Page 1

MAINTENANCE

Outboard Care

To keep your outboard in the best operating condition, it is important that

your outboard receive the periodic inspections and maintenance listed in

the Inspection and Maintenance Schedule. We urge you to keep it

maintained properly to ensure the safety of you and your passengers, and

retain its dependability.

WARNING

!

Neglected inspection and maintenance service of your outboard or

attempting to perform maintenance or repair on your outboard if you are

not familiar with the correct service and safety procedures could cause

personal injury, death, or product failure.

Record maintenance performed in Maintenance Log at the back of this

book. Save all maintenance work orders and receipts.

SELECTING REPLACEMENT PARTS FOR YOUR OUTBOARD

We recommend using original Mercury Precision or Quicksilver

replacement parts and Genuine Lubricants.

WARNING

!

Using a replacement part that is inferior to the original part could result

in personal injury, death, or product failure.

EPA Regulations

All new outboards manufactured by Mercury Marine are certified to the

United States Environmental Protection Agency, as conforming to the

requirements of the regulations for the control of air pollution from new

outboard motors. This certification is contingent on certain adjustments

being set to factory standards. For this reason, the factory procedure for

servicing the product must be strictly followed and, wherever practicable,

returned to the original intent of the design. Maintenance, replacement, or

repair of the emission control devices and systems may be performed by

any marine spark ignition (SI) engine repair establishment or individual.

