Page 1

OPTOMMP PROTOCOL GUIDE

Used with:

groov EPIC Processors

groov RIO modules

SNAP PAC R-Series Controllers

SNAP PAC S-Series Controllers

SNAP PAC EB Brains

SNAP PAC SB Brains

SNAP Simple I/O™

SNAP Ethernet I/O™

SNAP Ultimate I/O™

SNAP-LCE Controller

E1 Brain Board

E2 Brain Board

G4EB2 Brain Boards

Form 1465-200714—July 2020

Page 2

OptoMMP Protocol Guide

Form 1465-200714—July 2020

Copyright © 2003–2020 Opto 22.

All rights reserved.

Printed in the United States of America.

The information in this manual has been checked carefully and is believed to be accurate; however, Opto 22 assumes no

responsibility for possible inaccuracies or omissions. Specifications are subject to change without notice.

Opto 22 warrants all of its products to be free from defects in material or workmanship for 30 months from the

manufacturing date code. This warranty is limited to the original cost of the unit only and does not cover installation, labor,

or any other contingent costs. Opto 22 I/O modules and solid-state relays with date codes of 1/96 or newer are guaranteed

for life. This lifetime warranty excludes reed relay modules, groov and SNAP serial communication modules, SNAP PID

modules, and modules that contain mechanical contacts or switches. Opto 22 does not warrant any product, components,

or parts not manufactured by Opto 22; for these items, the warranty from the original manufacturer applies. Refer to Opto

22 form 1042 for complete warranty information.

Wired+Wireless controllers and brains are licensed under one or more of the following patents: U.S. Patent No(s). 5282222,

RE37802, 6963617; Canadian Patent No. 2064975; European Patent No. 1142245; French Patent No. 1142245; British Patent

No. 1142245; Japanese Patent No. 2002535925A; German Patent No. 60011224.

Opto 22 FactoryFloor, groov, groov EPIC, groov RIO, mobile made simple, Optomux, and Pamux are registered trademarks of

Opto 22. Generation 4, groov Server, ioControl, ioDisplay, ioManager, ioProject, ioUtilities, mistic, Nvio, Nvio.net Web Portal,

OptoConnect, OptoControl, OptoDataLink, OptoDisplay, OptoEMU, OptoEMU Sensor, OptoEMU Server, OptoOPCServer,

OptoScript, OptoServer, OptoTerminal, OptoUtilities, PAC Control, PAC Display, PAC Manager, PAC Project, PAC Project Basic,

PAC Project Professional, SNAP Ethernet I/O, SNAP I/O, SNAP OEM I/O, SNAP PAC System, SNAP Simple I/O, SNAP Ultimate

I/O, and Wired+Wireless are trademarks of Opto 22.

ActiveX, JScript, Microsoft, MS-DOS, VBScript, Visual Basic, Visual C++, Windows, and Windows Vista are either registered

trademarks or trademarks of Microsoft Corporation in the United States and other countries. Linux is a registered

trademark of Linus Torvalds. ARCNET is a registered trademark of Datapoint Corporation. Modbus is a registered trademark

of Schneider Electric, licensed to the Modbus Organization, Inc. Wiegand is a registered trademark of Sensor Engineering

Corporation. Allen-Bradley, CompactLogix, ControlLogix, MicroLogix, SLC, and RSLogix are either registered trademarks or

trademarks of Rockwell Automation. CIP and EtherNet/IP are trademarks of ODVA. Raspberry Pi is a trademark of the

Raspberry Pi Foundation. The registered trademark Ignition by Inductive Automation® is owned by Inductive Automation

and is registered in the United States and may be pending or registered in other countries. CODESYS® is a registered

trademark of 3S-Smart Software Solutions GmbH.

groov includes software developed by the OpenSSL Project for use in the OpenSSL Toolkit. (http://www.openssl.org)

All other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

ii

OptoMMP Protocol Guide

Opto 22

Automation Made Simple.

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Welcome to OptoMMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Information Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Other Documents You May Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

For Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2: Overview of Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Programming Steps for Opto 22 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Communication Options that Do Not Require the OptoMMP Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessing Opto 22 Ethernet-Based Devices over the internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CAUTION: Multiple Communication Options Can Cause Conflict . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Understanding the Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Referencing Module and Channel Positions on I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

groov I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

groov RIO Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SNAP I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SNAP B-Series I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SNAP Digital-Only I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

E1 and E2 I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

G4EB2 I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuring I/O Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuring I/O Channels for groov I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuring I/O Channels for groov RIO Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuring I/O Channels for SNAP Analog/Digital I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Selecting Configuration Values for I/O Channel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

States (Digital Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Latches (Digital Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Counters (Digital Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Quadrature Counters (Digital Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Pulse Measurement (Digital Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Frequency or Period Measurement (Digital Inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

OptoMMP Protocol Guide iii

iii

Page 4

Digital Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Watchdog (Digital and Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Scaling (Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Minimum and Maximum Values (Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Offset and Gain (Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Clamping (Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Average Filter Weight (Analog Channels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Scratch Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Using Scratch Pad Bits for Events and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Types of Events, Alarms, and Reactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Steps for Configuring Events and Reactions—PAC Firmware R8.1 and Higher . . . . . . . . . . . . . . . . . . 41

Steps for Configuring Events and Reactions—PAC Firmware R8.0 and Lower . . . . . . . . . . . . . . . . . . . 42

Using Digital Events and Reactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Using Alarms and Reactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Using Serial Events and Reactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Using SNMP in Reactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Setting Up Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using Email . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Using Plugins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Streaming Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Traditional Streaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Custom Streaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Logging Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Configuring the Event and Memory Map Addresses to Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reading the Data from the Data Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Using PID Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

What is a PID? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PID Loops on Ethernet-based I/O Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Algorithm Choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Formatting and Interpreting Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Mask Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Unsigned 32-bit Integer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Digital Channel Data (4-Channel Modules) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

IEEE Float Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Analog Bank Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

iv

Chapter 3: Using OptoMMP Software Development Kits . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

C++ OptoMMP Software Development Kit for groov EPIC, groov RIO, and SNAP PAC . . . . . . . . . . . . . . . . . 63

A Few Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

.NET OptoMMP Software Development Kit for groov EPIC, groov RIO, and SNAP PAC . . . . . . . . . . . . . . . . . 64

Chapter 4: Using the OptoMMP Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Memory Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Communication Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Overview of Custom Application Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

OptoMMP Protocol Guide

Page 5

Sending Powerup Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Reading and Writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Streaming Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Configuring Parameters for Streaming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Receiving Streamed Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Configuring I/O Channels and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Reading Module Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Configuring I/O Channel Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Using I/O Channel Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Latches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Quadrature Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Minimum and Maximum Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Offset/Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Read and Write Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Packet Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Appendix A: Opto 22 Hardware Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Notes on Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Byte Ordering and Data Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

For Experienced OptoMMP Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

(Expanded) Analog & Digital Channel Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

(Expanded) Analog Channel Calc & Set—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

(Expanded) Analog Channel Read & Clear—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

(Expanded) Analog Channel Read—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

(Expanded) Analog Channel Write—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

(Expanded) Digital Channel Read—Read Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

(Expanded) Digital Channel—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

(Expanded) Digital Channel Read & Clear—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

(Expanded) Digital Packed Data—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

(Expanded) Digital Packed Must on/OFF (MOMO)—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Status Area Read—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Module Build Data–Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Quality of Data–Read Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Communications Port Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Serial Pass-Through—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Date and Time Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Status Area Write—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Modbus Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

OptoMMP Protocol Guide

v

Page 6

Network Security Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SSI Module Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Serial Module Identification—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Serial Module Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Serial Module and Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Wiegand Serial Module Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Wiegand Module and Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

SNAP-SCM-CAN2B Serial Module Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

SNAP-SCM-CAN2B Module and Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

HART Module Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

HART Module and Port Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

SNMP Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

FTP User Name/Password Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

PPP Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

PPP Status—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Streaming Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Digital Bank Read—Read Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Digital Bank Write—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Analog Bank Read—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Analog Bank Write—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Digital Channel Read—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Digital Channel Write—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

(Old) Analog Channel Read—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

(Old) Analog Channel Write—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

(Old) Analog and Digital Channel Configuration Information—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . 124

(Old) Digital Events and Reactions—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Digital Events - Expanded (formerly Timers)—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Addresses for SNAP Firmware R8.1 and Higher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Addresses for SNAP Firmware R8.0 and Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Custom Configuration Area—Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Custom Data Access Area—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Scratch Pad—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

(Old) Analog Channel Calculation and Set—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

(Old) Digital Read and Clear—Read Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

(Old) Analog Read and Clear/Restart—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Streaming—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Addresses for PR1 and RIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Addresses for PAC-R, EB, UIO, EIO, SIO, and G4EB2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Analog EU or Digital Counter (Feature) Packed Data—Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Digital Packed Data—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Alarm Event Settings—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Event Message Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Email Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Serial Event Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Wiegand Serial Event Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

High-Density Digital—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

vi

OptoMMP Protocol Guide

Page 7

High-Density Digital Read and Clear—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

High-Density Digital Write—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

PID Configuration and Status—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Public Tag Configuration—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Data Logging Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Data Log—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

PID Module Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Control Engine—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Serial Brain Communication—Read/Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

microSD Card—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

WLAN Status—Read Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

WLAN Configuration—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

WLAN Enable—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

IP Settings—Read/Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Appendix B: Rack and Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

SNAP PAC Processors and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Appendix C: SNAP Features Comparison Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Appendix D: groov EPIC and groov RIO Features and Comparison Charts . . . . . . . 169

groov RIO Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

groov EPIC System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Quality Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

OptoMMP Protocol Guide

vii

Page 8

viii

OptoMMP Protocol Guide

Page 9

1: Introduction

WELCOME TO OPTOMMP

OptoMMP is a memory-mapped protocol based on the IEEE 1394 standard. This protocol is used to create

custom software applications for remote monitoring, industrial control, and data acquisition using Opto 22

hardware products.

