Page 1

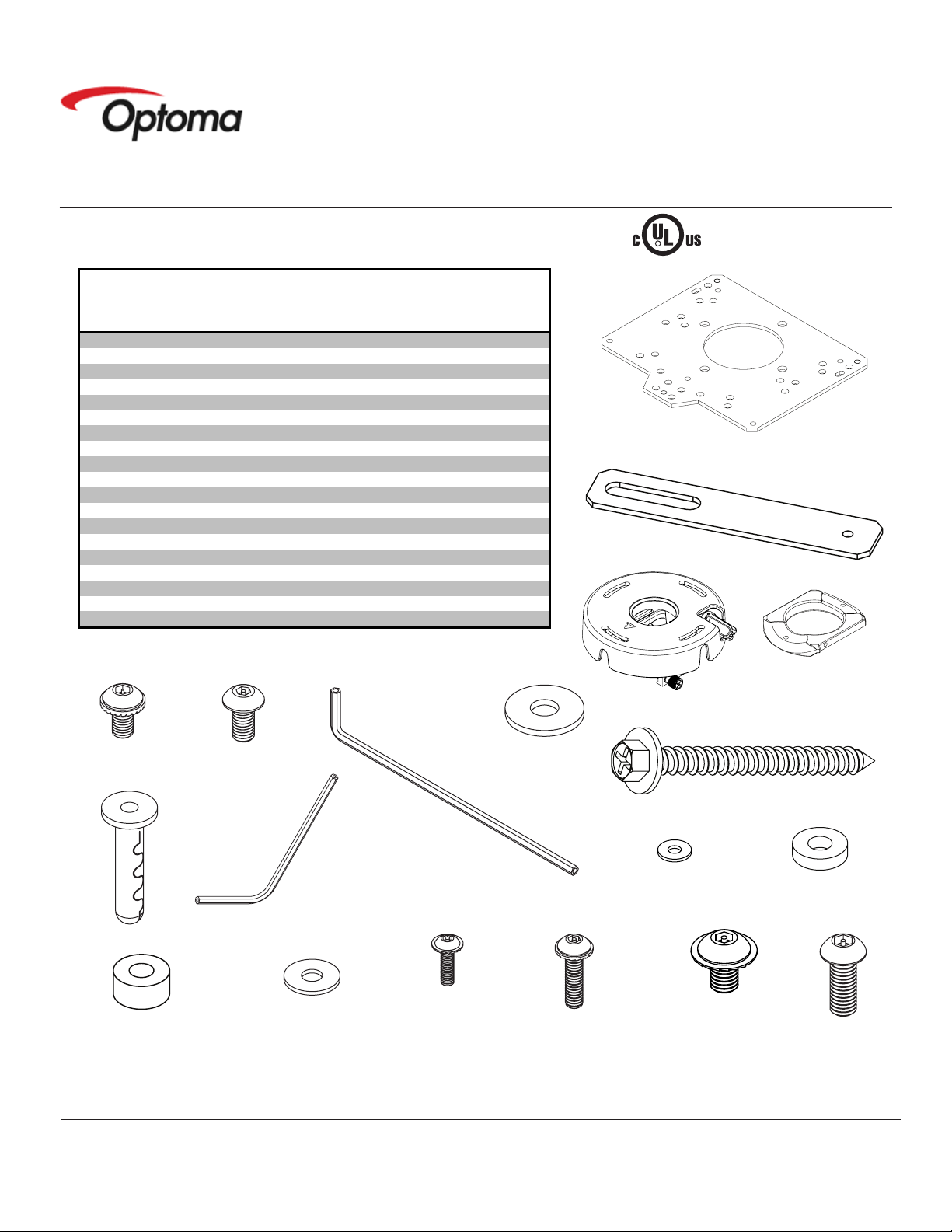

Description Qty. Part #

A

main plate 1 055-1939

B

extension bracket 4 055-1940

C

precision gear projector mount 1 055-KPRGU-B-3

D

10-32 x 3/8" socket pin serrated washer head screw

2

520-1151

E

10-32 x 1/4" socket pin with lock patch 1 520-1196

F

4 mm security allen wrench

1

560-9646

G

6.5 ID x 17.8 OD x 1.6 mm flat washer

2

540-1078

H

#14 x 2.5 hex phillips wood screw 2 5S1-015-C03

I

alligator anchor 2 590-0097

J

2 mm security allen wrench

1

560-1097

K

#4 flat washer 8 540-1049

L

.219 ID x .5 OD x .125 spacer

6

540-1032

M

.219 ID x .5 OD x .25 spacer

4

540-9413

N

#8 flat washer

8

540-1001

O

M3 x 12 mm socket pin serrated washer head screw 4 510-1003

P

M4 x 16 mm socket pin serrated washer head screw

4

510-1087

Q

M4 x 8 mm socket pin serrated washer head screw

4

510-1005

R

M6 x 16 mm socket pin screw

4

520-1132

AA

connection block

1

580-1065

Parts List

Installation and Assembly:

Optoma Universal Projector Mount By Peerless

This product is intended for use with UL

Model: BM-5001U

Max Load Capacity: 50 lb (22.6 kg)

Listed products and must be installed by a

qualied professional installer.

A

B

D

I

E

F

J

M

NOTE: The following pages show the attachment points and hardware required to attach main plate

to projectors.

NOTE: Before installation review the directory on page 2 to nd projector conguration.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 729-0307 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

