SNAP POWER SUPPLIES

Features

Built-in fuse, ON/OFF power switch, and LED indicator

>

Convenient panel mounting; optional DIN-rail mounting

>

Easy connections

>

Wide input voltage range

>

UL approved

>

Factory Mutual approved (except SNAP-PS5U and

>

SNAP-PS24U)

DESCRIPTION

SNAP power supplies provide the best source of AC or DC power for

your Opto 22 SNAP PAC hardware. Packaged in a compact and sturdy

housing, SNAP power supplies include a built-in fuse, an LED status

indicator, and an ON/OFF power switch for ease of use.

DATA SHEET

Form 1120-200129

PAGE 1

SNAP-PS5 power supply

The SNAP-PS24 and SNAP-PS24U power supplies are designed for

either of two purposes:

To provide primary power for a SNAP PAC S-series controller

To provide 24 volts of DC loop power for SNAP analog modules

mounted on a SNAP PAC rack

The SNAP-PS5, SNAP-PS5-24DC, and SNAP-PS5U power supplies

are designed to provide 5 VDC power for a SNAP PAC rack with an I/O

processor (SNAP PAC brain or R-series controller) and I/O modules

mounted on the rack. The combination of a rack, processor, and

modules is called an I/O unit.

Opto 22 recommends using one SNAP power supply for each I/O unit

and for each controller. Choose the power supply based on the load

required for the I/O unit. See the power requirements tables starting

on page 12 for help in determining the power supplies you need.

Additional information on using power supplies can be found in the

Opto 22 technical note Using Power Supplies with Opto 22 Systems

(form #1271, available on our website,

All SNAP power supplies except the SNAP-PS5-24DC require AC input

power. The SNAP-PS5U and SNAP-PS24U accommodate a wide range

of AC input voltages, from 100 to 250 VAC.

The SNAP-PS5-24DC DC-to-DC power supply requires a 24 VDC input

and is ideal for systems using DC backup power.

Each SNAP power supply can be mounted in one of two ways: next to

the controller or SNAP I/O unit it powers, using the standard

panel-mounting base, or directly on a DIN rail using the optional

35mm DIN-rail adapter.

AC or DC input power connections, as required by the model, are

made to a removable terminal strip on top of the power supply. DC

output power is then ready to be hooked up to the controller or rack

using the attached wiring harness.

SNAP power supplies work with Wired+Wireless™ PACs and I/O units

as well as standard wired PACs and I/O.

Notes for legacy hardware: SNAP power supplies are also

compatible with Ethernet-based SNAP Ultimate, SNAP Ethernet, and

SNAP Simple I/O, and with serial-based SNAP I/O units such as those

with a B3000, SNAP-HA, or SNAP-B3000-MODBUS brain.

Part Numbers

Part Description

SNAP-PS5

SNAP-PS5-24DC

SNAP-PS5U

SNAP-PS24

SNAP-PS24U

SNAP-PSDIN

SNAP-PSUDIN

SNAP Power Supply

120 VAC input; 5 VDC, 4 A output

SNAP Power Supply

24 VDC input; 5 VDC, 4 A output

SNAP Power Supply

100–250 VAC input; 5 VDC, 5 A output

SNAP Power Supply

120 VAC input; 24 VDC, 3/4 A output

SNAP Power Supply

100–250 VAC input; 24 VDC, 1-1/4 A output

35mm DIN-Rail Adapter for SNAP-PS5,

SNAP-PS24, or SNAP-PS5-24DC

35mm DIN-Rail Adapter for SNAP-PS5U or

SNAP-PS24U

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Form 1120-200129

SPECIFICATIONS

SNAP-PS5 SNAP-PS5-24DC SNAP-PS5U

Input Voltage 95–130 VAC, 47–63 Hz 18–32 VDC 100–250 VAC, 47–63 Hz

Output Voltage 5.1 ±0.1 VDC 5.1 ±0.1 VDC 5.1 ±0.1 VDC

Output Current 4.0 A 4.0 A 5.0 A

Maximum Input Current Draw 0.4 Amps at 120 VAC 1.3 Amps at 24 VDC 0.5 Amps at 120 VAC

