Page 1

Quad Pak AC Output

OAC5Q

Module

Features

Contains four single-channel I/O circuits.

Each module can be divided into two pairs with each

pair sharing a common connection.

used for controlling or switching AC loads.

Provides up to 4,000 Vrms of optical isolation between

field devices and control logic.

Features zero voltage turn-on and zero current turn-off

Description

Quad Pak modules contain the equivalent of four singlechannel I/O circuits in a single high-density package. Each

Quad Pak module can be divided into two pairs with each pair

sharing a common connection.

Quad Pak modules are designed to plug into the Quad Pak

high-density I/O mounting racks only and cannot be plugged

into single-channel racks. Quad Pak modules are designed to

work with a 5 VDC logic voltage only and can be used with

Optomux, Pamux, and Mistic protocol brain boards and

mounting racks as well as racks using a direct cable

connection to a computer.

Quad Pak AC Output Module

AC output modules are used for controlling or switching AC

loads. Each module provides up to 4,000 Vrms of optical

isolation between the field devices and the control logic. The

Quad Pak AC output module features zero voltage turn-on

and zero current turn-off.

Typical uses and applications for AC output modules include

switching the following loads:

Relays

Solenoids and Contactors

Motor Starters

Heaters

Lamps or Indicators

Part Numbers

Part Description

OAC5Q 4-Channel AC Output 12-280 VAC, 5 VDC Logic

DATA SHEET

Form 0486-161229

© 2012–2016 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trad emarks of their respective companies or organizations.

PAG E

1

Page 2

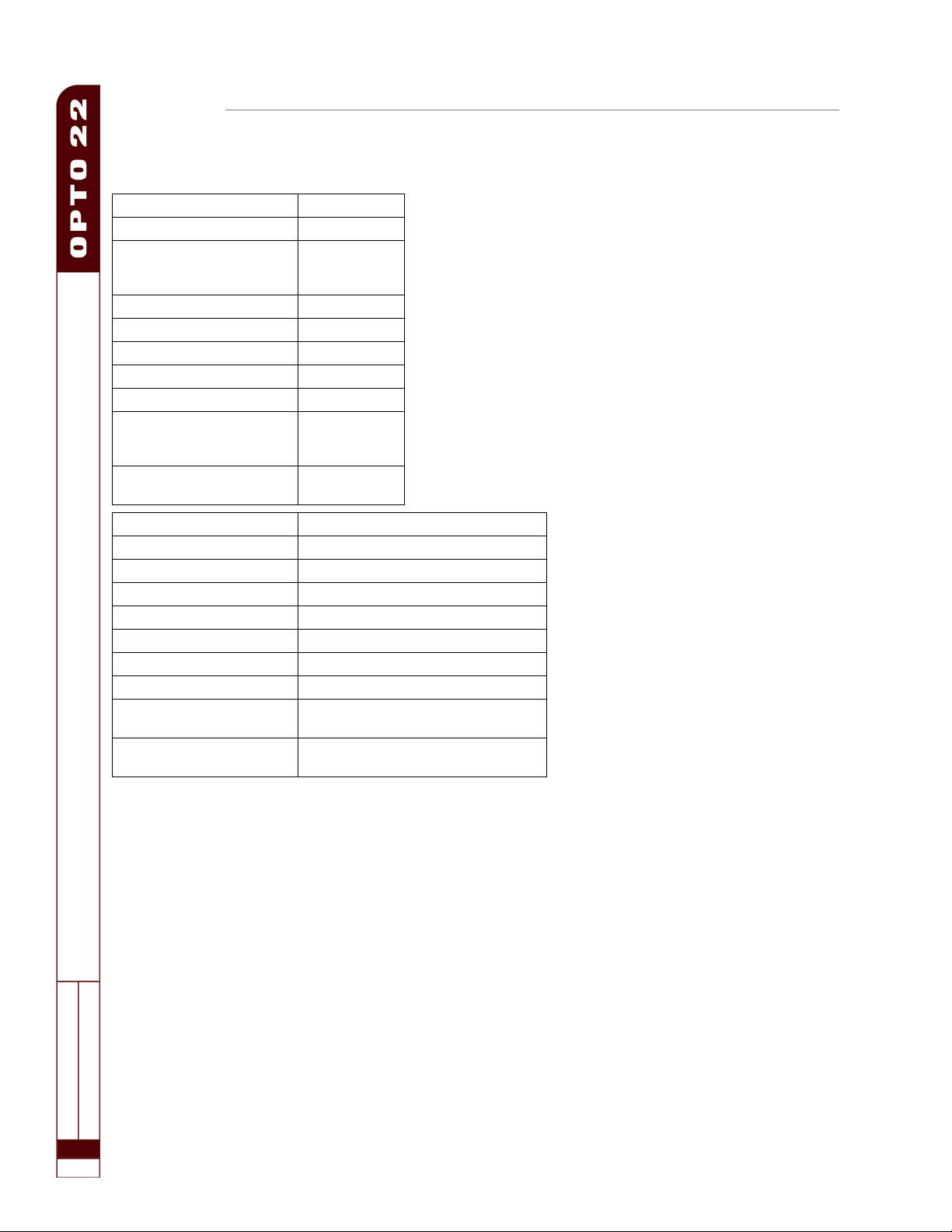

Specifications

Line Voltage–Nominal 120/240 VAC

Operating Voltage Range 12–280 VAC

Current Rating (per channel)

