OPTIMUM

MASCHINEN - GERMANY

Operating Manual

Version 1.0.5

Upright drilling machine

B34H 22" Item No. 3020334

B34H Vario 22" Item No. 3020338

2014

US

21.7.14 Page 1 Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Keep for future reference!

OPTIMUM

MASCHINEN - GERMANY

Table of Contents

1Safety

1.1 Safety warnings (warning notes) .................................................................................. 5

1.1.1 Classification of hazards ...................................... ... ... ... .... ... ... ... ... .... ............5

1.1.2 Other pictograms ...........................................................................................7

1.2 Proper use ....................................... ....................................... ... ... .... ... ... ... ...................8

1.3 Possible dangers caused by the upright drill. ............................................................... 8

1.4 Qualification of employees ........................................................................................... 9

1.4.1 Target group ..................................................................................................9

1.4.2 Authorized Personnel ........................................................... ... ... ... .... ... ... ... ... 9

1.5 Safety measures during operation .............................................................................. 10

1.6 Safety measures during operation .............................................................................. 10

1.7 Safety devices ............................................................................................................ 10

1.8 Safety check ...............................................................................................................11

1.9 EMERGENCY-STOP-BUTTON .................................................................................12

1.10 Drilling table ............................... ... ... ... .... ... ... ... .......................................... ... .... ... ....... 12

1.11 Separating protective devices .................................................................................... 13

1.11.1 Protective cover for the belt pulleys ............................................................13

1.11.2 Drill chuck guard .......................................................................................... 13

1.12 Personal protective equipment ...................................................................................13

1.13 Safety during operation .............................................................................................. 14

1.14 Safety during maintenance ......................................................................................... 14

1.14.1 Switching-off and securing the upright drill .................................................. 14

1.15 Use of lifting equipments ............................................................................................15

1.15.1 Mechanical maintenance work .................................................................... 15

1.16 Electrical .....................................................................................................................15

2 Technical Data

2.1 Power connection ....................................................................................................... 16

2.2 Cooling pump ............................................................... ... .... ....................................... 16

2.3 Drilling capacity .................. ... .... ... ... ... .... ... ... ... .......................................... ... .... ..........16

2.4 Spindle ................................... .................... ................... .................... ................... .......16

2.5 Drilling machine table ......... ... .... ... ... ... .... ... ... .......................................... ... ... .... ... ... ... . 16

2.6 Required space ......................... ... .......................................... ... ... .... ... ... ... .................16

2.7 Speeds .......................................................................................................................16

2.8 Environmental conditions ...........................................................................................17

2.9 Operating material ...................................................................................................... 17

2.10 Emissions ...................................................................................................................17

2.11 Dimensions B34 H ......................................................................................................18

2.12 Dimensions B34 H Vario ............................................................................................ 19

3 Assembly

3.1 Extent of supply .......................................................................................................... 20

3.2 Transport .................................................................................................................... 20

3.3 Storage .......................................................................................................................21

3.4 Installation and assembly ...........................................................................................21

3.4.1 Site requirements ....................... ... ... .... ... ... ... .......................................... ... . 21

3.4.2 Assembly ................................. ............................. ............................. .......... 2 2

3.4.3 Mounting the drilling table ............................................. .... ... ... ... .................23

3.4.4 Mount the drilling head ................................................................................ 25

3.5 Installing ..................................................................................................................... 25

2014

US

21.7.14Page 2 Upright drill B34 H/ B34 H Vario ; Version 1.0.5

OPTIMUM

MASCHINEN - GERMANY

3.6 Mounting ............................... ................ ................ ................ ................. ................ ..... 26

3.6.1 Installation drawings .......... ... ... .... ... ... ... .... ... ... .......................................... .. 27

3.7 First use ...................................................................................................................... 28

4 Operation

4.1 Safety ......................................................................................................................... 29

4.2 Control and indicating elements ................................................................................. 29

4.2.1 Upright drill B34 H (Vario) ........................................................................... 29

4.2.2 Control panel B34 H .................................................................................... 30

4.2.3 Drill depth stop ............................................................................................ 31

4.2.4 Control panel B34 H Vario .......................................................................... 31

4.3 Turn the machine on B34 H ....................................................................................... 33

4.4 Turn the machine on B34 H Vario .............................................................................. 33

4.5 Turn the machine off B34H and B34 H (Vario) ........................................................... 33

4.6 Digital drilling depth display ........................................................................................ 34

4.6.1 Design .......................................... ............................................................. ..34

4.6.2 Trouble shooting ......................................................................................... 35

4.7 Speed variation .......................................................................................................... 35