Dimensions

Weight 15 oz. (425.25 g) 15 oz. (425.25 g) 1.9 lbs (863.63 g)

Operating Temperature -20 to 70 °C -20 to 70 °C -20 to 70 °C

Storage Temperature -30 to 85 °C -30 to 85 °C -30 to 85 °C

Torque, connector screws 4.5 in-lb (0.51 N-m) 4.5 in-lb (0.51 N-m) 4.5 in-lb (0.51 N-m)

Fuse

Agency Approvals FM, UL, ATEX, DFARS

Warranty 30 months 30 months 30 months

See the drawings starting on

page 8.

Opto 22 PN: SNAP-FUSE1AB

Vendor PN: GDC-1A (Bussman)

See the drawings starting on

page 8.

Opto 22 PN: SNAP-FUSE2AB

Vendor PN: GDB-2A (Bussman)

FM, UL, CE, ATEX, RoHS,

DFARS

See the drawings on

page 10.

Internal fuse

UL, CE, RoHS, DFARS

DATA SHEET

PAGE 2

SNAP-PS24 SNAP-PS24U

Input Voltage 95–130 VAC, 47–63 Hz 100–250 VAC, 47–63 Hz

Output Voltage 24 ± 0.6 VDC 24 ± 0.1 VDC

Output Current 0.75 A 1.25 A

Maximum Input Current Draw 0.4 Amps @ 120 VAC 0.5 Amps @ 120 VAC

Dimensions

Weight 2.1 lbs (952.54 g) 1.9 lbs (863.63 g)

Operating Temperature -20 to 70 °C -20 to 70 °C

Storage Temperature -30 to 85 °C -30 to 85 °C

Torque, connector screws 4.5 in-lb (0.51 N-m) 4.5 in-lb (0.51 N-m)

Fuse

Agency Approvals FM, UL, CE, RoHS, DFARS UL, CE, RoHS, DFARS

Warranty 30 months 30 months

See drawings starting on

Opto 22 PN: SNAP-FUSE1AB Vendor

PN: GDC-1A (Bussman)

page 8. See drawings on page 10.

Internal fuse

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

I/O UNIT POWER REQUIREMENTS

The tables starting on page 12 will help you determine the power

supply needs for your system. Copy the power requirements

worksheet and complete one for each distributed I/O unit.

In addition, keep the following power recommendations in mind. For

more help with power supplies, see Opto 22 form #1271, Using Power

Supplies with Opto 22 Systems.

Use a single power supply per rack

In general, we recommend you use an independent, isolated,

regulated power supply locally with each rack. Local isolated supplies

offer these advantages:

Short supply conductors, which minimize losses

Power redundancy, so the failure of a single supply causes only a

single rack failure, not a total system failure

Fewer voltage drops and ground loops (Voltage drops and

subsequent ground loops may occur when power is distributed

over a large system.)

DATA SHEET

Form 1120-200129

PAGE 3

Always use a separate field supply

Use a separate power supply for the field side of the I/O. Using the

rack supply for field actuation and monitoring defeats the isolation

the I/O module offers and therefore increases the chance of a ground

loop within the control system. Additionally, a sudden change of

current on the field side can cause undesirable voltage fluctuations

that may interfere with the controller or I/O unit’s operation.

Power wiring guidelines

Use one power supply per I/O unit.

Use one power supply per controller.

Use 14 AWG wire.

SNAP power supplies have short wires to minimize voltage drop.

Do not extend the length of the wires.