If your sole method of communication with Opto 22 devices is through a PAC Control Basic or PAC Control

Professional strategy, then you probably don’t need to use this programming guide. Instead, the PAC Control

User’s Guide (form 1700) or the PAC Control User’s Guide, Legacy Edition (form 1710) for legacy hardware will

provide the information you need.

However, if you are developing custom applications for your Opto 22 devices, either instead of or in addition

to using PAC Control or other methods of communication, you’ll need the additional information provided in

this protocol guide.

OptoMMP works with the following Opto 22 hardware products:

Device type Part numbers

groov EPIC processors GRV-EPIC-PR1

groov RIO modules GRV-R7-MM1001-10

SNAP PAC R-series on-the-rack controllers

SNAP PAC S-series standalone controllers

SNAP PAC EB brains

SNAP PAC SB brains SNAP-PAC-SB1 SNAP-PAC-SB2

SNAP Simple I/O SNAP-ENET-S64

SNAP Ethernet I/O

SNAP Ultimate I/O

SNAP-LCE standalone controller SNAP-LCE

E1 digital brain board E1

E2 analog brain board E2

SNAP-PAC-R1

SNAP-PAC-R1-B

SNAP-PAC-R1-FM

SNAP-PAC-R1-W

SNAP-PAC-S1

SNAP-PAC-S1-FM

SNAP-PAC-S1-W

SNAP-PAC-EB1

SNAP-PAC-EB1-FM

SNAP-PAC-EB1-W

SNAP-B3000-ENET

SNAP-ENET-RTC

SNAP-UP1-ADS

SNAP-UP1-M64

SNAP-PAC-R2

SNAP-PAC-R2-FM

SNAP-PAC-R2-W

SNAP-PAC-S2

SNAP-PAC-S2-W

SNAP-PAC-EB2

SNAP-PAC-EB2-FM

SNAP-PAC-EB2-W

SNAP-ENET-D64

SNAP-UP1-D64

OptoMMP Protocol Guide 1

1

Page 10

ABOUT THIS GUIDE

G4EB2 brain boards

ABOUT THIS GUIDE

This user’s guide defines the OptoMMP protocol and includes the logical addresses for communicating with

Opto 22’s OptoMMP-based hardware.

It assumes that you are already familiar with programming in the format you’ve chosen to use. If you are using

our free OptoMMP SDKs, you’ll find documentation included in the download.

The guide also assumes that you have already installed the Opto 22 hardware. If you have not, see the

hardware user’s guide for instructions.

This guide includes the following sections:

Chapter 1: Introduction—information about the guide and how to reach Opto 22 Product Support.

Chapter 2: Overview of Programming—basic information you need for programming applications using

the OptoMMP protocol.

Chapter 3: Using OptoMMP Software Development Kits—programming your own applications using

our software development kits to hide the details of the memory map and the protocol.

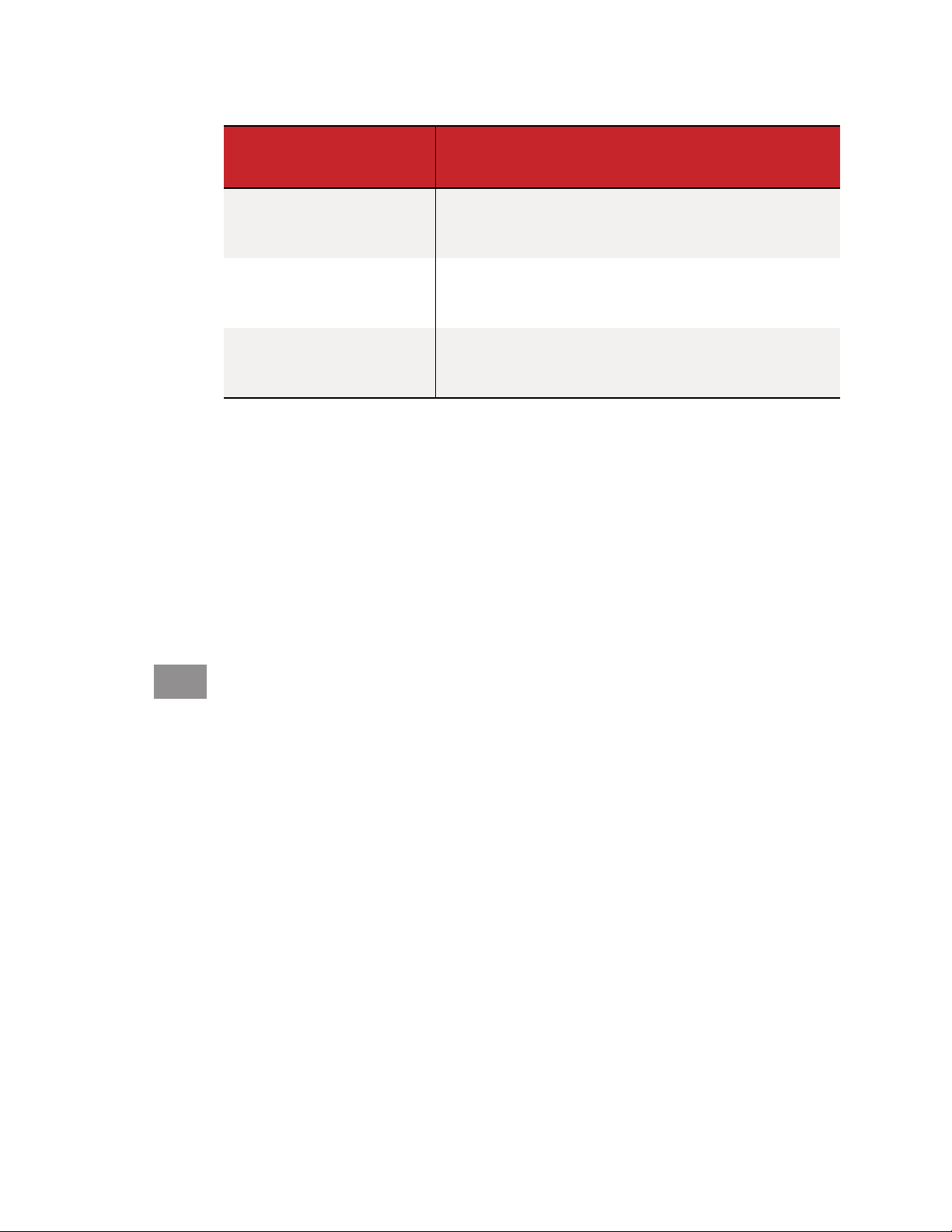

Device type Part numbers

G4EB2

G4D32EB2

G4D32EB2-UPG

Chapter 4: Using the OptoMMP Protocol—details of the OptoMMP protocol, including examples.

Appendix A: Opto 22 Hardware Memory Map—the complete memory map for Opto 22 devices using the

OptoMMP protocol.

Appendix B: Rack and Module Compatibility—a table listing part numbers, mounting racks, and the type

and number of I/O modules they can hold by product family.

Information Key

This guide includes information that applies to some types of Opto 22 memory-mapped products but not to

