BWS1500

Advanced Membrane

Separation System

Installation, Operation

& Maintenance Manual

Rev. 2.1

BWS1500-iom-manual_v2-1.indd

©2016 Procam Controls, Inc. All Rights Reserved

Manufactured By:

OptiPure Div. of

Procam Controls, Inc.

2605 Technology Drive, Bldg. 300

Plano, TX 75074

P: 972.881.9797 F: 972.422.6262

BWS1500 System Installation, Operation & Maintenance 2

General Information

Safety Warning

Electrical work should be performed by a qualied

electrician in accordance with all applicable

codes and regulations.

Service Contact

For local maintenance and service information

please contact your nearest Authorized Service

Representative. Service inquiries may be directed

to technical support at:

OptiPure div. of Procam Controls, Inc.

2605 Technology Dr. Bldg. 300

Plano, TX 75074 USA

Phone #: 972.881.9797

Fax #: 972.422.6262

E-mail correspondence to:

techsupport@optipure.net

Safety Instructions

1. Please read and follow these instructions

when connecting and using the system.

2. To avoid electrical shock, never touch the

inside of the electrical box. Only a qualied

technician should open the electrical box.

3. Never use the system if the power cord or

oat switch cable has been damaged. Do not

allow anything to rest on the power cord or

oat switch cable, and keep the cords away

from any place where people may trip over

them.

4. When disconnecting from the electric socket

hold the plug, not the cord.

5. If the processor does not function properly,

especially if there is an unusual sound or

smell coming from it, immediately unplug

the processor. Call your authorized service

representative.

Environmental Conditions

The BWS1500 is certied to operate under the

following conditions:

1. Altitude up to 2000 m.

2. Ambient temperature of 40-105°F (5 - 40°C).

3. Max relative humidity 80% at 88°F (31°C).

4. Main supply voltage not to exceed +/- 10%.

5. Installation category II.

6. Pollution degree II.

7. Indoor use only, protect from elements.

Explanation of Symbols

The following symbols are used on the water

processor. The symbols and their explanation is

given below:

Earth ground:

6. Unplug the processor and RP pump from the

AC outlet prior to any service.

7. Locate the RP Assembly as close as possible

to an AC outlet.

8. Securely bolt processor to wall before

operating.

9. Avoid cross-connections and install on cold

water supply only.

10. Use approved Air-Gaps when connecting to

drain lines.

11. Do not exceed system pressure rating and

use water hammer arrestors when water

hammer is evident.

12. Turn off Feed-Water supply before lter or

membrane cartridge replacement.

WARNING: Hazardous Voltage:

BWS1500 System Installation, Operation & Maintenance 3

Getting To Know Your System

The BWS1500 Advanced Membrane Separation System is designed specically for users that desire the ability to customize the TDS (Total Dissolved Solids) level or “Mineral Content” of the treated water. The BWS1500

utilizes a precision multi-turn Blending Valve to accomplish this with great accuracy. This system design maxi-

mizes the ability to accurately blend a calculated percentage of the ltered water with the product water exiting

the Membrane, providing an Optimized Water to your equipment with the characteristics that you desire.

120VAC

Power Cord

(Coming from bottom rear of bracket)

- Plug in to standard

wall outlet.

Emergency

Bypass Valve -

User can switch from

Optimized Water to

Untreated Water

when needed, by turning handle horizontal.

Feed water

Inlet 3/8” Push-To-Connect -

Connect to Water Supply

Valve.

3@ CTO-Q

Pre-Filters

PN: 300-05830

1 2 3

Blending

Valve - Allows precise adjust-

ment of optimized water TDS

(mineral content).

System Status Display & Bypass Switch

- LEDs show state of system. Bypass Switch turns

Processor OFF when system is in Emergency

Bypass.

Operating Pressure Gauge

Shows feed pressure only when processor is

operating (when level in storage tank is low).

Water Quality Indicator -

Operates momentarily, push purple

button to turn on. Push “IN” button

for the TDS of the water going into

your equipment. Push “OUT” button

for the TDS of the puried water

from the membrane.

Underside of Processor:

Reject Water Outlet

- 1/4” Push-to-Connect

- Connect to drain per local

regulations.

Optimized Water Outlet

- 3/8” Push-To-Connect

- Connect to Optimized Water Storage

Tank Inlet

Reject Flow Control Valve

NOTE: Never close Reject Flow Control Valve nor

limit Reject ow to less than Permeate ow!

Sample Port

- 3/8” Push-to-Connect - Used to ush pre

lters, gather a water sample, measure pro-

duction, or drain water from storage tank.

Pressurized

Optimized Water to Equipment Outlet

- 1/2” gray hose

- Connect to End User Equipment

Storage Tank/RP Return Line

-1/2” gray hose

- Connect to Repressurization Assembly Outlet

Normal

Operation

Items in green circles show a nor-

mal operating condition/position.

BWS1500 System Installation, Operation & Maintenance 4

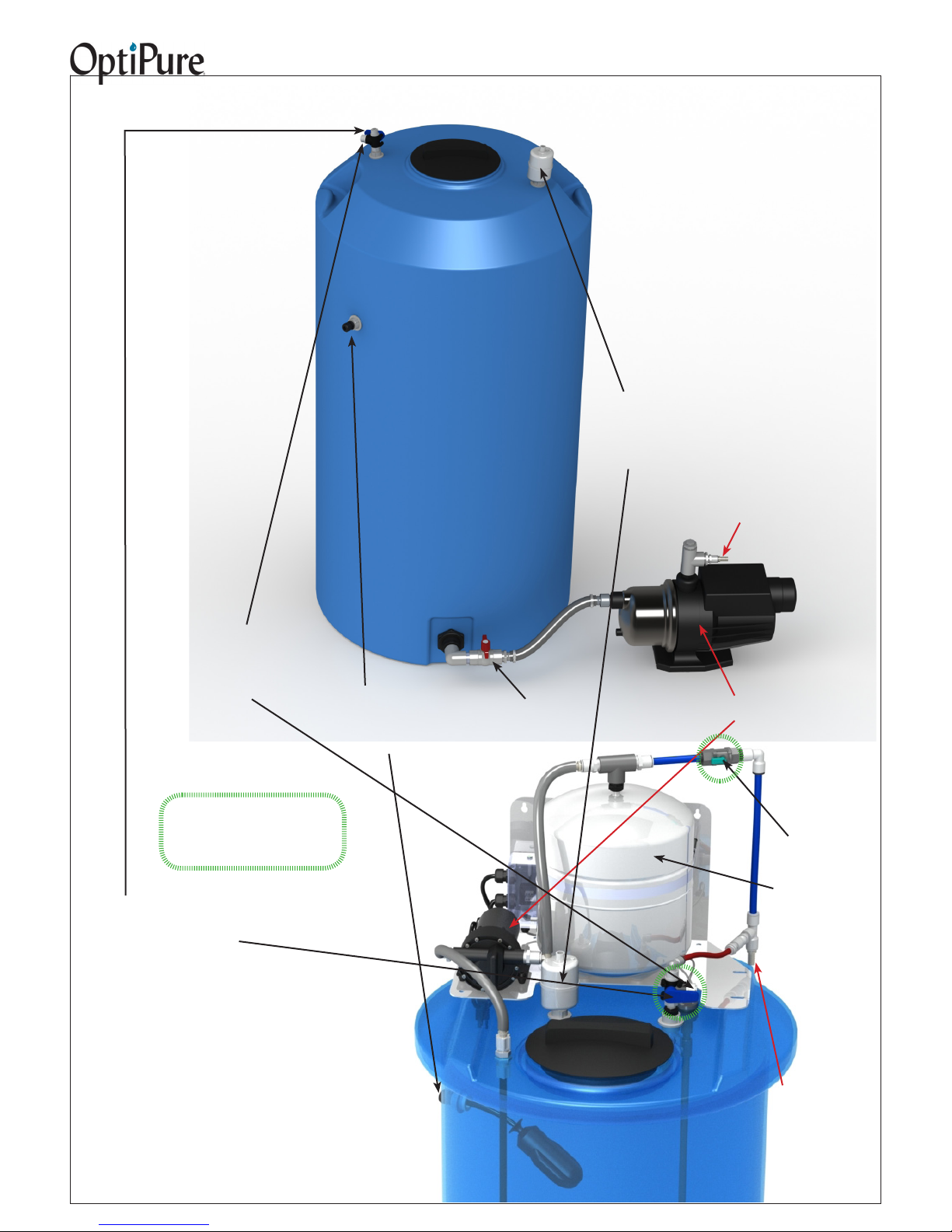

175 Gallon

Optimized Water

Storage Tank

with Separate RP

Pump

Absolute 0.2

micron

Hydrophobic

Air-Breather/

Filter

RP Pump Outlet

- Connect to Storage

Tank/RP Return Line connection on Processor

Optimized Water to

Storage Tank Inlet - 3/8”

Push-to-Connect - Connect

to Optimized Water Outlet on

Processor.

Items in green circles show a nor-

mal operating condition/position.

Tank Inlet Divert Valve

- Normally in Down position.

Turn handle to Up position

to divert Optimized water to

sample port.

High Level Float Switch

Cable

- Connect to Processor “Tank

Electrical Connection.”

Normal

Operation

50 Gallon

Optimized Water

Storage Tank/RP

Pump Assembly

Tank Outlet

Valve

Repressurization

Pump

120VAC - Plug in to

standard wall outlet.