If you power multiple I/O units or controllers from one power

supply, use a star wiring topology. Do not daisy-chain power

wiring from one device to the next.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

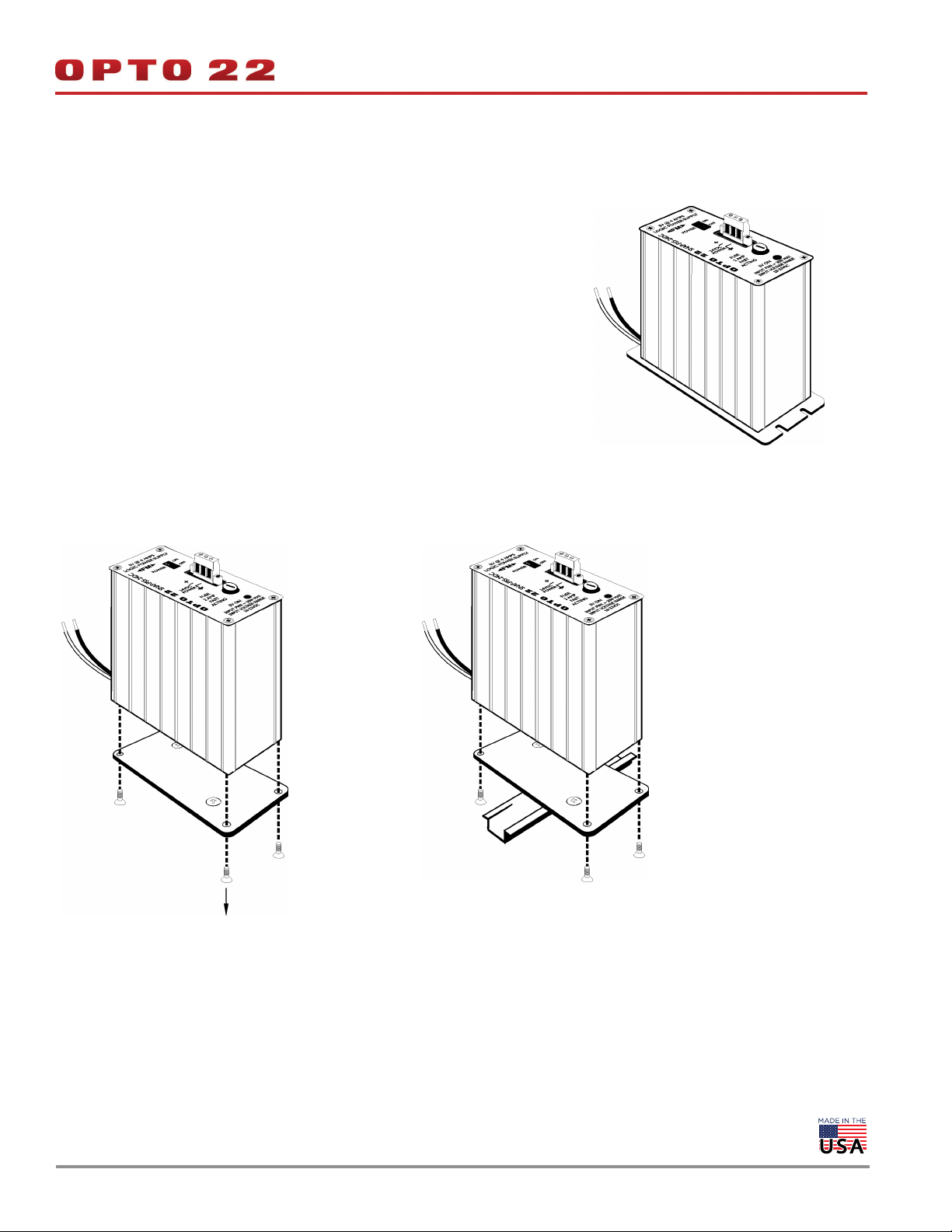

INSTALLATION

Panel Mounting (standard)

Mount the SNAP power supply in a location where the attached red and black power

wires will reach the “+” and “-” power terminals on the SNAP mounting rack or controller.

