Page 1

SNAP B-SERIES RACKS

Features

Secure mounting for SNAP I/O modules plus a SNAP brain or

>

on-the-rack SNAP controller

Analog, digital, and serial modules on the same rack

>

Panel or DIN-rail mounting

>

Modules snap into place

>

DESCRIPTION

NOTE: For racks to use with SNAP PAC controllers and brains, see

Opto 22 form #1684, the SNAP PAC Racks Data Sheet.

NOTE: M-series racks (such as the SNAP-M64), used with SNAP Simple

brains and SNAP-UP1-M64 controllers, have been replaced by SNAP

PAC racks. See form #1684.

DATA SHEET

Form 0784-190731

PAGE 1

SNAP B-Series Rack

All SNAP racks offer panel mounting and the option of DIN-rail

mounting. SNAP racks require a 5 VDC power source. SNAP-B4M,

SNAP-B8M, SNAP-B12M, SNAP-B16M, and SNAP-D64RS racks are

Factory Mutual approved.

SNAP B-series mounting racks are designed to hold an intelligent

SNAP I/O processor—either a SNAP brain or an on-the-rack

controller—and several I/O modules.

This rack family includes racks that are compatible with ARCNET and

serial SNAP brains, including those using Modbus® and Profibus®

protocols, and with some Ethernet-based SNAP Ultimate I/O™

on-the-rack controllers and SNAP Ethernet I/O™ brains. For specific

processor compatibility, see “Specifications” on page 3.

Since SNAP analog, digital, and serial I/O modules have the same

footprint, customers using most SNAP B-series racks can mix modules

on the same I/O mounting rack. However, module types, features, and

positions on the rack vary depending on the capabilities of the brain

or on-the-rack controller used. See the brain or controller data sheet

for details.

Field devices are wired directly to the top-mounted removable

connectors on the modules plugged into each rack. SNAP B-series

racks can accommodate up to 4, 8, 12, or 16 modules. The module

and rack design allows modules to simply “snap” on and off the

mounting rack.

SNAP racks use a retention rail locking system that holds modules

securely to the rack. Normally, a hold-down screw is not required.

However, for applications that require additional module security,

SNAP racks have provisions for two 4-40 by ½-inch standard machine

screws to hold each module in position.

MC and MC-P model racks provide an auxiliary screw-type terminal

strip for field wiring common connections such as loop power

distribution. MC racks use a fixed terminal strip, while MC-P racks use

removable connectors for easy maintenance (see enlarged view on

the following page).

Part Numbers

Part Description

SNAP-B4M* 4-module rack

SNAP-B8M* 8-module rack

SNAP-B12M* 12-module rack

SNAP-B16M* 16-module rack

SNAP-B8MC

SNAP-B12MC

SNAP-B16MC

SNAP-B8MC-P

SNAP-B12MC-P

SNAP-B16MC-P

SNAP-D64RS*

SNAP-FUSE7.5AB 7.5-amp fuse, 25-pack

SNAP-FUSE4AB 4-amp fuse, 25-pack

SNAP-FUSE1AB 1-amp fuse, 25-pack

SNAP-TEX-DRC10 SNAP PAC rack DIN-rail adapter clip, 10-pack

SNAP-TEX-REC10N

SNAP-TEX-REC10W

* Factory Mutual (FM) approved

8-module rack with extra terminal block for field

wiring

12-module rack with extra terminal block for field

wiring

16-module rack with extra terminal block for field

wiring

8-module rack with extra terminal block for field

wiring, pluggable

12-module rack with extra terminal block for field

wiring, pluggable

16-module rack with extra terminal block for field

wiring, pluggable

16-module rack for digital-only SNAP Ultimate,

SNAP Ethernet, and SNAP-PDPRS64 Profibus

brains

Narrow end cap for SNAP PAC racks DIN-rail

assemblies, 10-pack

Wide end cap for SNAP PAC racks DIN-rail

assemblies with terminal strips, 10-pack

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 2

DESCRIPTION (CONTINUED)