Buffer Tank

Valve

- Shown in

normal position

Buffer Tank

- Pre-charged air

bladder - 20 psi

Repressurization Assembly

Outlet

- 1/2” Hose Barb Connect to Storage

Tank/RP Return

Line connection on

Processor

BWS1500 System Installation, Operation & Maintenance 5

Installation Requirements

This section and the next provide the water, electrical

and space requirements for the BWS1500. Pay

special attention to the feed-water chemistry

requirements. Operating a system on water supplies

outside of these parameters may lead to premature

membrane failure. This product is for commercial

use only and must be installed and maintained in

accordance with manufacturer’s guidelines and local

regulatory plumbing and electrical codes.

Operating parameters

Typical Membrane TDS* rejection:

97+%

Feed Temperature: 40 - 100° F (4 - 38° C)

Feed pressure: 50 - 80 psi

(3.4 - 5.9 bar) at 3 gpm

Production** (at 77°F, 60 psi)

1500 gals/day,

62.5 gals/hr, 1.0 gpm

Recovery: up to 40%.

IMPORTANT NOTE: The nominal production rate

is strictly dependent on feed water temperature

and pressure. Reduced temperature or

pressure will reduce production. For example:

Operating pressure of 30 psi will cut production

by 50%. 48˚F feedwater will cut production by

50%.

Location

The system should be installed indoors, in the

proximity of the equipment (within 25 feet) and

protected from the elements. Do not let the processor

or storage tank freeze or be exposed to rain or direct

sunlight.

Post-treatment

Treated water stored in a tank may absorb organic

compounds from the tank, which can affect water

taste and odor. If product water is for consumption, an

optional post-treatment lter, such as an OptiPure

FX or QT carbon lter, should be installed after the

tank. If used, it is best installed as close to the point of

use as possible. Other specialized post-treatment is

also available.

Feed water connection

An adequate ow and pressure of water to the unit is

essential for successful operation. Provide a dedicated

3/4” water line to the vicinity of the installation. Install

a full-ow ball valve and pressure gauge with 3/4”

female pipe thread (user supplied) for connection to

installation hardware provided with the system. A 1/2”

male pipe thread x 1/2” push-to-connect adapter is

included in the installation kit.

*TDS (total dissolved solids) create conductivity in water and are

expressed in ppm or mg/l (parts per million or milligram per liter).

System Reject % depends on blended water setting.

**Nominal production @ 77°F (25°C) @ 500 ppm based on a 24 hr

day. Actual production will vary based on variations in blend setting,

water temperature, pressure, and TDS.

Drain

A drain should be located within 5 feet of the location

of the unit. Drain must allow a minimum ow of 5

gallons per minute. Compliance with most local

plumbing codes requires installation of an approved air

gap in the drain line. The drain connection should be

accessible for system set-up and service.

Electrical requirements

A power source with two outlets should be located

within 5 feet of the location of the unit.

Processor 120V, 60Hz 6 Amps

RP Pump 120V 60Hz 8 Amps

Feed-water chemistry

Feed TDS Up to 1200 ppm

Feed pH 6 - 10

Hardness 28 grains or less

Free chlorine <2 mg/l

Iron (Fe) 0.1 mg/l max.

Turbidity <0.05 NTU

Manganese 0.05 mg/l max.

Hydrogen sulde 0.0 mg/l

A water analysis must be conducted before installing

the system, or the information requested above can

be obtained from your local water utility. If your water

analysis shows that any of these parameters are not

within range, additional pretreatment and/or higher

frequency of maintenance may be required. Contact

your OptiPure distributor for assistance. The presence

of silica or occulants such as alum or cationic

polymers in the feedwater may cause membrane

fouling and may require special chemical pretreatment

or periodic membrane cleaning. Please note that

membrane failure due to fouling is not covered by the

warranty.

Storage Tank/RP Pump

The tank must be located within 10 feet of the water

processor unit. The oor beneath the storage tank

should be smooth, clean and free of sharp objects that

could puncture the bottom of the tank. Note: The tank

is atmospheric, with a sub-micron, hydrophobic air

breather lter.

For a 175 Gallon Tank, the separate RP Pump must

be placed next to the tank at a height even with the

bottom of the tank, or on a stand no more than 6”

above the bottom of the tank.

Optimized Water Lines to Equipment

Tubing, piping and associated ttings connecting

Optimized water lines to equipment shoud be food

grade material that meets NSF Std 51 or 61 with a

minimum pressure rating of 75 PSI. Optimized water

may react with most metal piping imparting a bad

taste. Plastic pipe or reinforced opaque beverage

tubing are acceptable choices for Optimized water

distribution. The larger inside diameter tubing or hose,

the better to minimize pressure drop.

BWS1500 System Installation, Operation & Maintenance 6

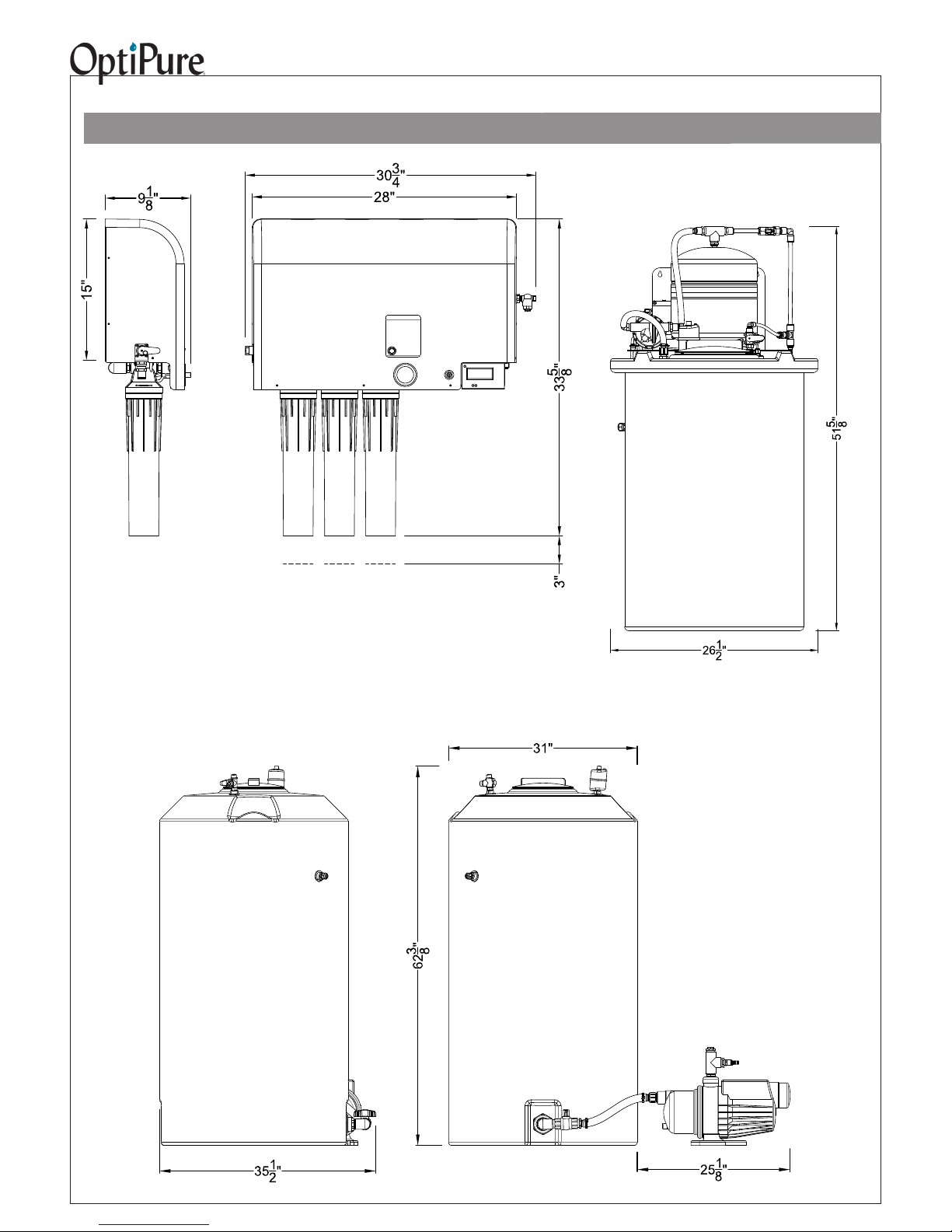

Equipment Dimensions

50 Gallon Tank

Repressurization Assembly

Processor

Left Side

Processor

Front View

View

IMPORTANT - ALLOW A MINIMUM OF 24” IN FRONT OF THE PROCESSOR FOR

MAINTENANCE AND SERVICE. DO NOT MOUNT SYSTEM ABOVE THE CEILING

OR IN A LOCATION THAT IS NOT EASILY ACCESSIBLE. WHEN THE 50 GAL. TANK

ASSEMBLY IS FULL OF OPTIMIZED WATER IT WILL WEIGH 450 LBS (THE 175 GAL.

TANK, 1500 LBS). ALWAYS LOCATE THE STORAGE TANK WHERE IT CAN BE ACCESSED DURING SERVICE.