Do not extend the wires.

DIN-Rail Mounting (optional)

1. For 35mm DIN-rail mounting, remove the four screws that fasten the panel mounting

base plate to the power supply. Keep screws in a safe place.

2. Remove panel mounting base plate.

3. In place of the panel mounting base plate, use the four screws removed in step 1 to

fasten the DIN-rail adapter (purchased separately) to the power supply.

4. Mount the SNAP power supply on the DIN rail (next to the power connector on the

I/O unit).

DATA SHEET

Form 1120-200129

PAGE 4

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

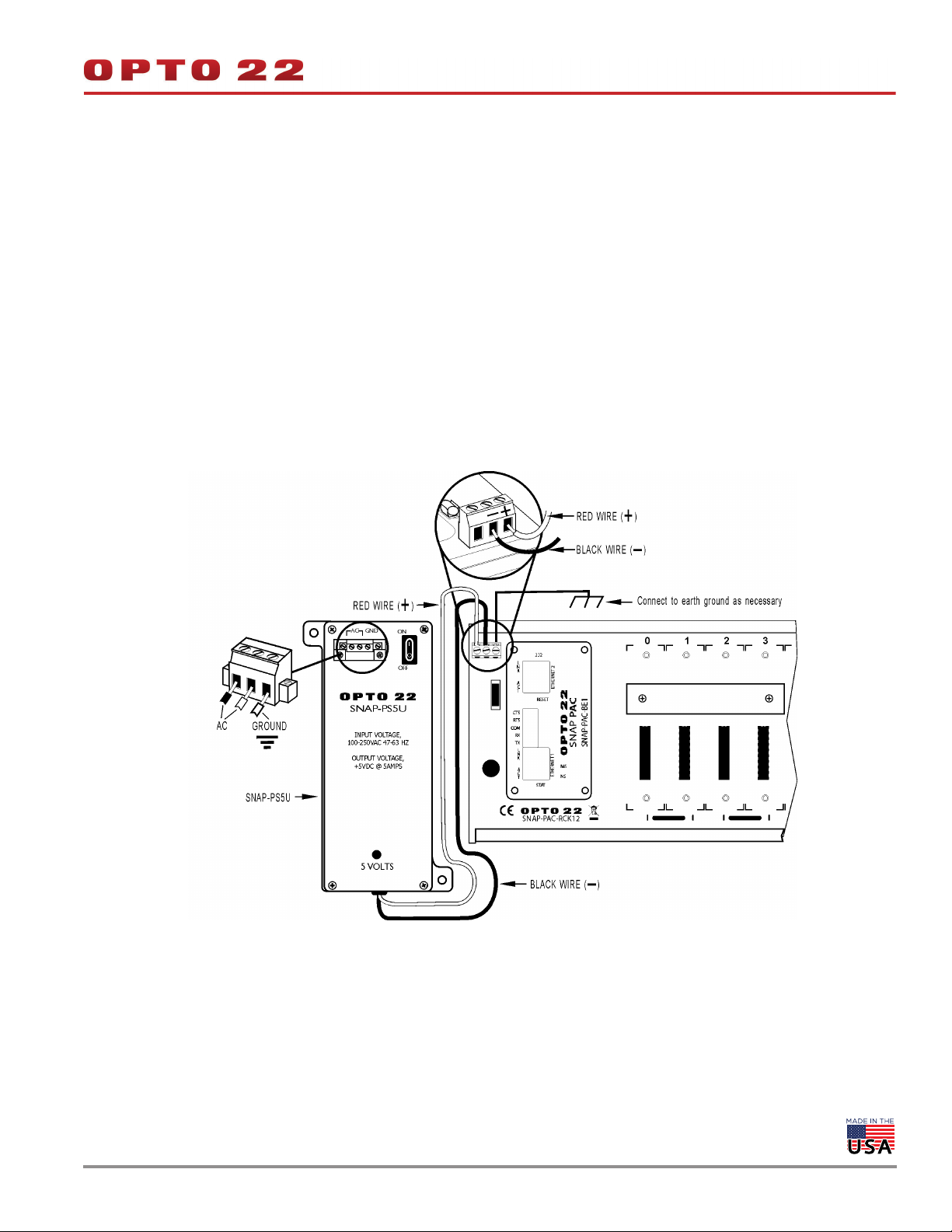

WIRING—PRIMARY POWER SUPPLY

DATA SHEET

Form 1120-200129

PAGE 5

Wiring to a Standalone Controller

1. For a controller, check the controller’s specifications in its data

sheet or user’s guide to make sure you have the correct power

supply for the controller’s requirements.

2. Follow directions in the controller’s user’s guide to wire the power

supply to the controller. The power supply’s red (or

white-and-red) wire is the positive wire; the black (or

white-and-black) wire is the negative wire.

Wiring to a SNAP I/O Unit

1. Using the power terminals on the SNAP mounting rack, attach the

red wire to the “+” terminal and the black wire to the “-” terminal.

2. For the SNAP-PS5 (not illustrated): Using the removable input

power connector on top of the power supply, apply 120 volts AC

power between the two terminals marked “AC.” The ground

terminal should be connected to ground.

3. For the SNAP-PS5-24DC (not illustrated): Using the removable

input power connector on top of the power supply, apply 24 volts

DC power between the two terminals marked “±DC.” The ground

terminal should be connected to ground.

4. For the SNAP-PS5U (illustrated below): Using the removable

input power connector on top of the power supply, apply 100–

250 volts AC power between the two terminals marked “AC.” The

ground terminal should be connected to ground.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

WIRING—LOOP POWER SUPPLY

DATA SHEET

Form 1120-200129

PAGE 6

1. Mount the SNAP-PS24 or SNAP-PS24U power supply in a location

