Page 1

DATA SHEET

Form 0859-180904

PAGE 1

SOLID-STATE RELAYS

Features

Rugged, epoxy encapsulation construction

>

4,000 volts of optical isolation

>

Subjected to full load test and six times the rated current

>

surge before and after encapsulation

Unique heat-spreader technology

>

Guaranteed for life

>

OVERVIEW

In 1974, Opto 22 introduced the first liquid epoxy-filled line of power

solid-state relays (SSR). This innovation in SSR design greatly improved

the reliability and reduced the cost of manufacturing. At that time, we

also incorporated into our manufacturing process 100% testing under

full-load conditions of every relay we produced.

By 1978, Opto 22 had gained such a reputation for reliability that we

were recognized as the world’s leading manufacturer of solid-state

relays. Through continuous manufacturing improvements and the

same 100% testing policy established over 40 years ago, Opto 22 is

Opto 22 Power Series SSR

still recognized today for the very high quality and reliability of all our

solid-state relays.

DESCRIPTION

Opto 22 offers a complete line of SSRs, from the rugged 120/240/380-volt

AC Series to the small footprint MP Series, designed for mounting

on printed circuit boards. All Opto 22 SSRs feature 4,000 volts of

optical isolation, and most are UL and CSA recognized. The innovative

use of room-temperature liquid epoxy encapsulation, coupled with

Opto 22’s unique heat-spreader technology, are key to mass

producing the world’s most reliable solid-state relays.

Part Numbers

Part Description

AC Switching

120A10 120 VAC, 10 Amp, AC Control

120A25 120 VAC, 25 Amp, AC Control

240A10 240 VAC, 10 Amp, AC Control

240A25 240 VAC, 25 Amp, AC Control

240A45 240 VAC, 45 Amp, AC Control

120D3 120 VAC, 3 Amp, DC Control

120D10 120 VAC, 10 Amp, DC Control

120D25 120 VAC, 25 Amp, DC Control

120D45 120 VAC, 45 Amp, DC Control

240D3 240 VAC, 3 Amp, DC Control

240D10 240 VAC, 10 Amp, DC Control

240Di10

240D25 240 VAC, 25 Amp, DC Control

240Di25

240D30-HS

240D45 240 VAC, 45 Amp, DC Control

240Di45

380D25 380 VAC, 25 Amp, DC Control

380D45 380 VAC, 45 Amp, DC Control

480D10-12 480 VAC, 10 Amp, DC Control, Transient Proof

480D15-12 480 VAC, 15 Amp, DC Control, Transient Proof

480D25-12 480 VAC, 25 Amp, DC Control, Transient Proof

480D25-HS

480D45-12 480 VAC, 45 Amp, DC Control, Transient Proof

240 VAC, 10 Amp, DC Control, with LED Indicators

240 VAC, 25 Amp, DC Control, with LED Indicators

240 VAC, 30 Amp, DC Control, with integrated

heatsink

240 VAC, 45 Amp, DC Control, with LED Indicators

480 VAC, 25 Amp, DC Control, Transient Proof,

with integrated heatsink

Part Description

AC Switching

575D15-12 575 VAC, 15 Amp, DC Control, Transient Proof

575D45-12 575 VAC, 45 Amp, DC Control, Transient Proof

575D30-HS

575Di45-12

MP120D2 or

P120D2

MP120D4 or

P120D4

MP240D2 or

P240D2

MP240D4 or

P240D4

MP380D4 380 VAC, 4 Amp, DC

Z120D10 Z Model, 120 VAC, 10 Amp, DC Control

Z240D10 Z Model, 240 VAC, 10 Amp, DC Control

DC Switching

DC60P or

DC60MP

DC200P or

DC200MP

DC60S-3 60 VDC, 3 Amp, DC Control

DC60S-5 60 VDC, 5 Amp, DC Control

Accessories

SAFETY COVER

SSR-HS

SSR-THERMOPAD

575 VAC, 30 Amp, DC Control, Transient Proof,

with integrated heatsink

575 VAC, 45 Amp, DC Control, Transient Proof,

with LED Indicators

120 VAC, 2 Amp, DC Control

P model is low profile

120 VAC, 4 Amp, DC Control

P model is low profile

240 VAC, 2 Amp, DC

P model is low profile

240 VAC, 4 Amp, DC

P model is low profile

60 VDC, 3 Amp, DC Control

P model is low profile

200 VDC, 1 Amp, DC Control

P model is low profile

Power Series SSR safety cover

Power Series SSR heatsink

Thermal conductive pad (pack of 10)

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 2

DATA SHEET

Form 0859-180904

PAGE 2

Every Opto 22 solid-state relay is subjected to full load test and six

times the rated current surge both before and after encapsulation.

This double testing of every part before it leaves the factory means

you can rely on Opto 22 solid-state relays. All Opto 22 SSRs are

guaranteed for life.

Accessories for the Power-Series SSRs include a safety cover, a

heatsink, and a matching thermal conductive pad. See page 3.

Power Series SSRs

Opto 22 provides a full range of Power

Series relays with a wide variety of voltage

(120–575 volts) and current options (3–45

amps). All Power Series relays feature 4,000

volts of optical isolation and have a high

PRV rating. Some Power Series relays

include built-in LEDs to indicate operation.

See page 4.

DC Series

The DC Series delivers isolated DC control to large OEM customers

worldwide. All DC control SSRs are LS TTL compatible.

AC Series

The AC Series offers the ultimate in solid state reliability. All AC Power

Series relays feature a built-in snubber as well as zero-voltage turn-on

and zero-current turn-off. Transient-proof models offer self protection

for noisy electrical environments.

Z Series SSRs

The Z Series employs a unique heat transfer

system that makes it possible for Opto 22

to deliver a low-cost, 10-amp, solid-state

relay in an all-plastic case. The push-on,

tool-free quick-connect terminals make the

Z Series ideal for high-volume OEM

applications. Operating temperature:

–40 °C to 100 °C. See page 7.

Printed Circuit Series SSRs

Opto 22’s Printed Circuit Series allows

OEMs to easily deploy solid-state relays on

printed circuit boards. Two unique

packages are available, both of which will

switch loads up to four amps. Operating

temperature: –40 °C to 100 °C. See page 9.

MP Series

The MP Series packaging is designed with a minimum footprint to

allow maximum relay density on the printed circuit board.

P Series

The P Series power relays provide low-profile [0.5 in. (12.7 mm)]

center mounting on printed circuit boards.

HS Series SSRs

The HS Series features an integrated heatsink,

which makes themsocool. These relays have

less thermal resistance inside, so heat

dissipates more easily than in a standard SSR

mounted to the same heatsink. With the

heatsink built-in, you don't have to select

one from a catalog, and installation is much

easier.Includes a DIN-rail adapter. See

page 13.

SPECIFICATIONS

(ALL POWER SERIES MODELS)

4,000 V optical isolation, input to output

Zero voltage turn-on

Zero-current turn-off

Turn-on time: 0.5 cycle maximum

Turn-off time: 0.5 cycle maximum

Operating temperature: –40 °C to 100 °C

Operating frequency: 25 to 65 Hz

(operates at 400 Hz with six times off-state leakage)

Coupling capacitance, input to output: 8 pF maximum

Hermetically sealed

DV/DT Off-state: 200 volts per microsecond

DV/DT commutating: snubbed for rated current at 0.5 power

factor

UL recognized

CSA certified

CE component

Torque specs for screws (this spec is both the recommended

torque and the maximum torque you should use):

Control terminals, 10 in-lb (1.13 N-m)

Field terminals, 18 in-lb (2.03 N-m)