Allow 3”

to remove

cartridges

175 Gallon Tank

with Repressurization

Pump

BWS1500 System Installation, Operation & Maintenance 7

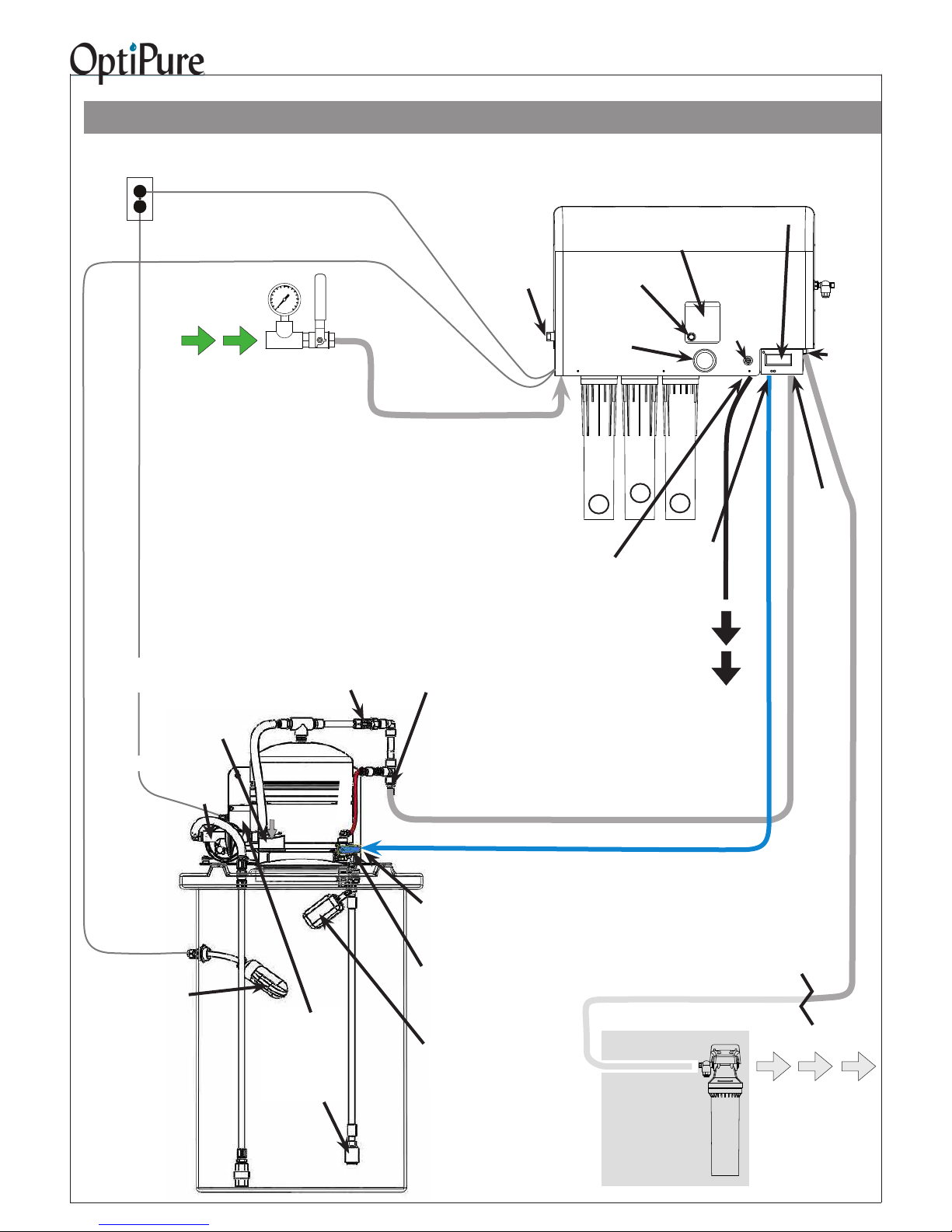

Typical Installation with 50 Gal. Atmospheric Tank

Important: Plumbing should be performed by a qualied plumber in accordance with local codes.

Power

120VAC, 2A

Tank High Level Float Switch Cable

Feed

Water

When installing, keep lines from the Processor to

the equipment as short as possible to minimize

pressure loss.

IMPORTANT - PROTECT PROCESSOR AND

TANK/RP PUMP FROM THE ELEMENTS. DO NOT

INSTALL IN DIRECT SUNLIGHT OR WHERE EXPOSED TO FREEZING TEMPERATURES OR RAIN.

Repressurization

Assembly

Power Cord

User-Supplied

Water Supply

Valve &

Pressure Gauge

Buffer Tank Valve

(Normally Open)

Emergency

Bypass Valve

Feed Water Line

- 1/2” Gray Hose with hose barb

inserts at both ends - from Water

Supply Valve to Feed Water Inlet

Repressurization

Assembly Outlet

(Hose Barb)

Processor

Operating

Pressure

Gauge

Feed

Water

Inlet

CTO-Q

1

Reject

Water

Outlet

Bypass

Switch

CTO-Q

Pre-Filter

2

(to Drain)

System

Status

CTO-Q

Pre-Filter

3

Optimized

Water

Outlet

Reject

Water

Water Quality

Monitor

Blending

Valve

-Set to

req'd

TDS

reading!

Pre-Filter

Sample

Port

Optimized

Water

to Eqpt

Storage

Tank/RP

Return

Drain Line - Black -

from Reject Outlet to Drain

Repressurization

120VAC

Processor

Control High

Level Float

Switch

(inside tank)

Air

Breather

Pump

Buffer

Tank

Low Level

Float Switch

(inside tank, with

Control Box attached to Buffer

Tank bracket)

Bypass

Pressurized Water Line

- 1/2" Gray Hose with hose barb inserts at both ends - from

Repressurization Assy Outlet to Storage Tank/RP Return

Optimized Water Line

Optimized

Water to

Storage Tank

Inlet (on valve)

Tank Inlet Divert Valve

(Valve normally in Down

position. Turn to Up position

to bypass Repressurization

Assy.)

Safety Float

Valve

(inside tank)

- Blue - from Optimized Water Outlet to Tank Inlet

Optional

Optimized Water

Storage Tank

- 50 gal. Atmospheric

Carbon

PostTreatment

Optimized Water Line - 1/2" Gray Hose

with hose barb insert - Make connection to

distribution and (optional) post-treatment.

Optimized

(Treated)

Water to

Equipment

BWS1500 System Installation, Operation & Maintenance 8

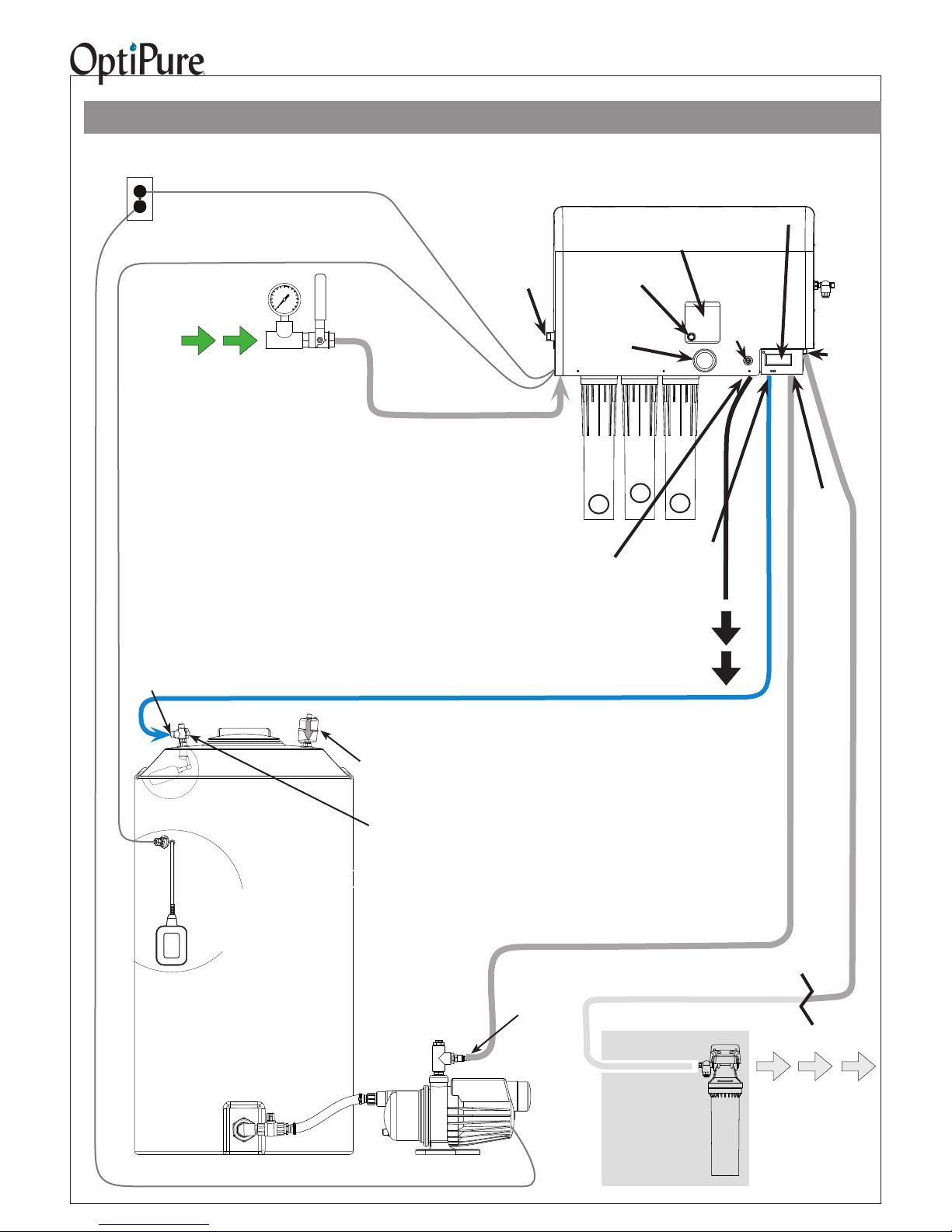

Typical Installation with 175 Gal. Atmospheric Tank

Important: Plumbing should be performed by a qualied plumber in accordance with local codes.