where the attached output power wires will reach the field

connector for SNAP analog modules or the terminal strip on SNAP

mounting racks that have the additional field wiring terminal

strips.

2. The white-and-red wire is the positive wire (24 VDC). The

white-and-black wire is the negative wire (24 VDC return). For

specific loop power wiring information, see Opto 22 forms #1065

analog modules (see Figure 1 below), or refer to form #0784 for

SNAP racks that have the additional field wiring terminal strip (see

Figure 2). See the next page for similar SNAP-PS24U wiring

diagrams.

3. Using the removable input power connector on top of the power

supply, apply 120 volts of AC power between the two terminals

marked “AC.” The ground terminal should be connected to

ground.

and #1066 if wiring directly to the field connectors on SNAP

Figure 1. SNAP-PS24 Used as a Loop Supply with the SNAP PAC System

This diagram shows the SNAP-PS24 used as the loop supply and a SNAP-PS5 used as the primary power supply.

Figure 2. SNAP-PS24 Used as a Loop Supply with Legacy Hardware

The SNAP-PS24 is used as the loop supply; a SNAP-PS5 is used as the primary power supply.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

WIRING—LOOP SUPPLY (CONTINUED)

Figure 1. SNAP-PS24U Used as a Loop Supply with the SNAP PAC System

This diagram shows the SNAP-PS24U used as the loop supply and a SNAP-PS5U used as the primary power supply.

DATA SHEET

Form 1120-200129

PAGE 7

Figure 2. SNAP-PS24U Used as a Loop Supply with Legacy Hardware

The SNAP-PS24U is used as the loop supply; a SNAP-PS5U is used as the primary power supply.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DIMENSIONS—SNAP-PS5, SNAP-PS24, AND SNAP-PS5-24DC

Panel Mount

DATA SHEET

Form 1120-200129

PAGE 8

The length of the red and black leads is 8.00 inches +/- .50 inches.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DIMENSIONS—SNAP-PS5, SNAP-PS24, AND SNAP-PS5-24DC

With DIN-Rail Adapter

DATA SHEET

Form 1120-200129

PAGE 9

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DIMENSIONS—SNAP-PS5U AND SNAP-PS24U

Panel Mount

SNAP-PS5U is shown; SNAP-PS24U has the same dimensions.