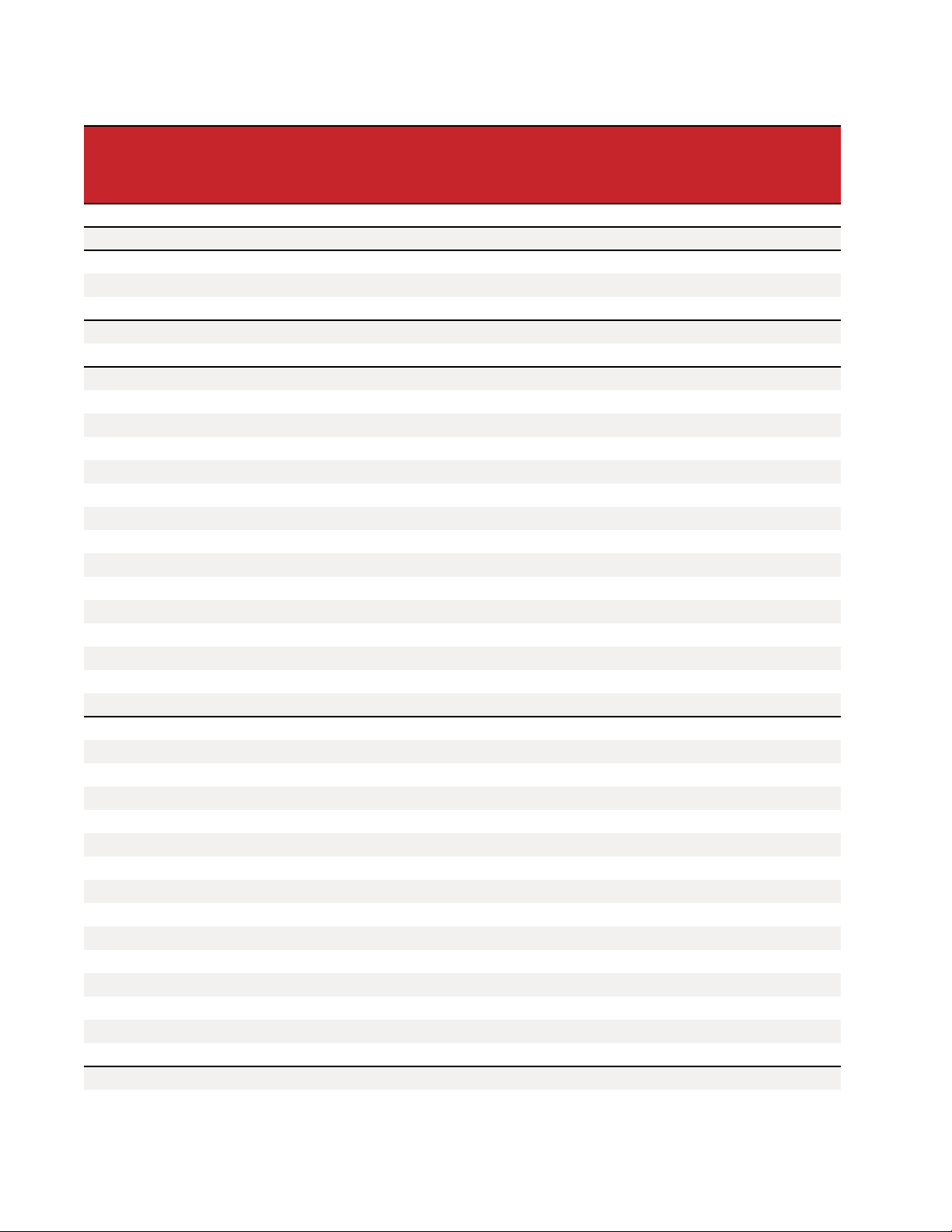

others. Sections are marked as follows to indicate the products that support them:

This text Indicates support by this hardware

PR1 groov EPIC PR1 processor

RIO groov RIO modules

PAC-R SNAP PAC R-series controllers

PAC-S SNAP PAC S-series controllers

EB SNAP PAC EB brains

SB SNAP PAC SB brains

UIO SNAP Ultimate I/O

EIO SNAP Ethernet I/O

SIO SNAP Simple I/O

LCE SNAP-LCE controllers*

E1 E1 brain boards

E2 E2 brain boards

G4EB2 G4EB2 brain boards

2

OptoMMP Protocol Guide

*As of January 2014, the SNAP-LCE is no longer available due to unavailability of essential parts.

Page 11

CHAPTER 1: INTRODUCTION

Other Documents You May Need

See the following additional guides for the information listed. Most guides are available on our website,

www.opto22.com; those that are not on the website are available with product purchase. The easiest way to

find a guide is to search on its form number.

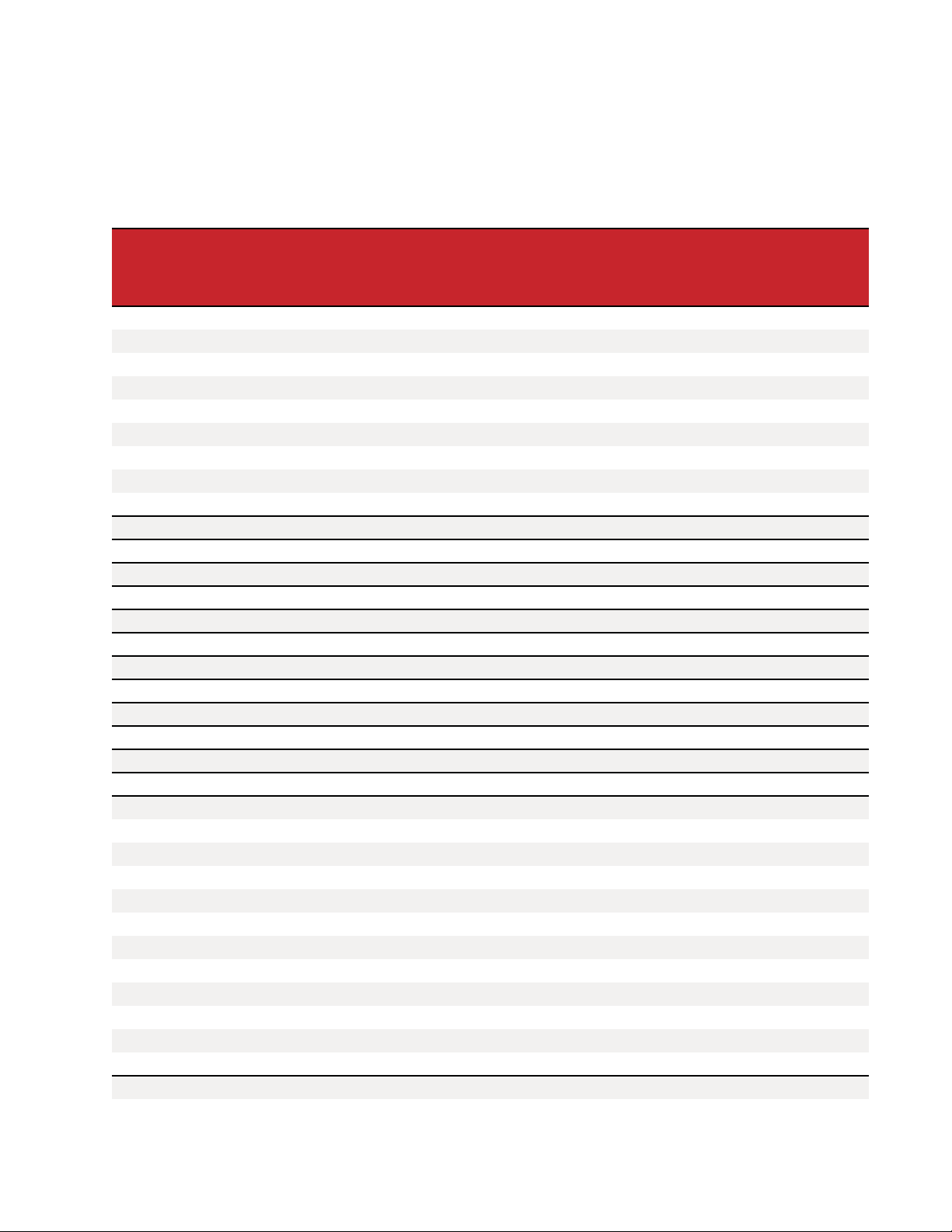

For this information See this guide Form #

Installing and using groov EPIC processors,

groov modules, and groov Manage software

Installing and using groov RIO modules groov RIO User’s Guide 2324

Installing and using a SNAP PAC R-series controller SNAP PAC R-Series Controller User’s Guide 1595

Installing and using a SNAP PAC S-series controller SNAP PAC S-Series Controller User’s Guide 1592

Installing and using a SNAP PAC EB or SB brain SNAP PAC Brains User’s Guide 1690

Installing and using a SNAP Ultimate, SNAP Ethernet, or SNAP Simple I/O unit

Installing and using a SNAP-LCE controller SNAP-LCE User’s Guide 1475

Installing and using an E1 or E2 brain board EI and E2 User’s Guide 1563

(For SNAP PAC Systems only) Assigning IP

addresses to SNAP PAC hardware, configuring

communications, doing real-time reads and writes,

updating firmware. For PAC-R, EB, SB, UIO, EIO,

SIO, E1/E2, and G4EB2 units, configuring I/O

channelsa and system functions.

Designing flowchart-based control programs for the

system (Requires a groov EPIC processor or

SNAP PAC controller; SNAP-LCE and SNAP

Ultimate controllers are partially supported)

Communicating with the system using OPC

Exchanging system data with popular databases

Communicating with Allen-Bradley Logix-based

PLCs or other systems using EtherNet/IP

Communicating with systems using Modbus/TCP Modbus/TCP Protocol Guide 1678

Communicating with an E1 or E2 I/O unit using the

Optomux protocol

a

This guide uses the terms point and channel interchangeably.

groov EPIC User’s Guide 2267

SNAP Ethernet-Based I/O Units User’s Guide 1460

PAC Manager User’s Guide, Legacy Edition 1714

PAC Control User’s Guide 1700

PAC Control Command Reference 1701

PAC Control Commands Quick Reference 1703

OptoOPCServer User’s Guide (included with

the purchase of OptoOPCServer)

OptoDataLink User’s Guide (included with the

purchase of OptoDataLink)

EtherNet/IP for SNAP PAC Protocol Guide 1770

Optomux Protocol Guide 1572

1439

1705

FOR HELP

If you have problems using the OptoMMP protocol and cannot find the help you need in this guide or on our

website, contact Opto 22 Product Support.

Phone: 800-TEK-OPTO (800-835-6786 toll-free

in the U.S. and Canada)

951-695-3080

Monday through Friday,

NOTE: Email messages and phone calls

to Opto 22 Product Support are

grouped together and answered in the

order received.

7 a.m. to 5 p.m. Pacific Time

Fax: 951-695-3017

Email: support@opto22.com

OptoMMP Protocol Guide

3

Page 12

FOR HELP

Opto 22 website: www.opto22.com

When calling for technical support, you can help us help you faster if you provide the following information to

the Product Support engineer:

• A screen capture of the Help > About dialog box showing software product and version (available by

clicking Help > About in the application’s menu bar).

• Opto 22 hardware part numbers or models that you’re working with.

• Firmware version (Available in PAC Manager by clicking Tools > Inspect. Available in groov Manage by

clicking Info and Help > About.)

• Specific error messages you saw.