N

C

AA

G

K

L

O P Q R

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

H

Page 2

1

T

V

0

0

W

0

W

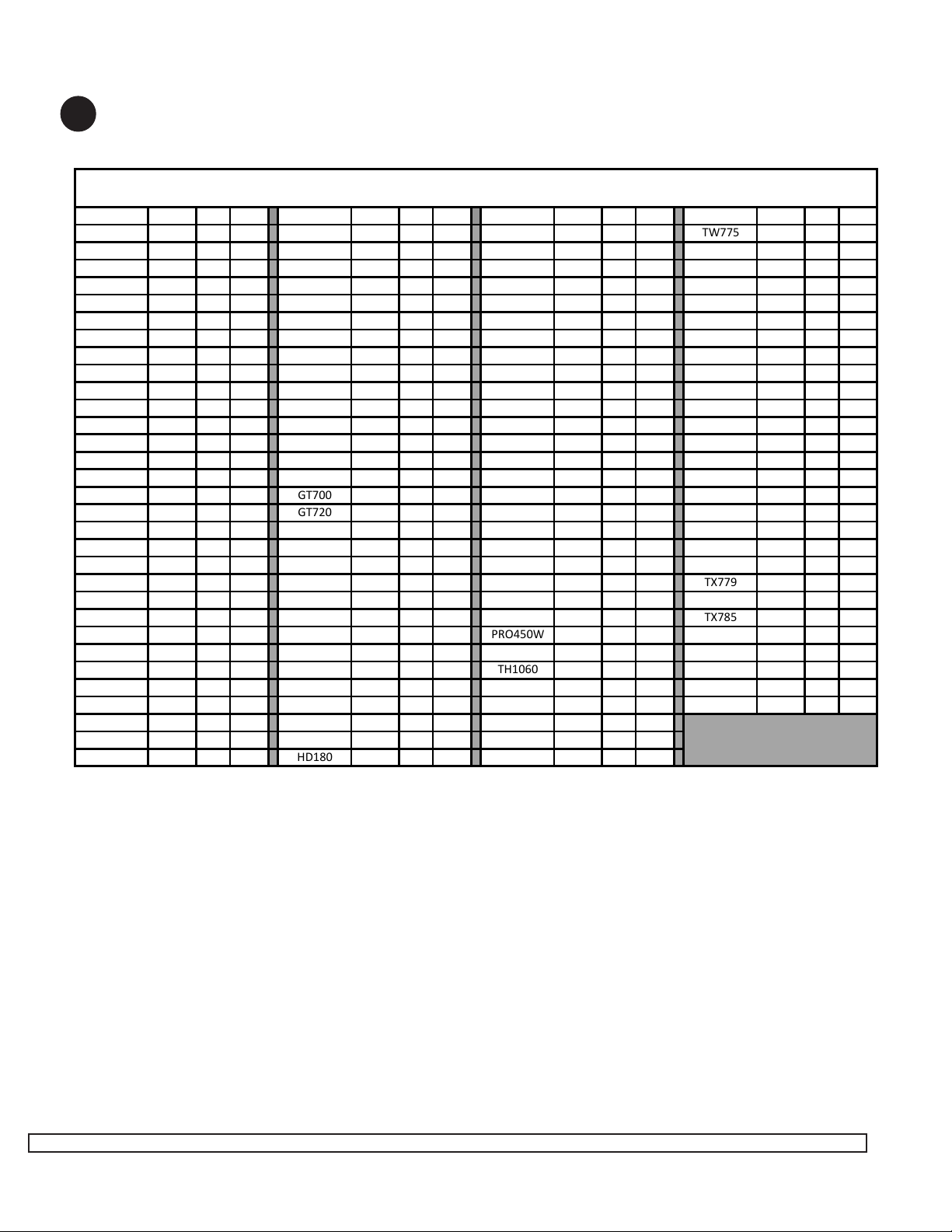

Locate Projector Model, Corresponding Page

ProjectorModelDirectory

Projector Config. Page Screw Projector Config. Page Screw Projector Config. Page Screw Projector Config. Page Screw