56

Page 2

MAINTENANCE

EPA Emissions

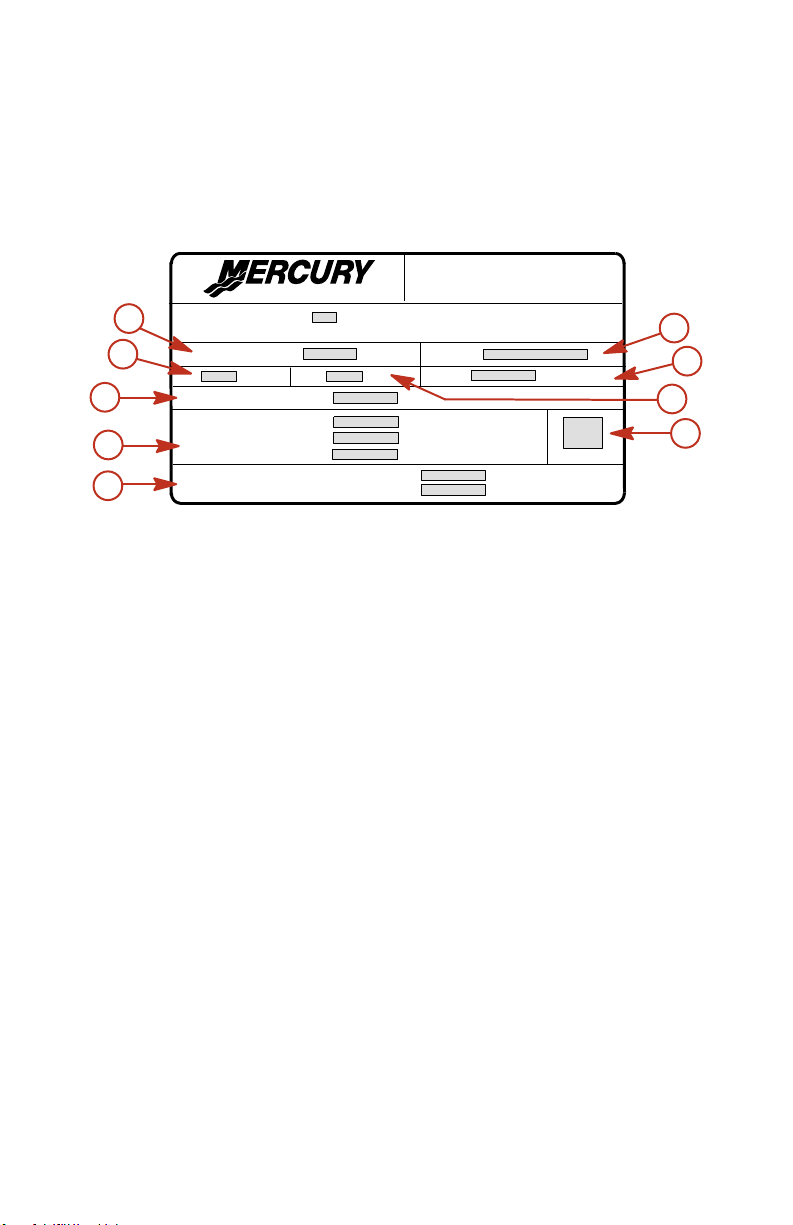

EMISSION CERTIFICATION LABEL

An emission certification label, showing emission levels and engine

specifications directly related to emissions, is placed on the engine at time

of manufacture.

EMISSION CONTROL

INFORMATION

This e ngine conforms to model year EPA regulations for Ma rine SI engines.

a

b

c

d

e

TIM ING (IN DE GREES):

Su pp ressor spar k pl ug:

Valv e C learan ce (C old) m m

Re fer to Ow ner' s Manual for require d m ainte na nce.

IDLE SPEED :

hp

Standa rd spa rk p lug :

:

GAP

a - Idle speed

b - Engine horsepower

c - Timing specification

d - Recommended spark plug

and gap

e - Valve clearance (if

applicable)

cc

Inta ke

Exhau st

FAM ILY:

FEL :

g/kW

h

f - Family number

g - Maximum emission output for

the engine family

h - Piston placement

i - Date of manufacture

f

g

h

i

ob01071

OWNER RESPONSIBILITY

The owner/operator is required to have routine engine maintenance

performed to maintain emission levels within prescribed certification

standards.

The owner/operator is not to modify the engine in any manner that would

alter the horsepower or allow emissions levels to exceed their

predetermined factory specifications.

Inspection And Maintenance Schedule

BEFORE EACH USE

• Check that lanyard stop switch stops the engine.

• Visually inspect the fuel system for deterioration or leaks.

• Check outboard for tightness on transom.

• Check steering system for binding or loose components.

57

Page 3

MAINTENANCE

• Visually check steering link rod fasteners for proper tightness. See

Steering Link Rod Fasteners.

• Check propeller blades for damage.

AFTER EACH USE

• Flush out the outboard cooling system if operating in salt or polluted

water. See Flushing the Cooling System.

• Wash off all salt deposits and flush out the exhaust outlet of the

propeller and gearcase with fresh water if operating in salt water.

EVERY 100 HOURS OF USE OR ONCE YEARLY,

WHICHEVER OCCURS FIRST

• Lubricate all lubrication points. Lubricate more frequently when used

in salt water. See Lubrication Points.

• Replace spark plugs at first 100 hours or first year. After that, inspect

spark plugs every 100 hours or once yearly. Replace spark plugs as

needed. See Spark Plug Inspection and Replacement.

• Replace fuel filter. See Fuel System.

• Replace compressor air intake filter. See Compressor Air Intake Filter.

• Inspect alternator belt. See Alternator Belt Inspection.

• Check corrosion control anodes. Check more frequently when used

in salt water. See Corrosion Control Anodes.

• Drain and replace gearcase lubricant. See Gearcase Lubrication.

• Check power trim fluid. See Checking Power Trim Fluid.

• Inspect battery. See Battery Inspection.

•

Check control cable adjustments.

•

Lubricate splines on the driveshaft and shift shaft.

• Check tightness of bolts, nuts, and other fasteners.

EVERY 300 HOURS OF USE OR THREE YEARS

• Replace water pump impeller (more often if overheating occurs or

reduced water pressure is noted).

BEFORE PERIODS OF STORAGE

• Refer to Storage procedure. See Storage section.

1.

1.

1.

Flushing The Cooling System

Flush the internal water passages of the outboard with fresh water after

each use in salt, polluted, or muddy water. This will help prevent a buildup

of deposits from clogging the internal water passages.