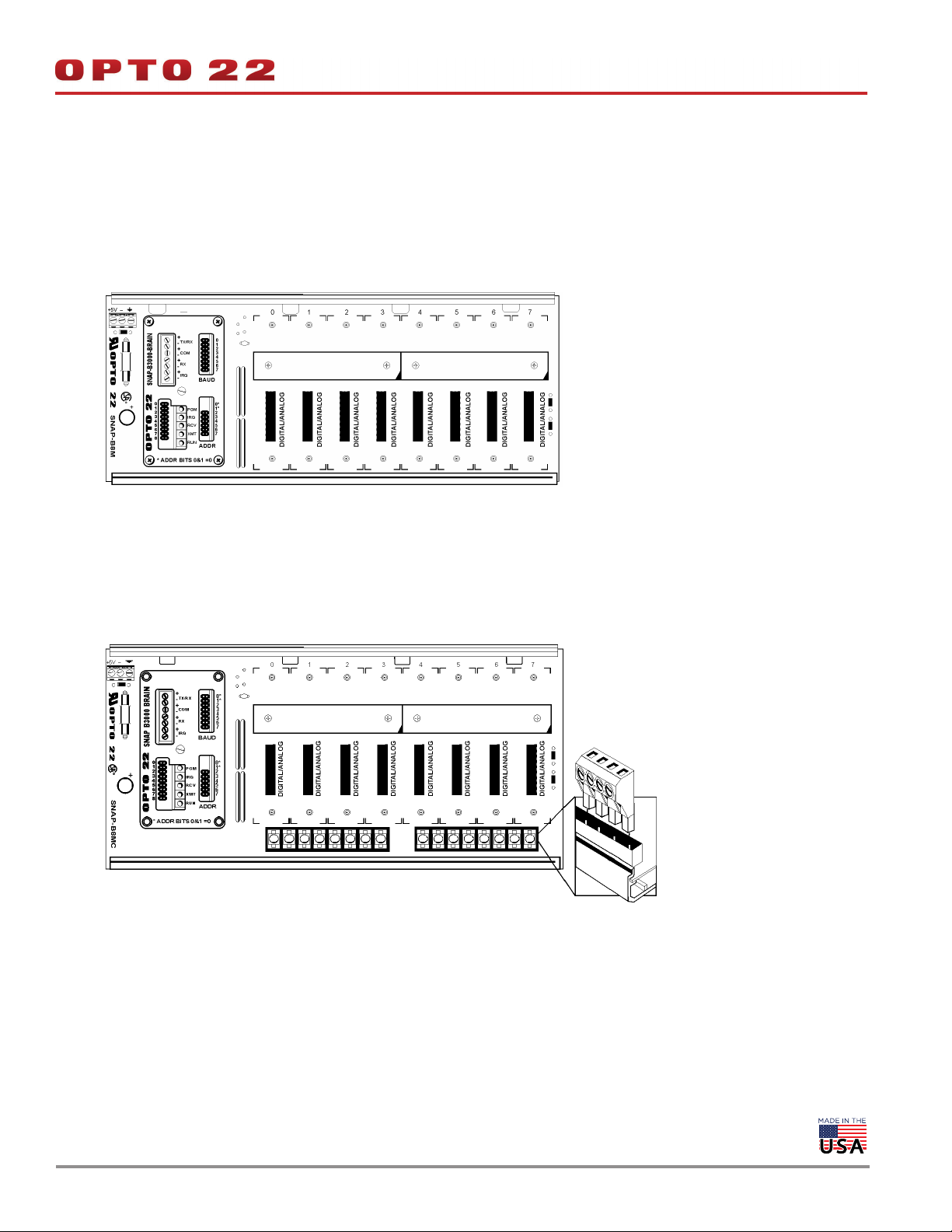

SNAP-B8M (8-Module Position I/O Mounting Rack)

Shown with B3000 brain (purchased separately)

DATA SHEET

Form 0784-190731

PAGE 2

SNAP-B8MC (8-Module Position I/O Mounting Rack)

Shown with B3000 brain (purchased separately)