DS611 F 7 4 EP1691 D 6 4 HD200X A 4 3 TW775 I 8 6

DS316 A 4 3 EP7155 D 6 4 HD640 A 4 3 TW1692 D 6 4

DS317 F 7 4 ES520 F 7 4 HD700X A 4 3 TWR1693 J 9 3

DV11 A 4 3 ES522 F 7 4 HD710 A 4 3 TX532 F 7 4

DX606V A 4 3 ES526 A 4 3 HD803 E 6 4 TX536 A 4 3

DX607 J 9 3 ET700XE A 4 3 HD806 E 6 4 TX542 A 4 3

DX608 B 5 3 EW536 A 4 3 HD808 I 8 6 TX612 A 4 3

DX609V A 4 3 EW1610 A 4 3 HD930 E 6 4 TX615 A 4 3

DX612 F 7 4 EX530 F 7 4 HD980 E 6 4 TX727 A 4 3

DX617 F 7 4 EX525S

DX619 A 4 3 EX532 F 7 4 HD6800 B 5 3 TX735 F 7 4

EP620 A 4 3 EX536 A 4 3 HD7000 A 4 3 TX761 A 4 3

EP721 A 4 3 EX542 A 4 3 HD7200 E 6 4 TX763 A 4 3

EP726S A 4 3 EX612 A 4 3 HD8000 E 6 4 TX765W G 7 4

EP727 A 4 3 EX615 A 4 3 HD8000‐L

EP728 A 4 3 GT700 A 4 3 HD8200 I 8 6 TX771 J 9 3

EP738 A 4 3 GT720 A 4 3 HD806ISF E 6 4 TX773 B 5 3

EP741 A 4 3 HC815 E 6 4 HD8600 I 8 6 TX774 J 9 3

EP751 C 5 3 HD20 A 4 3 HT720 A 4 3 TX775 J 9 3

EP758 C 5 3 HD22 A 4 3 HT108

EP759 C 5 3 HD32 A 4 3 HT120

EP761 A 4 3 HD65 A 4 3 PRO150S A 4 3 TX780 C 5 3

EP763 A 4 3 HD66 A 4 3 PRO350

EP747 B 5 3 HD70 A 4 3 PRO450W A 4 3 TX782W G 7 4

EP770 A 4 3 HD71 A 4 3 PRO520X A 4 3 TX1080 E 6 4

EP771 J 9 3 HD72 B 5 3 TH106

EP772 J 9 3 HD80 E 6 4 TS526 A 4 3 TX7156 D 6 4

EP774 J 9 3 HD80‐LV E 6 4 TS721 A 4 3 TXR774 J 9 3

EP780 C 5 3 HD82 I 8 6 TS725 F 7 4

EP910 E 6 4 HD86 I 8 6 TW536 A 4 3

EP1690 B 5 3 HD180 A 4 3 TW766

H 8 4 HD2200 A 4 3 TX728 A 4 3

E 6 4 TX770 A 4 3

E 6 4 TX778W G 7 4

E 6 4 TX779 K 10 4

A 4 3 TX785 I 8 6