• Version of your computer’s operating system.

4

OptoMMP Protocol Guide

Page 13

2: Overview of Programming

INTRODUCTION

Details of programming steps depend on the language or method you use for developing your custom

application, but some basic information is common to all languages and methods. This chapter includes the

following basic information you need in order to program for Opto 22 memory-mapped hardware:

In this chapter

Programming Steps for Opto 22 Devices...................................................................page 5

Communication Options...................................................................................................page 6

Understanding the Memory Map ................................................................................page 8

Referencing Module and Channel Positions on I/O Units..................................page 9

Configuring I/O Channels ..............................................................................................page 16

Configuring Channel Features......................................................................................page 31

Streaming Data ...................................................................................................................page 51

Logging Data........................................................................................................................page 54

Using PID Loops.................................................................................................................. page 55

Formatting and Interpreting Data..............................................................................page 58

PROGRAMMING STEPS FOR OPTO 22 DEVICES

In general, writing programs that can read from or write to Opto 22 memory-mapped devices through

OptoMMP memory maps involves six steps:

1. Connect to the device (not required for UDP).

2. Send a powerup clear (PUC) to the device.

3. Configure channels1 and channel features. (For instructions, see page 16).

4. (Optional) Configure event/reactions, security, streaming, and other functions (starting on page 39).

NOTE: Store configurations to flash memory if you want them to remain through power cycles.

5. Read and write to channels.

6. Disconnect from the device (not required for UDP). This step occurs only after all communication is

finished. The connection is left open during normal communications.

Before you start using OptoMMP, here is some important information you should understand about Opto 22

memory-mapped devices, I/O modules, and I/O channels.

1

This guide uses the terms point and channel interchangeably.

OptoMMP Protocol Guide 5

5

Page 14

COMMUNICATION OPTIONS

COMMUNICATION OPTIONS

PR1

RIO

PAC-R

PAC-S

EB

SB

UIO

EIO

SIO

LCE

E1

E2

G4EB2

To communicate with Opto 22 devices, you can use the OptoMMP protocol either by itself or in combination

with other communication methods. For example, your system could be running a PAC Control strategy,

providing data to a peer on the network, and communicating with a third-party HMI, all at the same time.

Communication options include:

Custom applications for Microsoft Windows® and Linux ®—You can use the OptoMMP protocol to build

custom applications from scratch. For details, see Chapter 4: Using the OptoMMP Protocol.

However, you can quick start your development process with two free Opto 22 software development kits

(SDKs), which you can download from our website at www.opto22.com:

• For C++®—the PAC-DEV-OPTOMMP-CPLUS software development kit (SDK).

The SDK supports Microsoft Windows® and Linux, and includes all documentation.

• For Visual Studio® 2010 through 2019—the PAC-DEV-OPTOMMP-DOTNET SDK for .NET developers. The

SDK supports Microsoft's .NET frameworks 4.0 through 4.8, and includes all documentation.

A groov Enterprise license is required to run custom applications on a groov EPIC processor. For details,

see the groov EPIC User’s Guide, (form 2267), available from the Opto 22 website.

Communication Options that Do Not Require the OptoMMP Protocol

None of the following communication options requires knowledge of the OptoMMP protocol:

PAC Control™—Most of the devices that use the OptoMMP protocol can be used with PAC Control, Opto 22’s

flowchart-based control development software. PAC Control Basic is included in your purchase of a groov EPIC

processor or SNAP PAC controller, and is also a free download from www.opto22.com. PAC Control

Professional adds more features and is available for purchase from our website or through an Opto 22

distributor.

CODESYS® Development System—(groov EPIC Systems only) groov EPIC processors can be programmed

using any IEC 61131-3 compliant language in CODESYS. For more information, see the groov EPIC User’s Guide.

Ignition Edge®—(groov EPIC Systems only) groov EPIC processors include Ignition Edge® software from

Inductive Automation® to connect to other devices, such as Allen-Bradley® PLCs, via OPC UA, and for efficient

IIoT communications using MQTT with Sparkplug B payload.

Node-RED—(groov EPIC and groov RIO only) Node-RED, an open-source tool for communicating data among

devices, databases, cloud applications, and APIs, is included in groov EPIC and groov RIO.

EtherNet/IP™—SNAP PAC controllers and SNAP PAC EB brains with firmware R8.3 and higher can also

communicate with Allen-Bradley® Logix-based PLCs and other systems that use EtherNet/IP. For details, see

the EtherNet/IP for SNAP PAC Protocol Guide (form 1770), available from our website.

Modbus®/TCP —Ethernet-based devices that use the OptoMMP protocol can also communicate using

Modbus/TCP. For more information about communicating with Opto 22 devices using Modbus/TCP, see the

Modbus/TCP Protocol Guide (form 1678), available from our website.

Optomux protocol—E1 and E2 brain boards can also communicate using the Optomux protocol over

Ethernet or serial networks. The Optomux Protocol Driver is documented in the Optomux Protocol Guide

(form 1572); the driver and the guide are available from our website.

Accessing Opto 22 Ethernet-Based Devices over the internet

Since Opto 22 Ethernet-based devices are just like any other hardware on the Ethernet network, you can

access them over the internet in exactly the same way you would access a computer; the details depend on

6

OptoMMP Protocol Guide

Page 15

CHAPTER 2: OVERVIEW OF PROGRAMMING

your network and internet connection. Consult your system or network administrator or your Internet Service

Provider (ISP) for more information.

CAUTION: Multiple Communication Options Can Cause Conflict

Any time you directly communicate with an Opto 22 memory-mapped device, make sure that you are not

causing conflicts with other communication options. For example, if you are using the memory map to

exchange data with an I/O unit, and that I/O unit is also controlled by a PAC Control strategy, be caref ul that

the two methods of reading and writing to the unit do not send conflicting directions to I/O. This

caution applies to all Opto 22 devices that have multiple communication options.

Some Opto 22 memory-mapped devices—groov EPIC processors, SNAP PAC R-series controllers, and SNAP

Ultimate brains—are a combination of I/O processor and controller: they handle both input/output

processing and flowchart-based control functions in the same device. Because input/output processing and

control are different functions, it’s sometimes easier to imagine these devices performing these tasks in

different “sides”: a control side and an I/O side.

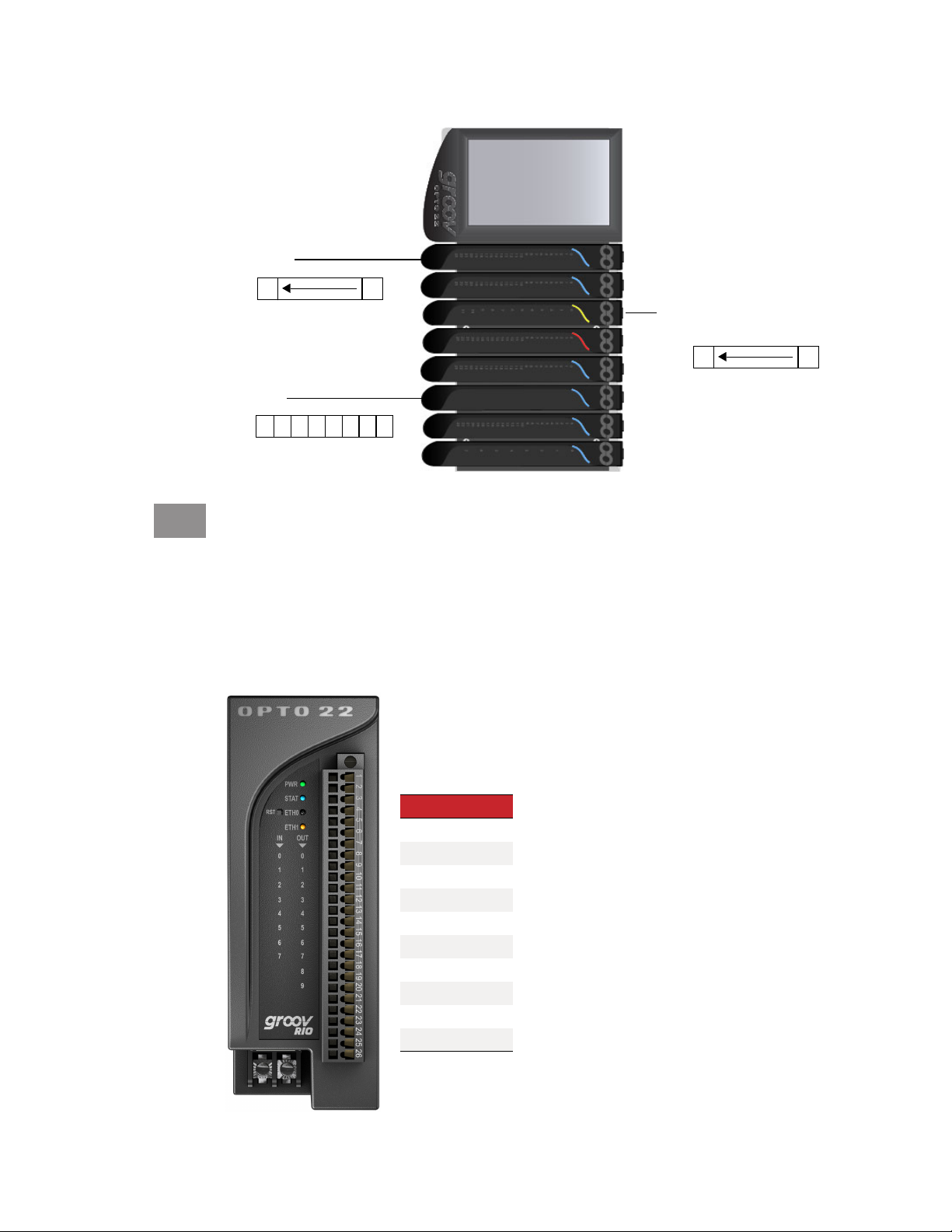

This image depicts a GRV-EPIC-PR1 and

groov I/O modules on a groov EPIC chassis.