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 3

DATA SHEET

Form 0859-180904

PAGE 3

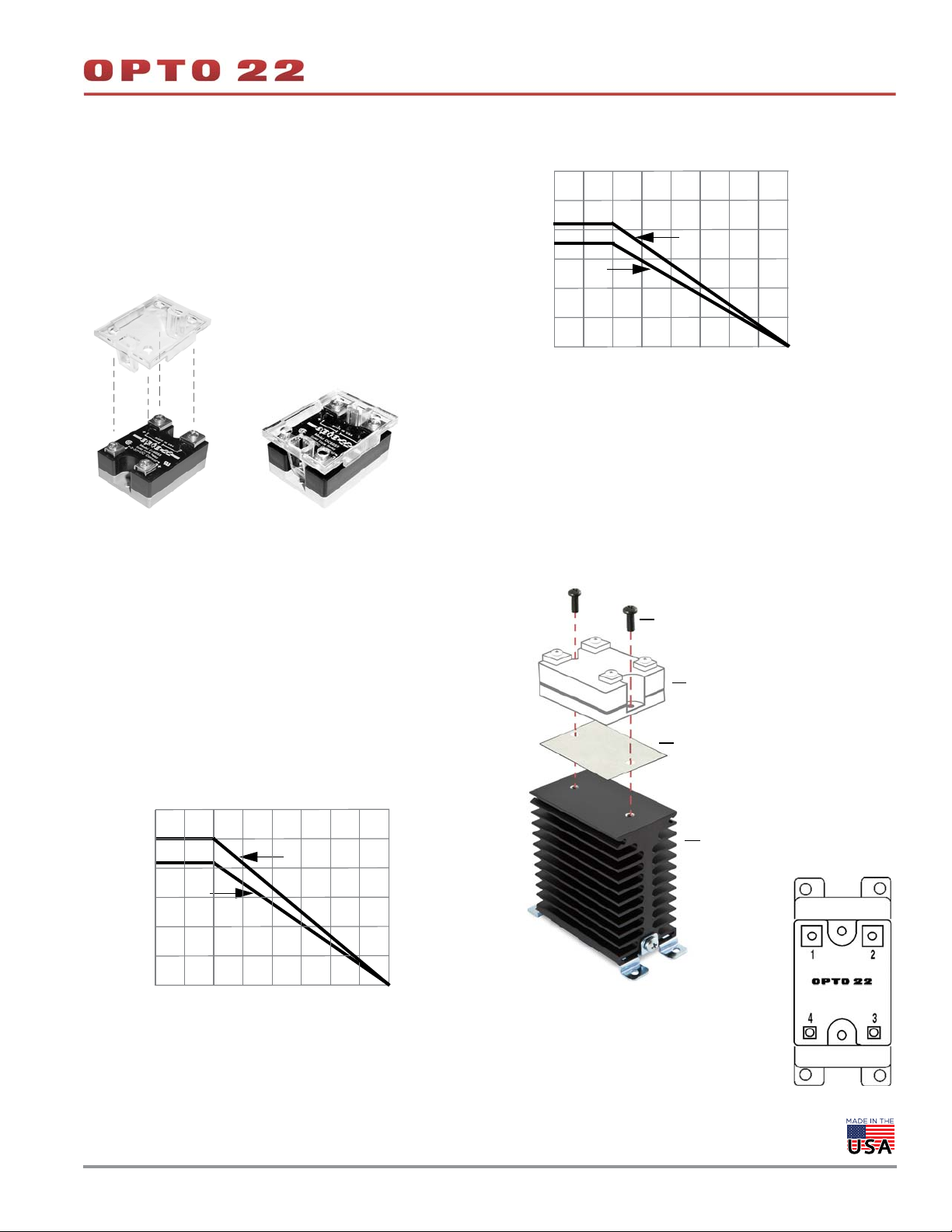

POWER SERIES SSR ACCESSORIES

Safety Cover

A plastic safety cover (Opto 22 part number SAFETY COVER) is

available for use with Opto 22 Power Series SSRs. The safety cover

reduces the chance of accidental contact with relay terminals, while

providing access holes for test instrumentation.

An optional plastic safety cover can be installed on a Power Series SSR.

SSR-HS Heatsink

Custom designed for the Power Series SSRs, the SSR-HS heatsink

provides excellent heat dissipation when mounted to the SSR with a

matching thermal conductive pad, used in place of silicon grease.

One thermal pad is included with the heatsink. Additional pads may

be purchased in packs of 10 (part number SSR-THERMOPAD).

DIN-rail adapter is included.

Thermal Ratings

The thermal ratings shown in the following graphs were obtained

with an SSR attached to a heatsink using a thermal conductive pad.

25 Amp Relay on SSR-HS Heatsink Derating

30

25

20

15

10

RMS

H

5

30 40 50 60 70 80 90 10020

V

Ambient Temperature (°C)

V: Heatsink mounted to a vertical surface

H: Heatsink mounted to a horizontal surface.

Heatsink Assembly

Before attaching the SSR, remove the protective film from both sides

of the thermal pad, then place the pad on the heatsink making sure to

align the holes. Secure the SSR to the heatsink with the two 8-32 x

3/8˝ panhead Phillips screws included in the kit. Use 20 in-lb (2.26

N-m) of torque.

Screws

See dimensional

drawing on page 12.

Power Series SSR

(not included)

Thermal conductive pad

45 Amp Relay on SSR-HS Heatsink Derating

30

25

20

15

10

RMS Amperes

5

H

30 40 50 60 70 80 90 10020

Ambient Temperature (°C)

V: Heatsink mounted to a vertical surface

H: Heatsink mounted to a horizontal surface.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

V

NOTE: To take advantage of the cooling effect

of natural air flow, mount the SSR/heatsink

assembly to a vertical surface with the Opto 22

logo right side up as shown here.

Heatsink

Page 4

DATA SHEET

Form 0859-180904

PAGE 4

AC POWER SERIES SPECIFICATIONS

Opto 22 provides a full range of Power Series relays with a wide variety of voltage (120–575) and current options (3–45 amps). All Power Series

relays feature 4,000 volts of optical isolation and have a high PRV rating. Operating temperature is –40 °C to 100 °C.

(Ambient temperature will affect the current rating.)

120/240/380 Volt

AC Line

Voltage

Nominal

Nominal

Model

Number

120D3 120 3* 85 1000 3VDC

120D10 120 10* 110 1000 3VDC

120D25 120 25* 250 1000 3VDC

120D45 120 45* 650 1000 3VDC

240D3 240 3* 85 1000 3VDC

240D10 240 10* 110 1000 3VDC

240Di10 240 10* 110 730 3VDC

240D25 240 25* 250 1000 3VDC

240Di25 240 25* 250 730 3VDC

240D45 240 45* 650 1000 3VDC

240Di45 240 45* 650 730 3VDC

380D25 380 25* 250 1000 3VDC

380D45 380 45* 650 1000 3VDC

120A10 120 10* 110 33K 85VAC

120A25 120 25* 250 33K 85VAC

240A10 240 10* 110 33K 85VAC

240A25 240 25* 250 33K 85VAC

240A45 240 45* 650 33K 85VAC

Notes: * Ambient temperature will affect the current rating. For details, see the Thermal Ratings chart.

** Operating Frequency: 25 to 65 Hz (operates at 400 Hz with 6 times the offstate leakage)

***jc = Thermal resistance from internal junction to base. Maximum internal junction temperature is 110 °C.

Current

Rating

(Amps)

1 cycle

Surge

(Amps)

Peak

Nominal

Signal Input

Resistance

(Ohms)

Signal

Pick-up

Voltage

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(280V allowed)

(280V allowed)

(280V allowed)

(280V allowed)

(280V allowed)

NOTE: Model numbers ending in -17 are replacement parts only. Their specifications are identical to

the same model n

Signal

Drop-out

Voltage

1 VDC 600 1.6 volts 2.5mA 12–140 30 4,000V

1 VDC 600 1.6 volts 7 mA 12–140 50 4,000V

1 VDC 600 1.6 volts 7 mA 12–140 250 4,000V

1 VDC 600 1.6 volts 7 mA 12–140 1750 4,000V

1 VDC 600 1.6 volts 5 mA 24–280 30 4,000V

1 VDC 600 1.6 volts 14 mA 24–280 50 4,000V

1 VDC 600 1.6 volts 14 mA 24–280 50 4,000V

1 VDC 600 1.6 volts 14 mA 24–280 250 4,000V

1 VDC 600 1.6 volts 14 mA 12–280 250 4,000V

1 VDC 600 1.6 volts 14 mA 24–280 1750 4,000V

1 VDC 600 1.6 volts 14 mA 24–280 1750 4,000V

1 VDC 800 1.6 volts 12 mA 24–420 250 4,000V

1 VDC 800 1.6 volts 12 mA 24–420 1750 4,000V

10 VAC 600 1.6 volts 7 mA 12–140 50 4,000V

10 VAC 600 1.6 volts 7 mA 12–140 250 4,000V

10 VAC 600 1.6 volts 14 mA 24–280 50 4,000V

10 VAC 600 1.6 volts 14 mA 24–280 250 4,000V

10 VAC 600 1.6 volts 14 mA 24–280 1750 4,000V

umber without the -17. For example, 240D10-17 is identical to 240D10.

