Page 1

Page 2

Page 3

PM-812/0

Modular system

PM-812/0 version 1.0

3

Page 4

PM-812/0

Modular system

PM-812/0 version 1.0

4

Table of contents

1. PM-812/0 MODULAR CHASSIS ............................................................................................. 5

1.1. DESCRIPTION ............................................................................................................ 5

1.2. FRONT VIEW .............................................................................................................. 5

1.3. REAR VIEW ................................................................................................................ 5

1.4. POWER SUPPLY .......................................................................................................... 6

1.5. CHASSIS GROUNDING ................................................................................................ 6

1.6. PM-812/0 BUS – INTERNAL CONFIGURATION ................................................................ 6

1.7. CASCADING CONNECTION OF SEVERAL PM-812/0 UNITS ................................................ 8

2. C-810LE INPUT CARD .......................................................................................................... 9

2.1. DESCRIPTION ............................................................................................................ 9

2.2. CONNECTION ............................................................................................................. 9

2.3. SETUP ....................................................................................................................... 9

3. C-810LS OUTPUT CARD ...................................................................................................... 11

3.1. DESCRIPCIÓN .......................................................................................................... 11

3.2. PROGRAM CHANNEL OUTPUT ..................................................................................... 11

3.3. PRIORITY CHANNEL OUTPUT ..................................................................................... 11

3.4. CONNECTION ........................................................................................................... 11

3.5. SETUP ..................................................................................................................... 12

3.6. INTERNAL CONNECTIONS ......................................................................................... 12

4. TECHNICAL FEATURES ....................................................................................................... 13

5. DOCUMENT VERSION TRACKING ....................................................................................... 13

6. GUARANTEE ....................................................................................................................... 14