4.7.1 Speed table B34H ....................................................................................... 36

4.7.2 Speed table B34H Vario ............................................................................. 36

4.8 Removing, mounting of drill chucks and drills ............................................................ 37

4.8.1 Mounting the drill chuck B34 H (Vario) ......................... ... ... .... ... ... ............... 37

4.8.2 Keyless drill chuck ....................................................................................... 37

4.8.3 Removing the tool or drill chuck with integrated drill drift .......... ... ... ... .... ... .. 38

4.9 Cooling ....................................................................................................................... 39

4.10 Before starting the working process ........................................................................... 40

4.11 During the working process ........................................................................................ 40

2014

5 Determining the cutting speed and the speed

5.1 Table cutting speeds / infeed ..................................................................................... 41

5.2 Speed table ................................................................................................................ 41

5.3 Examples to calculatory determine the required speed for your drilling machine ...... 43

6 Maintenance

6.1 Safety ......................................................................................................................... 45

6.1.1 Preparation ................................................................................................. 45

6.1.2 Restarting ........................................ ................................ ............................ 45

6.2 Inspection and maintenance ...................................................................................... 45

6.3 Repair ............................. ................................................ ............................................ 48

7 Spare parts - B34H/ B34H Vario

7.1 Parts drawing B34H ................................................................................................... 49

7.1.1 Drilling head B34H ...................................................................................... 49

7.1.2 Parts drawing drilling head 1 of 5 ................................................................ 50

7.1.3 Parts drawing drilling head 2 of 5 ................................................................ 51

7.1.4 Parts drawing drilling head 3 of 5 ................................................................ 52

7.1.5 Parts drawing drilling head 4 of 5 ................................................................ 53

7.1.6 Parts drawing drilling head 5 of 5 ................................................................ 54

7.1.7 Parts drawing drill chuck guard ................................................................... 55

7.1.8 Parts drawing column and drilling table .......... ... ... .... ... ... ... .... ... ... ... ... .... ... .. 56

7.2 Spare part list - B34H ................................................................................................. 57

7.3 Wiring diagram B34 H .......... ... ... .... ... ... ... .... ... ... .......................................... ... ... .... ... .. 60

7.4 Parts drawing B34H Vario .......................................................................................... 61

7.4.1 Drilling head B34H Vario ............................................................................. 61

US

21.7.14 Page 3 Upright drill B34 H/ B34 H Vario ; Version 1.0.5

OPTIMUM

MASCHINEN - GERMANY

7.4.2 Parts drawing drilling head 1 of 5 ................................................................62

7.4.3 Parts drawing drilling head 2 of 5 ................................................................63

7.4.4 Parts drawing drilling head 3 of 5 ................................................................64

7.4.5 Parts drawing drilling head 4 of 5 ................................................................65

7.4.6 Parts drawing drilling head 5 of 5 ................................................................66

7.4.7 Parts drawing drill chuck guard ...................................................................67

7.4.8 Parts drawing column and drilling table ................................ ... ... ... .... ..........68

7.4.9 Spare part list - B34H Vario .........................................................................69

7.4.10 Wiring diagram B34 H Vario ........................................................................72

7.4.11 Wiring diagram B34 H Vario ........................................................................73

8 Troubleshooting

9 Appendix

9.1 Copyright .................................................................................................................... 76

9.2 Terminology/Glossary ................................ .......................... ...................... ................. 76

9.3 LIMITED WARRANTY ...............................................................................................77

10Index

Preface

Changes The illustrations of the upright drill might in some details deviate from the illustrations of this

operating manual but this will have no influence on the operation of the upright drill.

Any changes in the construction, equipment and accessories are reserved for reasons of

enhancement. Therefore, no claims may be derived from the indications and descriptions.

Errors excepted!

2014

US

21.7.14Page 4 Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Safety

1 Safety

Glossary of symbols

OPTIMUM

MASCHINEN - GERMANY

calls on you to get in action

enumeration

This part of the operating manual

does explain the meaning and how to use the warning references contained in this operating

manual,

does explain how to use the upright drill machine,

highlights the dangers that might arise for you and others if these instructions are not fol-

lowed thoroughly,

informs you on how to prevent dangers.

In addition to this operating manual, please note

applicable laws and regulations,

legal regulations for preventing an accident,

the prohibition, warning and mandatory signs as well as the warning notes on the upright

drill.

Always keep the operating manual close to the upright dr ill for further reference.

INFORMATION

gives further advice

If you are not able to solve a problem using this manual, please do not hesitate to contact us for

further professional advice:

Exclusive USA Agent

LDS Industries, LLC

930 W. National Ave.

Addison, IL 60101

Tel.: 1-630-785-6437

1.1 Safety warnings (warning notes)

1.1.1 Classification of hazards

We classify the safety warnings into various levels. The table below gives an overview of the

classification of symbols (pictogram) and warning signs for each specific danger and its (possible) consequences.

Pictogram warning alert definition/consequence

DANGER!

WARNING!

Threatening danger that will cause serious injury or

death to people.

Risk: A danger that might cause serious injury or death

to a person.