Peak

Repetitive

Voltage

Maximum

Maximum

Output

Voltage

Drop

Off-State

Leakage

(mA)

Maximum**

Operating

Voltage

Range

(Volts AC)

I2t

Rating

t=8.3

(ms)

Isolation

Voltage

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

RMS

jc***

(°C/Watt)

(Watts/Amp)

11 1.7

1.3 1.6

1.2 1.3

0.67 0.9

11 1.7

1.3 1.6

1.3 1.6

1.2 1.3

1.2 1.3

0.67 0.9

0.67 0.9

1.2 1.3

0.67 0.9

1.3 1.6

1.2 1.3

1.3 1.6

1.2 1.3

0.67 0.9

Dissipation

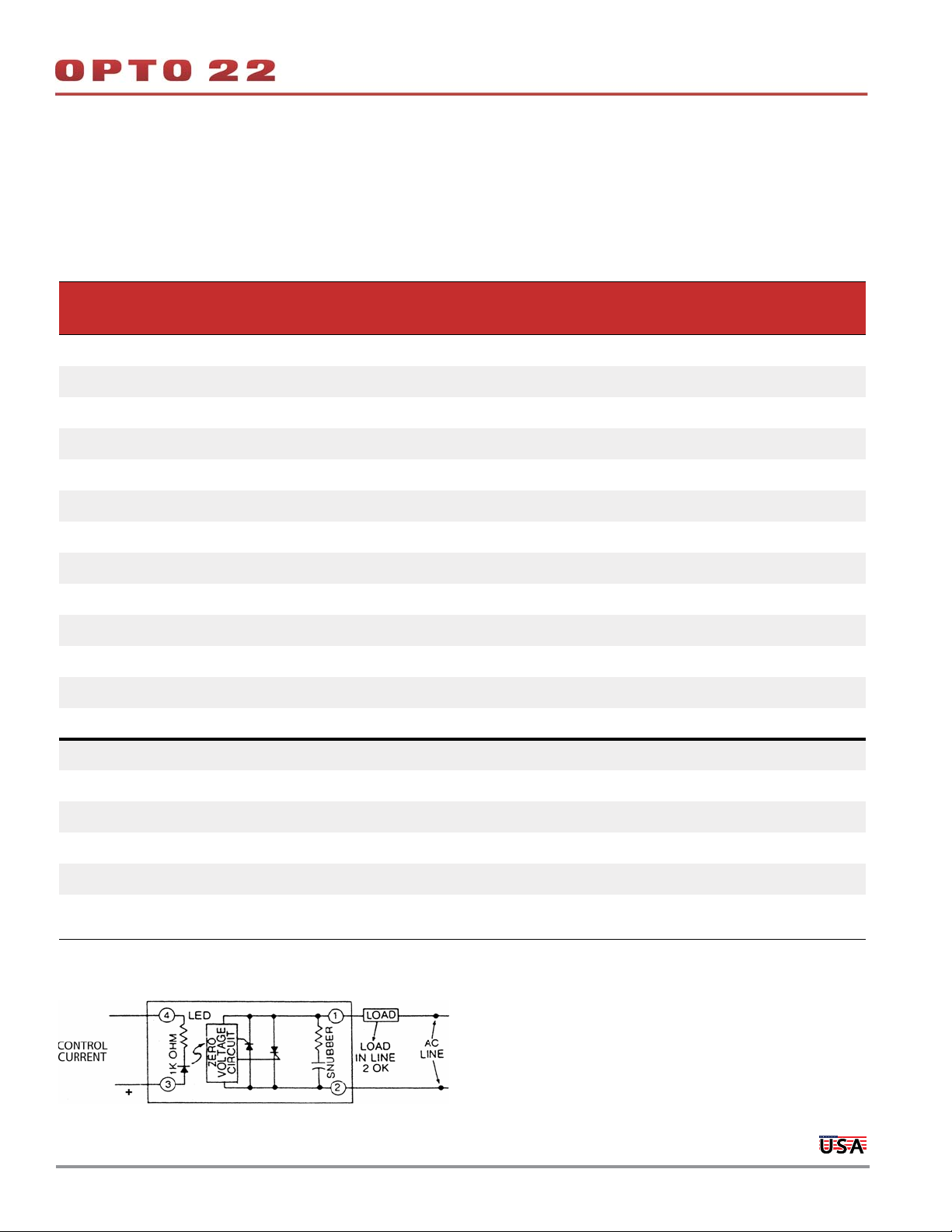

Connection Diagram, DC Power Series

Control Current varies with control voltage. For details, see “Control Current Calculation” on page 17.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 5

DATA SHEET

Form 0859-180904

PAGE 5

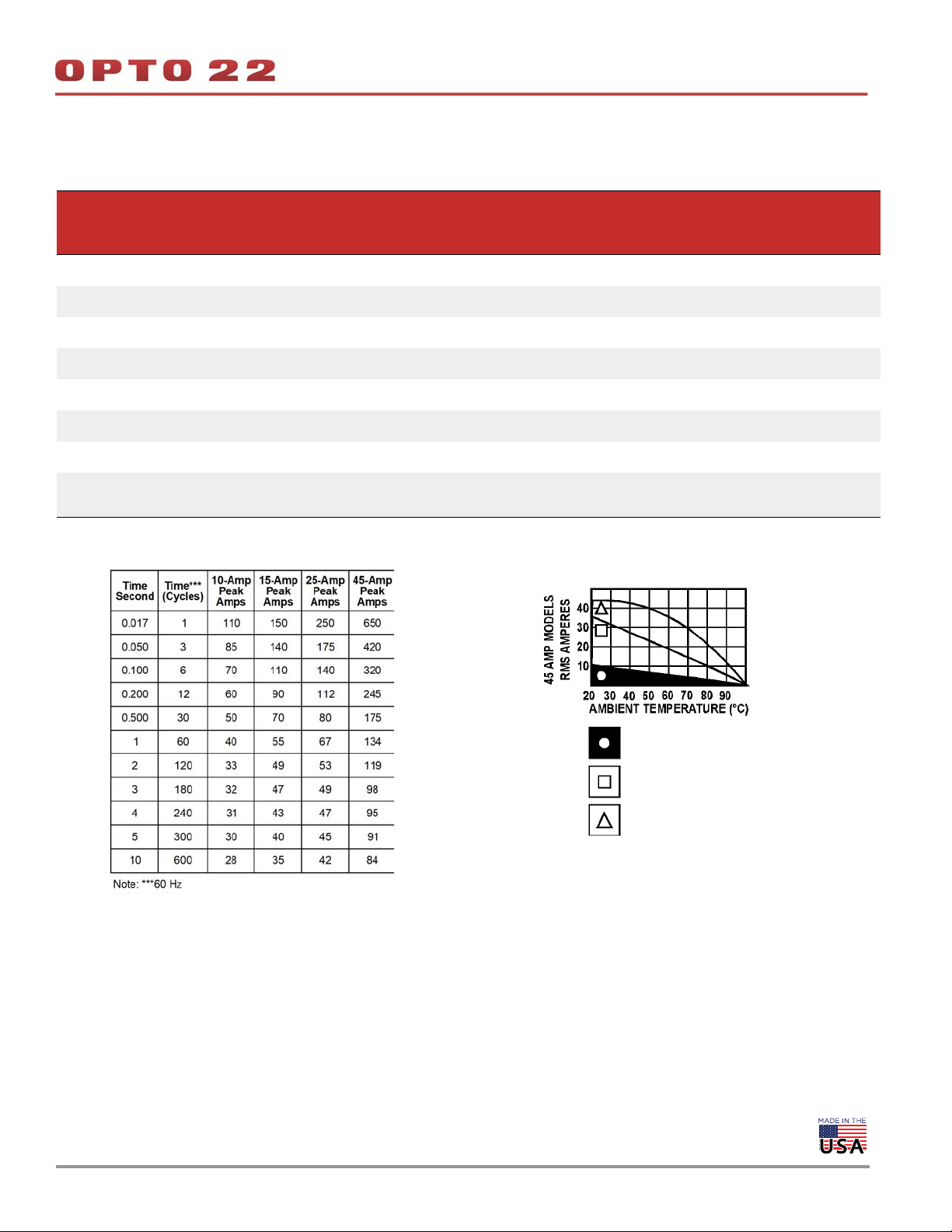

120/240/380 Volt (cont.)