Power Cord

When installing, keep lines from the Processor to the

Equipment as short as possible to minimize pressure loss.

IMPORTANT - PROTECT PROCESSOR AND TANK/RP PUMP

FROM THE ELEMENTS. DO NOT INSTALL IN DIRECT

SUNLIGHT OR WHERE EXPOSED TO FREEZING TEMPERATURES OR RAIN.

Storage Tank/

Repressurization Pump

Optimized Water to

Storage Tank Inlet (on valve)

Power

120VAC, 2A

Feed

Water

Power Cord

High Level Switch Cable

User-Supplied

Water Supply

Valve &

Pressure Gauge

Emergency

Bypass Valve

Feed Water Line

- 1/2” Gray Hose with hose barb

inserts at both ends - from Water

Supply Valve to Feed Water Inlet

Processor

Operating

Pressure

Gauge

Feed

Water

Inlet

CTO-Q

1

Reject

Water

Outlet

Bypass

Switch

CTO-Q

Pre-Filter

2

(to Drain)

System

Status

CTO-Q

Pre-Filter

3

Optimized

Water

Outlet

Reject

Water

Water Quality

Monitor

Blending

Valve

-Set to

req'd

TDS

reading!

Pre-Filter

Sample

Port

Optimized

Water

to Eqpt

Storage

Tank/RP

Return

Drain Line - Black -

from Reject Outlet to Drain

Safety Float Valve

(inside tank)

Processor Control

High Level Float

Switch

(inside tank)

Optimized Water

Storage Tank

- 175 gal. Atmospheric

Tank Outlet

Valve

Optimized Water Line

- Blue - from Optimized Water Outlet to Tank Inlet

Air

Breather

Tank Inlet Divert Valve

(Valve normally in Down

position. Turn to Up position to

measure water production.)

Pressurized Water Line

- 1/2" Gray Hose with hose barb inserts at both ends - from

Repressurization Assy Outlet to Storage Tank/RP Return

Repressurization

Pump

120VAC

RP Outlet

Optional

Carbon

PostTreatment

Optimized Water Line - 1/2" Gray Hose

with hose barb insert - Make connection to

distribution and (optional) post-treatment.

Optimized

(Treated)

Water to

Equipment

BWS1500 System Installation, Operation & Maintenance 9

Outside edge of

processor bracket

Plywood anchored to wall

11”

26.5”

27.75”

Wall Mounting

Before beginning installation of the system, remove the

plastic cover from the BWS1500 processor. Replace

cover at the end when installation and adjustments are

complete.

The processor should always be mounted where it is wellsupported, either using anchors in a cement wall, or using

the support of studs in a wall-board wall. Never mount it

directly to sheet-rock alone. Instead, mount it on a sheet

of plywood which is anchored to the wall studs, as shown

above.

Four user-supplied bolts or screws with a head diameter

between 3/8” and 1/2” (which will t into the keyholes in the

system bracket, but will not slip out when tightened) should

be used to hang the system. This will allow the unit to be

lifted off the bolts, if necessary for maintenance, without

removing all the bolts from the wall.

Mark the mounting screw locations with dimensions as

shown above. BE SURE TO ALLOW 3” BELOW THE

CARTRIDGES TO ALLOW FOR REMOVAL. Screw the

four bolts or screws in place, leaving approximately 1/4”

clearance between the bottom of each screw head and the

wall. Position the system over the mounting screws, and let

the bracket slip down into the keyholes. Tighten the screws.

Tighten all screws.

System Installation

Note: Do not plug in the power cord from the RP pump

until completing the section “System Start-Up”.

Refer to “Typical Installation” diagram on pages 7 & 8,

and “How to Use Our Quick-Connect Fittings” on the

last page of this manual, when making the following

connections.

A feed water ball valve and pressure gauge (user supplied)

should be installed to provide water to the system FEED

WATER INLET with the 1/2” gray hose (supplied). Hose,

tubing and ttings for making connections between the

processor, storage tank and drain are supplied in the

installation kit. Hose and tubing will need to be cut to

appropriate lengths.

1. Remove the tank lid. Inside the tank, the oat

valve may be secured for shipping. Remove any

wrapping on the oat to allow it to hang and move

freely.

2. DRAIN: Connect the 3/8” black tubing from the

installation kit to the REJECT WATER OUTLET on

the processor. Run the line to an appropriate drain.

15”

4. PROCESSOR TO TANK: Connect a piece of the

NOTE: When cutting the tubing, use a sharp tubing

cutter or blade and make a clean, straight cut before

inserting into a push-connect tting. When routing

tubing, do not make sharp bends or crimp the tubing.

5. TANK/RP PUMP - 175 Gallon Storage Tank Only:

6. TANK/RP PUMP TO PROCESSOR: Using two of the

7. HIGH LEVEL SWITCH CABLE: Route the cable coming

Observe local plumbing codes and supply an

appropriate air gap. (Any ttings for connecting to

the drain will need to be supplied by the customer.)

Fix tubing in place at the drain.

3. FEED WATER: Apply 3 wraps of Teon tape to the

1/2” FPT x 1/2” push-connect tting (supplied).

Screw the tting into the Feed Water Supply Ball

Valve and tighten (DO NOT OVERTIGHTEN).

Insert one of the supplied 1/2” Hose Insert x 1/2”

Tube Stem ttings into the 1/2” gray hose and

secure it with a hose clamp. (See “Hose Fitting

Assembly” photo.) Insert this tting into the pushconnect tting at the Feed Water Supply. Route

the hose to the Processor and cut to appropriate

length. Using another Hose Insert x Tube Stem

tting, connect the other end of the hose to the

FEED WATER INLET located on the Bypass Valve

on the left side of the Processor.

3/8” blue tubing to the OPTIMIZED WATER OUTLET

tting on the Processor. Connect the other end of this

tubing to the OPTIMIZED WATER INLET on the INLET

DIVERT VALVE (see photo) at the top of the Storage

Tank.

Place the pump near the storage tank, on the oor or

on a stand no more than 6” above the bottom of the

tank, with the pump inlet towards the tank. Using the

supplied 1” hose and large hose clamps, connect the

tank outlet hose barb to the pump inlet hose barb.

1/2” hose barb inserts (supplied), a piece of 1/2” gray

hose, and two hose clamps, connect hose from the

REPRESSURIZATION ASSEMBLY OUTLET on the

50 Gallon Repressurization Assembly - for the 175

Gallon Tank, the push-connect tting in the tee on top

of the RP Pump - to the STORAGE TANK/RP RETURN

LINE connection on the Processor.

from the high level switch through the hole in the rear

Hose Fitting Assembly

50 Gallon Storage Tank Connections

BWS1500 System Installation, Operation & Maintenance 10

Repressurization Assy

Outlet

Tank Inlet

Divert ValveShown in the

normal positon

Optimized

Water Inlet

Route cable from high

level switch from below,

up through the same hole

that the power cord passes

through (left rear of Processor metal bracket).

Tank Inlet

Divert ValveShown in the

normal positon

Optimized

Water Inlet

175 Gallon Storage Tank Inlet

Connecting 175 Gallon Storage Tank & RP Pump

left of the Processor bracket, to the electrical control

box on the Processor. Connect the AMP connector to

the HIGH LEVEL SWITCH connector located on the left

side of the box. (See photos.)

8. OPTIMIZED WATER TO EQUIPMENT: Connect a piece

of 1/2” ID gray hose to the OPTIMIZED WATER TO

EQUIPMENT outlet on the Processor with a 1/2” hose

barb insert and clamp (supplied). At a later time, the

other end of this line will be connected to the distribution

line that will deliver Optimized Water to the equipment,

but for now leave the line loose and route the loose end

of the gray hose into a drain or bucket. (Make certain

the hose length will reach the storage tank; this will

be required for the Start-Up procedure.) Prepare any

necessary plumbing to make the connection between

the 1/2” hose and the distribution line, which will be

completed in “Connect to Equipment”.

NOTE: If Post Filtration is used, it will be installed between

Routing High Level Switch Cable

Plug high level

switch cable into

connector on control

box.

High Level Switch Cable Connection

the Optimized Water Outlet and the designated equipment.

Install QT Cartridges

NOTE: Before installing the QT Cartridges make sure to

remove the plugs in the QT heads on the Processor.

Insert the CTO-Q cartridges into QT heads 1, 2 & 3 (starting

from the left side of the Processor) and turn to align arrows.

1 2 3

BWS1500 System Installation, Operation & Maintenance 11

Optional RP Assembly Location

For the 50 Gallon Tank only, the Repressurization Pump

and Buffer Tank assembly is on a stand that can be remote

from the storage tank. If this type of installation is required,

the RP Assembly should be built as a remote unit from the

OptiPure, with additional installation instructions supplied.

System Start-Up

Refer to illustrations “Typical Installation” (pages 7 & 8) and

“Switch Testing” (last page of this manual).

IMPORTANT: Before proceeding, position the Processor

EMERGENCY BYPASS VALVE in the “SERVICE” position,

and position the TANK INLET DIVERT VALVE in the down

position (Blue Valve Handle pointing sideways). For a 50

Gallon Tank, assure that the BUFFER TANK VALVE is

open. For a 175 Gallon Tank, ensure that the tank outlet

valve at the bottom of the tank is open (handle parallel to the

valve body).

1. Open the WATER SUPPLY VALVE. Plug the processor

power cord into a 120VAC outlet. Allow the lter

housings to ll, and then the pump will turn on. (Water

will ow into the tank and from the end of the 3/8” black

tubing routed to the drain. Allow several minutes to

ush the system until water ows smoothly into the tank

and also from the drain line. Check all of the plumbing

connections and correct any leaks if necessary.