Pluggable connector

for MC-P models

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 3

SPECIFICATIONS

DATA SHEET

Form 0784-190731

PAGE 3

Part Number Description

1

Power2

Requirements

I/O Processor3

Compatibility

Replacement

Fuse

Operating

Temperature

Relative

Humidity

5.0 to 5.2 VDC

SNAP-B4M 4-module mixed

@ 1.8 Amps

max

SNAP-B8M 8-module mixed

4

4

,

4

5.0 to 5.2 VDC

@ 2.6 Amps

max

5.0 to 5.2 VDC

@ 3.4 Amps

max

5.0 to 5.2 VDC

@ 4.2 Amps

max

5.0 to 5.2 VDC

@ 1.8 Amps

max

SNAP-UP1-ADS

SNAP-B3000-ENET

SNAP-ENET-RTC

B3000

B3000-HA

SNAP-B4

SNAP-B6

SNAP-BRS

SNAP-BRS-HA

SNAP-B3000-

MODBUS

SNAP-UP1-D64

SNAP-ENET-D64

SNAP-PDPRS64

SNAP-FUSE4A

5

or Bel

5HF4

SNAP-FUSE1A

or Buss5

GDC1A

0 to 70 °C

95%,

non-con-

densing

SNAP-B8MC

SNAP-B8MC-P

8-module mixed,

terminal block

8-module mixed,

pluggable terminal block

SNAP-B12M 12-module mixed

SNAP-B12MC

SNAP-B12MC-P

12-module mixed4,

terminal block

12-module mixed

pluggable terminal block

SNAP-B16M 16-module mixed

SNAP-B16MC

SNAP-B16MC-P

SNAP-D64RS

16-module mixed4,

terminal block

16-module mixed4,

pluggable terminal block

16-module digital only

(limited digital functions)

1 “Mixed” means the rack can hold analog, digital, and serial modules. Most Ethernet-based I/O processors handle all these types

of modules; other processors do not. See the processor’s data sheet for details.

2 Power requirements shown are for a rack, a processor, and a full load of 2-channel analog modules (for the SNAP-D64RS, a full

load of 4-channel digital modules). Power requirements for other SNAP modules are higher. See module data sheets.

3 “I/O Processor” means a SNAP brain or on-the-rack controller.

4 Four-channel SNAP digital modules can be used in positions 0–7 only.

5 Manufacturer’s part number (not available through Opto 22).

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 4

SPECIFICATIONS (CONTINUED)

