler Board.

EP1080 Series Condential 2-10

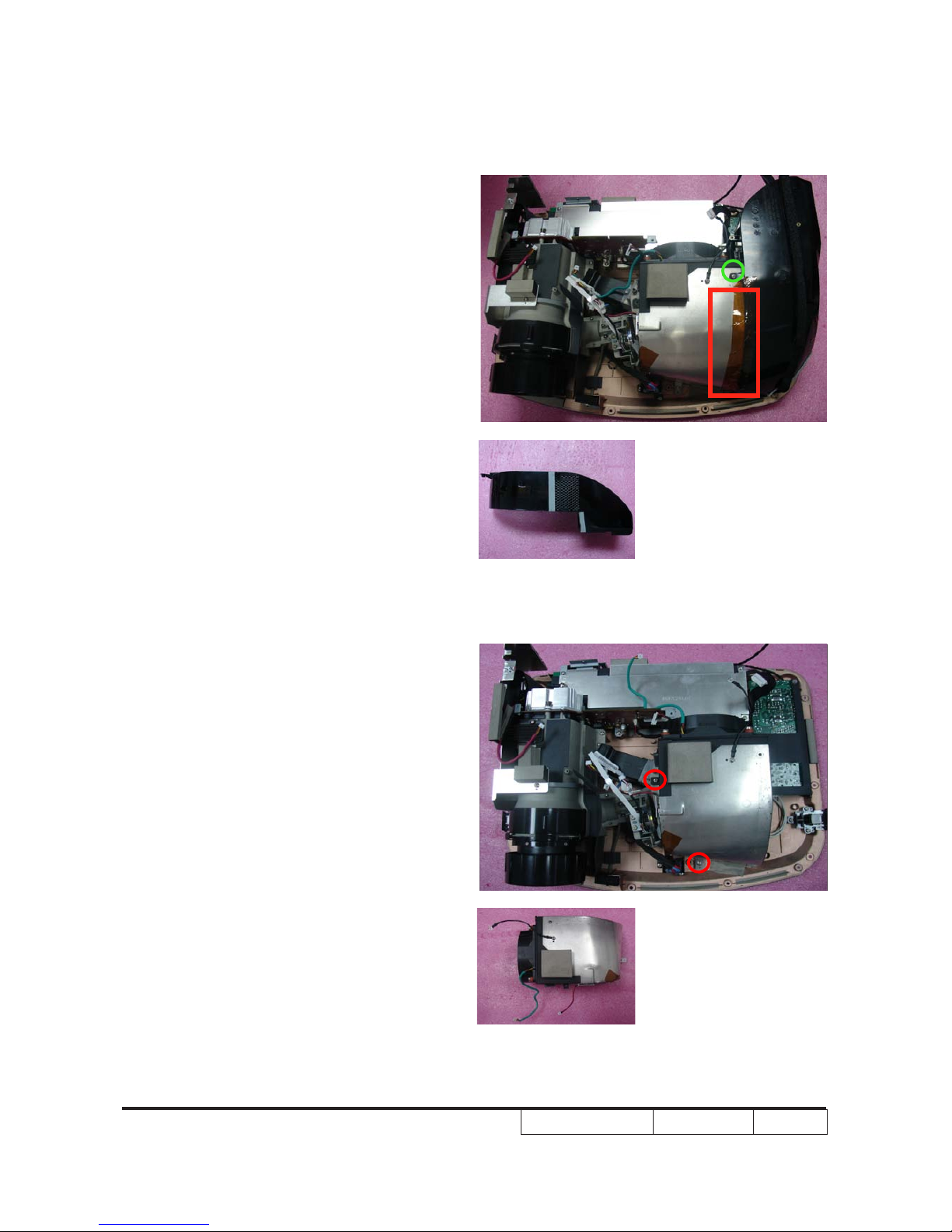

2-10 Disassemble Air Duct

1. Tear off 1 tape kapton (as red square).

2. Unscrew 1 screw (as green circle), then

disassemble Air Duct.