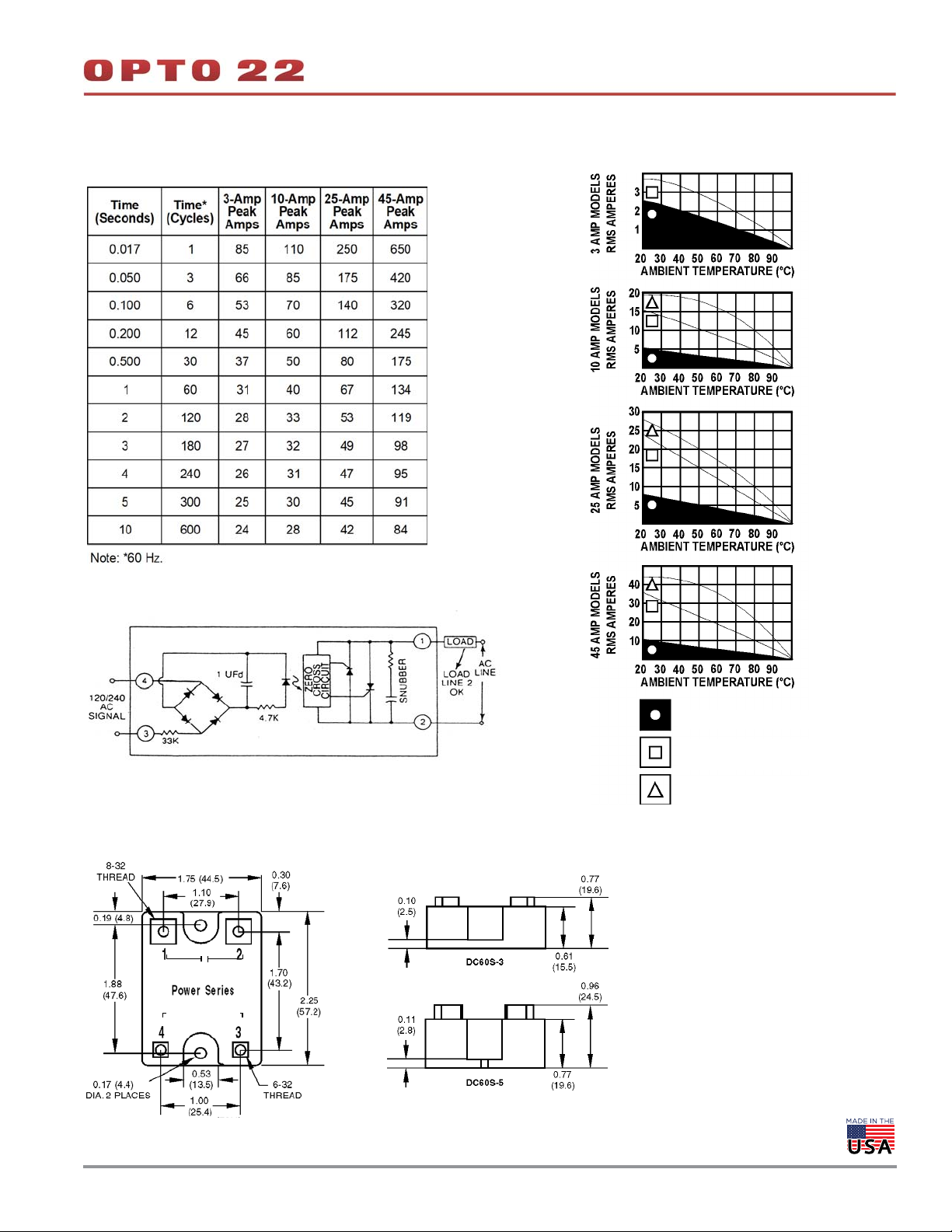

Surge Current Data

Connection Diagram, AC Power Series

Thermal Ratings

Ambient temperature will affect the current rating.

FREE AIR

MOUNTED ON A HEATSINK

WITH 2 °C/WATT RATING

Dimensional Drawings

MOUNTED ON A HEATSINK

WITH 1 °C/WATT RATING

NOTE: All dimensions are nominal. We do not recommend mounting the terminal side of the SSR to a flat PCB (printed circuit board) or other

flat surface, because there may be some variation in terminal height from one terminal to another and from one SSR to another.

Side view: Part numbers

Side view: Part numbers

DC60S3, 120D3, and

DC60S3, 120D3, and

240D3 only

240D3 only

3-32VDC

3-32VDC

+

+

Side view: All other

Side view: All other

part numbers

part numbers

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 6

480/575 Volt

DATA SHEET

Form 0859-180904

PAGE 6

Peak

Nominal

Signal

Input

Resistance

(Ohms)

Signal

Pick-up

Voltage

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

(32V allowed)

Peak

Signal

Drop-out

Voltage

Repetitive

Voltage

Maximum

1 VDC 1200 3.2 volts 11 mA 100–530 50 4,000V

1 VDC 1200 3.2 volts 11 mA 100–530 50 4,000V

1 VDC 1000 1.6 volts 11 mA 100–530 250 4,000V

1 VDC 1000 1.6 volts 11 mA 100–530 1750 4,000V

1 VDC 1200 3.2 volts 15 mA 100–600 90 4,000V

1 VDC 1000 1.6 volts 15 mA 100–600 1750 4,000V

1 VDC 1000 1.6 volts 15 mA 100–600 1750 4,000V

Maximum

Output

Voltage

Drop

Off-State

Leakage

(mA)

Maximum**

Model

Number

480D10-12 480 10* 110 1000 3VDC

480D15-12 480 15* 150 1000 3VDC

480D25-12 480 25* 250 1000 3VDC

480D45-12 480 45* 650 1000 3VDC

575D15-12 575 15* 150 1000 3VDC

575D45-12 575 45* 650 1000 3VDC

575Di45-12 575 45* 650 730 3VDC

Notes: * Ambient temperature will affect the current rating. For details, see the Thermal Ratings chart.

** Operating Frequency: 25 to 65 Hz (operates at 400 Hz with 6 times the offstate leakage)

***jc = Thermal resistance from internal junction to base. Maximum internal junction temperature is 110 °C.

Nominal

AC Line

Voltage

Nominal

Current

(Amps)

Rating

1 cycle

Surge

(Amps)

Surge Current Data Thermal Ratings

Ambient temperature will affect the current rating.

Operating

Voltage

Range

(Volts AC)

I2t

Rating

t=8.3

(ms)

Isolation

Voltage

RMS

RMS

RMS

RMS

RMS

RMS

RMS

jc***

(°C/Watt)

1.2 2.5

1.2 2.5

1.3 1.3

0.67 0.9

1.2 2.5

0.67 0.9

0.67 0.9

Dissipation

(Watts/Amp)

FREE AIR

MOUNTED ON A HEATSINK

WITH 2 °C/WATT RATING

MOUNTED ON A HEATSINK

WITH 1 °C/WATT RATING

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 7

Form 0859-180904

480/575 Volt (cont)

Dimensional Drawings

NOTE: All dimensions are nominal. We do not recommend mounting the terminal side of the SSR to a flat PCB (printed circuit board) or

other flat surface, because there may be some variation in terminal height from one terminal to another and from one SSR to another.

Side view: Part numbers

DC60S3, 120D3, and

240D3 only

DATA SHEET

PAGE 7

3-32VDC

+

Z SERIES SPECIFICATIONS

AC Power: 120/240 Volt

The Z Series employs a unique heat transfer system that makes it

possible for Opto 22 to deliver a low-cost, 10-amp, solid-state

relay in an all-plastic case. The push-on tool-free quick-connect

Z120D10 Z240D10

Nominal AC Line Voltage Nominal 120 240

Current Rating (Amps) 10* 10*

1 cycle Surge (Amps) Peak 110 110

Nominal Signal Input Resistance (Ohms) 1000 1000

Signal Pick-up Voltage

Signal Drop-out Voltage 1 VDC 1 VDC

Peak Repetitive Voltage Maximum 600 600

Maximum Output Voltage Drop 1.6 volts 1.6 volts

Off-State Leakage (mA) Maximum** 6 mA 12 mA

Operating Voltage Range (Volts AC) 12–140 24–280

2

I

t Rating t=8.3 (ms)

Isolation Voltage

jc*** (°C/Watt) Dissipation (Watts/Amp) 4 4

Notes:

* Ambient temperature will affect the current rating. For details, see the Thermal Ratings chart.

** Operating Frequency: 25 to 65 Hz (operates at 400 Hz with 6 times the offstate leakage).

***jc = Thermal resistance from internal junction to base. Maximum internal junction temperature is 110 °C.

3VDC (32V

allowed)

50 50

4,000 V

RMS

terminals make the Z Series ideal for high-volume OEM applications.

Operating temperature is –40 °C to 100 °C. (Ambient temperature will

affect the current rating.)

3VDC (32V

allowed)

4,000 V

Side view: All other

part numbers

NOTE: Part number Z240D10-17 is a

replacement part only. Its specifications

are identical to Z240D10.

RMS

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 8

AC Power: 120/240 Volt (cont.)

