Page 1

RACKS

CLASSIC

ST ANDARD DIGIT AL

DAT A SHEET

Form 515-040506

Description

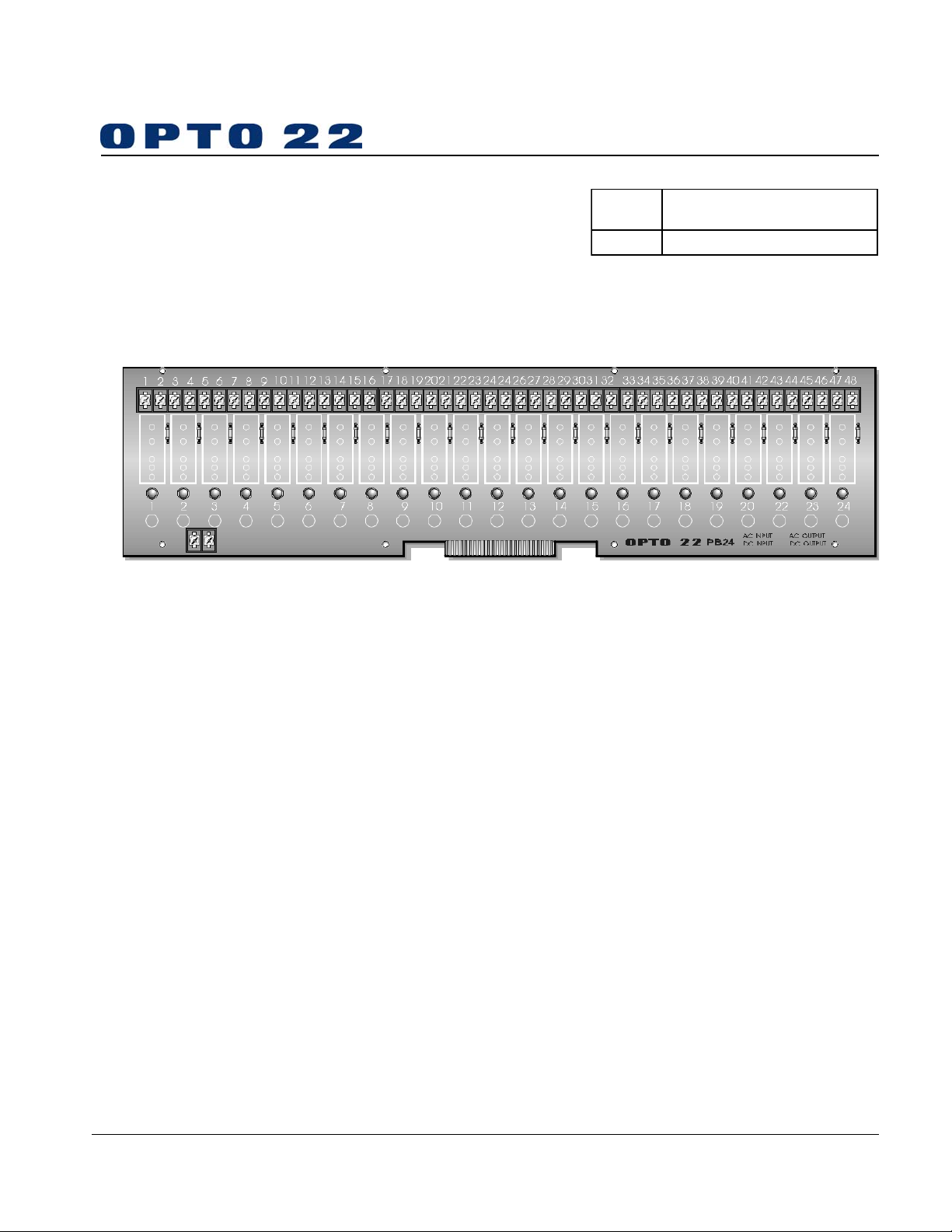

The PB24 I/O mounting rack can accommodate up to 24 single-channel Opto 22 standard

(Generation 1) I/O modules. The PB24 I/O mounting rack uses a 50-pin card edge connector for

interface to computer parallel I/O ports via a 50-conductor ribbon cable.