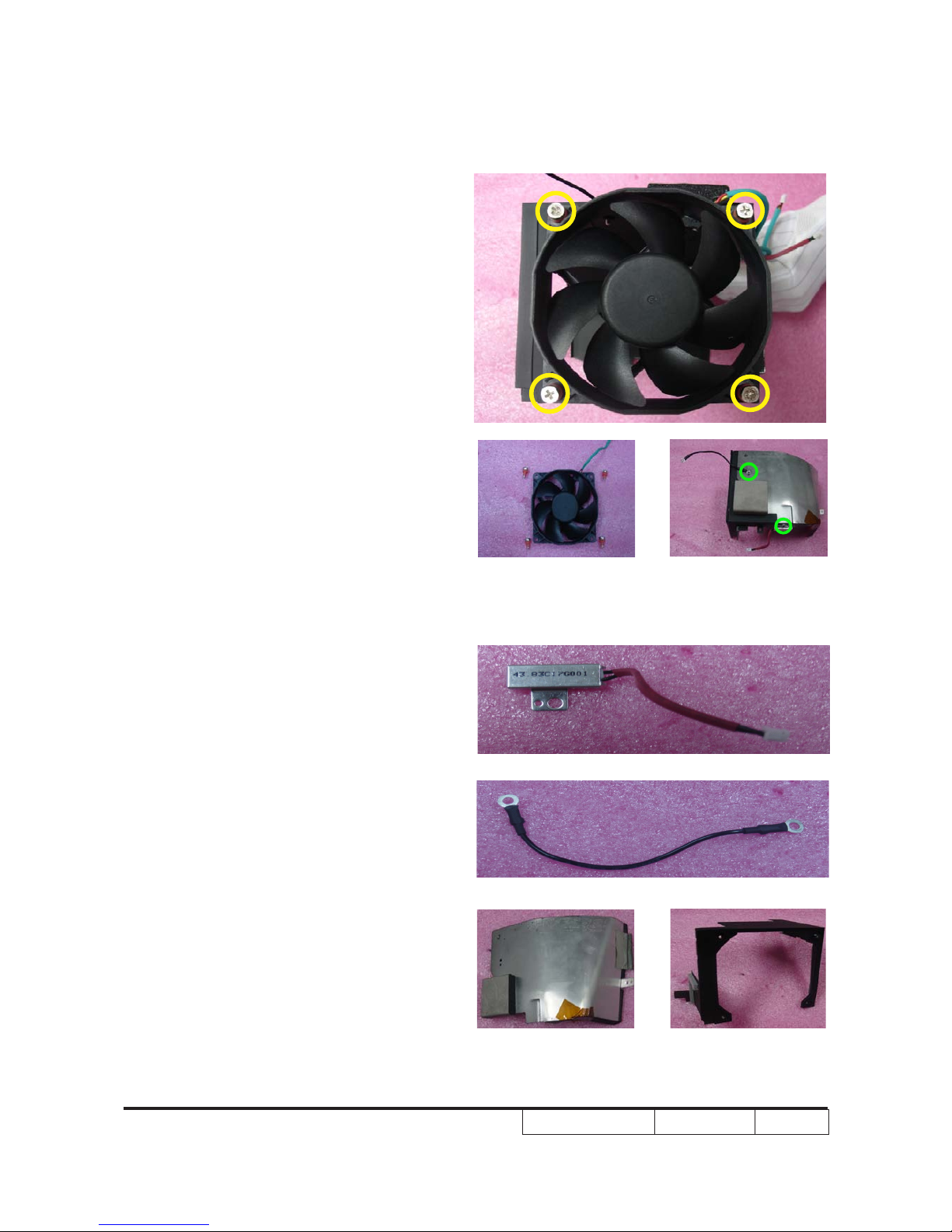

2-11 Disassemble System

Fan Module

1. Unscrew 2 screws (as red circle) and

disassemble Fan Module.

EP1080 Series Condential 2-11

2. Unscrew 4 screws (as yellow circle) and

separate Bracket and Fan.

3. Unscrew 2 screws (as green circle),

separate thermal switch and ground wire

and others.

EP1080 Series Condential 2-12

2-12 Disassemble Left

Shielding Module

1. Unscrew 3 screws (as red circle) and

disassemble Left Shielding Module.

2. Tear off mylar (as orange square),

unscrew 3 screws (as green circle) and

separate Fan and Left Shielding , then

tear off mylar (as blue square) from the

Left Shielding.

Note: - Take the Fan Module as the right

gesture.

the wrong gesture

the right gesture

EP1080 Series Condential 2-13

2-13 Disassemble Engine

Module

1. Disassemble 1 mylar (as orange square)

and EMI Gasket (as blue square).

2 .Unscrew 6 screws (as red circle) to

disassemble Engine Module.

3. Turn the Focus Ring as the yellow as the yellow

direction,then disassemble Focus Ring.disassemble Focus Ring.

EP1080 Series Condential 2-14

4. Unscrew 2 screws on the zoom ring

cover (as red circle),remove the Zoom

Ring as the picture.

2-14 Disassemble Color

Wheel Module

1. Unscrew 2 screws (as red circle) to

disassemble Color Wheel Module.

2. Unscrew 1 screw (as yellow circle) to

disassemble Photo Sensor Board from

Color Wheel Module.

Note: - Avoid to touch the glass parts of color

wheel.

EP1080 Series Condential 2-15

2-15 Disassemble DMD Chip

1. Unscrew 4 screws (as red circle) on the

heatsink bracket and separate all parts.

Note: - The manner of placing a DMD mask.

- Use an electrostatic ion gun to puff

the engine room in the DMD mask.