CAUTION!

Danger or unsafe procedure that might cause injury to

people or damage to property.

2014

21 / 07 / 2014 Page 5Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

Pictogram warning alert definition/consequence

ATTENTION!

Information

In the case of specific dangers, we replace the pictogram

Safety

Situation that could cause damage to the machine and

to the product and other types of damages.

No risk of injury to personnel.

Application advice and other important or useful information and notes.

No dangerous or harmful consequences for people or

objects.

General

danger

with a warning ofinjuries to

hands,

hazardous

electrical

voltage

,

or

rotating parts.

2014

US

21 / 07 / 2014Page 6 Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Safety

1.1.2 Other pictograms

OPTIMUM

MASCHINEN - GERMANY

Warning of

automatic start-up!

Activation forbidden!

Use safety shoes! Use protective gloves!

Wear a safety suit! Protect the environment!

Use safety glasses! Contact address

Disconnect main power!

Use ear protection!

2014

21 / 07 / 2014 Page 7Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

1.2 Proper use

WARNING!

In the event of improper use of the upright drill

• there may be a risk to personnel,

• there may be a risk to the machine and other items,

correct functioning of the upright drill may be affected.

The upright drill is designed and manufactured to be used in environments where there is no

potential danger of explosion. The upright drill is designed and manufactured to produce holes

in cold metal or other not health hazardous or non- flammable material by using a rotating cutting tool with several chucking grooves.

If the upright drill is used in any way other than described above, or modified without authorization, then the upright drill- is being used improperly.

We do not take liability for damage caused through improper use.

We would like to stress that any modifications to the construction, or technical or technological

modifications that have not been authorized will also render the warranty null and void.

It is also part of proper use that

the maximum values of the upright drill are complied with,

the operating manual is constantly observed,

inspection and maintenance instructions are observed.

Safety

„Technical Data“ on page 16

WARNING!

Very serious injury.

It is forbidden to make any modifications or alternations to the operating values of the

upright drill! They could endanger employees and cause damage to theupright drill.

1.3 Possible dangers caused by the upright drill.

The upright drill is state of the art.

Nevertheless, there is a residual risk as the upright drill operates with

high revolutions,

rotating parts,

electrical voltage and currents.

We have used construction resources an d safety techniques to minim ize the health risk to persons resulting from these hazards.

If the upright drill is used and maintained by employees who are poorly qualified, then there

might be a risk resulting from incorrect operation and unsuitable maintenance of the upright drill.

INFORMATION

Everyone involved in the assembly, commissioning, operation and maintenance must

be duly qualified,

strictly follow this operating manual.

Due to improper use

there is a risk for the employee,

the machine and further property might be endangered,

the function of the upright drill could be effected.

2014

US

21 / 07 / 2014Page 8 Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Safety

Always disconnect the upright drill if cleaning or maintenance work is being carried ou t.

WARNING!

The upright drill may only be used with the safety devices activated.

Disconnect the upright drill immediately whenever you detect a failure in the safety

device or when they are not mounted!

All additional installations carried out by the operator must incorporate the safety

devices prescribed.

This is your responsibility being the operator!

„Safety devices“ on page 10

1.4 Qualification of employees

1.4.1 Target group

This manual applies to

the operators,

the users,

the maintenance staff.

Therefore, the warning notes refer to both operation and maintenance of the upright drill.

OPTIMUM

MASCHINEN - GERMANY

Determine clearly and make a permanent decision in who will be responsible for the different

activities on the machine (operation, maintenance and repair).

Vague and unclear assignment of responsibilities constitute a safety hazard!

Always disconnect the main power of the upright drill. This will prevent it from being used by

unauthorised persons.

1.4.2 Authorized Personnel

WARNING!

Incorrect use and maintenance of the upright drill constitute a danger for the staff,

objects and the environment.

Only authorized persons may operate the upright drill!

Persons to operate and maintain should be trained technical staff and instructed by the ones

who are working for the operator and for the manufacturer.

The user must

Obligations

of the opera-

train the staff,

instruct the staff in regular intervals (at least once a year) on

tor

- all safety standards that apply to the bench drill and upright drill,

- the operation,

- accredited technical guidelines,

check the knowledge of the staff,

document training / instructions,

require the staff to confirm participation in training / instructions by means of a signature,

check if the staff is aware of safety rules and dangers in the workplace so that they observe

the operating manual.

2014

21 / 07 / 2014 Page 9Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

The user must

Safety

Obligations

of the user

Further

require-

ments to the

qualification

have followed a training on the operation of the upright drill,

know the function and performance,

before commissioning

- have read and understood the operating manual,

- be familiar with all safety devices and regulations.

For working on the following machine parts, additional requirements are being applied:

Electrical parts or operating agents: shall only be performed by an electrician or under the

guidance and supervision of an electrician.

