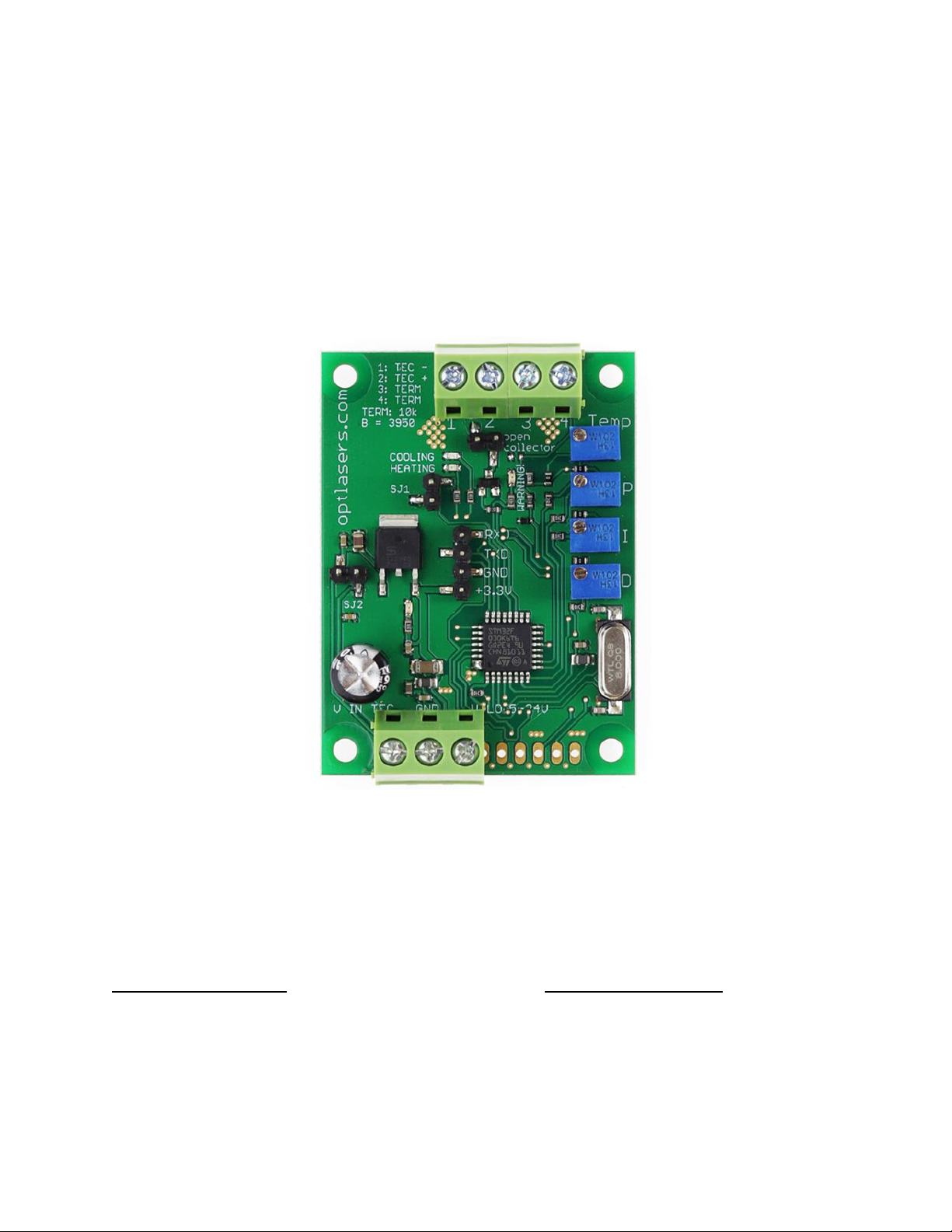

Opt Lasers TEC-8A-24V-PID-HC Operating Manual

TEC-8A-24V-PID-HC

Operating Manual

Contact and Shipping:

Company Information:

Tomorrow's System Sp. Z o.o.