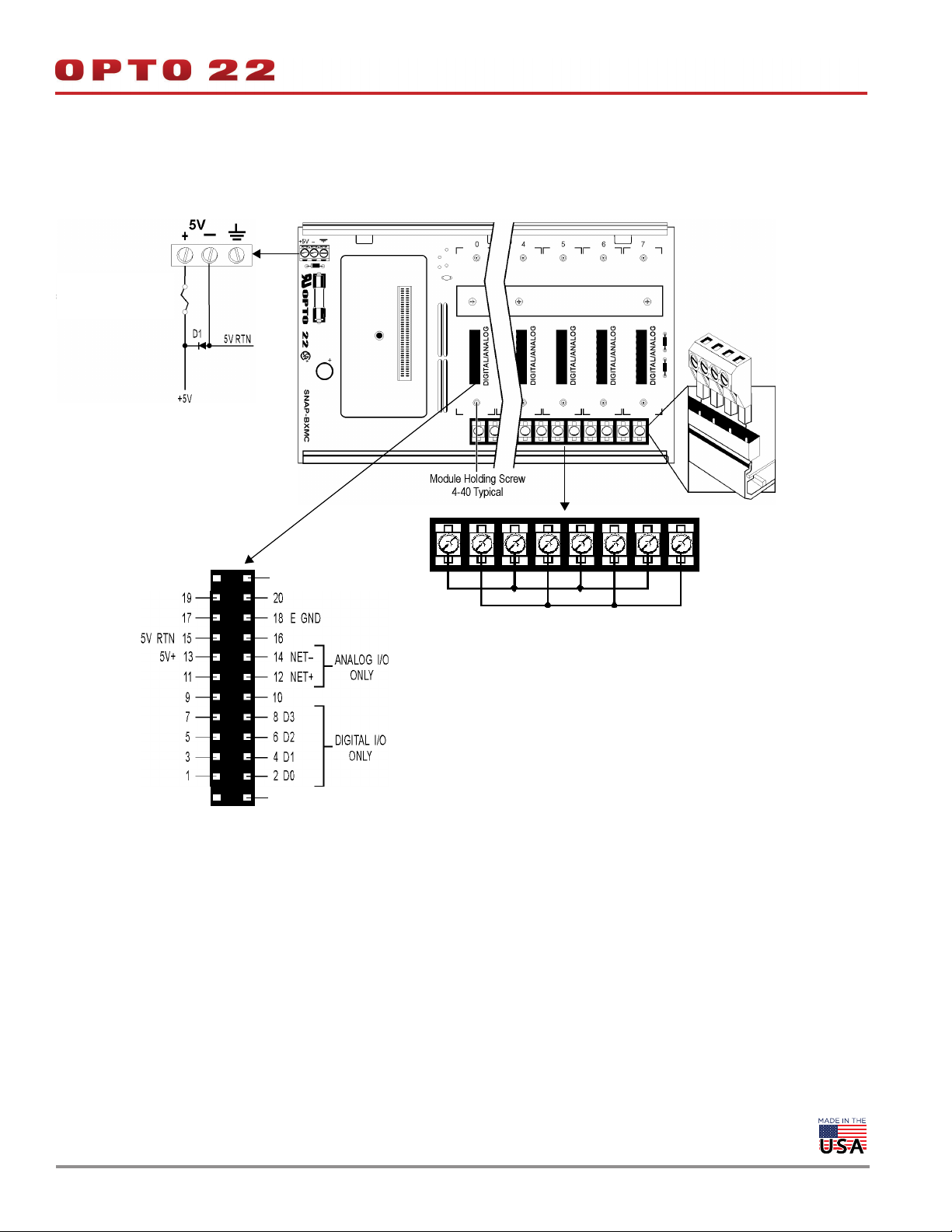

All models:

Power schematic

For fuse part numbers,

see Specifications on

page 3.

DATA SHEET

Form 0784-190731

PAGE 4

MC-P models

only: Pluggable

connector (wire

range 22–14 AWG)

All models: Module mating

connector pinout (female)

IMPORTANT: The mounting rack connector has 24 pins;

the module connector has 20 pins. The extra pins on the

mounting rack connector prevent misalignment of the

module during installation.

Extra pins for alignment

MC and MC-P models only: For detailed

information on terminal strip usage, see page 12

through page 16.