Thermal Ratings

Ambient temperature will affect the current rating.

DATA SHEET

Form 0859-180904

PAGE 8

Surge Current Data

FREE AIR

MOUNTED ON A HEATSINK

WITH 2°C/WATT RATING

Connection Diagram

Control Current varies with control voltage. For details, see “Control Current Calculation” on page 17.

Dimensional Drawings

NOTE: All dimensions are nominal. We do not

recommend mounting the terminal side of the SSR to

a flat PCB (printed circuit board) or other flat surface,

because there may be some variation in terminal

height or alignment from one terminal to another

and from one SSR to another.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 9

PRINTED CIRCUIT SERIES SPECIFICATIONS

AC Power: MP and P Series

DATA SHEET

Form 0859-180904

PAGE 9

The MP Series packaging is designed with a minimum footprint to

allow maximum relay density on the printed circuit board.

The P Series power relays provide low-profile for 0.5-inch (12.7 mm)

MP120D2

or P120D2

Nominal AC Line Voltage 120 120 240 240 380

Nominal Current Rating

(Amps)

1 cycle Surge (Amps)

Peak

Nominal Signal Input

Resistance (Ohms)

Signal Pick-up Voltage

Signal Drop-out Voltage 1 VDC 1 VDC 1 VDC 1 VDC 1 VDC

Peak Repetitive Voltage

Maximum

Maximum Output Voltage Drop

Off-State Leakage mA

Maximum**

Operating Voltage Range

(Volts AC)

2

t Rating t=8.3 (ms)

I

Isolation Voltage

jc*** °C/Watt 20 6.5 20 6.5 6.5

Dissipation Watts/Amp 1.2 1.2 1.2 1.2 1.2

Rating (Motor Load)

Notes: * Ambient temperature will affect the current rating. For details, see the Thermal Ratings chart.

** Operating Frequency: 25 to 65 Hz (operates at 400 Hz with 6 times the offstate leakage)

***jc = Thermal resistance from internal junction to base. Maximum internal junction temperature is 110 °C.

**** = P Series 32 volts maximum.

2* 4* 2* 4* 4*

20 85 20 85 85

1000 1000 1000 1000 1000

3VDC****

(24V allowed)

600 600 600 600 800

1.6 volts 1.6 volts 1.6 volts 1.6 volts 1.6 volts

5 mA 5 mA 5 mA 5 mA 5 mA

12–140 12–140 24–280 24–280 24–420

2 30 2 30 30

4,000 V

RMS

1 FLA at 120 VAC

6 LRA at 120 VAC

MP120D4

or P120D4

3VDC****

(24V allowed)

4,000 V

RMS

2.5 FLA at 240 VAC

6 LRA at 240 VAC

center mounting on printed circuit boards.

Operating temperature: –40 °C to 100 °C. (Ambient temperature will

affect the current rating.)

MP240D2

or P240D2

3VDC****

(24V allowed)

4,000 V

RMS

1 FLA at 120 VAC

15 LRA at 120 VAC

MP240D4

or P240D4

3VDC****

(24V allowed)

4,000 V

RMS

2.5 FLA at 240 VAC

15 LRA at 240 VAC

MP380D4

3VDC****

(24V allowed)

4,000 V

2.5 FLA at 380 VAC

15 LRA at 380 VAC

RMS

Connection Diagram

NOTE: Part numbers ending in -17 are replacement

parts only. Their specifications are identical to the

same part number without the -17. For example,

P240D4-17 is identical to P240D4.

Control Current varies with control voltage. For details, see “Control Current Calculation” on page 17.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 10

AC Power: MP and P Series (cont.)

DATA SHEET

Form 0859-180904

PAGE 10

Surge Current Data

Time

(Seconds)

0.017 1 20 85

0.050 3 18 66

0.100 6 15 53

0.200 12 11 45

0.500 30 9 37

1 60 8.5 31

2 120 8 28

3 180 7.5 27

4 240 7 26

5 300 6.5 25

10 600 6 24

Note: *60 Hz

Time*

(Cycles)

2-Amp

Peak Amps

Dimensional Drawings

NOTE: All dimensions are nominal.

4-Amp

Peak Amps

Thermal Ratings

Ambient temperature will affect the current rating.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 11

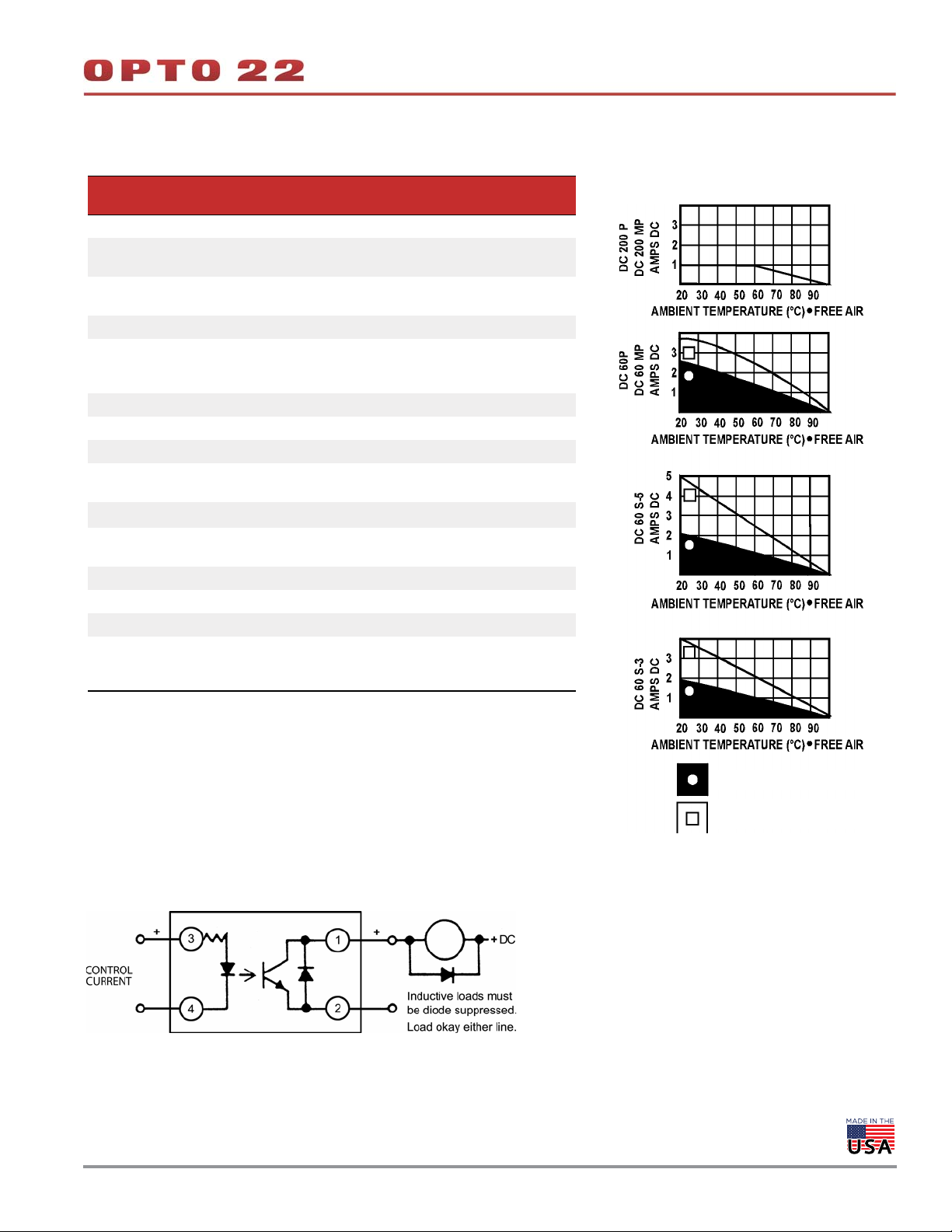

DC SWITCHING SERIES SPECIFICATIONS

DATA SHEET

Form 0859-180904

PAGE 11

DC60P or

DC60MP

Operating Voltage Range 5–60 VDC 5–200 VDC 5–60 VDC 5–60 VDC

Forward Voltage Drop

Nominal Current Rating

(Amps)

Off-State Blocking 60 VDC 250 VDC 60 VDC 60 VDC

Signal Pickup Voltage

Signal Dropout Voltage 1 VDC 1 VDC 1 VDC 1 VDC

Signal Input Impedance 1,000 ohms 1,000 ohms 1,000 ohms 1,000 ohms

1 Second Surge 5 amps 2 amps 5 amps 10 amps

Operating Temp. Range

Isolation Voltage

Off-State Leakage

Package Type P/MP series P/MP series Power series Power series

Turn-on Time 100 usec 100 usec 100 usec 100 usec

Turn-off Time 750 usec 750 usec 750 usec 750 usec

Notes: * Ambient temperature will affect the current rating. For details, see the Thermal

Ratings chart.

