OptiPure SX2-11 Service Manual

Installation, Operation & Maintenance Manual

for OptiPure ScaleX2

®

Systems

Models: SX2-11, SX2-12, SX2-12B

DO NOT DISCARD - GIVE THIS MANUAL TO THE OWNER AFTER INSTALLATION.

DO NOT DISCARD THIS MANUAL AFTER INSTALLATION.

THIS MANUAL CONTAINS IMPORTANT

OPERATION, MAINTENANCE AND PRECAUTIONARY INFORMATION. PLEASE PRESENT THIS MANUAL

TO USER/OPERATOR/OWNER AFTER INSTALLATION.

IT IS STRONGLY ENCOURAGED THAT YOU READ THIS MANUAL BEFORE INSTALLING SYSTEM TO

ENSURE THE BEST POSSIBLE INSTALLATION.

INSTALLATION MUST CONFORM TO ALL LOCAL AND STATE PLUMBING CODES AND REGULATIONS.

CONNECT SYSTEM TO COLD WATER SUPPLY ONLY. WATER TEMP. CAN NOT EXCEED 100°F/38°C.

SYSTEM MUST BE INSTALLED IN A VERTICAL AND UPRIGHT POSITION.

DO NOT USE WITH WATER THAT IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY

WITHOUT ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM.

FAILURE TO CHANGE CARTRIDGES PER RECOMMENDED INTERVALS WITH OPTIPURE REPLACE-

MENT CARTRIDGES MAY LEAD TO SYSTEM FAILURE AND PROPERTY DAMAGE.

Introduction

Your new OptiPure ScaleX2

®

FoodService Filtration System will condition the tap water providing optimum water

characteristics for their speci ed applications. The result is reduced equipment maintenance requirements, longer

equipment life and improved quality & consistency of your products. Proper system installation and routine lter

changes will ensure years of trouble-free operation and performance.

The ScaleX2

®

System is built with the nest and most advanced materials and each system is quality inspected and

pressure tested prior to shipment. With proper installation and routine maintenance, you will have years of trouble-free

operation.

Please refer to this manual when performing routine lter changes. The instructions make periodic maintenance quick

and easy, and ensure you will receive maximum bene t from your system.

