OptiPure OP350 Installation Manual

OP350

Advanced Membrane

Separation System

Installation, Operation

& Maintenance Manual

Rev. 2

OP350_iom-manual_v2.indd

©2015 Procam Controls, Inc. All Rights Reserved

Manufactured By:

OptiPure Div. of

Procam Controls, Inc.

2605 Technology Drive, Bldg. 300

Plano, TX 75074

P: 972.881.9797 F: 972.422.6262

OP350 System Installation, Operation & Maintenance 2

General Information

Safety Warning

Electrical work should be performed by a qualied

electrician in accordance with all applicable

codes and regulations.

Service Contact

For local maintenance and service information

please contact your nearest Authorized Service

Representative. Service inquiries may be directed

to technical support at:

OptiPure div. of Procam Controls, Inc.

2605 Technology Dr. Bldg. 300

Plano, TX 75074 USA

Phone #: 972.881.9797

Fax #: 972.422.6262

E-mail correspondence to:

techsupport@optipure.net

Safety Instructions

1. Please read and follow these instructions

when connecting and using the system.

2. To avoid electrical shock, never touch the

inside of the electrical box. Only a qualied

technician should open the electrical box.

3. Never use the system if the power cord or

oat switch cable has been damaged. Do not

allow anything to rest on the power cord or

oat switch cable, and keep the cords away

from any place where people may trip over

them.

4. When disconnecting from the electric socket

hold the plug, not the cord.

5. If the processor does not function properly,

especially if there is an unusual sound or

smell coming from it, immediately unplug

the processor. Call your authorized service

representative.

Environmental Conditions

The OP350 is certied to operate under the

following conditions:

1. Altitude up to 2000 m.

2. Ambient temperature of 40-105°F (5 - 40°C).

3. Max relative humidity 80% at 88°F (31°C).

4. Main supply voltage not to exceed +/- 10%.

5. Installation category II.

6. Pollution degree II.

7. Indoor use only, protect from elements.

Explanation of Symbols

The following symbols are used on the water

processor. The symbols and their explanation is

given below:

Earth ground:

6. Unplug the processor and RP pump from the

AC outlet prior to any service.

7. Locate the RP Assembly as close as possible

to an AC outlet.

8. Securely bolt processor to wall before

operating.

9. Avoid cross-connections and install on cold

water supply only.

10. Use approved Air-Gaps when connecting to

drain lines.

11. Do not exceed system pressure rating and

use water hammer arrestors when water

hammer is evident.

12. Turn off Feed-Water supply before lter or

membrane cartridge replacement.

WARNING: Hazardous Voltage:

OP350 System Installation, Operation & Maintenance 3

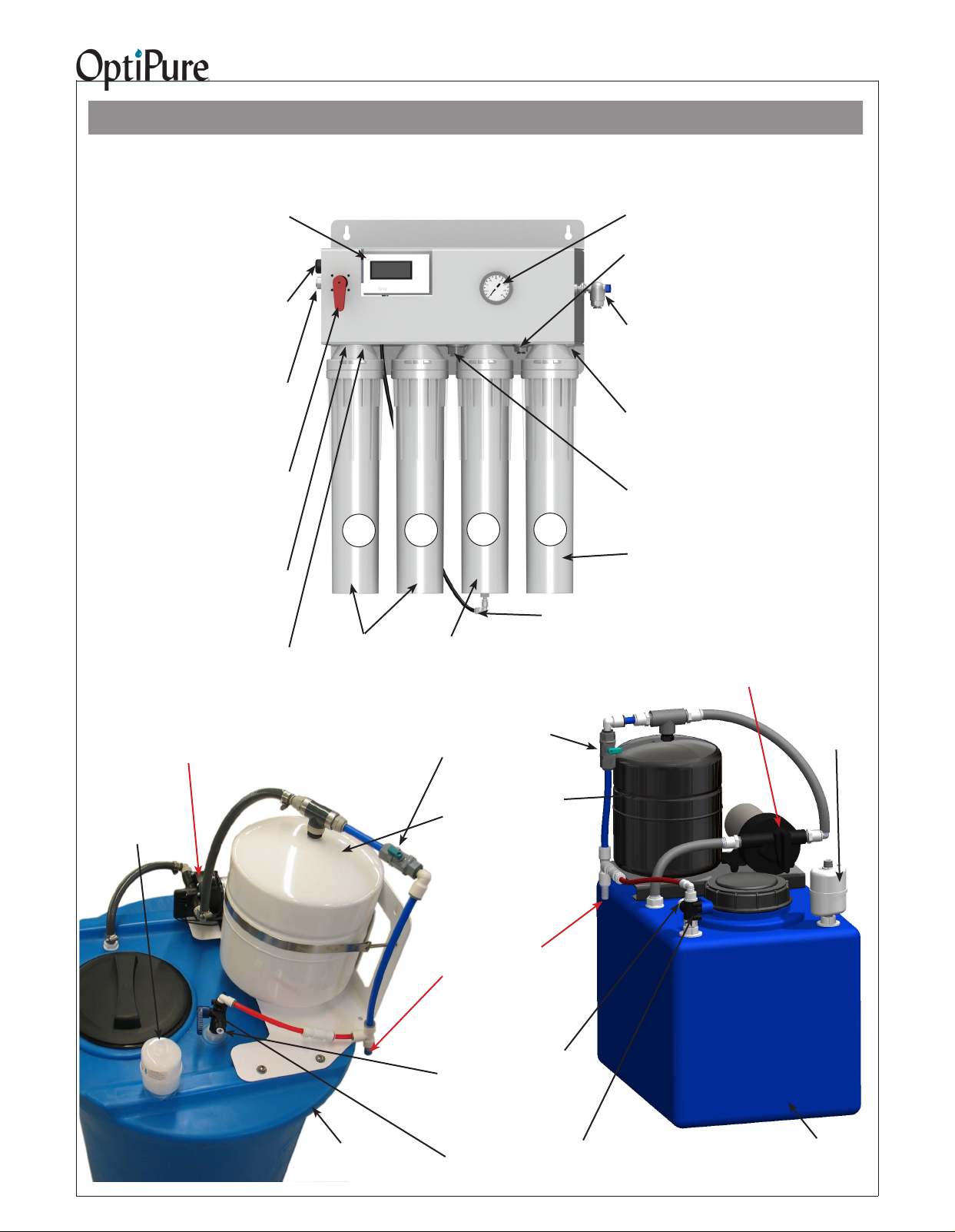

Getting To Know Your System

The OP350 Advanced Membrane Separation System is designed to purify feed water and remove dissolved minerals, and

then add back a consistent amount of a balanced blend of TDS (Total Dissolved Solids), or mineral content, in the treated

water, providing an Optimized Water to your equipment with the characteristics that you desire.

Water Quality Indicator - Operates

momentarily, push purple button to turn

on. Push “IN” button for the TDS of the

water going into your equipment. Push

“OUT” button for the TDS of the puried

water from the membrane.

120VAC

Power Cord

- Plug in to standard

wall outlet.

Feed water

Inlet 3/8” Push-To-

Connect -

Connect to Water Supply

Valve.

Emergency

Bypass Valve -

User can switch from

Optimized Water to

Untreated Water

when needed.

Reject Water Outlet

(behind lter) - 1/4” Push-

to-Connect - Connect to

drain per local regulations.

Reject Flow

Control Valve

(behind lter)

Repressurization Pump

120VAC - Plug in to standard

wall outlet.

Absolute 0.2

micron

Hydrophobic

Air-Breather/

Filter

1

2@ CTO-Q

Pre-Filters

PN: 300-05830

2

3 4

AMS-QT

Membrane

Cartridge

Buffer Tank Valve

Normally open, shown

closed. Used to shut off

water supply to downstream equipment.

Buffer Tank - Pre-charged

air bladder - 20 psi

Tank Level Float

Switch Cable (on

back side of tank)

- Connect to Processor

“Tank Electrical Connection.”

Membrane Reject Water

Tubing Connection

Operating

Pressure Gauge

Optimized Water

To Storage Tank

- 3/8” Push-To-Connect - Connect to

Optimized Water Storage Tank Inlet

Sample Port -

3/8” Push-to-Connect - Used ONLY to ush

pre lters, gather a water sample, measure

production, or drain water from storage tank.