** MP series maximum allowed control signal is 24 VDC.

1.5 volts

at 3 amps

3* 1* 3* 5*

3 VDC

32 Volts**

allowed

–40 °C to

100 °C

4,000 V

1 mA

maximum

RMS

DC200P or

DC200MP

1.5 volts

at 1 amp

3 VDC

32 Volts**

allowed

–40 °C to

100 °C

4,000 V

RMS

1 mA

maximum

DC60S-3 DC60S-5

1.5 volts

at 3 amps

3 VDC

32 Volts

allowed

–40 °C to

100 °C

4,000 V

1 mA

maximum

RMS

1.5 volts

at 5 amps

3 VDC

32 Volts

allowed

–40 °C to

100 °C

4,000 V

1 mA

maximum

RMS

Thermal Ratings

Ambient temperature will affect the current rating.

NOTE: When controlling an inductive load, like a solenoid or coil, a commutating diode

must be used. Install the commutating diode across the terminals of the load (not the SSR

terminals). This will protect the SSR from damage caused by voltage spikes when turning off

the load.

FREE AIR

MOUNTED ON A HEATSINK

WITH 2 °C/WATT RATING

Model DC60MP Basic Schematic (also applies to the other SSRs on this page)

Control Current varies with control voltage. For details, see “Control Current Calculation” on page 17.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 12

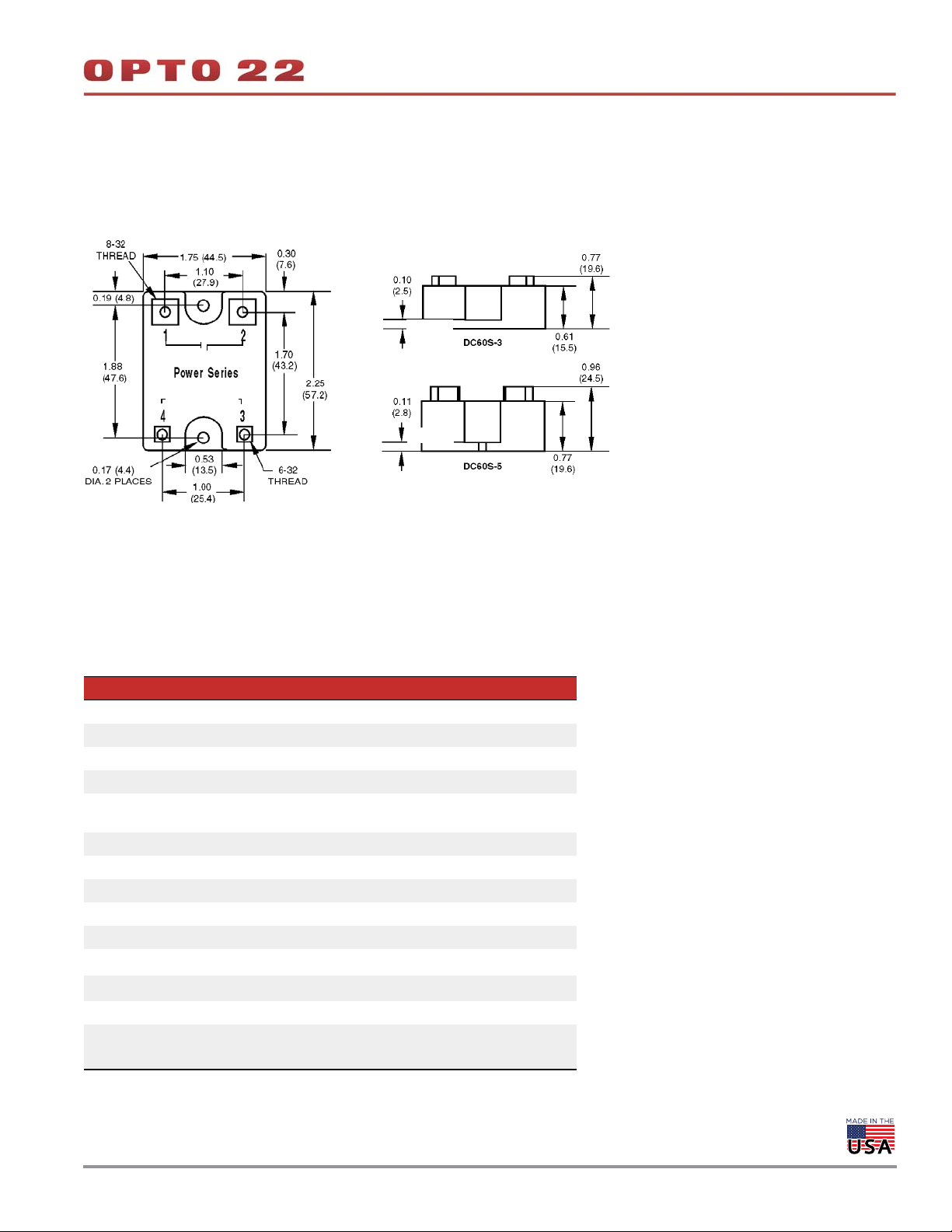

Dimensional Drawings

NOTE: All dimensions are nominal. We do not recommend mounting the terminal side of a Power Series or Z series SSR

to a flat PCB (printed circuit board) or other flat surface, because there may be some variation in terminal height or

alignment from one terminal to another and from one SSR to another. For mounting on PCBs, use the MP series or P series.

Side view: Part numbers DC60S3,

120D3, and 240D3 only

(+)

DATA SHEET

Form 0859-180904

PAGE 12

(+)

Power Series SSR with SSR-HS Heat Sink, top view

(+) (+)

Side view: All other part numbers

Power Series SSR with SSR-HS Heat Sink, side view

(+)

(+)

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 13

DATA SHEET

Form 0859-180904

PAGE 13

HS SERIES SPECIFICATIONS

The HS Series features an integrated heatsink, which makes themsocool.Because there isless thermal resistance internal to the unitthan in a

standard SSR mounted to the same heat sink, heat dissipates more easily. The built-in heatsink means you don't have to select a heatsink, and

installation is much easier. Each HS-series SSR has built-in hardware for screw mounting and a built-in DIN-rail adapter clip for mounting to a

35mm DIN rail.

Model Number 240D30-HS 480D25-HS 575D30-HS

Nominal AC Line Voltage 240 480 575

Operating Voltage Range (Volts AC) 24–280 100–530 100–600

Peak Repetitive Voltage Maximum 600 1000 1200

Off-State Leakage (mA) Maximum* 5 mA 10 mA 12 mA

Nominal Output Voltage Drop (RMS) 1.0 volts 1.0 volts 1.0 volts

Nominal Current Rating (Amps) 30** 25** 30**

1 cycle Surge (Amps) Peak 610 610 610

I2t Rating t=8.3 (ms)

Isolation Voltage (transient 4KV) 2,500V

Dissipation (Nominal Watts/Amp) 1.0 1.0 1.0

Signal Pick-up Voltage

Signal Drop-out Voltage 1 VDC 1 VDC 1 VDC

Nominal Signal Input Resistance (Ohms) 730 1000 1000

ja*** (°C/Watt) 2.2 2.2 2.2

Notes: * Operating Frequency: 25 to 65 Hz (operates at 400 Hz with 6 times the offstate leakage)

** Ambient temperature will affect the current rating. For details, see the associated Thermal Ratings chart.

*** ja = Thermal resistance from internal junction to base. Maximum internal junction temperature is 110 °C.

1550 1550 1550

RMS

4VDC

(32V allowed)

2,500V

RMS

4VDC

(32V allowed)

2,500V

RMS

4VDC

(32V allowed)

Surge Current Data, Peak Amps

Time

Second

0.0167 610 580

0.05 394 375

0.1 300 386

0.2 230 219

0.5 164 156

1 126 120

2 112 106

39287

48985

58581

10 79 75

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

60HZ 50HZ

Page 14

HS-SERIES (CONT.)

Thermal Ratings

Ambient temperature will affect the current rating.

30

DATA SHEET

Form 0859-180904

PAGE 14

30

25

20

15

10

RMS Amperes

5

30 Amp Models

30 40 50 60 70 80 90 10020

Ambient Temperature (°C)

A

B

25

20

15

10

RMS Amperes

5

25 Amp Models

30 40 50 60 70 80 90 10020

Ambient Temperature (°C)

A

B

A: Single relay or with 0.75” spacing between relays. Derate above 40 °C; subtract 0.5 amp/°C.