Part

Number

PB24 24-Channel I/O Mounting Rack

page 1/4

Description

Page 2

RACKS

CLASSIC

ST ANDARD DIGIT AL

DAT A SHEET

Form 515-040506

Specifications

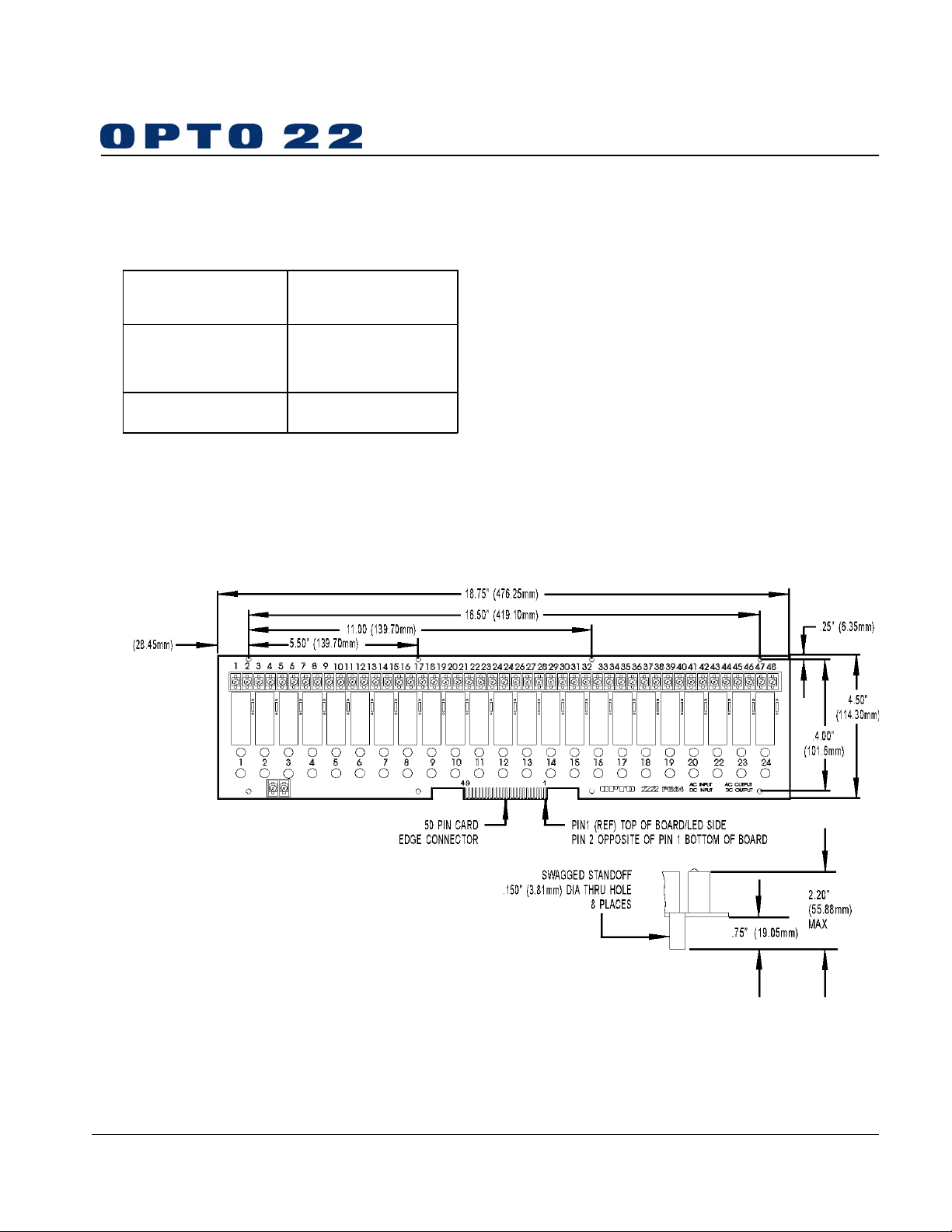

General Specifications

Operating Temperature

Interface Connector

Field

Logic

Compatible I/O Module

Family

Dimensions

page 2/4

0° to 70° C

95% relative humidity

Non-condensing

6-32 Screw Terminals

50-conductor edge card

connector

Standard (Generation 1)

Page 3

RACKS

CLASSIC

ST ANDARD DIGIT AL

DAT A SHEET

Form 515-040506

Connections

Module

Position

0471 & 2

1453 & 4

2435 & 6

3417 & 8

4399 & 10

5 37 11 & 12

6 35 13 & 14

73315 & 16

83117 & 18

92919 & 20

10 27 21 & 22

11 25 23 & 24

12 23 25 & 26

13 21 27 & 28

14 19 29 & 30

15 17 31 & 32

16 15 33 & 34

17 13 35 & 36

18 11 37 & 38

19 9 39 & 40

20 7 41 & 42

21 5 43 & 44

22 3 45 & 46

23 1 47 & 48

Control

(Edge

Connector)

page 3/4

Field

(Terminal

Strip)

NOTES:

1. Even pins on control connector are connected by etch to common.

2. +VCC and return connected to two-point terminal strips marked “+5V” and “GND”.