Tomorrow's System Sp. Z o.o.

Okulickiego 7/9 hala G39

Pułaskiego 125/35

05-500 Piaseczno

15-337 Białystok

Poland

Poland

tel.: +48 515 180 752

NIP: PL5423238556

Table of content

Product Description 3

Technical Data 4

Pinout 5

Electrical Wiring 6

Advanced Program 9

Opened/Not connected SJ1 jumper mode 9

Closed/Connected SJ1 jumper mode 10

Connectivity 11

Serial Protocol 12

Configuration command 12

Single byte commands 12

How to connect PC to TEC 8A-24V-PID 13

Communication via PuTTY: 15

Basic Program 18

Recommendations and Requirements 21

Protection 21

Related products 22

Product Description

TEC-8A-24V-PID-HC is improved digital temperature controller. The present

version can heat and cool without changing any jumpers. The controller is available

in two versions of the program: Basic and Advanced. Beyond the basic functionality,

Advanced version offers the possibility to set various parameters of the controller

using UART.

TEC-8A-24V-PID-HC has an open collector output which allows to use it as a

signal for other devices. Open collector will indicate when the measured

temperature is out of the Tmin/Tmax range. In addition to open collector, warning

LED will indicate this also. The indication LEDs show heating or cooling activity.

Also, the dimensions of the PCB are smaller and mounting holes were added.

You can use UART to read the temperature setpoint, actual temperature and

PID parameters values. To read accurately the value of the temperature use a

thermistor with BETA value of 3950 for basic and advanced versions and for

advanced ±100°C version you need a P0K1.202.3FW.B.007 thermistor.

Its small size, simplicity of regulation and versatility make it widely used in

many areas. It is dedicated to work with 12 V thermocouples (Peltier modules) yet

it does well with all modules whose supply voltage falls in the range of 5 to 24 V.

With the use of four trimmers, the temperature setpoint as well as values of

the PID controller parameters can be set. The controller operates in PWM mode

(Pulse Width Modulation) and can control currents of up to 8 A. For the temperature

sensor, it uses a standard 10k NTC B=3950 thermistor for basic and advanced

version and for advanced ±100°C version it uses a P0K1.202.3FW.B.007

thermistor. By default, the temperature setpoint is set to 25 degrees Celsius.

Due to the possibility to set the parameters of a PID controller, the driver can

be adapted to almost any system. Depending on the inertia of the system, properly

adjusted driver is able to maintain the desired temperature with an accuracy better

than ±0.05°C.

The current flowing through the Peltier cell depends on the supply voltage

used. Most of the common modules should be supplied with the voltage of 5 to 24V,

and the maximum current that flows through them is defined by a cell symbol.

The driver is working in TTL 3.3V standard.