B: Three relays side by side with 0.25” spacing. All relays with the same load. Derate above 40 °C; subtract 0.4 amp/°C.

NOTE: This data is for SSRs mounted to a horizontal surface. To take advantage

of the cooling effect of natural air flow, we recommend mounting HS-series SSRs

to a vertical surface with the Opto 22 logo right side up as shown here.

Dimensional Drawing

3.90" (99.1 mm)

3.50" (88.9 mm)

0.20" (5.1 mm)

1.25"

(31.8 mm)

0.25"

3.21" (81.6 mm)

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

(6.4 mm)

4.81"

(122.2 mm)

1.75"

(44.5 mm)

Page 15

APPLICATIONS: TIPS

Heat Sink Calculation

Like all semiconductor devices, SSR current ratings must be based on maximum internal junction temperature.

All Opto 22 SSRs operate conservatively at maximum internal junction temperatures of 110 °C. Use the equation below

to calculate the maximum allowable heat sink thermal resistance for your application. It is good engineering practice to

provide a margin for error instead of running the application right at the limits. If your application is near the thermal limit,

it can be helpful to add a fan to move air across the heat sink.

IMPORTANT: Thermally conductive grease must be used between the relay base and the heat sink.

DATA SHEET

Form 0859-180904

PAGE 15

Sample Calculation 1

120-volt, 20-amp load; 50 °C ambient air temperature

Model: 120D25 SSR.

See the last two columns of the table on page 4 for thermal resistance and dissipation values for the 120D25.

Also, see the note at the bottom of the table.

Dissipation: 1.3 watts/amp

Thermal resistance: 1.2 °C/watt

Maximum junction temperature: 110 °C

The calculation would be as follows:

This calculation indicates that you

should select a heat sink with a thermal

resistance of less than 1.1 °C/watt.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 16

Sample Calculation 2

240-volt,18-amp load, 25 °C ambient air temperature

Model: 240D45

See the last two columns of the table on page 4 for thermal resistance and dissipation values

for the 240D45. Also, see the note at the bottom of the table.

Dissipation: 0.9 watts/amp

Thermal resistance: 0.67 °C/watt

Maximum junction temperature: 110 °C

The calculation would be as follows:

This calculation indicates that you should

select a heat sink with a thermal resistance

of less than 4.6 °C/watt.

DATA SHEET

Form 0859-180904

PAGE 16

Duty Cycle Calculation

When solid-state relays are operated in an on/off mode, it may be advantageous to calculate

the RMS value of the current through the SSR for heat sinking or determining the proper

current rating of the SSR for the given application.

I

= RMS value of load or SSR

RMS

I

T1 = Time current is on

T2 = Time current is off

ION = RMS value of load current during on period

RMS

=

(ION)2 x T

T1 + T

1

2

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 17

DATA SHEET

Form 0859-180904

PAGE 17

Transformer Loads

Careful consideration should be given to the selection of the proper

SSR for driving a given transformer. Transformers are driven from

positive saturation of the iron core to negative saturation of the core

each half cycle of the alternating voltage. Large inrush currents can

occur during the first half cycle of line voltage if a zero-voltage SSR

happens to turn on during the positive half cycle of voltage when the

core is already in positive saturation. Inrush currents greater than 10

times rated transformer current can easily occur. The following table

provides a guide for selecting the proper SSR for a given transformer

rating.

Control Current Calculation

All Opto 22 DC-controlled SSRs have a control circuit consisting of

1000 ohms in series with an Optocoupler LED.

The LED will drop 1 volt, so the voltage across the internal resistor will

be 1 volt less than the control voltage.

The control current (I C ) can be calculated from the control voltage

(VC ) as follows:

IC = (VC - 1)/1000

Examples:

3 VDC control voltage:

IC = (3 - 1)/1000 = 0.002 A (2 mA)

32 VDC control voltage:

I

= (32 - 1)/1000 = 0.031 A (31 mA)

C

For control voltages above 32 VDC, an external resistor can be added

in series with the SSR to limit the control current. Also, if the device

driving the control current to the SSR is limited, you can limit the

control current by using an external resistor (Re).

IC = (VC - 1)/ (Re + 1000)

Re = [(VC - 1)/(IC)] -1000

Solenoid Valve and Contactor Loads

All Opto 22 SSRs are designed to drive inductive loads such as

solenoid valves and electromechanical contactors. The built-in

snubber in each SSR assures proper operation into inductive loads.

The following table is a guide in selecting an SSR to drive a solenoid or

contactor.

To limit the control current to 2 mA, this simplifies to:

Re = 500 (VC - 3)

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 18

DATA SHEET

Form 0859-180904

PAGE 18

Opto 22 SSRs for controlling single-phase motors are shown in the

following tables:

Solid-State Relays in Series

In applications requiring higher voltage, two Opto 22 SSRs may be

operated in series for double the voltage rating. The built-in snubber

in each SSR assures proper voltage sharing of the two SSRs in series. In

the following diagram, two 240-volt, 45-amp SSRs are connected in

series for operation on a 480-volt line. The control is shown with a

parallel hook-up but it should be noted that a serial connection can

also be implemented.

Lamp Loads

Since all Opto 22 AC output SSRs use zero-voltage turn-on, they are

ideal for driving incandescent lamps, because the initial inrush current

into a cold filament is reduced. The life of the lamp is increased when

switched by a zero-voltage turn-on SSR. The following table is a guide

to selecting an Opto 22 SSR for switching a given incandescent lamp.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 19

DATA SHEET

Form 0859-180904

PAGE 19

Heater Loads

Care should be taken in selecting a SSR for driving a heater load if the

load is cycled on and off in a continuous manner as might occur in a

temperature control application. Constant cycling can cause thermal

fatigue in the thyristor chip at the point where the chip bonds to the

lead frame. Opto 22 employs a thick copper lead frame for mounting

the SCR chips in the power series SSRs to eliminate thermal fatigue

failures. In addition, Opto 22 recommends operating any SSR at 75%

rated current for cycling heater loads to ensure complete reliability.

The following table is a guide to selecting the proper SSR for a given

heater load.*

Single-Phase Reversing Motor Control (cont.)

The resistors are unnecessary if the control circuit is designed

to ensure that one SSR is off before the other SSR is on.

Three-Phase Motor Control

* Ambient temperature will affect the current rating. For details, see

the Thermal Ratings charts.

Single-Phase Reversing Motor Control

The circuit diagram below illustrates a typical 1 Ø motor winding

inductance and the phase shift capacitor can cause twice-line voltage

to appear across the open SSR. A 240-volt SSR should be used for a

120-volt line. During the transition period when one SSR is turned on

and the other SSR is going off, both SSRs may be on. In this case, the

capacitor may discharge through the two SSRs, causing large currents

to flow, which may destroy the SSRs. The addition of RL as shown will

protect the SSRs from the short circuit capacitor discharge current.

Three-phase motors may be controlled by solid-state relays as shown.

A third SSR as shown is optional, but not necessary. The control

windings may be connected in series or parallel. Care should be taken

to ensure that the surge current drawn by the motor does not exceed

the surge current rating of the SSR.

240 Volt Three-Phase Motor 480 Volt Three-Phase Motors

SSR MODEL MOTOR SSR MODEL MOTOR

SSR MODEL MOTOR 480D10-12 1-½ HP

Z240D10 3/4 HP 480D15-12 1-½ HP

240D10 3/4 HP

240A10 3/4 HP

240D25 2 HP

240A25 2 HP

240D45 3 HP

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 20

DATA SHEET

Form 0859-180904

PAGE 20

Three-Phase Reversing Motor Control

Three-phase reversing motor control can be implemented with four

SSRs as shown in the connection diagram. The SSRs work in pairs with

SSR1 and SSR3 operated for rotation in one direction and SSR2 and

SSR4 operated for rotation in the reverse direction. The resistor R1 as

shown in the connection diagram protects against line-to-line shorts

if SSR1 and SSR4 or SSR3 and SSR2 are on at the same time during the

reversing transition period. Use the following table as a guide to the

proper selection of an SSR for this application.

FAQ: SSR APPLICATIONS

Q : What is a solid-state relay?

A: A solid-state relay (SSR) is a semiconductor device that can be used

in place of a mechanical relay to switch electricity to a load in many

applications. Solid-state relays are purely electronic, normally

composed of a low current “control” side (equivalent to the coil on an

electromechanical relay) and a high-current load side (equivalent to

the contact on a conventional relay). SSRs typically also feature

electrical isolation to several thousand volts between the control and

load sides. Because of this isolation, the load side of the relay is

actually powered by the switched line; both line voltage and a load

(not to mention a control signal) must be present for the relay to

operate.