Pressurized

Optimized Water Outlet -

1/2” gray hose

-Connect to End User Equipment

Tank Repressurization Return-

1/2” gray hose - Connect to Repressurization Assembly Outlet

MA-Q15 Mineral

Addition Cartridge

Repressurization Pump

120VAC - Plug in to standard

wall outlet.

Absolute 0.2

micron

Hydrophobic

Air-Breather/

Filter

Optimized Water

Storage Tank

- 50 gal. Atmospheric

Repressurization

Assembly Outlet

- 1/2” Hose Barb Connect to Pressurized

Water Inlet on Processor

Optimized Water to

Storage Tank Inlet - 3/8”

Push-to-Connect - Connect

to Optimized Water Outlet on

Processor.

Tank Inlet Divert Valve

- Normally in Down position. Turn handle

to Up position to divert Optimized water

to sample port.

Optimized Water

Storage Tank

- 16 gal. Atmospheric

OP350 System Installation, Operation & Maintenance 4

Installation Requirements

This section and the next provide the water, electrical

and space requirements for the OP350. Pay

special attention to the feed-water chemistry

requirements. Operating a system on water supplies

outside of these parameters may lead to premature

membrane failure. This product is for commercial

use only and must be installed and maintained in

accordance with manufacturer’s guidelines and local

regulatory plumbing and electrical codes.

Operating parameters

Typical Membrane TDS* rejection:

97+%

Feed Temperature: 40 - 100° F (4 - 38° C)

Feed pressure: 50 - 80 psi

(3.4 - 5.9 bar) at 1 gpm

Production** (at 77°F, 60 psi)

350 gals/day,

14.6 gals/hr, 0.24 gpm

Recovery: up to 33%.

IMPORTANT NOTE: The nominal production rate

is strictly dependent on feed water temperature and

pressure. Reduced temperature or pressure will

reduce production. For example: Operating pressure

of 30 psi will cut production by 50%. 48˚F feedwater

will cut production by 50%.

Location

The system should be installed indoors, in the

proximity of the equipment (within 25 feet) and

protected from the elements. Do not let the processor

or storage tank freeze or be exposed to rain or direct

sunlight.

Additional Optional Post-treatment

Treated water stored in a tank may absorb organic

compounds from the tank, which can affect water

taste and odor. If product water is for consumption, an

optional post-treatment lter, such as an OptiPure

FX or QT carbon lter, should be installed after the

tank. If used, it is best installed as close to the point of

use as possible. Other specialized post-treatment is

also available.

Feed water connection

An adequate ow and pressure of water to the unit is

essential for successful operation. Provide a dedicated

1/2” water line to the vicinity of the installation. Install

a full-ow ball valve and pressure gauge with 1/2”

female pipe thread (user supplied) for connection to

installation hardware provided with the system. A 1/2”

*TDS (total dissolved solids) create conductivity in water and are

expressed in ppm or mg/l (parts per million or milligram per liter).

**Nominal production @ 77°F (25°C) @ 500 ppm based on a 24

hr day. Actual production will vary based on variations in water

temperature, pressure, and TDS.

male pipe thread x 3/8” push-to-connect adapter is

included in the installation kit.

Drain

A drain should be located within 5 feet of the location

of the unit. Drain must allow a minimum ow of 2

gallons per minute. Compliance with most local

plumbing codes requires installation of an approved air

gap in the drain line. The drain connection should be

accessible for system set-up and service.

Electrical requirements

A power source with two outlets should be located

within 5 feet of the location of the unit.

Processor 120V, 60Hz 6 Watts

RP Pump 120V 60Hz 2 Amps

Feed-water chemistry

Feed TDS Up to 1200 ppm

Feed pH 6 - 10

Hardness 28 grains or less

Free chlorine <2 mg/l

Iron (Fe) 0.1 mg/l max.

Turbidity <0.05 NTU

Manganese 0.05 mg/l max.