2. Test the high level oat switch. With the tank lid

removed and the system running, raise and tilt the

processor control oat (in the tank). As you raise the

oat upward, the ball inside the oat will roll from one

end of the oat to the other, activating the switch.

• With the oat in the upright position, the water

processor should shut off the water ow. The pump

should turn off and there should be an LED light

indicating “Tank Full” on the control box.

• Lower the oat allowing the ball to drop back down.

The water should begin owing again after a delay.

3. The Storage Tank must have about 14 gallons in it to

start-up and purge the Repressurization Assembly. You

can quickly ll the storage tank to the appropriate

level using the “System Bypass” on the processor.

To do this:

• Route the 1/2” gray hose from the processor

OPTIMIZED WATER TO EQUIPMENT outlet directly

into the storage tank lid opening.

NOTE: Before performing the next step, be certain to

rmly grip the gray hose.

• Turn the EMERGENCY BYPASS VALVE on the

processor to the “BYPASS” position. This will allow

feed water to bypass the processor and quickly ll the

storage tank.

• When the tank lls approximately 14 gallons

(1/3 full with the 50 gal. tank, or 2 feet of water

in the 175 gal. tank), return the PROCESSOR

EMERGENCY BYPASS VALVE to the “SERVICE”

position.

NOTE: Before performing the next step, be certain to

rmly grip the gray hose.

4. Plug the power cord from the RP pump into the outlet.

For a 175 Gallon Tank, turn on the RP Pump (button

on top of pump). Water should begin to ow rapidly from

the Storage Tank to the Processor and back into the

Storage Tank through the gray hose. Allow the pump

to recirculate the water for several minutes until all the

air is purged from the Repressurization Assembly (50

Gallon Tank), or from the RP Pump (175 Gallon Tank).

As the air is purged, the pump will begin to run more

smoothly and the water owing from the gray hose will

become steady.

5. Unplug the RP Pump cord.

Connect to Equipment

Refer to the illustration “Typical Installation” on pages 7 & 8.

1. Remove the 1/2” gray hose that was routed into the

storage tank (from the Optimized Water Outlet at the

Processor) and make the connection to the distribution

line that delivers Optimized Water to post-treatment (if

used) and to designated equipment.

2. Ensure that any manual or automated valves on the

connected equipment are closed. Plug the RP Pump

power back in (and turn it on if a 175 Gallon Tank). The

pump will run and build pressure (on a 50 Gallon Tank,

it will ll the Buffer Tank until the pressure in the Buffer

Tank reaches 70 psi), and then the RP Pump will shut

off.

3. Open downstream valves at the equipment to allow

water to ow and air to purge through the post-treatment

(if used) and from the distribution lines. When purging

distribution lines do not allow the water level in the

storage tank to drop below the bottom outlet tting

(on 175 Gallon Tank). On a 50 Gallon Tank, the pump

will shut off automatically if the water level drops

too low. (Add more water to the tank if necessary.)

Once distribution lines are ushed and all air is purged,

close the equipment valves. When there is no demand

for water the RP Pump will shut off automatically.

4. Before proceeding, follow these steps to empty the

storage tank of untreated feed water:

• Connect a piece of 3/8” blue tubing into the push-to-

connect tting of the SAMPLE PORT VALVE on the

right side of the processor, and route the other end of

the tubing into a drain or bucket.

• Open the Sample Port Valve to drain water from the

storage tank. When the pump begins to suck air (or,

with a 50G tank, it shuts off), close the Sample Port

Valve.

5. Replace and tighten the lid onto the storage tank.

System Blend Adjustment

IMPORTANT: The TDS Blend must be properly adjusted

before operating the connected equipment. If you do

not know the “TARGET TDS” SET THE BLEND “IN”

between 60 and 80. The owner/operator should consult

with their OptiPure Dealer or contact the OptiPure factory for

assistance in determining an appropriate TDS Target Range.

An improper TDS Blend setting or failure to properly

maintain the system can cause damage to equipment.

Factors that can impact the TDS of the Optimized Water

include changes in water pressure and temperature,

BWS1500 System Installation, Operation & Maintenance 12

seasonal changes in water quality, and municipal source

blending practices. To assure maintaining your target TDS

range year-round we recommend periodically checking the

“IN” TDS and making adjustments as needed.

Optimized Water TDS - Blending Adjustment

1. Allow the system to operate for at least 5 minutes before

continuing to Step 2.

2. Push the purple “POWER” button on the Water

Quality Monitor located on the upper left corner. It will

immediately display the “IN” or Optimized Water - TDS

(Total Dissolved Solids) in PPM (parts per million). By

adjusting the blend valve you are able to change the

“IN” TDS to the desired Target Range.

3. Within 30 seconds, push the “OUT” button to display the

Permeate Water TDS (from the RO membrane).

4. If the “IN” TDS is outside of the desired range:

• Turn the Blending Valve knob counter-clockwise to

open the Blending Valve, increasing the amount of

Filtered Water blending with the RO water, thereby

increasing the TDS of the Optimized Water.

• Turn the Blending Valve know clockwise to close the

Blending Valve, decreasing the amount of Filtered

Water blending with the RO water, thereby decreasing

the TDS of the Optimized Water.

5. Once the desired TDS is obtained allow the system

to run for several minutes, periodically checking the

“IN” TDS. Make smaller incremental adjustments as

necessary until the TDS “Target” is achieved.

Complete the Installation

Transition to Owner/Operator

The FINAL STEP is to meet with the Owner/Operator,

familiarize them with the system and complete the Post-

Installation Check List.

The system is now in “normal operating” mode and

the storage tank will ll with Optimized Water from the

Processor. Complete the “Post Installation Checklist” to

Conrm Normal Operation and System Settings.

Allow the storage tank to ll before beginning operation

of the connected equipment.

Emergency Bypass Operation

The System Bypass is used for any interruption of Optimized

Water ow (such as lter change or component failure), to

bypass the processor and RP assembly and allow ow of

tap water to the equipment. To place the system in Bypass

mode, place the Bypass Switch on the Controller in the

“System Disable” position to turn off the Processor Pump.

Unplug or turn off the RP Pump. Turn the Emergency Bypass

Valve on the Processor to the “System Bypass” position.

When normal operation is restored, toggle the Bypass

Switch, plug in/turn on the RP Pump, and turn the Bypass

Valve to the “Service” position.

What are all those parts and what do they do?

This section will give you an overview of how the

system works. Refer to diagram on following page.

• Incoming water is ltered by the prelters (1), which

remove sediment, chlorine and organics.

• When the Emergency Bypass Valve (2) is in the normal

SERVICE mode, water ows through the Processor.

When the Bypass Valve (2) is in System Bypass mode,

the water is diverted directly out to the equipment,

bypassing both the Processor and the Tank/RP Pump.

• When water in the Storage Tank (3) is at a low storage

level, the High Level Float Switch (4) drops, causing the

Switch to close, causing the Solenoid Valve (5) in the

Processor to open and allowing ltered water to ow

through the Processor. The Pressure Switch (6) closes

when there is sufcient water pressure to operate the

system, allowing the Pump (7) to operate, pressurizing

the water owing to the Membrane (8). The Membrane

feed water pressure is indicated by the Operating

Pressure Gauge (9). Some ltered water is also diverted

away through the Blending Valve (10).

• The water owing to the Membrane (8) is split by the

Membrane into a pure water stream (“permeate”) and

a reject water stream. The Pressure Regulator Valve

(11) allows some of the reject water to recirculate back

to the Pump (7). The rest of the reject water, controlled

by the Reject Flow Control Valve (12), ows out to the

drain. Recirculating a portion of the reject water causes

a higher ow velocity through the Membrane, serving to

clean the Membrane surface and increase Membrane

life.

• The pure water stream from the Membrane continues

through the Permeate Check Valve (13), blends with the

metered ltered water from the Blending Valve (10) to

create an Optimized water stream which then goes on to

the Storage Tank (3) through the Tank Inlet Divert Valve

(14) on top of the Tank. Air in the tank is displaced by

the incoming water and vented out of the Sub-Micron Air

Breather (15).

• When the tank completely lls, the High Level Float

Switch (4) rises, causing the switch to open, causing the

Solenoid Valve (5) to close, stopping the ow through

the Processor.

• When the “IN” button is actuated on the Water Quality

Monitor (16), it measures the TDS of the Optimized

Water in the Optimized Water Line going to the storage

tank. When the “OUT” button is actuated, the Water

Quality Monitor (16) indicates the TDS of the pure water

BWS1500 System Installation, Operation & Maintenance 13

Feed

Processor

2

21

To User

Equipment

16

9

5

1

8

11

6

7

12

10

13

18

19

17

22

23

14

4

24

20

15

3

stream exiting the Membrane (8). The Water Quality

Monitor is battery powered with two AA batteries. It will

automatically shut-off after 30 seconds.

• As long as the Low Level Float Switch (24)

detects a minimum level of water in the Tank, the

Repressurization (“RP”) Pump (17) is enabled to draw

from the Atmospheric Storage Tank (3) and dispense

Optimized water by way of the Buffer Tank (19 - on a

50 Gallon Tank only) through the Processor and the

Pressurized Water Check Valve (18). (Note that, due

to the design of the RP Pump used with the 175 Gallon

Tank, no Buffer Tank and no Low Level Float Switch are

needed.) When the pressure drops in the Buffer Tank

(with 50 G Tank) or downstream (with 175 G Tank), the

RP Pump runs until pressure is restored, then shuts off.