Q : What are the advantages of using an SSR over a mechanical relay?

A: There are many applications that require a moderate amount of

power (W to kW) to be switched on and off fairly rapidly. A good

example would be the operation of a heater element in a

controlled-temperature system. Typically, the amount of heat put into

the system is regulated using pulse-width modulation turning a

fixed-power heating element on and off for time periods ranging

from seconds to minutes. Mechanical relays have a finite cycle life, as

their components tend to wear out over thousands to millions of

cycles. SSRs do not have this problem; in the proper application, they

could be operated almost infinitely.

Q : What are the limitations of using an SSR?

A: SSRs have a few limitations when compared to the capabilities of

their mechanical counterparts. First, because the relay is

semiconductor-based, it will never turn all the way on, nor off. This

means that in the “on” state, the relay still has some internal resistance

to the flow of electricity, causing it to get hot. When in the “off” state,

the relay will exhibit a small amount of leakage current, typically a few

mA. This leakage can conspire to keep some loads, especially ones

with a high impedance, from turning off! Additionally, SSRs are more

sensitive to voltage transients; while Opto 22 relays are very well

transient-protected, if a relay gets hit hard enough a sufficient

number of times, it will die or degrade. This makes SSRs less ideal for

driving highly inductive electromechanical loads, such as some

solenoids or motors. SSRs should also never be used for applications

such as safety power disconnects, because even in the off state,

leakage current is present. Leakage current through an SSR also

implies the presence of a potentially high voltage. Even though the

relay is not conducting a large amount of current, the switched

terminal will still be “hot,” and thus dangerous.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 21

DATA SHEET

Form 0859-180904

PAGE 21

Q: Which SSRs should I use with a printed circuit board (PCB)?

A: If you are mounting SSRs to a PCB, use the MP or P series SSRs

which are designed for that purpose.

We do not recommend mounting the terminal side of a Power Series

or Z series SSR to a flat PCB (or to any other flat surface), because there

may be some variation in terminal height or alignment from one

terminal to another and from one SSR to another.

Q : Do you make multi-pole or multi-throw SSRs?

A: Opto 22 manufactures only single-pole, single-throw SSRs. If

multi-phase operation is required, just use a relay on each phase.

Because of the limitations on semiconductor devices of the type used

in SSRs, it is not practical to build single-device multi-throw SSRs.

However, an alternative to multi-throw operation may be

accomplished with multiple relays.

Q : Can I hook up SSRs in parallel to achieve a higher current

rating?

A: No. There is no way to guarantee that two or more relays will turn

on simultaneously when operated in parallel. Each relay requires a

minimum voltage across the output terminals to function; because of

the optical isolation feature, the “contact” part of the SSR is actually

powered by the line it switches. One relay turning on before the other

will cause the second relay to lose its turn-on voltage, and it won’t

ever turn on, or at least not until the first relay fails from carrying too

much current.

Q : What does a “zero-crossing” turn-on circuit refer to?

A: An AC sine wave will be positive for the first half of each cycle and

negative for the second half of each cycle. The voltage will cross

through zero when the sine wave changes from the positive

half-cycle to the negative half-cycle, and vice versa. So the voltage

crosses through zero twice with each full AC sine wave cycle.

“Zero-crossing” turn-on means that the SSR will only turn on when

the AC sine wave passes through zero voltage. The actual turn-on will

occur at or near zero voltage. All Opto 22 AC output solid-state relays

are designed with a zero-crossing turn-on circuit. Zero-voltage

turn-on has the benefit of minimizing electrical noise. All Opto 22 AC

output solid-state relays use a zero-current turn-off circuit as well.

Q : Can I use an AC SSR to switch DC?

A: No. Because of the zero-crossing circuit described above, the relay

will most likely never turn on, and even if it is on, it will most likely not

be able to be turned off.

Q : Can I use a DC SSR to switch AC?

A: No. The semiconductor device used in Opto 22’s DC SSRs is

polarized. It may break down and conduct for the portion of the

waveform that is reversed in polarity.

Q : Can a DC SSR be used to switch an analog signal?

A: This is not recommended at all. First, the voltage drop across the

relay will cause signal loss. Second, the conduction characteristics of

the SSR are very non-linear at low operating voltages and currents.

Use a mechanical relay; it will work much better.

Q : What agency approvals do your SSRs carry?

A: In general, Opto 22 relays carry UL, CSA, and CE approval. See

http://support.opto22.com. Additionally, some SSRs contain

VDE-approved optocouplers; contact Opto 22 for more

FAQ: SSR TROUBLESHOOTING

Q : My SSR does not function anymore. What may have happened?

A: There is no “normal” mode of failure for SSRs. They just stop

working, by refusing to turn on or off. An improper installation is often

to blame for an SSR failure, as these are very simple, reliable devices. If

you have a failed SSR, it is important to look at the normal operating

parameters of that relay within the larger system to make sure that the

relay being used is appropriate to the application, and that the relay is

being properly installed in the system. The three most common

causes of SSR failure are as follows:

SSR improperly matched to load. The relay was destroyed by

overheating from carrying too much current too long.

SSR insufficiently protected. Remember, a semiconductor is

less tough than a simple metal contact. Reverse voltages

exceeding the PRV rating of the relay will cause damage. Voltage

spikes on the switched line, perhaps from inductive kickback, may

have destroyed one or more of the internal switching devices.

Remember to use snubbers, transorbs, MOVs, and/or

commutating diodes on highly inductive loads.

SSR improperly installed. The SSR was not mounted to a large

enough heat sink, or no thermal compound was used, causing

the relay to overheat. Also, insufficient tightening of the load

terminals can cause arcing and ohmic heating of the relay.

Opto 22 recommends 18 inch-pounds of torque on the load

screw terminals. Similar failures have also been attributed to the

use of crimp-on terminal lugs or spades; make sure such terminals

are tightly crimped, and even drip some solder into the joint to

ensure good electrical contact and protection from corrosion.

Q : How can I test my SSR?

A: It is not possible to test an SSR by the same methods used to test

mechanical relays; a typical SSR will always show an infinite

impedance to a resistance meter placed across the output terminals.

There are a few reasons for this. First, the SSR requires a small amount

of power to operate, derived from whatever voltage source is placed

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 22

on the load terminals. A typical multimeter will not supply sufficient

voltage to cause the relay to change state. Second, AC SSRs contain

zero-voltage turn-on and zero-current turn-off circuits. The SSR will

not be able to turn on unless there is AC voltage connected to the

output terminals. Most test equipment will supply a DC voltage to the

relay, so it will never see the zero-voltage transition it requires to turn

on. To test an SSR, it is best to operate it at the actual line voltage it

will be used at, driving a load such as a large light bulb.

Q : I have an SSR driving a load. The load turns on okay, but

never seems to turn off, unless I remove power from the relay

entirely. What might be happening?

A: This is normally a problem when using an SSR with a

high-impedance load, such as a neon lamp or a small solenoid. Loads

like these often have relatively large initial currents, but relatively small

“hold in” currents. The result is that the off-state leakage current

through the relay (see previous section) is insufficient to cause the

load to turn on to start with, but sufficient to keep it on, once started.

The solution is to place a power resistor, sized for 8–10 times the rated

maximum leakage current for the SSR in parallel with the load. Make

sure that this resistor has a high enough power rating for the

application. For example, for a 5 mA leakage current at 120 VAC, a

resistor drawing 50 mA would be desirable. Using Ohm’s Law, the

resistor value becomes 2,400 ohms. This resistor will dissipate 6 watts,

so a 7.5 or 10-watt size power resistor should be used.

DATA SHEET

Form 0859-180904

PAGE 22

Q : I have a new AC SSR driving a solenoid. It turns on okay

once, but will not turn on again. What is going on?

A: Some solenoids, some types of halogen lights, and some types of

strobe lights incorporate a diode in series with the coil or filament.

This causes the light to behave as a half-wave rectifier. Opto 22 SSRs

have a built-in R-C snubber circuit in parallel with the output. The

capacitor in this circuit charges up but cannot discharge through the

series diode, causing a voltage to appear across the SSR terminals.

Because the SSR must detect the AC waveform cross through zero

volts on the load terminals, it will not be able to turn on again. The

solution here would be to put a high-value resistor (several tens of

Kohms) across the terminals of the relay, to allow the capacitor to

drain its charge.

© 2006–2018 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Loading...

Loading...