Hydrogen sulde 0.0 mg/l

A water analysis must be conducted before installing

the system, or the information requested above can

be obtained from your local water utility. If your water

analysis shows that any of these parameters are not

within range, additional pretreatment and/or higher

frequency of maintenance may be required. Contact

your OptiPure distributor for assistance. The presence

of silica or occulants such as alum or cationic

polymers in the feedwater may cause membrane

fouling and may require special chemical pretreatment

or periodic membrane cleaning. Please note that

membrane failure due to fouling is not covered by the

warranty.

Storage Tank

The tank must be located within 10 feet of the water

processor unit. The oor beneath the storage tank

should be smooth, clean and free of sharp objects that

could puncture the bottom of the tank. Note: The tank

is atmospheric, with a sub-micron, hydrophobic air

breather lter.

Optimized Water Lines to Equipment

Tubing, piping and associated ttings connecting

Optimized water lines to equipment shoud be food

grade material that meets NSF Std 51 or 61 with a

minimum pressure rating of 75 PSI. Optimized water

may react with most metal piping imparting a bad

taste. Plastic pipe or reinforced opaque beverage

tubing are acceptable choices for Optimized water

distribution. The larger inside diameter tubing or hose,

the better to minimize pressure drop.

OP350 System Installation, Operation & Maintenance 5

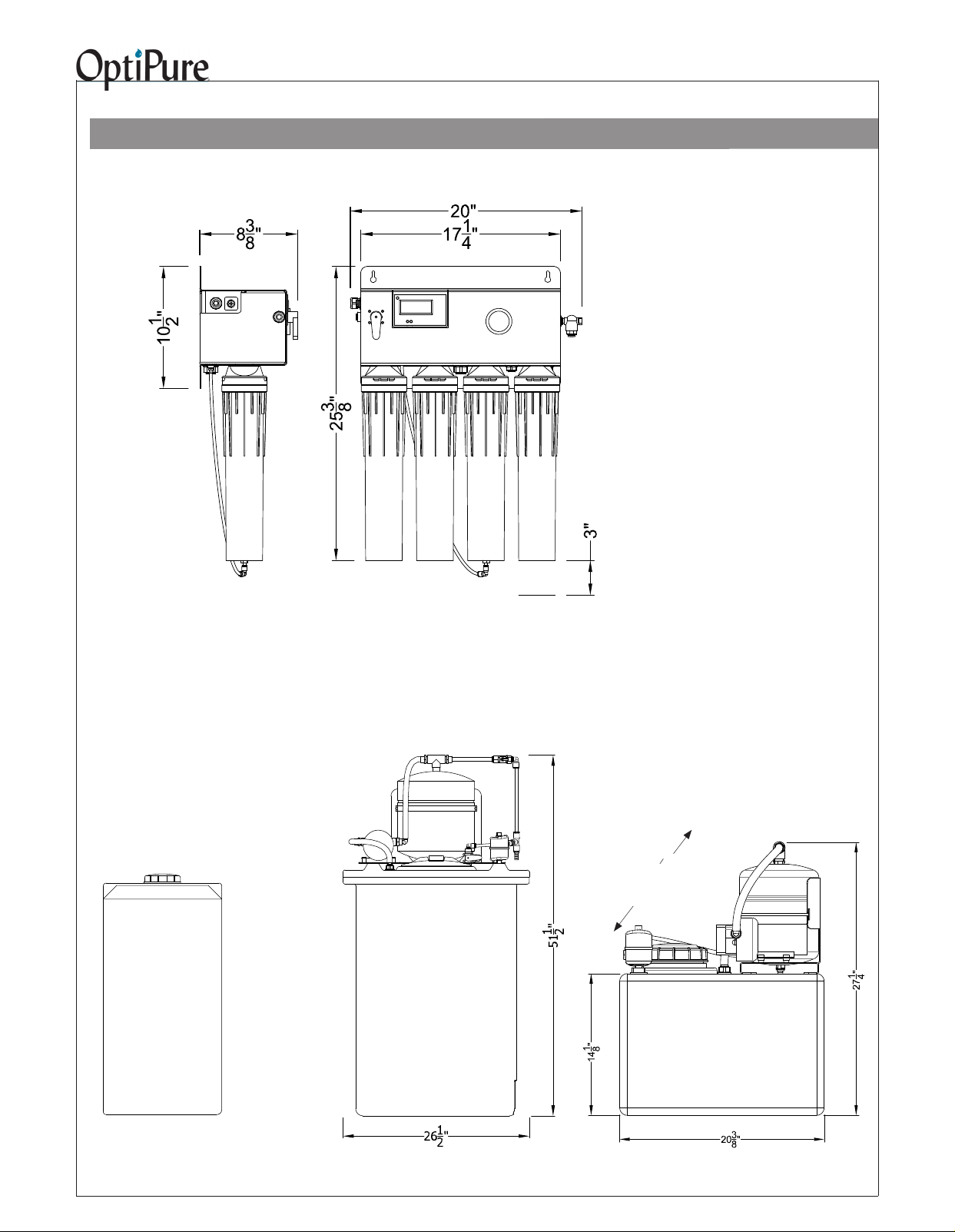

Equipment Dimensions

IMPORTANT - ALLOW A MINIMUM

OF 24” IN FRONT OF THE PROCESSOR FOR MAINTENANCE

AND SERVICE. DO NOT MOUNT

SYSTEM ABOVE THE CEILING OR

IN A LOCATION THAT IS NOT EASILY ACCESSIBLE. WHEN THE 50

GAL. TANK ASSEMBLY IS FULL OF

OPTIMIZED WATER IT WILL WEIGH

450 LBS (THE 16 GAL. TANK, 140

LBS). ALWAYS LOCATE THE

STORAGE TANK WHERE IT CAN BE

ACCESSED (OR IS ACCESSIBLE)

DURING SERVICE.

Processor

Left Side

View

Optional Atmospheric

Storage Tank

175 Gallon Tank,

31” dia. x 68” tall

Processor

Front View

Tank Assembly (50 gal.)

Allow 3”

to remove

cartridges

Tank Assembly (16 gal.)

”