Extra pins for alignment

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 5

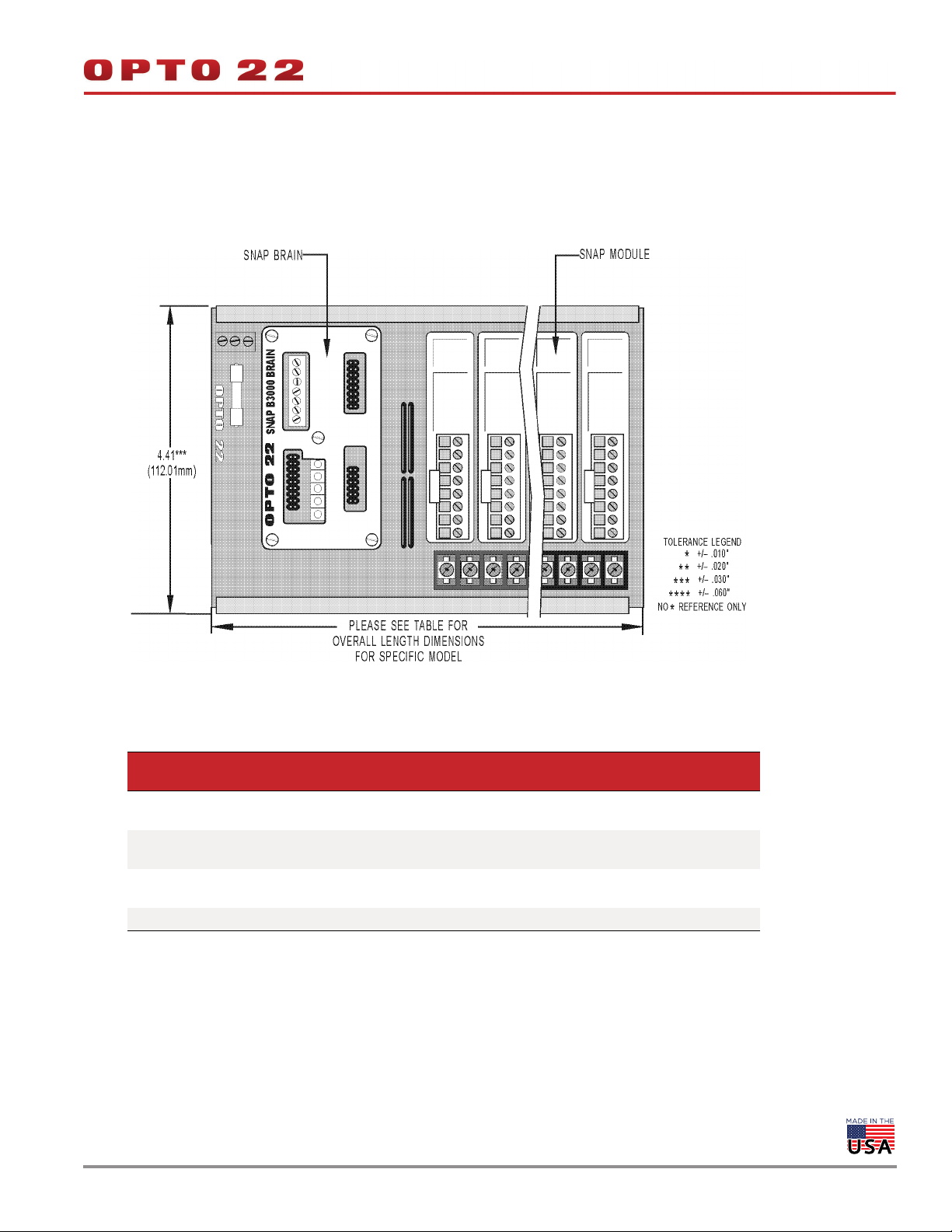

DIMENSIONAL DRAWINGS

Dimensions—SNAP-D64RS Rack and B-Series Racks with Terminal Strips

NOTE: Brain is shown as a sample

for placement only. See page 3

for brain-rack compatibility.

DATA SHEET

Form 0784-190731

PAGE 5

Overall Length Dimensions (SNAP-D64RS and B-series racks with terminal strips)

Part Number Description

SNAP-B8MC

SNAP-B8MC-P

SNAP-B12MC

SNAP-B12MC-P

SNAP-B16MC

SNAP-B16MC-P

SNAP-D64RS 16-module rack, digital only 4.41 112.01 15.25 387.35

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

8-module rack for other brains,

with terminal block

12-module rackfor other brains,

with terminal block

16-module rackfor other brains,

with terminal block

Width

(inches)

4.41 112.01 9.25 234.95

4.41 112.01 12.25 311.15

4.41 112.01 15.25 387.35

Width

(mm)

Length

(inches)

Length

(mm)

Page 6

DIMENSIONAL DRAWINGS (CONTINUED)

Dimensions—B-Series Racks Without Terminal Strips

DATA SHEET

Form 0784-190731

PAGE 6

Overall Length Dimensions (B-series racks without terminal strips)

Part Number Description

SNAP-B4M 4-module rack 3.91 99.31 6.24 158.41

SNAP-B8M 8-module rack 3.91 99.31 9.24 234.70

SNAP-B12M 12-module rack 3.91 99.31 12.24 310.90

SNAP-B16M 16-module rack 3.91 99.31 15.24 387.10

Width

(inches)

Width

(mm)

Length

(inches)

Length

(mm)

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 7

DIMENSIONAL DRAWINGS (CONTINUED)

SNAP-D64RS Rack and B-Series Racks with Terminal Strips:

Right Side View with DIN-Rail Option Installed

DATA SHEET

Form 0784-190731

PAGE 7

Processor Height* Processor Part Number Rack

SNAP-UP1-ADS

SNAP-B3000-ENET

4.12 in. (104.6 mm)

3.70 in. (95.9 mm)

* Height listed is from the processor’s mounting surface to the highest part of the processor. Height does not include wiring or cables.

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

SNAP-ENET-RTC

SNAP-UP1-D64

SNAP-ENET-D64

B3000

SNAP-B4

SNAP-B6

SNAP-BRS

B3000-HA

SNAP-BRS-HA

SNAP-B3000-MODBUS

B-series

SNAP-D64RS

B-series

Page 8

DIMENSIONAL DRAWINGS (CONTINUED)

B-Series Racks Without Terminal Strips:

Right Side View with DIN-Rail Option Installed

DATA SHEET

Form 0784-190731

PAGE 8

Processor Height* Processor Part Number

4.12 in. (104.6 mm)

3.70 in. (95.9 mm)

* Height listed is from the processor’s mounting surface to the highest part

of the processor. It does not include wiring or cables.