1. These items should be serviced by an authorized dealer.

58

Page 4

MAINTENANCE

Use a Mercury Precision or Quicksilver accessory (or equivalent) flushing

attachment.

WARNING

!

To avoid possible injury when flushing, remove the propeller. Refer to

Propeller Replacement.

1. Remove propeller. Refer to Propeller Replacement. Install the flushing

attachment so the rubber cups fit tightly over the cooling water intake.

ob01604

2. Attach a water hose to the flushing attachment. Turn on the water and

adjust the flow so water is leaking around the rubber cups to ensure

the engine receives an adequate supply of cooling water.

ob00570

3. Start the engine and run it at idle speed in neutral shift position.

IMPORTANT: Do not run engine above idle when flushing.

4. Adjust water flow (if necessary) so excess water continues leaking out

from around the rubber cups to ensure the engine is receiving an

adequate supply of cooling water.

ob00571

5. Check for a steady stream of water flowing out of the water pump

indicator hole. Continue flushing the outboard for 3 to 5 minutes,

carefully monitoring water supply at all times.

59

Page 5

MAINTENANCE

6. Stop the engine, turn off the water, and remove the flushing

attachment. Reinstall the propeller.

Flushing The Cooling System ‑ Models With

Accessory Hose Flush Attachment

Flush the internal water passages of the outboard with fresh water after

each use in salt, polluted, or muddy water. This will help prevent a build up

of deposits from clogging the internal water passages.

1. Thread a water hose into hose adaptor.

2. Remove dust cover and push the host adaptor into the flush connector

until it locks (snaps) in place.

a

a - Flush connector

b - Button

NOTE: Engine can be stopped or running at idle speed in neutral when

flushing the cooling system. Do not flush engine using a water source that

exceeds 6.5 kPa (45 psi).

3. Turn on the water and flush the cooling system for a minimum of 3

minutes.

NOTE: The hose adaptor shuts off the water flow whenever it is

disconnected from the flush connector.

4. Push button in to release the hose adaptor.

5. Reinstall dust cover.

b

d

c

ob01605

c - Hose adaptor

d - Dust cover

FREEZING TEMPERATURE

The water should be drained out of the engine flush hose if there is a

chance of freezing temperature. Drain water as follows:

1. Remove water hose from the hose adaptor.

2. Insert the adaptor only into the flush connector.

3. Tilt the outboard up until all the water has drained out of the hose.

60

Page 6

MAINTENANCE

Top Cowl Removal And Installation

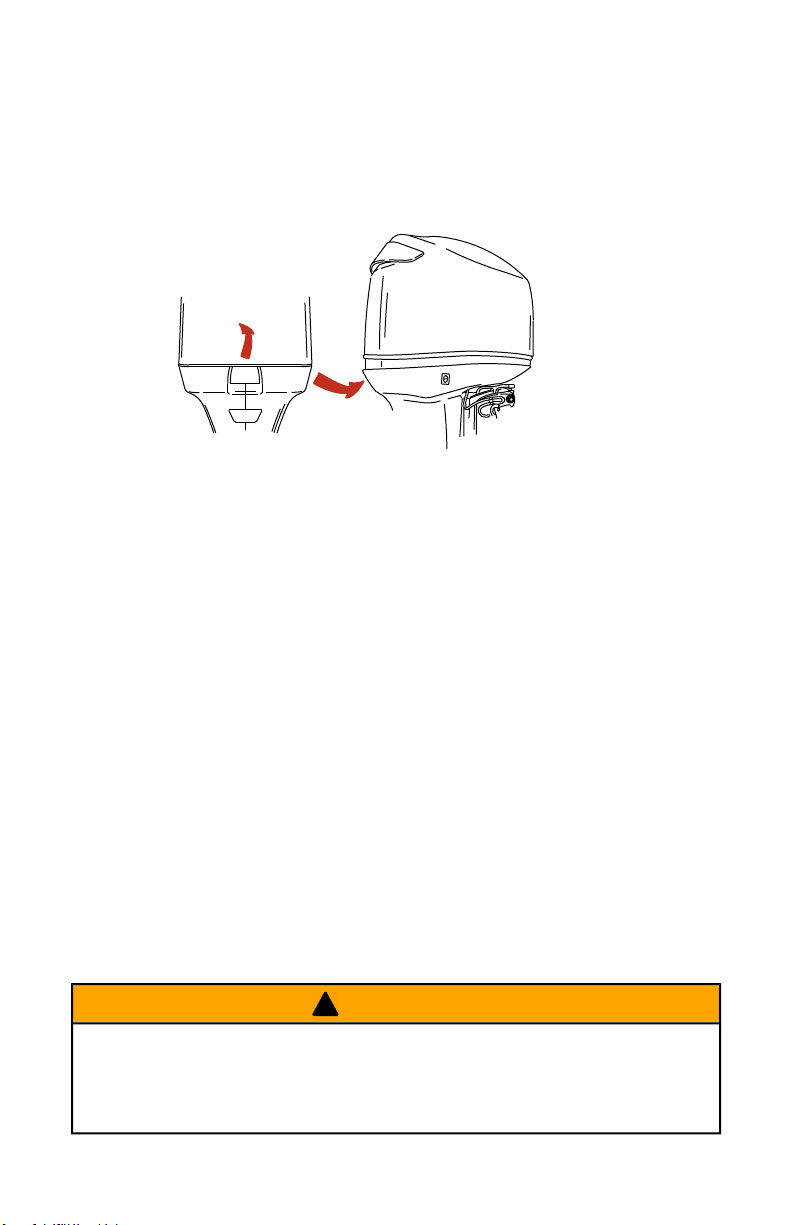

REMOVAL

1. Unlock the rear latch by pushing lever up.

2. Lift rear of cowl and disengage front hook.

ob01606

INSTALLATION

1. Engage the front hook and push cowl back over the cowl seal.

2. Push cowl down and move the rear latch lever down to lock.

Cleaning Care for Top Cowl

IMPORTANT: Dry wiping (wiping the plastic surface when it is dry) will

result in minor surface scratches. Always wet the surface before cleaning.

Follow cleaning and waxing procedure.

CLEANING AND WAXING PROCEDURE

1. Before washing, rinse the top cowl with clean water to remove dirt and

dust that may scratch the surface.

2. Wash the top cowl with clean water and a mild non‑abrasive soap.

Use a soft clean cloth when washing.

3. Dry thoroughly with a soft clean cloth.

4. Wax the surface using a non‑abrasive automotive polish (polish

designed for clear coat finishes). Remove the applied wax by hand

using a clean soft cloth.

Fuel System

WARNING

!

Avoid serious injury or death from gasoline fire or explosion. Carefully

follow all fuel system service instructions. Always stop the engine and do

not smoke or allow open flames or sparks in the area while servicing any

part of the fuel system.

61

Page 7

MAINTENANCE

Before servicing any part of the fuel system, stop engine and disconnect

the battery. Drain the fuel system completely. Use an approved container

to collect and store fuel. Wipe up any spillage immediately. Material used

to contain spillage must be disposed of in an approved receptacle. Any fuel

system service must be performed in a well ventilated area. Inspect any

completed service work for sign of fuel leakage.

FUEL LINE INSPECTION

Visually inspect the fuel line and primer bulb for cracks, swelling, leaks,

hardness, or other signs of deterioration or damage. If any of these

conditions are found, the fuel line or primer bulb must be replaced.

FUEL FILTER REPLACEMENT

Removal

1. Use the shaft of a screwdriver between the lugs on the filter cap and

unscrew the filter.

a

b

ob01673

a - Filter b - O‑rings

Installation

1. Lubricate the O‑ring seals with oil.

2. Install the fuel filter and tighten securely.

IMPORTANT: Visually inspect for fuel leakage from the filter while

squeezing the primer bulb until firm, forcing fuel into the filter.

DRAINING WATER FROM THE FUEL FILTER CHAMBER

NOTE: If a sufficient amount of water has accumulated in the fuel filter

chamber, the warning system will turn on. Draining the water from the fuel

filter chamber is required.

