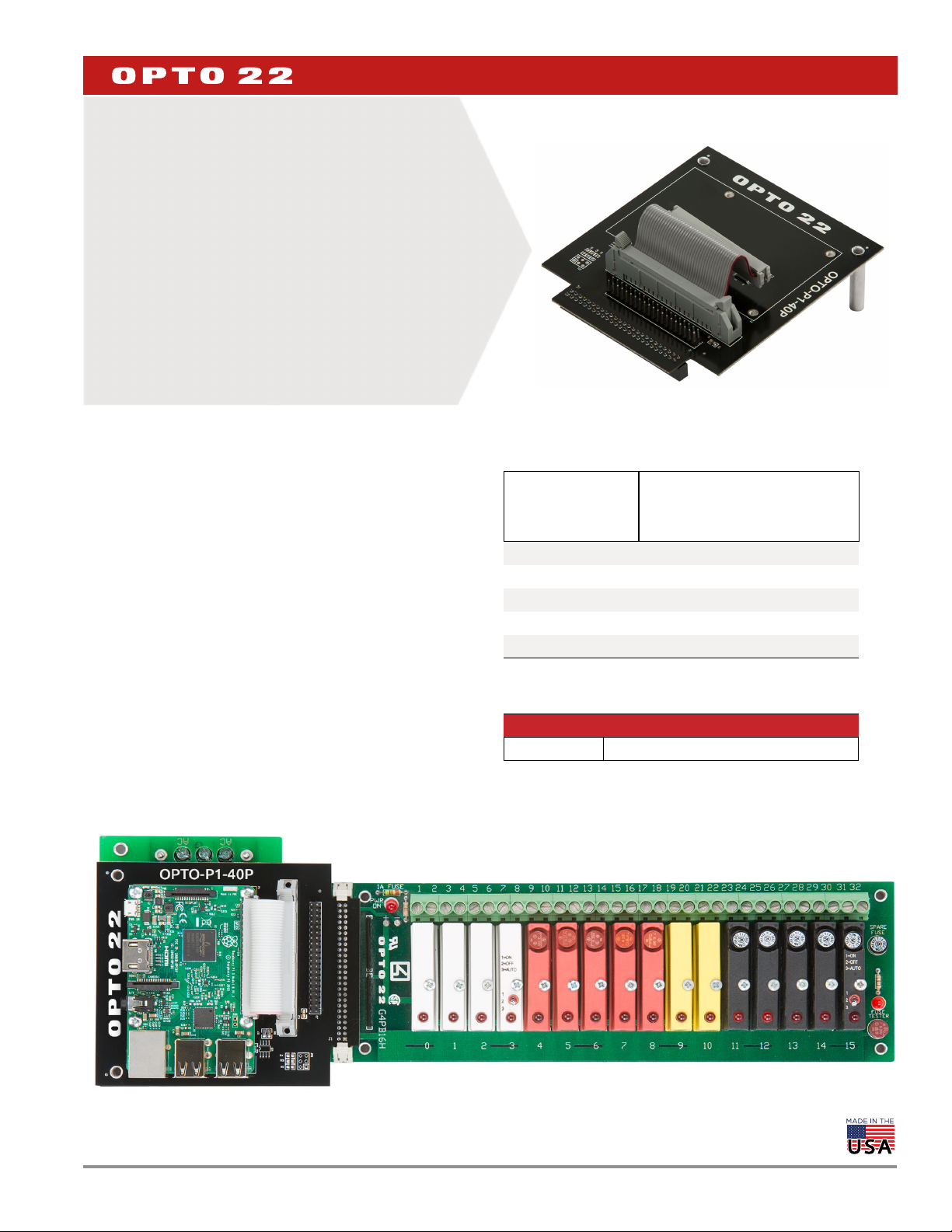

DIGITAL I/O CARRIER BOARD FOR

RASPBERRY PI

Features

Provides a GPIO interface between a Raspberry Pi®

>

I/O modules on select Opto 22 mounting racks

Perfect for prototyping, proofs of concept, and environments

>

in which an industrially hardened controller isn’t required

Auxiliary 40-pin connector supports HAT add-on boards using

>

UART, SPI, or I

Includes interface cable, Pi board mounting standoffs, and

>

2

C

spare fuses for mounting racks

Code samples available at developer.opto22.com

>

DESCRIPTION

Imagine safely and reliably sensing and switching 5-60 VDC, 120 VAC,

and 240 VAC loads with a Raspberry Pi. Well, now you can!