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

SNAP-UP1-ADS

SNAP-B3000-ENET

B3000

SNAP-B4

SNAP-B6

B3000-HA

SNAP-ENET-RTC

SNAP-BRS

SNAP-BRS-HA

SNAP-B3000-MODBUS

Page 9

MOUNTING

DATA SHEET

Form 0784-190731

PAGE 9

NOTE: If you are not using hold-down screws, the SNAP rack assembly

should be mounted horizontally.

Use the following steps to mount racks as shown in the diagrams on

the next two pages.

Preferred Method: Template

(Product on site)

1. Use SNAP rack mounting extrusion as template.

2. Be sure to use the diagrams on the next two pages to determine

required product and option clearances.

Center-to-Center Length (All Models)

Part Number Description

SNAP-B4M 4-module rack 4.01 in. 2

SNAP-B8M

SNAP-B8MC

SNAP-B8MC-P

SNAP-B12M

SNAP-B12MC

SNAP-B12MC-P

SNAP-B16M

SNAP-B16MC

SNAP-B16MC-P

SNAP-D64RS

8-module rack 3.51 in. 3

12-module rack 5.01 in. 3

16-module rack 4.34 in. 4

Center-to-Center

Length

Alternate Method: Prefabrication of Panels

(No product on site)

Mounting holes are in sets of two, located on lower left and upper

right with respect to a center line (CL).

1. Using the diagrams on the next two pages, determine CL1

mounting hole positions. (CL1 is located on the left side of all

SNAP rack mounting extrusions.)

2. Use the center-to-center length specification table below to

determine the offset between center lines and the number of

center line positions for each model.

3. Repeat the process for each center line position.

Number of Center

Positions

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 10

MOUNTING (CONTINUED)

SNAP-D64RS Rack and B-Series Racks with Terminal Strips:

Typical Plain View of SNAP Mounting Extrusion

DATA SHEET

Form 0784-190731

PAGE 10

See instructions and table on page 9.

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 11

MOUNTING (CONTINUED)

B-Series Racks Without Terminal Strips:

Typical Plain View of SNAP Mounting Extrusion

DATA SHEET

Form 0784-190731

PAGE 11

See instructions and table on page 9.

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 12

WIRING DIAGRAMS—B-SERIES MODELS WITH TERMINAL STRIPS

Terminal Strip Usage—Digital

Example: Digital Input Using Terminal Strip

NOTE: Consult the SNAP module

data sheet for your specific

module for additional wiring

DATA SHEET

Form 0784-190731

PAGE 12

Example: Digital AC Output Using Terminal Strip

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 13

WIRING DIAGRAMS—B-SERIES MODELS WITH TERMINAL STRIPS

Terminal Strip Usage—Digital (continued)

Example: Digital DC Output (Sourcing) Using Terminal Strip

NOTE: Consult the SNAP module

data sheet for your specific

module for additional wiring

DATA SHEET

Form 0784-190731

PAGE 13

Example: Digital DC Output (Sinking) Using Terminal Strip

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 14

WIRING DIAGRAMS—B-SERIES MODELS WITH TERMINAL STRIPS

Terminal Strip Usage—Analog

Example: Analog Input (Current: Negative) Using Terminal Strip

NOTE: Consult the SNAP module

data sheet for your specific

module for additional wiring

DATA SHEET

Form 0784-190731

PAGE 14

Example: Analog Input (Current: Positive) Using Terminal Strip

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 15

WIRING DIAGRAMS—B-SERIES MODELS WITH TERMINAL STRIPS

Terminal Strip Usage—Analog (continued)

Example: Analog Output (4–20 mA Current: Sourcing) Using Terminal Strip

NOTE: Consult the SNAP module

data sheet for your specific

module for additional wiring

DATA SHEET

Form 0784-190731

PAGE 15

Example: Analog Output (4–20 mA Current: Sinking) Using Terminal Strip

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 16

WIRING DIAGRAMS—B-SERIES MODELS WITH TERMINAL STRIPS

Terminal Strip Usage—Analog (continued)

Example: Analog Input (Voltage) Using Terminal Strip

NOTE: Consult the SNAP module

data sheet for your specific

module for additional wiring

DATA SHEET

Form 0784-190731

PAGE 16

© 2001–2019 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Loading...

Loading...