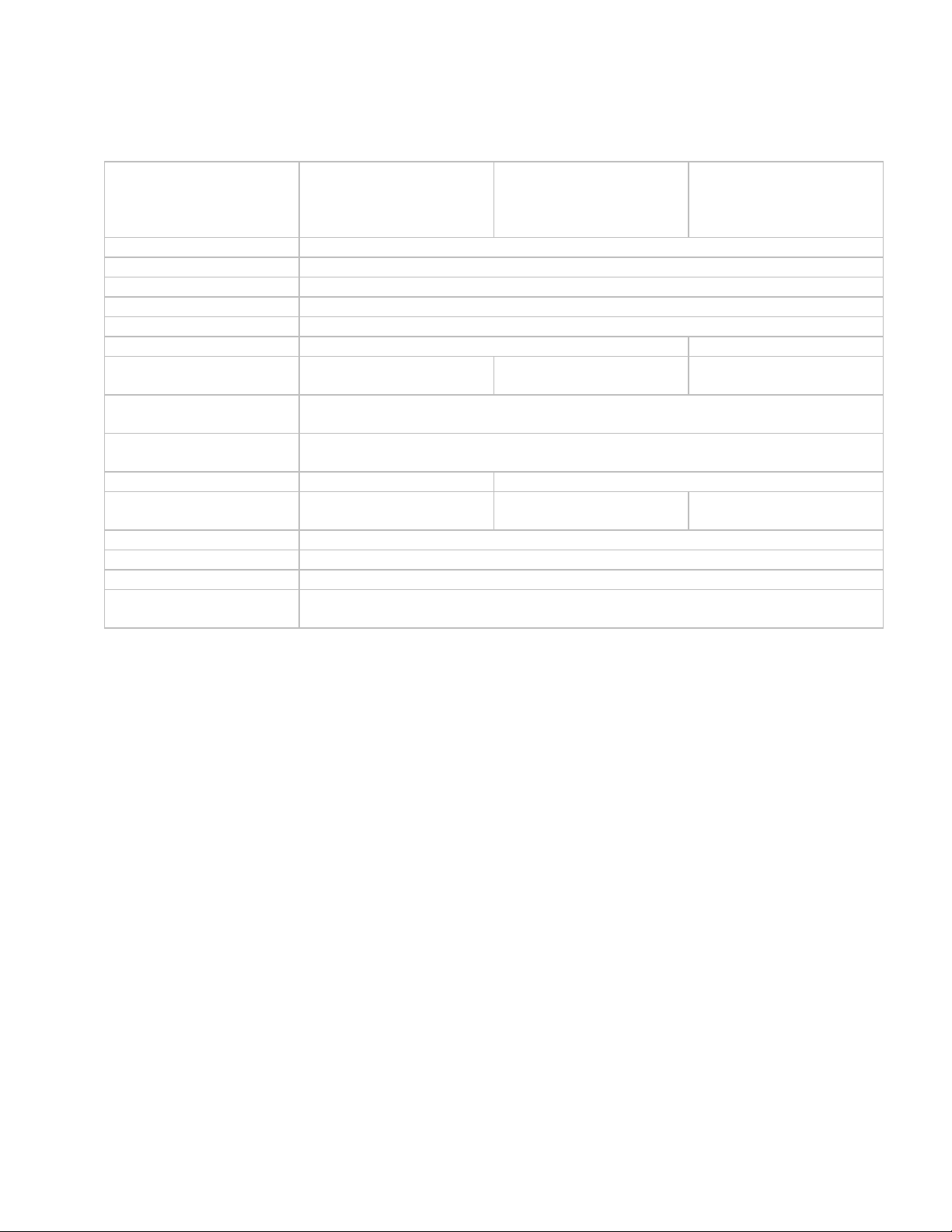

Technical Data

RS232 Programmable

Temperature

Controller ±100°C

(Advanced)

RS232 Programmable

Temperature

Controller

(Advanced)

Temperature

Controller (Basic)

Maximum current

8A

Input Voltage (V LOG)

5 – 24 V

Input Voltage (V TEC)