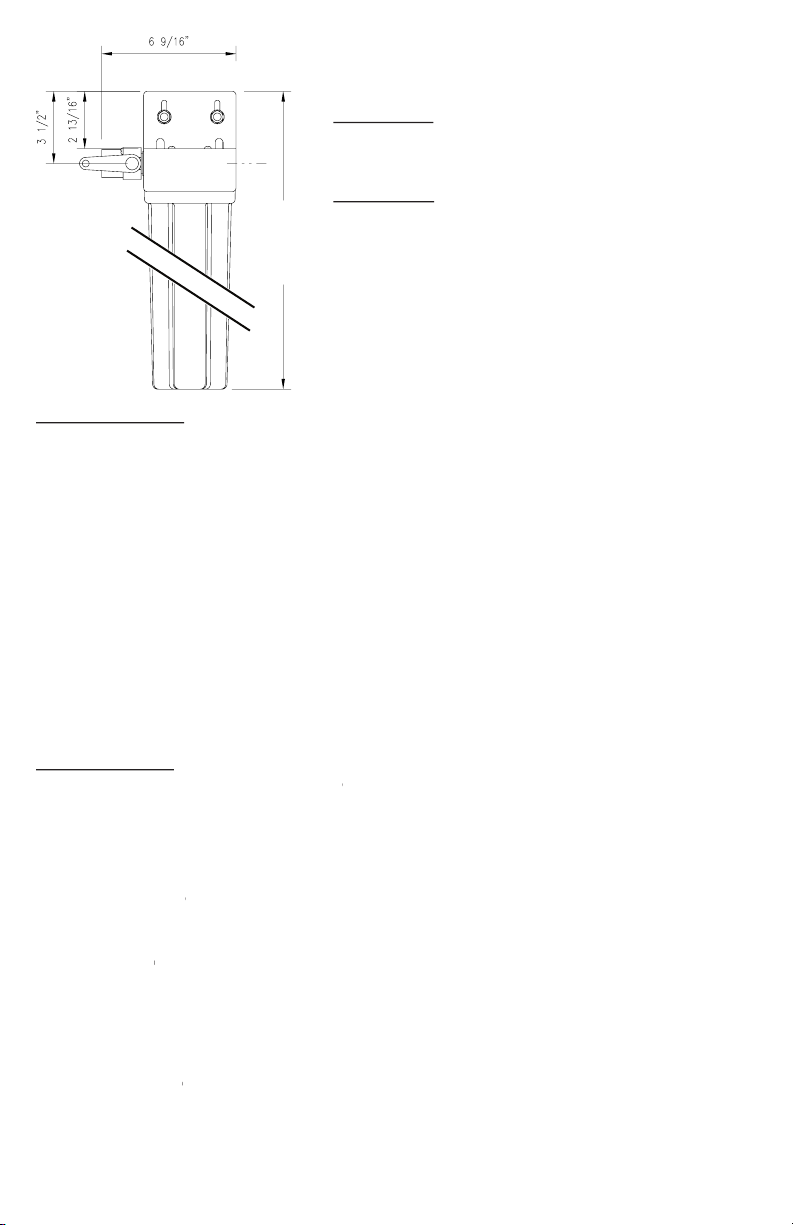

System Speci cations & Dimensions

System Speci cations & Dimensions

Maximum Pressure:

125 psi/8.6 bar

Maximum Temperature:

100°F/38°C, Min.: 35°F/2°C

Inlet/Outlet Connections:

1/2” fnpt

Capacity:

Change ScaleX2

®

Cartridge at least once a year. Change CTO cartridges at gallon rating or at least every

6 months or when pressure gauge needle enters the red zone on the outlet gauge while water is flowing through the

filter system under normal operating conditions.

SX2-1iom908

Foodservice Filtration Systems

Foodservice Filtration Systems

®

SCALEX2

SYSTEMS MUST NOT BE USED IN CONJUNCTION WITH POLYPHOSPHATE OR ANY OTHER

SCALE INHIBITOR.

®

DO NOT INSTALL FILTERS DOWNLINE FROM THE SCALEX2

SYSTEM. SCALEX2® MUST BE THE LAST

FILTER SYSTEM BEFORE THE EQUIPMENT.

Installation Precautions

• Do

NOT

install system on line pressure above 125 psi.

• Do

NOT

install the system backwards with the feed water line connected to the outlet.

• Do

NOT

use liquid pipe compounds for tting connections. USE a maximum of two to three wraps of te on tape.

Do

NOT

allow system to freeze. Turn off water supply to housing and drain housing if temperature falls below 32°F.

• Do

NOT

install system in direct sunlight or where system is exposed to harsh chemicals or may be subjected to

being struck by moving equipment, carts, mops or any other item that may cause damage.

water hammer is evident, install water hammer arrestors before OptiPure unit.

• Do

NOT

overtighten tting connections into inlet valve our housing outlet.

•

Always

back-up valves and ttings with a wrench when installing a tting to avoid turning the valve.

Position the OptiPure unit in a suitable location downstream from existing lters. The direction of ow through the

OptiPure unit is always left to right; keep this in mind when determining installation location. Do NOT mount the

OptiPure system near any source of heat. Also, do not mount the system above any device or area that would be

adversely affected by water.

Installation Procedure

®

System, locate water supply cut-off valve and turn off.

Determine if water line has an existing water treatment system. If so, examine system for use of polyphosphate

Anchor the ScaleX2

®

System on a wall stud or suitable mounting material spanning wall studs.

®

system. Use 2-3 wraps of te on tape and brace the inlet ball valve on the system with a wrench

when connecting the feed water line.

®

®

system could be provided in the line to facilitate ushing when changing lters.

or other scale inhibitors. ScaleX2® will not be effective if used in conjunction with other scale inhibitors. Remove

the scale inhibitors from the water line or discontinue installation.

must be upright and vertical.

System

Loading...

Loading...