Before starting work on electrical parts or operating agents, following measures are to be performed in the following order.

disconnect main electrical power

Ensure that the machine cannot be turned on again

check that there is no voltage

1.5 Safety measures during operation

1.6 Safety measures during operation

CAUTION!

Risk due to inhaling health hazardous dusts and mist.

Depending on the material being processed and any additional dusts and mist in the

work area, conditions might impair your health.

Make sure that the generated health hazardous dusts and mist are safely removed at the

point of origin and are collected and/ or filtered from the working area. Use an appropriate dust collection/ filter unit.

CAUTION!

Risk of fire and explosion by using flammable materials or cooling lubricants.

Take additional preventive measures in order to safely avoid health hazards befor e processing flammable materials (e.g. aluminum, magnesium) or before using flammable

additives (e.g. solvents).

1.7 Safety devices

Operate the upright drill only with properly functioning safety devices.

Stop the upright drill immediately if there is a failure in the safety device or if it is not functioning

for some reason.

It is your responsibility!

If the safety device has been activated or has failed, the upright drill must only be operated

again when

the cause of the failure has been removed,

you have made sure that there is no existing danger for persons or objects.

2014

US

21 / 07 / 2014Page 10 Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Safety

WARNING!

If you bypass, remove or override a safety device in any other way , you are endangering

yourself and other persons working on the upright drill. The possible consequences are

the following

• injuries due to components or parts of components flying off a high speed,

• contact with rotating parts,

• fatal electrocution.

The upright drill includes the following safety devices:

an EMERGENCY-STOP switch,

a drilling machine table with T-slots to fasten the workpiece or a vise,

a protective cover for the pulleys with positioning switch.

WARNING!

The separating protective equipment wh ic h is made a va ilable and deliver ed tog eth er with

the machine is designed to reduce the risk of workpieces or fractions of them which

being expelled, but not to remove them completely.

1.8 Safety check

OPTIMUM

MASCHINEN - GERMANY

Check the upright drill at least once per shift. Inform the person responsible immediately of any

defect or change in the operation function .

Check all safety devices

at the beginning of each shift (with the machine stopped),

once a week (with the machine in operation),

after every maintenance and repair work.

Check that the prohibition, warning and information labels as well as the markings on the upright

drill

are legible (clean them, if necessary),

are complete.

INFORMATION

Use the following overview to organise the inspections.

General inspection

Item Inspection OK

Protective cover Mounted, securely tightened and not damaged

Signs, markings Installed and legible

Date: Inspector (signature):

Functional test

Item Inspection OK

EMERGENCY-STOPpush button

Date: Inspector (signature):

Once the emergency stop button is activated, the upright

drill should be switched off.

2014

21 / 07 / 2014 Page 11Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

EMERGENCY-

STOP-button

T-slots for clamping

blocks

(14 mm)

MASCHINEN - GERMANY

Functional test

Item Inspection OK

Safety

limit switch protective

cover

V-belts

drill chuck guard The upright drill must only switch on when the drill chuck

Date: Inspector (signature):

The upright drill must not switch on, if the protective cover

of the pulleys is opened.

guard is closed.