Page 5

PM-812/0

Modular system

PM-812/0 version 1.0

5

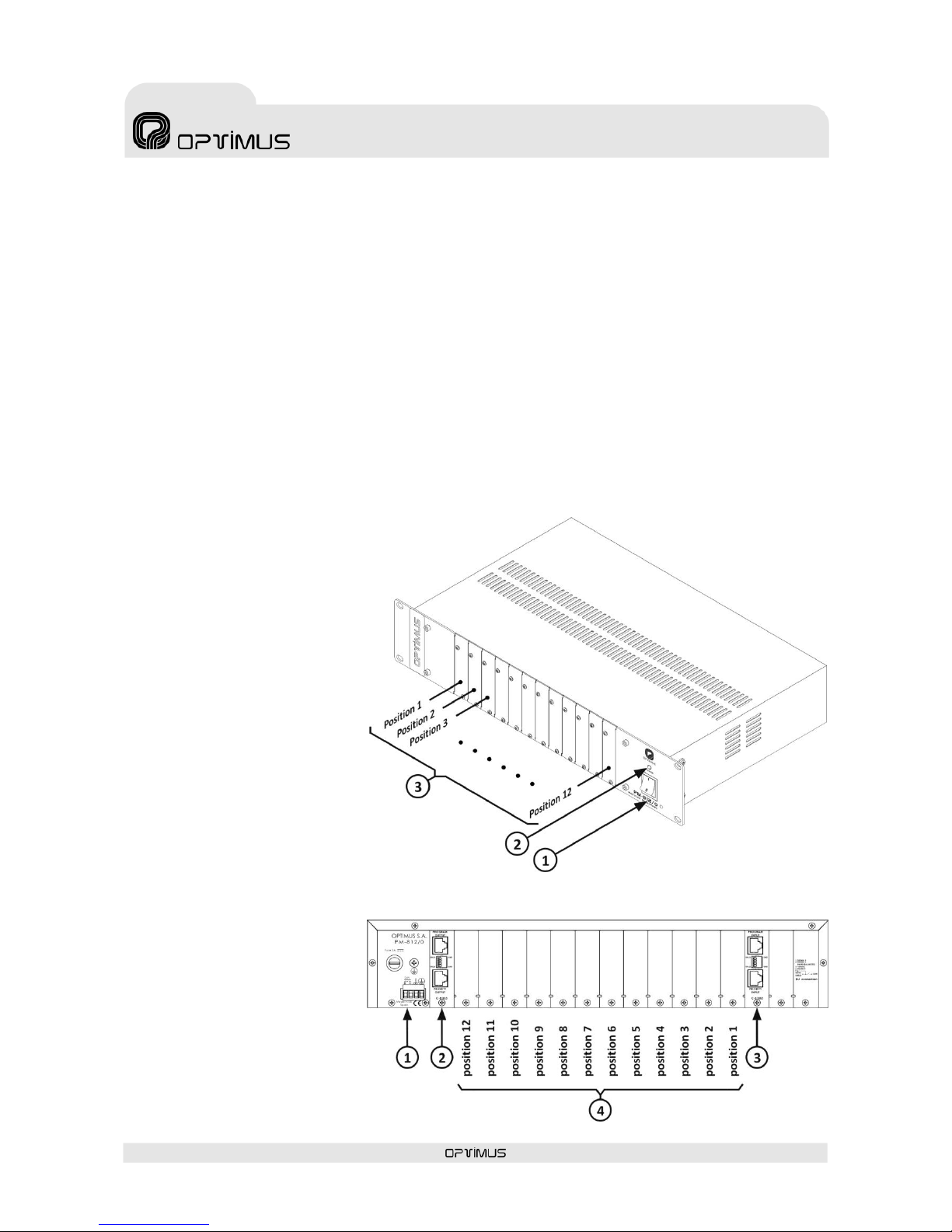

1. PM-812/0 MODULAR CHASSIS

1.1. DESCRIPTION

The PM-812/0 equipment is a modular frame that can house different card models series C-700

and C-800 (preamplifiers, microphone input cards, fault detection cards, message recording playback cards, etc.).

The default configuration consists of one input card (C-810LE), one output card (C-810LS) and a bus with

12 free positions between both two cards.

The cards can occupy one or more positions, depending on the model:

2 positions: C-810PAL, C-810SAL, C-810RP1, C-810RP4...

1 position: C-810LS, C-810LE, C-810PRJ, C-810PPA...

It features a program channel, where the program signals are mixed, and a priority channel, with a

cascading priorities system.

The bus was designed so as to be divided into several sections. In this way, each section (consisting of

one or more slots per card, as required) works as an independent chassis.

1.2. FRONT VIEW

1. ON/OFF switch.

2. ON/OFF LED indicator.

3. Blank front plates

(card positions 1 to 12).

1.3. REAR VIEW

1. Power supply plate

(see figure 3).

2. C810LS output card

(see section 3).

3. C810LE input card

(see section 2).

4. Blank rear plates

(card positions 1 to 12).

Figure 1

Figure 2

Page 6

PM-812/0

Modular system

PM-812/0 version 1.0

6

1.4. POWER SUPPLY

Use of a + 24 VDC / 3 A power supply is

recommended for the PM-812/0 (see figure 3,

number (1)).

Maximum power consumption is 2.5 A.

The power consumption varies depending on

the model and quantities of each card inserted

in the PM-812/0.

1.5. CHASSIS GROUNDING

For all P.A. systems it is very important that

there is only a single connecting point between

the signal ground and the power grounding

contact.

If the P.A. system consists of several pieces of equipment, they will probably be joined via the chassis

through a ground terminal for connection to the power supply or because they are mounted on a rack

stand.

If the grounds are also linked via the signal circuits, it is advisable to remove the jumper between the

ground and the chassis (see figure 3, number (2)) in all but one of the units.

1.6. PM-812/0 BUS – INTERNAL CONFIGURATION

The default setup of the PM-812/0 consists of an input card (C-810LE), an output card (C-810LS) and a

bus with 12 free card positions.

The cards have cascade priority, so that the card located in the OUT position has the lowest priority

ranking, followed by position 12, position 11, and so on up to position IN, which has the highest priority

ranking.

If the priority of more than one input is activated, only the signal from the card in the highest priority

position reaches the channel output.

In order to make the priority system more versatile, the bus has been designed so that it can be divided

into several sections. Thus, each section (consisting of one or more card slots as required) works as an

independent module.

To do this, the four jumpers between one slot and the next one must be cut, making one part of the bus

independent from the adjacent section. Each of the four jumpers cuts a different signal (priority audio,

program audio, priority between cards and priority bus). See figures 4 and 5.

Figure 3

Figure 4

Page 7

PM-812/0

Modular system

PM-812/0 version 1.0

7

In this way, an output card can be placed at the end of each section (in the position right before the

position where the jumpers have been disconnected) so that a PM-812/0 with 12 card positions can be

transformed into a PM-812/0 with several groups of cards, each group being independent from the rest,

and with cascade priority inside each group (see example in figure 7).