K 10 4 TX7155 D 6 4

G 7 4

2 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

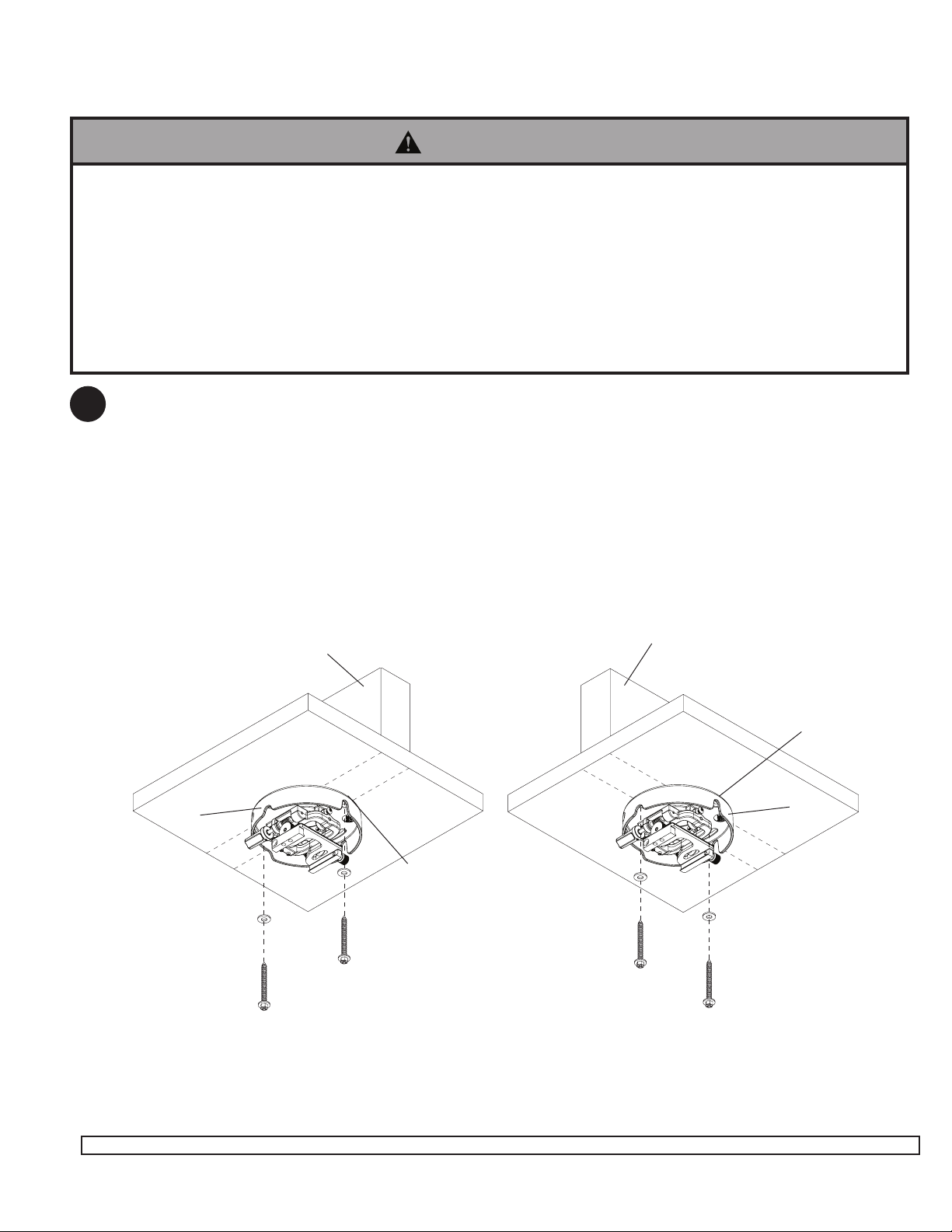

Page 3

Installation To Wood Joist Ceilings

WARNING

• Installer must verify that the supporting surface will safely support the combined load of the equipment and all

attached hardware and components.

• Tighten wood screws so that projector mount assembly is rmly attached, but do not overtighten. Overtightening

can damage the screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the stud. The use of an “edge to edge” stud nder

is highly recommended.

• Hardware provided is for attachment of mount through standard thickness drywall or plaster into wood studs. Installers are responsible to provide hardware for other types of mounting situations.

Place projector mount assembly (C) on ceiling as a template and mark the center of the two mounting holes. Make

2

sure that the mounting holes are in the center of the wood joist. Drill two 5/32” (4 mm) dia. holes to a minimum

depth of 2.5” (64 mm). Attach projector mount assembly (C) with two #14 x 2.5” (6 mm x 65 mm) wood screws (H)

and two 1/4” at washers (G) as shown in gure 2.1 or gure 2.2 depending on joist orientation.

Note: Mounting slots on projector mount assembly (C) allow for 30° (±15°) of swivel adjustment before fully

securing wood screws.

Tighten wood screws (H) using 3/8” (10 mm) socket wrench, phillips screwdriver or 10 mm open end wrench until

projector mount assembly (C) is rmly attached.