DATA SHEET

Form 1120-200129

PAGE 10

The length of the red and black leads is 9.00 inches +/- .50 inches.

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DIMENSIONS—SNAP-PSDIN

DATA SHEET

Form 1120-200129

PAGE 11

DIMENSIONS—SNAP-PSUDIN

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

POWER REQUIREMENTS TABLES

Opto 22 recommends using one power supply per I/O unit and one power supply per controller. See “I/O Unit Power

Requirements” on page 3 for additional

To determine power requirements for products not listed in these tables, see the data sheets for the individual products.

MPORTANT NOTE: For a SNAP-PS5 or a SNAP-PS5-24DC power supply, the total power required must not exceed 4 amps.

For a SNAP-PS5U, the total power required must not exceed 5 amps.

Controller Power Requirements

Standalone Controller or adapter card Power Req (VDC) Power Req. (Amps)

SNAP PAC S-series controllers (wired) 8–32 VDC* 10 VA**

Wired+Wireless S-series PACs 8–32 VDC 11.3 VA

SNAP-LCSX or -LCSX-PLUS controller 5 VDC 0.500

SNAP-LCM4 controller 5 VDC 1.000

M4-SENET-100 adapter card 5 VDC 1.000

M4SARC adapter card 5 VDC 0.200

M4DUALARC adapter card 5 VDC 0.150

Legacy hardware

M4SARCF adapter card 5 VDC 0.250

M4SARCFR adapter card 5 VDC 0.350

* SNAP-PAC-S1 controllers with serial numbers below 500,000 use 8–24 VDC.

** Uses 1 A if powered at 10V. To determine amps required, divide 10 by the number of

volts applied. Example: 10 / 24 V = 0.417 A (24 VDC input requires 0.417 A)

DATA SHEET

Form 1120-200129

PAGE 12

I/O Processor (Brain or On-the-Rack Controller) Power Requirements

Processor (Brain or Rack-mounted Controller) Power Req. (Amps)*

SNAP PAC R-series controllers (all wired models) 1.200

SNAP PAC R-series controllers (Wired+Wireless) 1.500

SNAP PAC EB and SB brains (all wired models) 0.750

SNAP PAC EB brains (Wired+Wireless) 1.000

SNAP Ultimate controller/brains (all models) 1.000

SNAP Ethernet brains 0.800

SNAP Simple I/O brains 0.500

B3000 (serial SNAP brain)

SNAP-D64RS

SNAP-B3000-Modbus

SNAP ARCNET brains

Legacy hardware

SNAP-B4

SNAP-B6

*Current from 5-volt supply

(Continued on following page)

0.500

1.000

1.000

1.500 if terminated

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

POWER REQUIREMENTS TABLES (CONTINUED)

I/O Unit (Processor, Rack, I/O Modules) Power Requirements Worksheet

I/O Unit (Processor, Rack, I/O Modules) Power Requirements Worksheet

X Power

Item Quantity

Item Quantity

SNAP processor (Enter Amps from Processor Power Require-

SNAP processor (Enter Amps from Processor Power Requirements table)

ments table)

SNAP-IDC5-SW digital input module

SNAP-IDC5-SW digital input module

SNAP-IDC5-SW-NC digital input module

SNAP-IDC5-SW-NC digital input module

SNAP-AITM-8 analog input module

SNAP-AITM-8 analog input module

Isolated analog input and output modules (part numbers ending

Isolated analog input and output modules (part numbers ending

in -i or iSRC) except SNAP-AITM-4i

in -i or iSRC) except SNAP-AITM-4i

All other 4-channel digital input and output modules except

All other 4-channel digital input and output modules except

mechanical relay outputs (not high-density digital modules)

mechanical relay outputs (not high-density digital modules)