Together, these devices are referred to as

an I/O unit.

The modules on the chassis connect with

devices (such as the motor) to monitor

and control them.

Monitoring and control are performed by

sending messages (commands) to

addresses in the groov EPIC processor’s

memory map.

On the control side, these Opto 22 devices have capabilities very much like a SNAP PAC S-series or SNAP-LCE

standalone controller: they typically run a control program developed in PAC Control software. (Some, like

groov EPIC, can run programs developed with other tools.) The control program provides the logic that

controls processes throughout the system. Within the program, PAC Control commands (programming

functions) read and write to the memory map in the I/O side to monitor and control I/O channels.

On the I/O side, these Opto 22 devices have features similar to a SNAP PAC EB brain or a SNAP Ethernet brain:

they read and write to I/O channels by using the memory map (see “Understanding the Memory Map” on

page 8).

IMPORTANT: Any time you are communicating with both the control side and the I/O side, plan carefully and use

caution. The control side reads from and writes to the I/O side just as other methods do directly. Make sure that data

being written directly to the I/O side does not conflict with control logic being executed in the main control program.

OptoMMP Protocol Guide

7

Page 16

UNDERSTANDING THE MEMORY MAP

UNDERSTANDING THE MEMORY MAP

NOTE: Appendix A: Opto 22 Hardware Memory Map shows all memory map addresses and the devices each section

supports.

PR1

RIO

PAC-R

PAC-S

EB

SB

UIO

EIO

SIO

LCE

E1

E2

G4EB2

Opto 22 memory-mapped devices use the IEEE 1394 specification as a standard for reading and writing data.

This standard specifies a memory-mapped model for devices on a network. Basically, each node (such as a

SNAP PAC brain) appears logically as a 48-bit address space2. To communicate with a device, you read from

and write to specific memory addresses in that space.

If you’re a progra mmer, you already know that a memory map is a data structure that matches a set of

logical addresses with physical addresses in the read/write memory hardware on a device. You can think of a

memory map as a lookup table, or if you’re familiar with programmable logic controllers (PLCs), it’s similar to a

PLC’s register.

In Opto 22 memory-mapped devices, a physical address might hold a single value of data, such as the state of

a single digital channel, counter data for a digital channel, the minimum value of an analog channel, or the

device’s firmware version. In your programming code, you use the logical address to reference the physical

address that holds the data you want to read or write to.

When you write to the memory map, the memory-mapped device responds by returning a packet that

indicates success or a failure code. When you perform a read, the memory-mapped device returns a packet

containing the data.

If you’re not a programmer, you can think of a

memory map (sometimes called a mem map) as a

collection of post office boxes. Each mailbox’s address

has a different owner who either has information you

want, or information you want to change.

To get or change the information, you send a message

(in the form of a structured packet of data) to the

mailbox address. For example, to get a device’s part

number, you send the message to address

0080. In response, you’ll get another packet of data

FFFF F030

containing—in this example—the part number.

Getting a part number is an example of reading a

memory map address. You can also write to the

memory map, for example, to change an I/O channel’s

configuration, its status, or its value.

8

OptoMMP Protocol Guide

Note that devices vary in how much of the memory map they support. For example, the SNAP PAC S-series

standalone controller does not support reading or writing to channels, since it is not directly connected to

channels. Similarly, a digital-only brain does not support analog sections of the memory map.

Also note that features included in the memory map may not always be the same as features available

through another protocol. For example, waveform generation is supported on an E2 using the Optomux

protocol, but it is not available on an E2 in OptoMMP. For a list of features supported by each device, see

Appendix C: SNAP Features Comparison Chart and Appendix D: groov EPIC and groov RIO Features and

Comparison Charts.

2

48 bits is equivalent to 6 octets. FFFF F110 0000 is an example of a 48-bit address space.

Page 17

CHAPTER 2: OVERVIEW OF PROGRAMMING

REFERENCING MODULE AND CHANNEL POSITIONS ON I/O UNITS

PR1

RIO

PAC-R

PAC-S

EB

SB

UIO

EIO

SIO

LCE

E1

E2

G4EB2

PR1

NOTE: You can use the reference model described in this section by all methods of communication listed in

“Communication Options” on page 6 except Modbus/TCP and Optomux. For Modbus I/O channel referencing, see

the Modbus chapter in the Modbus/TCP Protocol Guide (form 1678). For Optomux, see the Optomux Protocol

Guide

(form 1572).

Before you begin writing programs that read and write to the memory map addresses in Appendix A: Opto 22

Hardware Memory Map, you first need to know how to reference I/O modules and the channels on them.

Opto 22 I/O units are zero-based: that is, the first module position on the rack or chassis is position 0, and the

first channel on each module is channel 0. The number of channels on a module can vary from one to 32,

depending on the module family and part number. Because of this numbering and variation, it’s important to

understand them before you start reading and writing channel data.

Module and channel positions differ depending on the module family; see the section for yours:

groov I/O Units.................................................................................................. page 9

groov RIO Units...............................................................................................page 10

SNAP I/O Units (and M-series)..................................................................page 11

SNAP B-Series I/O Units............................................................................... page 11

SNAP Digital-Only I/O Units ......................................................................page 12

E1 and E2 I/O Units........................................................................................page 13

G4EB2 I/O Units...............................................................................................page 14

For serial modules, also see page 107.

groov I/O Units

I/O units whose I/O processor is a GRV-EPIC-PR1 are called groov I/O units. groov I/O chassis can hold 4, 8, or 16

I/O modules, and each module contains 8 to 24 channels, depending on the module. Several groov modules

offer a variety of features that you can configure. After you learn how to reference module and channel

positions, then continue to configuring channels and features:

• To configure groov I/O channels, see page 16

• To configure groov I/O features, see page 31.

The following diagram shows examples of groov modules mounted on a chassis, along with the processor.

The diagram also shows examples of how channels are identified on some of the modules.

OptoMMP Protocol Guide

9

Page 18

REFERENCING MODULE AND CHANNEL POSITIONS ON I/O UNITS

Module position 0, discrete,

24 channels:

Ch: 23 0

Module position 5, analog,

8 channels:

Ch:76543210

Module position 2, discrete,

12 channels:

Ch: 11 0

RIO

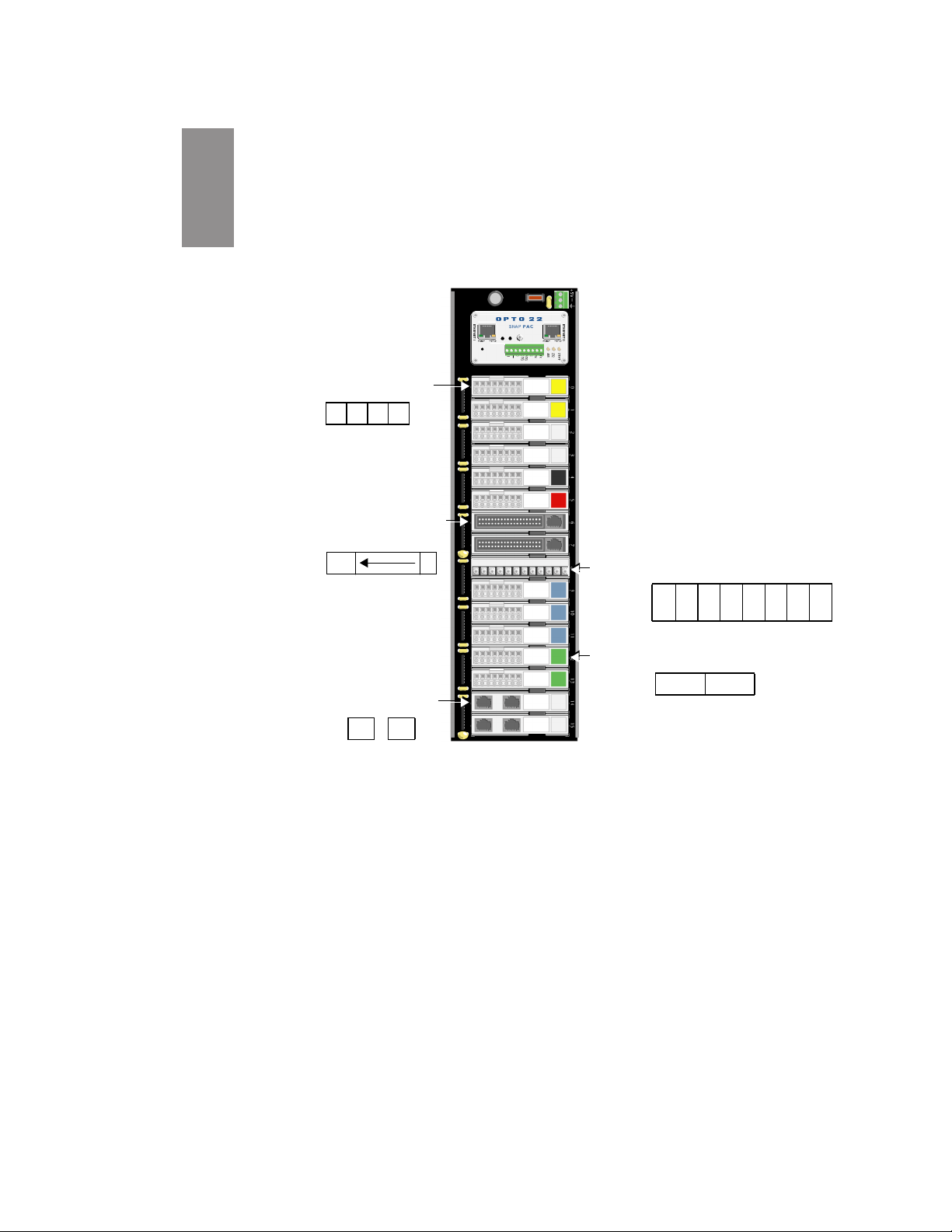

groov RIO Units

A groov RIO module contains an I/O and communications processor plus a specific number of multifunction,