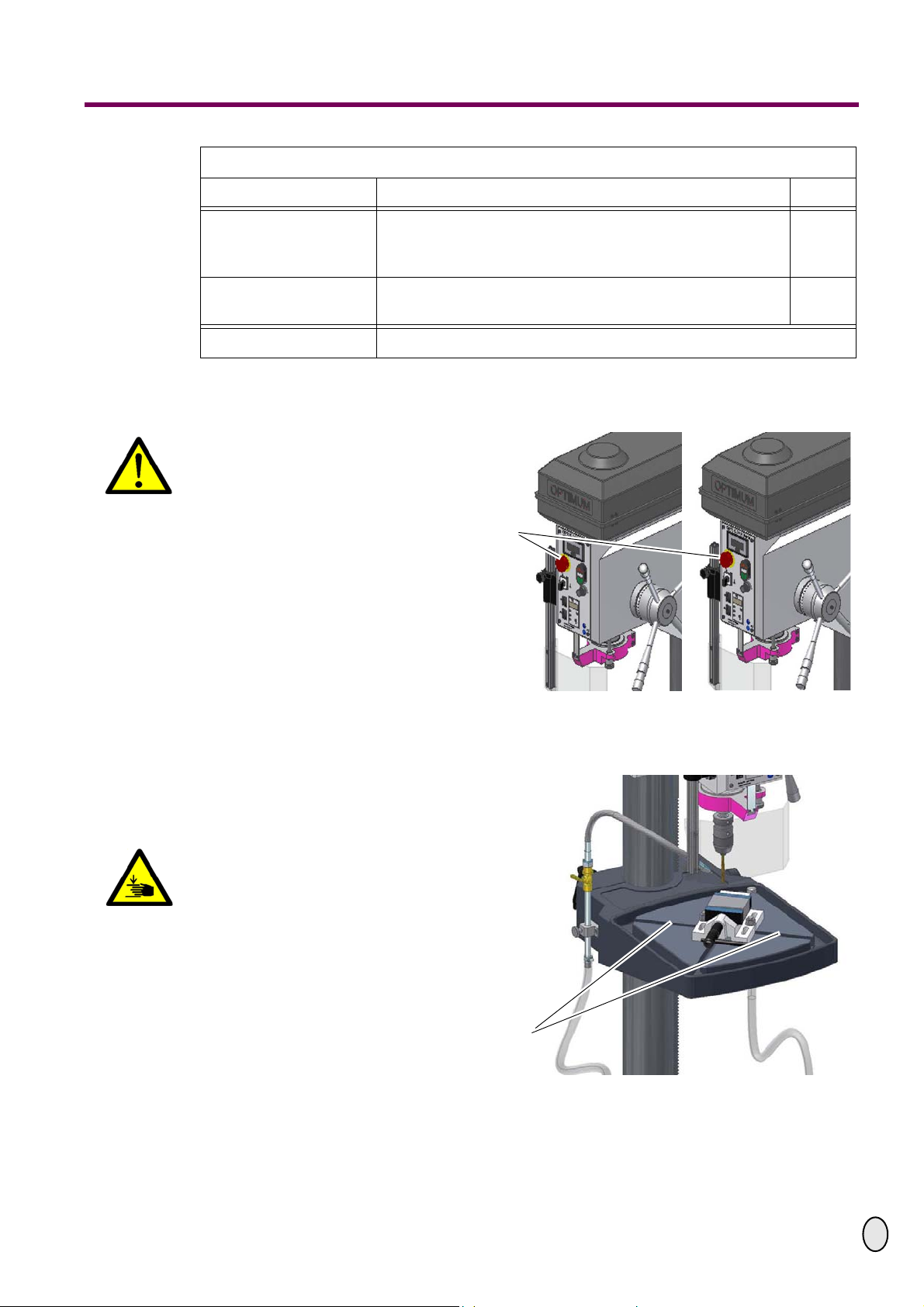

1.9 EMERGENCY-STOP-BUTTON

CAUTION!

After actuating the EMER-

GENCY-STOP-button the drilling spindle will turn some

more seconds depending on

the previously set speed.

.

Img.1-1: EMERGENCY-STOP B34 H (Vario)

1.10 Drilling table

The drilling table is equipped

with T-slots for clamping

blocks.

WARNING!

Risk of injury due to parts

flying off at high speed.

Securely fix the workpiece

on the drilling table.

Img.1-2: Drilling table

2014

US

21 / 07 / 2014Page 12 Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Safety