C

WOOD JOIST

G

H

g. 2.1

WOOD JOIST

FRONT OF

MOUNT

C

ARROW ON TOP OF PROJECTOR MOUNT ASSEM-

BLY INDICATES FRONT

OF MOUNT

G

H

g. 2.2

3 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 4

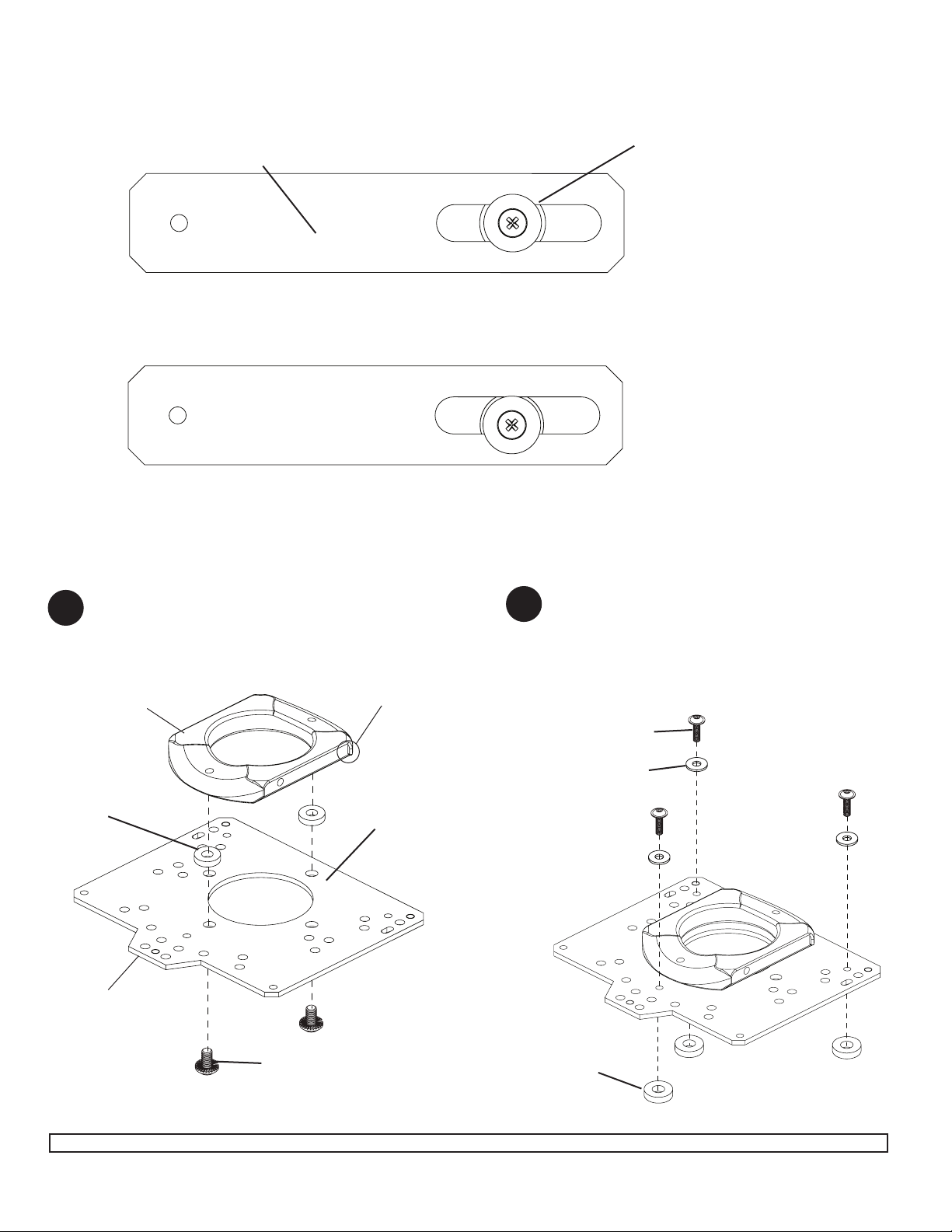

Note: When attaching extension brackets (B) be sure to keep fasteners in the center of the slot.

POSITION SCREW,

SPACER AND WASHER

B

IN CENTER OF SLOT

CORRECT

INCORRECT

Note: Refer to to the Projector Mount Directory for projector mounting pattern and fasteners.

CONFIGURATION A

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

(used in PRG) and .219 ID x .5 OD x .125 spacers (L).

AA

L

FRONT OF

PROJECTOR

SHOULDER

A

Attach plate (A) to projector using three

2

M3 x 12 mm socket pin serrated washer head

screws (O), #4 at washers (K) and spacers (L).

O

K

LD

4 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 5

CONFIGURATION B

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

AA

Attach plate (A) to projector using four

2

M3 x 12 mm socket pin serrated washer head

screws (O), #4 at washers (K) and spacers (L).

O

SHOULDER

L

FRONT OF

PROJECTOR

CONFIGURATION C

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

AA

D

SHOULDER

A

K

L

Attach plate (A) to projector using three

2

M3 x 12 mm socket pin serrated washer head

screws (O), #4 at washers (K) and spacers (L).

O

K

L

A

C

FRONT OF

PROJECTOR

D

5 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

L

Page 6

CONFIGURATION D

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

Attach plate (A) to projector using three

M4 x 16 mm socket pin serrated washer head

2

screws (P), and spacer (M).

AA

SHOULDER

L

FRONT OF

PROJECTOR

D

CONFIGURATION E

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

SHOULDER

AA

A

P

M

Attach three extension brackets (B) to plate

2

(A) using three M4 x 8 mm serrated socket pin

screws (Q). Attach extension brackets (B) to

projector using three .125” spacers (L), #4 at

washers (K), and three M3 x 12 mm socket pin

serrated washer head screws (O).

Q

L

A

O

K

FRONT OF

PROJECTOR

B

L

D

6 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 7

CONFIGURATION F

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

AA

SHOULDER

O

Attach two extension brackets (B) to plate

2

(A) using two M4 x 8 mm serrated socket pin

screws (Q). Attach plate (A) to projector using

one .25” spacer (M), and one M3 x 12 mm

screw (O). Attach extension brackets (B) to

projector using two M3 x 12 mm screws (O),

at washers (K), and .125” spacers (L).