• The Optional Post-Treatment Filter (20) is designed

to provide additional treatment based upon specic

application requirements. For beverage applications an

activated carbon lter is recommended.

• As Optimized Water is dispensed from the storage tank

by the Repressurization Pump (17), air is replaced

in the tank through the Sub-Micron (0.2 micron) Air

Breather (15).

• If the RP Pump (17) fails, water ow can be restored to

the equipment by turning the Emergency Bypass Valve

(2) to the “SYSTEM BYPASS” position. (The Bypass

Switch on the Controller must also be placed in the

“System Disable” position.) This allows tap water to

bypass the processor and RP assembly.

To Drain

• A Sample Port (21) allows sampling and draining of

Optimized Water from the Tank (drain by closing the

Feed Water Valve or unplugging the Processor to stop

lling of the Tank, and opening Sample Port) .

• The Tank Inlet Divert Valve (14) and/or Sample Port (21)

additionally provide(s) the ability to measure membrane

production. With a 175 Gallon Tank/RP Pump, this is

done by turning the Tank Inlet Divert Valve (14) to the

bypass or UP position and sampling at the Tank Inlet

Divert Valve. With a 50 Gallon Tank/Repressurization

Assy, this is done by closing the Buffer Tank Valve (22),

turning the Tank Inlet Divert Valve (14) to the bypass

or UP position and opening the Sample Port (21). This

diverts the permeate through the Bypass Check Valve

(23) and back to the Sample Port (21) at the Processor

where permeate can be sampled. Note that on a 175

Gallon Tank/RP Pump, there is neither a Buffer Tank

Valve (22) nor Bypass Check Valve (23). Instead, there

is a Tank Outlet Valve at the bottom of the Tank.

Repressurization Pump Details

50 Gallon Tank

The Repressurization Assembly with a 50 Gallon Storage

Tank includes a diaphragm pump controlled by an internal

Pressure Switch, and a Buffer Tank between the Pump and

the downstream equipment maintains downstream pressure. Water demand for downstream equipment is directly

supplied from the Buffer Tank, and deman can go on and

BWS1500 System Installation, Operation & Maintenance 14

off as necessary. The RP Pump is not directly affected by

downstream demand, and downstream equipment is also

not affected by the automatic starting or stopping of the RP

Pump. When the pressure drops sufciently in the Buffer

Tank, the Pump starts automatically and repressurizes the

Buffer Tank. The operating pressure for the Buffer Tank is

preset (to 70 psi) and is NOT eld adjustable. The pump

also incorporates check valves to keep the Buffer Tank and

downstream line pressurized. The pump is equipped with

auto-reset, thermal overload protection and is designed for

intermittent duty.

If the pump runs erratically, allow the pump to run to

open drain with valve fully open to purge air from the

pump head. Disconnect the power and reconnect several times to facilitate air purging.

The pump will prime only if all the pressure is relieved from

the outlet port. The pump is self-priming up to 11 ft. The

pump can run dry but will overheat and the pump overload

will shut the pump off.

175 Gallon Tank

The Repressurization Pump with a 175 Gallon Storage Tank

is a demand-controlled pump that maintains pressure downstream at all times. It shuts off automatically when there is no

demand for water.

Storage Tank Level Controls

(See also the Electrical Schematic at the end of this manual.)

When the Storage Tank becomes full, the High Level Float

Switch shuts off the Processor, preventing ow to the Tank.

50 Gallon Tank Low Level Control

For a 50 G Tank, if the tank is

empty, the Low Level Float Switch

automatically shuts off the RP

Pump. As long as the power cord

from the Tank/RP unit is plugged

in, and there is a minimal amount

of water in the Storage Tank, the

green light is illuminated on the

Control Box (attached to the Buffer

Tank bracket), indicating that power

is supplied to the RP Pump. This

light means the RP unit is enabled,

even though the RP Pump may

be automatically turned off when

the Buffer Tank is pressurized and

operation of the Pump is not needed.

175 Gallon Tank Low Level Control

Low Level Float Switch

Indicator light

As long as the Pump is placed at a height even with the bot-

tom of the tank, it will have a ooded suction from the tank

and will not require priming.

For a 175 G Tank, there is no Low Level Float Switch. The

RP Pump will automatically shut off if there is no water in the

tank.

BWS1500 System Installation, Operation & Maintenance 15

BWS1500 Processor Components

Black Tubing -

Reject Water Line

Motor -

PN: 701-01203

Pump -

PN: 700-82014

Bypass Valve -

PN: 520-12250

Membrane -

Housing PN: 205-84030

Membrane PN: 204-44021

“OUT” Permeate

Conductivity Probe

Permeate

Check Valve -

PN: 524-01030

Pressure Switch -

PN: 564-00111

Solenoid Valve -

PN: 714-10150

“IN” Optimized

Water Conductivity

Probe -

Sample Port

Valve -

PN: 520-12223

Pressurized

Water Check

Valve -

PN: 524-01035

Reject Flow

Control -

PN: 514-00440

RO Controller -

w/Tank Connection

PN: 764-31017

Pressure Gauge -

PN: 530-20018

CTO-Q PreFilters (x3) -

PN: 300-08115

Blending Valve -

PN: 514-00442

Water Quality Monitor -

PN: 530-40112

Pressure Regulator -

PN: 514-00555

Low-Pressure Spring PN:

514-00556

Red Tubing -

Blend Water Line

BWS1500 System Installation, Operation & Maintenance 16

50 Gallon Tank RP Assembly Components

Low Level

Control Relay -

(in Control Box)

PN: 740-01290

RP Pump -

PN: 704-35513

Air Breather -

PN: 300-40005

Tank Inlet Divert Valve -

PN: 520-12225

In normal operation, handle should be

down (horizontal). For measuring water

production or purging air from system,

turn Divert Valve handle up.

High Level Float Switch -

(inside tank)

PN: 740-01120

Controls Processor. When

tank is full, oat switch is in up

positon and switch inside oat

is open, causing Processor to

shut off.

Buffer Tank -

PN: 34050004

Float Valve -

(inside tank

beneath inlet)

PN: 520-01203

Buffer Tank Valve -

PN: 520-14501

Tank Bracket -

PN: 594-80510

Bypass

Check Valve-

PN: 524-01030

RP Assy

Outlet -

1/2” Hose Barb

Insert,

PN: 550-08730

Connect to

equipment inlet.

Optimized Water Inlet -

Connect line from Optimized

Water Outlet on BWS1500

processor.

Foot Valve -

(inside tank, at

base of pump

suction tube)

PN: 520-10221

Low Level

Float Switch -

(inside tank)

PN: 740-01116

50 Gal Storage Tank -

PN: 570-00056

BWS1500 System Installation, Operation & Maintenance 17

175 Gallon Tank/RP Pump Components

Tank Inlet Divert Valve -

PN: 520-12225

In normal operation, arrow on handle of valve

should point down towards tank. For sampling

Optimized Water Quality or purging air from

system turn Divert Valve handle so the arrow

points up towards the Sample Port.

Optimized Water Inlet -

Connect line from Optimized

Water To Storage Tank Outlet

on BWS1500 processor.

175 Gal Storage Tank -

PN: 570-00062

Float Valve -

(inside tank)

PN: 520-01203

Air Breather -

PN: 300-40005

High Level Float Switch -

(inside tank)

PN: 740-01120

Controls Processor. When tank is

full, oat switch is in up positon and

switch inside oat is open, discon-

necting power to Processor.

Tank Outlet

Valve Assy -

Connect to RP Pump

with 1” hose

RP Pump -

PN: 704-10335

BWS1500 System Installation, Operation & Maintenance 18

Product/Reject Flow Rate Adjustments

Introduction

The Reverse Osmosis membrane uses pressure to allow

pure water molecules to lter through its semipermeable

membrane separating pure water from dissolved solids

(salts) and other contaminants. In essence the membrane

splits feed water into two separate streams. One stream is

the water produced for use (product or pure water), and the

other contains the salts and contaminants ltered out by the

membrane (reject) carried away to the drain. The OptiPure

BWS1500 is designed to produce water at a 30% recovery

rate which means it uses water at a ratio two gallons of

reject water for each gallon of pure water produced. This is a

Product/Reject Ratio of 1/2.

The “pure water” produced by the membrane is not always

appropriate for use with food service equipment. The

BWS1500 system also allows blending ltered water with

the pure water to produce Optimized Water which can be

adjusted to provide the ideal characteristics for food service

equipment applications. Instructions for blending Optimized

water are on page 11.

Each system is adjusted at the factory for the proper

operating parameters.

In most cases the factory setting should not be changed.

However, due to certain conditions, an adjustment may

produce better operating efciency and membrane

performance. Conditions that can inuence the ideal

Product/Reject Flow Rate Ratio include feed water quality

(TDS level, Turbidity and specic contaminants such as

iron and silica), water temperature and water pressure. The

determination of whether to make a Product/Reject Flow

Rate adjustment is complex. An understanding of your water

chemistry and operating conditions is necessary in order

to safely deviate from the factory setting. It is strongly

recommended that you contact your OptiPure dealer or

the factory for assistance before changing the factory

setting.

Permeate Flow Rate Adjustment

The processed water (permeate) ow rate is directly

proportional to the system operating pressure (e.g. higher

pressure = higher ow, lower pressure = lower ow). The

system is set at the factory for proper operation at 70° F. The

operating pressure can be increased to compensate for low

temperature feed water, but only if the water temperature

will not later go up without a corresponding adjustment

being made to the operating pressure. The maximum safe

permeate ow rate is 1200 gpd/50 gph/0.83 gpm (4500

liters per day/190 liters per hour/3200 milliliters per

minute). Under no condition is it safe to operate the system

at higher permeate ow rates. Likewise, if your water

temperature is higher than 70° F, you should reduce the

operating pressure to bring the permeate ow rate down

to 1200 gpd. If you increase the operating pressure to

compensate for cold water in the winter, be sure to reduce

the pressure once the water warms up. Before making any

adjustment, turn the Blending Valve clockwise until it is

closed all the way. Remove Processor plastic cover. Locate

the pressure regulator on the right side of the Processor (see

photo). Loosen the lock nut on the regulator handle.