1

4

Width 14

Right Side View

OP350 System Installation, Operation & Maintenance 6

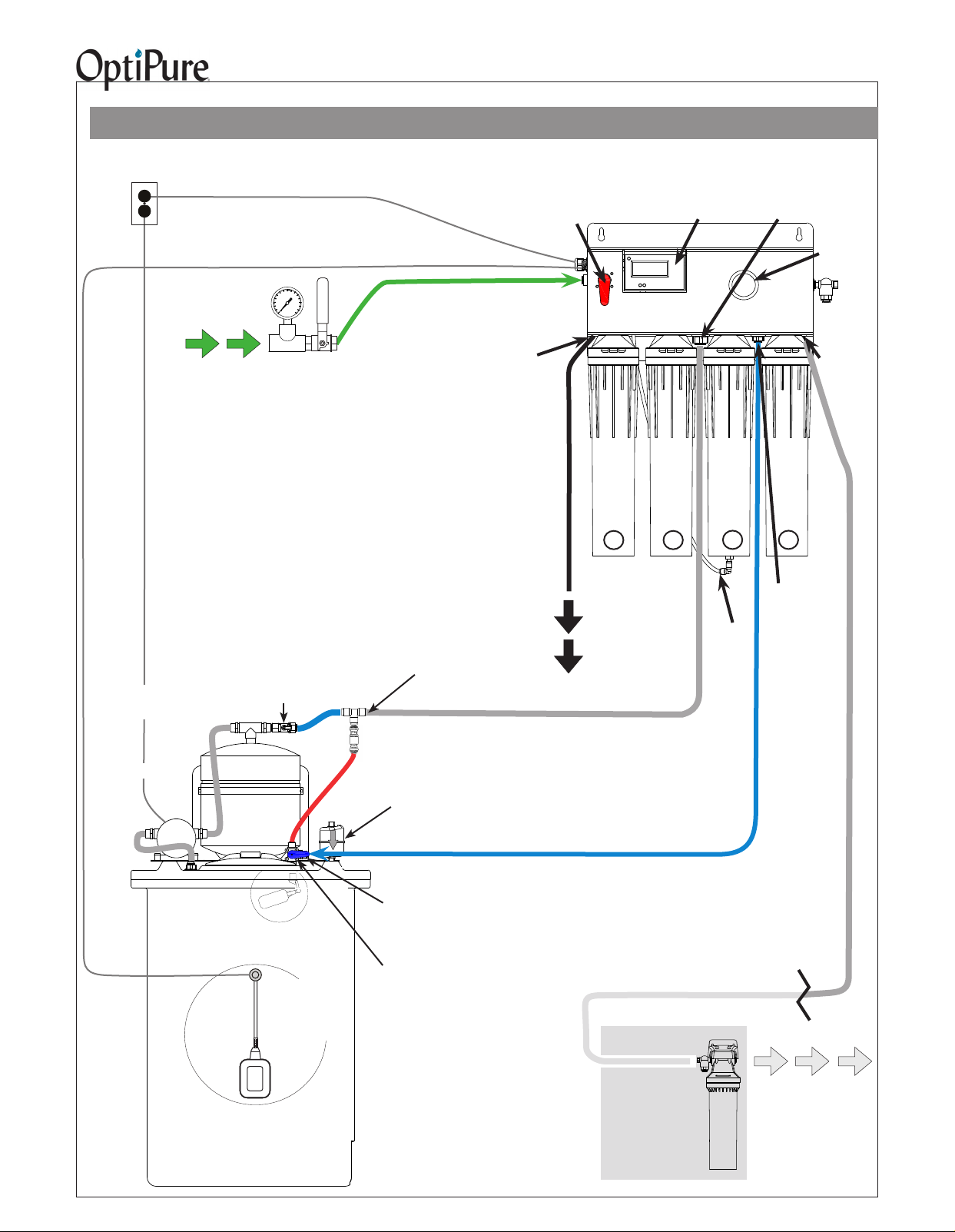

Typical Installation with 50 Gal. Atmospheric Tank

Important: Plumbing should be performed by a qualied plumber in accordance with local codes.

Tank

Repressurization

Return

Pressure

Gauge

Power

120VAC, 2A

Power Cord

Tank Switch Cable

Processor

Emergency

Bypass Valve Operating

Water Quality

Monitor

Feed

Water

When installing keep lines from the

Repressurization Assembly to the equipment as

short as possible to minimize pressure loss.

IMPORTANT - PROTECT PROCESSOR AND

REPRESSURIZATION ASSEMBLY FROM THE

ELEMENTS. DO NOT INSTALL IN DIRECT

SUNLIGHT OR WHERE EXPOSED TO FREEZING

TEMPERATURES OR RAIN. NEVER USE COPPER PIPE FOR OPTIMIZED WATER.

Repressurization

Assembly

Repressurization

Pump

120VAC

User-Supplied

Water Supply

Valve &

Pressure Gauge

Buffer Tank Valve

(Normally Open)

Buffer

Tank

Bypass

Feed Water Line -

Green - from Water Supply

Valve to Feed Water Inlet

Reject Water

Outlet

(behind lter)

Repressurization

Assembly Outlet

(Hose Barb)

