Page 1

Standard Analog Current

Output Modules

Features

Provides a a single channel of optically- isolated digital-

to-current conversion

The “T” module is transformer isolated, which

eliminates any ground loop problems

Modules plug into any Standard Classic analog I/O rack

and are secured by a captive screw

Description

The current output modules provide a single channel of

optically- isolated digital-to-current conversion. The “T”

module is transformer isolated, which eliminates any ground

loop problems. The DA3 and DA8 modules are UL approved.

Specifications

DA3 DA3T DA8

Output Current 4-20 mA 4-20 mA 4-20 mA

Minimal Current Draw 1.6 mA 1.6 mA 1.6 mA

Accuracy

Power Requirements

Agency Approvals UL, CE, RoHS, DFARS CE, RoHS, DFARS UL, CE, RoHS, DFARS

μA 16 μA 20 μA

16

20 mA at +15 (+/- 0.25) VDC

10 mA at -15 (+/- 0.25) VDC

24 mA at 5 VDC

22 mA at +15 (+/- 0.25) VDC

22 mA at -15 (+/- 0.25) VDC

24 mA at 5 VDC

Modules plug into any Standard Classic analog I/O rack and

are secured by a captive screw.

20 mA at +15 (+/- 0.25) VDC

10 mA at -15 (+/- 0.25) VDC

24 mA at 5 VDC

Standard Analog Current Output Modules

Response Time Full scale step change in 3 ms

Resolution 12 bits

Isolation

Input-to-Output

Input-to-Analog Supply (T Modules)

Temperature

Operating

Storage

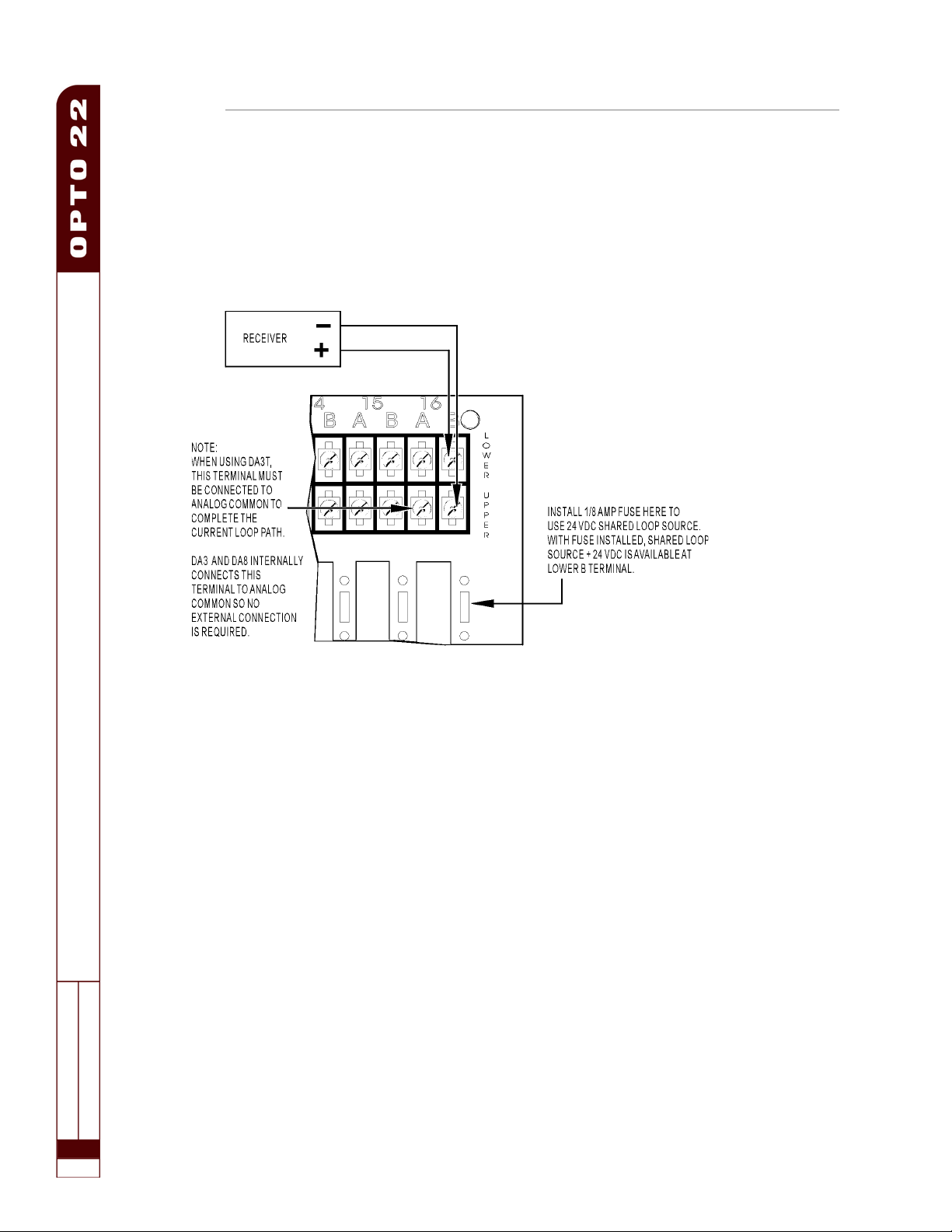

DA3T: All of the lower A terminals on the mounting rack are tied together.