NOTE: The handle of the regulator should never be

loosened by more than a turn or two, as loosening all

the way will allow the handle to come off and water to

spray out of the regulator.

Do not raise the operating pressure higher than 150 psi.

To increase the system operating pressure (and permeate

ow rate), turn the knob of the pressure regulator clockwise.

To decrease the pressure, turn it counterclockwise. After

achieving the desired pressure, tighten the lock nut on the

regulator. See “Measuring Product Flow Rate” on the next

page.

Reject Flow Rate Adjustment

The Reject Flow Rate is the amount of water used to carry

away the impurities rejected by the membrane. It is critical

that both the Product Flow Rate and the Reject Flow Rate

are measured to conrm the desired Product/Reject Ratio

has been achieved. The higher the ratio of product ow to

reject ow, the shorter the life of the membrane will be.

IMPORTANT: Never close the Reject Flow Control Valve,

and never adjust it such that the Reject ow rate is less

than the Permeate (Product) ow rate! This will cause

premature fouling and shorten membrane life.

To adjust the reject ow rate, locate the reject ow

control valve. Loosen the lock-nut (at the base of the valve

stem) just slightly.

IMPORTANT: Before adjusting Reject Flow Rate CLOSE

the BLENDING VALVE (turn clockwise all the way).

Reject Flow

Control

(Adjust with

Blend Valve

Closed)

– Never close it

nor limit Reject

ow to less

than Permeate

ow!

Pressure

Regulator

(Permeate

Flow Control)

Adjust with Blend

Valve Closed

BWS1500 System Installation, Operation & Maintenance 19

Operating Parameters

Ratio Oper

Product/ Temp PRODUCT FLOW RATE REJECT FLOW RATE

Reject (°F) (gal/day) (gpm) (L/day) (lpm) (gal/day) (gpm) (L/day) (lpm)

1/2 48 600 0.42 2270 1.6 2400 1.7 9000 6.3

1/2 60 816 0.57 3090 2.2 2400 1.7 9000 6.3

1/2 70 1040 0.72 3950 2.7 2400 1.7 9000 6.3

1/2 77 1200 0.83 4540 3.2 2400 1.7 9000 6.3

1/2 85 1360 0.95 5150 3.6 2400 1.7 9000 6.3

• The ow rates above are for 60 psi feed pressure.

• To convert gallons per minute (gpm) to ounces per minute, multiply gpm by 128.

• To convert gallons per minute (gpm) to milliliters per minute, multiply gpm by 3785.

To increase the reject ow rate, use a slot screw driver to

turn the valve stem counterclockwise. To reduce the reject

ow rate, turn it clockwise. A minor adjustment makes a

big difference in the ow rate, so begin with small (1/2 turn)

adjustments. After making an adjustment, measure the

reject and product water ow rates (described below). Make

additional adjustments until the desired Product/Reject Ratio

is achieved, then tighten the lock-nut.

Use the “Operating Parameters” table above as a guideline

for safe operating ow rates and ratios. This table provides

an indication as to how Feed Water temperature affects the

Product Water output of the system.

Measuring Product Flow Rate

Connect a piece of 3/8” tubing to the Sample Port on the

Processor and route it to a bucket or drain. If equipped with

a 175 Gallon Tank/RP Pump, connect another piece of

3/8” tubing to the top port of the Tank Inlet Divert Valve and

also route it to a bucket or drain. If the tank is full, turn the

Sample Port valve to the sample position and allow about

20 gallons to drain out of the storage tank, then close the

Sample Port valve. Turn the Tank Inlet Divert Valve to the

divert position (Up). If equipped with a 50 Gallon Tank/

Repressurization Assembly, then also close the Buffer

Tank Valve on the Repressurization Assembly and open the

Sample Port on the Processor. While the system is operating

in normal mode (Emergency Bypass Valve in Service

position), use a graduated cylinder or other measuring

vessel to collect and measure the amount of Permeate water

that is produced in 60 seconds. With a 50 Gallon Tank/

Repressurization Assembly, this water will be collected

from the Sample Port on the Processor. With a 175 Gallon

Tank/RP Pump, this water will be collected from the tubing

connected to the Tank Inlet Divert Valve on the top of the

Tank. To convert ounces per minute to gallons per minute,

divide ounces/min by 128. To convert milliliters per minute

to gallons per minute, divide ml/min by 3785. Multiply gpm

times 1440 to get gallons per day production.

When nished, turn the Tank Inlet Divert Valve to the Down

position and (with a 50 Gallon Tank/Repressurization

Assembly) close the Sample Port and open the Buffer Tank

Valve.

Measuring Reject Flow Rate

Access the Reject Drain Line and measure the ow in a similar way to that described in “Measuring Product Flow Rate.”

(Collect and measure reject ow for 60 sec, and convert if

necessary to gal/day. No operation of valves is necessary for

this.)

Limitations on Adjustment of Reject Flow Rate

The factory sets the Product/Reject Ratio to 1:2 with the

Blending Valve closed based on 60 psi Operating Pressure

and 77°F. Never close Reject Flow Control Valve nor limit

Reject ow to less than Permeate ow!

The membrane is rated for a target daily output of 1200

gallons per day of Product Water when the feed water

temperature is 77°F and the operating pressure is 60 psi.

Do not exceed the rated output of 1200 gpd/50 gph/0.83

gpm (4500 liters per day/190 liters per hour/3200

milliliters per minute). Always keep in mind that feed

water temperature and pressure will affect the Product

Water output. Depending on feed water pressure and

temperature it may not be possible to achieve the rated

production of 1200 gpd.

Blending Impact on Product/Reject Ratio

Once the Blending Valve is opened to blend Filtered Water

with the RO Product Water the combined Optimized Water

ow rate will be greater than the Product Flow Rate. For

example, if the Feed Water TDS is 300 ppm, the membrane

product water TDS will be 9-15 ppm. If your desired

Optimized Water TDS is 75 ppm, then you will be adding

approximately 9% of the Filtered Water to your RO product

water, increasing your Optimized Water ow from 30%

recovery to 39% recovery.

In this example, your daily Optimized Water Production is

approximately 1540 gpd at 77°F Feed Water temperature

and 60 psi Operating Pressure.

BWS1500 System Installation, Operation & Maintenance 20

Processor Controller Overview

The controller display will indicate the status of the

Processor. The controller also manages all the automatic

functions of the BWS1500 System, such as automatic

ushes, stopping the pump when the tank is full, and

protecting the pump by monitoring inlet pressure and

controlling time delays. The following overview will provide

an understanding of the primary controller functions.

Normal Operation

1. System On/Running: With power supplied to the

Processor, the Feed Water Valve opened, the Bypass

Valve in “Service” position, and the tank not full, the

“Inlet Solenoid Valve” red LED will turn on, indicating

that the valve has been opened, and the “RO Pump”

LED will ash green. After a brief delay, the pump will

start running and the “RO Pump” LED will be steady on

red.

2. Full Tank: When the tank becomes full, the pump will

stop running and “Tank Full” green LED will come on.

When the tank has been depleted, the system will start.

3. System Disable: When the Bypass Switch on the front

of the Controller is in the Disable position, the pump

will not operate and the “System Disable” LED will ash

red. Place the switch in Disable position when using the

Bypass Valve to allow unltered water to pass through

to equipment (such as during lter changes).

Problem Conditions

1. Low Inlet Pressure Fault: If the pressure at the pump

inlet drops below 10 psi, the pump will automatically

turn off, and the “Low Pressure” LED will turn on red. If

sufcient inlet pressure is restored, then after a delay,

the pump will be turned on again.

NOTE: If low feed pressure exists, then service is required. The usual

cause of low feed pressure is a prelter assembly that has loaded up

with dirt.

2. Low Pressure Fault Shutdown: The controller

monitors low-pressure faults, and if they occur

repeatedly, it will shut down the system to protect it

from incessant cycling. Once shut down, the system will

not immediately startup again even if the pressure is

restored. After remaining off for an hour, the system will

allow startup again if sufcient inlet pressure is restored.

Also see note above.

3. Low Pressure Timeout: When the system is turned

on, the feed water solenoid valve is opened so that the

controller can monitor inlet pressure. When the feed

water solenoid valve is open, water can slowly pass

Controller Electrical Connections

through the processor under line pressure. To prevent

indenite processing of water under this condition

(inlet pressure that is insufcient to operate normally),

persistent low pressure will eventually result in a Low

Pressure Fault Shutdown as above, and the feed water

solenoid valve will be closed. Also see note above.

BWS1500 System Installation, Operation & Maintenance 21

Routine Maintenance

Sample

Port

Bypass

Valve

Normally, the most frequent routine maintenance

required on the system is periodic replacement of

the carbon/sediment pre-lters and the optional post-

treatment cartridge. The CTO-Q cartridges should be

changed every 1 month to 2 months, depending on

water usage. In areas with high levels of sediment

and other contaminants the CTO-Q cartridges may

require more frequent changes.