To install any card in the bus, you must remove the jumper between contacts 8 and 9 in the bus

connector (see figure 6).

The bus jumpers between card positions 4 and 5 (J34, J35, J36 and J37) and between card positions 8

and 9 (J18, J19, J20 and J21) are removed.

Two more output cards (card positions 4 and 8) are installed.

Thus, a PM-812/0 with 12 cards can be turned into three independent PM-812/0.

Figure 5

Figure 6

Card position

Priority ranking

Card position

Priority ranking

Figure 7

Page 8

PM-812/0

Modular system

PM-812/0 version 1.0

8

1.7. CASCADING CONNECTION OF SEVERAL PM-812/0 UNITS

Several PM-812/0 units can be connected in cascade form through the signal input and output cards (see

figure 8).

Any input of the card selected as priority of the first PM-812/0 (A) will have priority over any input of the

following unit – PM-812/0 (B) – and so on, preserving the range of internal priorities of each PM-812/0.

Figure 8

Page 9

PM-812/0

Modular system

PM-812/0 version 1.0

9

2. C-810LE INPUT CARD

2.1. DESCRIPTION

This card has a program and priority input, with a sensitivity of 0 dB.

The signal applied to these inputs (extension inputs) goes directly through

the bus to the output card (C-810LS).

In combination with the output card, several PM-812/0 modules can be

connected, keeping the cascade priority (see PM-812/0, section 1.7.).

2.2. CONNECTION

The card uses 8-pin RJ45 connectors with metal housing.

2.3. SETUP

Each of the two inputs has a dipswitch that is accessible from the rear plate of the card, which enables

separation of the wire shield from the ground circuit.

To separate the shield from the ground, move the dipswitch to the OFF position (dipswitch number 4 for

the program channel and dipswitch number 1 for the priority channel). See figures 11 and 12.

This is especially useful in installations with noise problems due to ground loops.

Figure 9

Figure 10

Figure 11

Figure 12

Page 10

PM-812/0

Modular system

PM-812/0 version 1.0

10

Optionally, these inputs can be connected to a balancing transformer (T700) by disconnecting jumpers J1

and J2 for program input, and J3 and J4 for priority input, and connecting the transformers as shown in

figure 13.

Figure 13

Page 11

PM-812/0

Modular system

PM-812/0 version 1.0

11

3. C-810LS OUTPUT CARD

3.1. DESCRIPCIÓN

This card has one program and one priority output. Both are of a 0 dB

sensitivity and balanced by means of a transformer.

It receives both program and priority channel signals from the bus.

The card allows connection of the oscillator card, the C-810MA microphone

card and the vu-meter card for displaying program and priority levels (see

section 3.6).

In combination with the input card, it allows connection of several

PM-812/0 modules, keeping cascade priority (see PM-812/0, section

1.7).

3.2. PROGRAM CHANNEL OUTPUT

A transformer-balanced output that provides the sum of all the signals

from cards set up as program cards and the program input of the C-810LE

card, with a level of 0 dBu.

3.3. PRIORITY CHANNEL OUTPUT

A transformer-balanced output that provides the signal from the priority activated card, with a

level of 0 dB.

If the priority of more than one input is activated, only the highest-priority input signal reaches the

priority channel output.

3.4. CONNECTION

The card uses 8-pin RJ45 connectors with metal housing.

Figure 14

Figure 15

Page 12

PM-812/0

Modular system

PM-812/0 version 1.0

12

3.5. SETUP

Each of the two channels (program and priority) has a

dipswitch that is accessible from the rear plate of the

card, which enables separation of the wire shield from

the ground circuit.

To separate the shield from the ground, move the

dipswitch to the OFF position (dipswitch number 4 for

the program channel and dipswitch number 1 for the

priority channel). See figures 16 and 17.

This is especially useful in installations with noise

problems due to ground loops.

3.6. INTERNAL CONNECTIONS

CONECTORES K1 y K2

These are two inputs used to connect the C-810MA/C-710MA microphone card.

K1: K1 is used to mix the microphone signal (0 dB) with the PM-812/0’s other program signals. The

microphone signal is output through the PROGRAM OUTPUT of the C-810LS card.