- If there are scrapes or dirt on the

DMD chip when using a magnifying

glass to have a close look, use an

electrostatic ion gun to clean it.

- To double check and see if the pin is

out of shape.

2-16 Disassemble LVPS

Module

1.Unscrew 6 screws (as red circle).

2. Disassemble LVPS Module holder, mylar,Disassemble LVPS Module holder, mylar,

AC Inlet Bracket.

EP1080 Series Condential 2-16

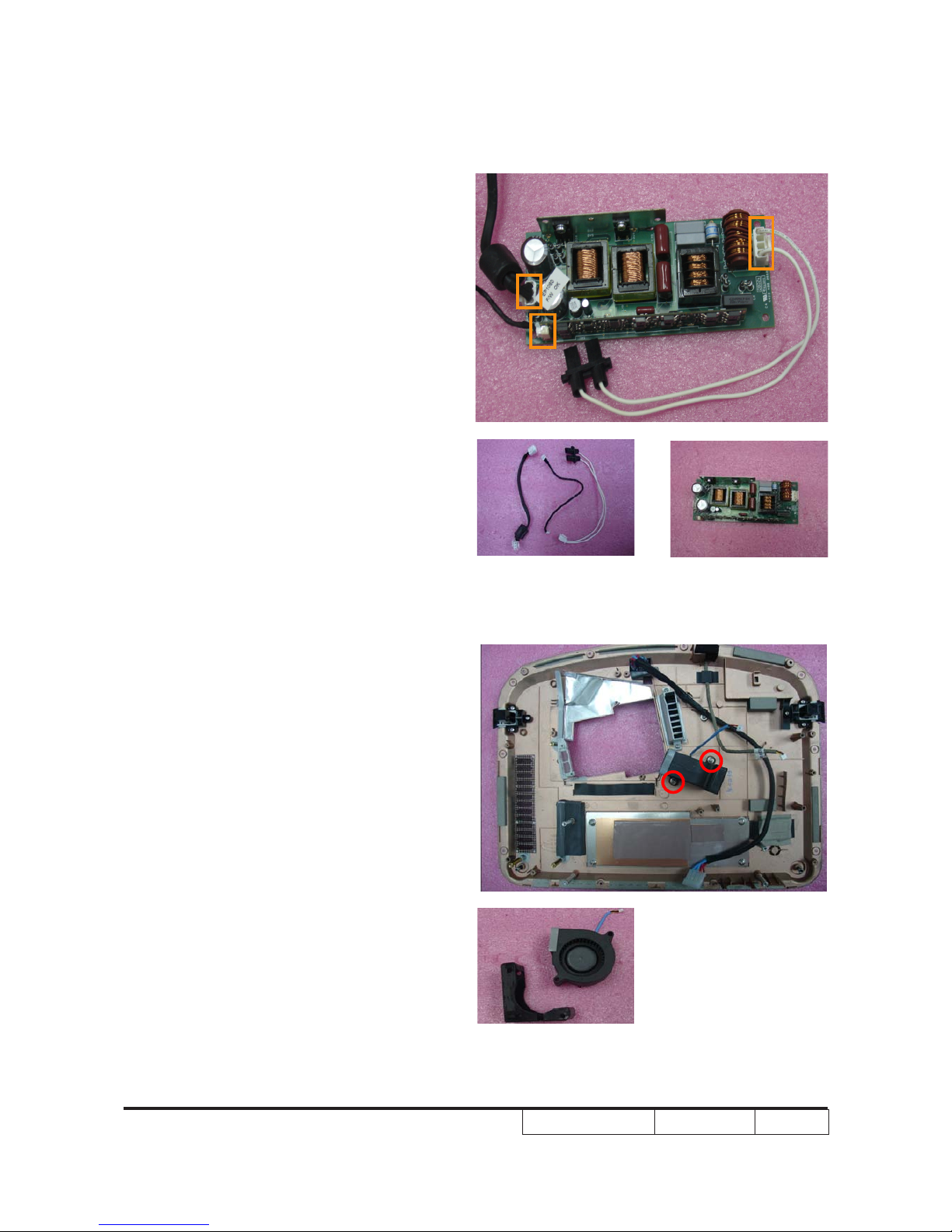

2-17 Disassemble Ballast

Module

1. Unsrew 5 srews (as red circle),and

disassemble Ballast Module.

3. Unplug 2 connectors (as green square).

4. Unplug 1 connector (as yellow square)(as yellow square)

and separate LVPS and the wire .and separate LVPS and the wire .

EP1080 Series Condential 2-17

2-18 Disassemble Blower

Module

1. Unscrew 2 screws (as red circle).

2. Remove the Blower Module and

separate Blower and Rubber.

2. Unplug 3 connectors (as orange square)

and all wires,then dissassemble Ballast

Module.

Loading...

Loading...