protective

cover

clamping screw

drill chuck guard

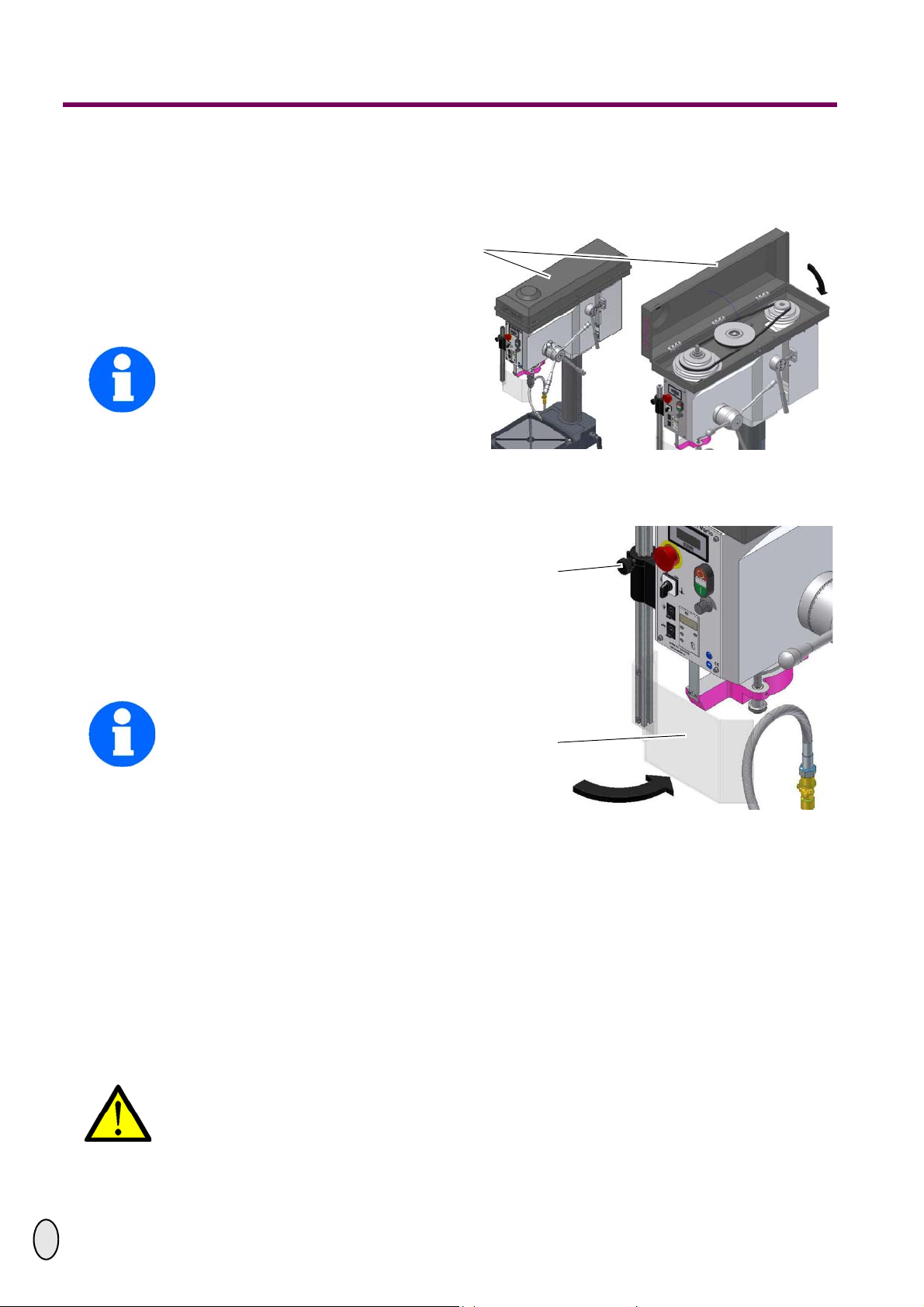

1.11 Separating protective devices

1.11.1 Protective cover for the belt pulleys

A protective cover for the belt

pulleys is mounted on the drilling head. A switch is integrated

in the protective cover which

monitors that the cover is

closed.

INFORMATION

YOU CANNOT START THE

MACHINE IF THE PROTECTIVE COVER IS NOT CLOSED.

1.11.2 Drill chuck guard

Adjust the drill chuck guard to the correct height before you start working.

OPTIMUM

MASCHINEN - GERMANY

Img.1-3: Protective cover

2014

To do so, detach the clamping screw,

adjust the required height and

retighten the clamping screw.

A switch is integrated in the fixture of

the drill chuck guard which monitors

that the cover is closed.

INFORMATION

YOU CANNOT START THE

MACHINE IF THE DRILL CHUCK

GUARD IS NOT CLOSED.

Img.1-4: Drill chuck guard

1.12 Personal protective equipment

For certain work, personal protective equipments is required. Such as:

safety helmet,

protective safety glasses or face guard,

protective gloves,

safety shoes with steel caps,

ear protection.

Before starting work, make sure that the prescribed personal protective equipment is available

at the workplace.

CAUTION!

Dirty or eventually contaminated personal protective equipments might cause disease.

Clean your personal protective equipment

• after each use,

• regularly once a week.

21 / 07 / 2014 Page 13Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

Personal protective equipment for special work

Protect your face and your eyes: Wear a safety helmet with a face guard for every work, especially for the kind of work where your face and eyes are exposed to hazards.

Use protective gloves when lifting or handling pieces with sharp edges.

Wear safety shoes when fitting, dismantling or transporting he a vy com p on e nts.

1.13 Safety during operation

In the description of work with and on the upright drill we highlight the dangers specific to that

work.

WARNING!

Before activating the upright drill, double check that this will

• not endanger other people,

• not cause damage to equipment.

Safety

Avoid unsafe working practice:

Make sure that your work does not endanger anyone.

The instructions of this manual must be observed strictly during assembly, operation, mainte-

nance and repair.

Do not work on the upright drill if your concentration is reduced, for example, because you

are taking medication.

Observe the regulations for the prevention of accidents issued by your association for the

prevention of accidents and safety in the workplace or other inspection authorities.

Inform the inspector of any danger or failure.

Stay at the machine until all rotating parts have come to a halt.

Use the prescribed personal protective equipment. Make sure to wear a well-fitting work suit

and a hairnet, if necessary.

Do not use protective gloves when drilling.

1.14 Safety during maintenance

Inform the operating staff on time of any repair and maintenance work.

Report all safety-relevant changes or performance details of the upright drill. Document all

changes, have the operating manual changed accordingly and train the machine operators.

1.14.1 Switching-off and securing the upright drill

Turn the upright drill off using the main switch and use a padlock to prevent the switch from

being turned on without authorisation or by acc i dent.

All machine components and hazardous voltages are disconnected. Only the points marked with

this pictogram are not included.