multi-signal I/O channels. Multifunction means channels can be configured as either inputs or outputs;

multi-signal means channels can be configured for different signal inputs. For example, the groov RIO part

number GRV-R7-MM1001-10 includes a processor and ten I/O channels, eight of which are software

configurable as analog or discrete inputs or outputs with a variety of signals, and two of which are Form C

mechanical relays.

All channels on a groov RIO module are considered to be in module position 0. Channel positions are:

GRV-R7-MM1001-10

Channel Positions

Module position = 0

Pins Channel

1–3 0

4–6 1

7–9 2

10–12 3

13–14 4

15–16 5

17–18 6

19–20 7

21–-23 8

24–26 9

To configure channels, see page 20.

To configure channel features, see page 31.

10

OptoMMP Protocol Guide

Page 19

CHAPTER 2: OVERVIEW OF PROGRAMMING

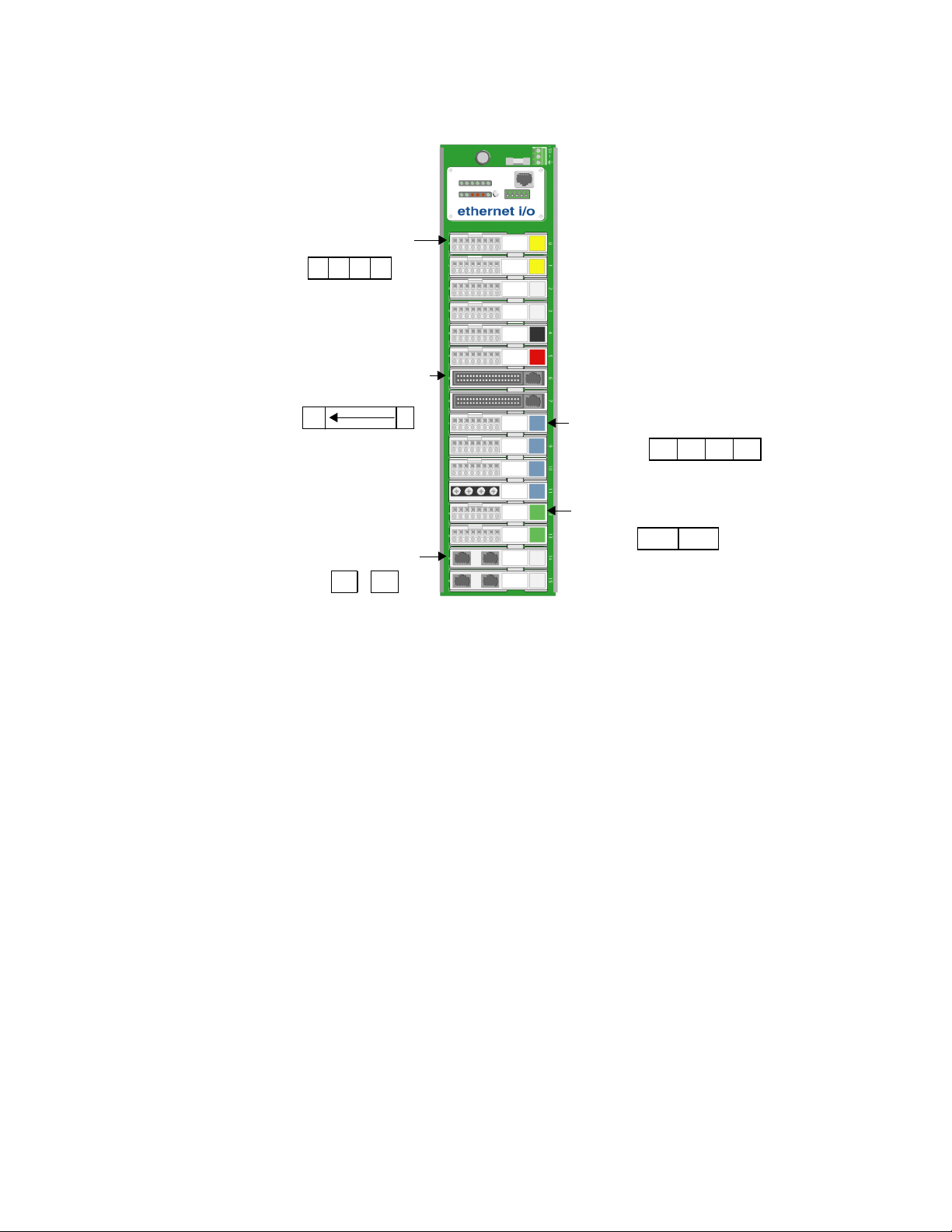

PAC-R

EB

SB

UIO

EIO

SIO

SNAP I/O Units

I/O units whose I/O processor’s part number begins with “SNAP” are called SNAP I/O units. For example,

I/O units with a SNAP-PAC-R1, SNAP-EB1, or SNAP-ENET-S64 as the I/O processor are all SNAP I/O units.

SNAP mounting racks may hold 4, 8, 12, or 16 I/O modules, and the modules can be analog, digital, or serial.

Each module contains 1 to 32 channels (points), depending on the module. Examples of modules are shown

in the following diagram.

NOTE: Module support,

functions, and positions vary by

processor.

Module position 0, 4-ch digital:

Channels: 3 2 1 0

Module position 6, high-density

digital:

Channels

:31 0

Module position 8, analog:

Channels

Module position 12, analog:

Channels

Module position 14, serial:

Ports: B A

76543210

:

:1 0

For more information about SNAP I/O channels, see page 21; for SNAP I/O features, see page 31.

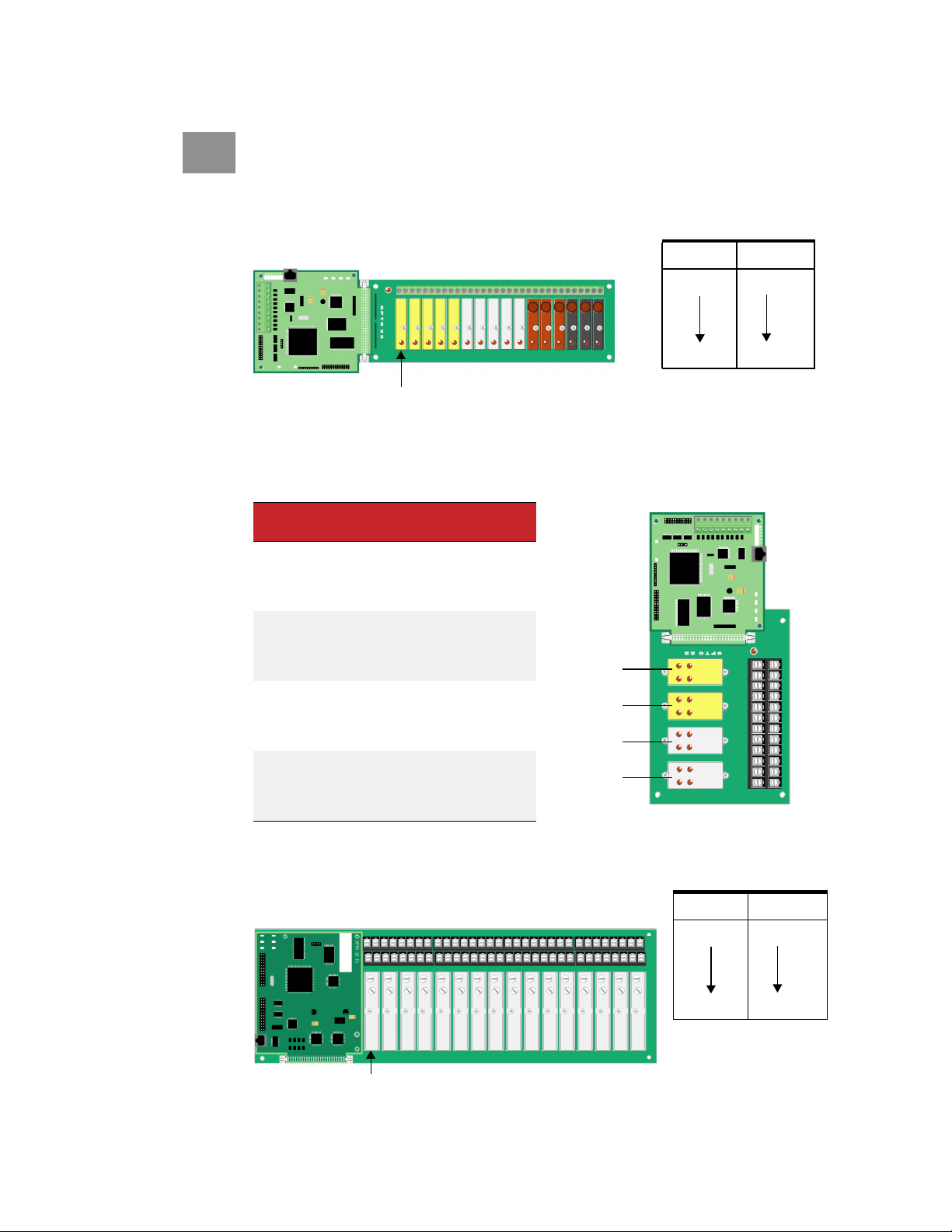

SNAP B-Series I/O Units

NOTE: SNAP B-series racks and the processors compatible with them are not recommended for new development.