62

Page 8

MAINTENANCE

1. Pull the drain hose off the right side fitting. Hold open end of the hose

over a container.

2. Loosen drain screw and drain the fuel filter chamber.

b

a

a - Drain hose

b - Right side fitting

3. Retighten drain screw and reattach hose.

IMPORTANT: Visually inspect for fuel leakage from the drain screw by

squeezing the primer bulb until firm, forcing fuel into the chamber.

c - Drain screw

c

ob01674

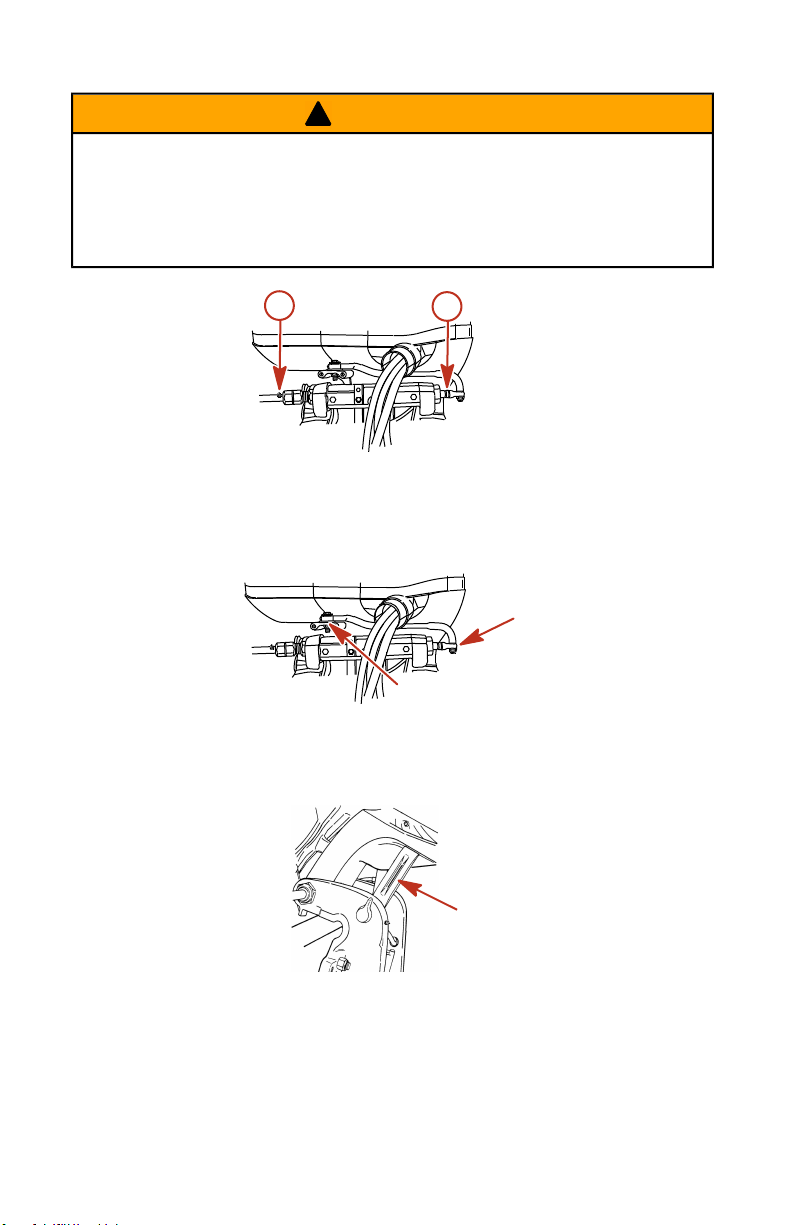

Steering Link Rod Fasteners

IMPORTANT: The steering link rod that connects the steering cable to the

engine must be fastened using special washer head bolt ("a" ‑ Part Number

10‑849838) and self‑locking nylon insert locknuts ("c" & "d" ‑ Part Number

11‑826709113). These locknuts must never be replaced with common nuts

(non‑locking) as they will work loose and vibrate off freeing the link rod to

disengage.