With Opto 22's Digital I/O Carrier Board for Raspberry Pi,

your Pi can harness the power and performance of world-class,

industrially hardened digital input/output (I/O) modules. Use your Pi

to switch industrial-level electrical loads far beyond the Pi's built in 3.3

VDC GPIO pins, and monitor and control electrical loads required for

real-world devices like industrial motors, pumps, and sensors.

The Carrier Board works with any model Pi with a 40-pin header

connector. Just insert the board’s interface cable into your Pi's GPIO

connector, and snap the board onto a compatible Opto 22 rack.

Use the rack's power supply to power the Pi, and then use your

favorite Pi-supported programming language to read and write to up

to 16 digital I/O points. (Mounting rack, power supply, and I/O

modules are sold separately.)

and digital

DATA SHEET

Form 2199-200302

PAGE 1

OPTO-P1-40P

OPTO-P1-40P

Also, the Carrier Board’s auxiliary 40-pin GPIO connector lets other

Pi-compatible peripherals access the Pi’s unused pins.

Specifications

Interface connectors

Raspberry Pi: Two 40-pin GPIO header connectors

I/O rack: One 50-conductor header connector

Operating temperature -20 to 70 °C

Storage Temperature -40 to 85 °C

Relative Humidity 95%, non-condensing

Agency Approvals CE, RoHS, DFARS

Warranty 30 months from date of manufacture

Part Number

Part Description

OPTO-P1-40P Digital I/O Carrier Board for Raspberry Pi

Digital I/O Carrier Board for Raspberry Pi

Shown with Raspberry Pi, G4 I/O modules, mounting rack, and power supply

(all sold separately).

Raspberry Pi® is a trademark of the Raspberry Pi Foundation.