Use SNAP PAC racks and processors instead.

SNAP B-series mounting racks can hold up to 4, 8, 12, or 16 Opto 22 SNAP I/O modules. (Not all modules are

supported by these processors; for details, see Legacy and Current SNAP Product Comparison and Compatibility

Charts, form 1693.) Analog, serial, and high-density digital modules (digital modules with more than four

channels) can be placed in any position. For the larger racks, 4-channel digital modules can be placed in

positions 0–7 only. Each module contains 1 to 32 channels, depending on the module. Examples of modules

are shown in the following diagram.

OptoMMP Protocol Guide

11

Page 20

REFERENCING MODULE AND CHANNEL POSITIONS ON I/O UNITS

Module position 0, 4-ch digital:

Channel: 3 2 1 0

Module position 6, high-density

digital:

NOTE: 4-channel digital modules can be

placed in positions 0–7 only.

All other modules can be placed in any

position.

Channels

:31 0

Module position 14, serial:

Ports: B A

Module position 8, analog:

Channels: 3 2 1 0

Module position 12, analog:

Channels: 1 0

SNAP Digital-Only I/O Units

NOTE: Digital-only racks and processors are not recommended for new development. Use SNAP PAC racks and

processors instead.

The SNAP-D64RS mounting rack is compatible with SNAP-UP1-D64 and SNAP-ENET-D64 processors. The rack

holds up to 16 4-channel SNAP digital I/O modules. Analog, serial, and high-density digital modules are not

supported. Module position 0 is the position closest to the processor.

12

OptoMMP Protocol Guide

Page 21

CHAPTER 2: OVERVIEW OF PROGRAMMING

E1

E2

E1 and E2 I/O Units

I/O units using a digital E1 or analog E2 brain board normally use modules containing only one channel, and

the maximum number of channels on the rack is 16. Examples of E1 and E2 I/O units are shown below.

E1 shown with G4 modules.

Since each module has just one channel, use only the first

channel for each module in the memory map.

Module # Channel #

00

15

0

0

Module position 0

E1 with Quad Pak modules.

Quad Pak modules have four input or four output channels, but each

channel is treated as if it were a separate one-channel module.

Module position on

Quad Pak rack

0

1

2

3

Module

number

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

Channel

number

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

2

3

E2 with G1 modules.

Since each module has just one channel, use only the first

channel for each module in the memory map.

Module position 0

Module # Channel #

00

15

0

0

OptoMMP Protocol Guide

13

Page 22

REFERENCING MODULE AND CHANNEL POSITIONS ON I/O UNITS

G4EB2

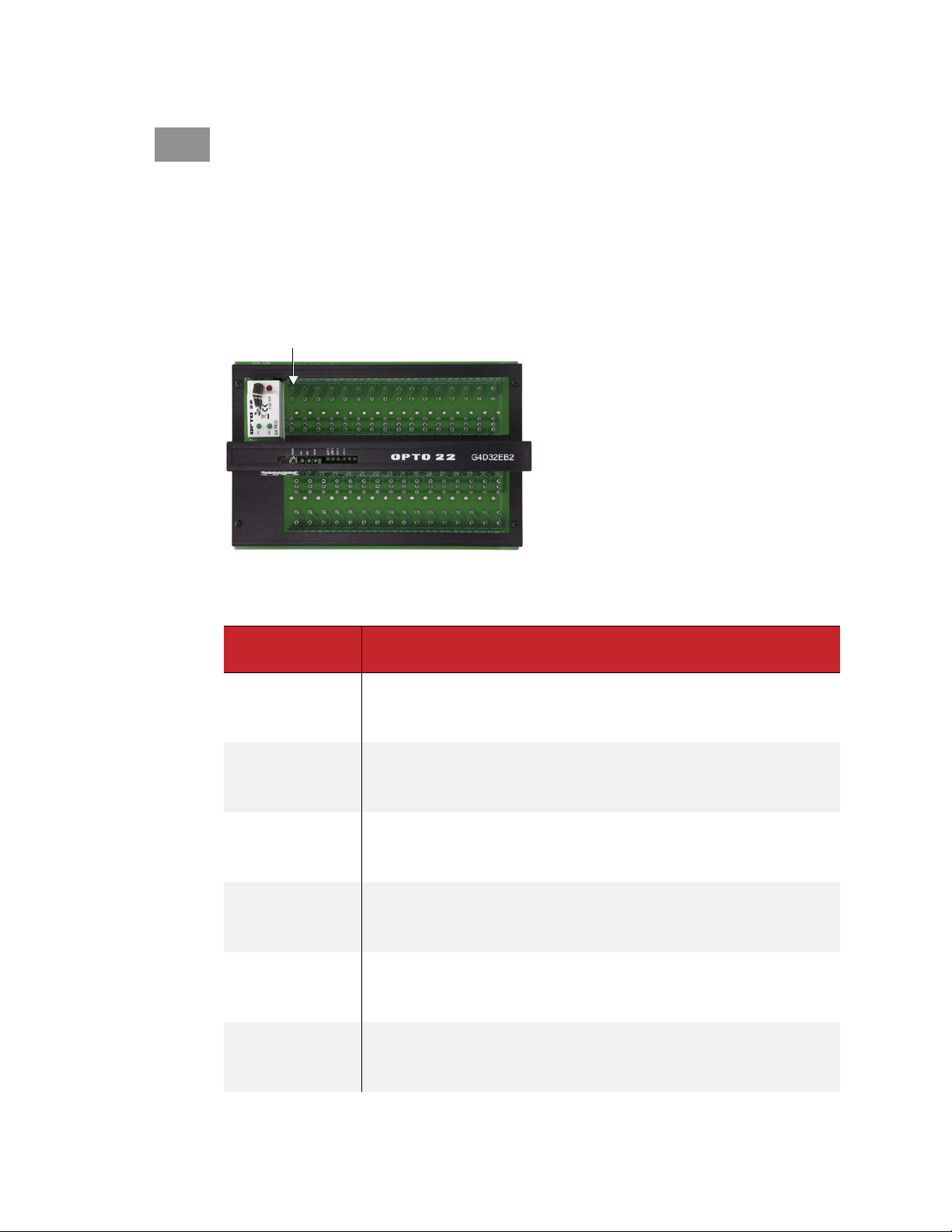

G4EB2 I/O Units

These I/O units include part numbers G4EB2, G4D32EB2, and G4D32EB2-UPG. Each I/O unit has 32 total

channels, all of them digital. They may use G4 modules, which each have one channel, or Quad Pak modules,

which each have four channels of the same type (all four digital inputs or all four digital outputs).

G4EB2 brains with G4 modules

Each module has just one channel (point). However, in the memory map they are addressed like Quad Pak

racks (see page 15). The difference is that with G4s, you can mix input and output modules within the same

group of four channels.

Module position 0

The following table shows Channel Configuration addresses as an example of how to reference channels on a

rack with G4 modules.

G4 rack Memory Map equivalent

Module position Module number Channel number Starting address for channel config

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

0

0

0

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

5

5

5

5

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

F010 0000

F010 00C0

F010 0180

F010 0240

F010 3000

F010 30C0

F010 3180

F010 3240

F010 6000

F010 60C0

F010 6180

F010 6240

F010 9000

F010 90C0

F010 9180

F010 9240

F010 C000

F010 C0C0

F010 C180

F010 C240

F010 F000

F010 F0C0

F010 F180

F010 F240

14

OptoMMP Protocol Guide

Page 23

CHAPTER 2: OVERVIEW OF PROGRAMMING

G4 rack Memory Map equivalent

Module position Module number Channel number Starting address for channel config

24

25

26

27

28

29

30

31

6

6

6

6

7

7

7

7

0

1

2

3

0

1

2

3

F011 2000

F011 20C0

F011 2180

F011 2240

F011 5000

F011 50C0

F011 5180

F011 5240

G4EB2 brains with Quad Pak modules

Quad Pak modules have four input or four output channels per module, so each group of four channels must

be configured as either inputs or outputs.

Module position 0 (channels 0–3)

The following table shows Channel Configuration addresses as an example of how to reference channels on a

PB32HQ rack with Quad Pak modules.