21 / 07 / 2014Page 14 Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

2014

US

Safety

1.15 Use of lifting equipments

WARNING!

Use of unstable lif ting and load-suspension gear that might break under load can cause

very serious injuries or even death.

Check the lifting and load-suspension gear on

• sufficient load capacity,

• perfect condition.

Observe the regulations for the prevention of accidents issued by your association for

the prevention of occupational accidents and safety in the workplace or other inspection

authorities.

Fasten the loads properly. Do not walk under lifted loads!

1.15.1 Mechanical maintenance work

Remove all protection and safety devices before starting maintenance w ork and re-install them

once the work has been completed, such as:

covers,

safety indications and warning signs,

earth (ground) cables.

OPTIMUM

MASCHINEN - GERMANY

If you remove protection or safety devices, refit them immediately after completing the work.

Check if they are working properly!

1.16 Electrical

Have the machine and / or the electrical equipment checked regularly, at least every six months.

Eliminate immediately all defects such as loose connections, defective wires, etc.

A second person must be present during work on live components, to disconnect the power in

case of an emergency.

Disconnect the upright drill immediately if there is a malfunction in the power supply!

„Maintenance“ on page 44

2014

21 / 07 / 2014 Page 15Safety Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

2 Technical Data

The following data which give dimensions and weight are the manufacurer’s authorised machine

data

.

Technical Data

2.1 Power connection

Motor input capacity 3HP, 230V, 3PH, 60Hz 3HP, 230V, 1PH, 60Hz

2.2 Cooling pump

Motor power - 40W, 230V, 60Hz

2.3 Drilling capacity

drilling capacity in steel 34mm (1.138“)

throat 285mm (11.22“)

Spindle travel 160mm (6.30“)

2.4 Spindle

Spindle taper 4 MT

2.5 Drilling machine

table

B34 H B 34 H Vario

B34 H B 34 H Vario

B34 H B 34 H Vario

B34 H B 34 H Vario

B34 H B 34 H Vario

dimension of the table

length x width of the working surface

T- Slot dimension 14mm (0.551“)

maximum distance spindle - table 790mm (31.102“)

maximum distance

spindle - base

working surface base

length x width of the working surface

2.6 Required space

height 2500mm (98.425“)

depth 1700mm (66.93“)

width 1500mm (59.055“)

2.7 Speeds

spindle speeds [RPM] 150 - 4000 73 - 4000

Number of stages 9

400 x 500mm (15.748“ x 19.685“)

1025 (40.354“)

370 x 386mm

(14.567 x 15.197“)

B34 H B 34 H Vario

B34 H B 34 H Vario

390 x 400mm

(15.354 x15.748“)

2014

US

21 / 07 / 2014Page 16 Technical Data Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Technical Data

OPTIMUM

MASCHINEN - GERMANY

2.8 Environmental

2.9 Operating material

Column, blank steel parts acid-free lubricant, e.g. machine oil, engine oil

2.10 Emissions

The noise level (emission) of the mill drill machine is below 76 dB(A). If the mill drill machine is

installed in an area where various machines are in operation, the acoustic influence (immission)

on the operator of the mill drill machine may exceed 85 dB(A).

INFORMATION

This numeric value had been measured on a new machine under conventional operating conditions. Depending on the age or wear of the machine, the noise behavior of the machine might

change.

Furthermore, the extent of the noise emission is also depending on manufacturing

influence factors, such as speed, material and clamping conditions.

conditions

temperature 41 - 95 °F

rel. humidity 25 - 80 %

toothed rack commercial lubricating grease

Coolant lubricant UNIMET ASF 192, Mineral 1:10 (approx. 4.75

B34 H B 34 H Vario

B34 H B 34 H Vario

quarts)

INFORMATION

The mentioned numerical value is an emission level and not necessarily a safe

working level.

Unless the degree of noise emission and the degree of noise disturbance are depending on one

another it is not possible to use it in ord er to reliably determine if it is necessary to take further

preventive measures or not.

The following factors influence the actual degree of the noise disturbance of the

operator:

• Characteristics of the working chamber, e.g. size or damping behavior,

• Other noise sources, e.g. the number of machines,

• Other processes proceeding nearby and the period during which the operator is exposed to

the noise.

Consult OSHA, state and local regulations in order to determine compliance, dangers and risks

to the operator.

CAUTION!

The machine operator has to wear an appropriate ear protection dep ending on the overall

stress caused by noise and on the basic limit values.

We generally recommend using a sound and ear protection.

2014

21 / 07 / 2014 Page 17Technical Data Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

MASCHINEN - GERMANY

2.11 Dimensions B34 H

Technical Data

Img.2-1: Dimensions B34H

2014

US

21 / 07 / 2014Page 18 Technical Data Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Technical Data

2.12 Dimensions B34 H Vario

OPTIMUM

MASCHINEN - GERMANY

2014

21 / 07 / 2014 Page 19Technical Data Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

Img.2-2: Dimensions B34H Vario

OPTIMUM

MASCHINEN - GERMANY

3 Assembly

3.1 Extent of supply

When the machine is delivered, check immediately that the machine has not been damaged

during transport and that all components are included. Compare the parts supplied the information on the packaging list.