L

FRONT OF

PROJECTOR

D

CONFIGURATION G

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

SHOULDER

AA

A

M

Q

O

K

L

B

Attach three extension brackets (B) to plate

2

(A) using three M4 x 8 mm serrated socket pin

screws (Q). Attach extension brackets (B) to

projector using three .125” spacers (L), #4 at

washers (K), and three M3 x 12 mm socket pin

serrated washer head screws (O).

Q

L

A

O

K

FRONT OF

PROJECTOR

B

L

D

7 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 8

CONFIGURATION H

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

SHOULDER

AA

Attach four extension brackets (B) to plate

2

(A) using four M4 x 8 mm serrated socket pin

screws (Q). Attach extension brackets (B) to

projector using four .125” spacers (L), #4 at

washers (K), and four M3 x 12 mm socket pin

serrated washer head screws (O).

L

FRONT OF

PROJECTOR

D

CONFIGURATION I

Attach connection block (AA) to plate (A)

1

using two #10-32 x 3/8” serrated socket pin

screws (D) and .219 ID x .5 OD x .125 spacers (L).

SHOULDER

AA

A

Q

O

K

B

L

Attach four extension brackets (B) to plate

2

(A) using four M4 x 8 mm serrated socket pin

screws (Q). Attach extension brackets (B) to

projector using four .125” spacers (L), and four

M6 x 16 mm socket pin serrated washer head

screws (R).

Q

L

A

R

B

FRONT OF

PROJECTOR

L

D

8 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 9

CONFIGURATION J

Attach connection block (AA) to plate (A)

1

using two #10-32 x 3/8” serrated socket

pin screws (D) and .219 ID x .5 OD x .125

spacers (L).

AA

SHOULDER

Attach one extension bracket (B) to plate (A)

2

using one M4 x 8 mm serrated socket pin

screw (Q). Attach plate (A) to projector using

two .125” spacers (L), one #4 at washer (K),

one #8 at washer (N) and two M3 x 12 mm

screws (O). Attach extension bracket (B) to

projector using one M3 x 12 mm screw (O),

at washers (K), and .125” spacers (L).

O

L

FRONT OF

PROJECTOR

D

A

L

O

O

K

B

Q

K

N

L

L

B

Q

FRONT OF PROJECTOR

TOP VIEW

9 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 10

CONFIGURATION K

Attach connection block (AA) to plate (A) using

1

two #10-32 x 3/8” serrated socket pin screws (D)

and .219 ID x .5 OD x .125

spacers (L).

AA

SHOULDER

P

Attach two extension brackets (B) to plate

2

(A) using two M4 x 8 mm serrated socket pin

screws (Q). Attach plate (A) to projector using

one .25” spacer (M), and one M4 x 16 mm

screw (P). Attach extension brackets (B) to

projector using two M4 x 16 mm screws (P),

at washers (K), and .125” spacers (L).

L

FRONT OF

PROJECTOR

D

A

M

Q

B

P

K

L

10 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Page 11

Attaching Adapter Plate to Projector Mount

WARNING

• Do not lift more weight than you can handle. Use additional man power or mechanical lifting equipment to safely

handle placement of the screen.

Slide connection block (AA) with precision gear projector mount (C) as shown. Tighten captive screw to secure

3

precision gear projector mount (C).

ARROW

INDICATES

FRONT OF

MOUNT

FRONT OF MOUNT

C

AA

CAPTIVE SCREW

IMPORTANT: For security installations, insert one #10-32 x 1/4" socket pin screw (E) through precision gear pro-

4

jector mount (C) and into connection block (AA) as shown. Tighten screw using 4mm security allen wrench (F).

C

AA

E

11 of 11

Visit the Peerless Web Site at www.peerlessmounts.com For customer care call 1-800-865-2112 or 708-865-8870.

ISSUED: 04-20-09 SHEET #: 056-9019-7 09-07-10

Loading...

Loading...