© 2016–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

DATA SHEET

Form 2199-200302

PAGE 2

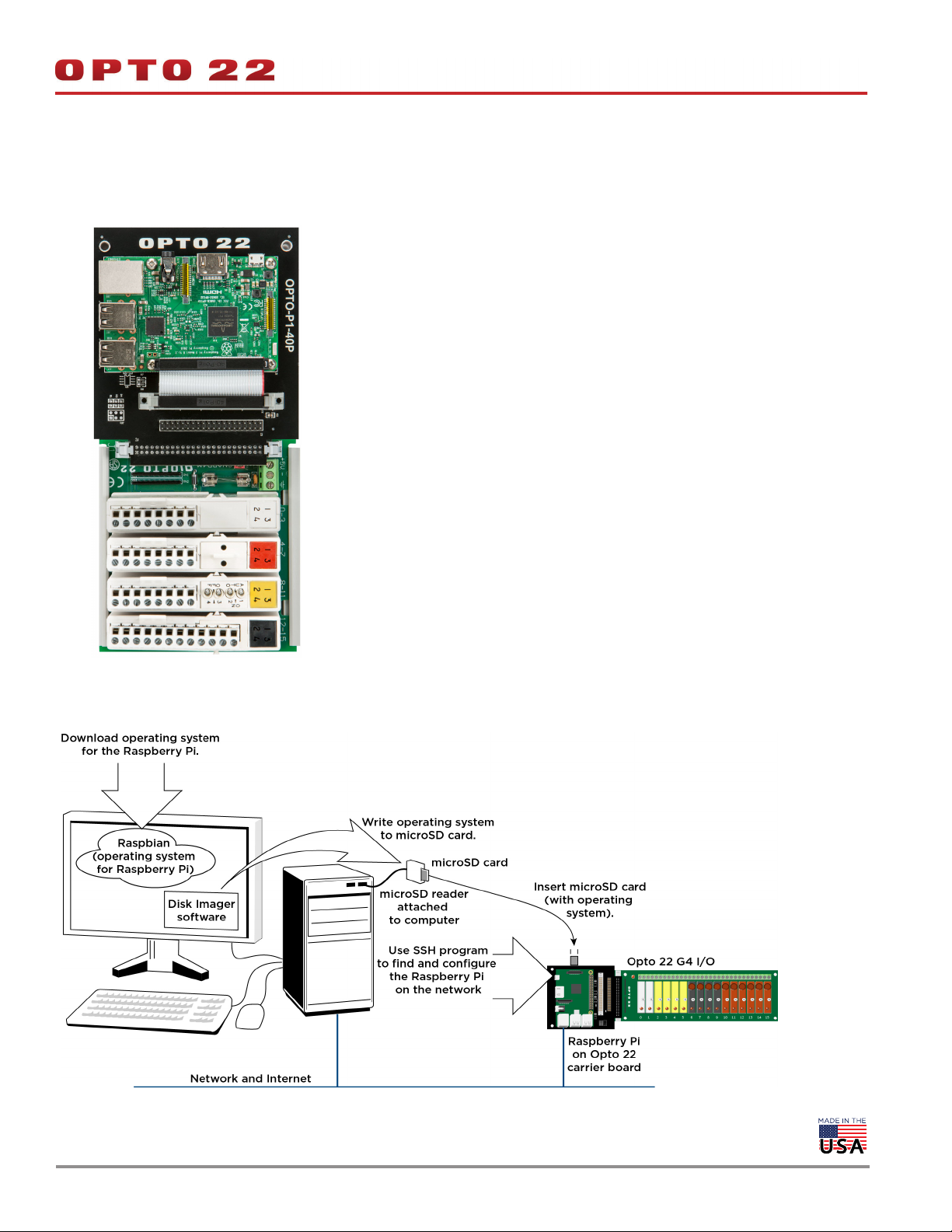

Digital I/O Carrier Board for Raspberry Pi

Shown with Raspberry Pi, SNAP I/O modules, and mounting rack (all

sold separately).

HERE’S WHAT YOU NEED

Raspberry Pi (any model with a 40-pin GPIO header connector,

including Raspberry Pi Models A+ and B+, Pi 2 Model B, Pi 3

Model B, and Pi Zero)

Digital I/O Carrier Board for Raspberry Pi

I/O mounting rack

I/O modules

Power supply

G4 or SNAP?

If you don’t already have I/O for your project, base your choice on the

sensors and actuators you plan to use.

Opto 22 G4 I/O has 1 point per module. Input modules are used

to sense field signals. Each output module is individually fused

and can switch up to 3 A.

(For G4 I/O see page 3.)

Opto 22 SNAP I/O takes up less space with 4 points per module

and costs less per point. Most output modules can switch up to

0.75 A per point or a total of 3 A per module. SNAP-OMR6

modules can switch up to 6 A.

(For SNAP I/O, see page 4.)

If you prefer to use Quad Pak or G1 I/O digital modules, the Carrier

Board also supports the PB16HQ, PB4H, PB8H and PB16H racks.

Physical Setup

Opto 22 I/O has been field-proven for nearly 40 years and is available

worldwide. Most I/O modules carry Opto 22’s Limited Lifetime

Warranty. For details, see

© 2016–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

G4 I/O MOUNTING RACKS

These racks can accommodate up to 10 AWG wire. The logic supply is

fused with a 1 A fuse.

DATA SHEET

Form 2199-200302

PAGE 3

power supply to ensure sufficient, consistent, and reliable power to all

devices connected to the Pi.

G4 Power Supplies Input Voltage Output Current

G4 Mounting Racks

G4PB16H Holds 16 I/O modules

G4PB8H Holds 8 I/O modules

G4 I/O MODULES

G4 I/O modules have a built-in LED status indicator to display the

point’s on/off status.

NOTE: 15 and 24 VDC logic modules are not supported.