3.2 Transport

Center of gravity

Attachment positions (marking the positions for

the attachment position gear)

Assembly

Prescribed transport position (marking the top

side)

Means of transportation to be used

Weights

WARNING!

Machine part s falling off forklift trucks or other transport vehicles could cause very seri-

ous or even fatal injuries. Follow the instructions and information on the transport case.

WARNING!

Use of unstable lifting equipment and load-suspension devices that b rea k u nder load ca n

cause very serious injury or even death.

Check that the lifting and load-suspension gear has sufficient load capacity and that it is

in perfect condition. Observe the rules for preventing accidents issued by your association for the prevention of occupational acc idents and safety in the workplace or other

inspection authorities.

Hold the loads properly. Never walk under suspended loads!

2014

US

21 / 07 / 2014Page 20 Assembly Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Assembly

3.3 Storage

ATTENTION!

Improper storage may cause important parts to be damaged or destroyed.

Store packed or unpacked parts only under the following ambient conditions.

Please follow the instructions and indications on the transportation box.

Fragile goods (goods require careful handling)

Protect against humidity and humid environments

„Environmental conditions“ on page 17.

OPTIMUM

MASCHINEN - GERMANY

Prescribed position of the packaging box (marking

the top side – arrows pointing upward)

Maximum stacking height

Example: non-stackable – do not pile any further

packaging boxes on top of the first packaging box

3.4 Installation and assembly

3.4.1 Site requirements

Organize the working space around the upright drill according to the local safety regulations.

INFORMATION

In order to provide for good functionality and high machining accuracy as well as long durability

of the machine the site should fulfill certain criteria.

Observe the following items:

The device must only be installed and operated in dry ventilated places.

Avoid places nearby machines generating chips or dust.

The site has to be vibration-free, i.e. at a distance from presses, planing machines, etc.

The substructure has to be appropriate for upright drill. Also make sure that the load bearing

capacity and the evenness of the floor are appropriate.

The substructure has to be prepared in a way that possibly used coolant cannot penetrate

into the ground.

Protruding parts such as stops, handles, etc. need to be secured by measures provided by

the customer if necessary in order to avoid dangers for persons.

Provide sufficient space for assembly and operating staff as well as for material transport.

Also allow for accessibility for setting and maintenance works.

2014

Make sure that the main power of the drilling machine is freely accessible.

21 / 07 / 2014 Page 21Assembly Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

Column

Hexagon socket

screws

Base

Column

Hexagon socket

screws

Base

MASCHINEN - GERMANY

Provide for sufficient illumination (minimum value: 47 Lumens/ft², measured at the tool tip). In

case of insufficient intensity of illumination provide for additional illumination i.e. by a separate workplace illuminator.

INFORMATION

The main power of the upright drill has to be freely accessible.

3.4.2 Assembly

WARNING!

Danger of crushing when assembling and installing the machine components.

Fitting the machine base and the drill column

Place the machine base

on the ground and

attach the column on

the base.

Hexagon socket screws

are provided to fix the

base.

Assembly

Img.3-1: Assembling column

Img.3-2: Assembling column

2014

US

21 / 07 / 2014Page 22 Assembly Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Assembly

Drilling table

Rack

Column

Locking screws

Spacer

Locking screws

Hexagon socket

screws

Crank handle

3.4.3 Mounting the drilling table

Push the rack into the drill-

ing table

Adjust the rack within the

drilling table in a way that

the teeth of the rack came

in with the worm gear of the

drilling table.

Push the drilling table with

the rack on the drilling column.

OPTIMUM

MASCHINEN - GERMANY

Img.3-3: Assembling drilling table

Mount the spacer.

Mount the crank handle for

the height-adjustment of

the drilling table.

Secure the crank handle

and the spacer with the

locking screws and hexagon socket screws respectively.

Img.3-4: Assembly crank handle

2014

21 / 07 / 2014 Page 23Assembly Upright drill B34 H/ B34 H Vario ; Version 1.0.5

US

OPTIMUM

Drilling table

bushing

Axial bearing

Clamping levers

drilling table

cooling equipment

column

cooling agent hoses

MASCHINEN - GERMANY

Mount axial bearing, bush-

ing and clamping lever.

Mount cooling equip-

ment.

Mount all cooling agent

hoses and fasten you

these with the hose

clamps.

Assembly

Img.3-5: Assembling drilling table

Img.3-6: Assembly drilling table

2014

US

21 / 07 / 2014Page 24 Assembly Upright drill B34 H/ B34 H Vario ; Version 1.0.5

Loading...

Loading...