Quad Pak rack Memory Map equivalent

Module position

0

1

2

3

4

Channel

number

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Module number

0

0

0

0

1

1

1

1

2

2

2

2

3

3

3

3

4

4

4

4

Channel

number

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

0

1

2

3

Starting address for

channel config

F010 0000

F010 00C0

F010 0180

F010 0240

F010 3000

F010 30C0

F010 3180

F010 3240

F010 6000

F010 60C0

F010 6180

F010 6240

F010 9000

F010 90C0

F010 9180

F010 9240

F010 C000

F010 C0C0

F010 C180

F010 C240

OptoMMP Protocol Guide

15

Page 24

CONFIGURING I/O CHANNELS

Quad Pak rack Memory Map equivalent

Module position

5

6

7

CONFIGURING I/O CHANNELS

Before you can read or write to I/O channels, you must make sure channel types and channel features are

configured as required.

Channel

number

20

21

22

23

24

25

26

27

28

29

30

31

Module number

5

5

5

5

6

6

6

6

7

7

7

7

Channel

number

0

1

2

3

0

1

2

3

0

1

2

3

Starting address for

channel config

F010 F000

F010 F0C0

F010 F180

F010 F240

F011 2000

F011 20C0

F011 2180

F011 2240

F011 5000

F011 50C0

F011 5180

F011 5240

PR1

See the section for your I/O unit:

groov I/O units................................................................................................. page 16

groov RIO units................................................................................................ page 20

SNAP analog/digital I/O units.................................................................. page 21

SNAP digital-only and G4EB2 I/O units ............................................... page 29

E1 and E2 brain boards ...............................................................................page 29

Configuring I/O Channels for groov I/O Units

You can configure groov I/O units in three ways:

• PAC Cont rol—If you are programming a strategy with PAC Control (R10.0 or higher), configure channels

while you are programming the strategy.

• groov Mana ge—If your control program is not a PAC Control strategy, configure channels in groov

Manage, either on the groov EPIC processor’s touchscreen or remotely from a computer or mobile device.

Configurations are automatically saved to flash memory.

• OptoMMP—If OptoMMP is the ONLY communication to the groov I/O unit, then configure I/O channels

by selecting the appropriate configuration values as described below.

groov I/O Module Types and Channel Types

The table beginning on page 17 shows configuration values for groov I/O modules, divided by module and

channel types.

• Some modules provide or accept several ranges of values per channel, which is why they have multiple

channel types. If a module offers more than one range, choose the range you want from the Description

column and read across to the Channel ID (hex) column to find the corresponding configuration value.

For example, suppose the module in position (slot) 0 on the chassis is a GRV-IV-24 and you want to

monitor a range of ±10 V on the first two channels (channels 0 and 1). You find the module’s range in the

Description column and read across to see that the appropriate configuration value is 0x60000017.

• Some modules provide or accept only certain configuration values on specific channels. Those modules

list the specific channel that accepts a specific configuration value in the “Applies To” column. If the

16

OptoMMP Protocol Guide

Page 25

CHAPTER 2: OVERVIEW OF PROGRAMMING

column says “all”, that means all channels on that module accept all the configuration values available for

that module.

After you select the configuration value for the module and channel type, go to page 31 to select the correct

configuration value for a specific feature.

Part number

GRV-CSERI-4 all RS232 0C00001E 08000026 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 2-Wire, no termination, no bias 0C00001E 08000027 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 2-Wire, termination, no bias 0C00001E 08000028 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 2-Wire, no termination, bias 0C00001E 08000029 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 2-Wire, termination, bias 0C00001E 0800002A 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 4-Wire, no termination, no bias 0C00001E 0800002B 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 4-Wire, termination, no bias 0C00001E 0800002C 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 4-Wire, no termination, bias 0C00001E 0800002D 4 N/A N/A N/A

GRV-CSERI-4 all RS485, 4-Wire, termination, bias 0C00001E 0800002E 4 N/A N/A N/A

GRV-IAC-24 all Digital Input 5000000F 50000000 24 N/A N/A N/A

GRV-IACDCTTL-24 all Digital Input 50000005 50000000 24 N/A N/A N/A

GRV-IACDCTTLS-24 all Simple Digital Input 54000007 54000000 24 N/A N/A N/A

GRV-IACHV-24 all Digital Input 50000010 50000000 24 N/A N/A N/A

GRV-IACHVS-24 all Simple Digital Input 54000008 54000000 24 N/A N/A N/A

GRV-IACI-12 all Digital Input 5000000C 50000000 12 N/A N/A N/A

GRV-IACIHV-12 all Digital Input 5000000D 50000000 12 N/A N/A N/A

GRV-IACIHVS-12 all Simple Digital Input 54000009 54000000 12 N/A N/A N/A

GRV-IACIS-12 all Simple Digital Input 5400000A 54000000 12 N/A N/A N/A

GRV-IACS-24 all Simple Digital Input 5400001D 54000000 24 N/A N/A N/A

GRV-IDC-24 all Digital Input 50000011 50000000 24 N/A N/A N/A

GRV-IDCI-12 all Digital Input 5000000E 50000000 12 N/A N/A N/A

GRV-IDCIFQ-12 0 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 1 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 2 Digital Input with Quadrature Index 5000001A 50000030 12 N/A N/A N/A

GRV-IDCIFQ-12 3 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 4 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 5 Digital Input with Quadrature Index 5000001A 50000030 12 N/A N/A N/A

GRV-IDCIFQ-12 6 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 7 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 8 Digital Input with Quadrature Index 5000001A 50000030 12 N/A N/A N/A

GRV-IDCIFQ-12 9 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 10 Digital Input with Quadrature 5000001A 5000002F 12 N/A N/A N/A

GRV-IDCIFQ-12 11 Digital Input with Quadrature Index 5000001A 50000030 12 N/A N/A N/A

GRV-IDCIS-12 all Simple Digital Input 5400000B 54000000 12 N/A N/A N/A

Description

Applies To

(hex)

Module ID

(hex)

Channel ID

Default

Channels

per module

Units

Low Scale

Full Scale

OptoMMP Protocol Guide

17

Page 26

CONFIGURING I/O CHANNELS

Part number

GRV-IDCS-24 all Simple Digital Input 54000016 54000000 24 N/A N/A N/A

GRV-IICTD-12 all ICTD Temperature Probe 6000001F 60000031 12 °C -270 150

GRV-IMA-24 all ±20 mA 60000001 60000014 24 mA -20 20

GRV-IMA-24 all 0-20 mA 60000001 60000015 24 mA 0 20

GRV-IMA-24 all 4-20 mA 60000001 60000016 24 mA 4 20

GRV-IMAI-8 all 0-20 mA 60000020 60000015 8 mA 0 20

GRV-IMAI-8 all 4-20 mA 60000020 60000016 8 mA 4 20

GRV-ITM-12 all ±1200 mV 60000026 60000002 12 mV -1200 1200

GRV-ITM-12 all ±600 mV 60000026 60000003 12 mV -600 600

GRV-ITM-12 all ±300 mV 60000026 60000004 12 mV -300 300

GRV-ITM-12 all ±150 mV 60000026 60000005 12 mV -150 150

GRV-ITM-12 all ±75 mV 60000026 60000006 12 mV -75 75

GRV-ITM-12 all ±50 mV 60000026 60000007 12 mV -50 50

GRV-ITM-12 all ±25 mV 60000026 60000008 12 mV -25 25

GRV-ITM-12 all Type B Thermocouple (°C) 60000026 60000009 12 °C 0 1820

GRV-ITM-12 all Type E Thermocouple (°C) 60000026 6000000C 12 °C -270 1000

GRV-ITM-12 all Type J Thermocouple (°C) 60000026 6000000E 12 °C -210 1200

GRV-ITM-12 all Type K Thermocouple (°C) 60000026 6000000F 12 °C -270 1372

GRV-ITM-12 all Type N Thermocouple (°C) 60000026 60000010 12 °C -270 1300

GRV-ITM-12 all Type R Thermocouple (°C) 60000026 60000011 12 °C -50 1768

GRV-ITM-12 all Type S Thermocouple (°C) 60000026 60000012 12 °C -50 1768

GRV-ITM-12 all Type T Thermocouple (°C) 60000026 60000013 12 °C -270 400

GRV-ITMI-8 all ±1200 mV 60000006 60000002 8 mV -1200 1200

GRV-ITMI-8 all ±600 mV 60000006 60000003 8 mV -600 600

GRV-ITMI-8 all ±300 mV 60000006 60000004 8 mV -300 300

GRV-ITMI-8 all ±150 mV 60000006 60000005 8 mV -150 150

GRV-ITMI-8 all ±75 mV 60000006 60000006 8 mV -75 75

GRV-ITMI-8 all ±50 mV 60000006 60000007 8 mV -50 50

GRV-ITMI-8 all ±25 mV 60000006 60000008 8 mV -25 25

GRV-ITMI-8 all Type B Thermocouple (°C) 60000006 60000009 8 °C 0 1820

GRV-ITMI-8 all Type E Thermocouple (°C) 60000006 6000000C 8 °C -270 1000

GRV-ITMI-8 all Type J Thermocouple (°C) 60000006 6000000E 8 °C -210 1200

GRV-ITMI-8 all Type K Thermocouple (°C) 60000006 6000000F 8 °C -270 1372

GRV-ITMI-8 all Type N Thermocouple (°C) 60000006 60000010 8 °C -270 1300

GRV-ITMI-8 all Type R Thermocouple (°C) 60000006 60000011 8 °C -50 1768

GRV-ITMI-8 all Type S Thermocouple (°C) 60000006 60000012 8 °C -50 1768

GRV-ITMI-8 all Type T Thermocouple (°C) 60000006 60000013 8 °C -270 400