G4 Inputs

Model Field Voltage Special Features

G4IAC5 90–140 VAC/VDC

G4IAC5A 180–280 VAC/VDC

G4IAC5L 90–140 VAC/VDC

G4IAC5MA 90–140 VAC/VDC Diagnostic switch

G4IDC5

G4IDC5D 2.5–28 VDC Low voltage input

G4IDC5G 35–60 VDC/VAC

G4IDC5MA

G4SWIN NA Simulates input

10–32 VDC

12–32 VAC

10–32 VDC

12–32 VAC

Low input resistance

Diagnostic switch

PBSC 12/24 VDC 1.5 A

Powering Peripherals

If your Pi uses USB-powered peripherals (like hard drives or WiFi

dongles), you’ll need a power supply that puts out more current:

Connect a 5 V power supply rated 2.5 A to 5 A to the G4 rack’s

power terminals.

Replace the G4 rack’s standard 1 A fuse with the 5 A fuse

FUSE05B

—10 pack) included with the Carrier Board.

(part

Mapping: GPIO Pins to G4 Modules

G4 Outputs

Model Field Voltage Special Features

G4OAC5 12–140 VAC @ 3 A

G4OAC5A 24–280 VAC @ 3 A

G4OAC5A5 24–280 VAC @ 3 A Normally closed

G4OAC5MA 12–140 VAC @ 3 A Diagnostic switch

G4OAC5AMA 24–280 VAC @ 3 A Diagnostic switch

G4ODC5 5–60 VDC @ 3 A

G4ODC5A 5–200 VDC @ 3 A

G4ODC5MA 5–60 VDC Diagnostic switch

G4SWOUT NA Simulates output

G4 POWER SUPPLIES

Although it’s possible to power the rack and I/O modules from the Pi,

Opto 22 recommends powering the components from the rack’s

© 2016–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

SNAP I/O Mounting Rack

If you’ve decided to use SNAP I/O modules in your Pi project, the

Carrier Board works with the SNAP-D4M mounting rack. The

SNAP-D4M holds 4 SNAP I/O modules (a total of 16 points).

The rack ships with a 1 A fuse. If you are using USB peripherals, replace

it with a 4 A fuse. For convenience, one is included with the

OPTO-P1-40P Carrier Board.

SNAP I/O MODULES

SNAP I/O modules have four points, and each point has an LED to

indicate its status.

SNAP Inputs

Model Field Voltage Special Features

SNAP-IAC5

SNAP-IAC5A

SNAP-IAC5MA

SNAP-IDC5

SNAP-IDC5D

SNAP-IDC5G

SNAP-IDC5-HT

SNAP-IDC5MA

SNAP-IDC5-SW

SNAP-IDC5-SW-NC

90–140 VAC/VDC

180–280 VAC/VDC

120 VAC/VDC

24 VAC/VDC

5 VDC

48 VAC/VDC

24 VAC/VDC

24 VAC/VDC

15 VDC

15 VDC

4 isolated channels,

manual/auto switches

Leakage-tolerant

4 isolated channels,

manual/auto switches

Dry contact,

normally open

Dry contact,

normally closed

DATA SHEET

Form 2199-200302

PAGE 4

SNAP Outputs (Continued)

Model Field Voltage Special Features

Mechanical Power

SNAP-OMR6T-C

5–30 VDC

0–250 VAC

Relay, Form C, with integrated transient suppression

Powering a Pi and SNAP I/O

When using the SNAP-D4M with your Pi and SNAP I/O, attach a

5 VDC @ 200 mA (max.) power supply to the rack. Powering the

components from the rack’s power supply ensures sufficient,

consistent, and reliable power to all devices connected to the Pi.

Mapping: GPIO Pins to SNAP I/O Modules

SNAP Outputs

Model Field Voltage Special Features

SNAP-OAC5

SNAP-OAC5-I

SNAP-OAC5MA

SNAP-ODC5SRC

SNAP-ODC5SNK

SNAP-ODC5ASNK

SNAP-ODC5MA

SNAP-ODC5-I

SNAP-ODC5A-I

SNAP-OMR6-C

12–250 VAC

12–250 VAC

12–250 VAC

5–60 VDC

5–60 VDC

5–200 VDC

5–60 VDC

5–60 VDC

5–200 VDC

5–30 VDC

0–250 VAC

4 isolated channels

4 isolated channels,

manual/auto switches

Load sourcing

Load sinking

Load sinking

4 isolated channels,

manual/auto switches

4 isolated channels

4 isolated channels

Mechanical Power

Relay, Form C

Read and Write with Pi

It’s easy to read and write to Opto 22 I/O points using your favorite

Pi-supported language like Python, Node-RED, Pi Terminal,

Pi Filesystem GPIO, and many more.