K2: K2 is used when the user wishes to give absolute priority to the microphone over all other PM-812/0

priority inputs. The microphone signal is output through the PRIORITY OUTPUT of the C-810LS card.

K3 AND K4 CONNECTORS

These connectors are used to connect the oscillator

card.

K3: Oscillator signal input for the priority channel.

The signal uses the card’s PRIORITY OUTPUT.

K4: Oscillator signal input for the program channel.

The signal uses the card’s PROGRAM OUTPUT.

K5 AND K6 CONNECTORS

These outputs are used to connect two external vumeters in order to display the program or priority

channel signal level.

K5: Displays the priority channel signal level.

K6: Displays the program channel signal level.

Figure 16

Figure 17

Figure 18

Page 13

PM-812/0

Modular system

PM-812/0 version 1.0

13

4. TECHNICAL FEATURES

PM-812/0

Power Supply

24 Vdc

Consumption (PM-812/0 + C-810LE + C-810LS)

40 mA

Dimensions (mm)

482.6 (w) x 89 (h) x 290 (d)

19” Rack units

2

Weight

4.1 Kg

Finish

Black painted iron

Tarjeta C-810LE

Program Input Sensitivity

0 dBu

Priority Input Sensitivity

0 dBu

Tarjeta C-810LS

Program output impedance

600 Ohms

Priority output impedance

600 Ohms

Program output sensitivity

0 dBu

Priority output sensitivity

0 dBu

5. DOCUMENT VERSION TRACKING

Reference system

Type of Document

Confidentiality

N/A

Analogue systems

Installation and operation guide

Rev

Date

Modifications Content

Written by:

1.0

October 12

First version

R&D Department

Approved By

Function

Date

Ferran Gironès i Puig

R&D Director

10/2012

WARNING. This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Page 14

PM-812/0

Modular system

PM-812/0 version 1.0

14

6. GUARANTEE

1. GUARANTEE CERTIFICATE

1. OPTIMUS S.A. guarantees that its products are free from material and

manufacturing defects when they are first delivered to the purchaser.

2. In accordance with the conditions outlined here, OPTIMUS S.A.

guarantees its products for two (2) years from the date on which the

purchaser acquires the product. If, within this guarantee period, defects

appear which are not due to factors outlined in section 2, OPTIMUS S.A.

shall replace or repair the unit using equivalent, new or reconstructed

replacement parts, as it deems fit. If replacement parts are applied which

improve the unit, OPTIMUS S.A. reserves the right to charge the client for

the additional cost of these components.

3. No guarantee benefits shall be provided other than those cited here.

4. In order to claim the guarantee rights, it shall be an essential

requirement to present the original purchase invoice or the guarantee

certificate.

2. GUARANTEE PROVISIONS

1. In the event that the product had to be modified or adapted to

comply with local requirements concerning technical specifications or

safety, and if the country in question is not the country for which the

product was originally designed and manufactured, defects are not

considered to be material or manufacturing defects. Furthermore, the

guarantee does not cover the execution of these modifications or

adaptations, regardless of whether or not they have been carried out

correctly. Nor shall OPTIMUS S.A. be responsible for any costs under this

guarantee for these types of modifications.

2. The guarantee shall not entitle the purchaser to inspection or free

maintenance or repair of the unit, particularly if the defects are due to

inappropriate use. Nor do the guarantee rights cover defects in wearing

parts that become worn as a result of normal wear and tear. Wearing

parts are, in particular, potentiometers, switches/keys, and similar parts.

3. The guarantee does not cover defects in the equipment unit caused

by:

Abuse or incorrect use of the unit for purposes other than those for

which it is intended, in non-compliance with the service and

maintenance instructions specified in the Manual and/or Technical

Instructions for the unit.

Connection or use of the product in a manner that does not

correspond to the technical or safety requirements of the country in

which the unit is used.

Installation in conditions other than those indicated in the Manual

and/or Technical Instructions.

Deficiency or interruptions in the electricity supply or installation

defects which imply use in abnormal conditions.

Damage caused by other equipment units that are connected to the

product.

The use or installation of Software (programmes), interfaces, parts or

supplies not provided and/or not authorised by OPTIMUS S.A.

Failure to use the original packaging for transportation.

Damage caused by force majeure or other causes not attributable to

OPTIMUS S.A.