63

Page 9

MAINTENANCE

WARNING

!

Disengagement of a steering link rod can result in the boat taking a full,

sudden, sharp turn. This potentially violent action can cause occupants

to be thrown overboard exposing them to serious injury or death.

a

b

c

d

a - Special washer head bolt (10‑849838)

b - Flat washer (2)

c - Nylon insert locknut (11‑826709113)

d - Nylon insert locknut (11‑826709113)

Description Nm lb. in. lb. ft.

Special washer head bolt 27 20

Nylon insert locknut "d" 27 20

Nylon insert locknut "c" Tighten until seats, then back off 1/4 turn

Assemble steering link rod to steering cable with two flat washers and

self‑locking nylon insert locknut. Tighten locknut until it seats, then back

nut off 1/4 turn.

Assemble steering link rod to engine with special washer head bolt and

self‑locking nylon insert locknut. First torque bolt, then torque locknut to

specifications.

ob00676

Fuse Replacement

IMPORTANT: Always carry spare 5 and 20 AMP fuses.

The electrical wiring circuits on the outboard are protected from overload

by fuses in the wiring. If a fuse is blown, try to locate and correct the cause

of the overload. If the cause is not found, the fuse may blow again.

64

Page 10

MAINTENANCE

Open the fuse holder and look at the silver colored band inside the fuse. If

band is broken, replace the fuse. Replace fuse with a new fuse with the

same rating.

a

c

5

20

f

a - Good fuse

b - Blown fuse

c - SmartCraft data bus circuit ‑ 5 amp fuse

d - Accessories ‑ 20 amp fuse

e - Ignition coil circuit ‑ 20 amp fuse

f - Electric fuel pump/ECM driver power/oil pump circuit ‑ 20 amp

fuse

b

d

20

20

e

ob01607

Corrosion Control Anode

Your outboard has corrosion control anodes at different locations. An

anode helps protect the outboard against galvanic corrosion by sacrificing

its metal to be slowly corroded instead of the outboard metals.

Each anode requires periodic inspection, especially in salt water which will

accelerate the erosion. To maintain this corrosion protection, always

replace the anode before it is completely eroded. Never paint or apply a

protective coating on the anode as this will reduce effectiveness of the

anode.

65

Page 11

MAINTENANCE

The gearcase has two corrosion control anodes, one on each side. A third

anode is installed on the bottom of the transom bracket assembly.

a

a - Anode (2) on each side of

gearcase

b

b - Anode on transom bracket

assembly

ob00677

Battery Inspection

The battery should be inspected at periodic intervals to ensure proper

engine starting capability.

IMPORTANT: Read the safety and maintenance instructions which

accompany your battery.

1. Turn off the engine before servicing the battery.

2. Add water as necessary to keep the battery full.

3. Make sure the battery is secure against movement.

4. Battery cable terminals should be clean, tight, and correctly installed.

Positive to positive and negative to negative.

5. Make sure the battery is equipped with a nonconductive shield to

prevent accidental shorting of battery terminals.

Battery Information

CAUTION

!

Hex nuts must be used to secure battery leads to battery posts to avoid

loss of electrical power.

• Do not use deep cycle batteries. Engines must use a marine starting

battery with 1000 MCA, 800 CCA or 180 Ah.

• When connecting engine battery, hex nuts must be used to secure

battery leads to battery posts. Torque nuts to specification.

Description Nm lb. in. lb. ft.

Hex nuts 13.5 120

66

Page 12

MAINTENANCE

IMPORTANT: Battery cable size and length is critical. Refer to engine

installation manual for size requirements.

Decal needs to be placed on or near battery box for future service

reference. One 5/16 in. and one 3/8 in. hex nut are supplied per battery for

wing nut replacement. Metric hex nuts are not supplied.

NOTICE - DTS & Optimax Engines

DO NOT USE DEEP CYCLE BA TTERIES!