These provide a convenient tie point for shared loop source return. To use the

DA3T with a common loop supply, connect any one lower A terminal to the

shared loop source "-", then jumper upper A to lower A for each DA3T.

4,000 Vrms

4,000 Vrms

0 °C to 70 °C

- 25 °C to 85 °C

Part Numbers

Part Description

DA3 4-20 MA Output

DA3T 4-20 MA Output Isolated

DA8 0-20 MA Output

© 2011–2014 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or regist ered trademarks of their respective companies or organiz ations.

Form 0442-140410

PAG E

1

DATA SHEET

Page 2

Connections

Standard Analog Current Output Modules

Standard Analog Current Output Modules

DATA SHEET

Form 0442-140410

PAG E

2

© 2011–2014 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 3

Standard Analog Current Output Modules

Connections (continued)

Standard Analog Current Output Modules

© 2011–2014 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or regist ered trademarks of their respective companies or organiz ations.

Form 0442-140410

PAG E

3

DATA SHEET

Page 4

Schematics

Standard Analog Current Output Modules

Standard Analog Current Output Modules

DATA SHEET

Form 0442-140410

PAG E

4

© 2011–2014 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Page 5

More About Opto 22

Products

Opto 22 develops and manufactures reliable, flexible, easy-to-use

hardware and software products for industrial automation,

energy management, remote monitoring, and data acquisition

applications.

groov

groov

puts your system on your mobile device. With zero

programming, you can build mobile operator interfaces to

monitor and control systems from Allen-Bradley, Siemens,

Schneider Electric, Modicon, and many more. Web-based

puts mobile-ready gadgets at your fingertips. Tag them from your

existing tag database, and they automatically scale for use on any

device with a modern web browser. See

information and your free trial.

groov.com

SNAP PAC System

Designed to simplify the typically complex

process of selecting and applying an

automation system, the SNAP PAC

System consists of four integrated

components:

SNAP PAC controllers

PAC Proje c t

SNAP PAC brains

SNAP I/O

SNAP PAC Controllers

Programmable automation controllers

(PACs) are multifunctional, modular controllers based on open

standards.

Opto 22 has been manufacturing PACs for over two decades. The

standalone SNAP PAC S-series, the rack-mounted SNAP PAC Rseries, and the software-based SoftPAC™ all handle a wide range

of digital, analog, and serial functions for data collection, remote

monitoring, process control, and discrete and hybrid

manufacturing.

SNAP PACs are based on open Ethernet and Internet Protocol (IP)

standards, so you can build or extend a system easily, without the

expense and limitations of proprietary networks and protocols.

Wired+Wireless™ models are also available.

PAC Project S o f t ware Su ite

Opto 22’s PAC Project Software Suite provides full-featured, costeffective control programming, HMI (human machine interface)

development and runtime, OPC server, and database connectivity

software for your SNAP PAC System.

Control programming includes both easy-to-learn flowcharts and

optional scripting. Commands are in plain English; variables and I/

O point names are fully descriptive.

PAC Project Basic offers control and HMI tools and is free for

download on our website, PAC Project

™

Software Suite

™

groov

for more

essional, available for separate purchase, adds one SoftPAC,

Prof

OptoOPCServer, OptoDataLink, options for controller redundancy

or segmented networking, and support for legacy Opto 22 serial

mistic™ I/O units.

SNAP PAC Brains

While SNAP PAC controllers provide central control and data

distribution, SNAP PAC brains provide distributed intelligence for

I/O processing and communications. Brains offer analog, digital,

and serial functions, including thermocouple linearization; PID

loop control; and optional high-speed digital counting (up to 20

kHz), quadrature counting, TPO, and pulse generation and

measurement.

SNAP I/O

I/O provides the local connection to sensors and equipment.

Opto 22 SNAP I/O offers 1 to 32 points of reliable I/O per module,

depending on the type of module and your

needs. Analog, digital, and serial modules are

all mixed on the same mounting rack and

controlled by the same processor (SNAP PAC

brain or rack-mounted controller).

Quality

Founded in 1974, Opto 22 has established a

worldwide reputation for high-quality products.

All are made in the U.S.A. at our manufacturing

facility in Temecula, California. Because we

test each product twice before it leaves our

factory, rather than only testing a sample

of each batch, we can guarantee most

solid-state relays and optically isolated I/O

modules for life.

mprehensive technical support for Opto 22 products. Our staff

co

of support engineers represents decades of training and

experience. Support is

Additional support is always available on our website: how-to

videos, OptoKnowledgeBase, self-training guide, troubleshooting

and user’s guides, and OptoForums.

In addition, hands-on training is available for free at our

ntact Opto 22 headquarters at

co

or 951-695-3000, or visit our website at

© 2014 Opto 22. All rights reserved. Dimensions and specifications are subject to change. Brand or product names used herein are trademarks or registered trademarks of their respective companies or organizations.

Form 1335-131203

Loading...

Loading...