Pressurized Water Line

- 1/2" Gray Hose with hose barb inserts at both

ends - from Repressurization Assy Outlet to Tank

Repressurization Return

Air

Breather

Feed

Water

Inlet

CTO-Q

Pre-Filter

Drain Line - Black -

from Reject Outlet to Drain

1

Reject

Water

(to Drain)

CTO-Q

Pre-Filter

2

AMS-QT

Membrane Cartridge

QTMA15-1

3 4

Optimized

Water

to Storage

Tank

Connection

Water Tubing

Membrane Reject

Sample

Port

Optimized

Water

Outlet

to Eqpt

Mineral Addition

Safety Float

Valve

(inside tank)

Optimized Water

Storage Tank

- 50 gal. Atmospheric

Processor

Control Float

Switch

(inside tank)

Optimized

Water to

Storage Tank

Inlet (on valve)

Tank Inlet

Divert Valve

(Valve normally

in Down position.

Turn to Up position

to bypass Repres-

surization Assy.)

Optimized Water Line - Blue

- from Optimized Water Outlet to MA PostTreatment, & from MA Post-Treatmt to Tank Inlet

Optional

Carbon

PostTreatment

Optimized Water Line - 1/2" Gray Hose

with hose barb insert - Make connection to

distribution and (optional) post-treatment.

Optimized

(Treated)

Water to

Equipment

Loading...

Loading...