@ 20° C Ambient

@ 45° C Ambient

One Cycle Surge 80 amps

Logic Voltage–Nominal 5 VDC

Logic Voltage Range (Vcc) 4–8 VDC

Logic Pickup Voltage 4.0 VDC

Logic Dropout Voltage 2.3 VDC

Logic Input Current

@ Nominal Logic Voltage

(lout in Schematic Diagram)

Control Resistance (Rc in Schematic Diagram)

Peak Repetitve Voltage 500 volts

Operating Ambient Temperature -30 to 70 °C

Isolation Input-to-Output 4,000 Vrms

Minimum Load Current 20 milliamps

Operating Frequency 25–65 Hz

Quad Pak AC Output Module

Turn-on Time 1/2 cycle maximum-zero voltage

Turn-off Time 1/2 cycle maximum-zero current

DV/DT-Off-state snubbed for rated 0.5 power factor load

Output VOltage Drop Maximum

Peak

Off-state Leakage

@ Nominal Voltage-60Hz

3 amps 2 amps

12 mA

220 ohms

1.6 volts

5 milliamps, ms

Quad Pak AC Output Module

DATA SHEET

PAG E

2

Form 0486-161229

© 2012–2016 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 3

Quad Pak AC Output Module

Dimensions

Schematics

Quad Pak AC Output Module

© 2012–2016 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trad emarks of their respective companies or organizations.

Form 0486-161229

PAG E

3

DATA SHEET

Page 4

Connections

Quad Pak AC Output Module

Quad Pak AC Output Module

DATA SHEET

PAG E

4

Form 0486-161229

© 2012–2016 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 5

More About Opto 22

Products

Opto 22 develops and manufactures reliable, easy-to-use, open

standards-based hardware and software products deployed

worldwide.

Industrial automation, process control, building automation,

industrial refrigeration, remote monitoring, data acquisition,

Industrial Internet of Things (IIoT), and information technology

applications all rely on Opto 22.

groov

Monitor and control your

equipment from anywhere

using your smartphone or

tablet with groov. Build your

own mobile app easily—just

drag, drop, and tag. No

programming or coding. Visit

groov.com

information and your free trial.

SNAP PAC System

Developer- and IIoT-ready, the SNAP PAC System connects

physical assets to databases and applications using open

standards. The SNAP PAC System consists of four integrated

components:

SNAP PAC controllers

PAC Proj e ct

SNAP PAC brains

SNAP I/O

SNAP PAC Controllers

SNAP PAC programmable

automation controllers handle a

wide range of digital, analog, and

serial functions for data collection,

remote monitoring, process control,

and discrete and hybrid manufacturing.

For IIoT applications and easier integration with company

systems, standalone and rack-mounted SNAP PACs include a

built-in HTTP/HTTPS server and

program interface). The REST API gives you secure, direct access

to I/O and variable data using your choice of programming

languages. No middleware, protocol converters, drivers, or

gateways needed.

Based on open Ethernet and Internet Protocol (IP) standards,

SNAP PACs make it easier to build or extend a system without the

expense and limitations of proprietary networks and protocols.

PAC P roj e c t Softwa re Su i t e

Opto 22’s PAC Project Software Suite offers full-featured, costeffective control programming, HMI (human machine interface),

OPC server, and database connectivity software.

™

Software Suite

™

RESTful API

for more

(application

Control programming includes both easy-to-learn flowcharts and

optional scripting. Commands are in plain English; variables and

I/O point names are fully descriptive.

PAC Project Basic offers control and HMI tools and is free for

download on our website, PAC Project

rofessiona

P

software-based controller, OptoOPCServer, OptoDataLink,

options for controller redundancy or segmented networking, and

support for legacy Opto 22 serial

SNAP PAC Brains

While SNAP PAC controllers provide central control and data

distribution, SNAP PAC brains provide distributed intelligence for

I/O processing and communications. Brains offer analog, digital,

and serial functions, including thermocouple linearization, local

PID loop control, watchdog, totalizing, and much more.

SNAP I/O

I/O provides the local connection to sensors and equipment.

Opto 22 SNAP I/O offers 1 to 32 points of reliable I/O per module.

Analog, digital, and serial modules are mixed on one mounting

rack and controlled by a SNAP PAC brain or rack-mounted PAC.

l, available for separate purchase, adds one SoftPAC

mistic™ I/O units.

Quality

Founded in 1974, Opto 22 has established a worldwide

reputation for high-quality products. All are made in the U.S.A. at

our manufacturing facility in Temecula, California.

Because we test each product twice before it leaves

our factory, rather than only testing a sample of each

batch, we can guarantee most solid-state relays and

optically isolated I/O modules for life.

ditional support is always available on our website: how-to

Ad

videos, OptoKnowledgeBase, self-training guide, troubleshooting

and user’s guides, and OptoForums.

In addition, hands-on training is available for free at our

© 2013–2016 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trade marks of their respective companies or organizations.

Form 1335-160810

Loading...

Loading...