3. At each module position on the field terminal strip, the lower number is always

connected to pin 1 of the I/O module.

4. Odd pins are on the top of the board (LED side).Even pins are on the bottom.

Page 4

RACKS

CLASSIC

ST ANDARD DIGIT AL

DAT A SHEET

Form 515-040506

Schematics

page 4/4

© 1991–2004 Opto 22. All rights reserved. All trademarks, trade names, logos, and service marks referenced herein belong to their respective companies.

Page 5

LATEST PRODUCTS

COMPANY INFORMATION

Products

DAT A SHEET

Opto 22 produces a broad array of reliable, flexible hardware and

Form 515-040506

software

data acquisition, and machine-to-machine (M2M) applications.

SNAP Ethernet Systems

flexibility in their network connectivity and in the software applications

they work with. The physical network may be a wired Ethernet network, a

cellular wireless network, or a modem. A wide variety of software

applications can exchange data with SNAP Ethernet systems, including:

Controllers provide central control and data distribution. I/O units provide

local connection to sensors and equipment.

products for industrial automation, remote monitoring, enterprise

Based on the Internet Protocol (IP), SNAP Ethernet systems offer

Opto 22’s own ioProject™ suite of control and HMI software

Manufacturing resource planning (MRP), enterprise management,

and other enterprise systems

Human-machine interfaces (HMIs)

Databases

Email systems

OPC client software

Custom applications

Modbus/TCP software and hardware.

SNAP Ethernet system hardware consists of controllers and I/O units.

RACKS

CLASSIC

ST ANDARD DIGIT AL

Opto 22 Software

s ioProject and FactoryFloor

Opto 22’

suites provide full-featured and cost-effective

control, HMI, and OPC software to power your

Opto 22 hardware. These software applications

help you develop control automation solutions, build

easy-to-use operator interfaces, and expand your

manufacturing systems’ connectivity.

Quality

In delivering hardware and software solutions for worldwide device

management and control, Opto 22 retains the highest commitment to

quality

. We do no statistical testing; each product is made in the U.S.A.

and is tested twice before leaving our 160,000 square-foot manufacturing

facility in T

relays and optically-isolated I/O modules

emecula, California. That’s why we can guarantee solid-state

®

software

for life

.

page 5/4

SNAP OEM Systems

Opto 22 SNAP OEM I/O systems are highly configurable, programmable

processors intended for OEMs, IT professionals, and others who need to

use custom software with Opto 22 SNAP I/O modules.

can read and write to analog, simple digital, and serial

I/O points on SNAP I/O modules using easily

implemented file-based operations. Applications can

be developed using several common development

tools and environments, including C or C++, Java,

and shell scripts.

M2M Systems

systems to the machines, devices, and environments you want to monitor

control, or collect data from. M2M systems often use wireless cellular

communications to link remote facilities to central systems over the Internet,

or to provide monitoring and control capability via a cellular phone.

interface and communications hardware, data service plan, and

Web portal—in one easy-to-use package.

®

Linu

x

applications running on these systems

Machine-to-machine (M2M) systems connect your business computer

Opto 22’s Nvio™ systems include everything you need for M2M—

Other Resources

OptoInfo CDs

Custom integration and development

Hands-on customer training classes.

About Opto 22

Opto 22 manufactures and develops hardware and software products

for industrial automation, remote monitoring, enterprise data acquisition,

and machine-to-machine (M2M) applications. Using standard,

,

commercially available Internet, networking, and computer technologies,

Opto 22’s input/output and control systems allow customers to monitor,

control, and acquire data from all of the mechanical, electrical, and

electronic assets that are key to their business operations. Opto 22’s

products and services support automation end users, OEMs, and

information technology and operations personnel.

Founded in 1974 and with over 85 million Opto 22-connected devices

deployed worldwide, the company has an established reputation for

quality and reliability.

© 2004-2005 Opto 22. All rights reserved. All trademarks, trade names, logos, and service marks referenced herein belong to their respective companies.

Loading...

Loading...