Pre-Filter change procedure

1. Unplug the RP Pump power cord.

2. Toggle the Bypass Switch (on the Processor

control box) to turn off the Processor pump. Either

close the Water Supply Valve (shutting off all

water ow), or put the Emergency Bypass Valve

(left side of the Processor) in the System Bypass

position (allowing untreated water to continue to

ow to the equipment).

3. Wait a moment for system pressure to drain off.

4. Once the system pressure has been relieved,

remove the three CTO-Q cartridges by turning a

quarter-turn to the left and pulling down on the

cartridge.

5. Install the new CTO-Q cartridges into the QT

heads by aligning the notches and pushing up,

then turn a quarter-turn to the right.

6. Install a piece of 3/8” tubing in the Sample Port

on the Processor (if using a 50 Gallon Tank/RP

Assy), or in the top port of the Tank Inlet Divert

Valve (on a 175 Gallon Tank/RP), and direct the

tubing to a bucket or drain.

7. Turn the Tank Inlet Divert Valve to the Bypass

Mode (Handle Pointing UP). If using a 50 Gallon

Tank/RP Assy, then also open the Sample Port on

the Processor.

8. Open the Water Supply Valve and put the

Emergency Bypass Valve in the “SERVICE”

Bypass

Switch

CTO-Q Pre-Filters

PN: 300-08115

Change Every

3 to 6 months

position, allowing water to run into the new PreFilter cartridges and through the Tank Inlet Divert

Valve to drain, and purging air from the system.

9. Once the air has been purged and lters ushed,

return the Tank Inlet Divert Valve to the Normal

position (handle horizontal or down). If using a 50

Gallon Tank/RP Assy, close the Sample Port on

the Processor.

10. Check for leaks.

11. Plug in the RP Pump power cord.

Optional Post-treatment cartridge change

procedure (if applicable)

1. Close the ball valve at the inlet to the PostTreatment assembly.

2. Remove the existing cartridge and discard.

3. Install the new cartridge.

4. Open the ball valve and the RP pump should

actuate lling the housing with water.

Storage Tank Cleaning

If the Storage Tank becomes dirty, regular cleaning

and sanitization may be required. (Request a Storage

Tank Cleaning Guide from OptiPure.) The Tank can be

emptied for cleaning by doing the following:

1. Close the Water Supply Valve

2. Connect 3/8” tubing from the Sample Port on the

Processor to the drain.

3. Open the Sample Port. The RP Pump should operate, pumping water to the drain until the Tank is

nearly empty.

4. Unplug the RP Pump power cord.

5. When nished, close Sample Port, plug in RP

Pump, and open Water Supply Valve.

RP Pump Motor Brushes

Over time or with heavy usage, the motor brushes in

the RP Pump can become worn, causing the Pump to

no longer operate reliably. (See “RP Pump Does Not

Turn On” under Trouble-Shooting for symptoms.) For

a system with heavy usage, it may be necessary to replace motor brushes under a preventive maintenance

schedule, such as annually. To restore a Pump with

worn brushes, order and install Brush Kit 704-39905,

which is supplied with instructions.

Buffer Tank Pre-Charge Pressure

Very slowly over time, the air pre-charge in the RP Assembly Buffer Tank can diminish, reducing the ability

of the Buffer Tank to maintain downstream pressure.

Annually, the pre-charge should be checked using a

tire gauge on the valve, which is on the side or bottom

of the Buffer Tank. If it is lower than 20 psi, air should

be added to restore it to 20 psi.

BWS1500 System Installation, Operation & Maintenance 22

Trouble-Shooting

Problem Possible Cause Resolution

Running out of water. Valves in incorrect operating position

Processor or RP Pump not turning

on when it should

Pressure feeding pump reduced due

to loaded Pre-Filters

Very cold Feed Water temperature

Low Feed Water Pressure (LED will

indicate “Low Pressure”.)

Demand exceeds system capacity

High Level Float Switch Open (LED

will indicate “Tank Full”.)

Poor water quality. Blend Valve mis-adjusted

Membrane failure

Short membrane life. Product/Reject Ratio mis-adjusted

Poor Feed Water quality, presence of

iron, silica or non-calcium carbonate

hardness

Short Pre-Filter life Heavy sediment loading Add FXAF01-12 or -12B for added Pre-Filter protection

Processor Either Does Not

Shut Off or Turn On

Processor Does Not Turn

On

(See also “Processor

Either Does Not Shut Off

or Turn On” above.)

Water Quality Monitor will

not turn on

On 50 Gal Tank: RP Pump

Does Not Turn On

High Level Float Switch not functioning (LED will indicate incorrect “Tank

Full” status.)

Controller Bypass Switch left in OFF

position (LED will indicate “System

Disable”)

Loaded Pre-Filters or Low Feed

Water Pressure (LED will indicate

“Low Pressure”.)

Solenoid Valve not functioning

Pressure Switch not functioning

Dead batteries Replace batteries by sliding Water Quality Monitor up and removing the six

No power to Pump (Green LED Off

at top of Control Box - attached to

Buffer Tank bracket)

Low water level in Tank (Green LED

on Control Box is Off)

RP Pump motor brushes worn

RP Pump damaged

Ensure the Processor Bypass Valve is in Service position, the Repressurization Assy (RP) Tank Divert Valve is in Down position, & Buffer Tank Valve

(50 Gal Storage Tank) or Tank Outlet Valve (175 Gal Storage Tank) is Open

(handle parallel to valve body).

See “Processor Does Not Turn On” and “RP Pump Does Not Turn On”

below

Pre-Filters need to be replaced

Raise water temp to increase production or determine if higher capacity

system is required

Resolve restriction in Feed Water Supply upstream of Processor

Determine if the demand is unusual or inconsistent, or resize system

Remove Storage Tank lid and actuate Float Switch up and down

Follow steps to adjust Blending Valve

Replace membrane

Measure and adjust the Reject Flow Rate

Determine Feed Water quality by obtaining a water quality report from city

water supply utility or contact your OptiPure dealer

Remove Storage Tank lid and actuate Float Switch up and down. Observe

“Tank Full” LED indicator on Controller.

Replace High Level Float Switch

Actuate Bypass Switch on front of controller

Pump will not turn on if pressure feeding pump is insufcient. Replace Pre-

Filters or resolve issue with Feed Water Pressure.

Possible Solenoid Valve issue: LED indicates “Inlet Solenoid Valve” but

Operating Pressure gauge shows 0 psi. Replace Solenoid Valve.

Possible Pressure Switch issue: LED indicates “Low Pressure” even though

pressure is sufcient. Replace Pressure Switch.

(Contact OptiPure dealer for help with troubleshooting Solenoid Valve or

Pressure Switch.)

screws on the back cover. Remove cover to access battteries.

If LED is On, RP Pump is operational (Pump will turn on only when the Buffer Tank is empty). If LED is Off, ensure power cord is plugged into an outlet

with power (check circuit breaker), & that there is water in Tank. If LED will

not turn On (with power & water in tank), there may be a problem with Low

Level Float Switch or Relay.

Allow Processor to partially ll Tank with water. Green LED indicates RP

Pump is operational, & will turn on when Buffer Tank is empty.

Try bumping the RP Pump with your hand. If it turns on temporarily, the

brushes are probably worn. Order & install Brush Kit 704-39905.

(Green LED is On, Buffer Tank is empty) If bumping RP Pump yields no

response, Pump could be damaged or brushes may still be worn. Call for

service.

BWS1500 System Installation, Operation & Maintenance 23

Trouble-Shooting, Continued

On 175 Gal Tank: RP

Pump Does Not Turn On

On 50 Gal Tank: RP Pump

runs intermittently or

rough.

On 50 Gal Tank: RP Pump

cycles on-off frequently

No power to Pump

RP Pump switch Off

Error on RP Pump

Air trapped in pump head.

RP Pump motor brushes worn

Low air pre-charge in Buffer Tank

(possible on aged system)

Ensure power cord is plugged into outlet with power (check circuit breaker).

Press switch on top of RP Pump to turn it On.

Check the top of the RP Pump for errors, contact OptiPure to resolve errors.

Unplug pump temporarily and open downstream valve to empty Buffer Tank.

See “RP Pump motor brushes worn” above.

Empty Buffer Tank and re-charge air pressure to 20 psi.

Electrical Schematic, 50 Gal Low Level Float Switch / RP Pump

Indicator Lamp

(Illuminated when pump is armed and tank has water in it)

AC

RP Pump

4.8 SFA

Heat Sink – Aluminum

1.6"x4.6"x0.125"Thick

Low Level

Float Switch

Relay

D

F

E

B

A

C

BWS1500 System Installation, Operation & Maintenance 24

How to Use Our Push-to-Connect Fittings

Fitting Overview

Fitting Body

Collet/Gripper

(Dark Gray)

To Attach Tubing:

To ease insertion, moisten end of tubing with fresh

water or 3% hydrogen peroxide solution.

Push tubing straight in.

2

Resistance will be felt when the

tubing meets the O ring.

Tubing Preparation

The outside of the tubing must be

free of knicks and gouges.

Cutaway view of tting and tubing

1

Keep pushing until the

resistance is overcome

and the tubing rests

against the stop.

Cut tubing with a plastic tubing cutter or a

razor knife. Make a clean, square cut.

After cutting, make sure the end of the tube is

round. Correct any out of roundness that may have

occured in cutting the tubing.

Tube Stop

O-Ring

3

To Remove Tubing:

Press collet in to release grippers. While holding the collet

in, pull out on the tubing.

It may be necessary to use a partially open crescent wrench

or similar device to hold both sides of the collet in while

pulling the tubing out.

High Level Switch Testing

Switch Test:

Float UP,

Processor OFF

Float DOWN,

Processor ON

Loading...

Loading...