5 – 24 V

Serial Interface

3.3V Logic, 1 start bit = 0, 8 data bits, no parity, 1 stop bit = 1

Serial Transmission

Yes

Serial Reception

Yes

No

Temperature

Stabilization Accuracy

±2°C*

±2°C

±2°C

Temperature Tracing

Accuracy

±0.05°C

Cooling or heating

work

Yes

Temperature sensor

P0K1.202.3FW.B.007

10k NTC B=3950

Temperature range

Tmin and Tmax

-100 to +100°C

0 to +50°C

0 to +50°C

Heat sink required

No

Dimensions

45 x 60 mm

Mounting holes

37 x 52 mm

Mounting holes

diameter

3.2 mm

* Applicable for the range ±50°C. For the range ±100°C accuracy is ±3°C

Pinout

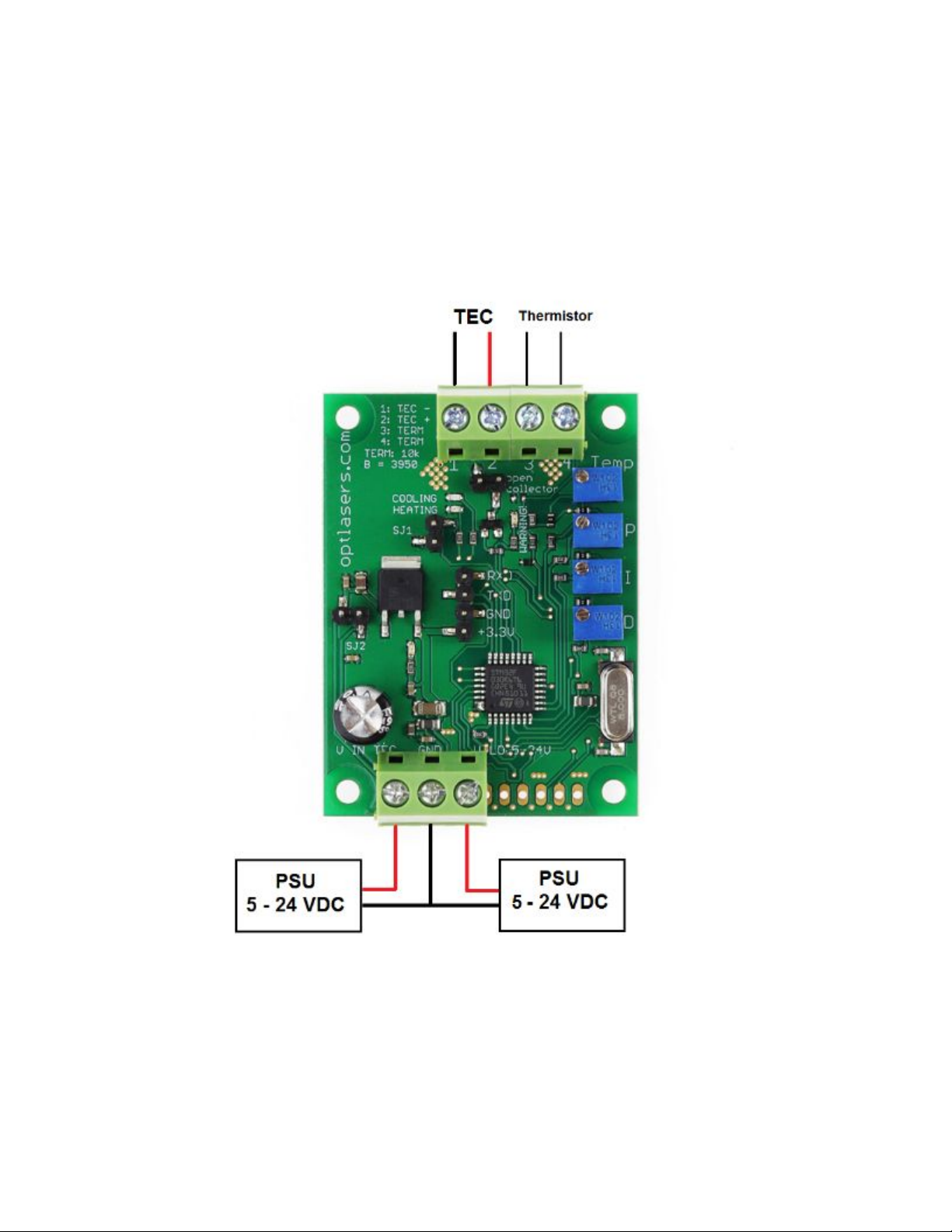

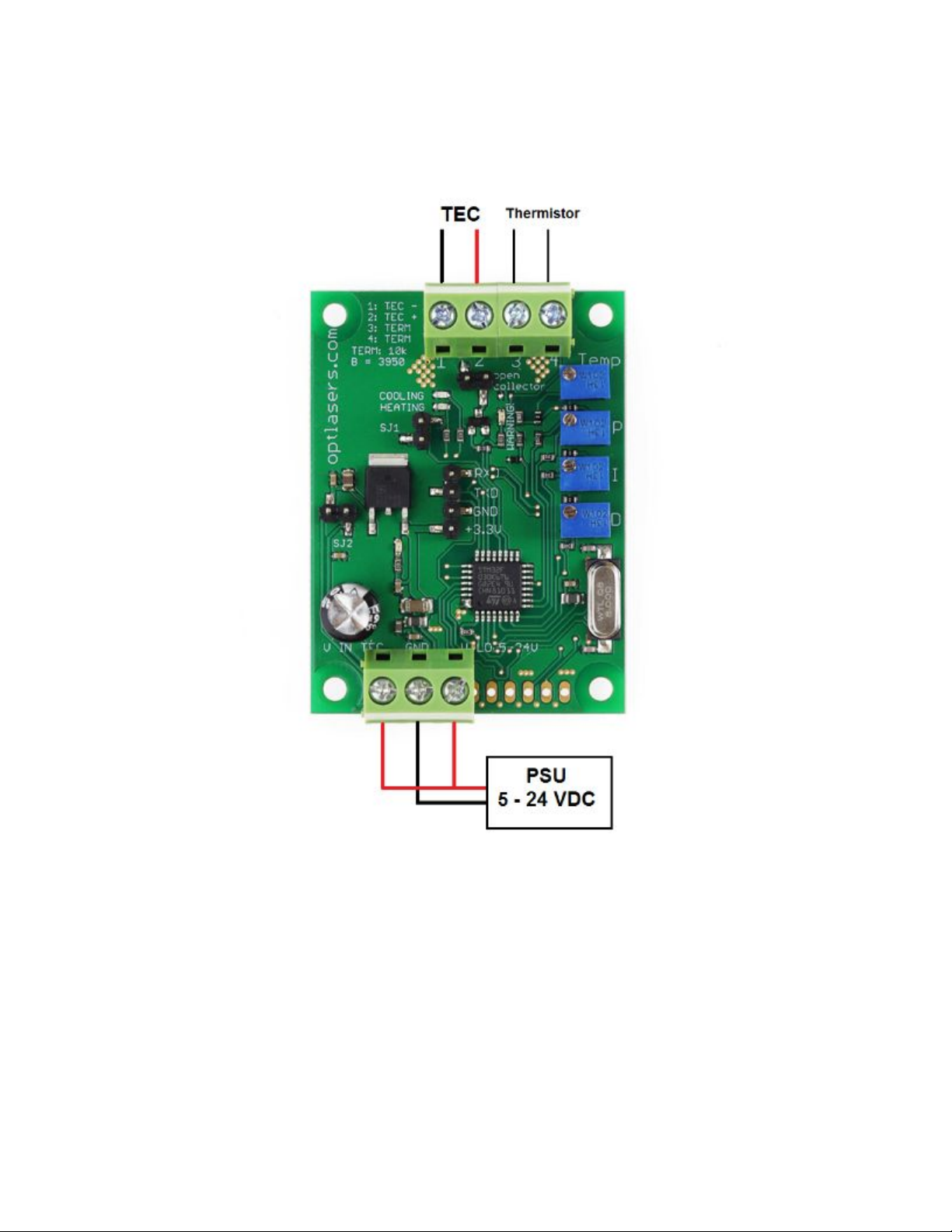

Electrical Wiring

The TEC-8A-24V-PID-HC driver can be power supplied in three different ways.

1. Using two PSUs:

2. Using one PSU:

3. Using one PSU with closed SJ2:

Loading...

Loading...