DTS (Digital Throttle and Shift) applications and

Optimax engines must use a marine starting

battery with 1000 MCA, 800 CCA, or 180 Ah.

rating.

IMPORT ANT :

Battery cable size and length is critical. Refer to

engine installation manual for size requirements.

Place decal on or near battery box for future service

reference. 5/16" and 3/8" hex nuts supplied for

wing nut replacement. Metric hex nuts not supplied.

Propeller Replacement

IMPORTANT: Propellers used on this product require the Mercury Marine

Flo‑Torq III type hub or equivalent.

13.5Nm (120 lbs. in.)

DO NOT

USE WING

NUTS.

37-895387

3486

WARNING

!

If the propeller shaft is rotated while the engine is in gear, there is the

possibility that the engine will crank over and start. To prevent this type

of accidental engine starting and possible serious injury caused from

being struck by a rotating propeller, always shift outboard to neutral

position and remove spark plug leads when you are servicing the

propeller.

1. Shift outboard to neutral (N) position.

N

ob00351

67

Page 13

MAINTENANCE

IMPORTANT: Refer to Spark Plug Inspection and Replacement for

removing spark plug leads.

2. Remove spark plug leads to prevent engine from starting.

ob00375

3. Straighten the bent tabs on the propeller nut retainer.

ob00376

4. Place a block of wood between gearcase and propeller to hold

propeller and remove propeller nut.

ob00377

5. Pull propeller straight off shaft. If propeller is seized to the shaft and

cannot be removed, have the propeller removed by an authorized

dealer.

6. Coat the propeller shaft with Quicksilver or Mercury Precision

Lubricants Anti‑Corrosion Grease or 2‑4‑C.

ob00378

68

Page 14

MAINTENANCE

Tube Ref No. Description Where Used Part No.

94

95

Anti-Corrosion Grease Propeller shaft

2-4-C Propeller shaft

IMPORTANT: To prevent the propeller hub from corroding and seizing to

the propeller shaft (especially in salt water), always apply a coat of the

recommended lubricant to the entire propeller shaft at the recommended

maintenance intervals and also each time the propeller is removed.

7. Flo‑Torq III Drive Hub Propellers ‑ Install forward thrust hub,

replaceable drive sleeve, propeller, thrust hub, propeller nut retainer

and propeller nut onto the shaft.

92-802867A

1

92-802859A

1

a b c d

a - Propeller nut

b - Propeller nut retainer

c - Rear thrust hub

e f

d - Propeller

e - Replaceable drive sleeve

f - Forward thrust hub

3223

8. Place a block of wood between gearcase and propeller and torque

propeller nut to specifications.

Description Nm lb. in. lb. ft.

Propeller nut 75 55

9. Secure propeller nut by bending three of the tabs into the thrust hub

grooves.

ob00422

69

Page 15

MAINTENANCE

Spark Plug Inspection And Replacement

WARNING

!

Avoid serious injury or death from fire or explosion caused by damaged

spark plug boots. Damaged spark plug boots can emit sparks. Sparks

can ignite fuel vapors under the engine cowl. To avoid damaging spark

plug boots, do not use any sharp object or metal tool such as pliers,

screwdriver, etc. to remove spark plug boots.

1. Remove the spark plug leads. Twist the rubber boots slightly and pull

off.

ob00375

2. Remove the spark plugs to inspect. Replace spark plug if electrode is

worn or the insulator is rough, cracked, broken, blistered or fouled.

ob00423

3. Set the spark plug gap to specifications.

ob00424

Spark Plug

Spark plug gap 0.80 mm (0.030 in.)

4. Before installing spark plugs, clean off any dirt on the spark plug seats.

Install plugs finger tight, and then tighten to the specified value.

Description Nm lb. in. lb. ft.

Spark plug 27 20

70

Page 16

MAINTENANCE

Compressor Air Intake Filter

The filter should be changed every 100 hours of operation, or once a

season.

IMPORTANT: Never run the engine without the air filter.