SNAP mechanical power relay output modules

SNAP mechanical power relay output modules

SNAP-AICTD, AICTD-43 analog input modules

SNAP-AICTD, AICTD-43 analog input modules

High-density digital input and output modules

High-density digital input and output modules

SNAP-AIMA-32, SNAP-AIMA-iH4, SNAP-AIV-32, and

SNAP-AIMA-32, SNAP-AIMA-iH4, SNAP-AIV-32, and

SNAP-AITM-4i analog input modules

SNAP-AITM-4i analog input modules

All analog output modules except SNAP-AOA-iSRC and

All analog output modules except SNAP-AOA-iSRC and

SNAP-AOD-29-HFi

SNAP-AOD-29-HFi

SNAP-AOD-29-HFi 0.300

SNAP-AOD-29-HFi 0.300

SNAP-AIPM power monitoring module

SNAP-AIPM power monitoring module

SNAP-AIPM-3, SNAP-AIPM-3V power monitoring modules

SNAP-AIPM-3, SNAP-AIPM-3V power monitoring modules

SNAP-AILC and AILC-2 load cell modules

SNAP-AILC and AILC-2 load cell modules

SNAP-AIRTD-8U analog input module

SNAP-AIRTD-8U analog input module

SNAP-AIARMS analog input module

SNAP-AIARMS analog input module

SNAP-AIVRMS analog input module

SNAP-AIVRMS analog input module

SNAP-AICTD-8

SNAP-AICTD-8

SNAP-AIMA, AIMA-4

SNAP-AIMA, AIMA-4

SNAP-AITM and AITM-2 analog input modules

SNAP-AITM and AITM-2 analog input modules

SNAP-AIMV-4

SNAP-AIMV-4

SNAP-AIV, AIV-4

SNAP-AIV, AIV-4

SNAP-AIRTD analog input module

SNAP-AIRTD analog input module

SNAP-AIR40K-4

SNAP-AIR40K-4

SNAP-AIR400K-8

SNAP-AIR400K-8

SNAP-AIRATE analog input module

SNAP-AIRATE analog input module

SNAP-AIRATE-HFi analog input module 0.210

SNAP-AIRATE-HFi analog input module 0.210

SNAP-SCM-ST2 and SNAP-SCM-SSI serial modules

SNAP-SCM-ST2 and SNAP-SCM-SSI serial modules

SNAP-SCM-232, SNAP-SCM-485-422, SNAP-SCM-PROFI

SNAP-SCM-232, SNAP-SCM-485-422, SNAP-SCM-PROFI

SNAP-SCM-MCH16 not powering a breakout board

SNAP-SCM-MCH16 not powering a breakout board

SNAP-SCM-MCH16 powering a breakout board

SNAP-SCM-MCH16 powering a breakout board

Total

Total

4

4

analog input module

analog input module

3

3

, and AIMA-84 analog input modules

, and AIMA-84 analog input modules

3

3

and AIMV2-43 analog input modules

and AIMV2-43 analog input modules

3

3

, and AIV-84 analog input modules

, and AIV-84 analog input modules

3

3

analog input module

analog input module

4

4

analog input module

analog input module

4

4

4

4

4

4

4

4

3

3

4

4

3

3

4

4

4

4

3

3

2

2

2

2

1

1

X Power

Req. (Amps)

Req. (Amps)

0.200

0.200

0.050

0.050

0.160

0.160

0.150

0.150

0.100

0.100

0.120

0.120

0.135

0.135

0.170

0.170

0.190

0.190

0.200

0.200

0.250

0.250

0.700

0.700

Total Power

Total Power

Required (Amps)

Required (Amps)