Visit developer.opto22.com for code samples and tips for using your Pi

to read and write to Opto 22 I/O modules.

NOTE: Opto 22 I/O modules use negative true logic; that is,

a zero bit means On and a 1 bit means Off.

When reading and writing to I/O points, remember that 0 is On and 1 is

Off.

© 2016–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

MAPPING OVERLAY FOR RASPBERRY PI

Place this overlay over your Pi’s GPIO pins for a handy mapping reference.

You can download the template from developer.opto22.com.

DATA SHEET

Form 2199-200302

PAGE 5

DIMENSIONAL DRAWING

OPTO-P1-40P

© 2016–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

More about Opto 22

PRODUCTS

Opto 22 develops and manufactures reliable, easy-to-use, open

standards-based hardware and software products. Industrial

automation, process control, building automation, industrial

refrigeration, remote monitoring, data acquisition, and industrial

internet of things (IIoT) applications worldwide all rely on Opto 22.

groov EPIC® System

Opto 22’s groov Edge Programmable

Industrial Controller (EPIC) system gives

you an industrially hardened system with

guaranteed-for-life I/O, a flexible Linux®based processor with gateway functions,

and software for your automation and IIoT

applications.

groov EPIC I/O

groov I/O connects locally to sensors and

equipment with up to 24 channels on each I/O module. Modules

have a spring-clamp terminal strip, integrated wireway, swing-away

cover, and LEDs indicating module health and discrete channel status.

groov I/O is hot swappable, UL Hazardous Locations approved, and

ATEX compliant.

groov EPIC Processor

The heart of the system is the groov EPIC processor. It handles a wide

range of digital, analog, and serial functions for data collection,

remote monitoring, process control, and discrete and hybrid

manufacturing.

In addition, the EPIC provides secure data communications among

physical assets, control systems, software applications, and online

services, both on premises and in the cloud.

Configuring and troubleshooting I/O and networking is easier with

the EPIC’s integrated high-resolution color touchscreen. Authorized

users can manage the system locally on the touchscreen or on a

monitor connected via the HDMI or USB ports.

groov RIO

groov RIO revolutionizes remote I/O by offering a single, compact,

PoE-powered industrial package with web-based configuration,

commissioning, and flow logic software built in, plus support for

multiple OT and IT protocols.

Standing alone, it meets the needs of small, variable I/O count

applications, especially those that require

data logging or data communications,

commonly found in IIoT applications.

groov RIO can also be used with a

Modbus/TCP master or as remote I/O for

a groov EPIC system.

Older products

From solid state relays (our first products)

to world-famous G4 and SNAP I/O, to

SNAP PAC controllers, older Opto 22

products are still supported and still

doing the job at thousands of installations worldwide. You can count

on us to give you the reliability and service you expect, now and in the

future.

QUALITY

Founded in 1974, Opto 22 has established a worldwide reputation for

high-quality products. All are made in the U.S.A. at our manufacturing

facility in Temecula, California.

Because we test each product twice before it leaves our factory rather

than testing a sample of each batch, we can afford to guarantee most

solid-state relays and optically isolated I/O modules for life.

groov EPIC Software

Software included in the groov EPIC processor:

PAC Control engine to run PAC Control and PAC Display

CODESYS Runtime engine to run IEC61131-3 compliant programs

built with CODESYS Development System

Optional access to the Linux operating system through a secure

shell (SSH) to download and run custom applications

groov View for building your own device-independent HMI,

viewable on the touchscreen, PCs, and mobile devices

Node-RED for creating simple logic flows from pre-built nodes

Ignition Edge® from Inductive Automation®, with OPC-UA drivers

to Allen-Bradley®, Siemens®, and other control systems, and MQTT

communications with Sparkplug for efficient IIoT data transfer

© 2001–2020 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Form 1335-200129

Loading...

Loading...