REMOVAL

1. Remove three screws and filter cover from engine.

2. Remove filter from the cover.

b

a

ob01608

a - Cover b - Filter

INSTALLATION

1. Install filter into cover.

2. Fasten filter cover with three screws.

Alternator Belt Inspection

WARNING

!

Avoid possible serious injury. Make sure engine is shut off and ignition

key is removed before inspecting belt.

1. Inspect the alternator belt and have it replaced by an authorized dealer

if any of the following conditions are found.

a. Cracks or deterioration in the rubber portion of the belt.

b. Belt surfaces rough or uneven.

71

Page 17

MAINTENANCE

c. Signs of wear on edges or outer surfaces of belt.

ob01609

Lubrication Points

1. Lubricate the following with Quicksilver or Mercury Precision

Lubricants Anti‑Corrosion Grease or 2‑4‑C.

Tube Ref No. Description Where Used Part No.

94

95

Anti-Corrosion Grease Propeller shaft

2-4-C Propeller shaft

92-802867A

1

92-802859A

1

• Propeller Shaft ‑ Refer to Propeller Replacement for removal and

installation of the propeller. Coat the entire propeller shaft with

lubricant to prevent the propeller hub from corroding and seizing

to the shaft.

ob00378

2. Lubricate the following with Quicksilver or Mercury Precision

Lubricants 2‑4‑C or Special Lubricant 101.

72

Page 18

MAINTENANCE

Tube Ref No. Description Where Used Part No.

Swivel bracket, tilt

34

95

Special Lubricant 101

2-4-C

support lever, tilt tube,

steering cable grease

fitting

Swivel bracket, tilt

support lever, tilt tube,

steering cable grease

fitting

• Swivel Bracket ‑ Lubricate through fitting.

• Tilt Support Lever ‑ Lubricate through fitting.

a

b

ob00683

a - Swivel bracket b - Tilt support lever

• Tilt Tube ‑ Lubricate through fitting.

92-802865A

1

92-802859A

1

ob01610

• Steering Cable Grease Fitting (If equipped) ‑ Rotate steering wheel

to fully retract the steering cable end into the outboard tilt tube.

Lubricate through fitting.

73

Page 19

MAINTENANCE

WARNING

!

The end of the steering cable must be fully retracted into the outboard

tilt tube before adding lubricant. Adding lubricant to steering cable when

fully extended could cause steering cable to become hydraulically

locked. A hydraulically locked steering cable will cause loss of steering

control, possibly resulting in serious injury or death.

a

a - Fitting b - Steering cable end

3. Lubricate the following with light weight oil.

• Steering Link Rod Pivot Points ‑ Lubricate pivot points.

b

ob01612

ob01613

Checking Power Trim Fluid

1. Tilt outboard to the full up position and engage the tilt support lever.

74

ob00687

Page 20

MAINTENANCE

2. Remove fill cap and check fluid level. The fluid level should be even

with the bottom of the fill hole. Add Quicksilver or Mercury Precision

Lubricants Power Trim & Steering Fluid. If not available, use

automotive (ATF) automatic transmission fluid.

ob00688

Gearcase Lubrication

When adding or changing gearcase lubricant, visually check for the

presence of water in the lubricant. If water is present, it may have settled

to the bottom and will drain out prior to the lubricant, or it may be mixed

with the lubricant, giving it a milky colored appearance. If water is noticed,

have the gearcase checked by your dealer. Water in the lubricant may

result in premature bearing failure or, in freezing temperatures, will turn to

ice and damage the gearcase.

Examine the drained gearcase lubricant for metal particles. A small amount

of metal particles indicates normal gear wear. An excessive amount of

metal filings or larger particles (chips) may indicate abnormal gear wear

and should be checked by an authorized dealer.

DRAINING GEARCASE

1. Place outboard in a vertical operating position.

2. Place a drain pan below outboard.

3. Remove vent plugs and fill/drain plug and drain lubricant.

a

b

ob00441

a - Vent plugs b - Fill/drain plug

75

Loading...

Loading...