DATA SHEET

Form 1120-200129

PAGE 13

1

1

1 Current from 5-volt supply

1 Current from 5-volt supply

2 Can be used with SNAP PAC R-series controllers and SNAP PAC brains, SNAP Simple, and SNAP Ultimate

2 Can be used with SNAP PAC R-series controllers and SNAP PAC brains, SNAP Simple, and SNAP Ultimate

3 Can be used with SNAP PAC R-series controllers and SNAP PAC brains, SNAP Simple, SNAP Ethernet, and

3 Can be used with SNAP PAC R-series controllers and SNAP PAC brains, SNAP Simple, SNAP Ethernet, and

SNAP Ultimate

SNAP Ultimate

4 Can be used with SNAP PAC systems only

4 Can be used with SNAP PAC systems only

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

More about Opto 22

PRODUCTS

Opto 22 develops and manufactures reliable, easy-to-use, open

standards-based hardware and software products. Industrial

automation, process control, building automation, industrial

refrigeration, remote monitoring, data acquisition, and industrial

internet of things (IIoT) applications worldwide all rely on Opto 22.

groov EPIC® System

Opto 22’s groov Edge Programmable

Industrial Controller (EPIC) system gives

you an industrially hardened system with

guaranteed-for-life I/O, a flexible Linux®based processor with gateway functions,

and software for your automation and IIoT

applications.

groov EPIC I/O

groov I/O connects locally to sensors and

equipment with up to 24 channels on each I/O module. Modules

have a spring-clamp terminal strip, integrated wireway, swing-away

cover, and LEDs indicating module health and discrete channel status.

groov I/O is hot swappable, UL Hazardous Locations approved, and

ATEX compliant.

groov EPIC Processor

The heart of the system is the groov EPIC processor. It handles a wide

range of digital, analog, and serial functions for data collection,

remote monitoring, process control, and discrete and hybrid

manufacturing.

In addition, the EPIC provides secure data communications among

physical assets, control systems, software applications, and online

services, both on premises and in the cloud.

Configuring and troubleshooting I/O and networking is easier with

the EPIC’s integrated high-resolution color touchscreen. Authorized

users can manage the system locally on the touchscreen or on a

monitor connected via the HDMI or USB ports.

groov RIO

groov RIO revolutionizes remote I/O by offering a single, compact,

PoE-powered industrial package with web-based configuration,

commissioning, and flow logic software built in, plus support for

multiple OT and IT protocols.

Standing alone, it meets the needs of small, variable I/O count

applications, especially those that require

data logging or data communications,

commonly found in IIoT applications.

groov RIO can also be used with a

Modbus/TCP master or as remote I/O for

a groov EPIC system.

Older products

From solid state relays (our first products)

to world-famous G4 and SNAP I/O, to

SNAP PAC controllers, older Opto 22

products are still supported and still

doing the job at thousands of installations worldwide. You can count

on us to give you the reliability and service you expect, now and in the

future.

QUALITY

Founded in 1974, Opto 22 has established a worldwide reputation for

high-quality products. All are made in the U.S.A. at our manufacturing

facility in Temecula, California.

Because we test each product twice before it leaves our factory rather

than testing a sample of each batch, we can afford to guarantee most

solid-state relays and optically isolated I/O modules for life.

groov EPIC Software

Software included in the groov EPIC processor:

PAC Control engine to run PAC Control and PAC Display

CODESYS Runtime engine to run IEC61131-3 compliant programs

built with CODESYS Development System

Optional access to the Linux operating system through a secure

shell (SSH) to download and run custom applications

groov View for building your own device-independent HMI,

viewable on the touchscreen, PCs, and mobile devices

Node-RED for creating simple logic flows from pre-built nodes

Ignition Edge® from Inductive Automation®, with OPC-UA drivers

to Allen-Bradley®, Siemens®, and other control systems, and MQTT

communications with Sparkplug for efficient IIoT data transfer

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Form 1335-200129

Loading...

Loading...