4. The following elements are not covered by this guarantee:

All plastic surfaces and all parts exposed to outdoor conditions which

have been scratched or damaged as a result of normal or abnormal

use.

Breakages, knocks, damage due to a fall or scratches caused by

moving the unit in anyway.

Damage caused by tests, use, maintenance, installation or

inappropriate adjustments, or as a result of any alteration or

modification of any kind not carried out by a Service Authorised by

OPTIMUS S.A. in compliance with this guarantee.

Damage to persons or property that might be caused by the improper

use of the equipment, including lack of maintenance.

5. The guarantee shall not be valid whenever the following is observed:

Amendments or corrections made to the details of the guarantee

certificate or purchase invoice.

Failure to produce the original invoice or the absence of a date on

this.

Absence of the serial or batch number on the equipment.

6. In the case of personal computers, the guarantee will not cover the

elimination of computer viruses, the restoration of programmes damaged

by these or the reinstallation of the disk following its deletion.

7. The rights of this guarantee are invalidated if the product has been

repaired or opened by staff unauthorised by OPTIMUS S.A.or by the client

himself.

8. If OPTIMUS S.A. were to establish before the client that the damage

affecting the unit does not entitle a claim to be made under the

guarantee, the costs of checking the equipment incurred by OPTIMUS S.A.

shall be borne by the client.

9. Products not covered by the guarantee shall only be repaired once

payment has been effected by the client. In the event that the guarantee

rights do not apply, OPTIMUS S.A. shall duly inform the client. If, within a

period of 6 weeks from this communication, no written repair order is

received from the client confirming acceptance of the costs, OPTIMUS S.A.

shall return the unit in question to the client. In this case, the transport

and packaging costs shall be invoiced separately and payment shall be

made on delivery. In the event that a repair order is sent by the client,

confirming that he assumes the costs of repair, the transport and

packaging costs shall be invoiced additionally, and also separately.

10. If the equipment needs to be transferred to the Authorised Service

Centre, transportation shall be effected by the responsible party according

to the guarantee, who will also bear the freight and insurance costs.

11. In the event of a defect, OPTIMUS S.A. guarantees that the repair

and/or replacement of parts so that the unit operates correctly will be

made within a period of no more than 30 days. Nevertheless, OPTIMUS

S.A. would like to clarify that the normal period does not exceed 30 days.

12. All parts or products replaced as part of the guarantee services shall

become the property of OPTIMUS S.A.

3. TRANSFER OF GUARANTEE

The guarantee is solely awarded to the original purchaser (principal client)

and is not transferable. With the exception of OPTIMUS S.A., no third

party (dealers, etc.) is authorised to award additional guarantees on

behalf of OPTIMUS S.A.

4. CLAIMS FOR DAMAGE

In the event that OPTIMUS S.A. cannot provide a suitable guarantee

service, the purchaser shall not be entitled to claim any indemnity for

damages arising.

The responsibility held by OPTIMUS S.A. is limited in all cases to the

invoicing price of the product.

5. RELATION WITH OTHER GUARANTEE RIGHTS AND NATIONAL

LAW

1. This guarantee does not affect the rights of the purchaser with respect

to the vendor arising from the contract of sale accomplished.

2. These conditions of the guarantee provided by OPTIMUS S.A. are valid

as long as they do not contradict the corresponding national law on

guarantee provisions.

3. OPTIMUS S.A. guarantees that this product complies with the safety

regulations in force in the country.

THIS LIMITED GUARANTEE DECLARATION IS THE EXCLUSIVE GUARANTEE

OFFERED BY OPTIMUS S.A. ALL OTHER EXPLICIT OR IMPLICIT

GUARANTEES ARE EXCLUDED, AND THIS ALSO APPLIES TO GUARANTEES

OF MARKETABILITY AND SUITABILITY FOR A PARTICULAR PURPOSE.

(EXCEPT WHEN THESE GUARANTEES ARE REQUIRED BY AN APPLICABLE

LAW). NO GUARANTEE, EITHER EXPLICIT OR IMPLICIT, SHALL BE

APPLIED ONCE THE GUARANTEE PERIOD HAS EXPIRED.

OPTIMUS S.A.

Export Department

C/ Barcelona 101

17003 – GIRONA (SPAIN)

Tel.+34 972203300 - Fax.+34 972218413

e-mail : export@optimus.es 1999/44/CE

Page 15

Page 16

Loading...

Loading...